Patents

Literature

34results about How to "No contact friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

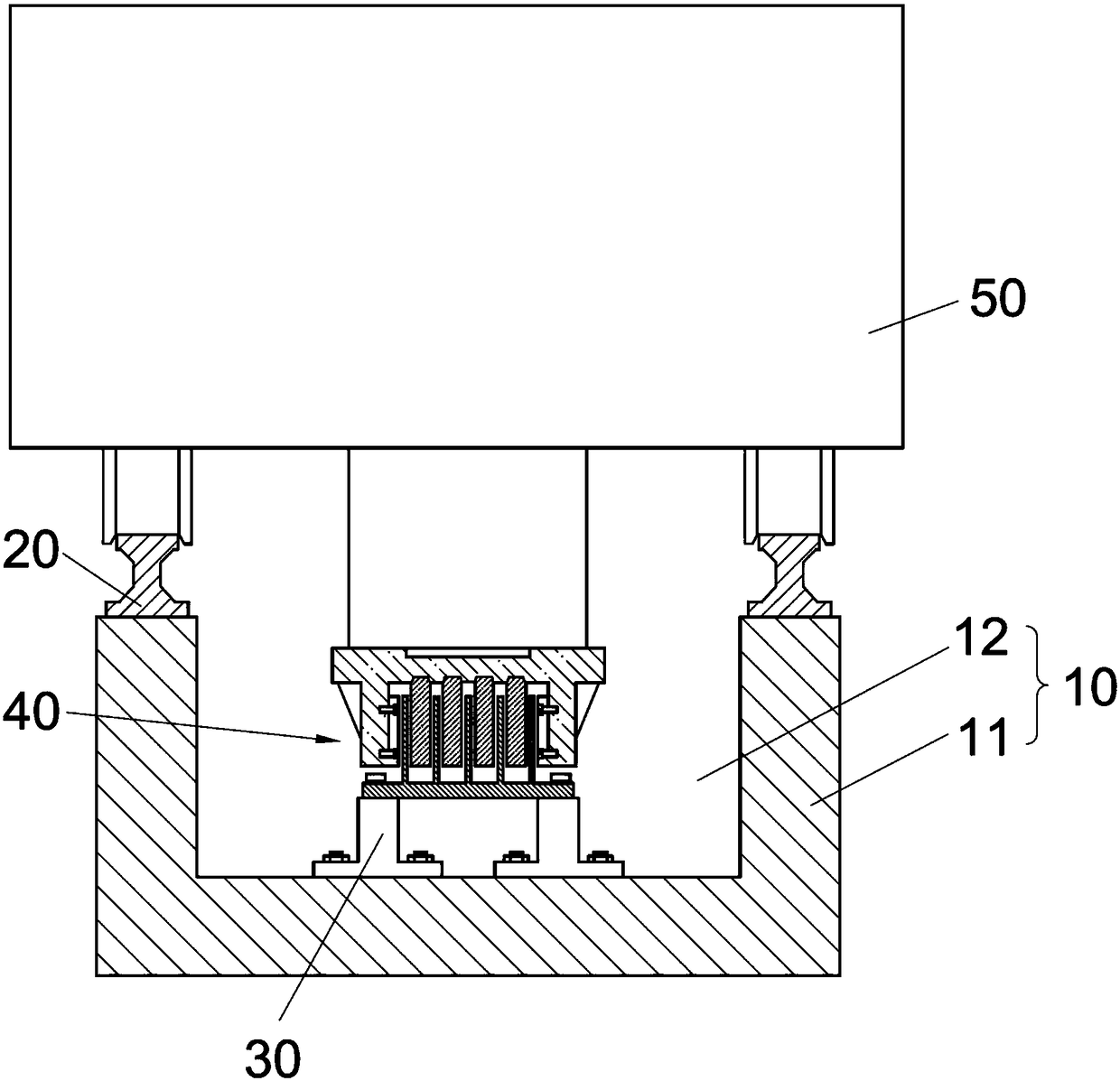

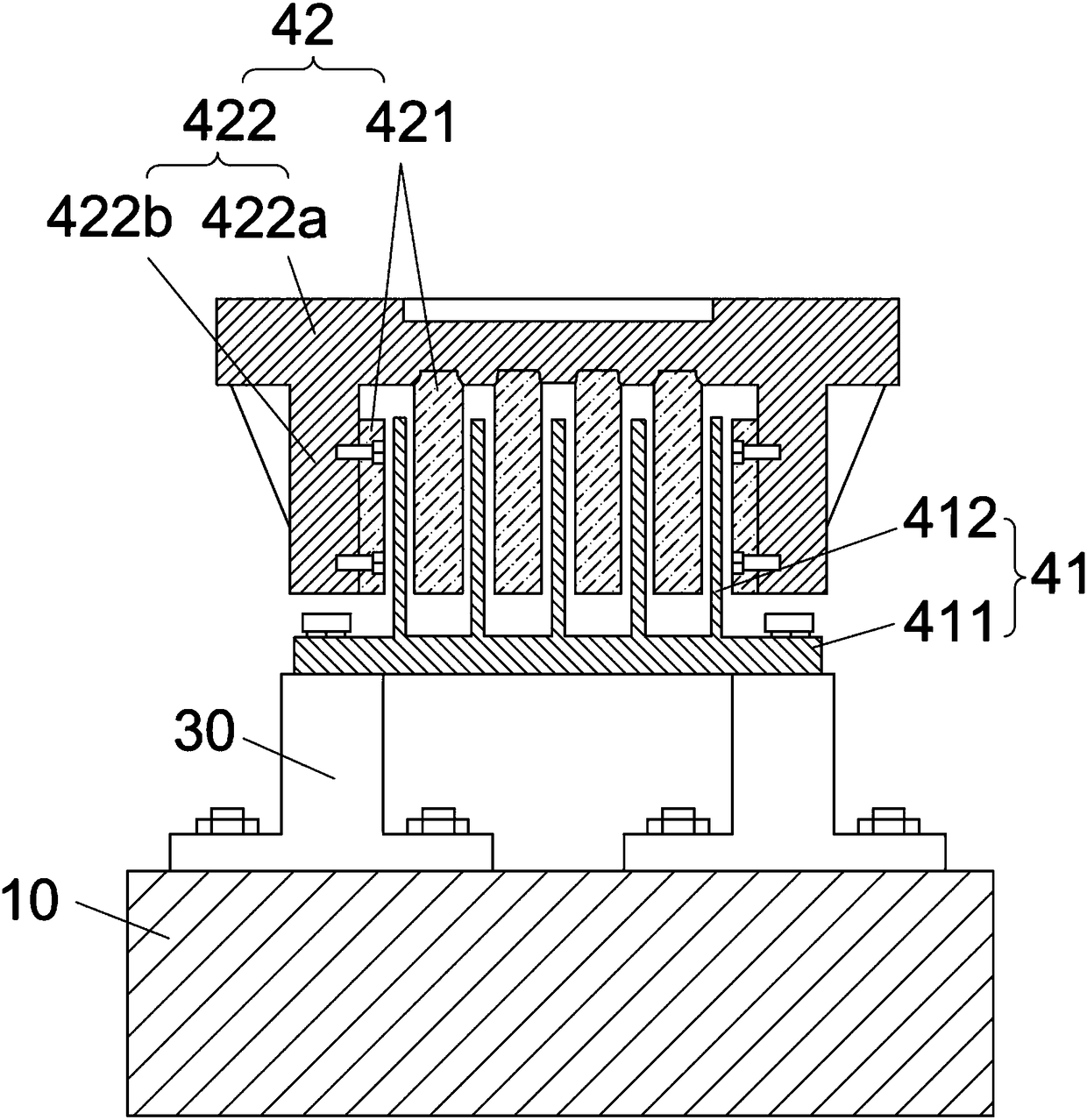

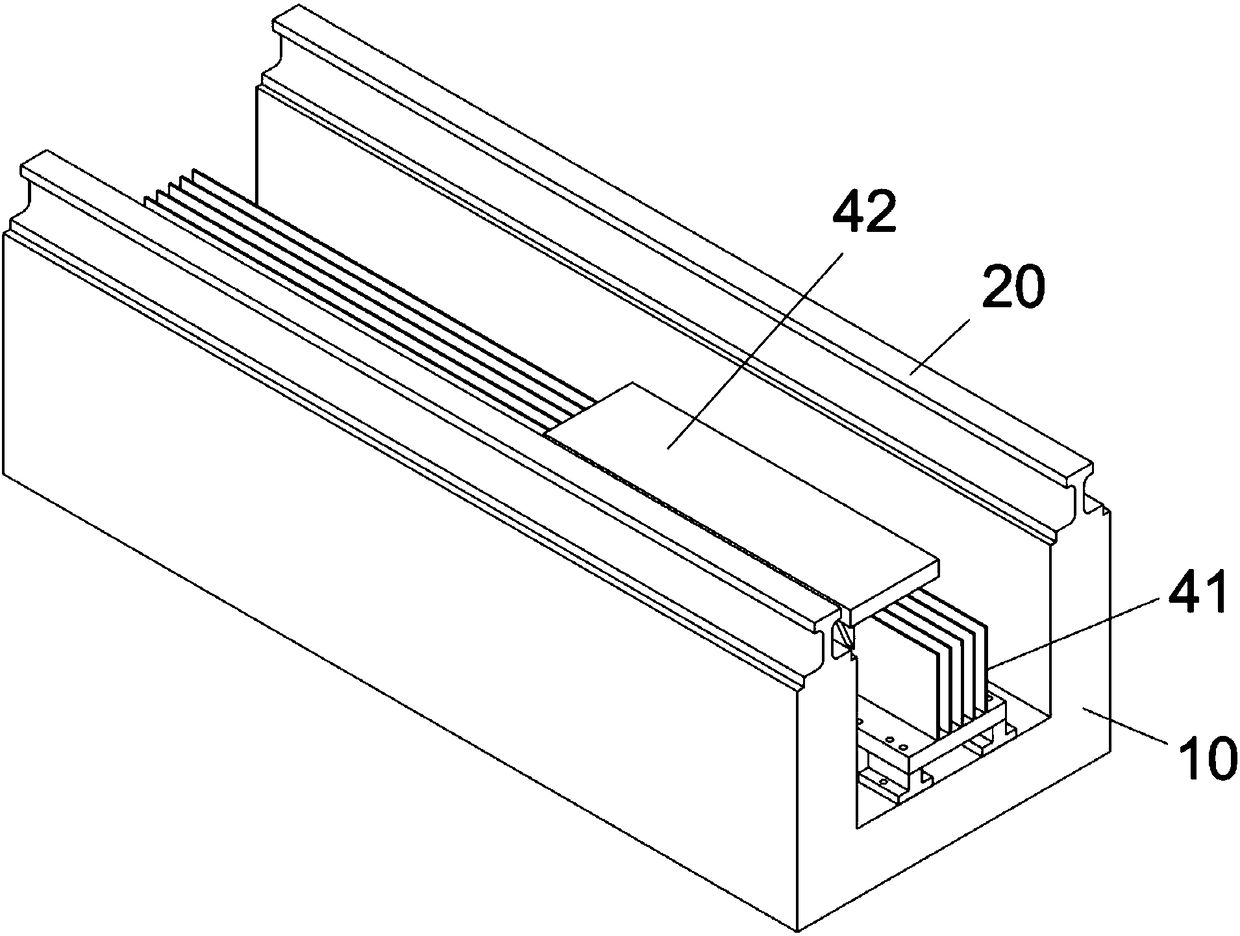

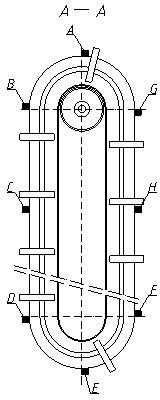

Tentering shaping conveying device for magnetic suspension functional fabric

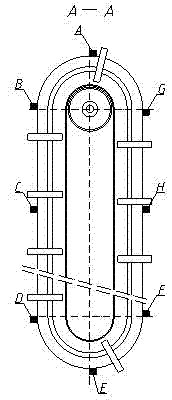

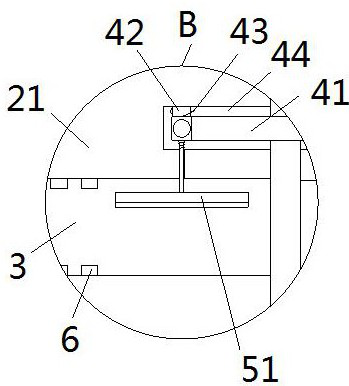

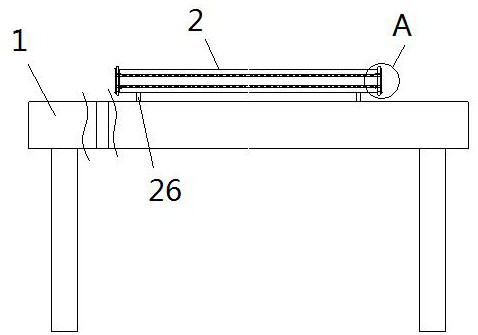

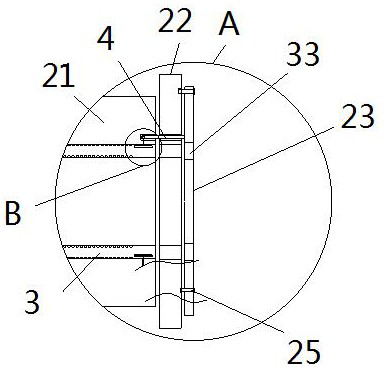

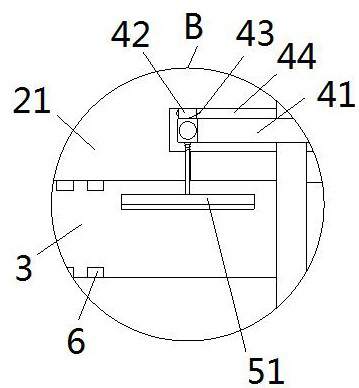

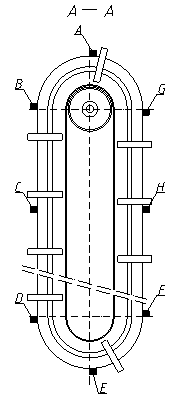

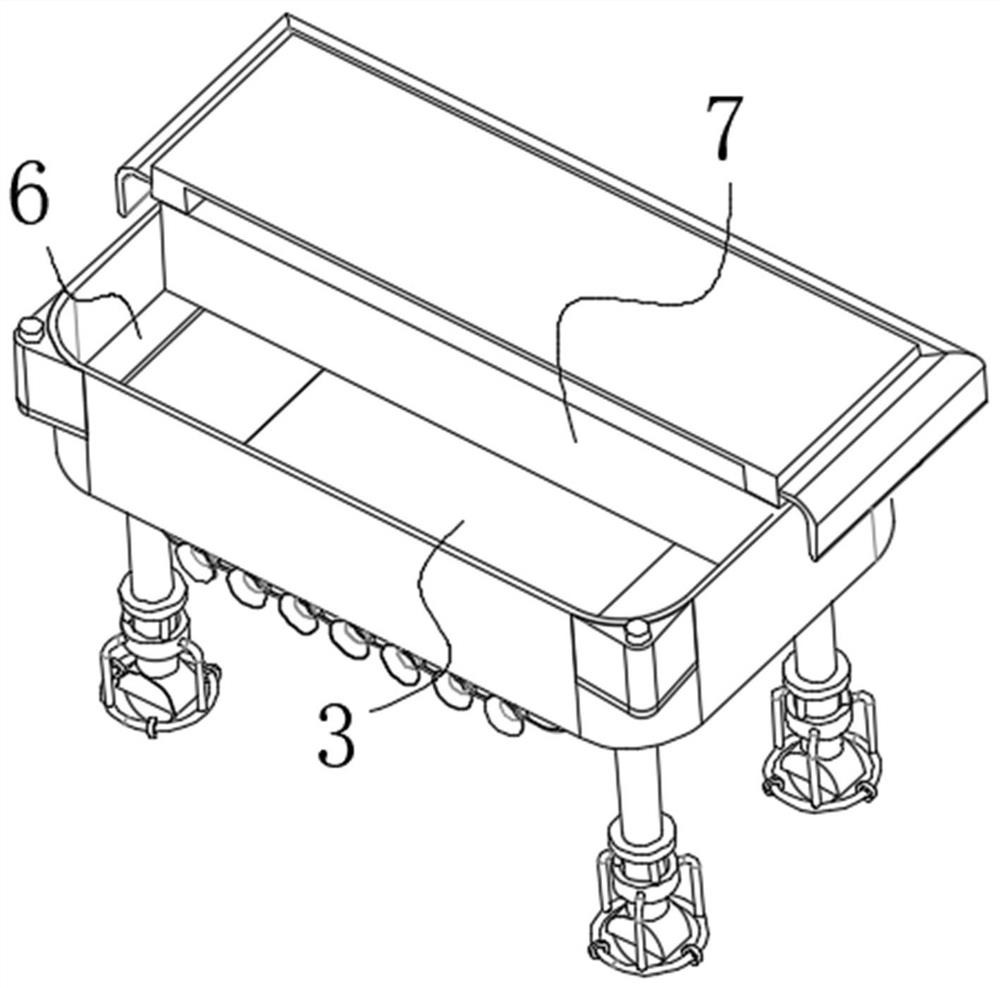

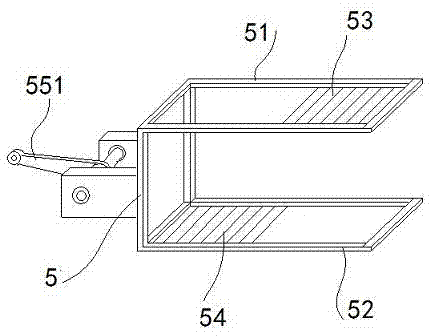

The invention discloses a tentering shaping conveying device for a magnetic suspension functional fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:苏州盛泽科技创业园发展有限公司

