MEMS broadband piezoelectric energy collector based on PDMS film structure

A technology of piezoelectric energy and thin-film structure, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve problems such as narrow working frequency bands, and achieve easy production and low volume The effect of reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

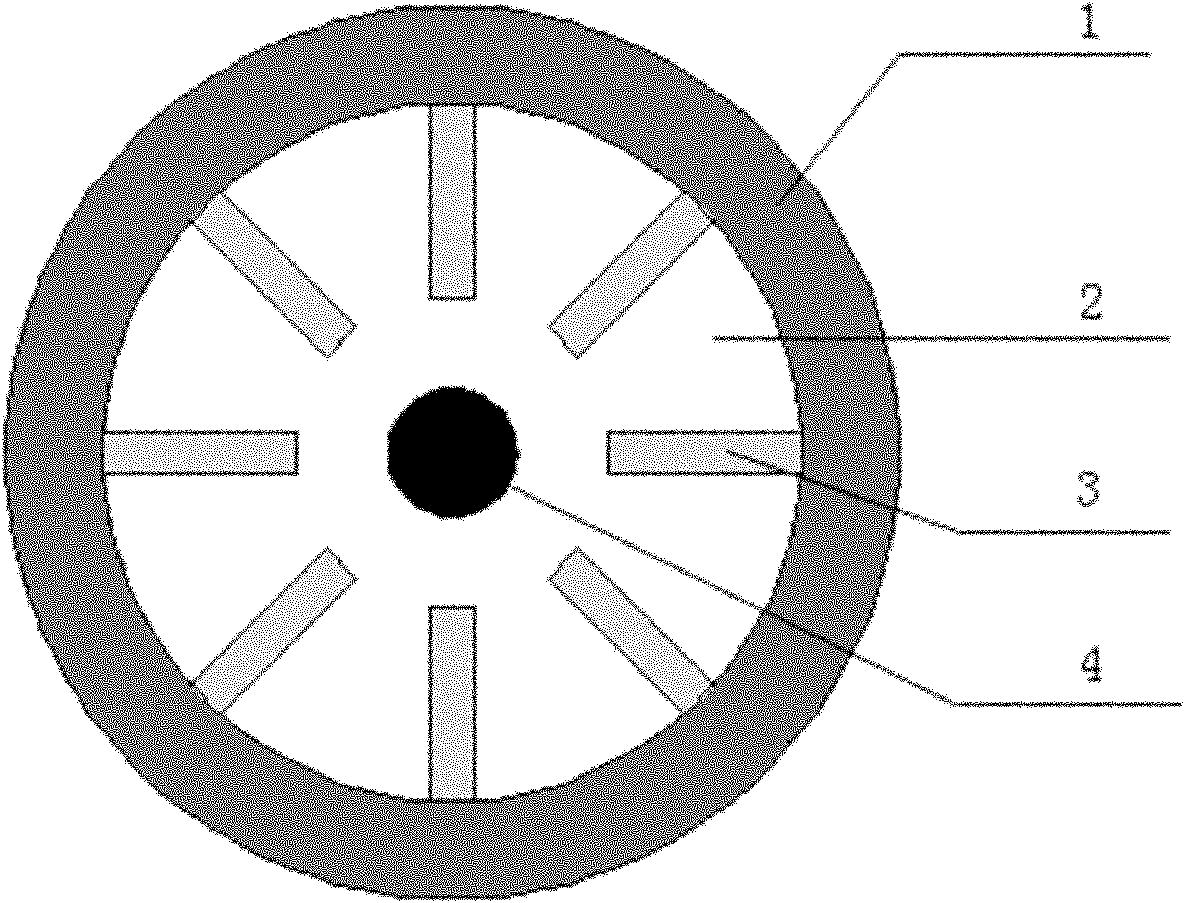

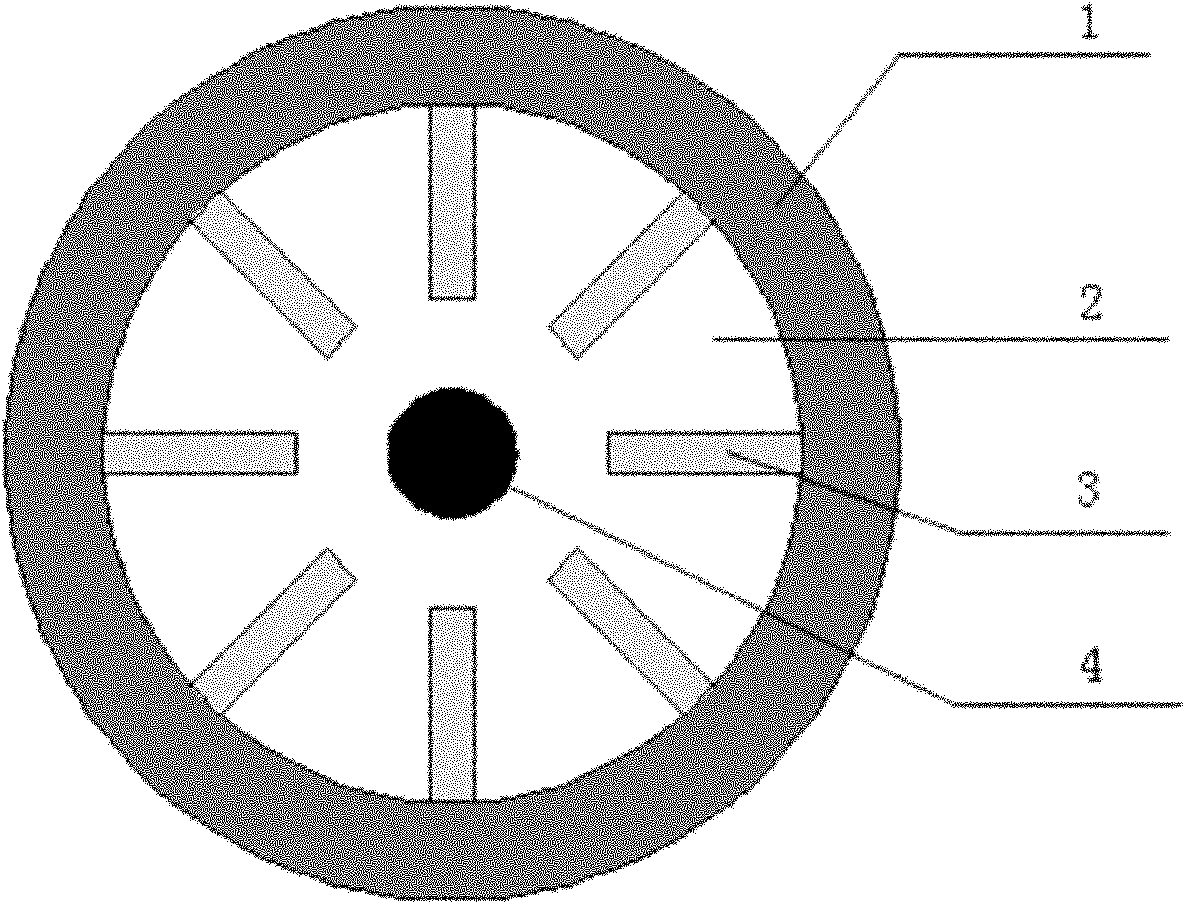

[0017] like figure 1 As shown, this embodiment includes: a circular frame 1, a PDMS film 2 arranged in the circular frame, a piezoelectric cantilever beam 3 and a quality block 4, wherein: eight piezoelectric cantilever beams 3 are radially embedded in the PDMS film 2 and one end is fixed on the circular frame 1 and the other end is suspended, the mass block 4 is embedded in the PDMS film 2 and is located at the center of the circular frame 1.

[0018] The length of the piezoelectric cantilever beam 3 is smaller than the inner diameter of the circular frame 1;

[0019] The piezoelectric cantilever be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com