Patents

Literature

269 results about "Eddy current brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An eddy current brake, also known as an induction brake, electric brake or electric retarder, is a device used to slow or stop a moving object by dissipating its kinetic energy as heat. However, unlike friction brakes, in which the drag force that stops the moving object is provided by friction between two surfaces pressed together, the drag force in an eddy current brake is an electromagnetic force between a magnet and a nearby conductive object in relative motion, due to eddy currents induced in the conductor through electromagnetic induction.

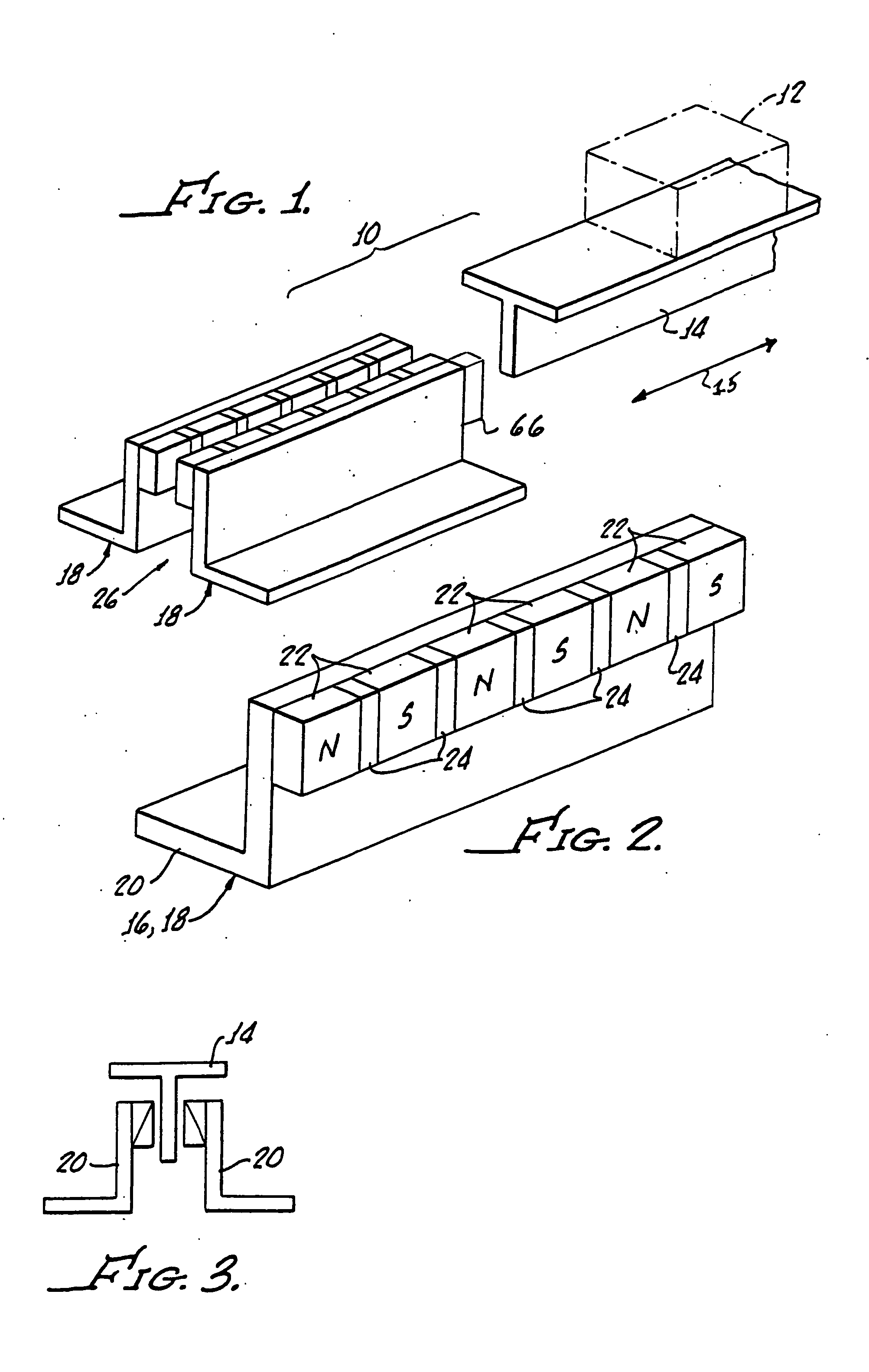

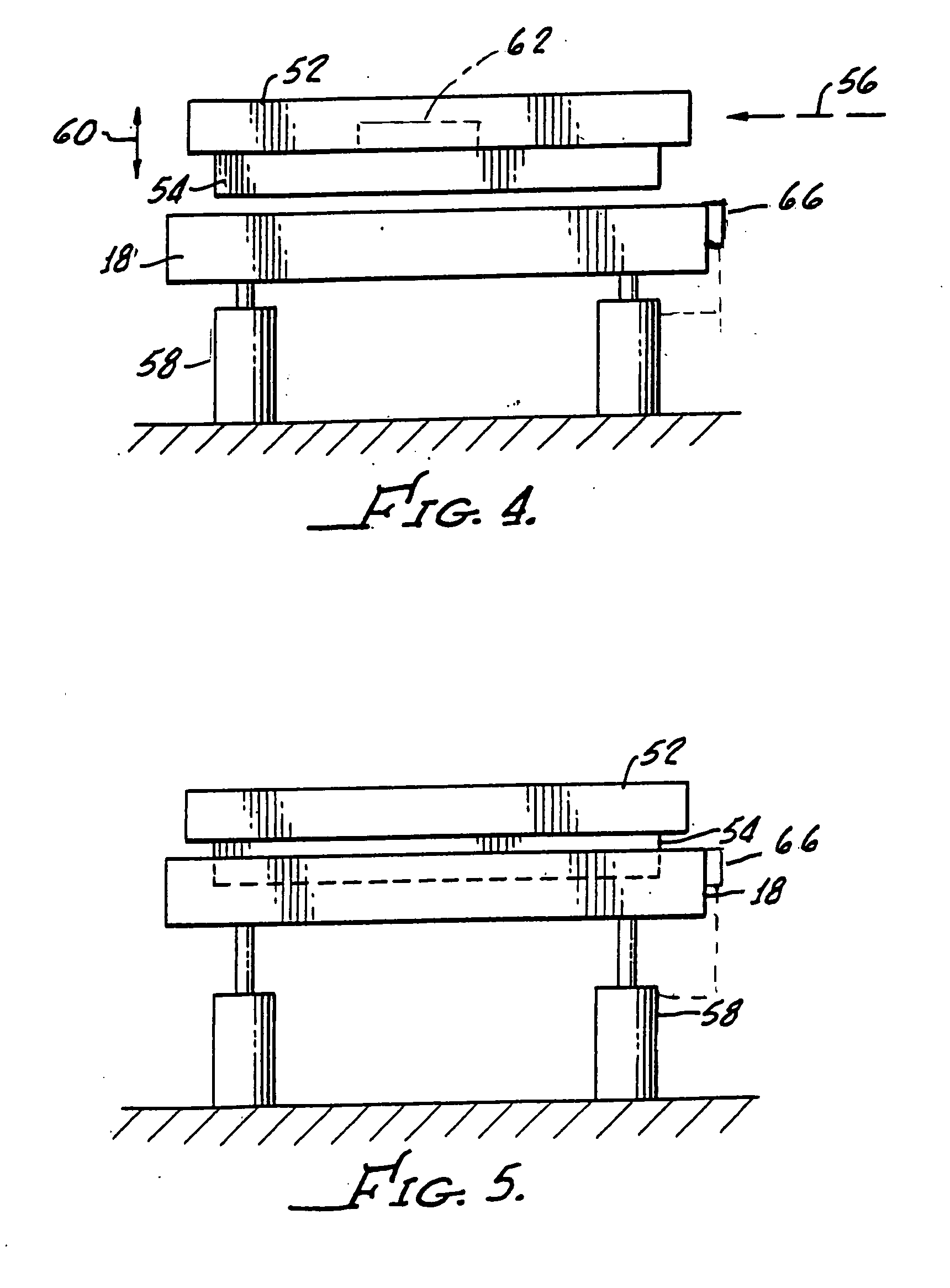

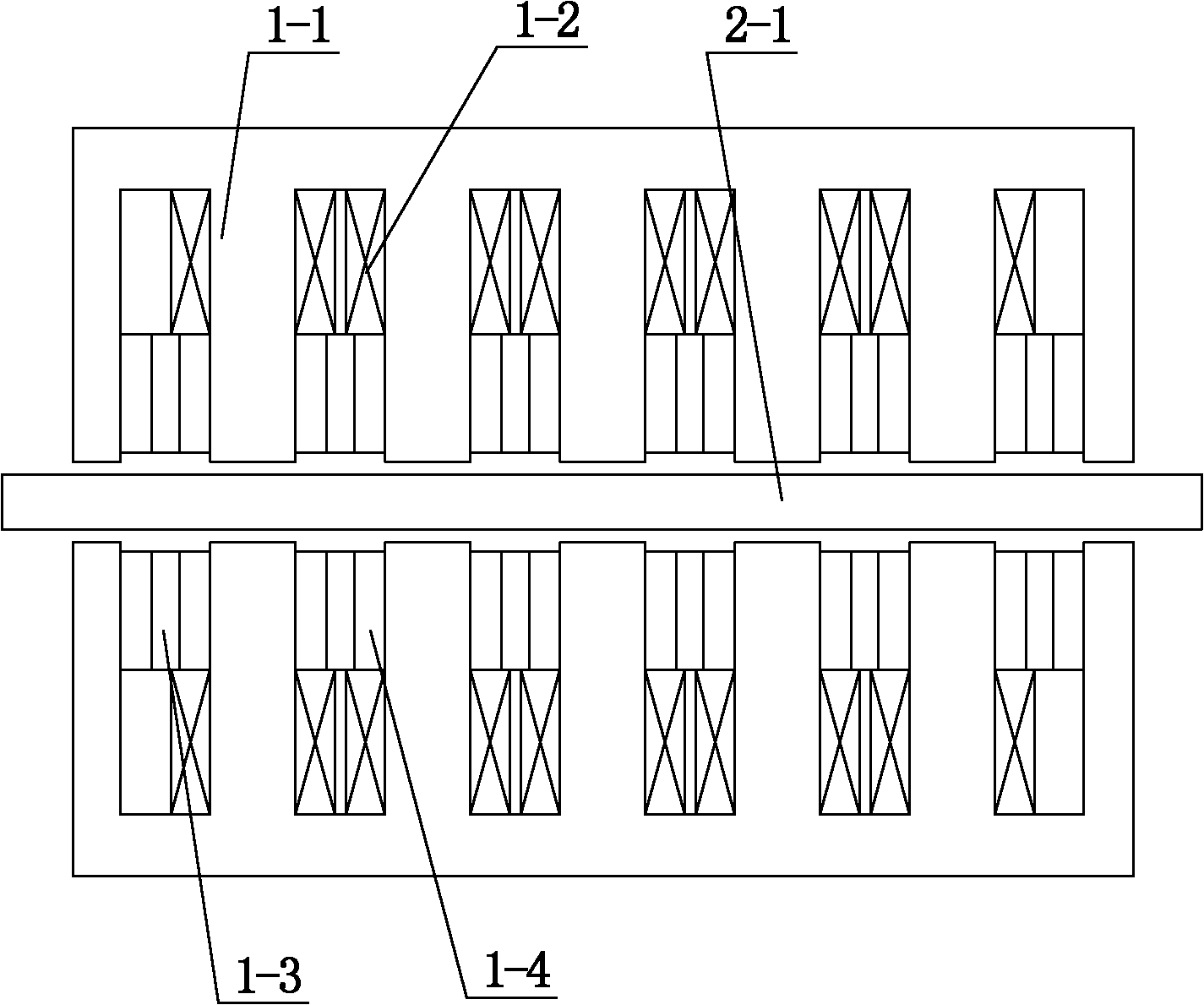

Eddy current braking apparatus with adjustable braking force

InactiveUS20060278478A1Adjustable distanceGuaranteed uniform velocityDynamo-electric brakes/clutchesElectrodynamic brake systemsEngineeringLinearity

An eddy current brake includes a diamagnetic member, a first support wall and a second support wall with the first and second linear arrays of permanent magnets disposed on the walls facing one another. Apparatus is provided for moving at least one of the walls in order to control eddy current induced in the member in the passage of the member therepast to adjust the braking force between the magnets and the member. Apparatus is also provided for causing the velocity of the member to change the braking force between the magnets and the member.