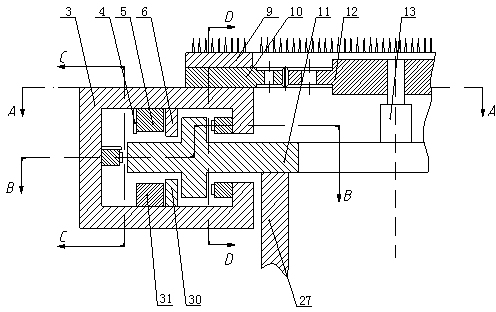

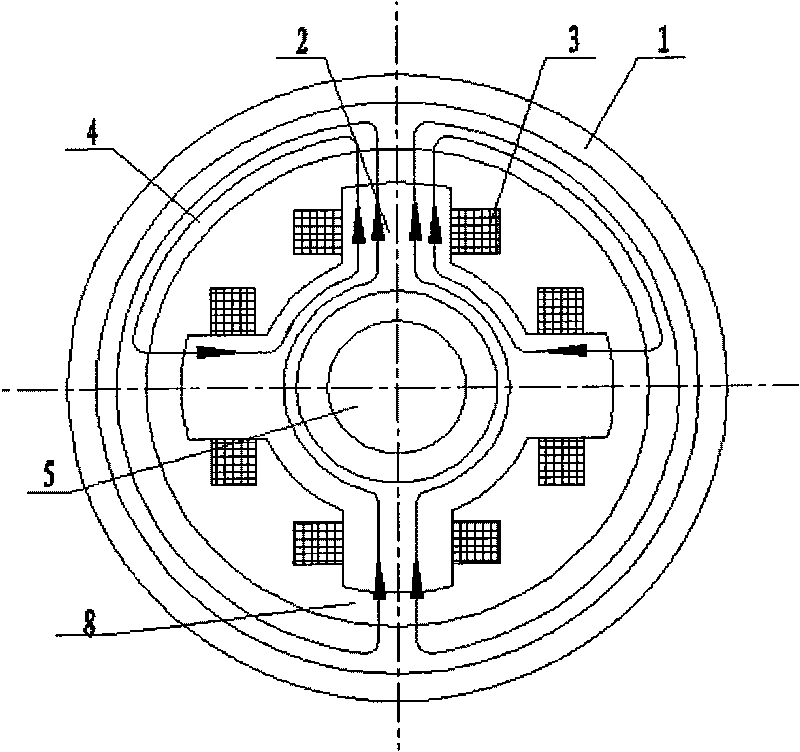

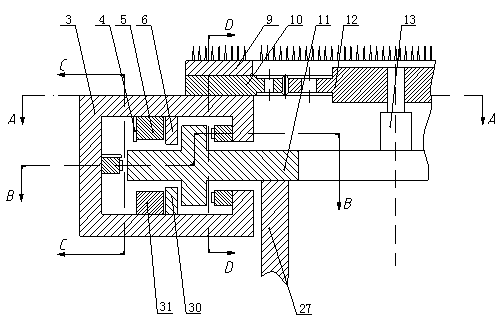

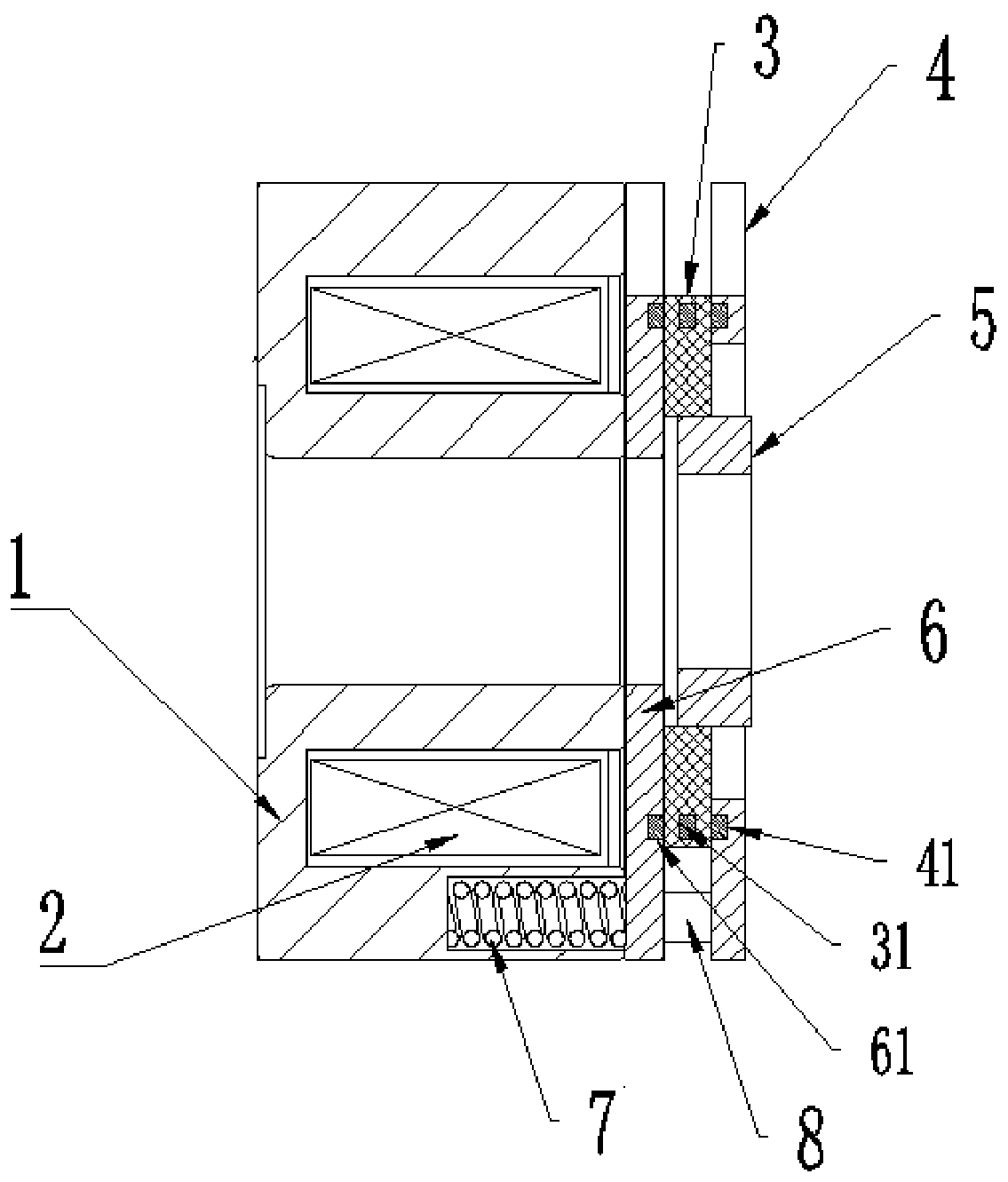

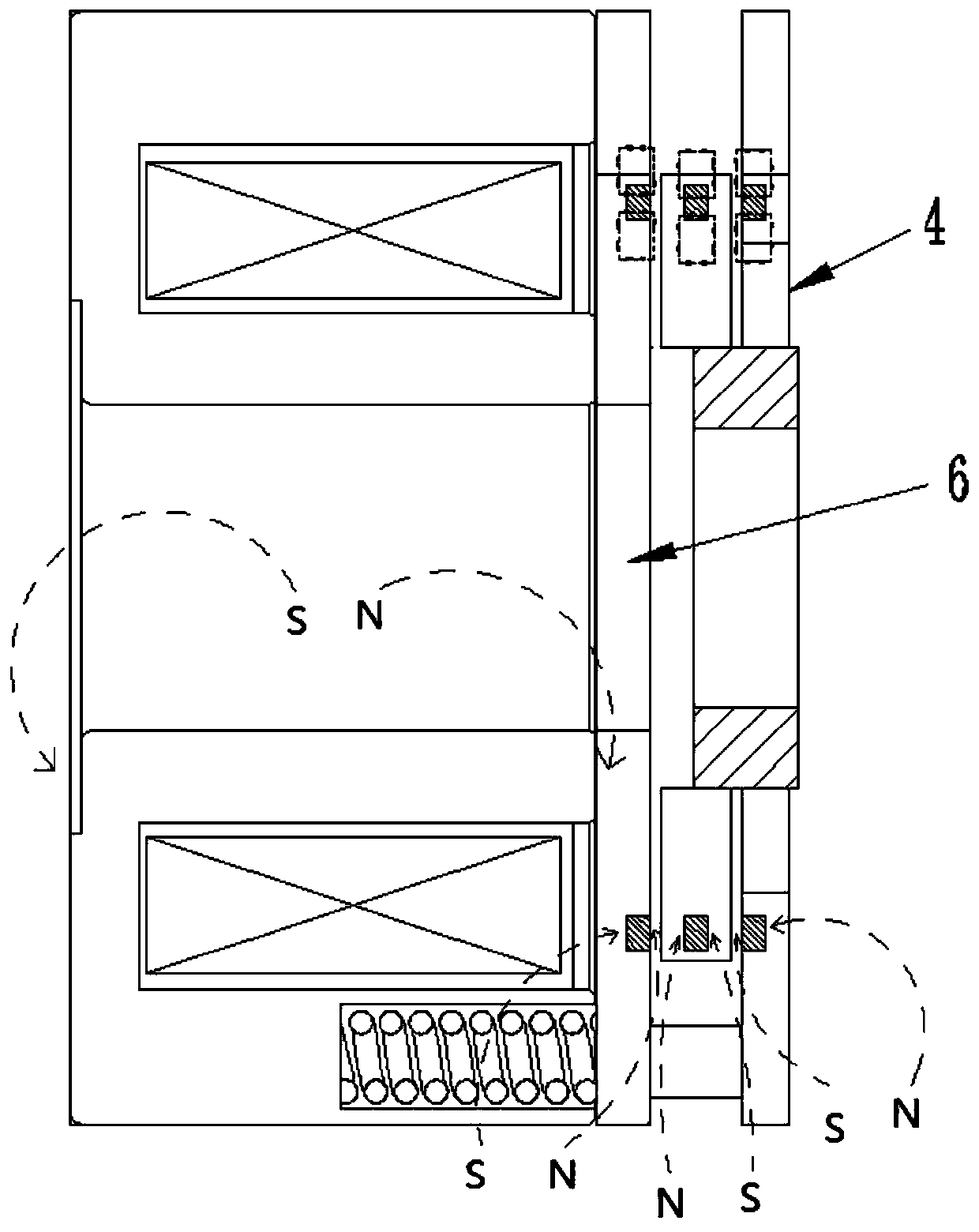

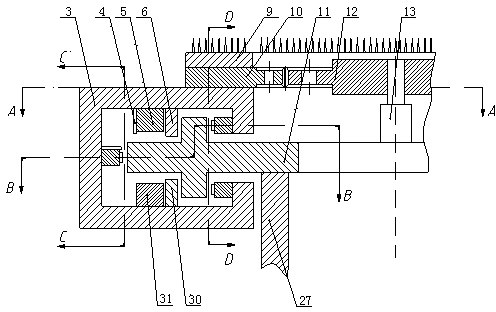

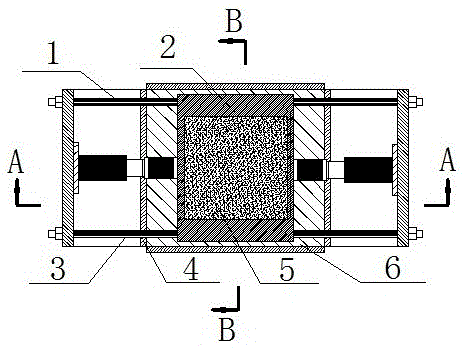

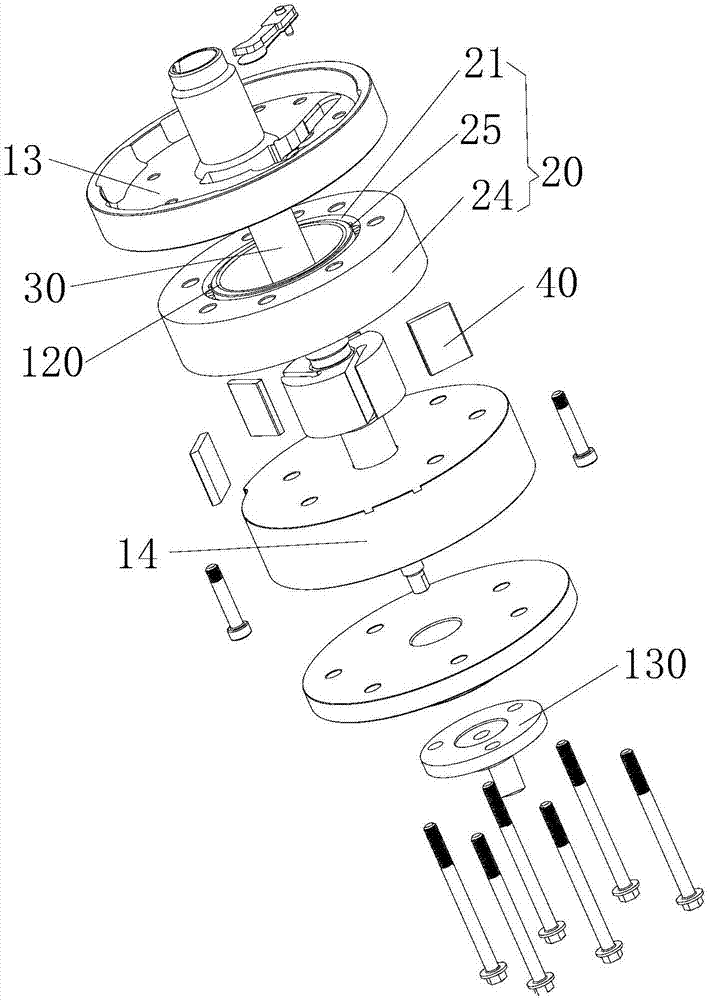

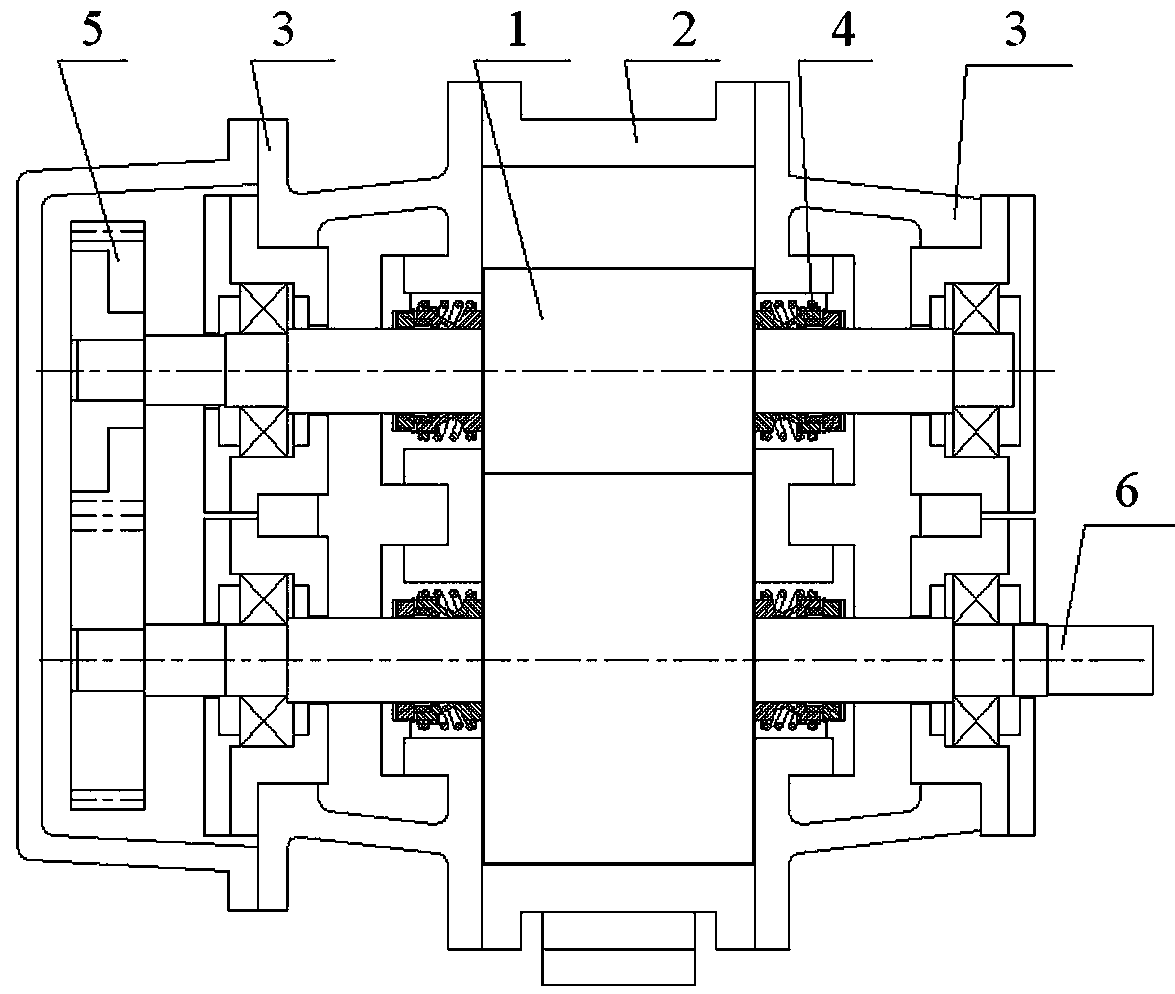

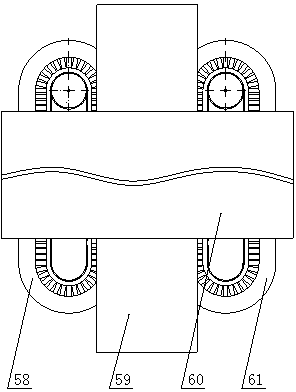

Low power consumption outer rotor radial magnetic bearing with upper-attracting and lower-repulsing structure of permanent magnet

The invention relates to a low power consumption outer rotor radial magnetic bearing with an upper-attracting and lower-repulsing structure of a permanent magnet, belonging to the field of the magnetic suspension bearing. The magnetic bearing consists of an outer magnetic-conducting ring, an outer magnetic-insulating ring, stator iron cores, an exciting coil, an inner permanent magnetic semi-ring, rotor iron cores, an inner magnetic-insulating ring, an inner magnetic-conducting ring, an outer permanent magnetic ring, air gaps and a rotating shaft, wherein eight electromagnetic poles and four permanent magnetic poles are established in the positive and negative directions of an X axis and a Y axis of the stator iron core in total; the inner magnetic-insulating ring is arranged among permanent magnetic iron cores and an electromagnetic iron core on a stator; the inner permanent magnetic semi-ring is clamped between the two permanent magnetic iron cores in the negative direction of the Y axis of the stator by the inner magnetic-conducting ring; the air gaps are arranged among the stator iron cores and the rotor iron cores; the outer magnetic-insulating ring is arranged between a permanent magnetic iron core ring and an electromagnetic iron core ring; the outer magnetic-conducting ring is arranged between the permanent magnetic iron core ring and the permanent magnetic iron core ring; and the outer permanent magnetic ring is clamped at the middle part of the outer permanent magnetic ring. The structure can solve the problems of gravity and power consumption of the rotating shaft of the magnetic suspension bearing, thus leading the bearing to have the advantages of low power consumption, reliable performance and convenient manufacture and the like. In addition, the low power consumption outer rotor radial magnetic bearing can be used as no-contact support parts of rotating equipment, such as a wind-driven generator, a motor, a molecular pump, a high-speed bearing.

Owner:SHANDONG UNIV OF SCI & TECH

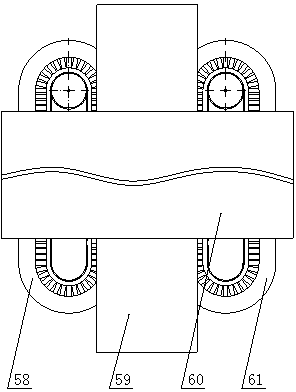

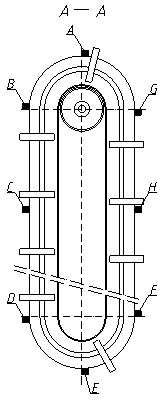

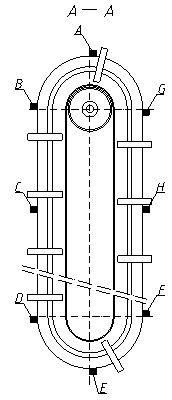

Coating fabric stentering shaping and transporting device with magnetic levitation function

The invention discloses a coating fabric stentering shaping and transporting device with magnetic levitation function. The device comprises support blocks. A runway type static guide rail is arranged on the support block. The runway type static guide rail is sleeved with magnetic levitation movement guide rails. The magnetic levitation movement guide rail is provided with a gear belt. The gear belt is provided with a plurality of needle felts. An arc end of the static guide rail is provided with a rotation motor. The rotation motor is provided with a gear disk. The gear disk is engaged with the gear belt. The device of the present invention has a reasonable structure, is applicable for a plurality of functional coating fabric production situations, and has advantages of no contact friction, low energy consumption, high movement precision, low noise and the like. In addition, with the device of the present invention, the repair maintenance period of the system can be effectively prolonged.

Owner:南通大学技术转移中心有限公司

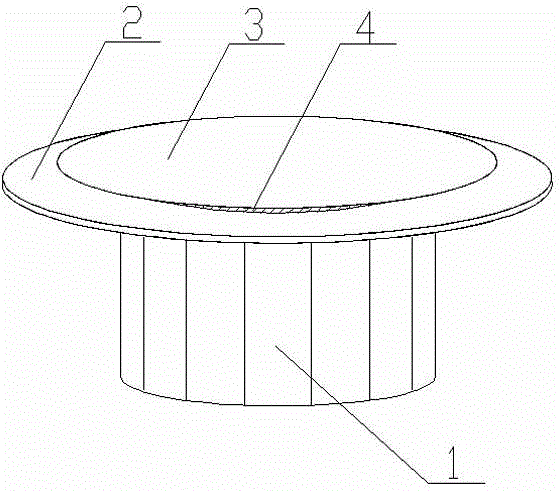

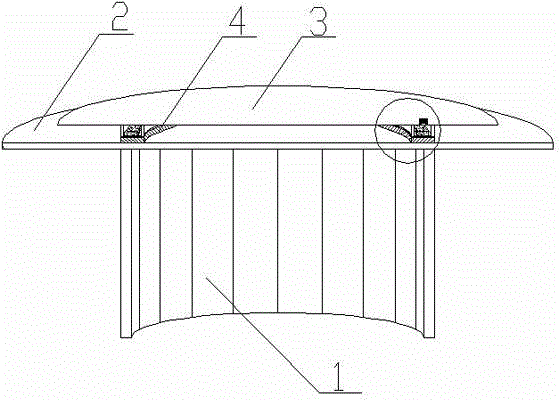

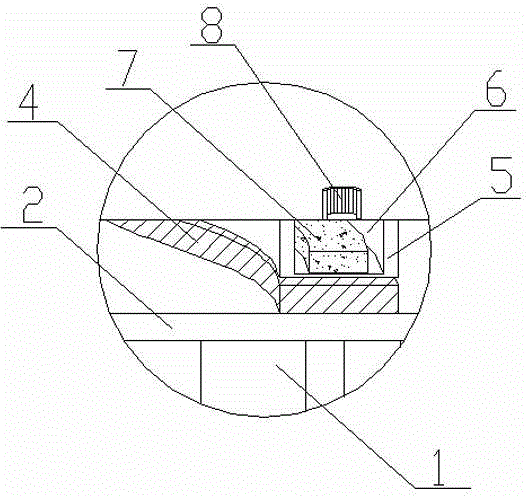

Passive high-temperature superconducting magnetic levitation rotating dining-table

InactiveCN104886924AThe overall structure is simpleEasy to useRevolvable tablesFeetPhysicsMagnetic flux

The invention provides a passive high-temperature superconducting magnetic levitation rotating dining-table. The passive high-temperature superconducting magnetic levitation rotating dining-table comprises a supporting pedestal, a dining-table body and a rotating tabletop; an annular Halbach array permanent magnet is fixed on the upper surface of the dining-table body, while an annular dewar container having the same diameter is fixed on the lower surface of the dining-table body; a groove is formed in the upper surface of the dewar container in the circumferential direction, so that the dewar container and the lower surface of the rotating tabletop can be formed into a cavity structure; a YBCO high-temperature superconducting block is arranged at the bottom of the groove; the YBCO high-temperature superconducting block is capable of capturing the magnetic flux generated by the permanent magnet under a field cooling condition to be the same with the opposite surface of the Halbach array permanent magnet in magnetism; a liquid nitrogen filling opening for adding liquid nitrogen into the cavity structure is further formed in the rotating tabletop. The passive high-temperature superconducting magnetic levitation rotating dining-table is capable of realizing free suspension and rotation without electric control and power supply; as a result, the fault rate of the dining-table is greatly reduced and the dining-table is good in practical effect.

