High-performance dustproof mechanical sealing structure

A mechanical seal, high-performance technology, used in engine seals, mechanical equipment, electromechanical devices, etc., can solve the problems of easy grease leakage, dust entry, bearing wear, etc., and achieve good sealing effect and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

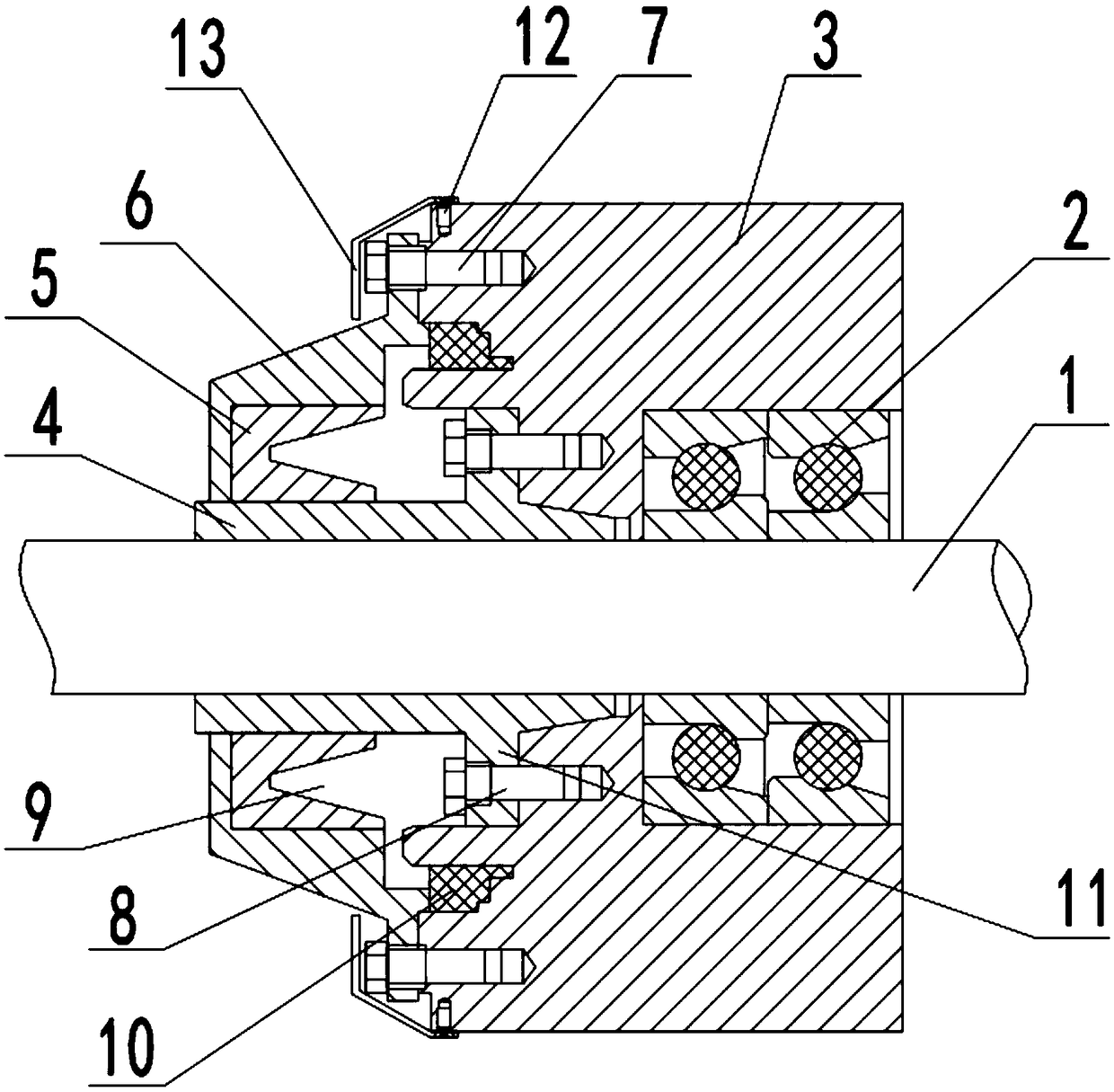

[0016] see figure 1 , in an embodiment of the present invention, a high-performance dust-proof mechanical seal structure, including a rotor 1 passing through a gear box 3, a bearing 2, a tensioning sleeve 4 and an outer end cover 6, and the gear box 3 is in the corresponding position of the rotor 1 An outer end cover 6 is installed at the position where it passes through, and the outer end cover 6 is fixed on the gear box 3 by a plurality of fastening screws 7, and a bearing 2 is installed between the inner wall of the gear box 3 and the rotor 1, where The outer end cover 6 has a dustproof function, and in order to further improve its dustproof performance, the outer cover of the rotor 1 is provided with a tensioning sleeve 4, in order not to affect the normal rotation of the rotor 1, the tensioning sleeve 4 and the rotor 1 are clearance fit, the outer circumference of the tensioning bushing 4 is provided with a circle of steps 11, the steps 11 are fixedly connected with the s...

Embodiment 2

[0018] see figure 1 , on the basis of Embodiment 1, in order to further improve the dustproof performance, this embodiment has made the following improvements, specifically:

[0019] (1) The bottom of the outer end cover 6 is filled with sealing glue between the tightening shaft sleeves 4. Although the sealing performance of the sealing glue is affected under high vibration and high heat conditions, it can also reduce the penetration into the outer end. The amount of dust inside the cover 6.

[0020] (2) The seal ring one 5 is a lip seal ring, and its cross section is a V-shaped surface 9, and the seal ring one 5 is enclosed with the tensioning shaft sleeve 4, the outer end cover 6 and the side wall of the gear box 3 to form a sealing ring. The structure of the chamber has a good sealing effect and no contact friction. It has the advantages of both contact sealing and non-contact sealing, and has good sealing performance.

[0021] (3) A sealing ring 2 10 is installed at the ...

Embodiment 3

[0023] see figure 1 , on the basis of Embodiment 1, this embodiment also has a dustproof cover 13 fixed on the outside of the gearbox 3, and one end of the dustproof cover 13 is fixed on the edge of the gearbox 3 by a plurality of screws 12 to prevent The other end of the dust cover 13 extends obliquely to the outside of the outer end cover 6, and the fastening screw 7 is encapsulated inside, which can greatly reduce the entry of dust or impurities into the outer end cover 6.

[0024] Combining with Examples 1-3, the working principle of the present invention is described: looking inward from the outside of the gear box 3, that is, looking from left to right, when external dust enters the outer end cover 6, it will first be affected by the dust cover 13 And the blocking of the outer end cover 6, even if a very small amount of dust can enter the outer end cover 6, it will stay on the side wall composed of the sealing ring 5 and the tightening sleeve 4, the outer end cover 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com