Owner:MAGNETAR TECH

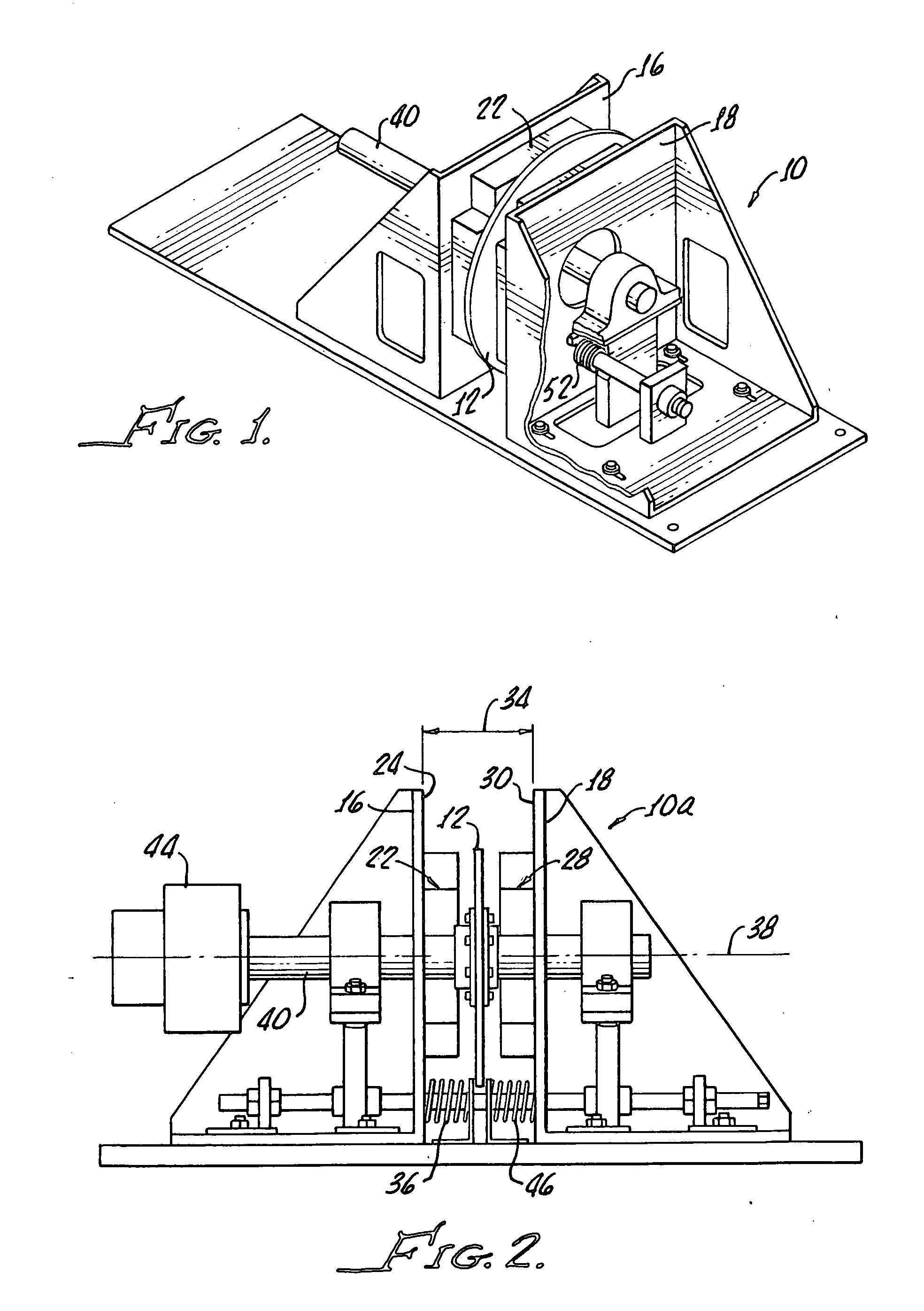

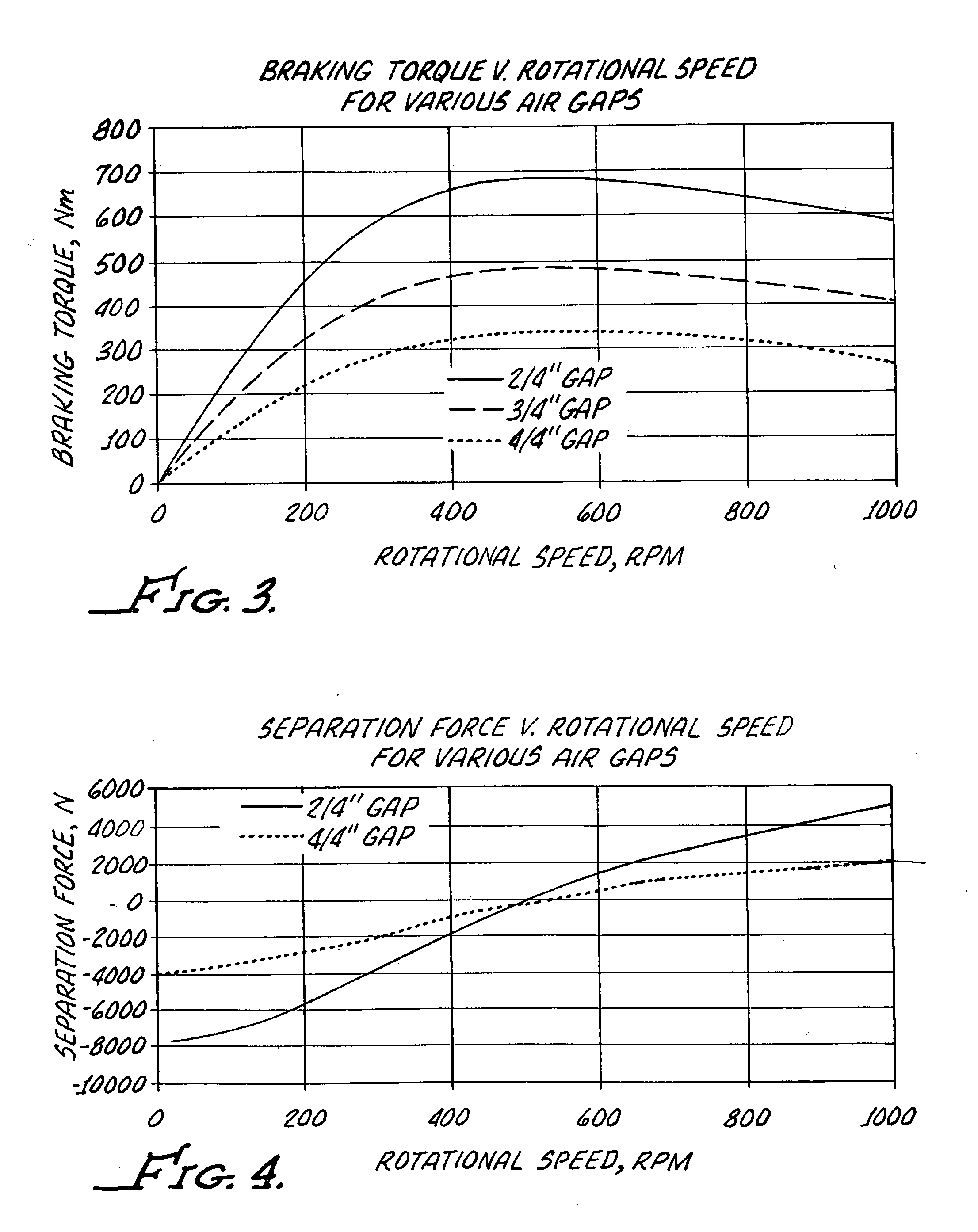

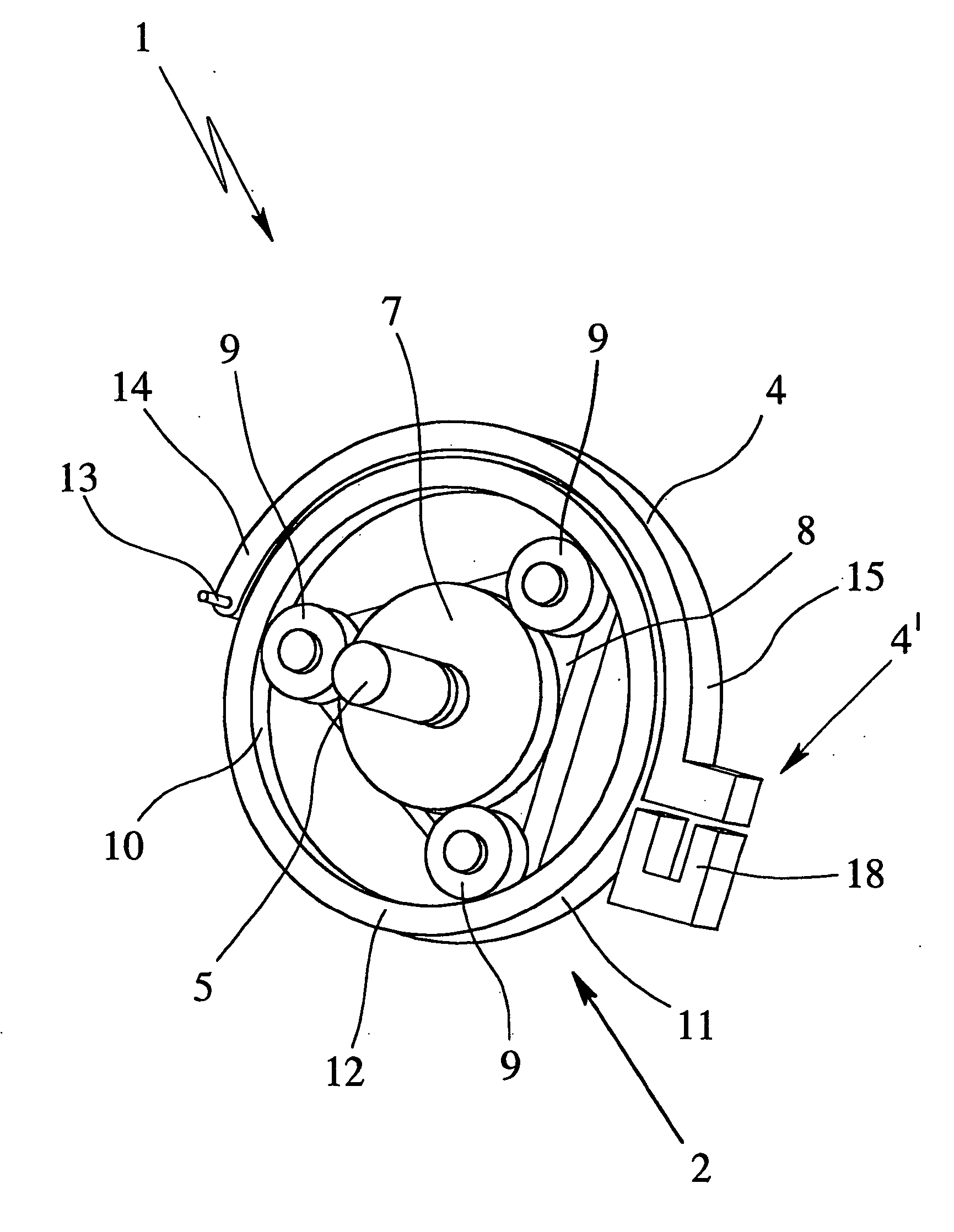

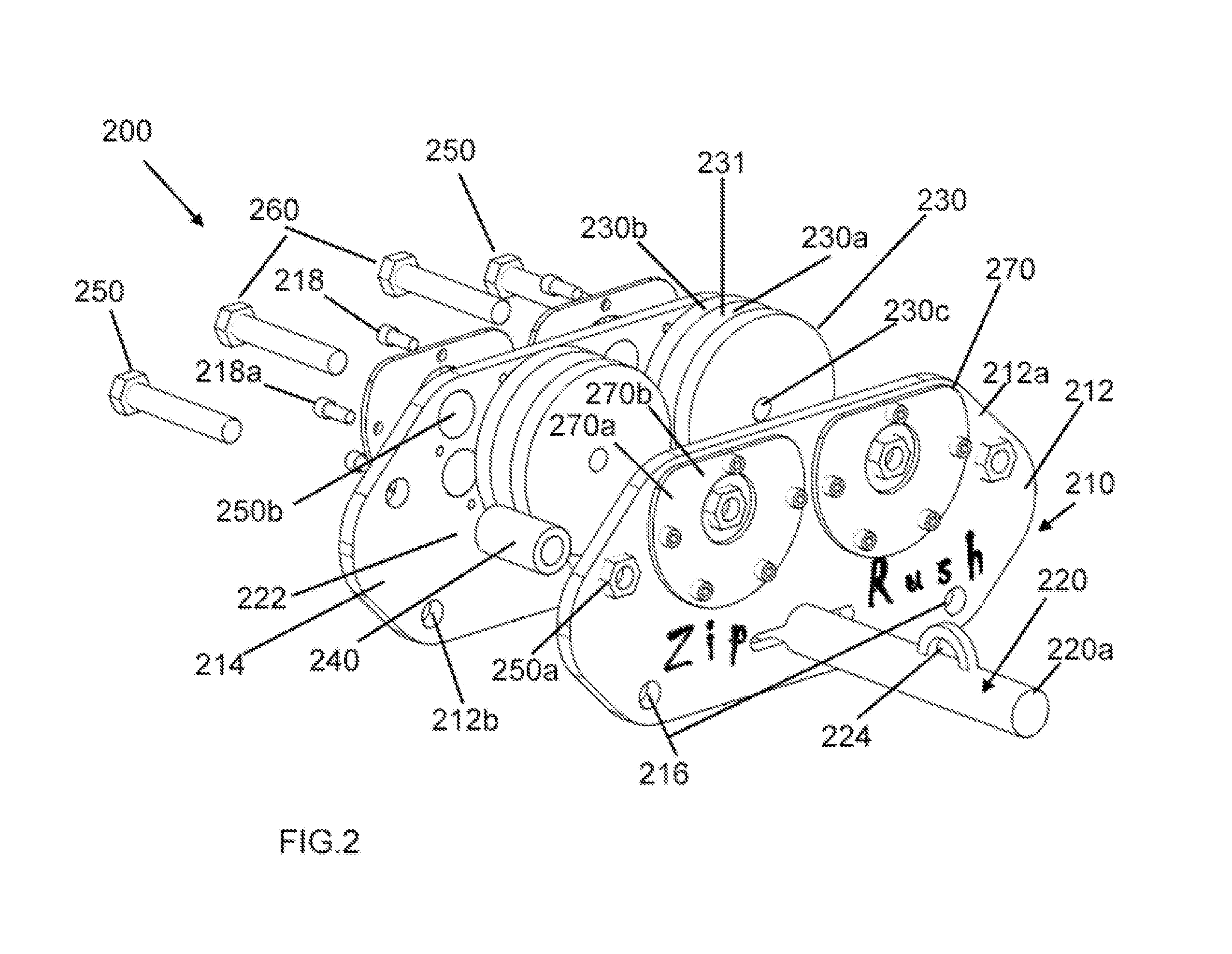

Axial rotary eddy current brake with self-adjustable braking force

InactiveUS20080105503A1Non-rotating vibration suppressionAsynchronous induction clutches/brakesEngineeringAxial rotation

An axial rotary eddy current brake with self adjustable braking force includes two spaced apart support structures defining a gap therebetween, at least two permanent magnets opposingly disposed in said gap and supported by the support structure in a spaced apart relationship and a diamagnetic disk disposed for rotation between the magnets, rotation of the disk causing an eddy current braking force between the magnets and the disk. Biasing apparatus is provided for moving at least one of the magnets as a function of disk rotational speed in order to control the braking force.

