Stop iron and pole shoe integrated overflow type inverse proportion decompression electromagnetic valve with

A decompression solenoid valve and overflow type technology, which is applied in the direction of functional valve type, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve problems such as unloading systems, and achieve stable product assembly and anti-pollution The effect of good ability and excellent pressure regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

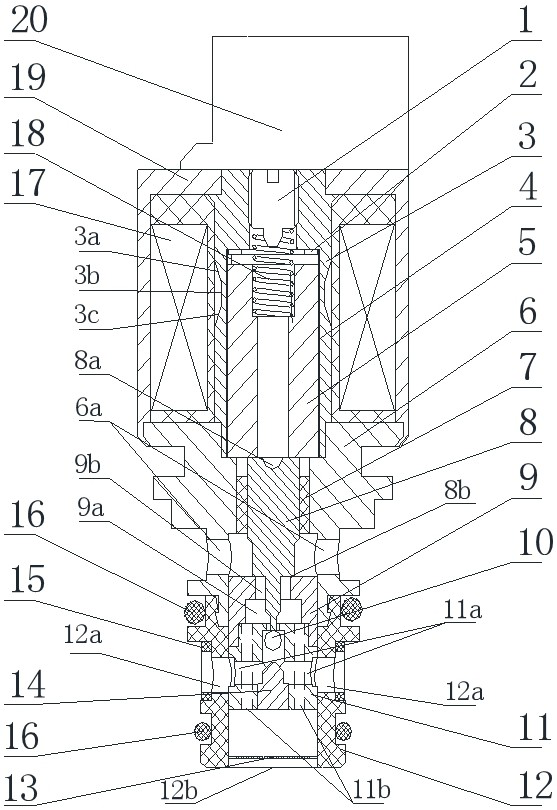

[0020] The present invention will be further described below in conjunction with accompanying drawing.

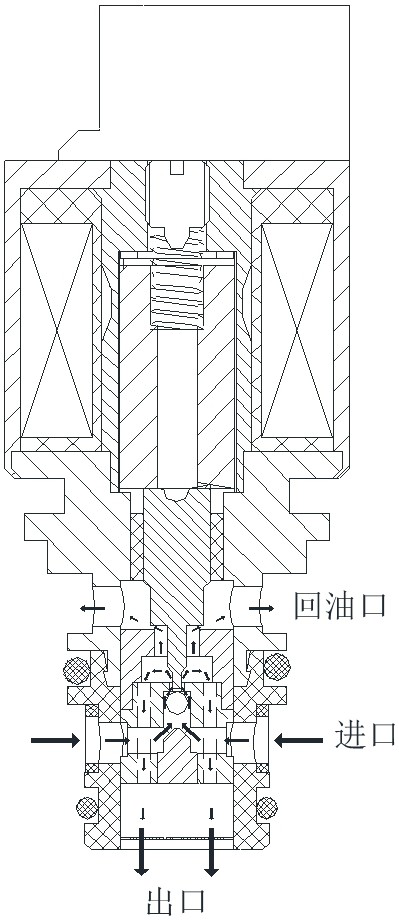

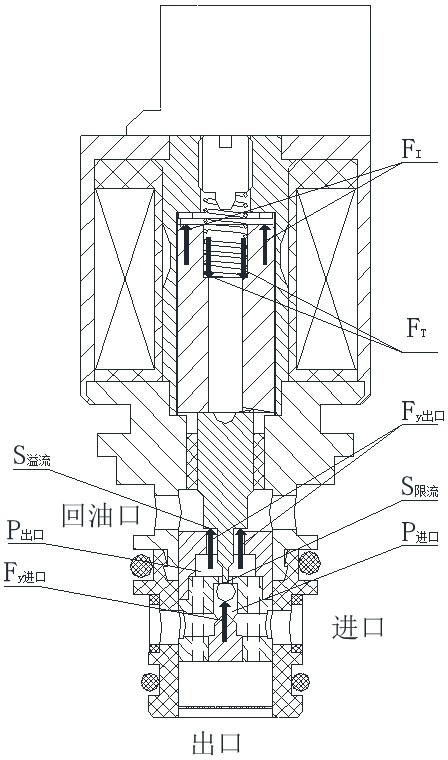

[0021] See attached figure 1 , the present invention provides an overflow type inverse proportional decompression solenoid valve with an unloading function integrated with an iron stopper and a pole piece. Bearing 7, ejector rod 8, valve seat 9, steel ball 10, ball valve body 11, installation valve body 12, outlet filter screen 13, ball valve seat 14, inlet filter screen 15, O-ring 16, coil 17, adjustment spring 18, Yoke 19 and connector 20 form.

[0022] Adjusting screw 1 cylindrical surface is provided with thread, and lower end is provided with raised small cone, is made of metal material, is installed in the threaded hole of stop iron 3, and the lower part compresses adjusting spring 18. The spacer 2 is a ring-shaped sheet made of non-magnetic metal material and placed in the large hole of the iron stopper 3 . The iron stopper 3 is a multi-section cylindrical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com