Owner:LUOYANG INST OF SCI & TECH

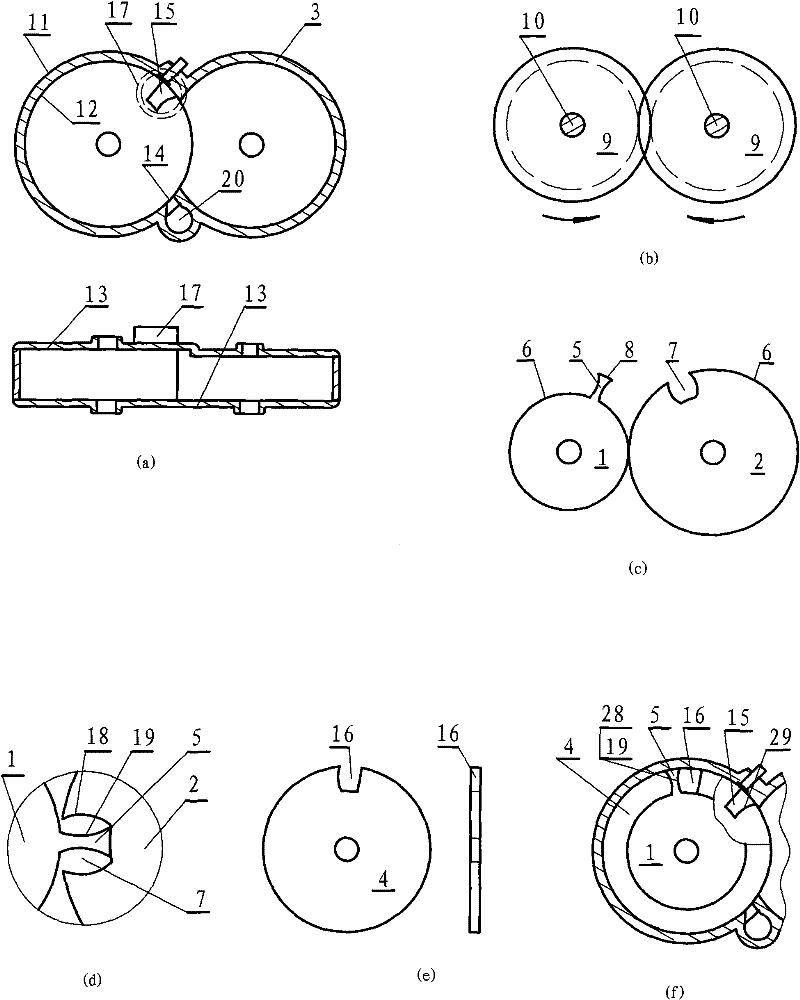

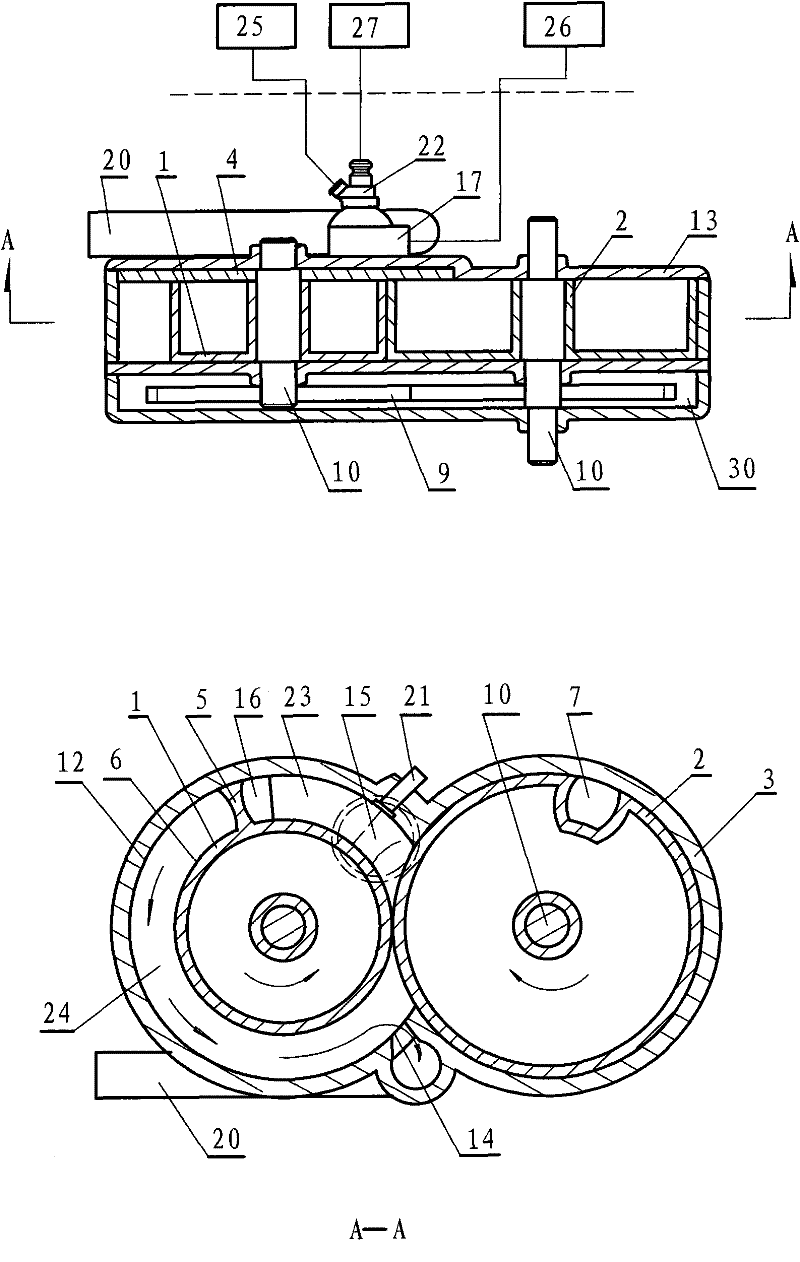

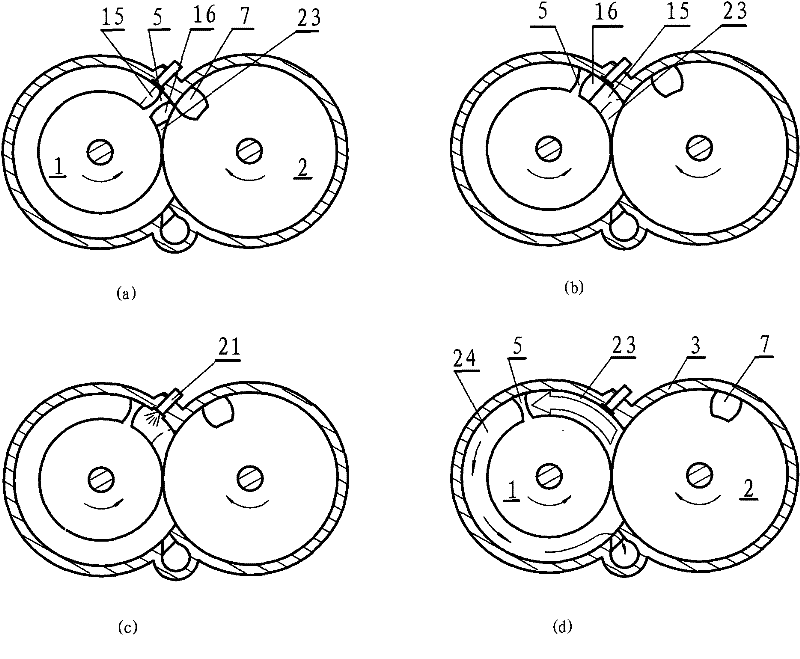

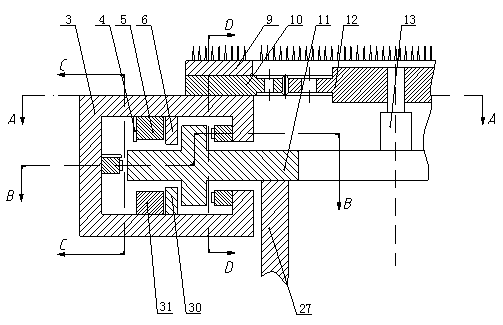

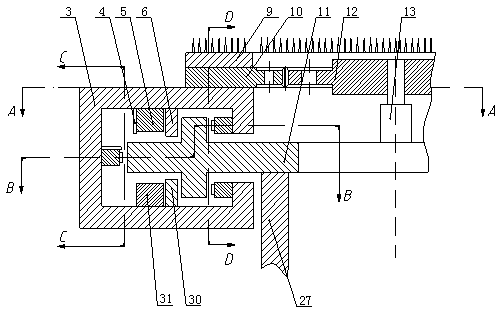

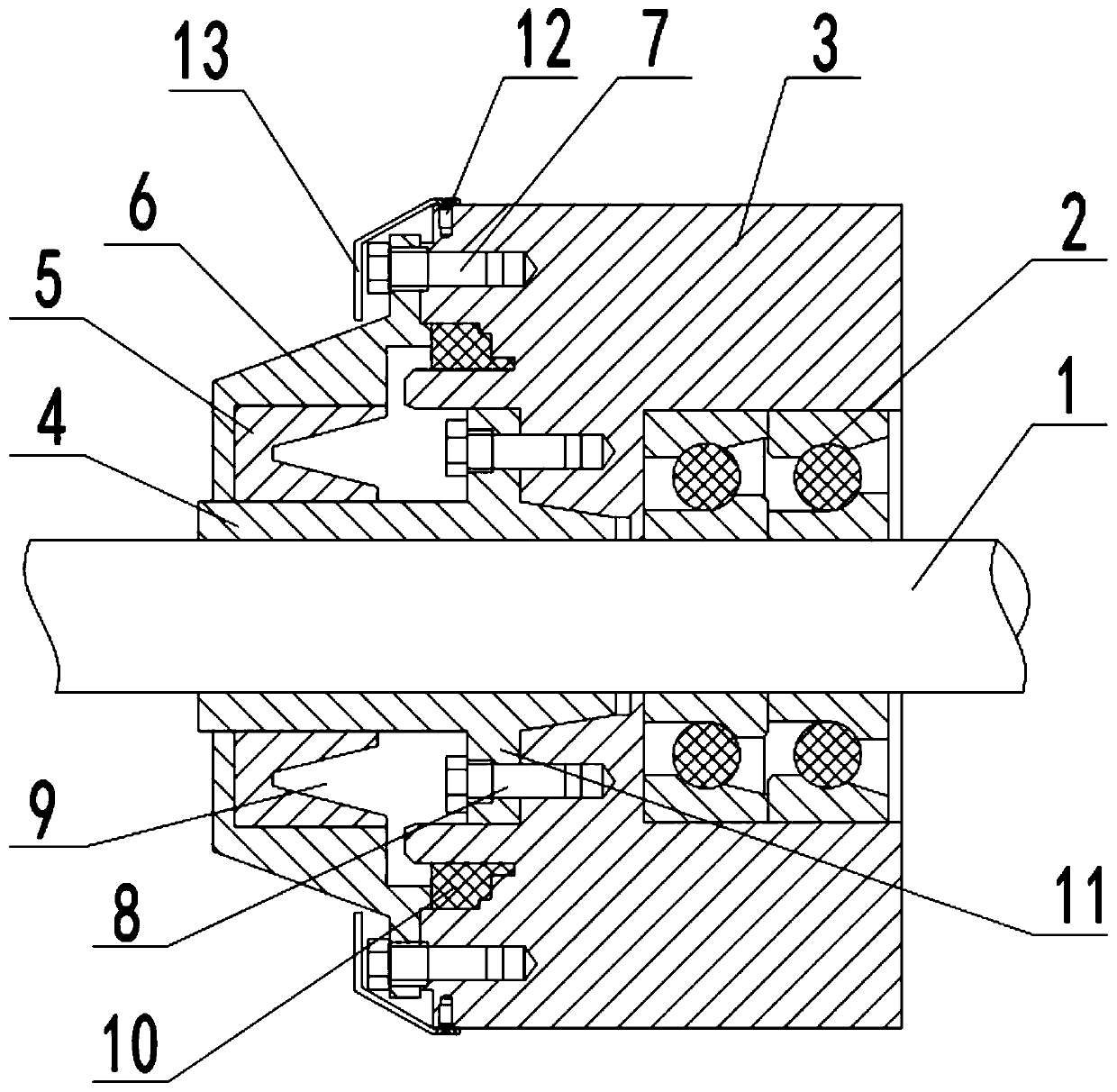

Double-wheel rotor engine

InactiveCN102330598AHigh efficiency of converting into mechanical kinetic energyImprove efficiencyInternal combustion piston enginesCombustion chamberEngineering

The invention relates to a double-wheel rotor engine. Double wheels comprise a cam (1) and a concave wheel (2) and are arranged in a transverse 8-shaped cylinder body (3), an independent tooth (5) of the cam (1) is used as a piston to rotate in an annular air cylinder, the annular air cylinder is separated into a combustion chamber (23) and an exhaust air chamber (24) by the concave wheel (2), and the ignition combustion is directly carried out after the combustion chamber (23) sucks high-pressure air and pressurized fuel oil. The fuel gas work application and the waste gas exhaust are simultaneously carried out, when the exhaust air chamber (24) is emptied, once work application is simultaneously completed, then, the independent tooth (5) rotates from a groove (7) of the concave wheel (2), a new combustion chamber (23) is generated and is rapidly enlarged, the high-pressure air and the pressurized fuel oil are sucked for work application through combustion, and the cyclic work is constantly carried out in such a way.

Owner:张竞生

Tentering shaping conveying device for functional coated fabric

The invention discloses a tentering shaping conveying device for a functional coated fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:义乌市鼎莎针织有限公司

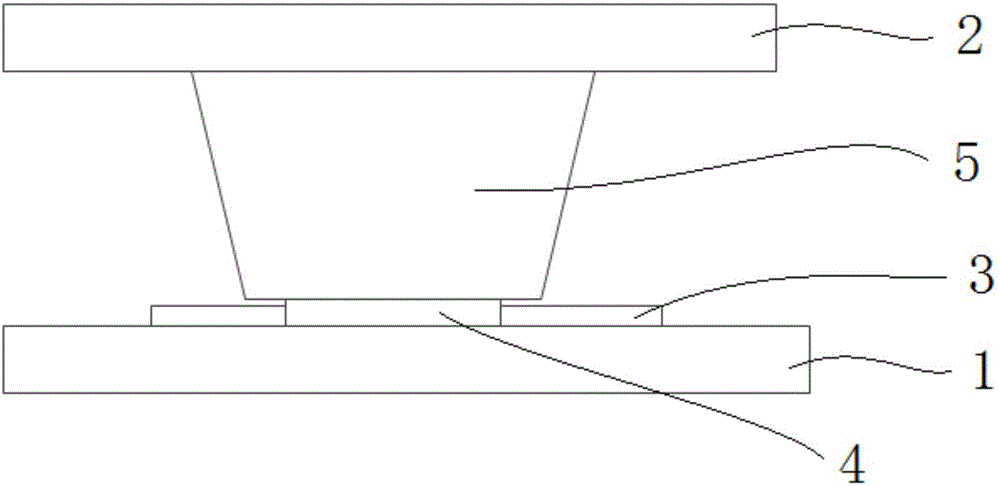

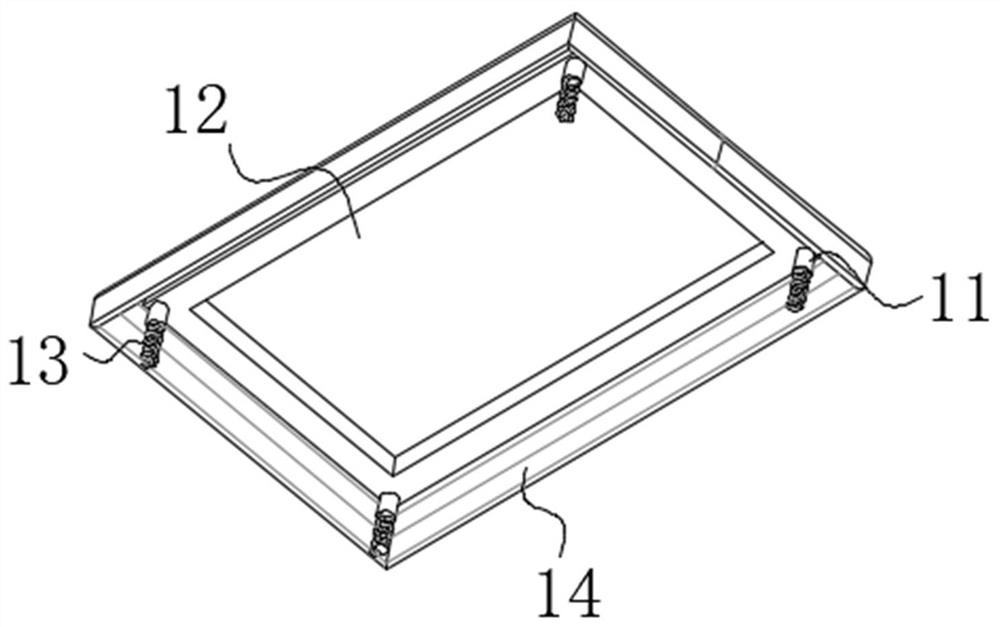

Built-in touch panel and display device

ActiveCN106773347AIncrease productivityDoes not affect thicknessNon-linear opticsInput/output processes for data processingLiquid-crystal displayDisplay device

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Electromagnetic brake and friction plate assembly thereof