Owner:MAGNETAR TECH

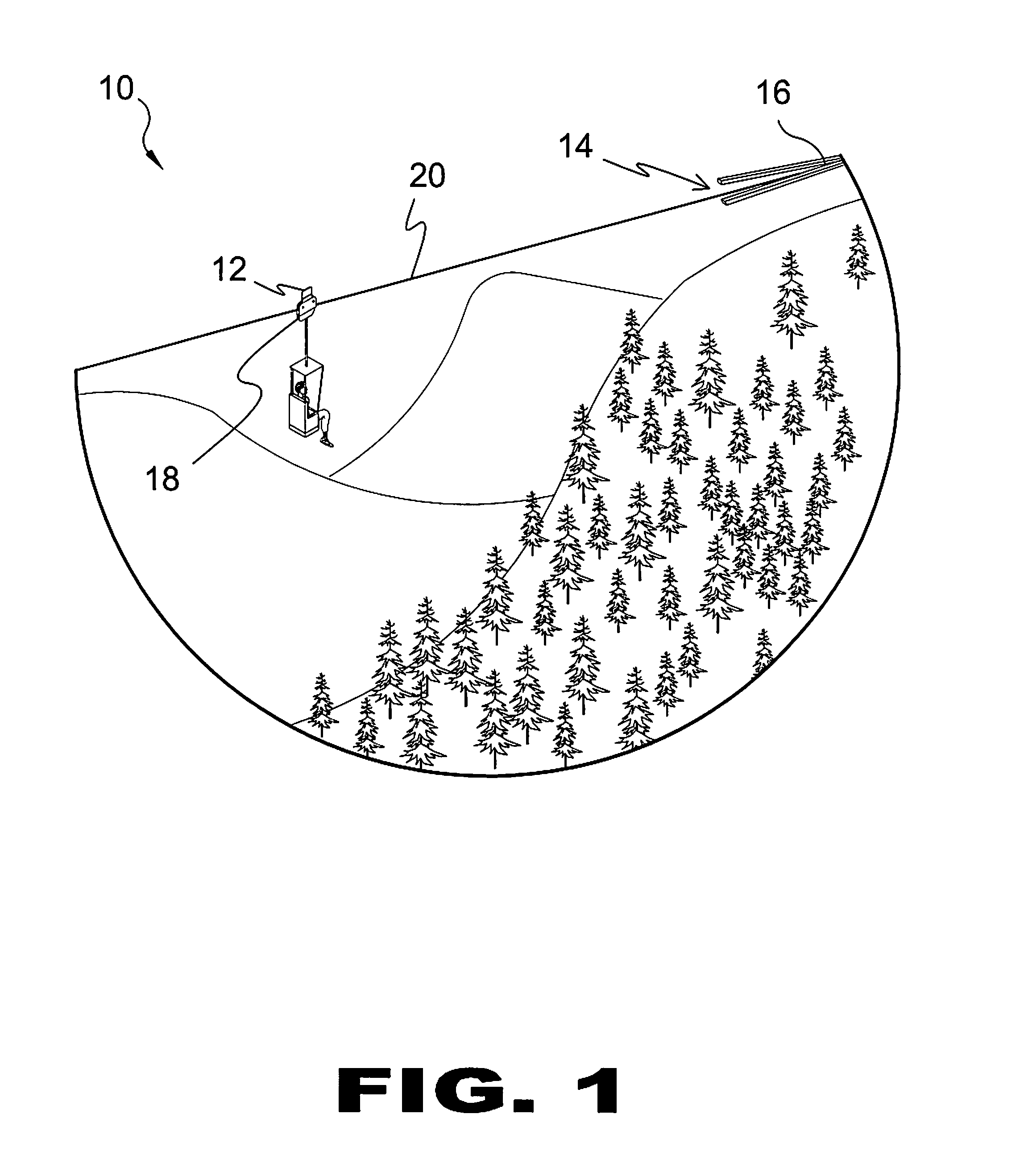

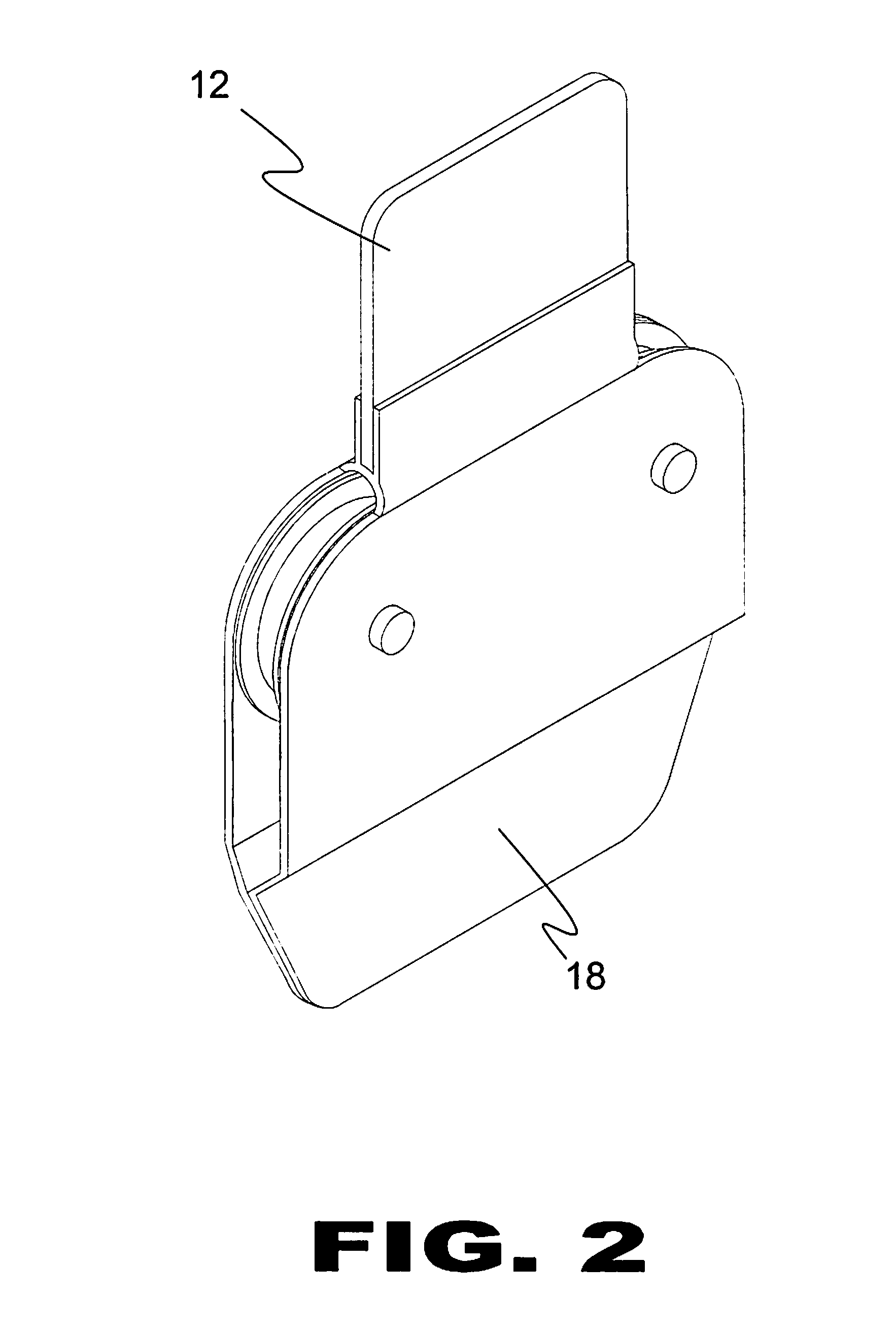

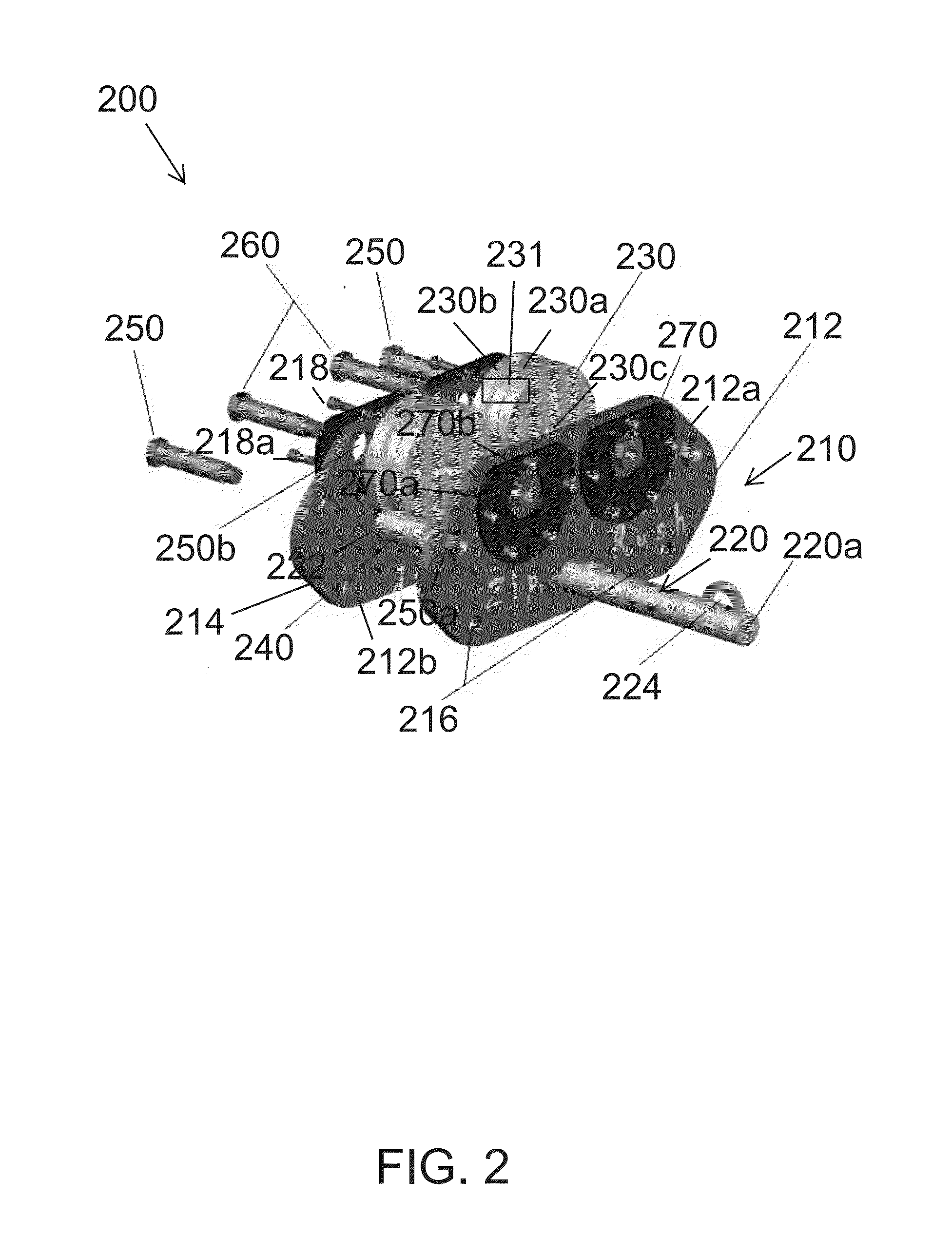

Eddy current braking system for trolley zip line cable

InactiveUS8037978B1Increase valueEasy to moveElectrodynamic brake systemsAsynchronous induction clutches/brakesElectrical conductorEngineering

An eddy current magnetic braking system that is based on drag created when a conductor moves through a stationary magnetic field. As the magnetic field increases the drag value also increases. The invention provides a magnetic braking system for use on zip line / cable rides and trolleys. Alternate designs of the present invention include a magnetic braking system having a trolley that moves on a zip line / cable to a brake block which is connected to a pulley cable, as the trolley pushes the brake block, the pulley moves the conductor into a magnetic field creating an eddy current brake that slows the trolley to a stop.

