Continuous drill rod lifting and placing device for well drilling

A drill pipe and drilling technology, which is applied in the field of continuous lifting and unloading drill pipe devices, can solve the problems of inability to continuously lift or press down, and achieve the effects of good pressure regulation performance and stable output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

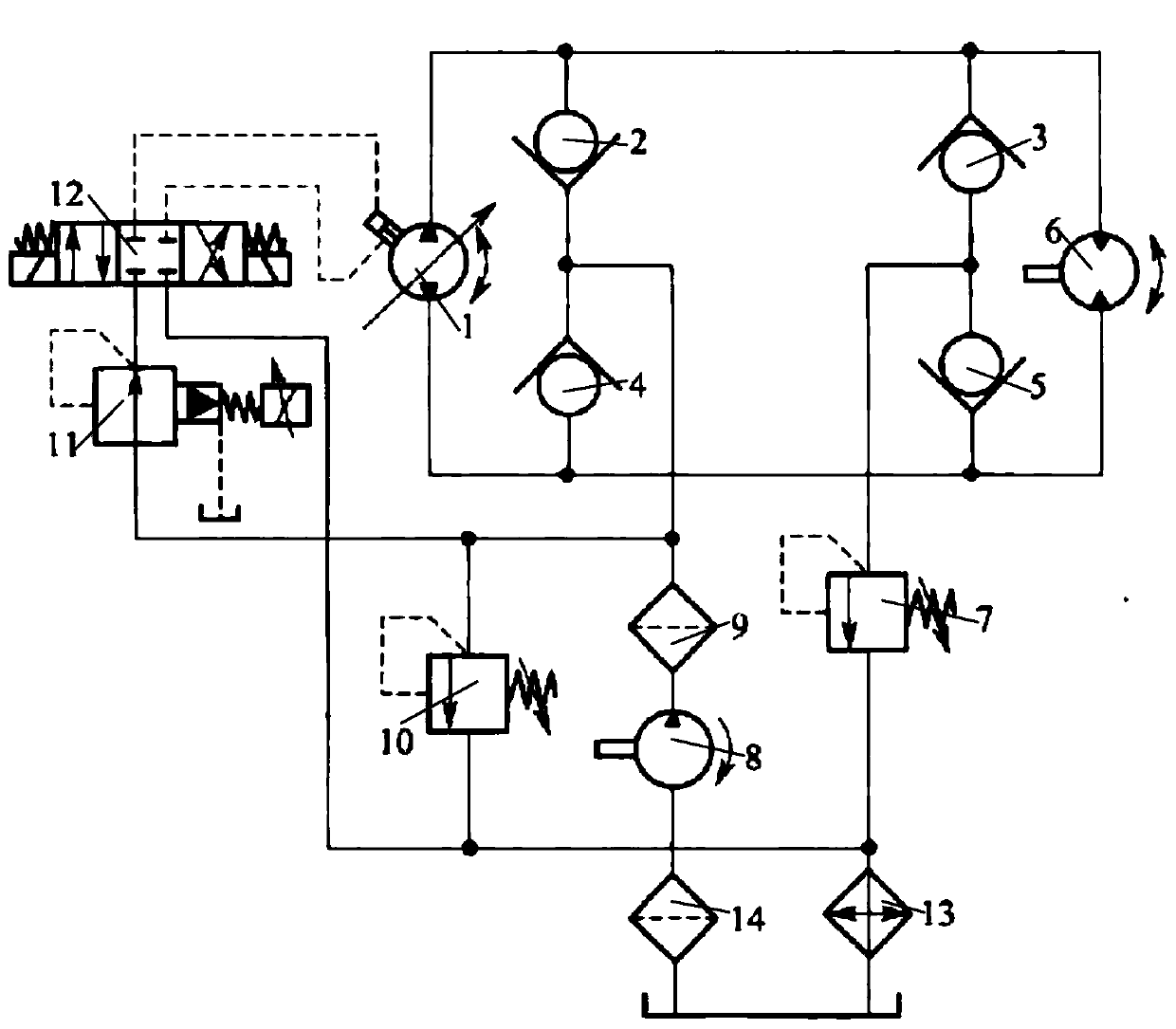

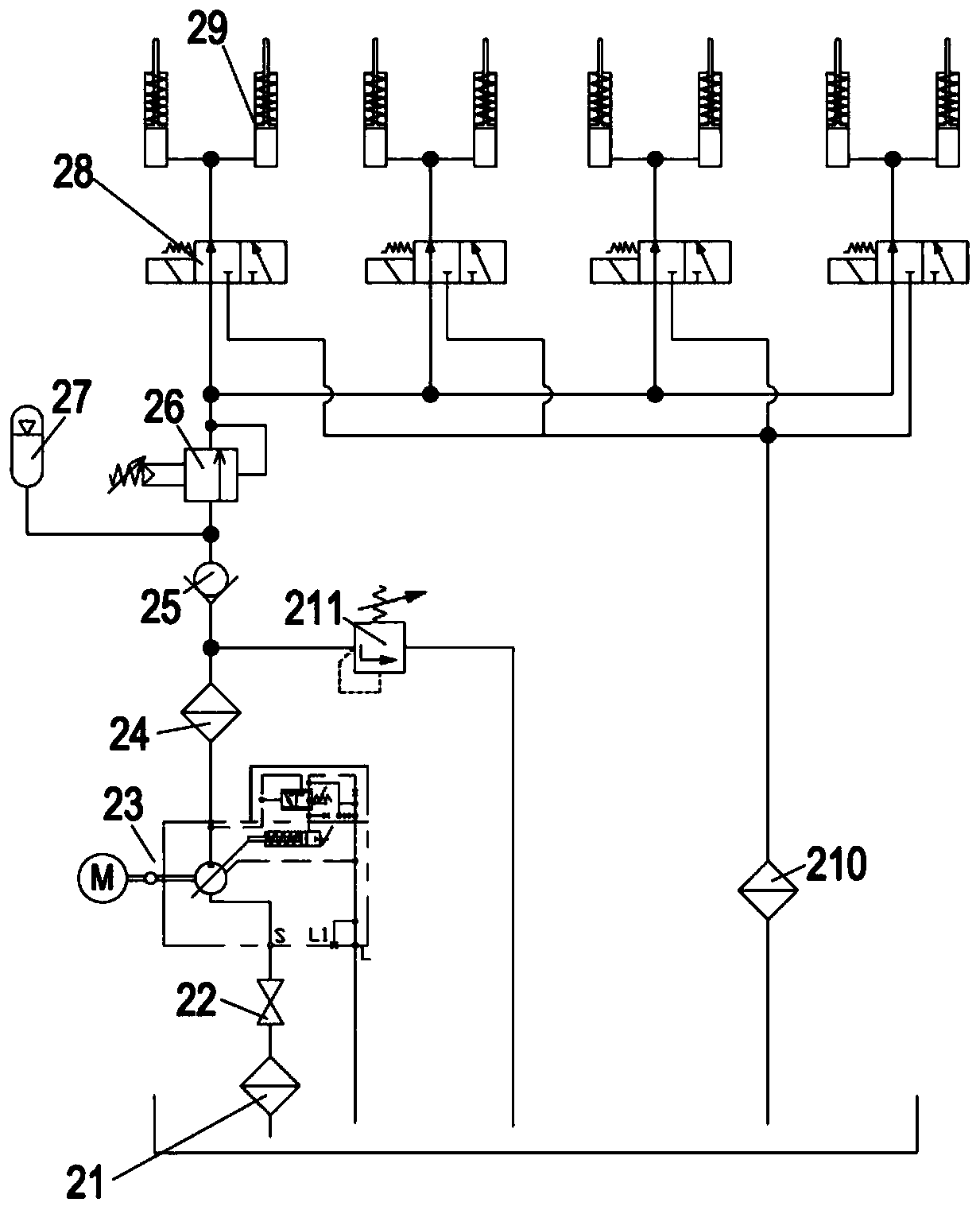

[0020] Such as Figure 1-3 As shown, a continuous lifting drill pipe device for drilling, including a hydraulic system, the hydraulic system includes the following parts:

[0021] The injector circuit is used to control the lifting and lowering of the drill pipe;

[0022] Slip chain compression circuit;

[0023] Chain tensioning circuit.