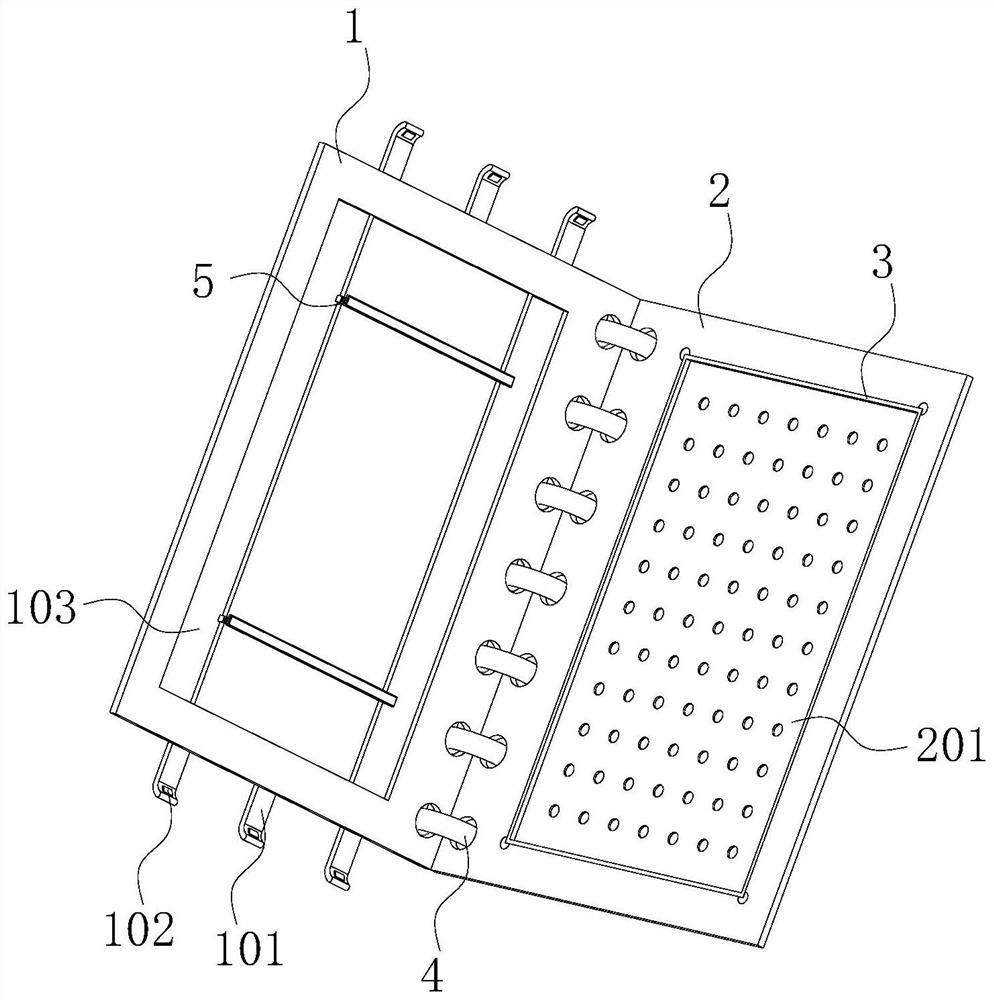

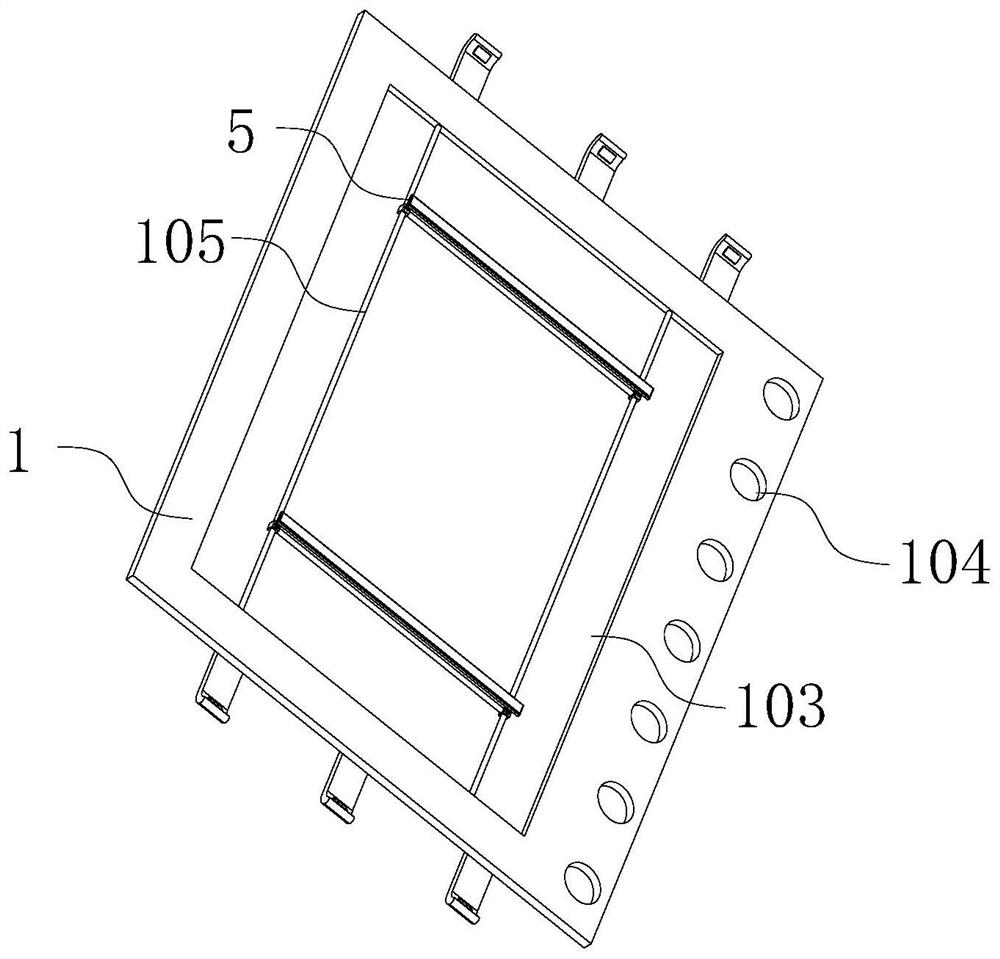

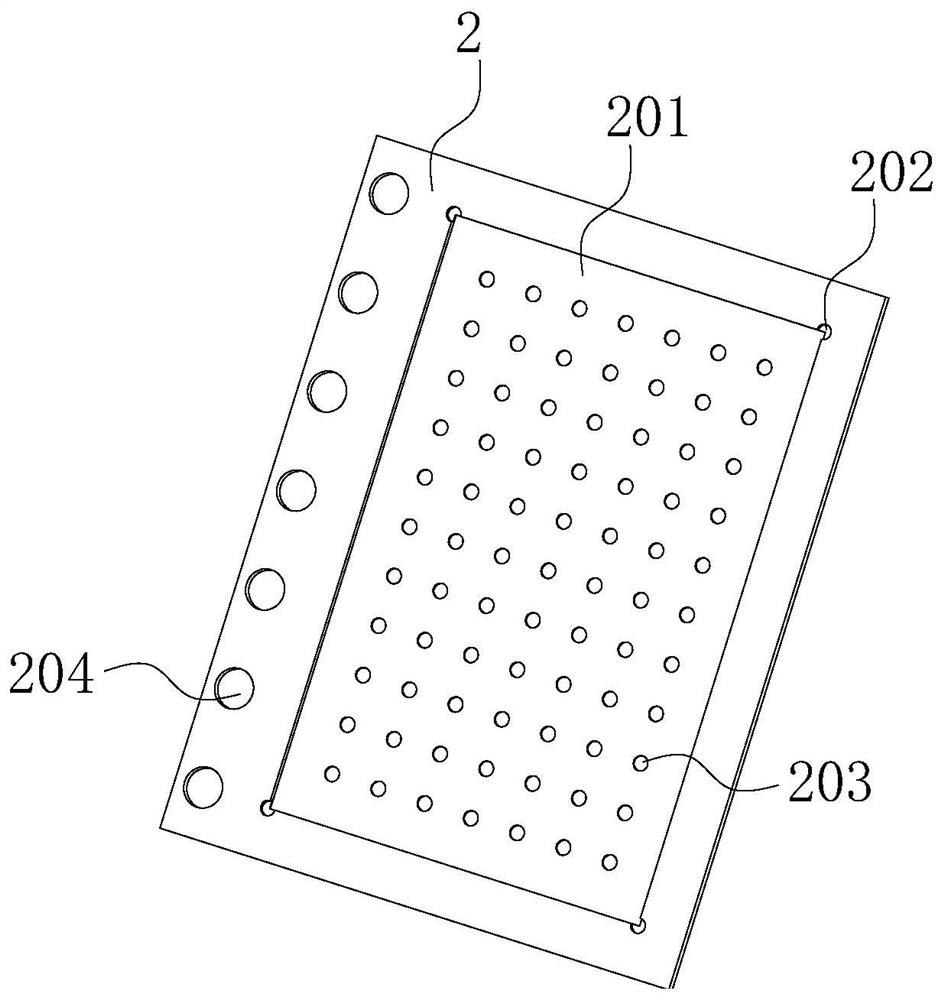

PendingCN110131338AGuaranteed reliabilityNo contact frictionBrake actuating mechanismsFriction liningElectric power equipmentEngineering

The invention provides an electromagnetic brake and a friction plate assembly thereof, and relates to the technical field of electric power equipment. The friction plate assembly comprises an armature, a friction plate and a baffle plate which are coaxially overlapped, wherein a connecting column is connected to one side of the baffle plate; the armature sleeves the connecting column and can slidealong the connecting column; the friction plate is limited between the baffle plate and the armature; the armature, the friction plate and the baffle plate are magnetic; mutual repelling force is generated between the armature and the friction plate; and the mutual repelling force is also generated between the friction plate and the baffle plate. A clearance is formed between a stator and the friction plate in electrifying engineering; the friction plate is rotated between the armature and the baffle plate under the effect of magnetic repelling force, so that two end surfaces of the frictionplate in rotating are prevented from contact and friction, and the dust, noise and abrasion caused by friction are minimized, and as a result, the reliability of the electromagnetic brake is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Tentering shaping conveying device for magnetic suspension functional fabric

The invention discloses a tentering shaping conveying device for a magnetic suspension functional fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:苏州盛泽科技创业园发展有限公司

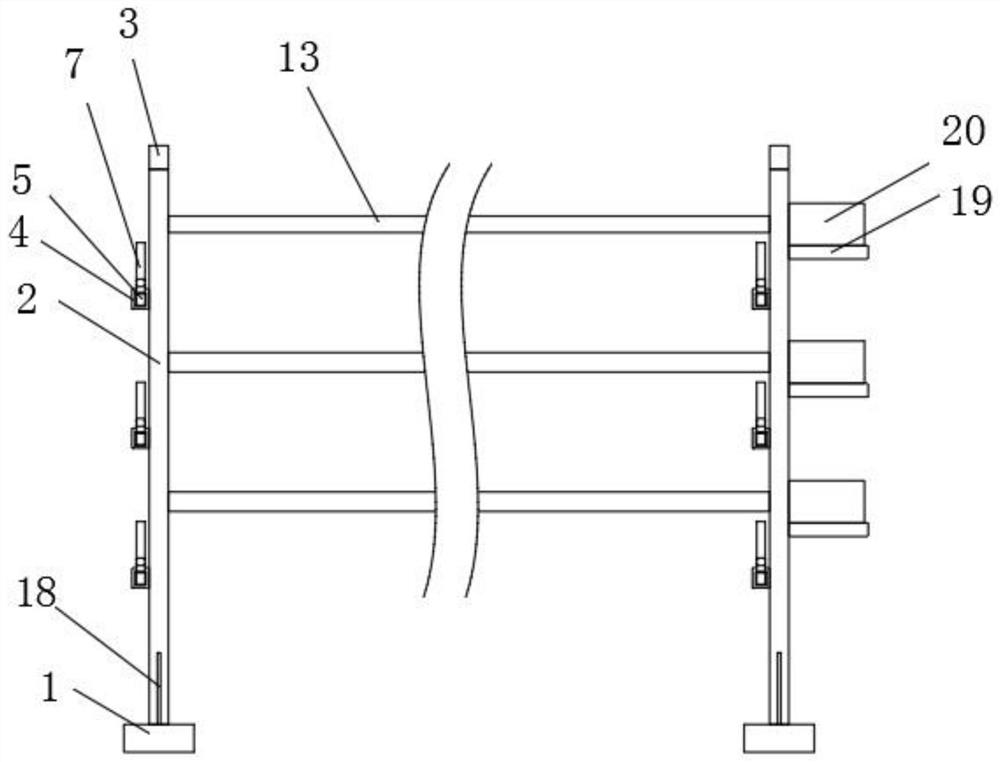

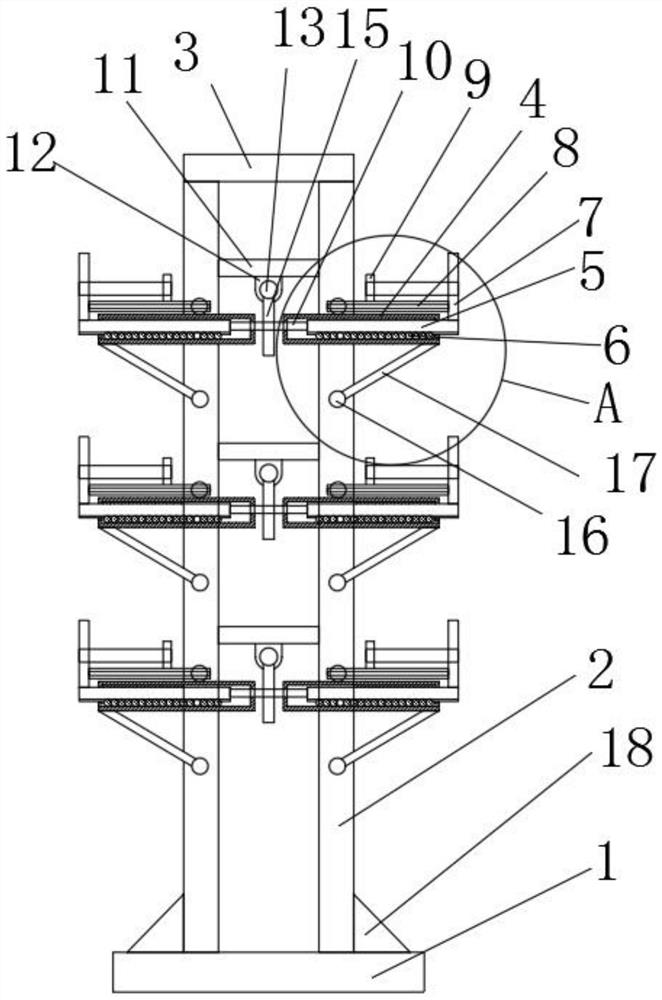

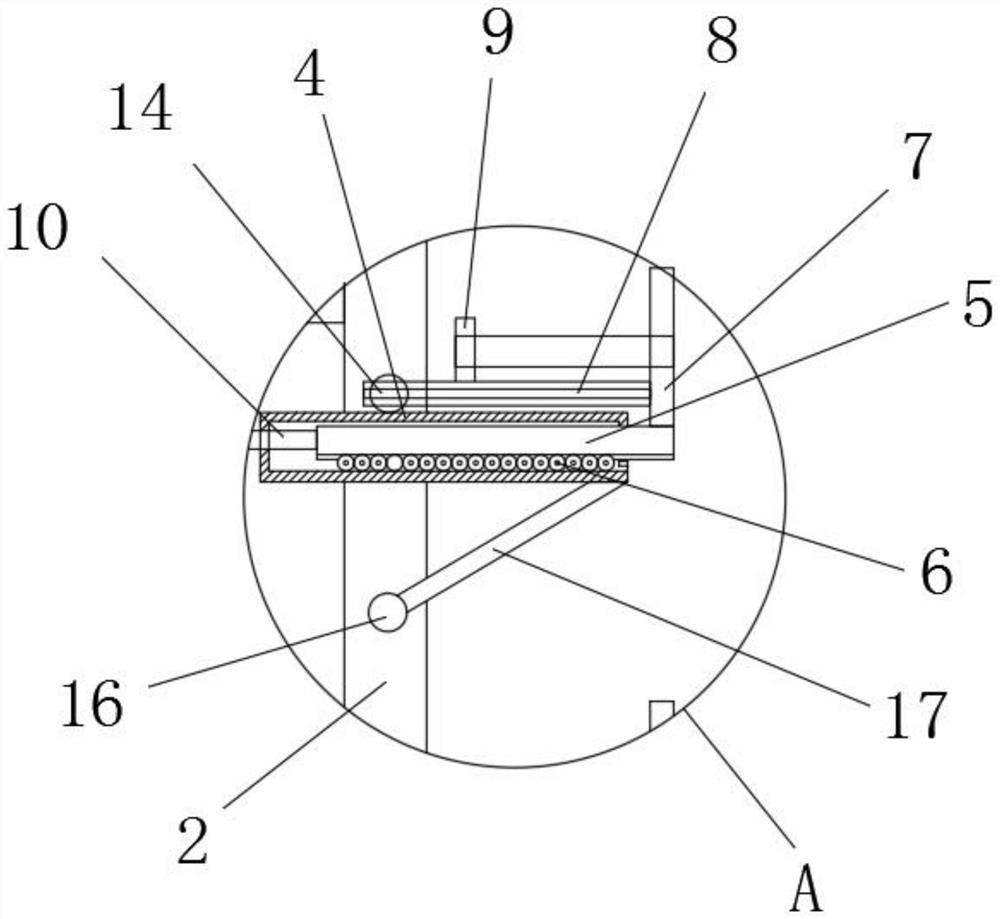

Linkage structure for drawer type three-dimensional material warehouse

The invention discloses a linkage structure for a drawer type three-dimensional material warehouse, and belongs to the technical field of material storage equipment. The linkage structure for the drawer type three-dimensional material warehouse comprises a base, wherein two stand columns are fixedly connected to the upper end of the base, the upper ends of the two stand columns on the same base are fixedly connected through a stand column connecting beam, a plurality of drawer sliding cylinders are fixedly connected to the stand columns, the drawer sliding cylinders are vertically arranged atequal intervals, and the drawer sliding cylinders on the two stand columns are arranged in a mirror symmetry mode. According to the linkage structure, the labor intensity for drawer movement can be effectively reduced, the drawers on the two sides are fixed on the two stand columns respectively, so that the supporting stability of the device is greatly improved, the drawers on the two sides shareone set of linkage structure, the number of linkage mechanisms is reduced, the production cost of equipment is reduced, the linkage mechanism is arranged between the drawers on the two sides, so thatdamage of the linkage mechanism caused by external factors can be effectively prevented, and continuous production and processing of a workshop are guaranteed.

Owner:WUXI YUSHEN HYDRAULIC MACHINERY

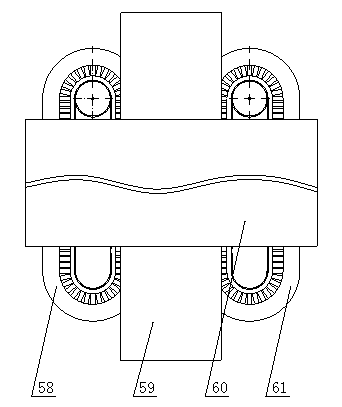

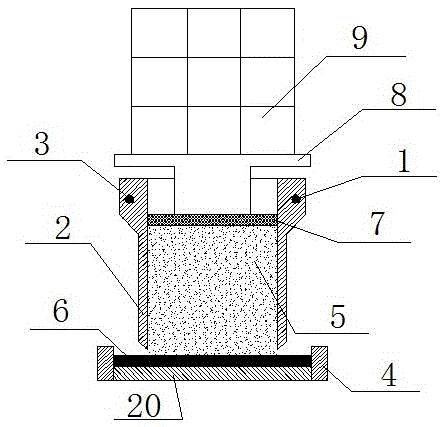

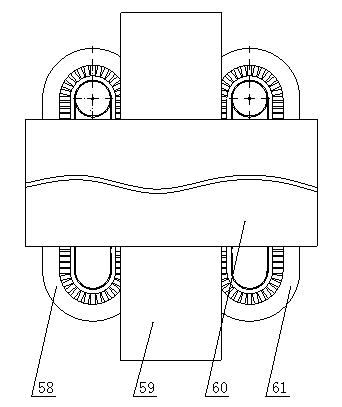

A test device and method for steel-soil interface shear characteristics considering the thickness of the shear band

InactiveCN103344508BNo contact frictionMaterial strength using steady shearing forcesSoil scienceStructural engineering

The purpose of the invention is to provide a steel-soil interface shear characteristic testing device and method considering the thickness of the shear band. The apparatus includes a shear box, a base plate and spacers. The base plate has a horizontal upper surface carrying the steel plate to be tested, the shear box has a hollow cavity for containing the soil sample to be tested, and also includes guide rails I and II fixed above the base plate and parallel to each other. When the steel plate to be tested is placed on the bottom plate, there is a gap between the lower end of the shear box and the upper surface of the steel plate to be tested. The spacer is filled in the gap. The test using the above device includes the following steps: 1) Fix the steel plate to be tested; 2) Insert the gasket into the gap; 3) Load the soil sample to be tested into the shear box; 4) Pull out the gasket; Apply a horizontal load parallel to the guide rail and reverse, and shear failure occurs at the steel-soil interface; 6) Apply a horizontal load in the opposite direction to step 5) on the shear box; 7) Repeat steps 5) and 6) several times.

Owner:CHONGQING JIAOTONG UNIVERSITY

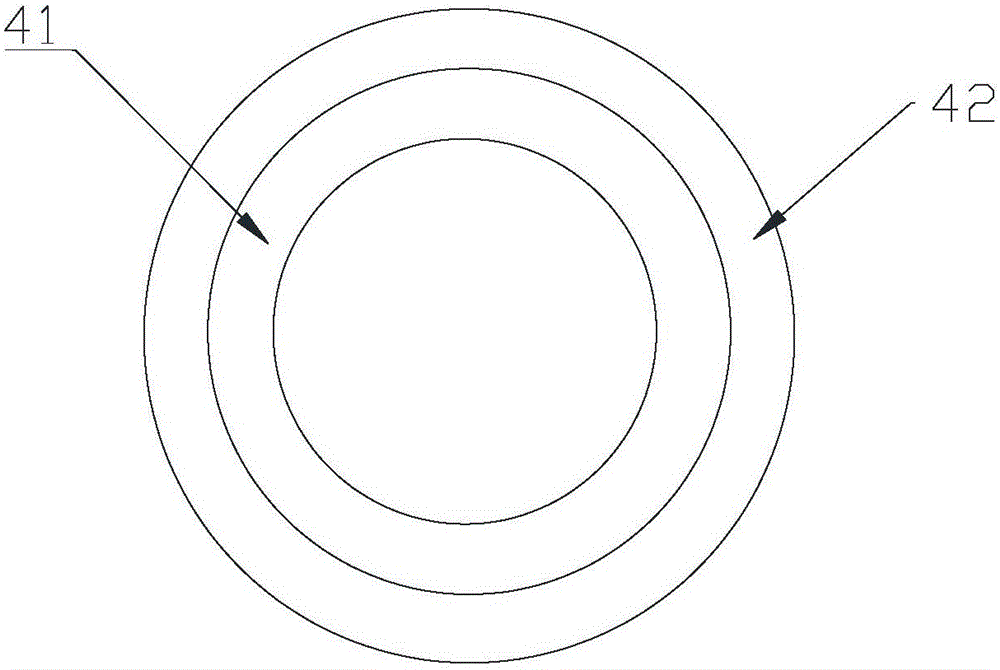

Pump body assembly and compressor with pump body assembly

PendingCN107514365AHigh working reliabilityImprove performancePump controlRotary/oscillating piston pump componentsEngineeringMechanical engineering

The invention provides a pump body assembly and a compressor with the pump body assembly. The pump body assembly comprises two structural parts, a bearing type air cylinder arranged between the two structural parts and at least one antifriction structure; the bearing type air cylinder comprises an outer ring and an inner ring capable of rotating relative to the outer ring; at least one antifriction structure arranged on the inner ring faces the end face of the corresponding structural part, and friction between the bearing type air cylinder and the structural parts is reduced. The problems that in the prior art, the bearing type air cylinder in the pump body assembly is prone to wear, and the reliability of the pump body assembly is reduced are effectively solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