Owner:BOREN DANIEL

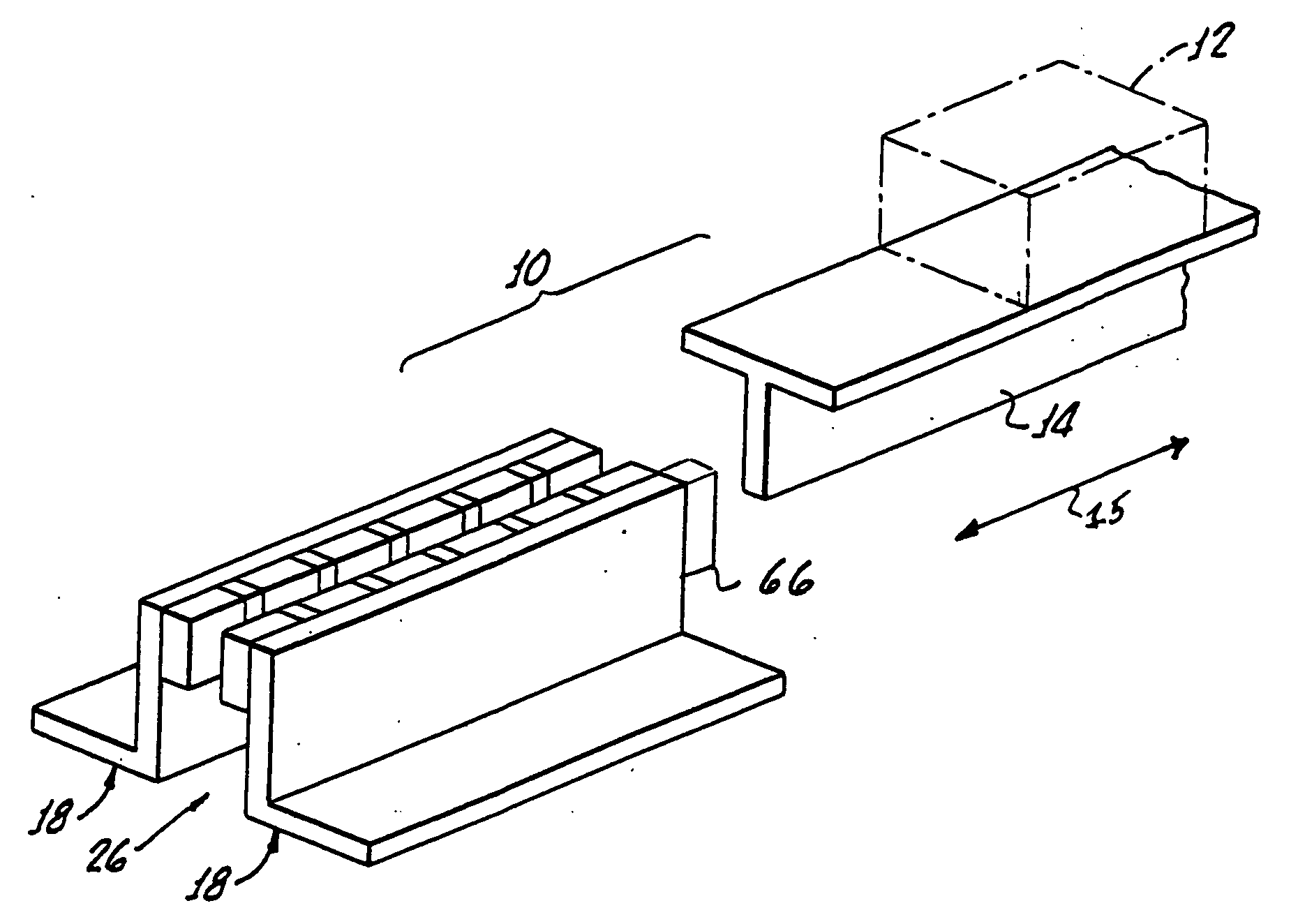

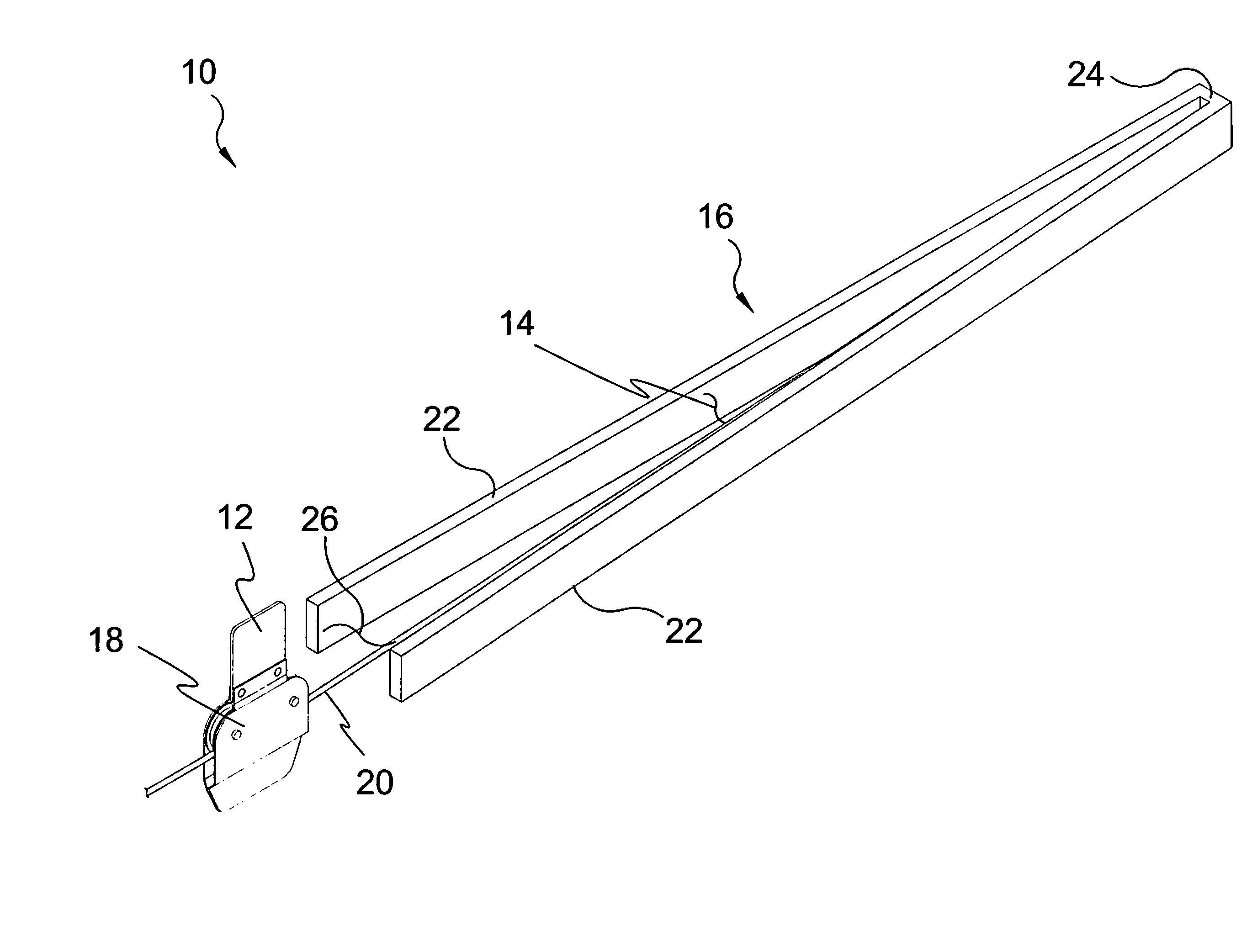

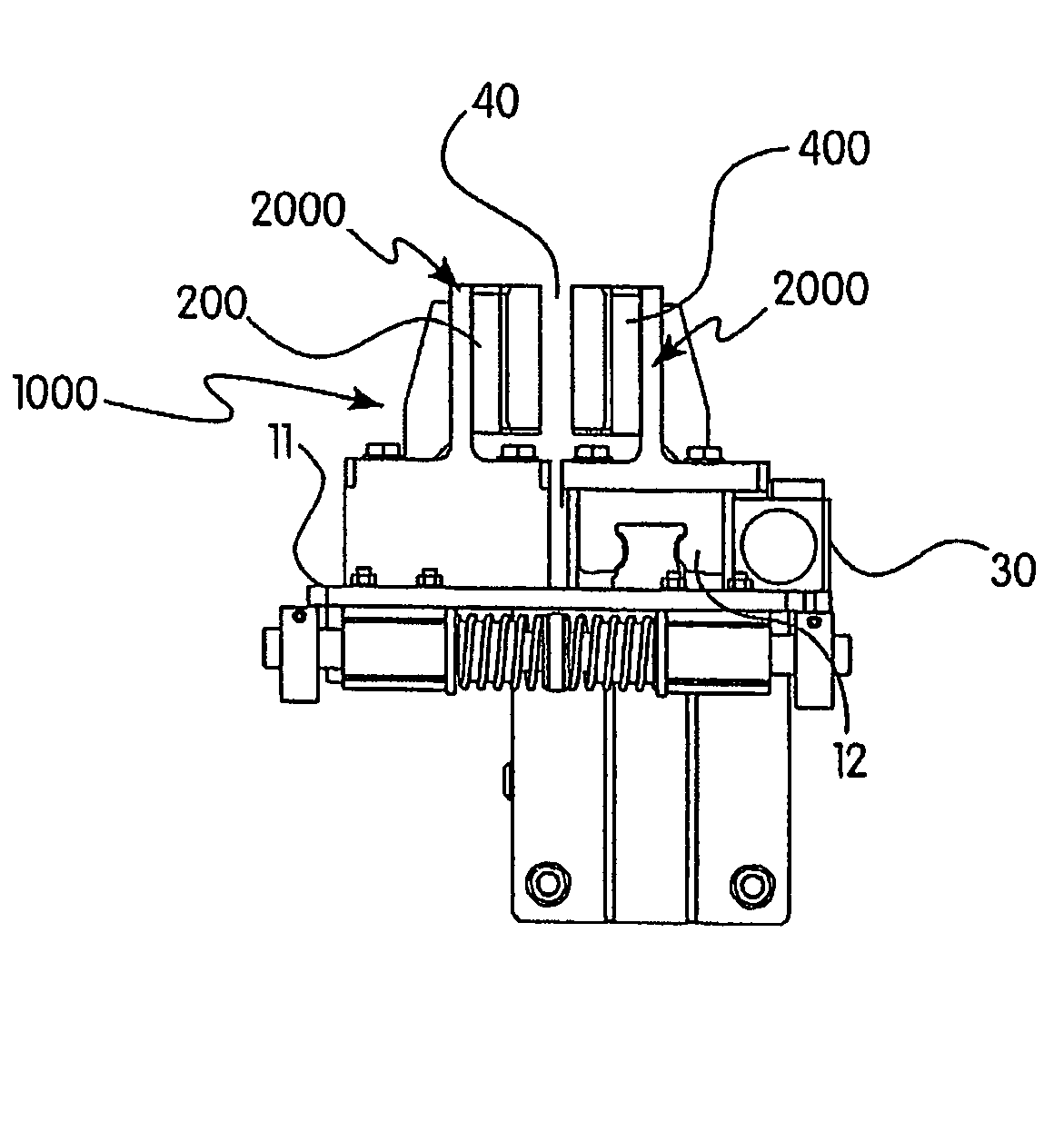

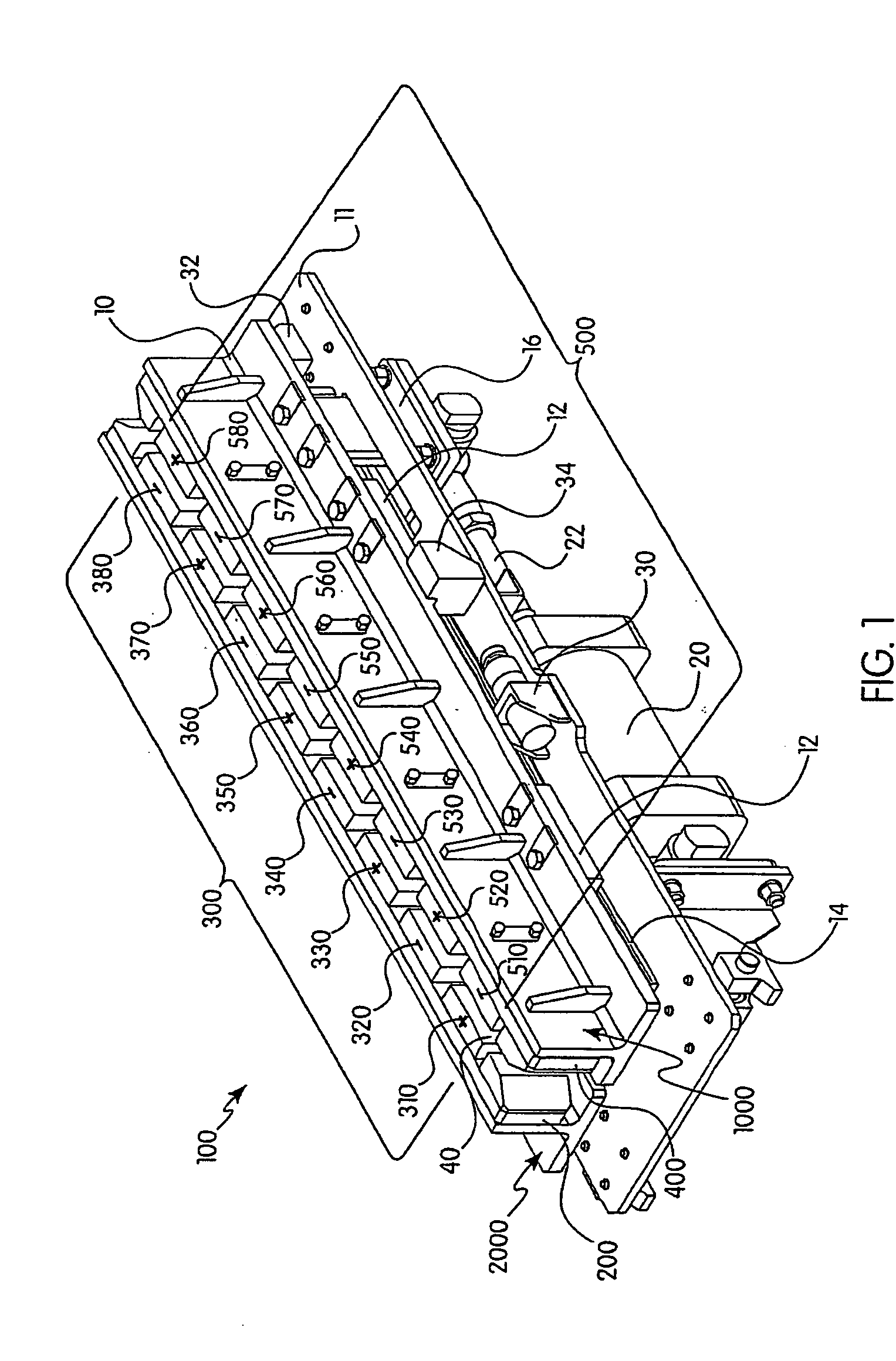

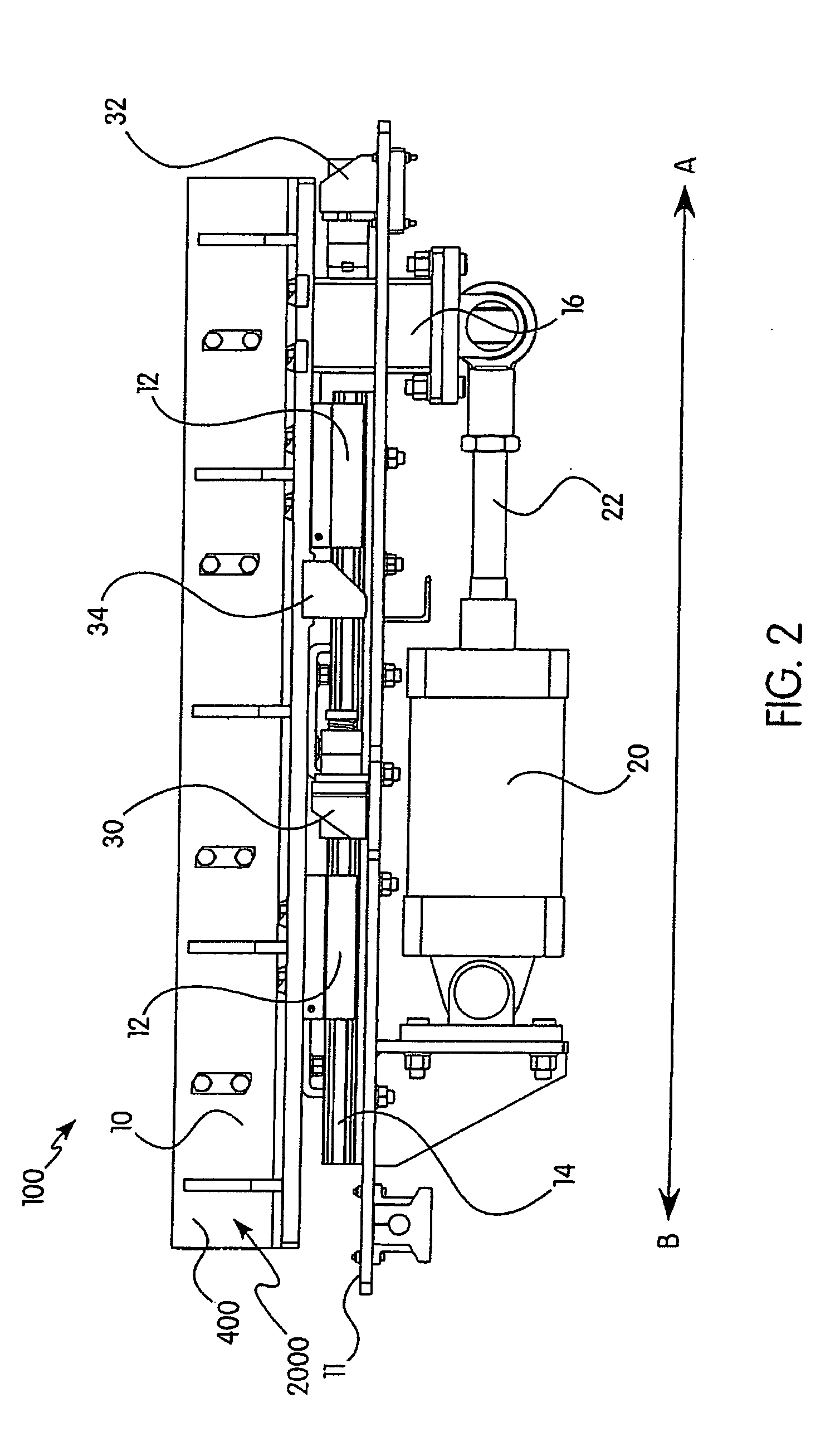

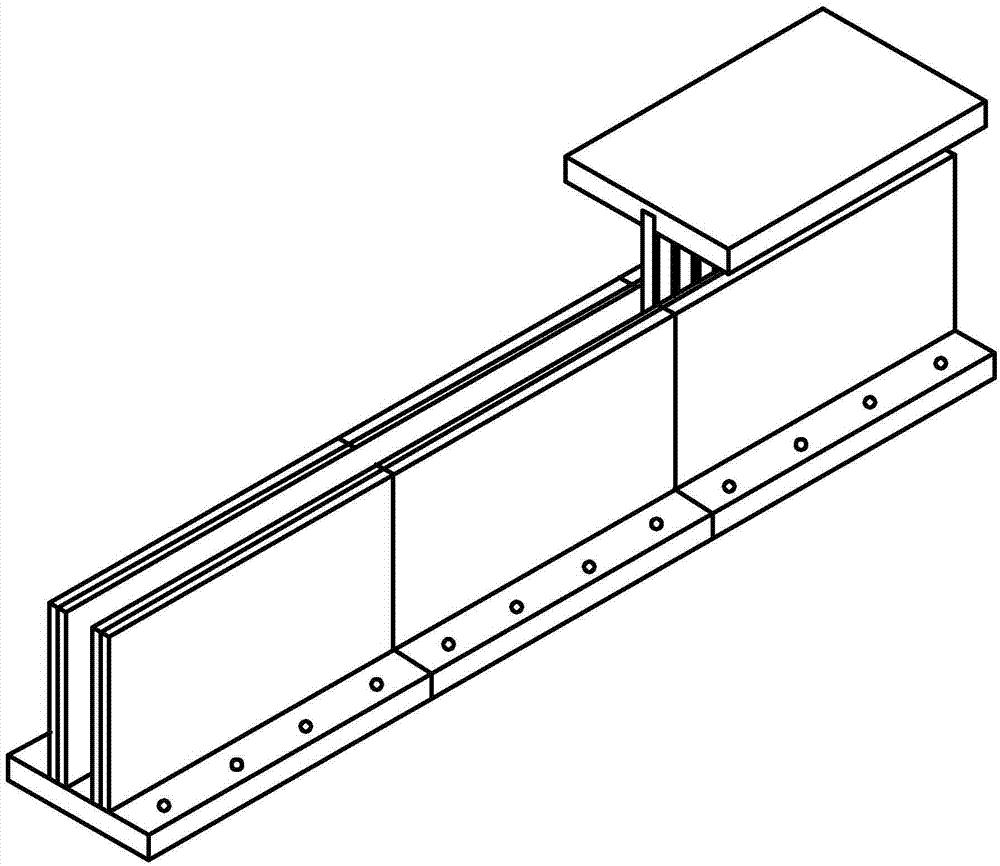

Selectively incrementally actuated linear eddy current braking system

ActiveUS20050263356A1Brake force be applyElectrodynamic brake systemsAsynchronous induction clutches/brakesEngineeringEddy current brake

The invention is an incrementally actuated eddy current braking system. The system comprises first and second primary members, which further comprise arrays of permanent magnets arranged in alternating polarity. The respective magnets of the arrays face one another. A means for incremental displacement is drivingly connected to at least one of the primary members enabling the movement of said members relative to one another.

