A linear eddy current braking device and a linear carrying device

A technology of eddy current braking and linear electric, which is applied in the direction of asynchronous induction clutch/brake, etc., can solve the problems of rapid reduction and limitation of braking force, achieve large braking force, low noise, and improve braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

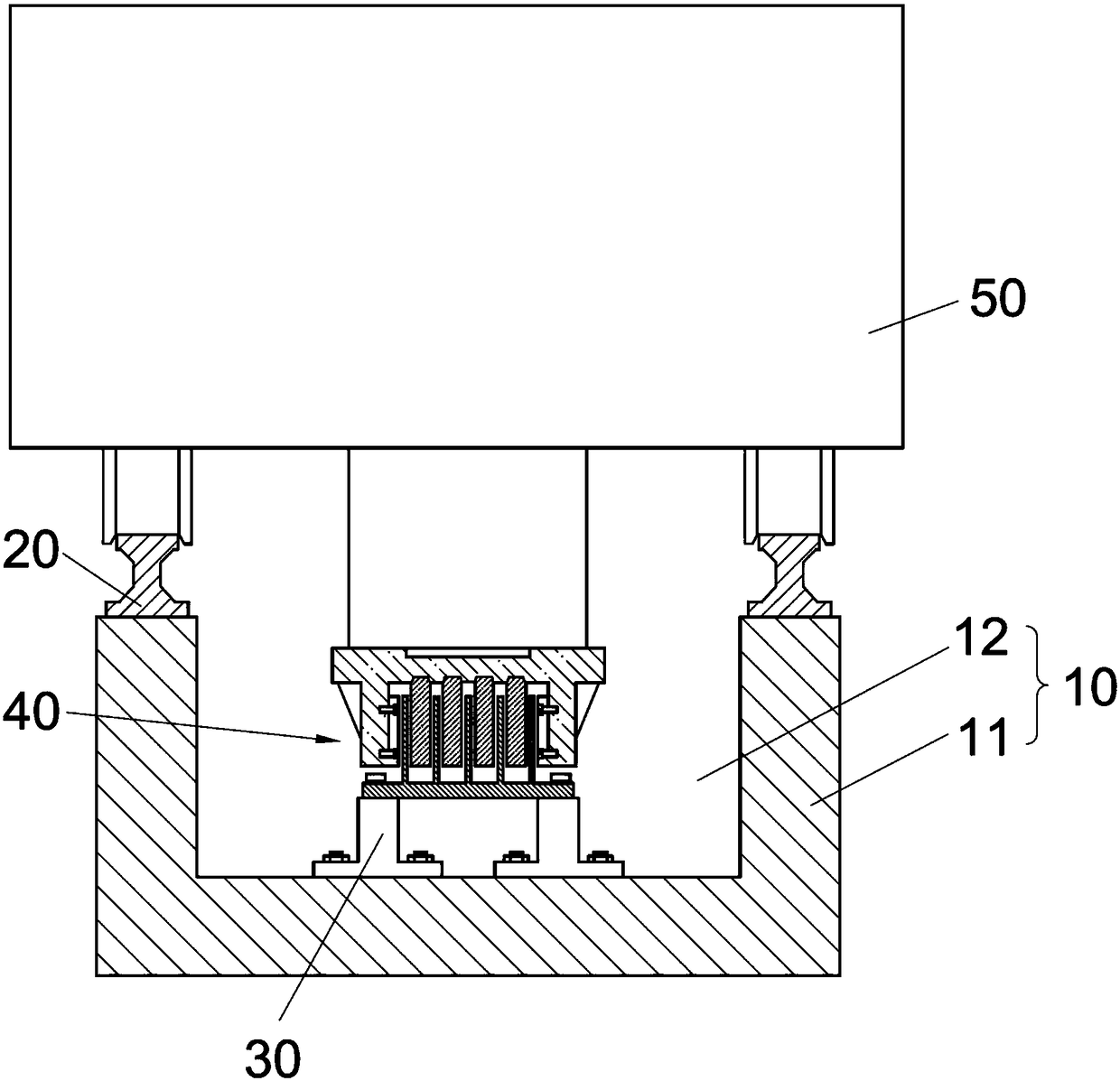

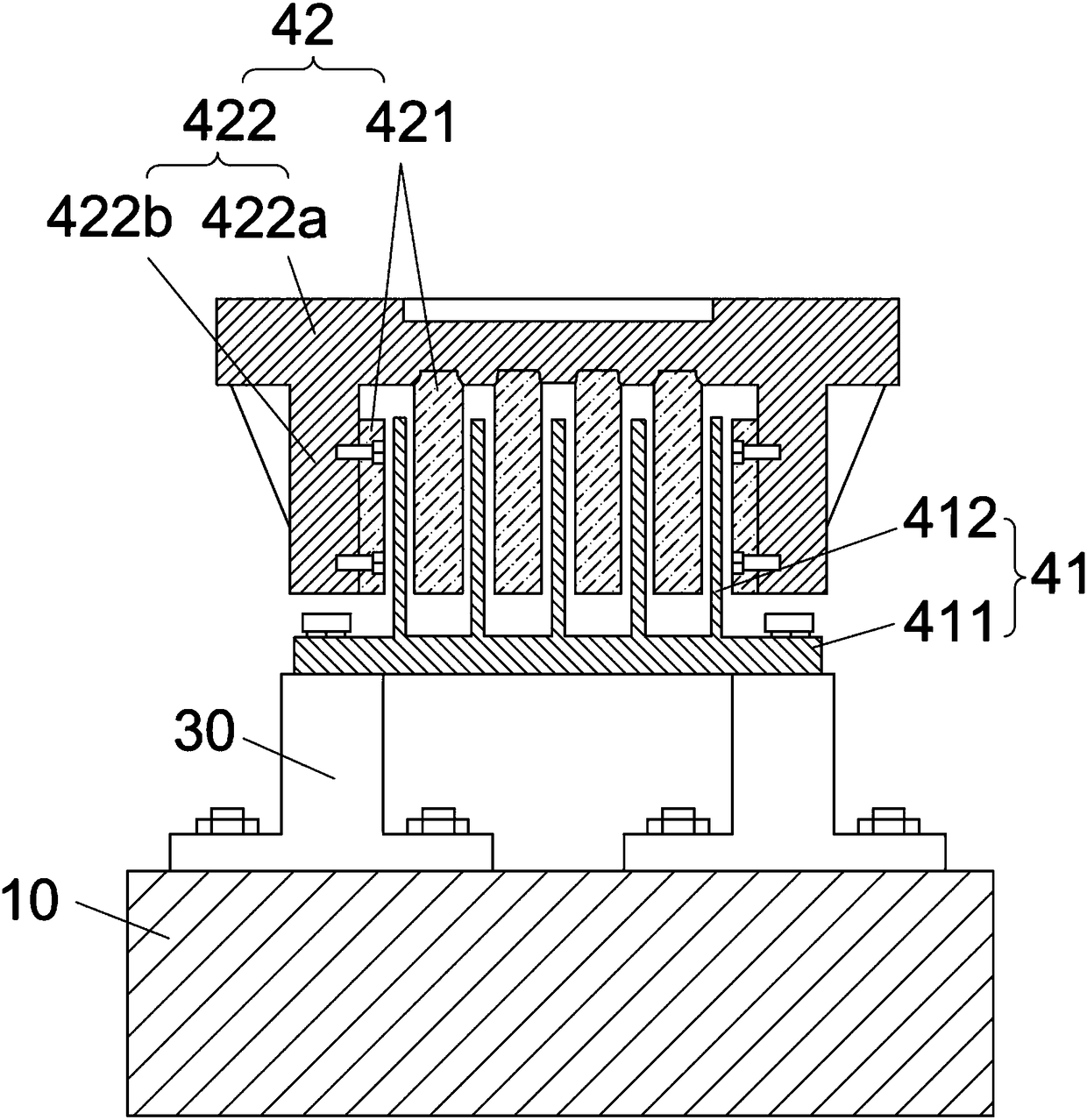

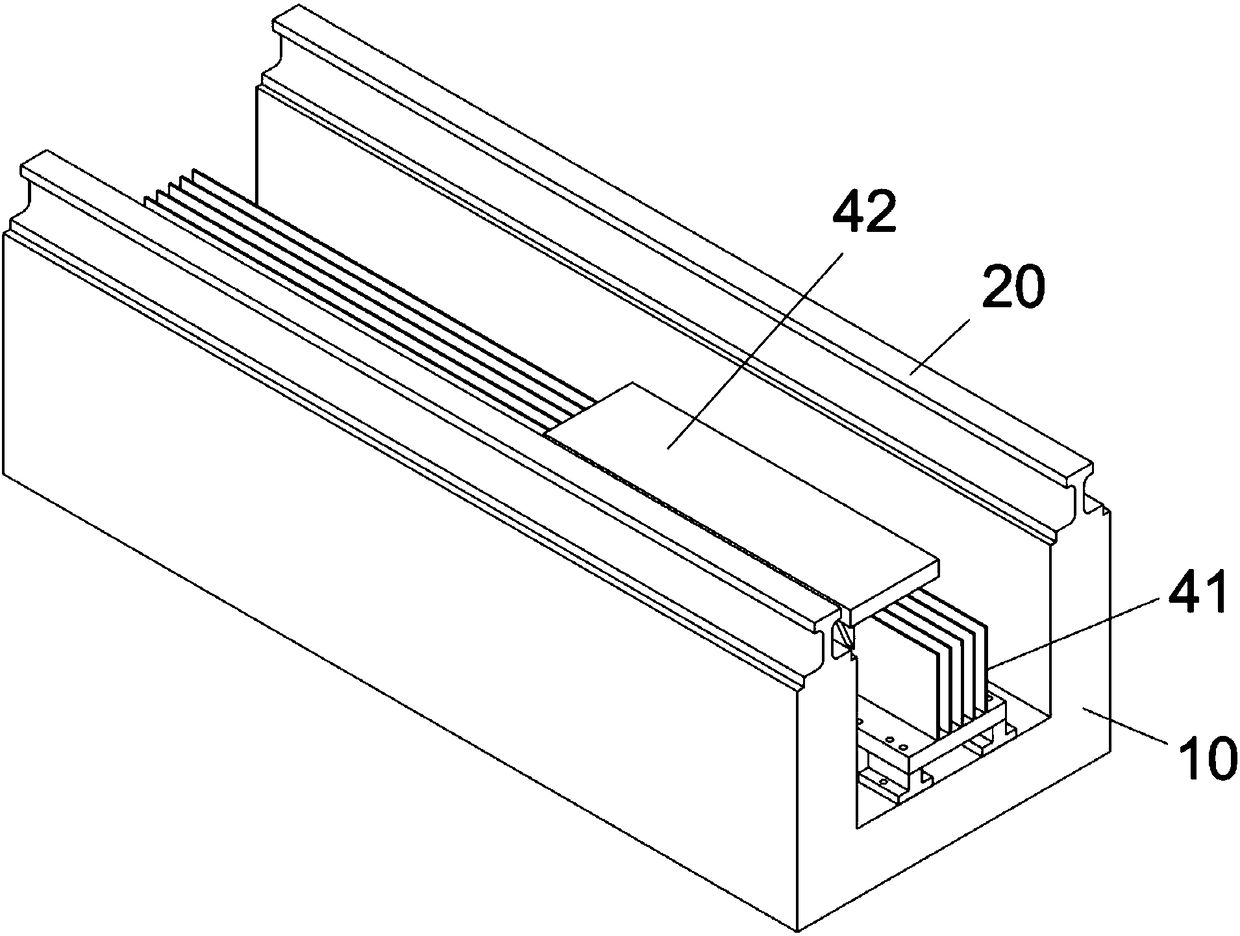

[0032] refer to Figure 1-7 , the linear eddy current braking device 40 of the present invention includes a stator 41 and a mover 42 .

[0033] The stator 41 includes a base plate 411 and a number of conductor pieces 412 arranged on the base plate 411 at equal intervals along the width direction of the base plate 411. The conductor pieces 412 are multi-stage structures made of materials with different resistivities, and are arranged along the braking direction. , the resistivity of the conductor sheet 412 decreases sequentially.

[0034] The mover 42 includes a connecting seat 422 and a number of permanent magnets 421 arranged at equal intervals along the width direction of the connecting seat 422 arranged on the connecting seat 422. The permanent magnets 421 distributed on both sides have a thickness of 421 and are distributed between the two sides. 1 / 2 of the thickness of the permanent magnets 421, and the number of the permanent magnets 421 is one more than the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com