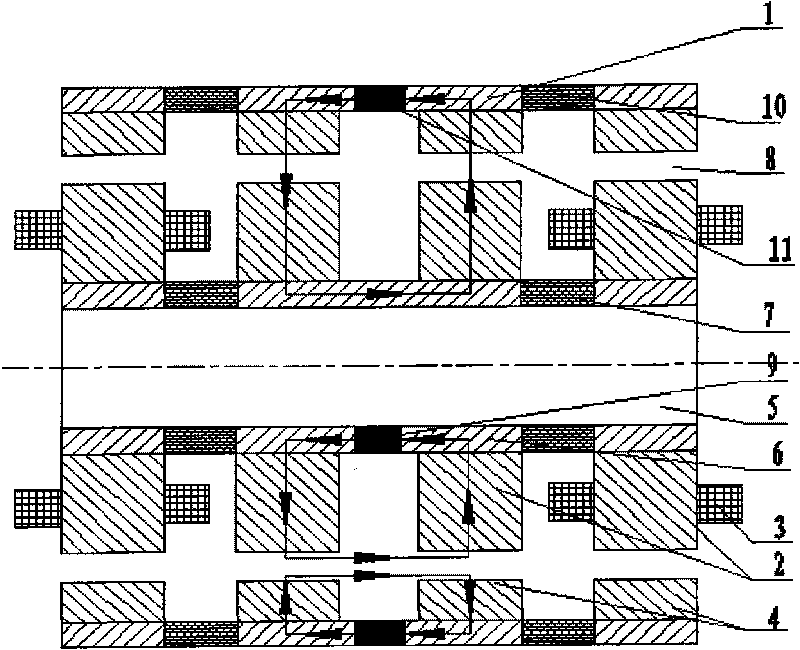

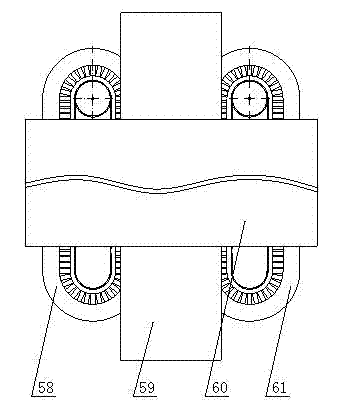

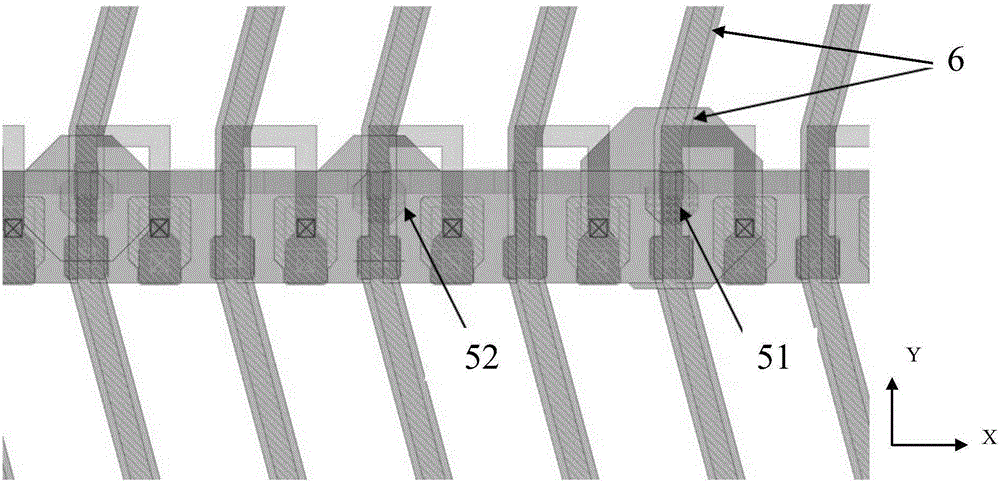

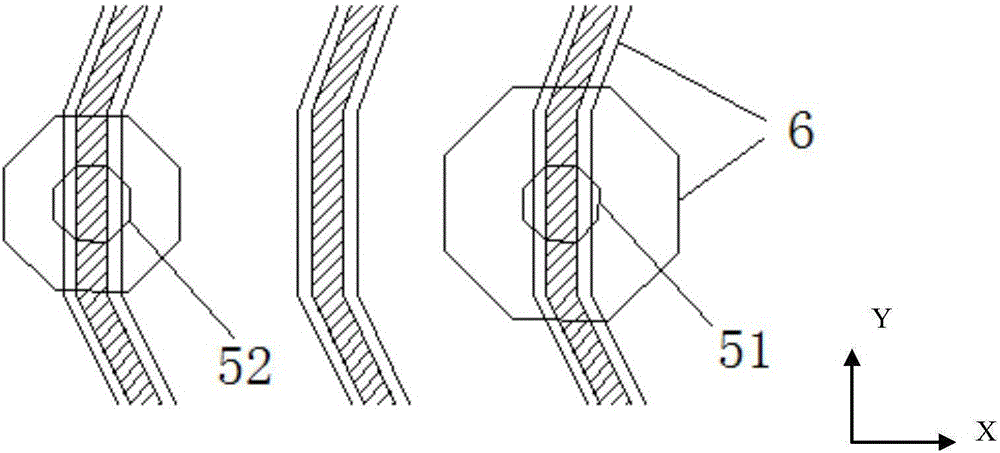

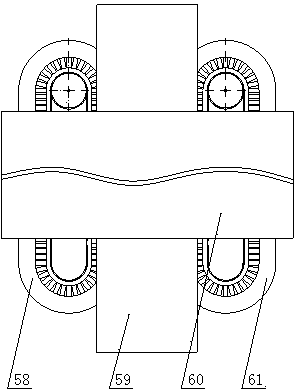

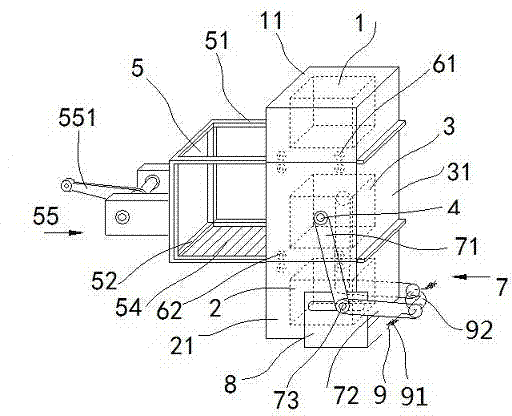

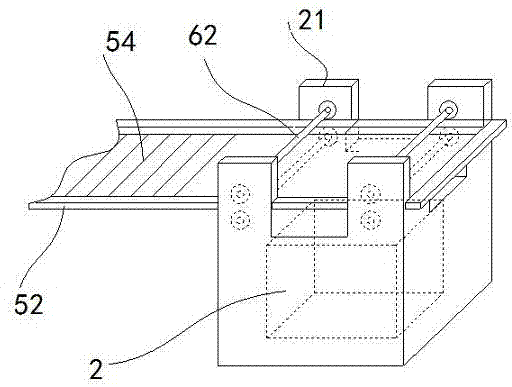

A linear eddy current braking device and a linear carrying device

ActiveCN105896877BNo contact frictionReduce noiseAsynchronous induction clutches/brakesEngineeringMulti segment

The invention discloses a linear current vortex brake apparatus and a linear carrying apparatus. The linear current vortex brake apparatus includes a stator and a mover, wherein the stator includes a substrate and a plurality of conductor sheets which are arranged on the substrate at uniform intervals in the width direction of the substrate; each conductor sheet utilizes a multi-segment structure made of materials with different resistivity; in the brake direction, the resistivity of each conductor sheet is successively reduced in the brake direction; the mover includes a connecting base and a plurality of permanent magnets which are arranged on the connecting base at uniform intervals in the width direction of the connecting base; the thickness of the permanent magnets at two side edges is a half of the thickness of the permanent magnets between the two side edges; the quantity of the permanent magnets is one more than the quantity of the conductor sheets; and the conductor sheets of the stator and the permanent magnets of the mover are respectively inserted into the mutual gaps. For the linear current vortex brake apparatus and the linear carrying apparatus, as a vortex brake apparatus which is made of segmented materials and uses a comb structure is utilized, stronger braking force can be continuously provided.

Owner:CHENGDU MAOYUAN TECH

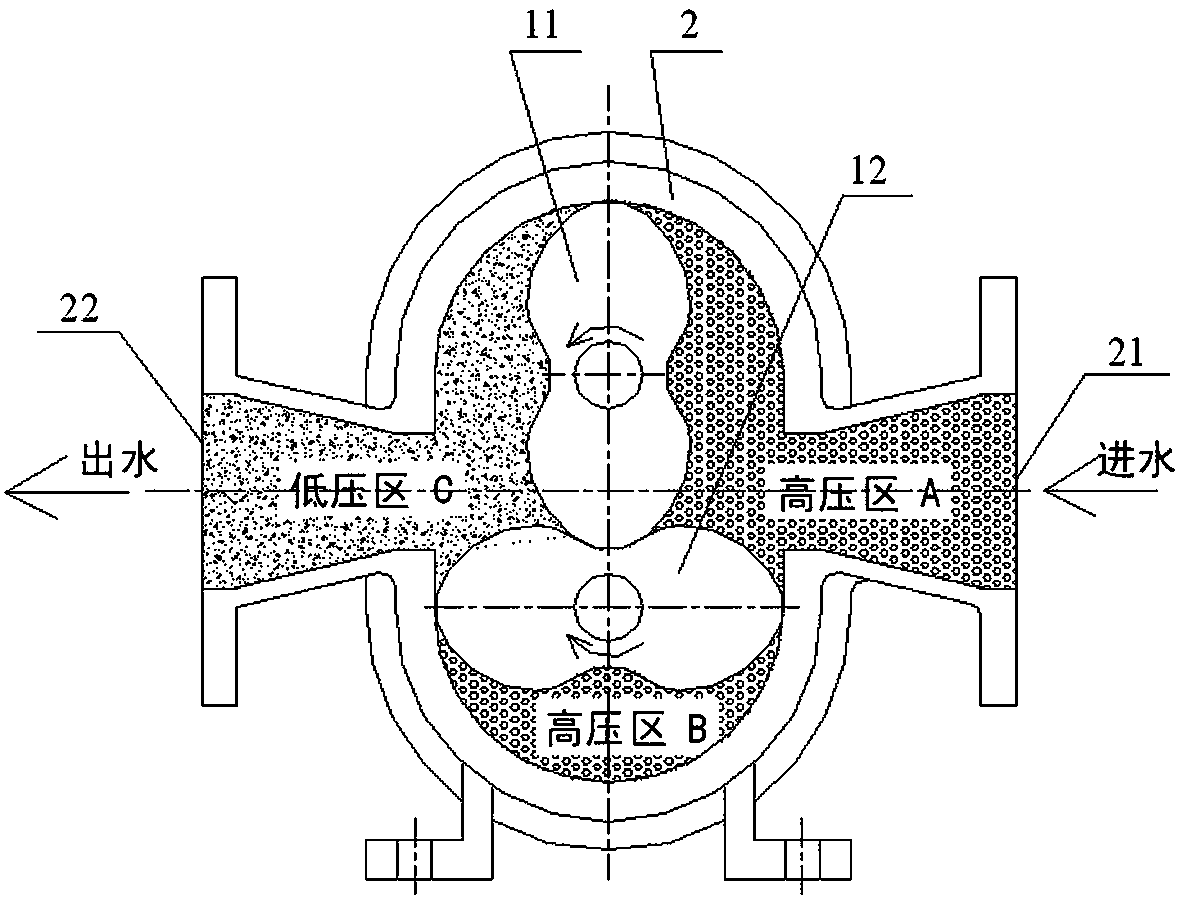

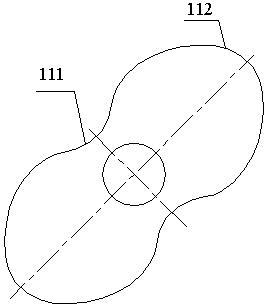

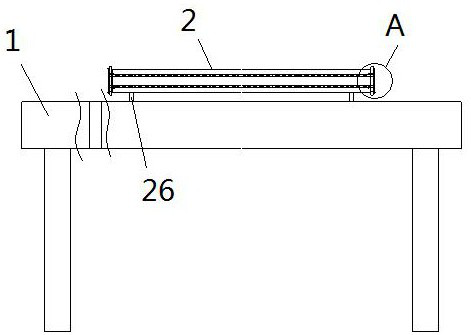

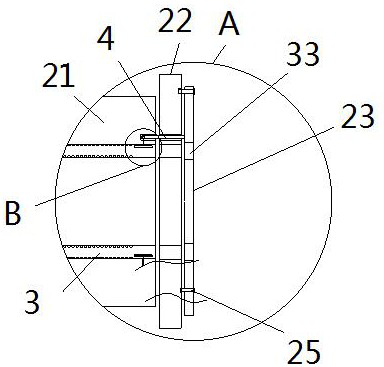

Capacity type micro water turbine, and fixed mixing ratio device based on water turbine

PendingCN110185576AReduce the chance of interferenceContinuous operationRotary piston enginesCouplingWater turbine

The invention relates to a capacity type micro water turbine, and a fixed mixing ratio device based on the water turbine. The capacity type micro water turbine comprises a capacity chamber and a turning wheel structure rotatably arranged in the capacity chamber, wherein a water inlet and a water outlet are further formed in the front side and the back side of the capacity chamber; the turning wheel structure comprises a first cam turning wheel and a second cam turning wheel meshing with each other up and down; the first cam turning wheel and the second cam turning wheel are provided with the axial cross sections being in '8' shapes, and comprise valley type sections arranged in arc shapes and ridge type sections arranged as conjugate curves; the valley type sections and the ridge type sections are arranged alternately at intervals; and the first cam turning wheel and the second cam turning wheel synchronously rotate in a cavity along the opposite directions. According to the capacity type micro water turbine, through arranging the water turbine and a capacity pump, after solvent liquid enters the turning wheel structure, a pressure difference is formed, and the water turbine is driven to rotate so as to drive the capacity pump to rotate through a coupler; and each time the water turbine rotates for a circle, the flowing solvent volume is a fixed value, and the volume of soluteliquid pumped by the capacity pump rotating for a circle each time is further a fixed value, so that the fixed mixing ratio of a mixing solution is realized.

Owner:新乡市豫通泵业有限公司

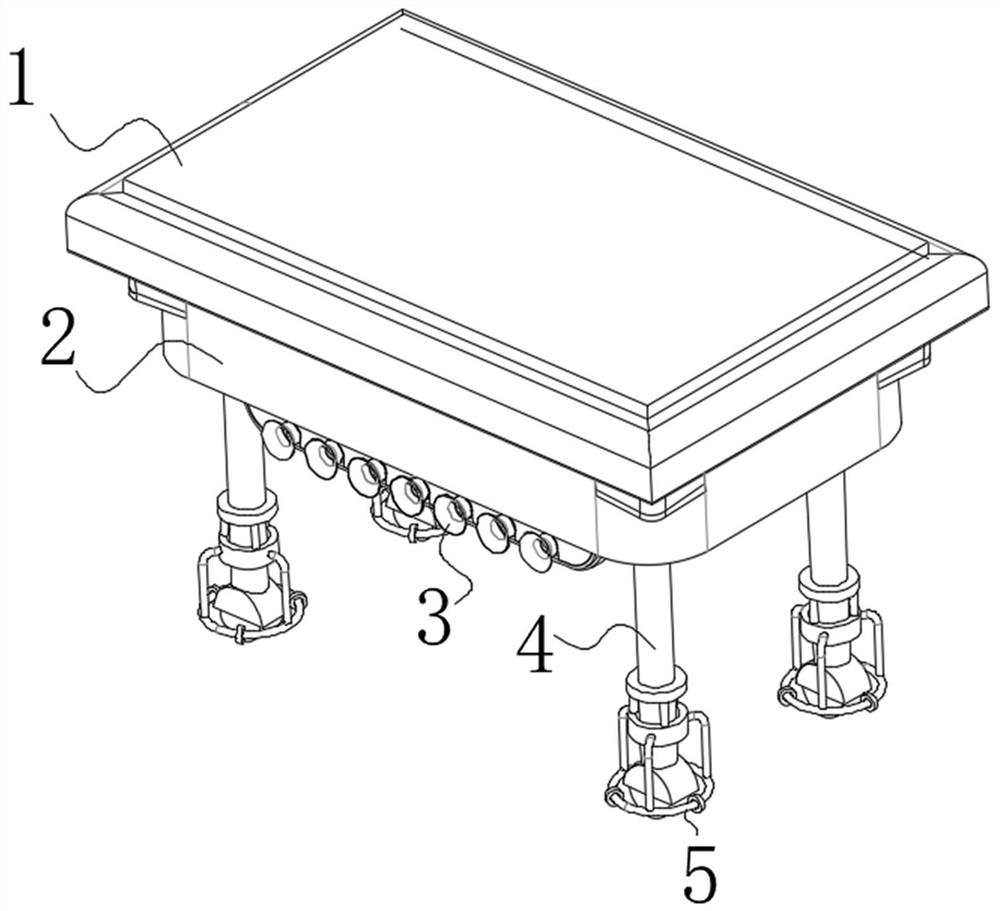

A special desk for computer with cable management mechanism

ActiveCN112515348BAchieve protectionImprove cable management efficiencyOffice tablesFurniture partsSoftware engineeringDesk

Owner:山东云尚信息科技股份有限公司

Special computer desk with wire arrangement mechanism

ActiveCN112515348AAchieve protectionImprove cable management efficiencyOffice tablesFurniture partsEngineeringDesk

The invention relates to the technical field of computer desks, and discloses a special computer desk with a wire arrangement mechanism. The special computer desk comprises a desk body, the wire arrangement mechanism is arranged on the rear side of the top of the desk body, the wire arrangement mechanism comprises a wire arrangement column, a side plate and a limiting fan plate, and six groups offirst threading holes and second threading holes penetrating through the left and right ends of the wire arrangement column are formed in the wire arrangement column. According to the special computerdesk with the wire arrangement mechanism, connecting wire bodies of a computer are arranged in the first threading holes and the secondthreading holes of the wire arrangement column, so that the wirebodies of the computer are protected, and the problems that the wire bodies are exposed in the air, are easily contaminated by dust and need to be wiped and cleaned periodically are solved; and besides, independent arrangement and distinguishing of the wire bodies are achieved, the different types of wire bodies are placed in six sets of independent first threading holes and six sets of independent second threading holes correspondingly, and the classified wire bodies are separated from one another and stored independently, so that the problem that the wire bodies are wound and disordered issolved, and the wire arrangement efficiency is further improved.