Owner:VELOCITY MAGNETICS

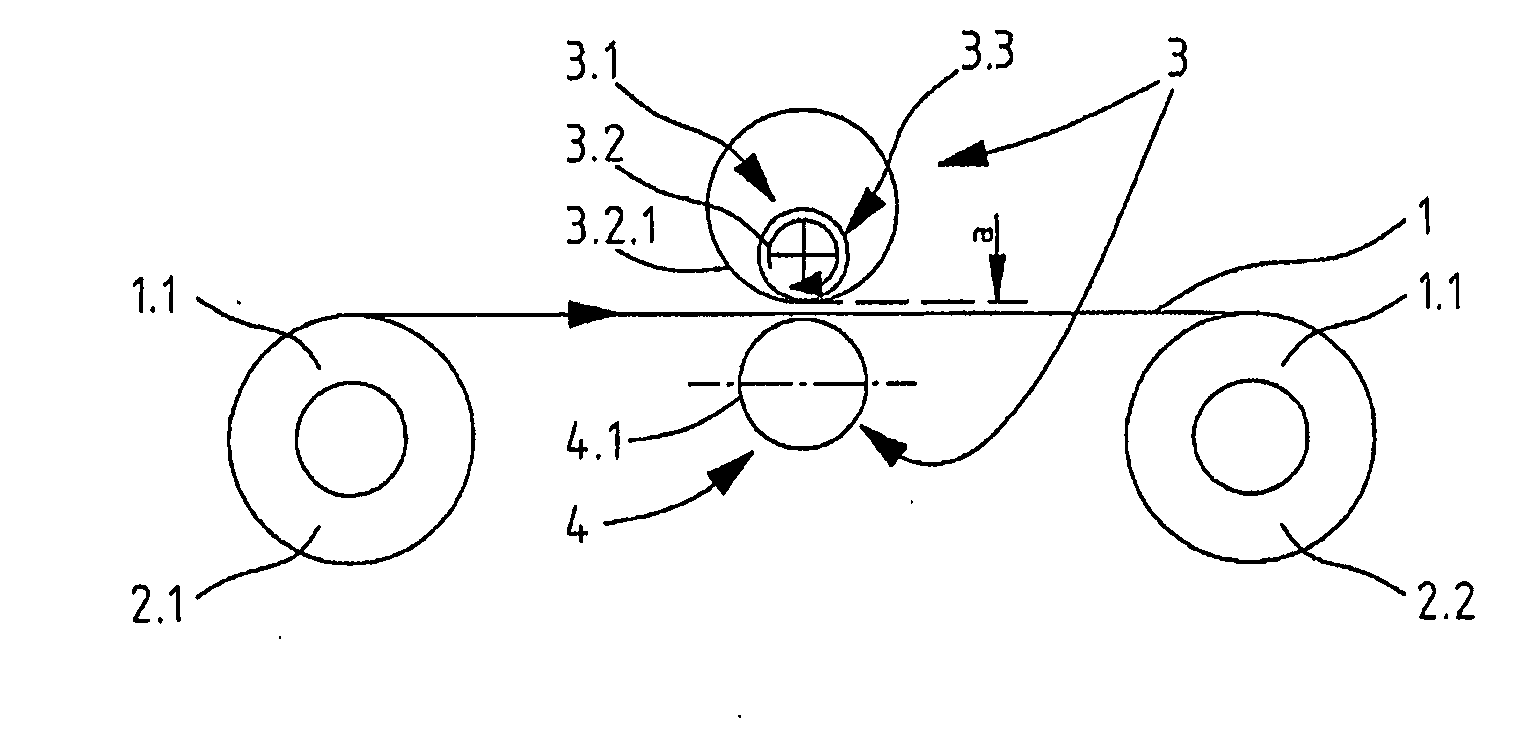

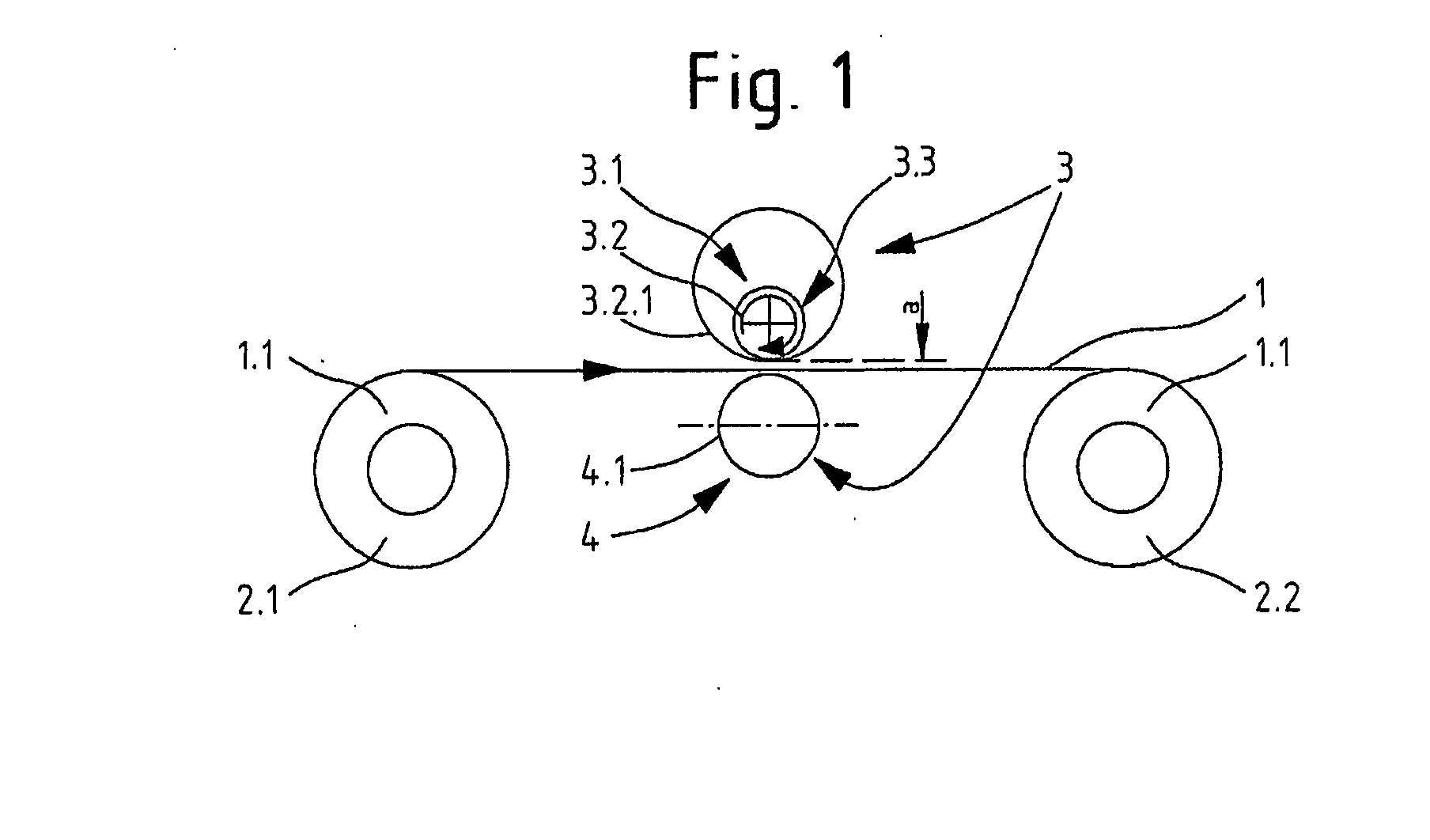

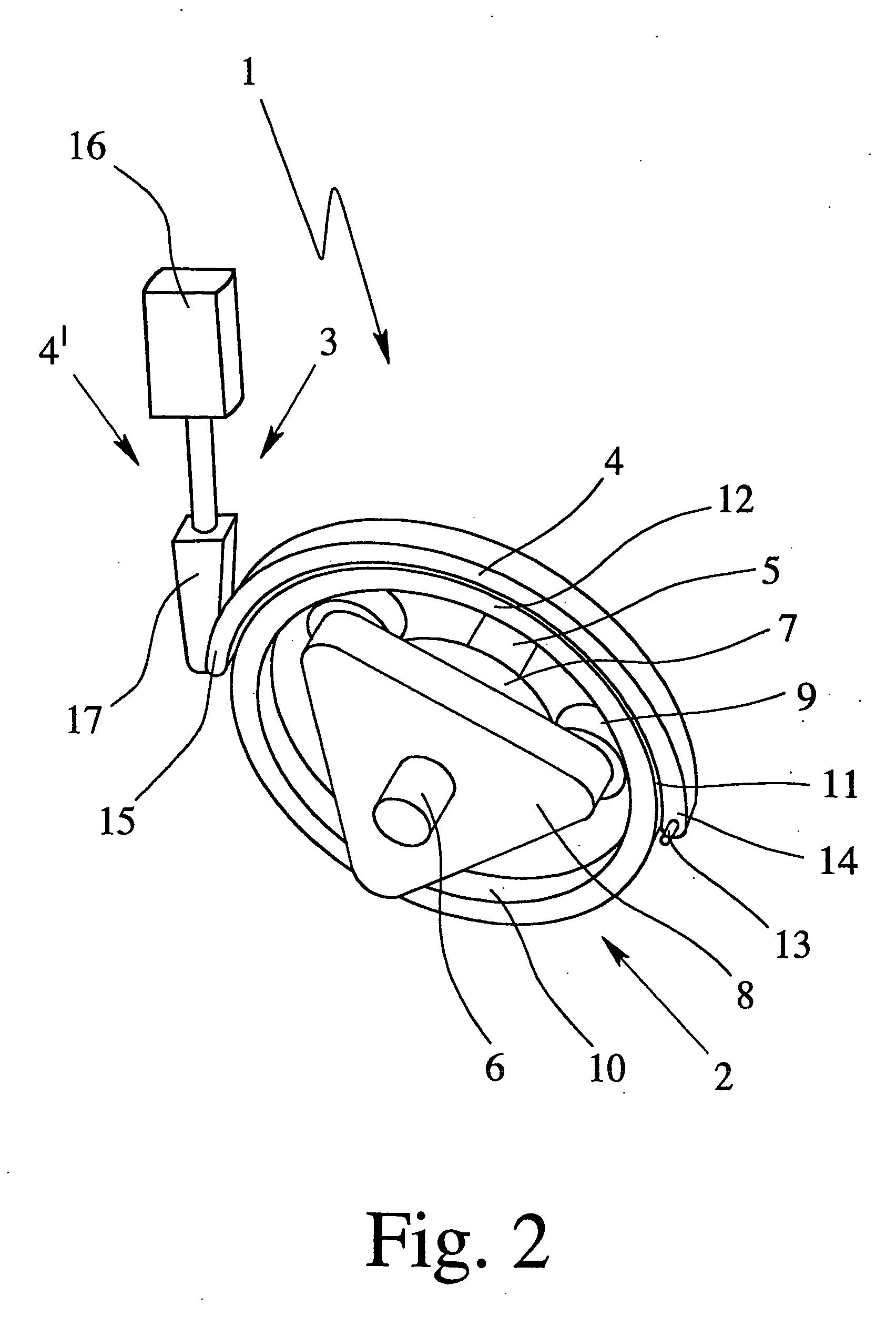

Method For Braking A Running Metal Strip And Unit For Carrying Out The Method

InactiveUS20090026303A1Simple designAC motor controlDigital data processing detailsEngineeringEddy current brake

The method and unit for braking a metal strip (1), running off a wind-out coiler (2.1) in the form of a coil (1.1) and running onto a wind-on coiler (2.2) again, are to guarantee that a surface of the metal strip remains undamaged and a full effective braking force is exerted on the metal strip (1) by means of an eddy current brake (3.1) with a rotating magnet system (3.2). The above is achieved, whereby the braking force is exerted on the metal strip (1) by means of an induced counter-torque against a support bearing (4) to one side in a non-contact manner, whereby the support bearing (4) may be embodied as a counter roller (4.1).

