Magnetic-bearing motor

A magnetic bearing and motor technology, applied in the field of motors, can solve the problems of high heat, shortened service life, and offset of the rotating shaft 132 of the C-shaped buckle, and achieve good rotation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

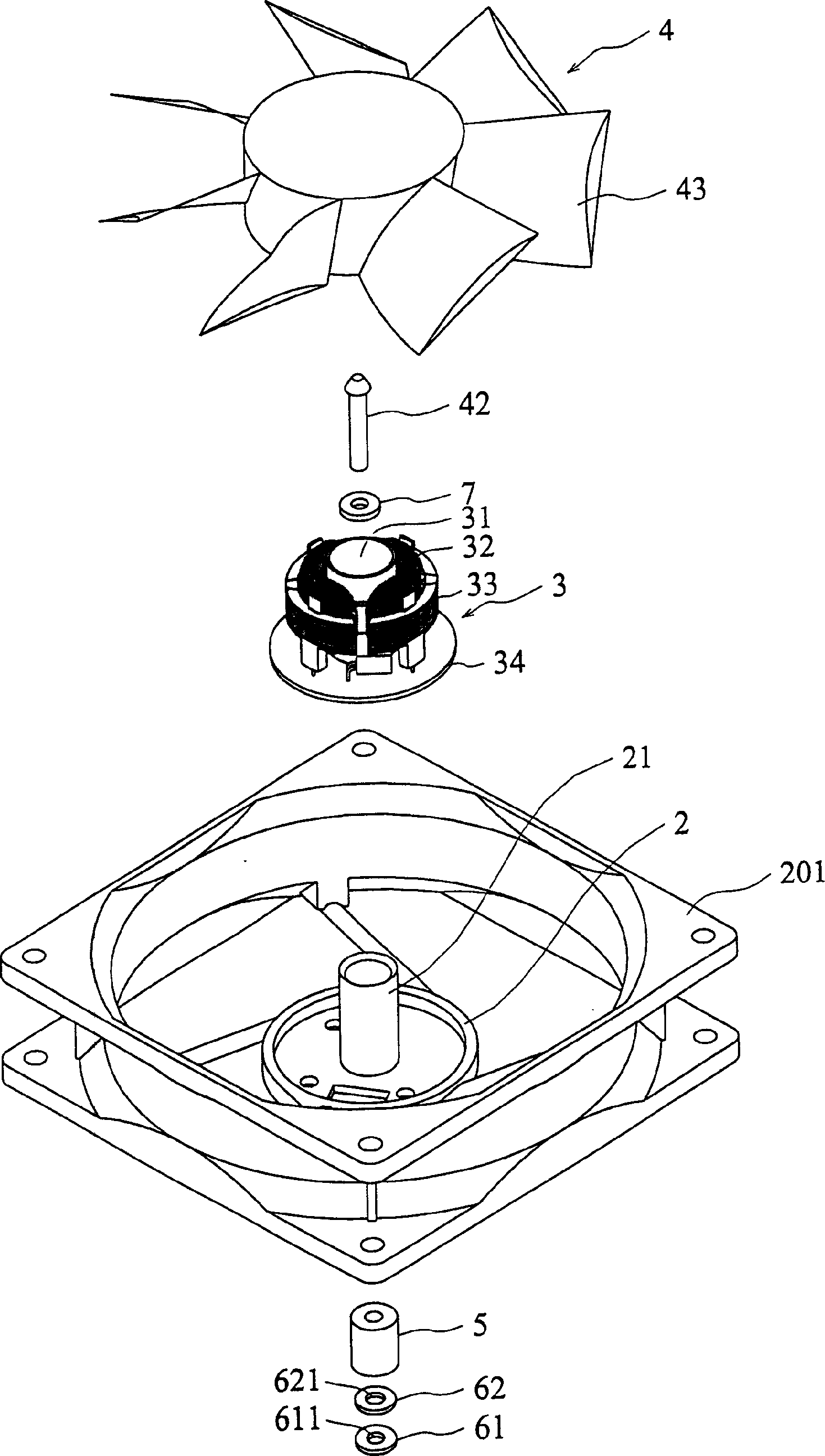

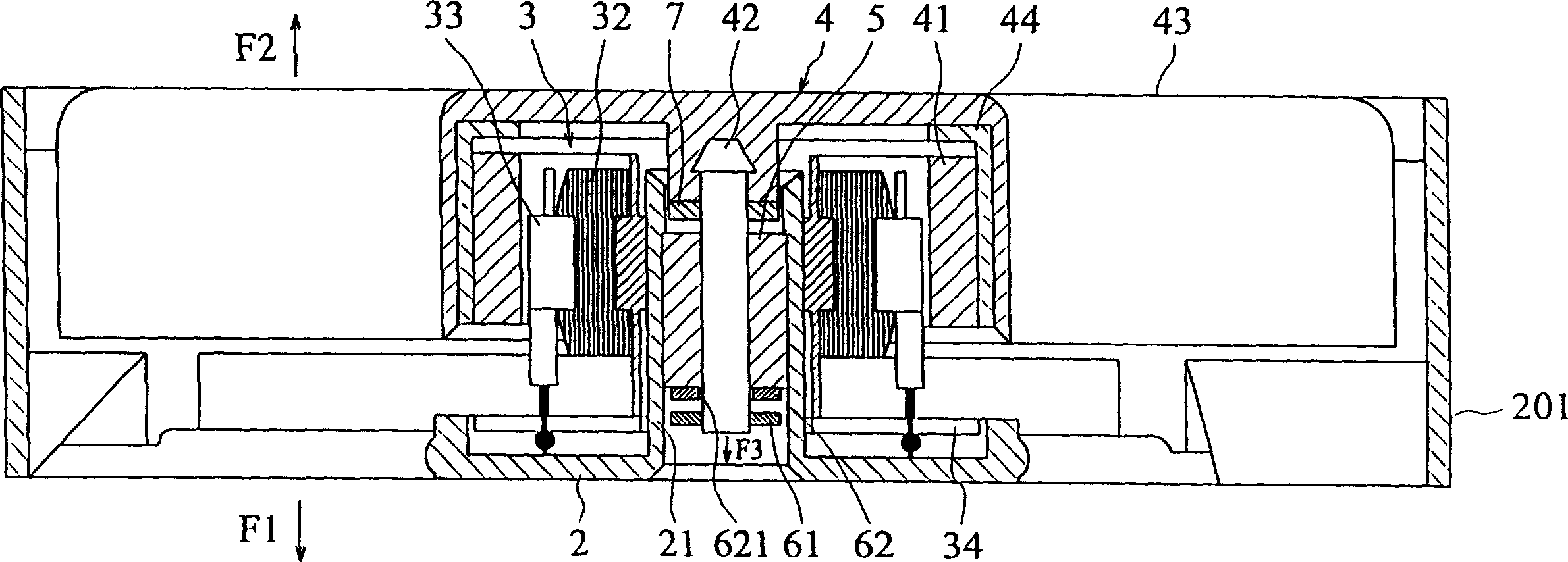

[0045] see figure 2 , 3 As the first preferred embodiment of the present invention, the magnetic bearing motor of the present invention includes: a base 2, a stator 3, a rotor 4, a bearing 5, a magnetic element group, and an elastic washer 7, wherein:

[0046] The base 2 is located at the center of a fan frame 201 , and the two are combined into one body. A bearing seat 21 is arranged at the center of the base 2 .

[0047] The center of the stator 3 is provided with a socket 31, and the periphery of the socket 31 is provided with a coil 32 and a silicon steel sheet 33, and a circuit board 34 is provided below, and the coil 32, the silicon steel sheet 33, and the circuit board 34 are electrically connected. , the sleeve portion 31 fits and is fixed outside the bearing seat 21 of the base 2 .

[0048] The rotor 4 is provided with a hollow cylindrical body 44 with an open end, its outer peripheral wall is combined with a fan blade 43, its inner peripheral wall is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com