Owner:山东云尚信息科技股份有限公司

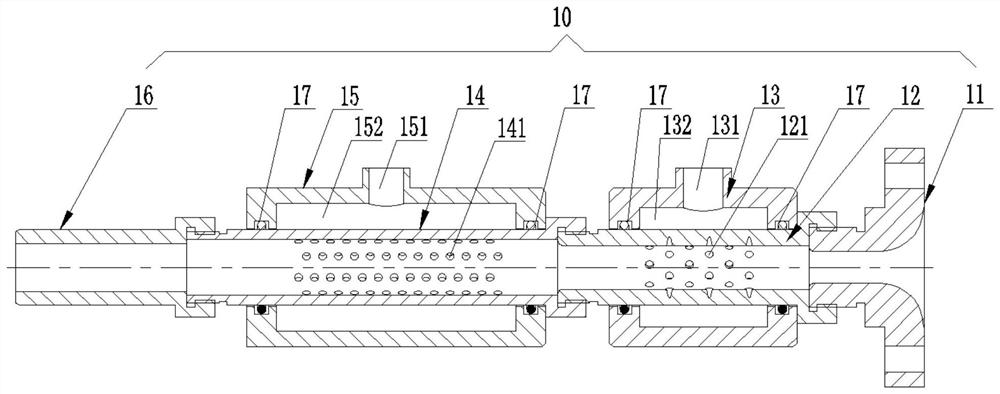

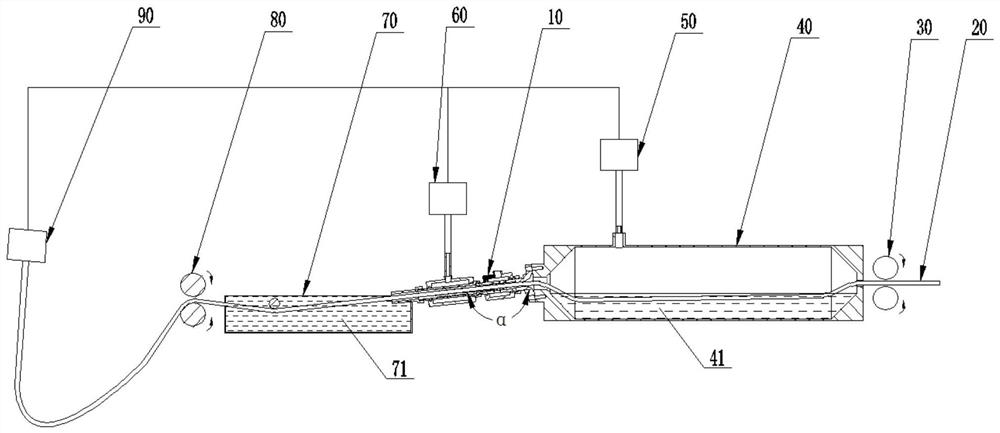

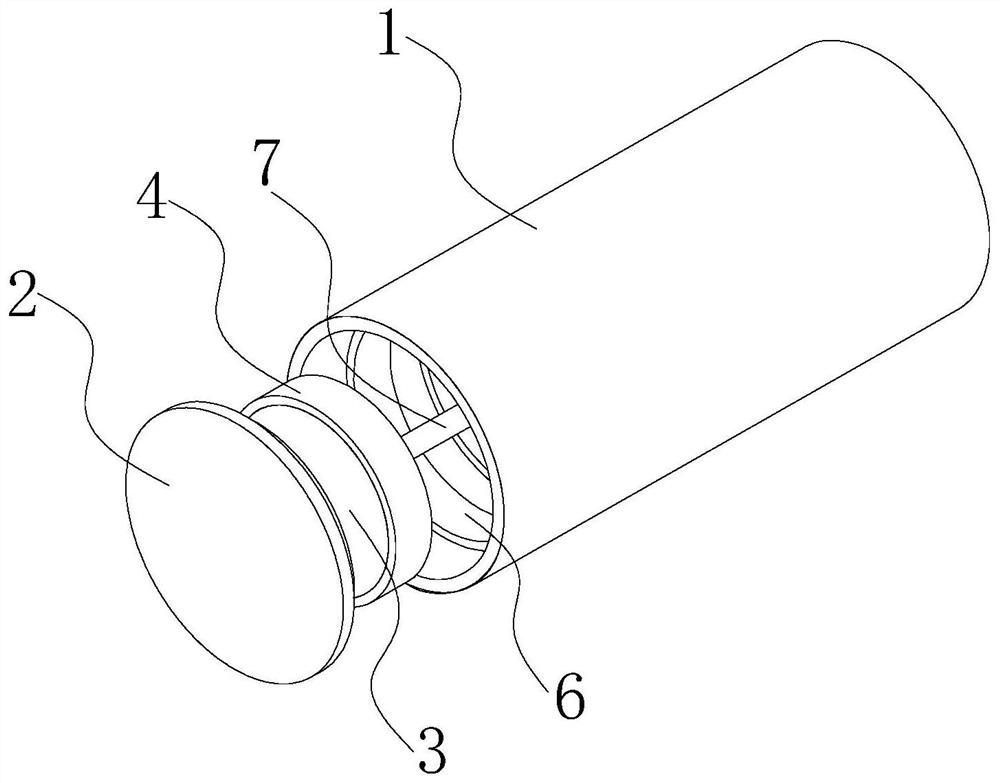

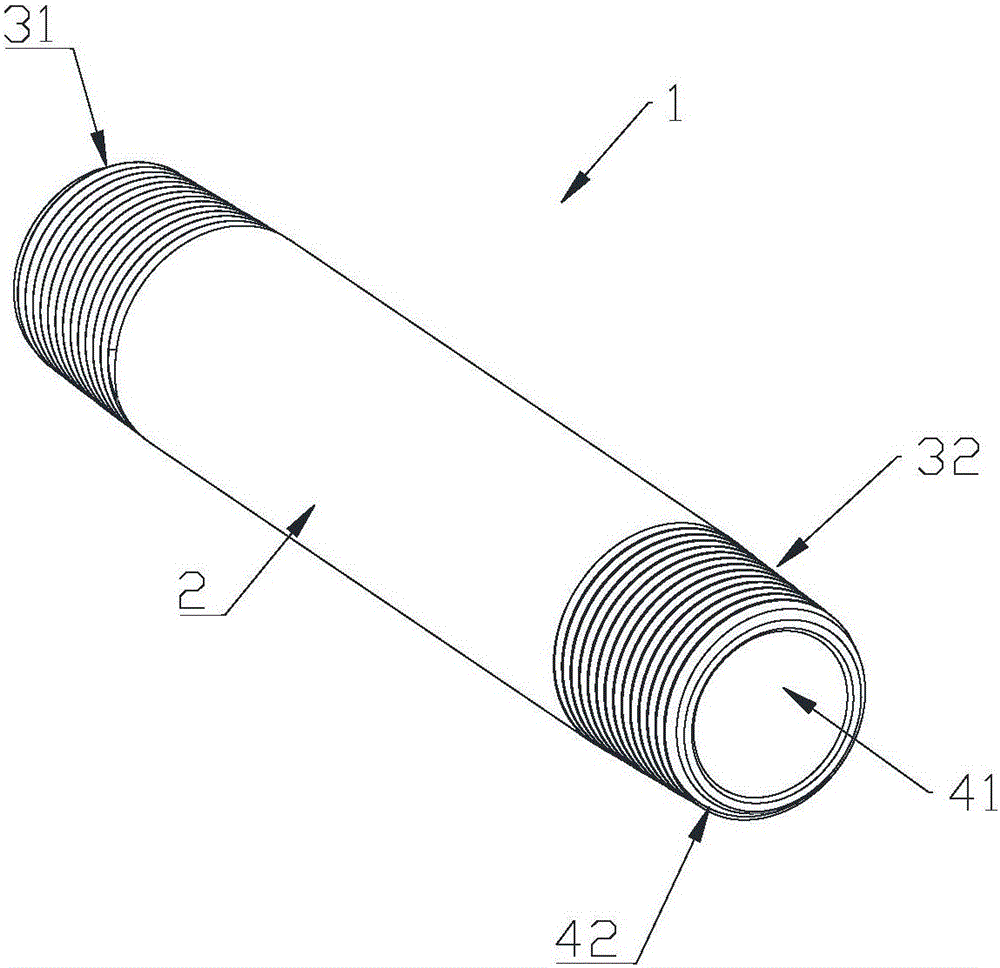

Minor-caliber thick-wall heat shrinkable pipe expansion mold and expansion system thereof

The invention discloses a minor-caliber thick-wall heat shrinkable pipe positive pressure expansion mold and an expansion system thereof. The expansion mold comprises a mold butt joint flange, an exhaust pipe core, an expansion pipe core and a sizing pipe core which are sequentially and fixedly communicated, wherein an exhaust pipe core outer sleeve is arranged outside the exhaust pipe core in a sleeving way; an exhaust through hole used for exhausting is formed in the exhaust pipe core outer sleeve; an expansion pipe core outer sleeve is arranged outside the expansion pipe core in a sleevingway; an inflation hole is formed in the expansion pipe core outer sleeve; a pressure maintaining cavity is defined between the expansion pipe core outer sleeve and the expansion pipe core; a pluralityof small exhaust holes are formed in a position, surrounded by the exhaust pipe core outer sleeve, of the exhaust pipe core; and a plurality of small pressure maintaining holes are formed in a position, surrounded by the expansion pipe core outer sleeve, of the expansion pipe core. The minor-caliber thick-wall heat shrinkable pipe positive pressure expansion mold and the expansion system have theadvantages that the contact friction on the pipe inner walls of the heat shrinkable pipe and the expansion pipe core is reduced, or even avoided, so that the heat shrinkable pipe can maintain the performance of lower eccentricity, stable longitudinal shrinkage rate and smoothness.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

A self-powered downhole drilling tool vibration sensor based on triboelectric nanogenerator

ActiveCN112924014BSelf-poweredReduce radial sizeSubsonic/sonic/ultrasonic wave measurementUsing electrical meansVibration amplitudeNanogenerator

The invention provides a self-powered downhole drilling tool vibration sensor based on a triboelectric nanogenerator, comprising: a casing for connecting with the drilling tool; a slider slidably arranged in the casing, and a nanomaterial film is arranged on the surface of the slider; The friction electrode on the sliding path of the slider; a plurality of sensing electrodes arranged in the casing along the sliding direction of the slider; The friction electrodes are frictionally charged, and each sensing electrode generates electrostatic induction with the charged friction electrodes. The single-chip microcomputer detects the electrical signals generated on each sensing electrode, and calculates the vibration amplitude according to the positional relationship of each sensing electrode. The beneficial effects of the invention are as follows: the vibration amplitude and vibration frequency of the drilling tool can be calculated, so as to realize the monitoring of the working safety of the drilling tool; the axial vibration energy of the drilling tool is collected to supply power to the single-chip microcomputer, and the self-power supply of the sensor is realized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

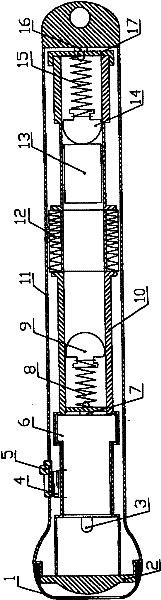

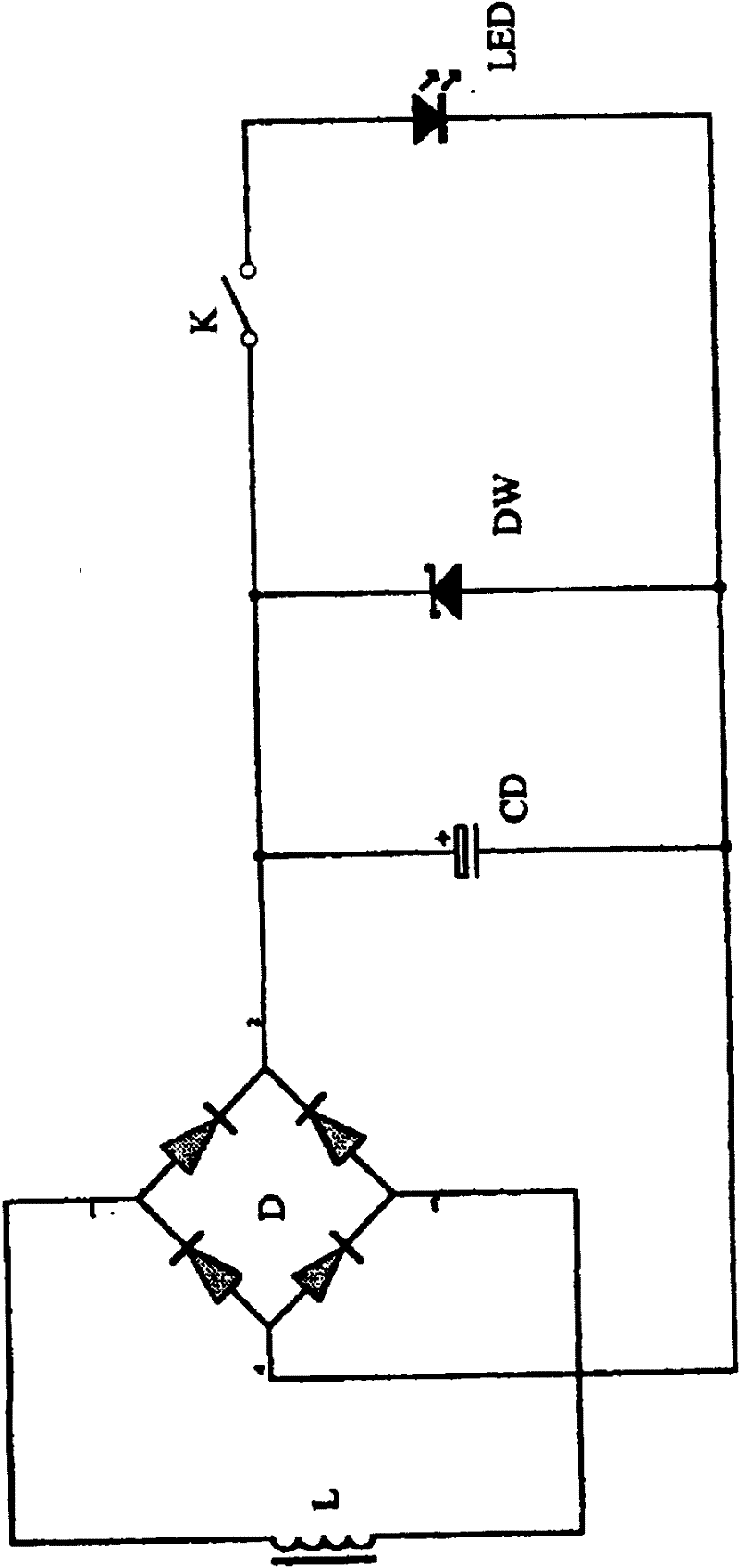

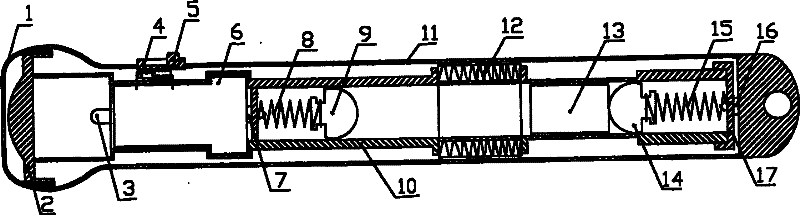

Permanent flashlight

InactiveCN102679173AAvoid pollutionExtended service lifeElectric circuit arrangementsElectric lighting with built-in generatorsCapacitanceEngineering

The invention relates to a permanent flashlight, which comprises a shell, a switch, a luminous body, and a condensing body and a condensing cover which are arranged at the head of the shell, wherein a main body in which a permanent magnet can be arranged and can move back and forth is arranged in the shell; a coil winds the main body, an output end of the coil is connected with the luminous body, namely a light-emitting diode (LED), through an electronic circuit, and elastic devices consisting of screws, springs and rubber heads are arranged at the front and rear ends of the permanent magnet; the switch is a magnetic switch and comprises a small magnet which is arranged on an outer wall of the shell and can move back and forth and a pair of upper and lower corresponding movable and static elastic reeds which are arranged in the shell and are positioned in a reed pipe in front of the small magnet; and the movable and static reeds are sealed in a glass tube, and contact pins at two ends of each of the movable and static reeds are connected in series between a capacitor and the LED. The permanent flashlight has the advantages that the energy is saved, and environmental pollution is avoided; and meanwhile, by the magnetic switch, contact friction is avoided; and therefore, the switch has long service life, the shell is fully sealed, and the permanent flashlight is high in waterproof performance, simple in structure and low in cost.

Owner:陆英

Large-caliber pump coupling metal hose

InactiveCN105864533AExtended service lifeNo contact frictionFlexible pipesRubber layered productsCouplingEngineering

The invention discloses a large-caliber pump coupling metal hose which comprises a hose body, wherein a first coupling end and a second coupling end are respectively arranged at the two ends of the hose body; the hose body is of a double-layered structure which comprises a rubber tube and a metal silk-woven tube from inside to outside; if the length of the metal hose is L, the radius of the rubber tube is r and the radius of the metal silk-woven tube is R, the relation is as follows: L=2r+3R and R=6r / 5; and the rubber tube and the metal silk-woven tube are fixedly connected through an elastic rubber layer. The large-caliber pump coupling metal hose disclosed by the invention comprises one inside rubber tube and one outside metal silk-woven tube, the rubber tube and the metal silk-woven tube are not separated, but fixedly connected through the elastic rubber layer, so that the rubber tube is not in contact friction with the metal silk-woven tube; meanwhile, the dimension design of the whole hose body is more scientific, so that the possibility of greatly bending the hose is reduced; and the rubber tube and the metal silk-woven tube are made of a material which is more resistant to ageing, so that the service life of the large-caliber pump coupling metal hose is greatly prolonged.

Owner:JIANGSU YANGGUANG MACHINERY MFG

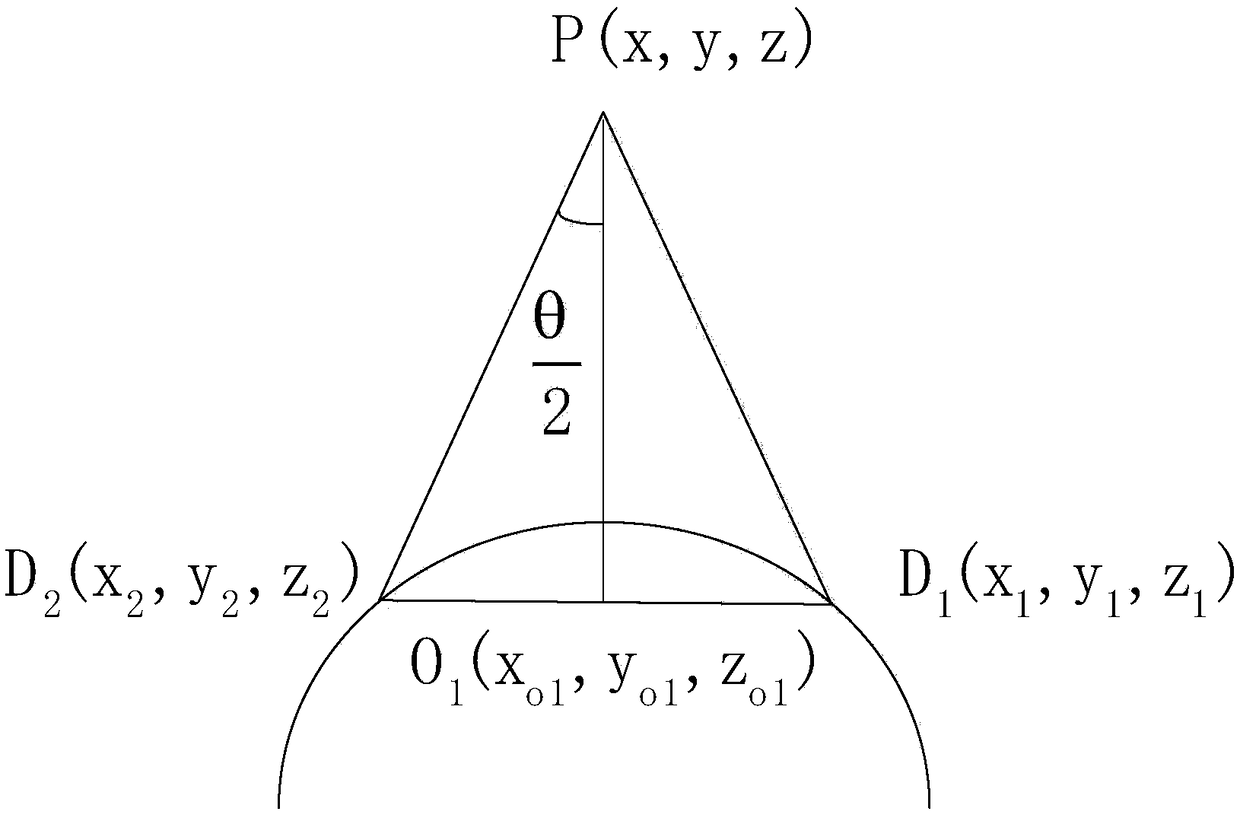

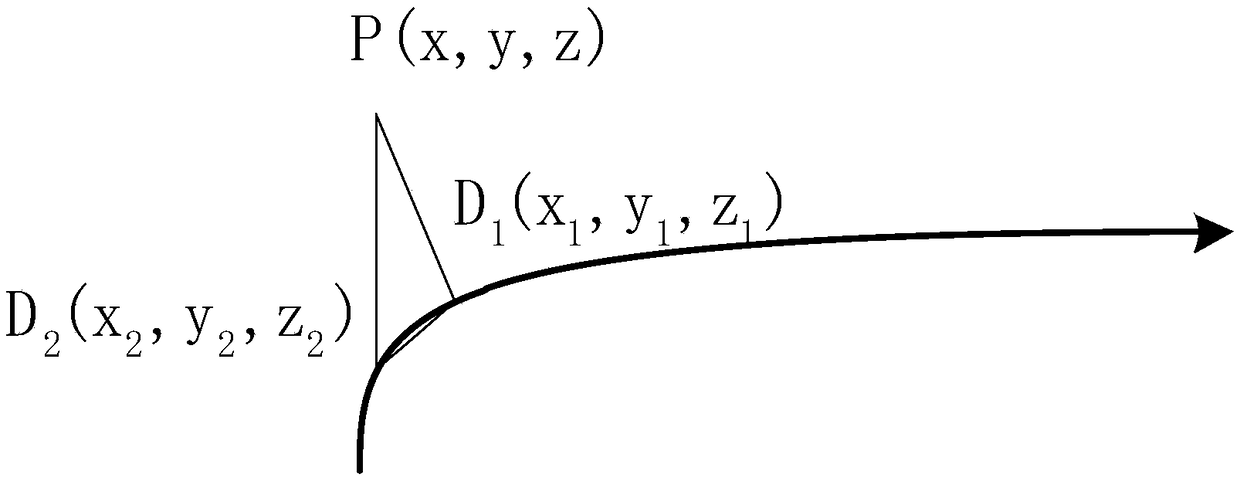

A Method for Determining Local Surface Normal Vectors Based on Dual Infrared Sensors