Owner:STEINERT ELEKTROMAGNETBAU

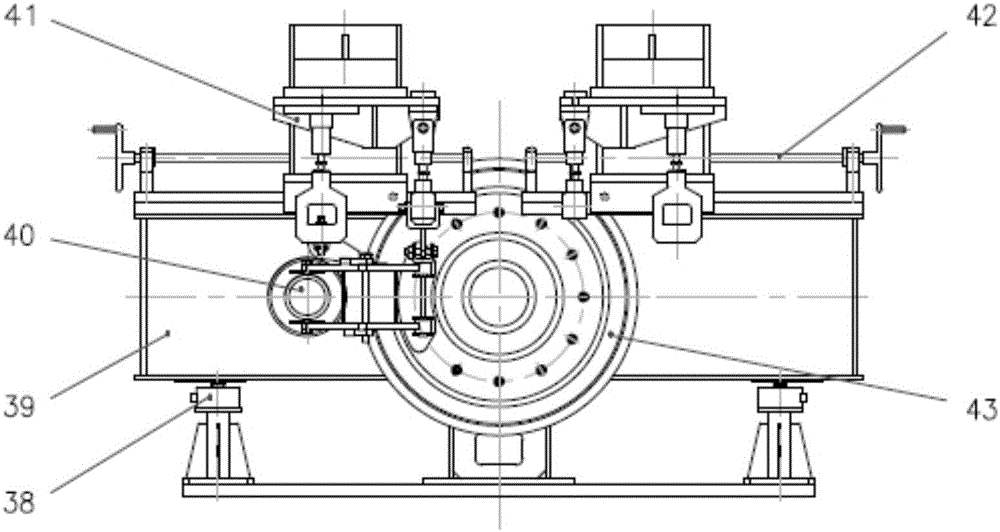

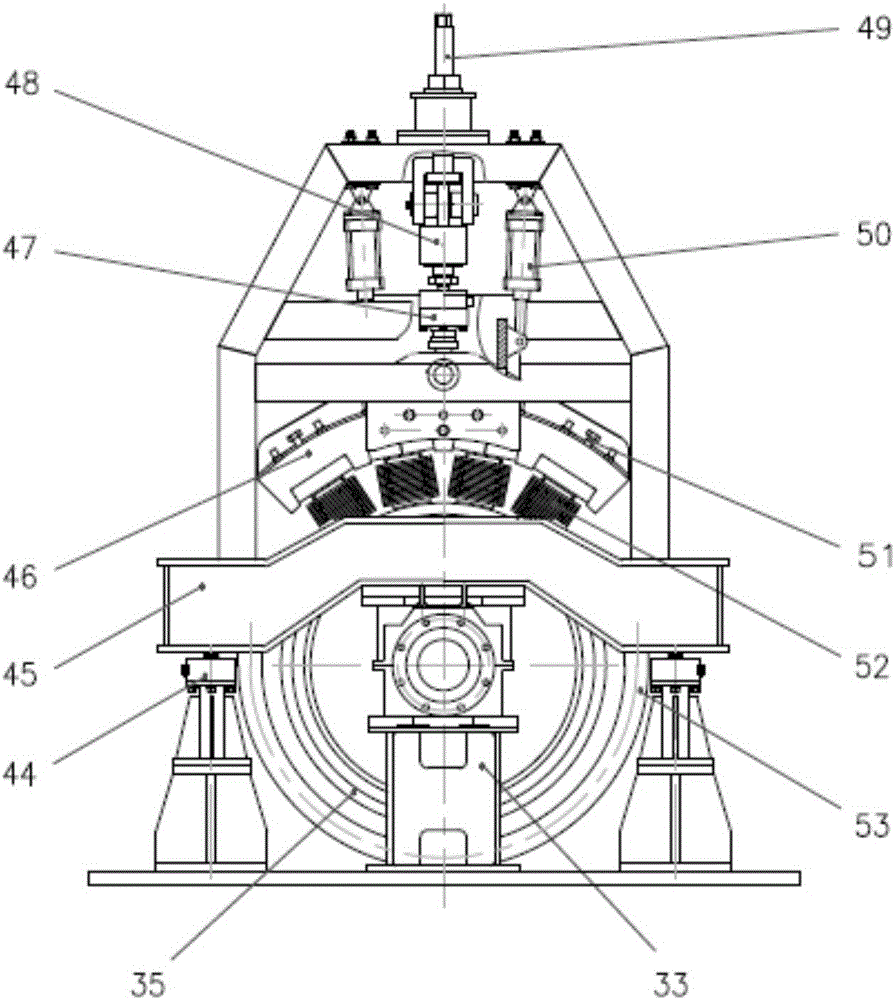

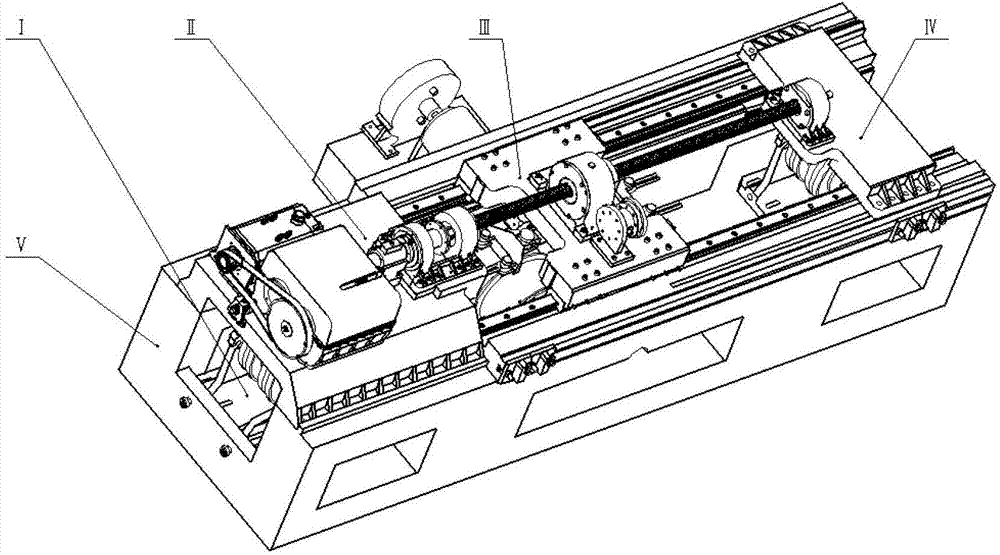

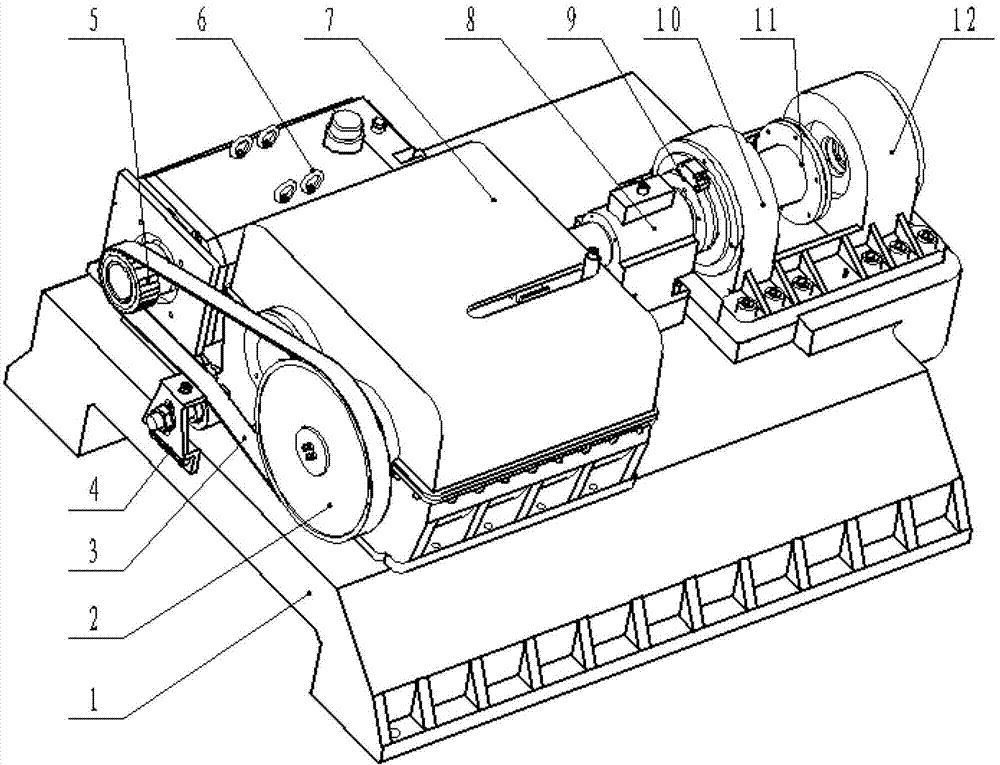

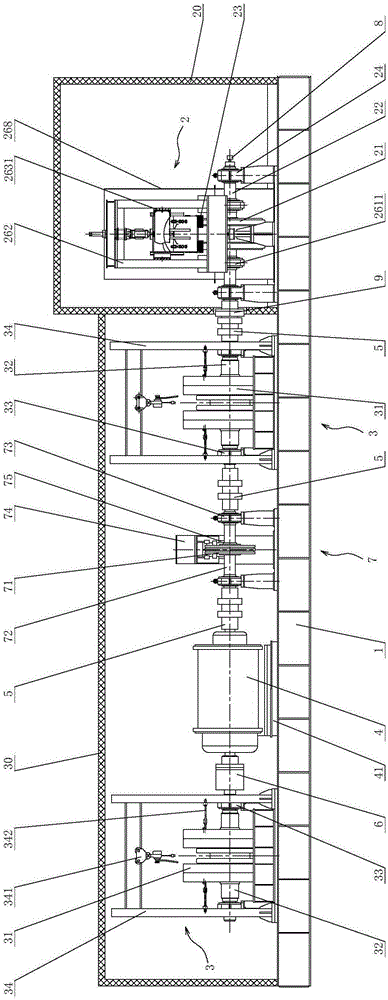

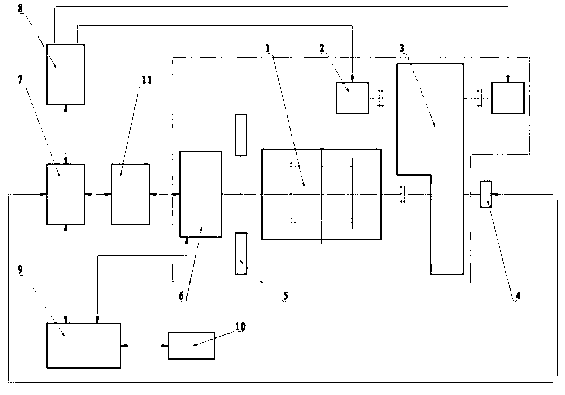

Rail vehicle multifunctional braking power testing platform

InactiveCN105738133AIncrease heating capacityInhibit temperature riseRailway vehicle testingTrack brakePower unit

The invention relates to a multifunctional braking power testing platform which comprises the components of a base; a power and inertia chamber which is arranged on the base and comprises a power unit and a mechanical inertia unit; a first testing chamber which is arranged on the base and is mounted on one end of the power and inertial chamber; and a second testing chamber which is arranged on the base and is mounted on the other end of the power and inertia chamber, wherein a first braking device in the first testing chamber is different from a second braking device of the second testing chamber. The multifunctional braking power testing platform can be used for disc braking, tread braking, eddy current braking or magnetic rail braking tests of high-speed train and other rail vehicles, thereby reproducing a braking energy conversion process in a 1:1 manner and testing braking performance in real time.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

