Built-in touch panel and display device

A touch panel and display device technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve problems affecting pixel aperture ratio, and achieve the effects of avoiding uneven liquid crystal alignment, improving production efficiency, and increasing aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Figure 4a For Embodiment 1 of the present invention, Figure 4b for Figure 4a A sketch of the combined Figure 4a and Figure 4b , the shape of the first projection 15 of the first contact surface of the spacer on the conductive line 14 is rectangular, and the conductive line 14 at the first projection 15 is continuous. Figure 4a In the X direction and the Y direction, respectively, in the X direction, the width of the first projection 15 is equal to or smaller than the width of the conductive line 14, and the first projection 15 extends along the Y direction, so the first projection 15 is completely located on the conductive line 14, that is, the spacer completely stands on the conductive wire 14 through the first contact surface. In FIG. set as Figure 5a Oval 25 in or as Figure 5b The oblong circle 35 in the center, this setting can ensure that the area of the first projection on the conductive wire 14 is the same as the design value, ensuring the support...

Embodiment 2

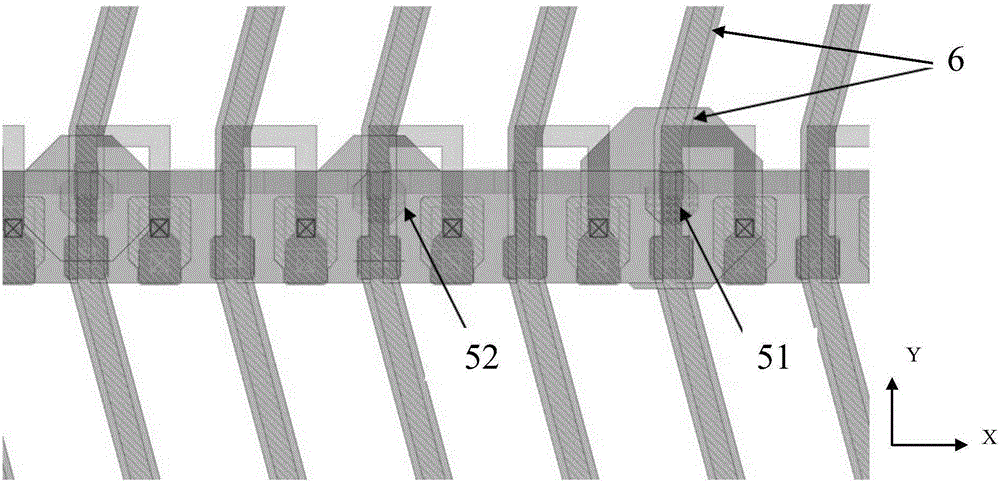

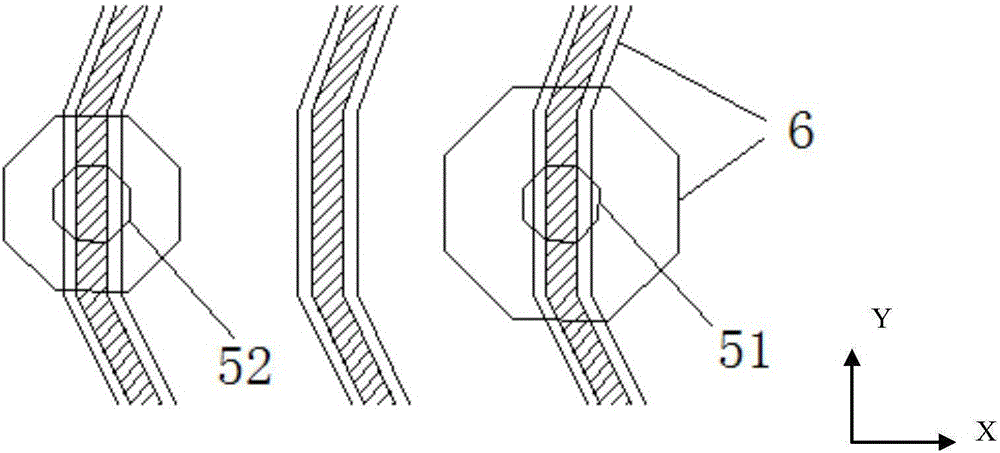

[0045] Figure 9a For the second embodiment of the present invention, Figure 9a is the view along the normal direction of the panel, Figure 9b for Figure 9a sketch of Figure 10 It is the sectional view of this embodiment. The difference between embodiment two and embodiment one is that in Figure 10 In, the thickness of the conductive wire 49 is greater than the first thickness in the first embodiment, in Figure 9a In the X direction and the Y direction, respectively, in the X direction, the width of the second contact surface 65 of the spacer is larger than the width of the conductive line 49, and the area of the second contact surface 65 is larger than that of the second contact surface in Embodiment 1. area, so that the spacer 59 rides on the conductive line 49, such as Figure 10 As shown, it helps the stability of the spacer 59, but the contact area between the spacer 59 and the conductive line 49 is still equal to the contact area in Embodiment 1. Since the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com