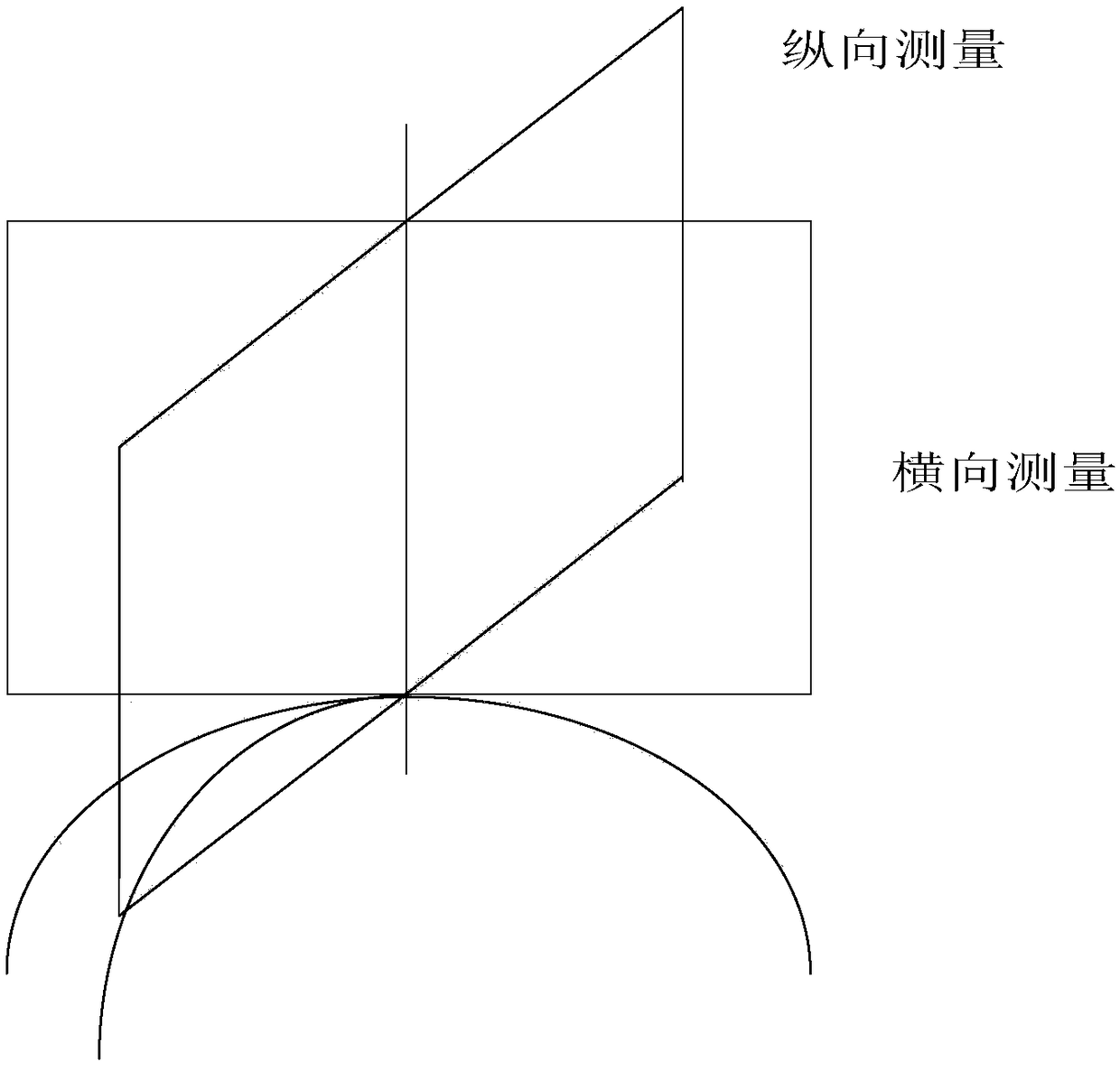

ActiveCN107063086BEasy to handleAvoid inefficiencyUsing optical meansLongitudinal planeTransverse plane

The invention relates to a local curved surface normal vector determining method based on double infrared sensors. The objective of the invention lies in solving a problem that a conventional measurement method cannot achieve the determining of a local curved surface normal vector. The method comprises two parts: lateral measurement and longitudinal measurement. The longitudinal measurement comprises the following steps: obtaining the coordinates of a robot nozzle in the geodetic coordinate system, and determining that the robot nozzle is located in a lateral plane which is perpendicular to a to-be-sprayed workpiece surface; the lateral measurement comprises the following steps: obtaining the coordinates P(x, y, z) of the robot nozzle in the geodetic coordinate system, recording the sampling points where the robot nozzle passes by in a moving process, and determining that the robot nozzle is in a longitudinal plane which is perpendicular to the to-be-sprayed workpiece surface; repeatedly carrying out the lateral measurement and longitudinal measurement, enabling the lateral plane to be intersected with the longitudinal plane, and determining the normal vector of the to-be-sprayed workpiece surface. The method is used in the spraying field.

Owner:宁波智能装备研究院有限公司

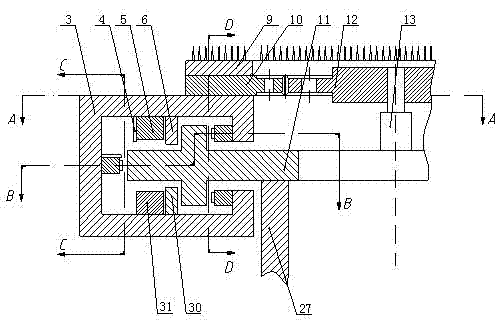

High-performance dustproof mechanical sealing structure

ActiveCN108730353AImprove sealingNo contact frictionEngine sealsSupports/enclosures/casingsEngineeringContact friction

The invention discloses a high-performance dustproof mechanical sealing structure. The high-performance dustproof mechanical sealing structure comprises a rotor penetrating through a gear box, a bearing, a straining shaft sleeve and an outer end cover, wherein the outer end cover is installed on a position, through which the rotor penetrates, of the gear box, the outer end cover is fixed on the gear box by virtue of a plurality of fastening screws, the bearing is installed between the inner wall of the gear box and the rotor, the straining shaft sleeve sleeves the rotor, the straining shaft sleeve is in clearance fit with the rotor, and the outer circumference of the straining shaft sleeve is provided with a circle of steps. The high-performance dustproof mechanical sealing structure has the beneficial effects that when external dust enters the outer end cover, the dust is firstly prevented by a dustproof cover and the outer end cover, even when little dust can enter the outer end cover, the dust can remain in a sealed chamber formed by encircling a sealed ring l, the straining shaft sleeve, the outer end cover and the side wall of the gear box, the dust cannot further enter the sealing structure, the sealing effect is good, no contact friction is produced, and the high-performance dustproof mechanical sealing structure integrates the advantages of the contact sealing and noncontact sealing, and has good sealing performance.

Owner:ANHUI NANFANG CHEM PUMP IND

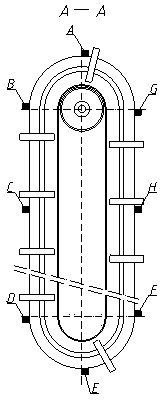

Tentering shaping conveying device for coated fabric

ActiveCN103015100BReasonable structureNo contact frictionLiquid surface applicatorsCoatingsLow noiseEngineering

The invention discloses a tentering shaping conveying device for a coated fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:义乌市鼎莎针织有限公司

Accounting-based bill fold with anti-loss function

The invention discloses an accounting-based bill fold with an anti-loss function, and relates to the technical field of accounting related equipment. The bill fold comprises an upper cover plate and a lower cover plate, a placement opening is formed in the middle of the upper end of the lower cover plate, an anti-abrasion ring is arranged on the inner side wall of the placement opening, clamping plates are arranged on the front portion and the rear portion in a mounting opening, anti-abrasion pads are fixed to the middles of the right sides of the clamping plates, and reset springs are fixed to the upper portions and the lower portions of the left sides of the clamping plates. Movable blocks are fixed to the positions, corresponding to the mounting opening, of the reset springs, split rings are arranged at the opposite angles between the upper cover plate and the lower cover plate, and arc-shaped rods are arranged at the openings of the split rings. According to the bill fold, the reset springs push the clamping plates and extrude bills, so that the loss of the bills is avoided, anti-abrasion rings and the anti-abrasion pads protect the bills, damage to the surfaces of the bills is avoided, meanwhile, the arc-shaped rods move into the split rings, so that the upper cover plate and the lower cover plate are quickly disassembled and cleaned, and dirt on the surfaces of the bills is avoided.

