Magnetic energy power machine

An energy and power technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of low efficiency of magnetic power machines, and achieve the effects of high utilization rate of magnetic energy, convenient transmission, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

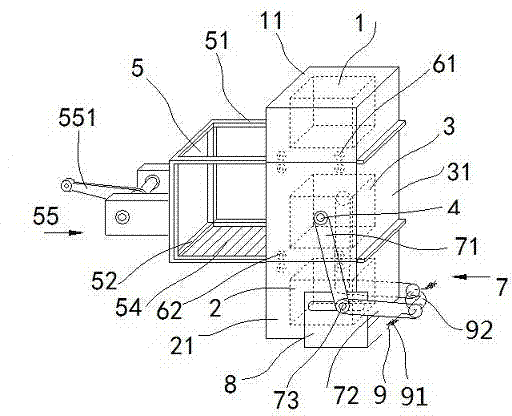

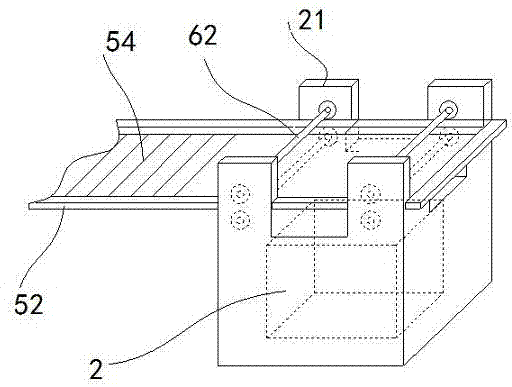

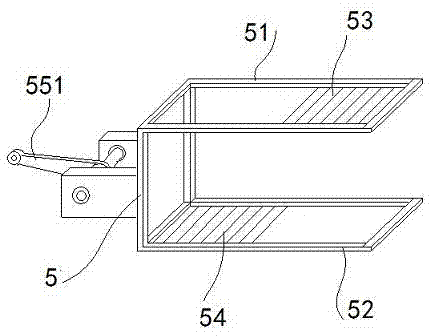

[0032] Embodiment 1: as figure 1As shown, a magnetic power machine includes a frame, a fixed magnet 1, a fixed magnet 2 2, a moving magnet 3 and a stirring magnet plate. The fixed magnet 1 and the fixed magnet 2 have the same structure, and the fixed magnet 1 is fixedly connected with a lower end. The first protective cover 11 is an opening, the fixed magnet 2 2 is fixedly connected with a protective cover 21 whose upper end is open, and the outer side of the moving magnet 3 is fixed with a protective cover 31 whose upper and lower ends are open; the fixed magnet 1 passes through the protective cover 1. 11 is fixed on the upper end of the frame, the fixed magnet 2 2 is fixed on the lower end of the frame at the corresponding part of the fixed magnet 1 1 through the protective cover 2 21, and the moving magnet 3 can be slid up and down on the fixed magnet 1 and the fixed magnet 2 2. In the neutral position in the middle, the distance of the neutral position is larger than th...

Embodiment 2

[0043] Embodiment 2: The transmission mechanism of the output power includes two connecting rods arranged symmetrically on the left and right, and the upper ends of the two connecting rods are respectively connected with the circular shaft 1 fixed on the right side of the third protective cover and the circular shaft 2 on the left side of the protective cover 3. The lower ends of the two connecting rods are connected with the two ends of the crankshaft arranged at the lower part of the frame respectively, and the axis of the first round shaft, the axis of the second round shaft, the axis of the moving magnet and the axis of the crankshaft are in the same plane; The moving magnet of this structure can be compared to the piston of an internal combustion engine. The internal combustion engine relies on the piston to push the crankshaft through the connecting rod to do work, while the present invention relies on the moving magnet to push the crankshaft through the connecting rod...

Embodiment 3

[0044] Example 3: The upper end face of the protective cover 1 has a through hole, the lower end surface of the protective cover 2 has a through hole, and the fixed magnetization 1 passes through the through hole on the upper end face of the protective cover 1, the frame, the upper frame of the stirring magnet plate frame, and the stirring magnet. The plate 1 and the fixed magnet 1 establish the upper magnetic circuit; the fixed magnet 2 establishes the lower magnetic circuit through the through hole on the lower end surface of the protective cover 2, the frame, the lower frame of the stirring magnet plate frame, the stirring magnet plate 2 and the fixed magnet 2, and the rest of the structure Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com