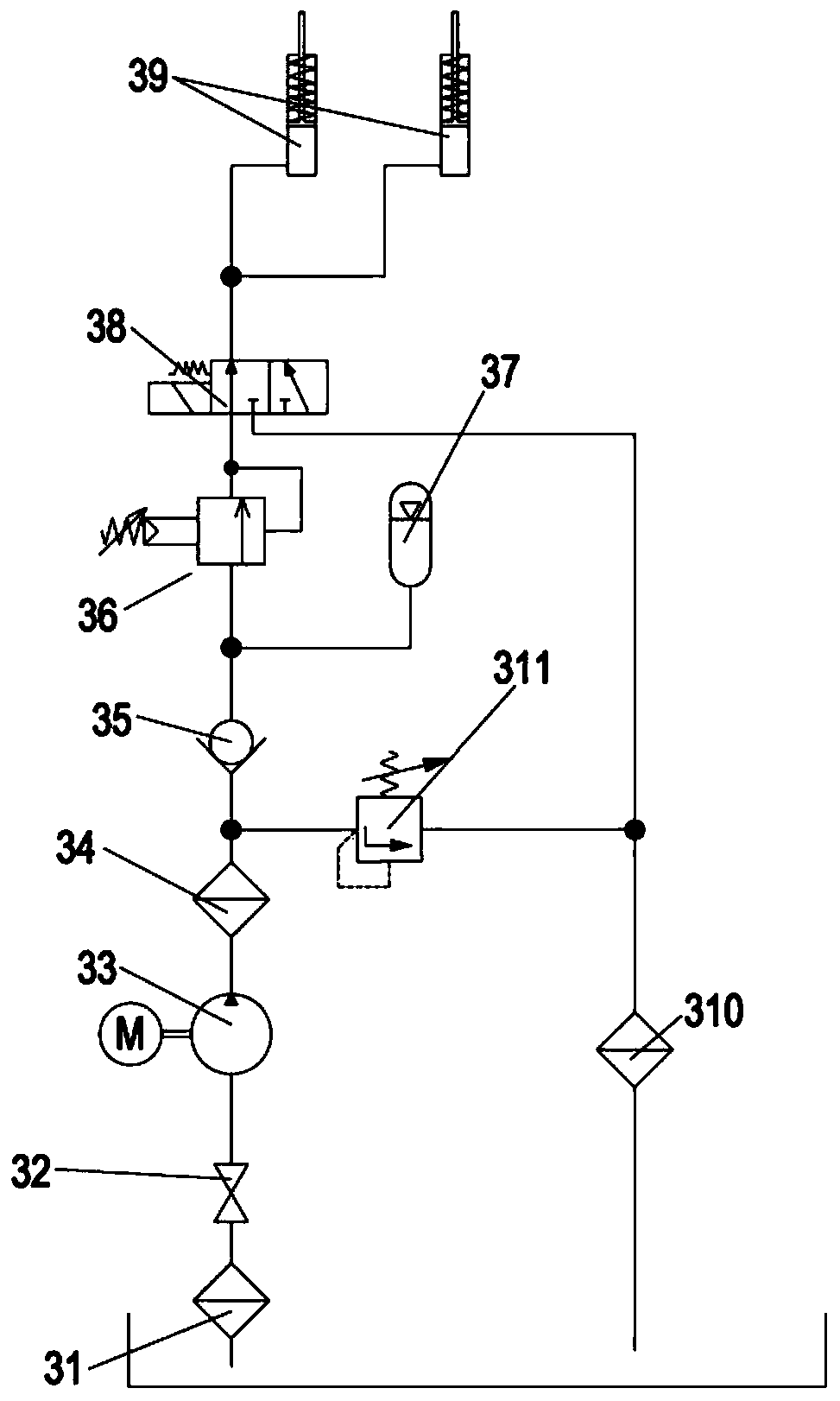

[0024] Such as image 3 As shown, the above-mentioned chain tensioning circuit includes a tensioning circuit oil suction filter 31, a tensioning circuit ball valve 32, a tensioning circuit quantitative pump 33, a tensioning circuit check valve 35, a tensioning circuit decompression valve 36, two tensioning circuit Position three-way reversing valve 38, chain tensioning oil cylinder 39, tensioning circuit oil return filter 310, tensioning circuit overflow valve 311, chain tensioning oil cylinder 39 is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com