Owner:TANGSHAN VOCATIONAL & TECHN COLLEGE

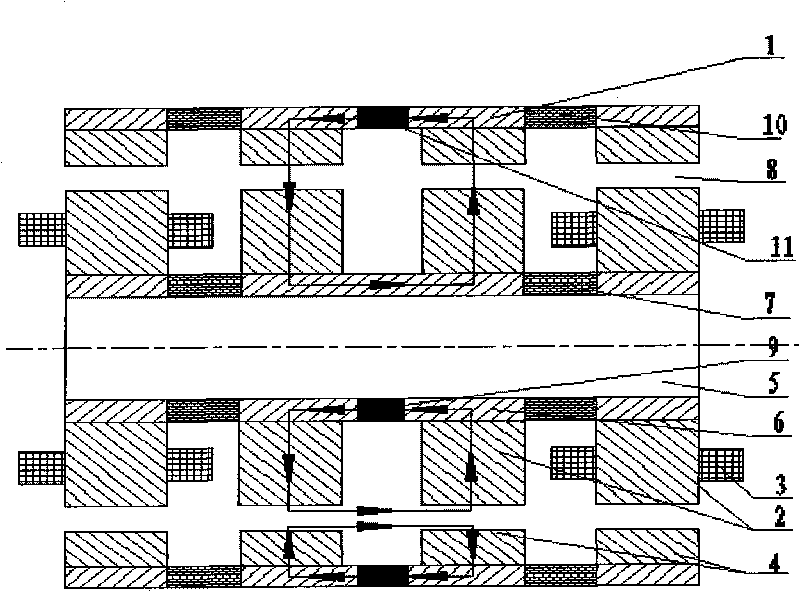

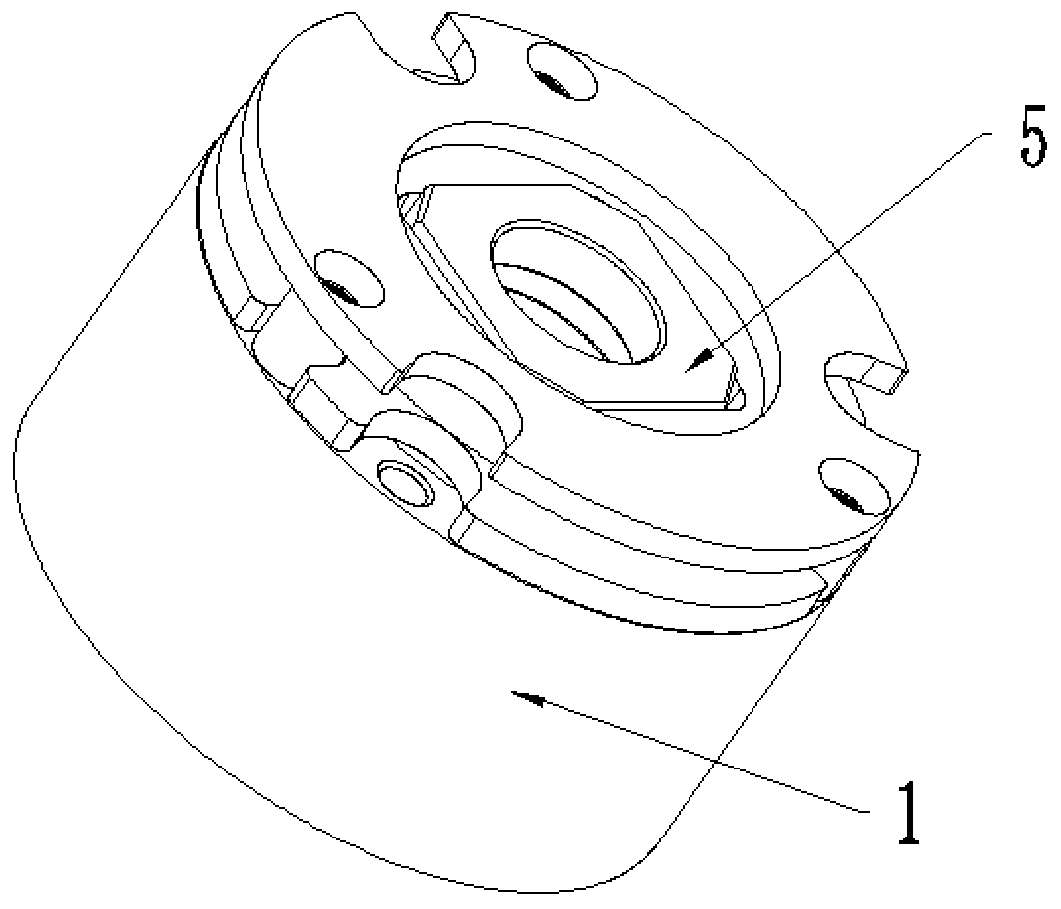

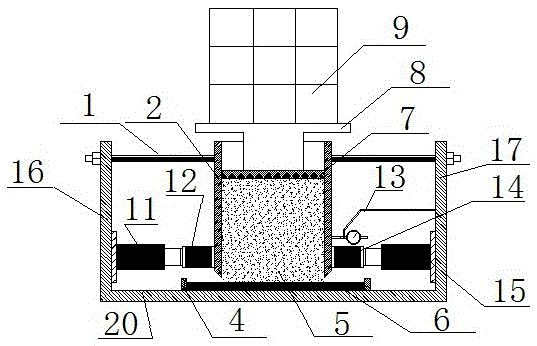

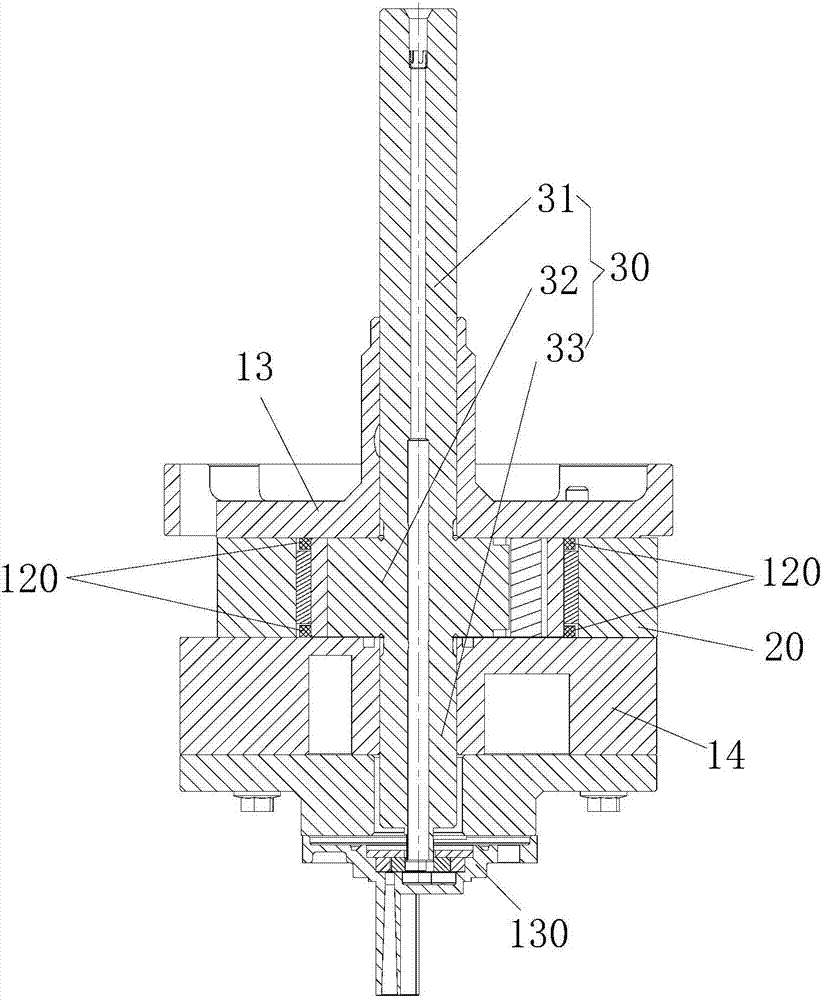

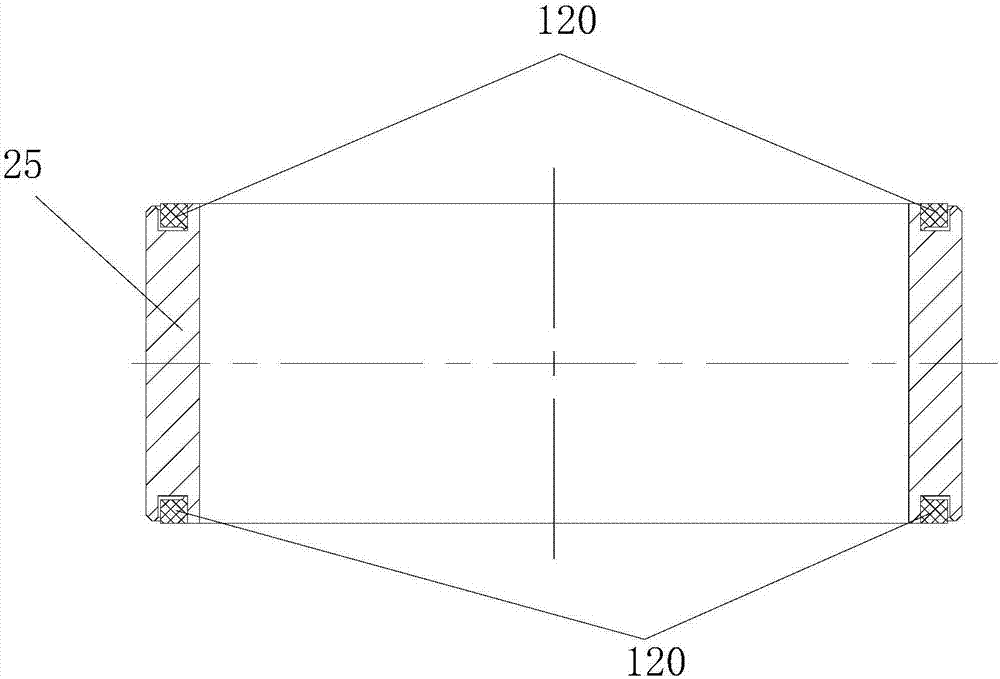

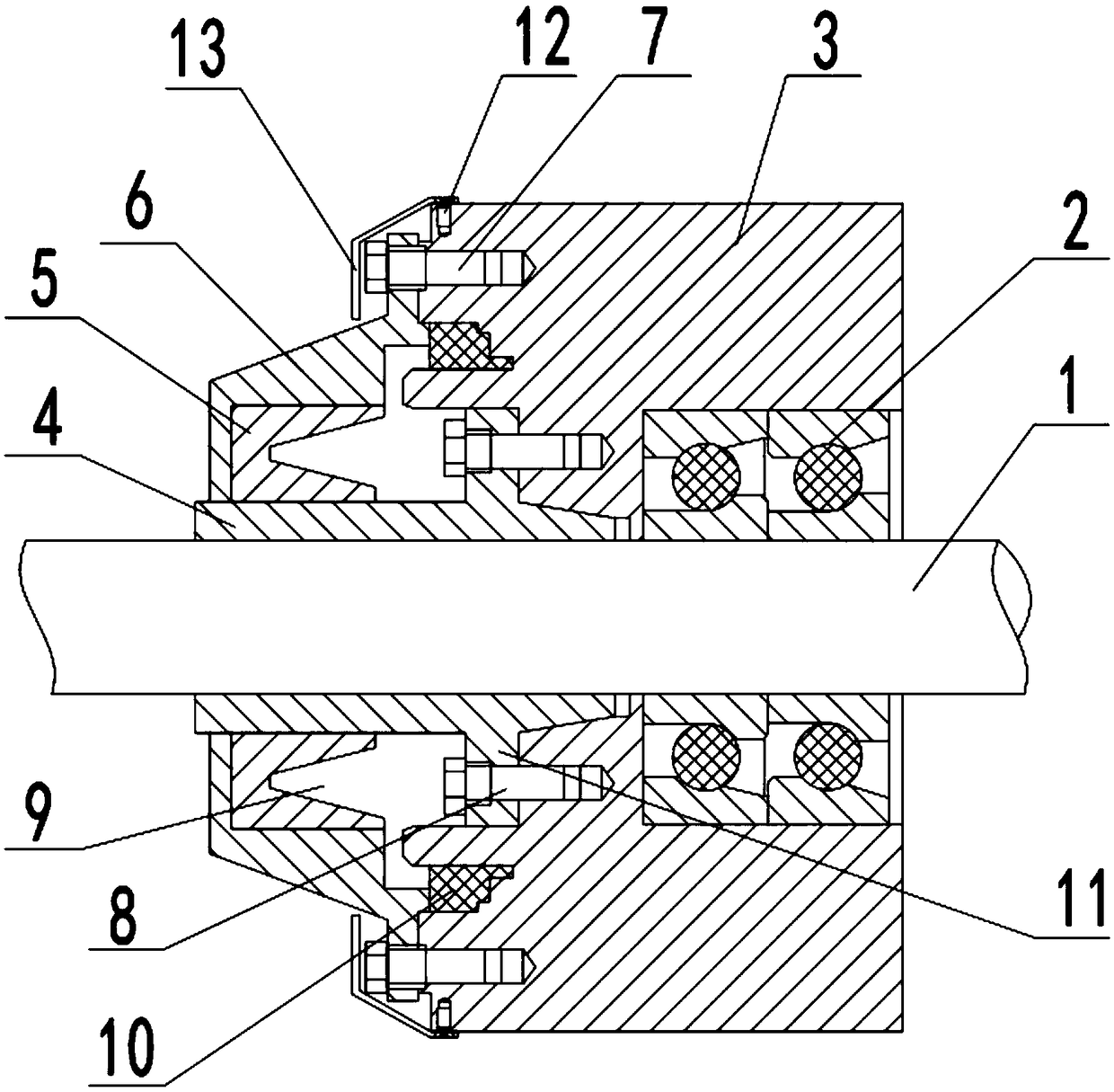

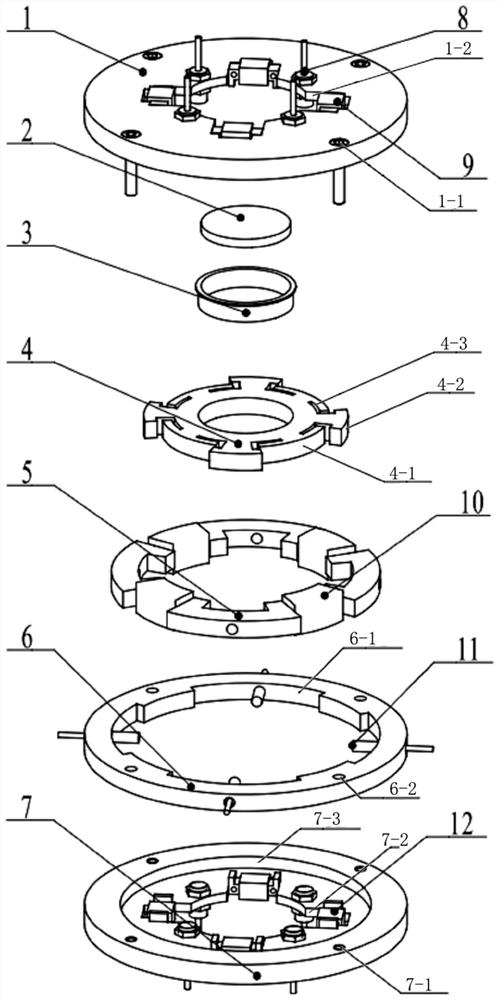

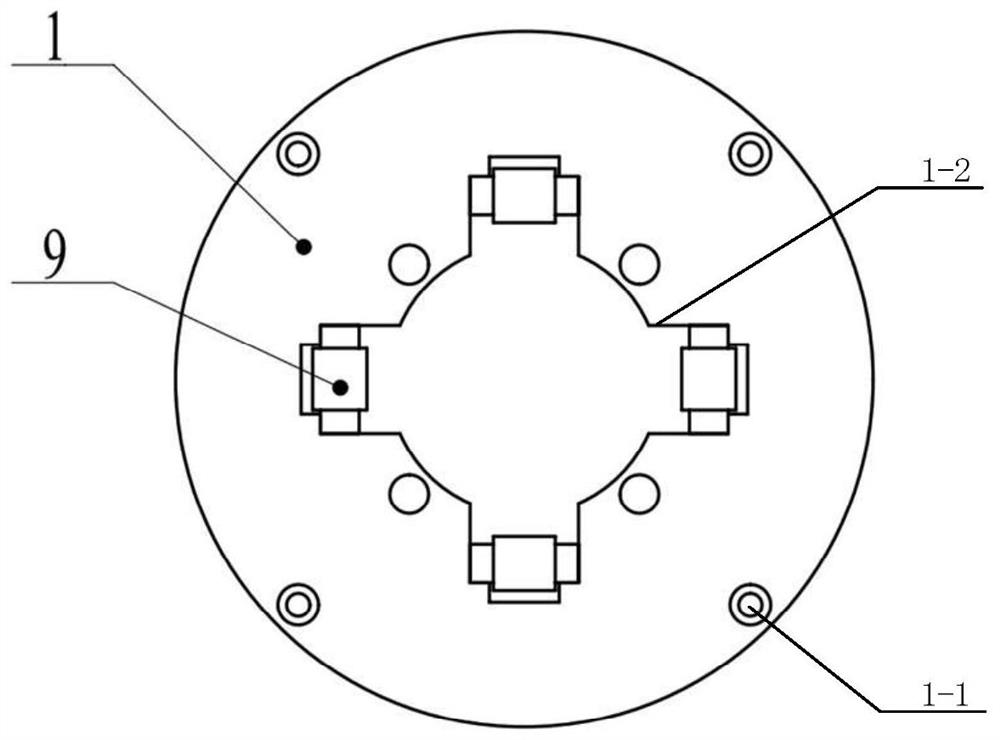

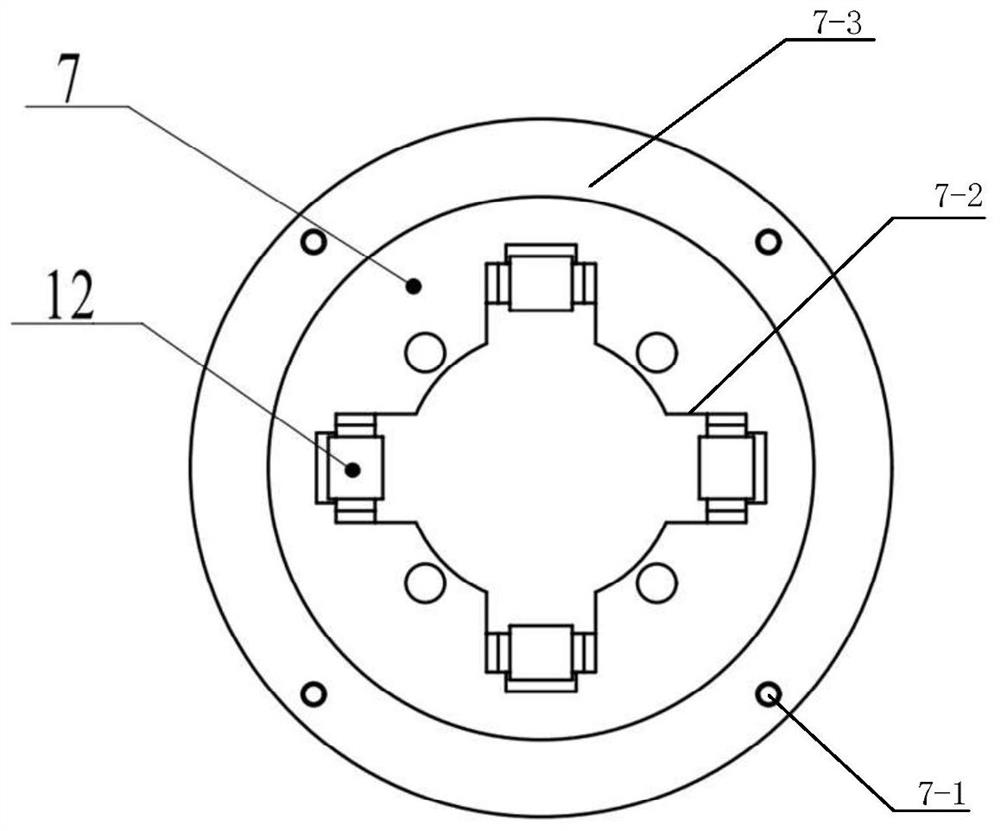

Magnetic levitation driver with 5DOF light-path control

PendingCN112122793AImprove response speedHigh control precisionMagnetic holding devicesLaser beam welding apparatusEngineeringMotor control

The invention discloses a magnetic levitation driver with 5DOF light-path control. The driver comprises an upper end cover 1, a floater 4, a radial stator 5, a connecting ring 6 and a lower end cover7, wherein the floater 4 is positioned in the radial stator 5, and an air gap is reserved between the floater 4 and the radial stator; the radial stator 5 is arranged in the connecting ring 6; and theupper end cover 1 and the lower end cover 7 are distributed on the two sides of the connecting ring 6. The magnetic levitation driver with 5DOF light-path control provided by the embodiment of the invention can realize five-degree-of-freedom motion control, is compact in structure, and has the characteristics of high response speed and high precision.

Owner:SHENYANG POLYTECHNIC UNIV

Park management service terminal

ActiveCN114760795AQuick disassemblyReduce cleaning frequencyCasings/cabinets/drawers detailsSupport structure mountingPark managementStructural engineering

The invention belongs to the field of park management, and particularly relates to a park management service terminal which comprises a placement frame, supporting legs are uniformly arranged at the bottom of the placement frame, the bottom of the placement frame is fixedly connected with the tops of the supporting legs, fastening devices are arranged on the outer surfaces of the supporting legs, and the outer surfaces of the supporting legs are movably connected with the tops of the fastening devices. A shielding device is arranged at the top of the containing frame, the top of the containing frame is movably connected with the bottom of the shielding device, a cooling device is arranged at the bottom of the containing frame, the top of the cooling device is fixedly connected with the bottom of the containing frame, the shielding device comprises a shielding plate, and positioning columns are evenly arranged at the bottom of the shielding plate. In order to overcome the defects in the prior art, the park management service terminal is provided, and the problem that after a traditional park management service terminal is used for a long time, the service life is shortened due to the poor heat dissipation effect is solved.

Owner:南通镜像城市技术有限公司

Magnetic energy power machine

InactiveCN103312227AImprove the utilization rate of magnetic energyFacilitate transmissionGenerators/motorsReciprocating motionElectric machinery

The invention discloses a magnetic energy power machine. The magnetic energy power machine comprises a machine frame, two fixed magnets, a moveable magnet and magnetism stirring iron plates, wherein the fixed magnet I and the fixed magnet II are fixedly connected with a protecting cover I and a protecting cover II; the moveable magnet is fixedly connected with a protecting cover III of which the upper end and the lower end are opened; the protecting cover I and the protecting cover II are fixedly connected to the upper end and the lower end of the machine frame; the moveable magnet is glidingly matched at a neutral position between the fixed magnet I and the fixed magnet II; the distance of the neutral position is larger than the height of the moveable magnet by a certain value; the same poles of the fixed magnet I and the moveable magnet are opposite; the same poles of the moveable magnet and the fixed magnet II are opposite; a magnetism stirring iron plate frame with an upper side frame and a lower side frame is arranged on one side of the machine frame; the magnetism stirring iron plate I is fixedly arranged at the right end of the upper side frame; the magnetism stirring iron plate II is fixedly arranged at the left end of the lower side frame; a rolling shaft group I is arranged at the lower end of the protecting cover I and clamps the upper side frame; a rolling shaft group II is arranged at the lower end of the protecting cover II and clamps the lower side frame; the left ends of the magnetism stirring iron plates are connected with a reciprocating mechanism and a motor; and the moveable magnet is connected with an output transmission mechanism through a round shaft I and a round shaft II connected to the left side and the right side of a protecting cover III. The magnetic energy power machine has the advantages that energy resources are saved, and labor-saving significance is great due to the fact that the rolling shaft group I and the rolling shaft group II are arranged.

Owner:章建成

Tentering shaping conveying device for functional coated fabric

The invention discloses a tentering shaping conveying device for a functional coated fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:义乌市鼎莎针织有限公司

A high-performance dust-proof mechanical seal structure

ActiveCN108730353BImprove sealingNo contact frictionEngine sealsSupports/enclosures/casingsEngineeringContact friction

The invention discloses a high-performance dustproof mechanical sealing structure. The high-performance dustproof mechanical sealing structure comprises a rotor penetrating through a gear box, a bearing, a straining shaft sleeve and an outer end cover, wherein the outer end cover is installed on a position, through which the rotor penetrates, of the gear box, the outer end cover is fixed on the gear box by virtue of a plurality of fastening screws, the bearing is installed between the inner wall of the gear box and the rotor, the straining shaft sleeve sleeves the rotor, the straining shaft sleeve is in clearance fit with the rotor, and the outer circumference of the straining shaft sleeve is provided with a circle of steps. The high-performance dustproof mechanical sealing structure has the beneficial effects that when external dust enters the outer end cover, the dust is firstly prevented by a dustproof cover and the outer end cover, even when little dust can enter the outer end cover, the dust can remain in a sealed chamber formed by encircling a sealed ring l, the straining shaft sleeve, the outer end cover and the side wall of the gear box, the dust cannot further enter the sealing structure, the sealing effect is good, no contact friction is produced, and the high-performance dustproof mechanical sealing structure integrates the advantages of the contact sealing and noncontact sealing, and has good sealing performance.

Owner:ANHUI NANFANG CHEM PUMP IND

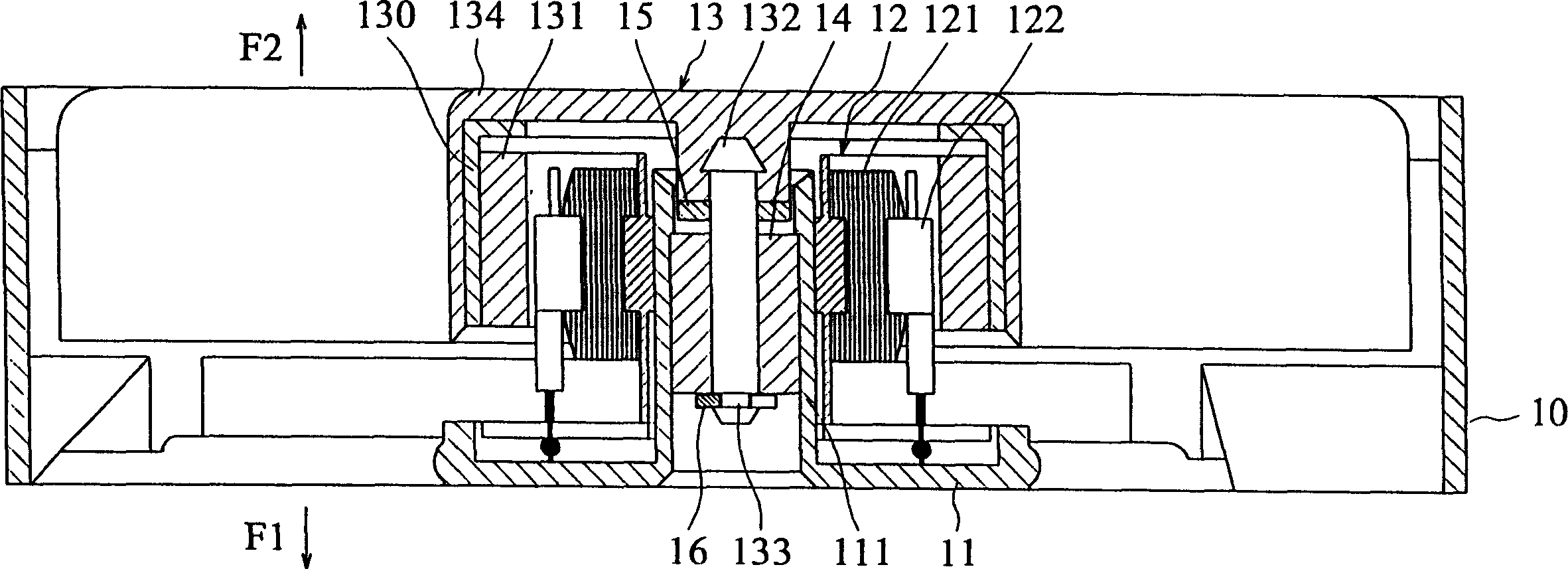

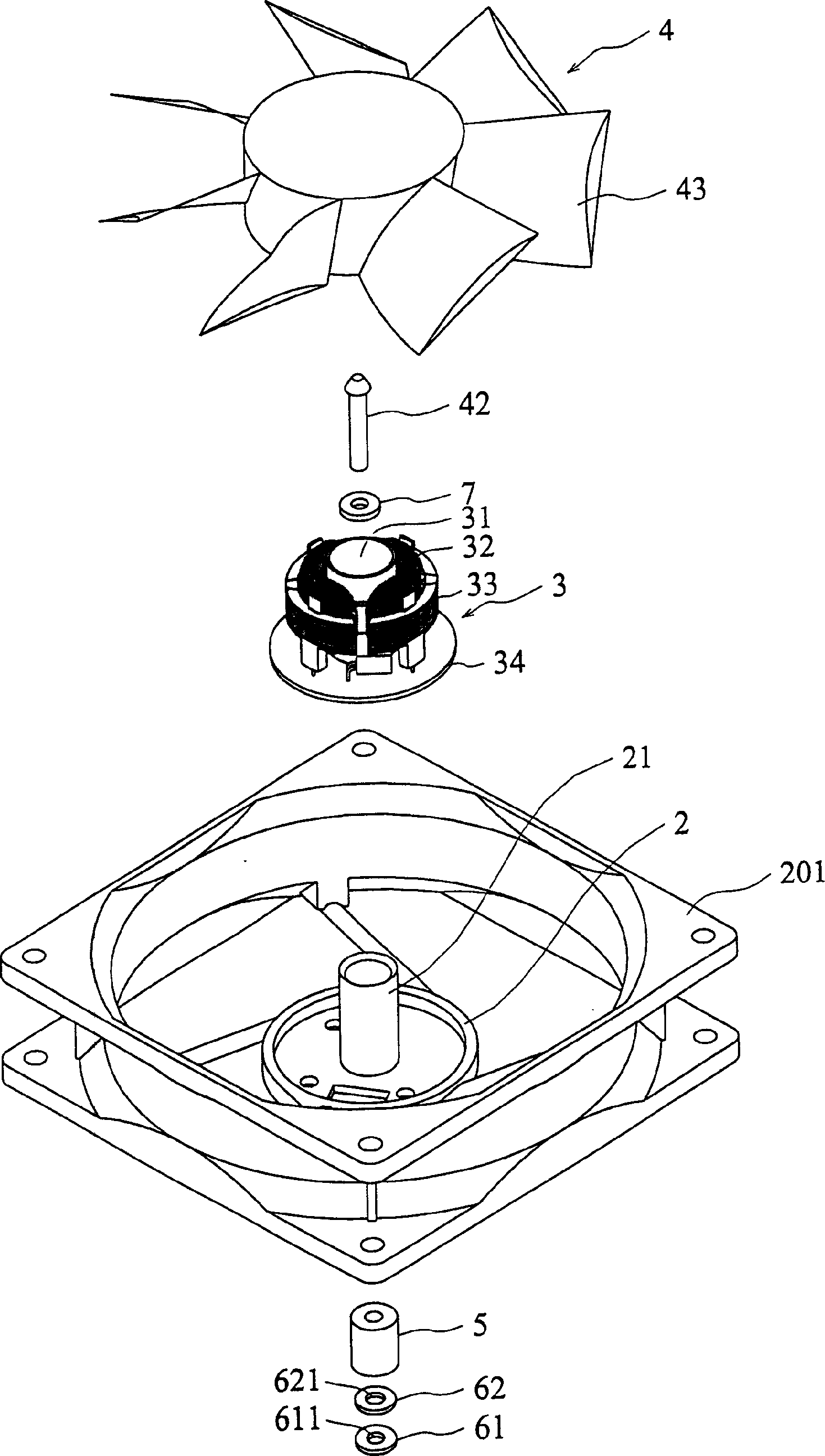

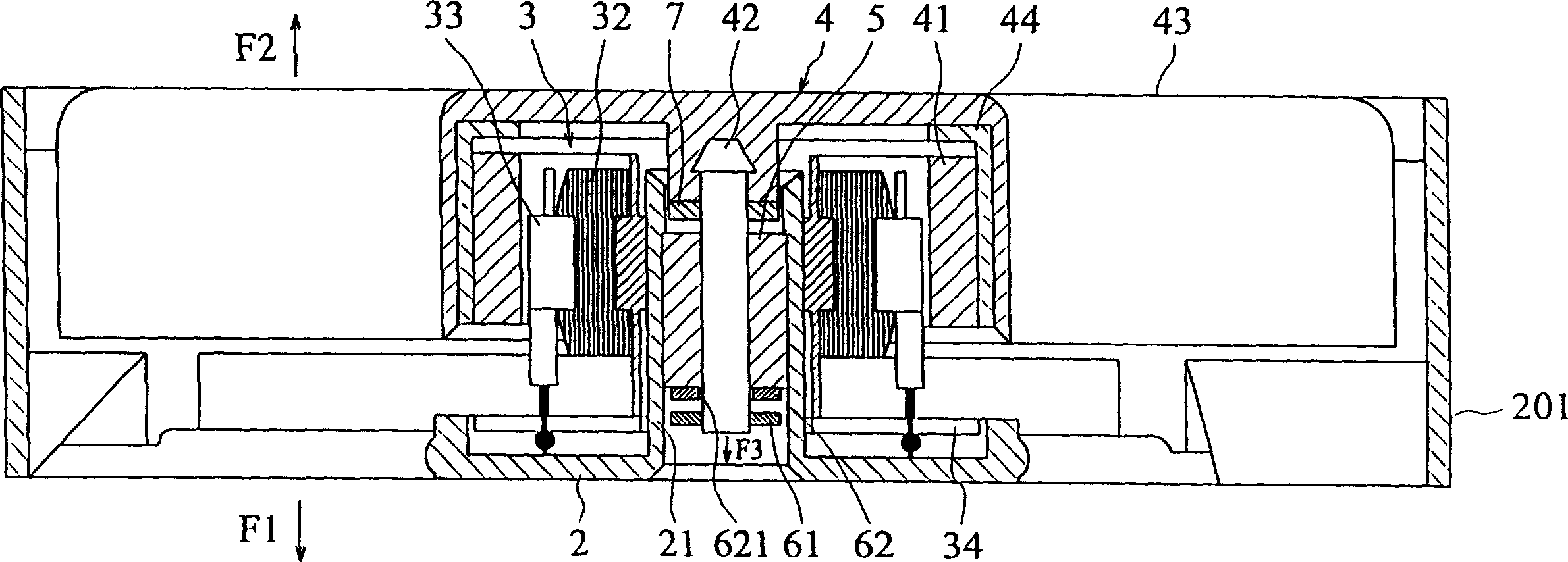

Magnetic-bearing motor

InactiveCN1185777CNo contact frictionNo friction lossMechanical energy handlingMagnetic bearingEngineering

The motor includes a support with pedestal, a stator fixed on the pedestal, a rotor with a shaft and being rotated on the exciting magnetic force, a bearing fixed on the pedestal to support the shaft, and a magnetic element combination including the first element fixed on the shaft and the second one fixed on the pedestal for the shaft on penetrate, with the first and the second elements producing magnetic forces. The present invention can position the shaft axially to avoid contact friction during rotation.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com