Magnetic levitation driver with 5DOF light-path control

A drive and magnetic levitation technology, applied in the laser field, can solve problems such as difficult to achieve multiple degrees of freedom, increased weight, and large inertia of the laser cutting head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

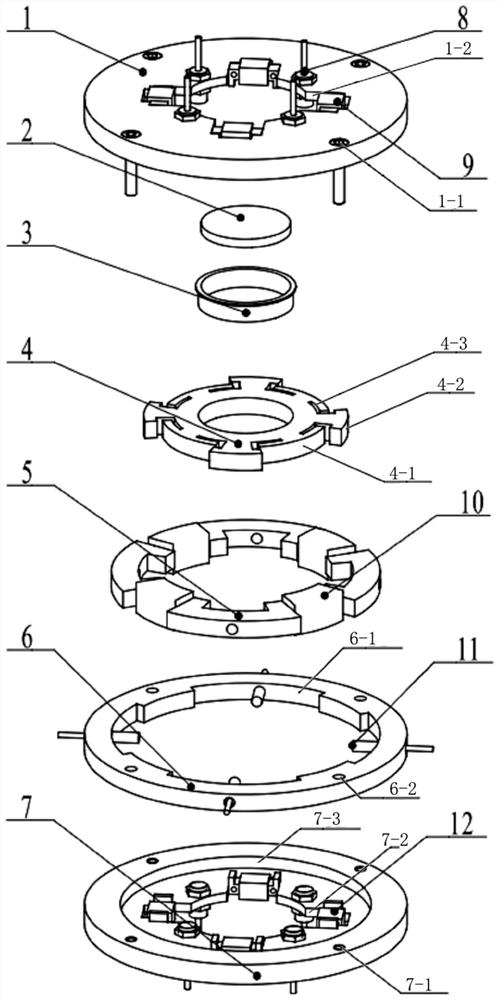

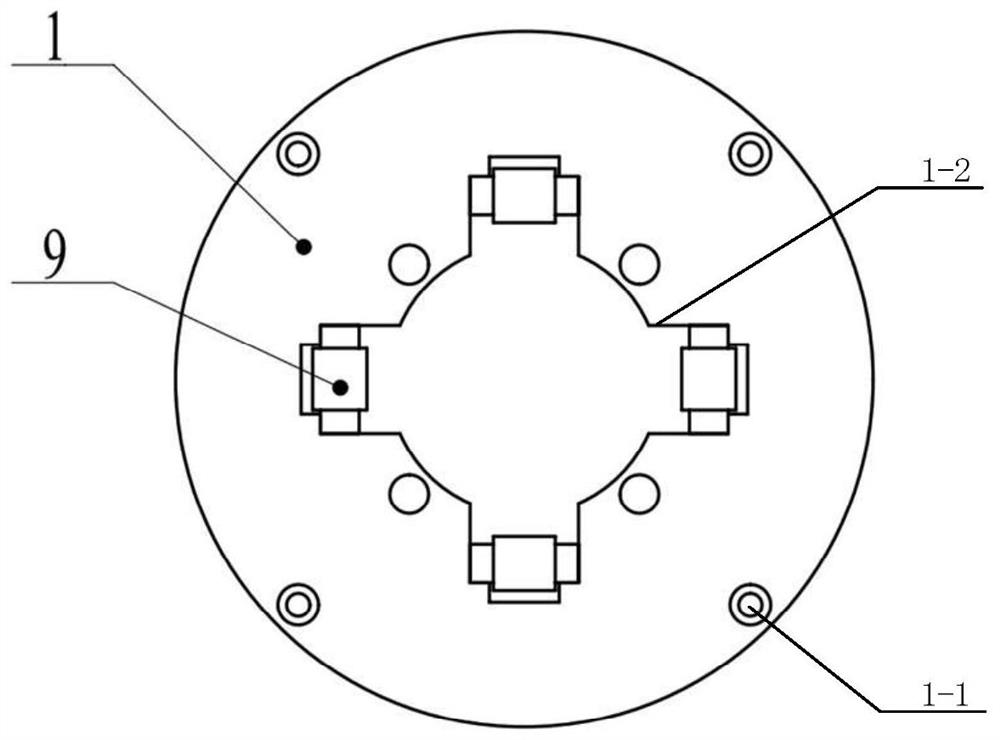

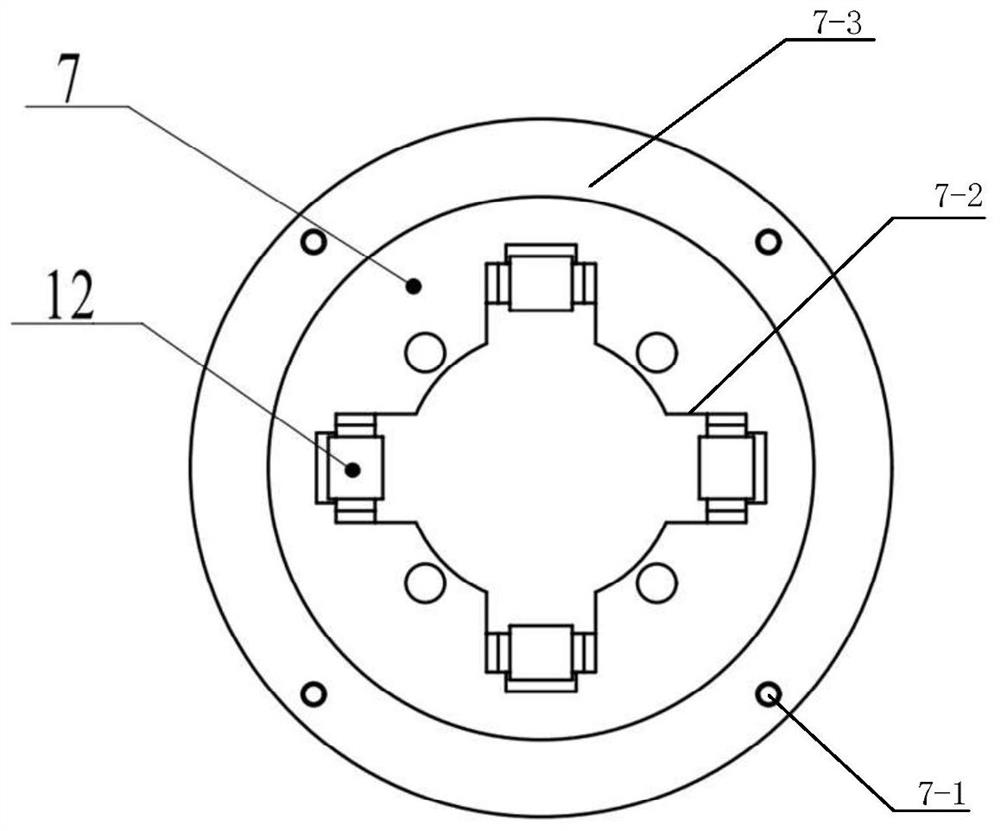

[0034] A 5DOF optical path control magnetic levitation driver, the driver includes an upper end cover 1, a float 4, a radial stator 5, a connecting ring 6 and a lower end cover 7; the float 4 is located in the radial stator 5, and a gap is left between the float 4 and the radial stator Air gap (the air gap here is the distance between the float and the radial stator coil. There is an air gap margin in the design to avoid the problem of out-of-control adsorption caused by too small air gap when the float moves in the x and y directions. There is also an air gap between the float and the axial stator coil), the radial stator 5 is installed in the connecting ring 6, and the upper end cover 1 and the lower end cover 7 are distributed on both sides of the connecting ring 6 (the connecting ring 6 is placed on the upper end cover 1 and the lower end cover 7);

[0035] Radial coils 10 are installed on the radial stator 5, and the radial coils 10 are at least four groups of even groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com