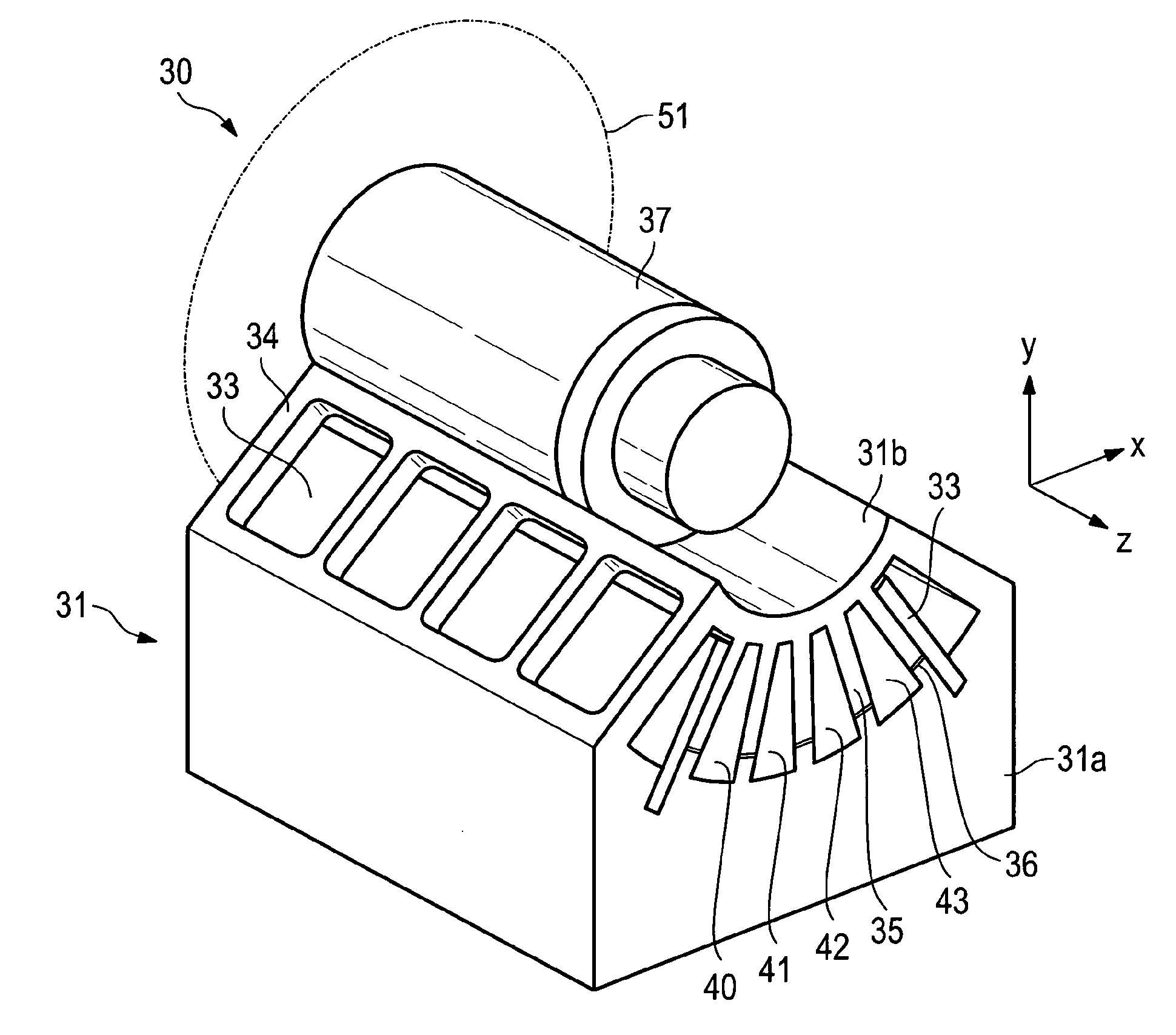

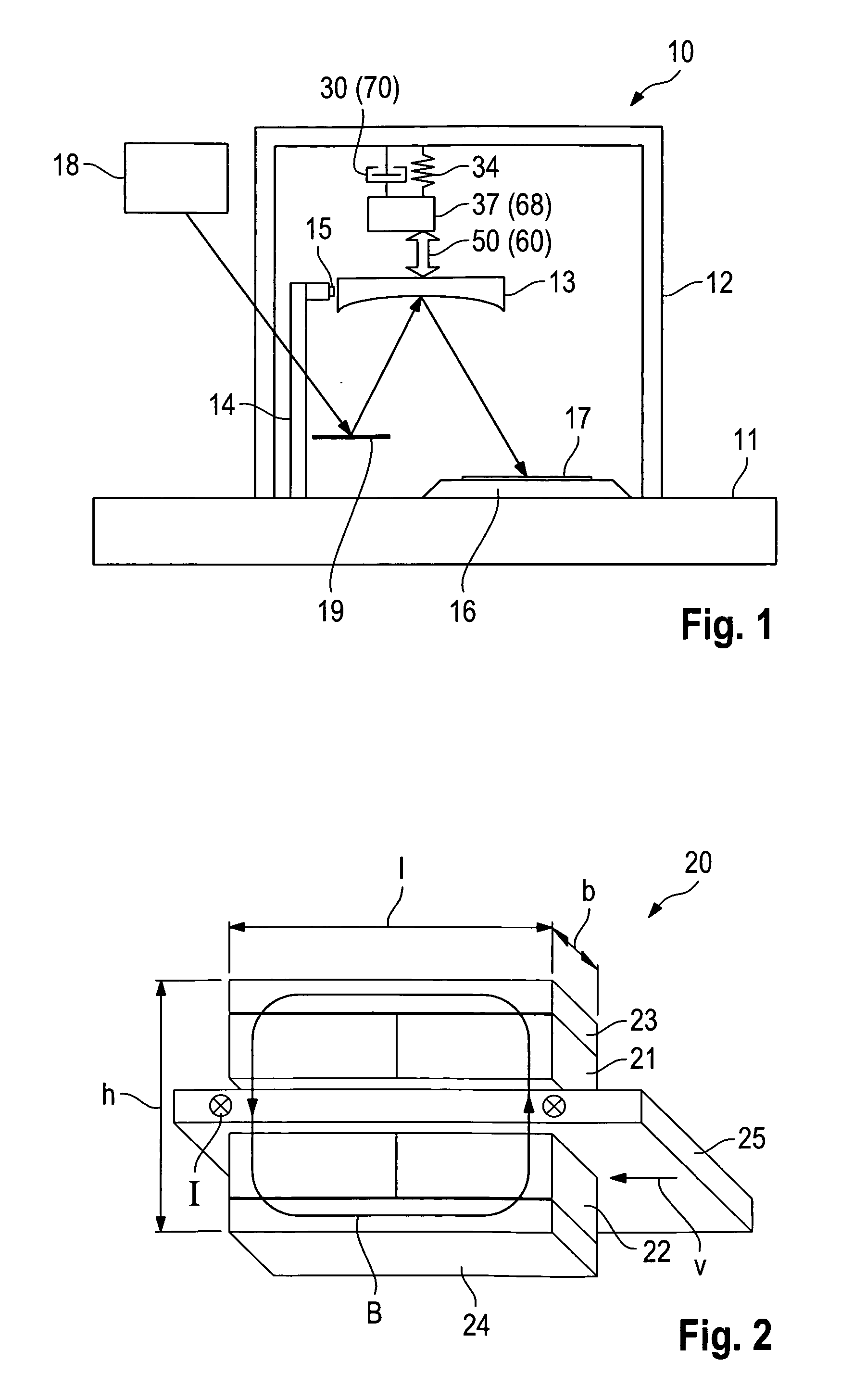

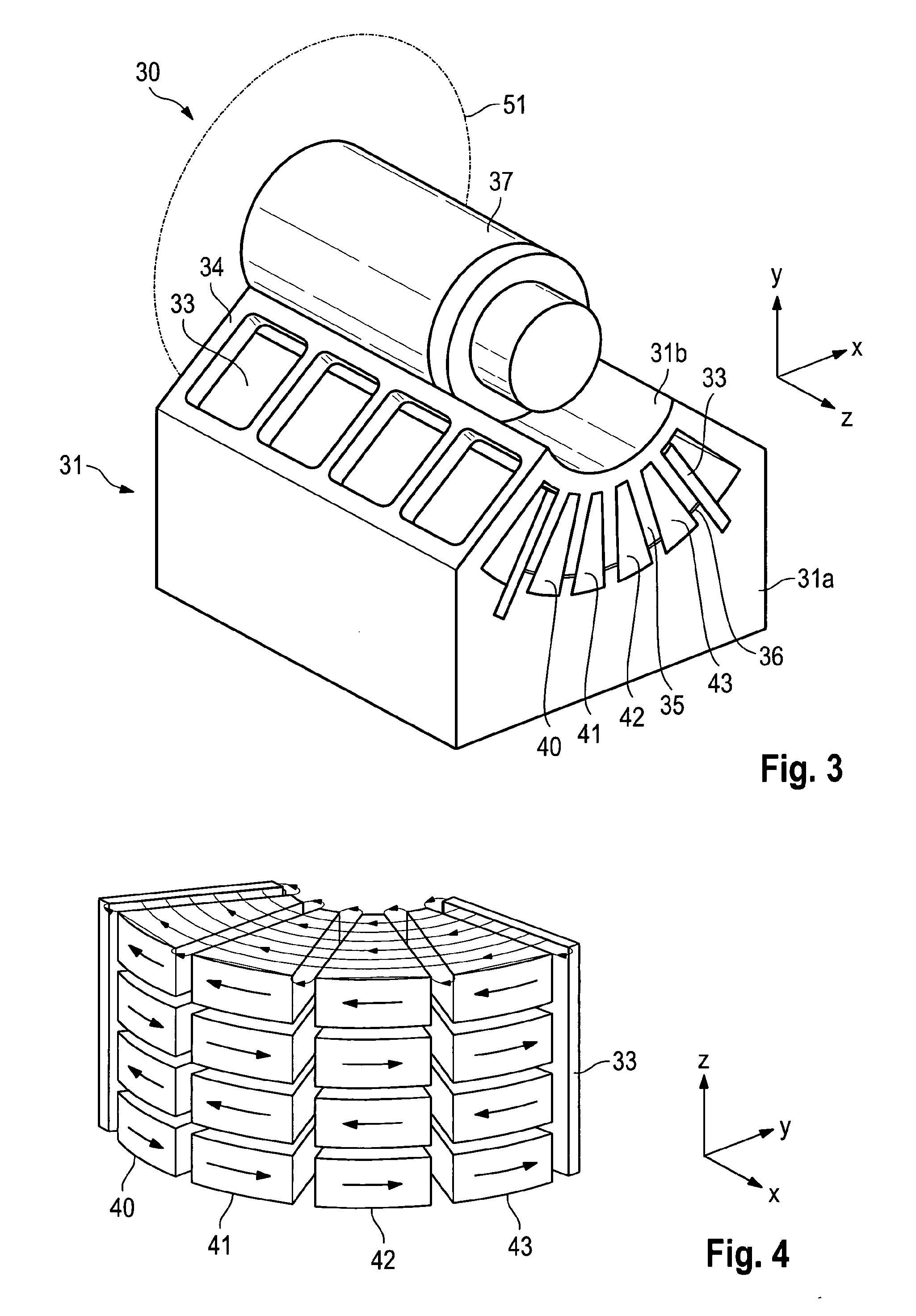

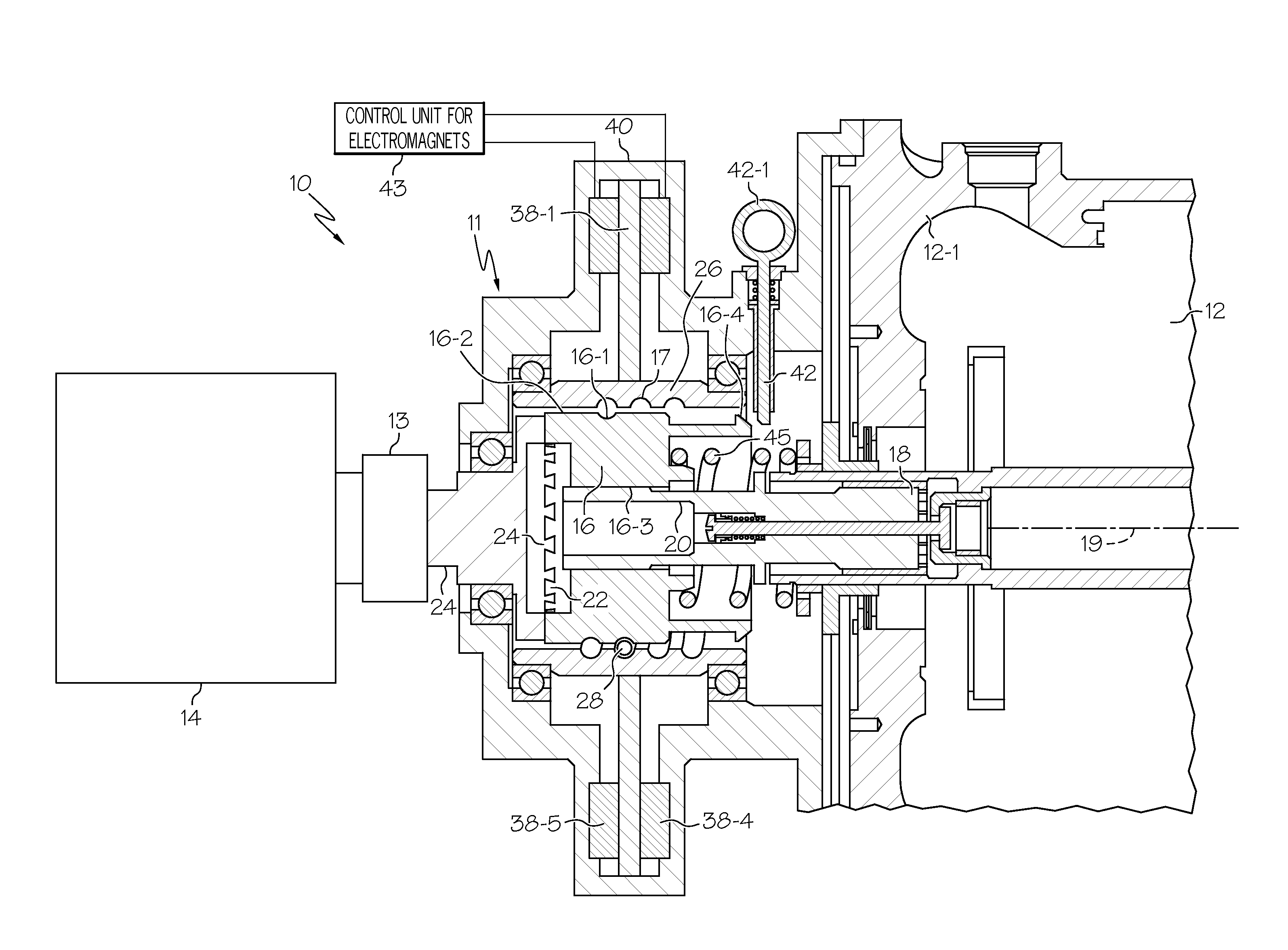

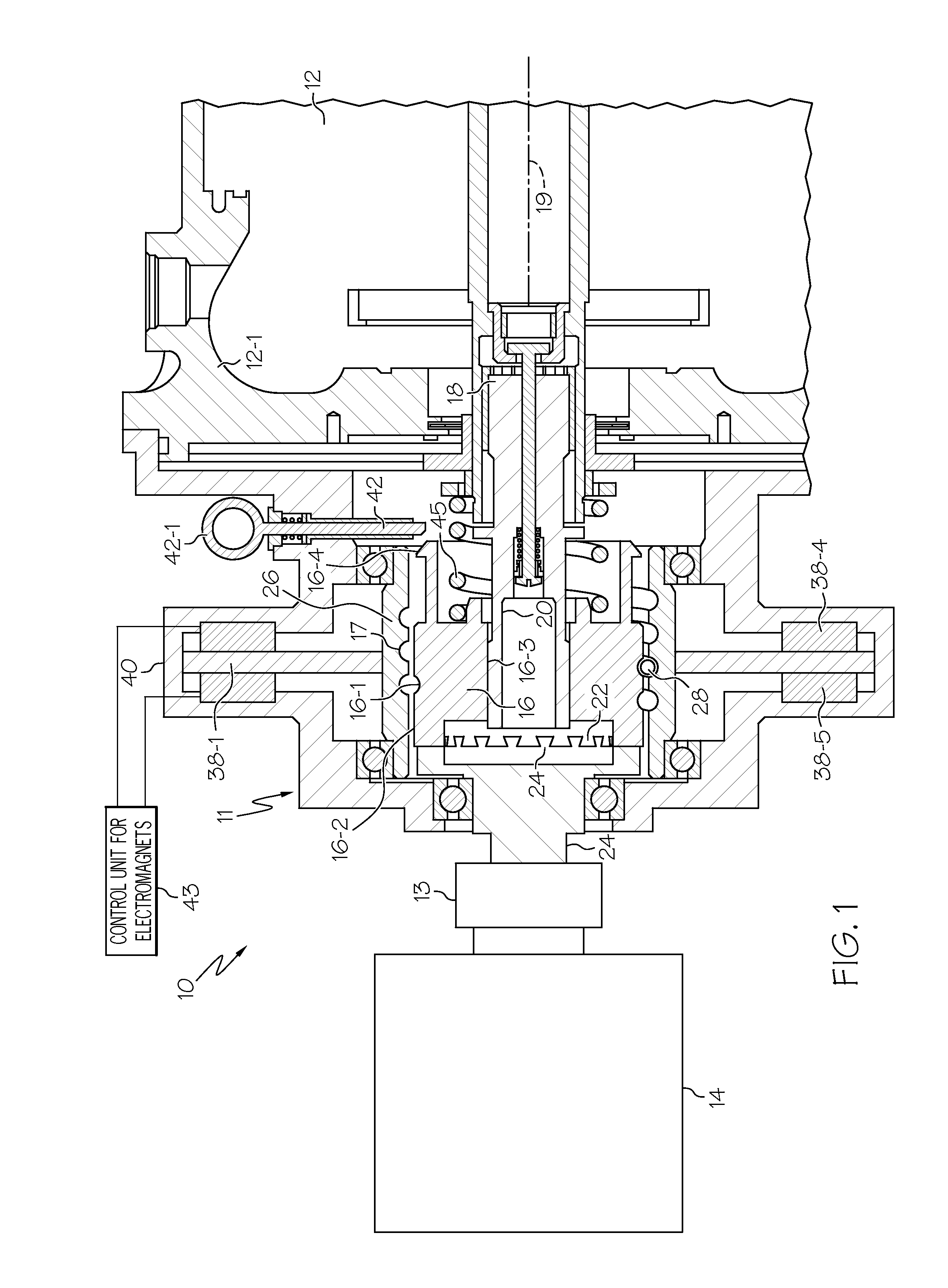

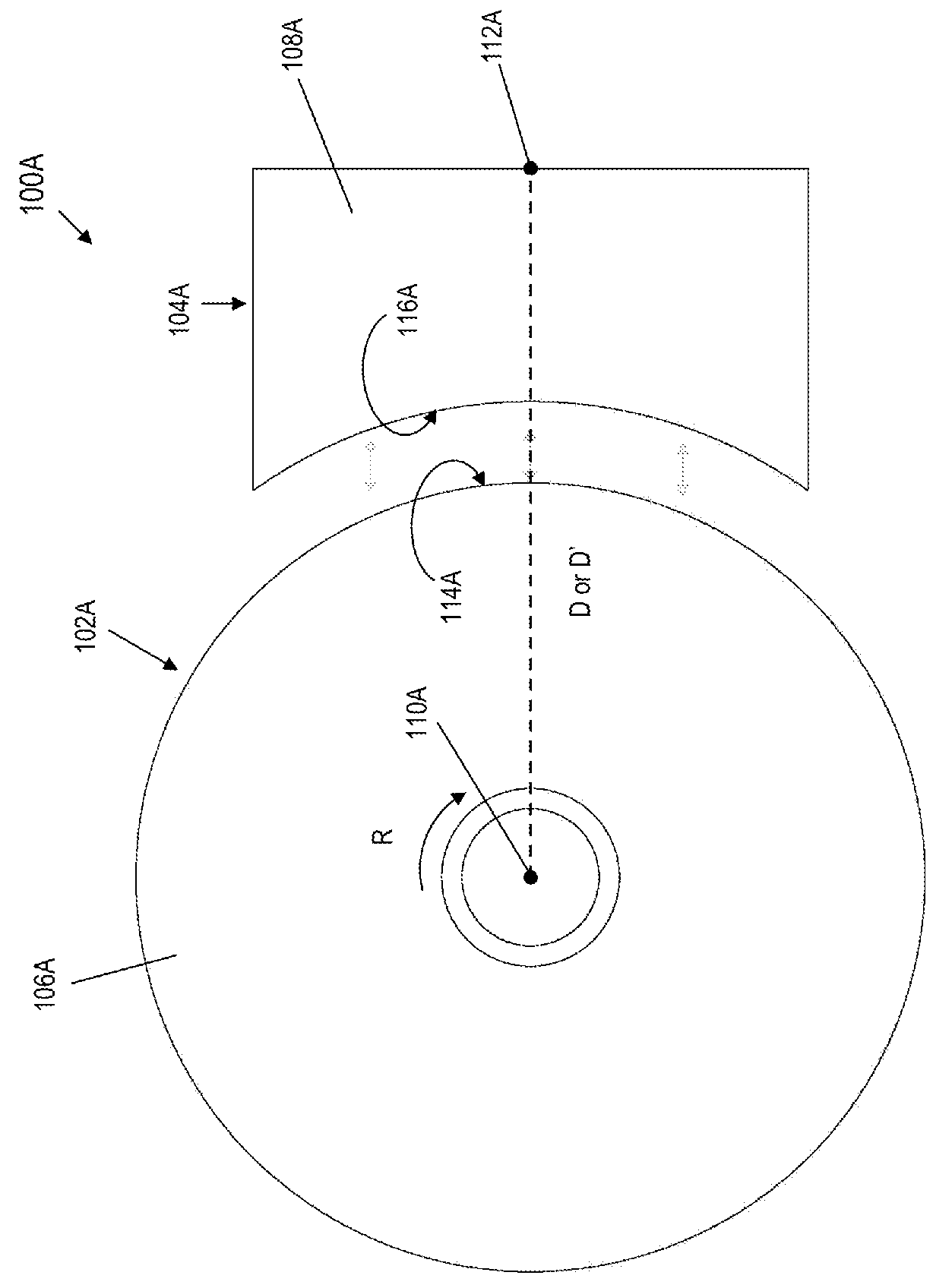

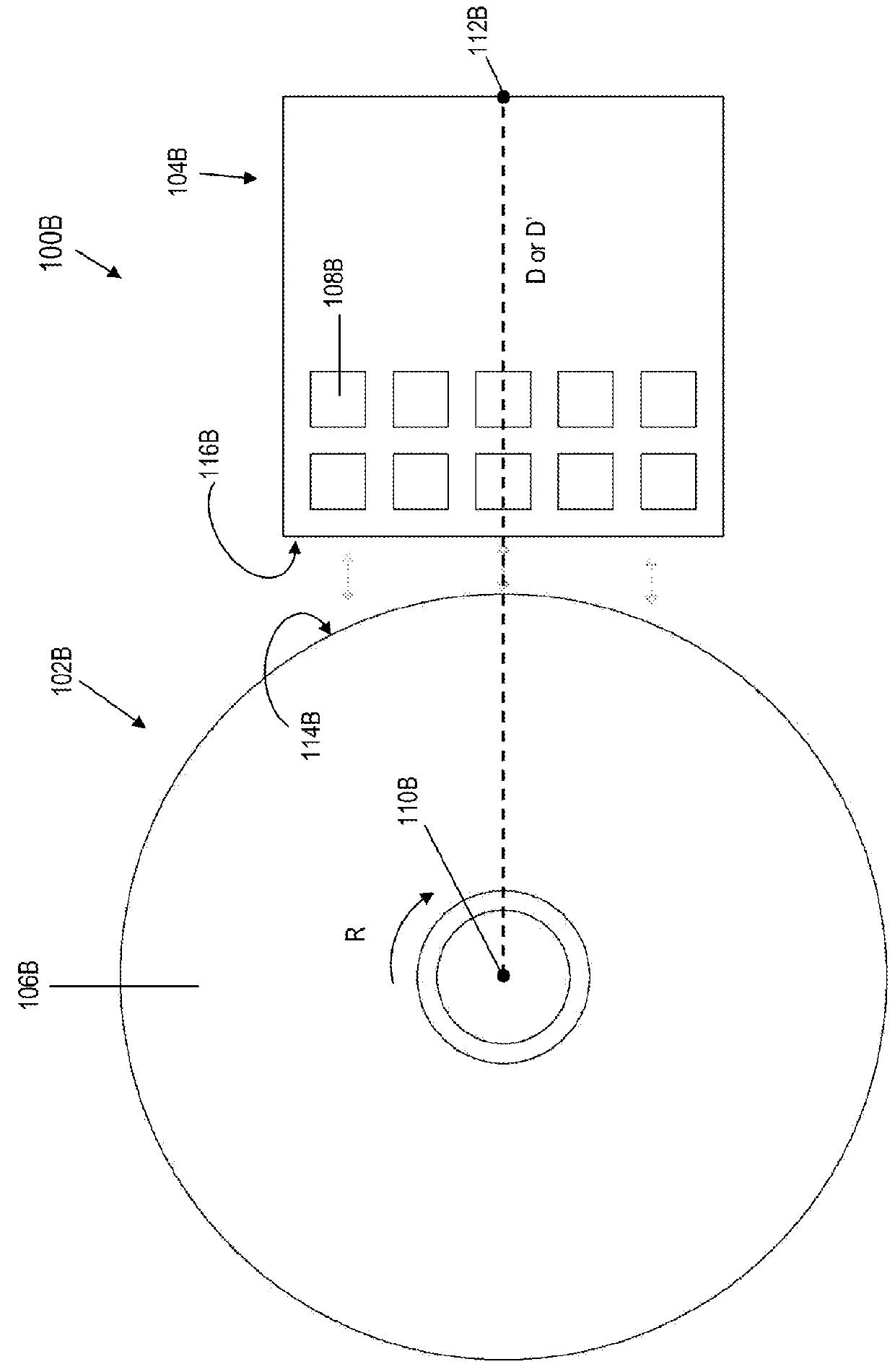

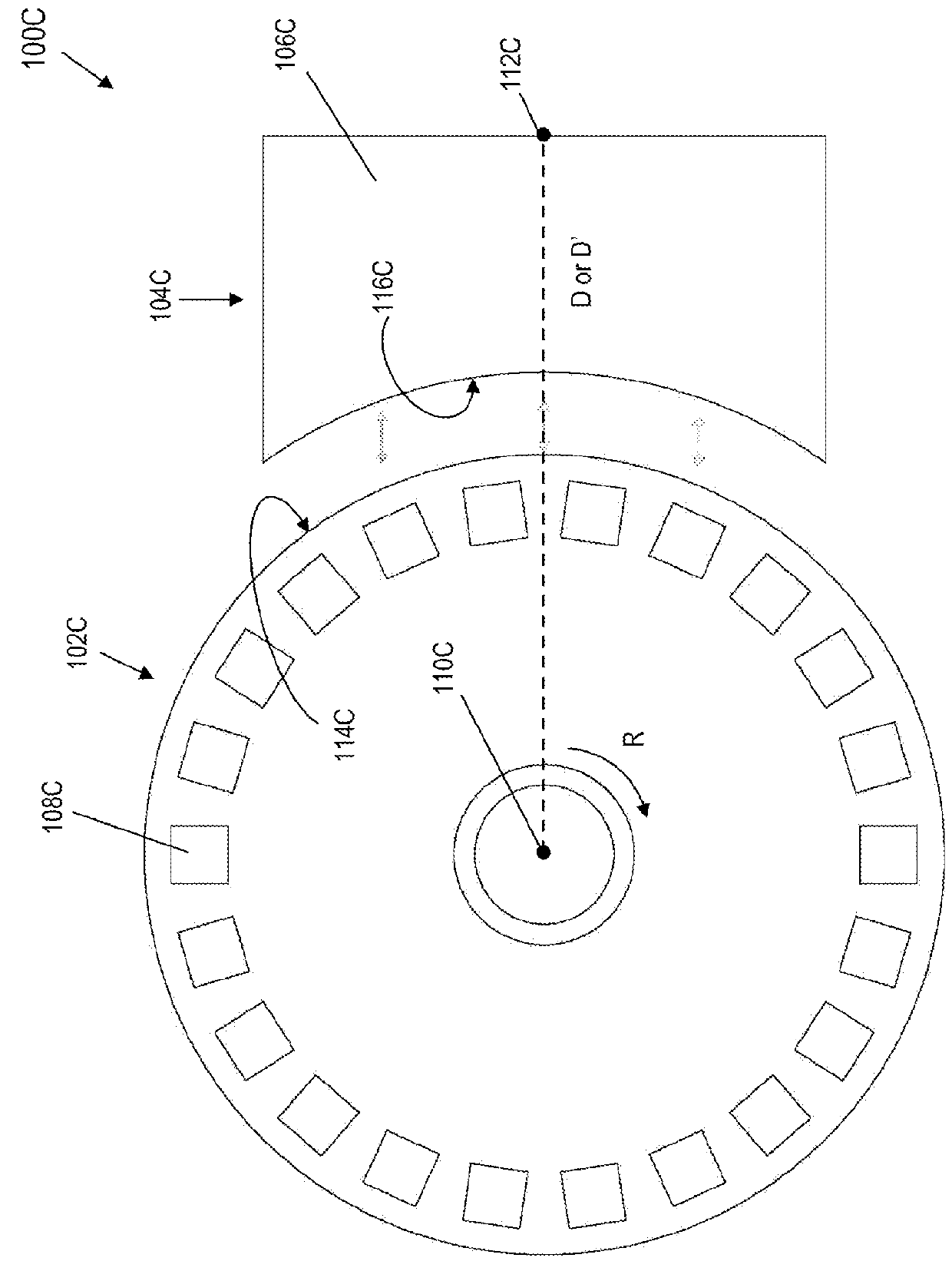

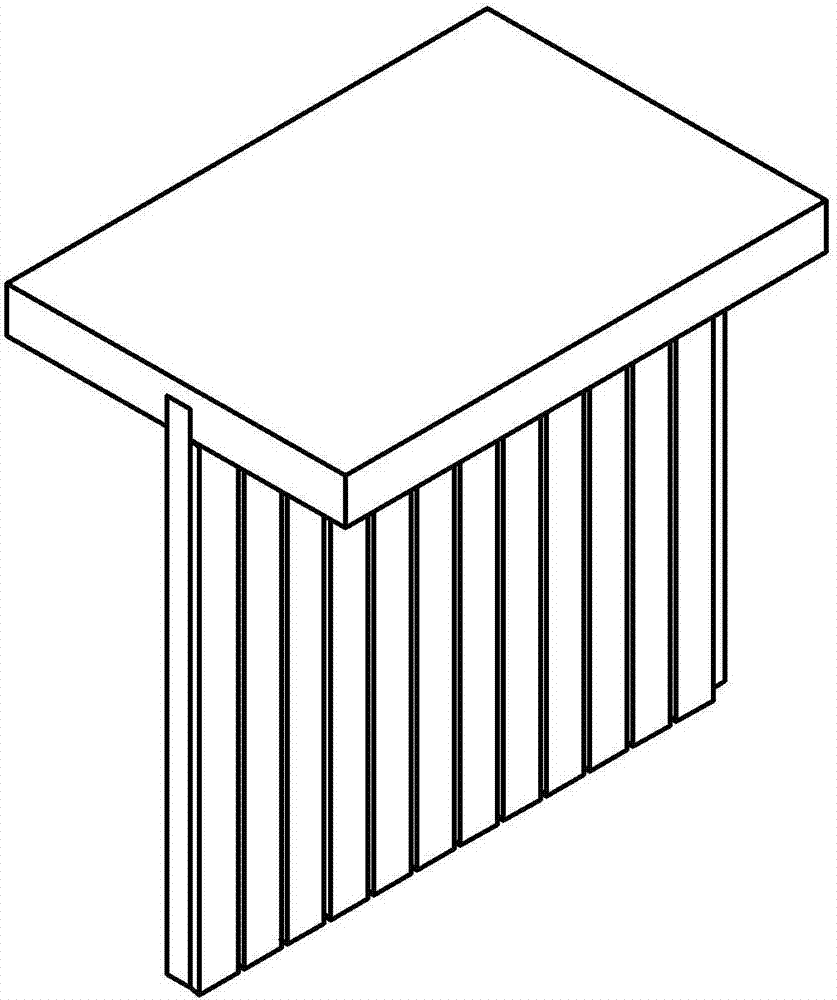

Lithography device with eddy-current brake

ActiveUS20140346909A1Reduce maintenanceEasy to useAsynchronous induction clutches/brakesPhotomechanical exposure apparatusLithographic artistRelative motion

A lithography device includes an eddy-current brake for damping the movement of a structural element of the lithography device. The eddy-current brake includes a plurality of magnets disposed in an arc-shaped arrangement, and a plurality of electrically conductive sheets arranged respectively between adjacent ones of the magnets. A relative movement between the magnets and the electrically conductive sheets in a direction to be damped inducing eddy currents in the electrically conductive sheets.

Owner:CARL ZEISS SMT GMBH

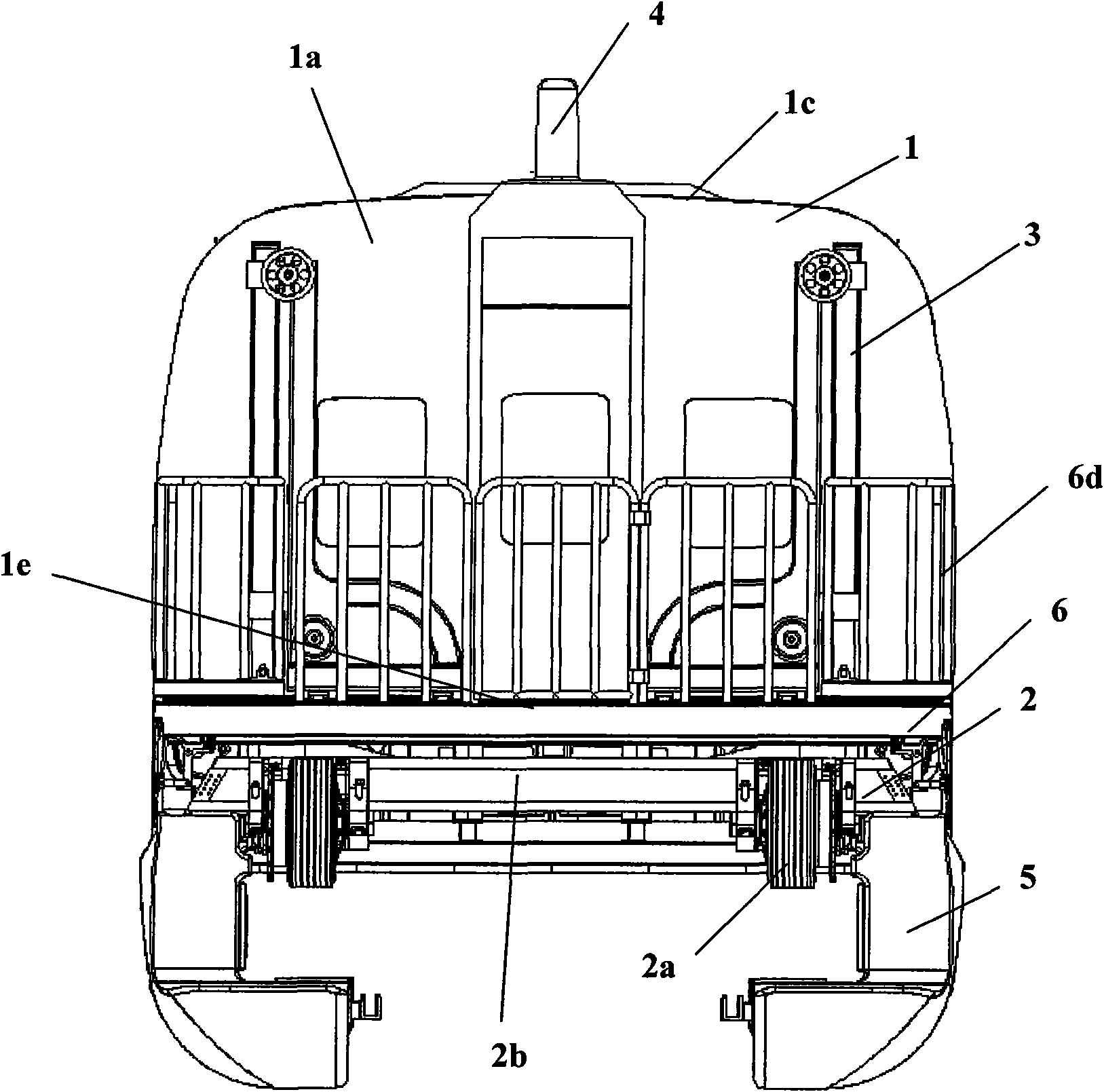

Travel structure of magnetic levitation type rail polling car

InactiveCN101624054AAchieving self-rescue abilityEfficient deliveryRailway inspection trolleysSliding/levitation railway systemsLow speedMotor drive

The invention provides a travel structure of a magnetic levitation type rail polling car, wherein the travel structure is fixedly arranged at the lower part of the bottom board of carriage of the rail polling car and comprises a plurality of floating frames which are sequentially arranged as well as a long stator linear motor traction device and an outer rotor motor driven supporting wheel device which are arranged on the floating frames; wherein the floating frames comprises a plurality of beam frames and corbel frames which are arranged at the two ends of the beam frame; the long stator linear motor traction device comprises a floating magnet module arranged on the corbel frame, a plurality of guiding magnet modules and a plurality of eddy braking magnet modules; the outer rotor motor driven supporting wheel device comprises a motor supporting wheel loading device which is arranged at the two ends of the beam frame and at the inner side of the corbel frame as well as an outer rotor motor supporting wheel arranged at the two ends of the bottom of the beam frame by the loading device. The invention can realize the compatible double traction pattern of long stator linear motor traction and outer rotor motor supporting wheel traction, so that the rail polling car can have the functions of high speed polling and low speed detection.

Owner:TONGJI UNIV

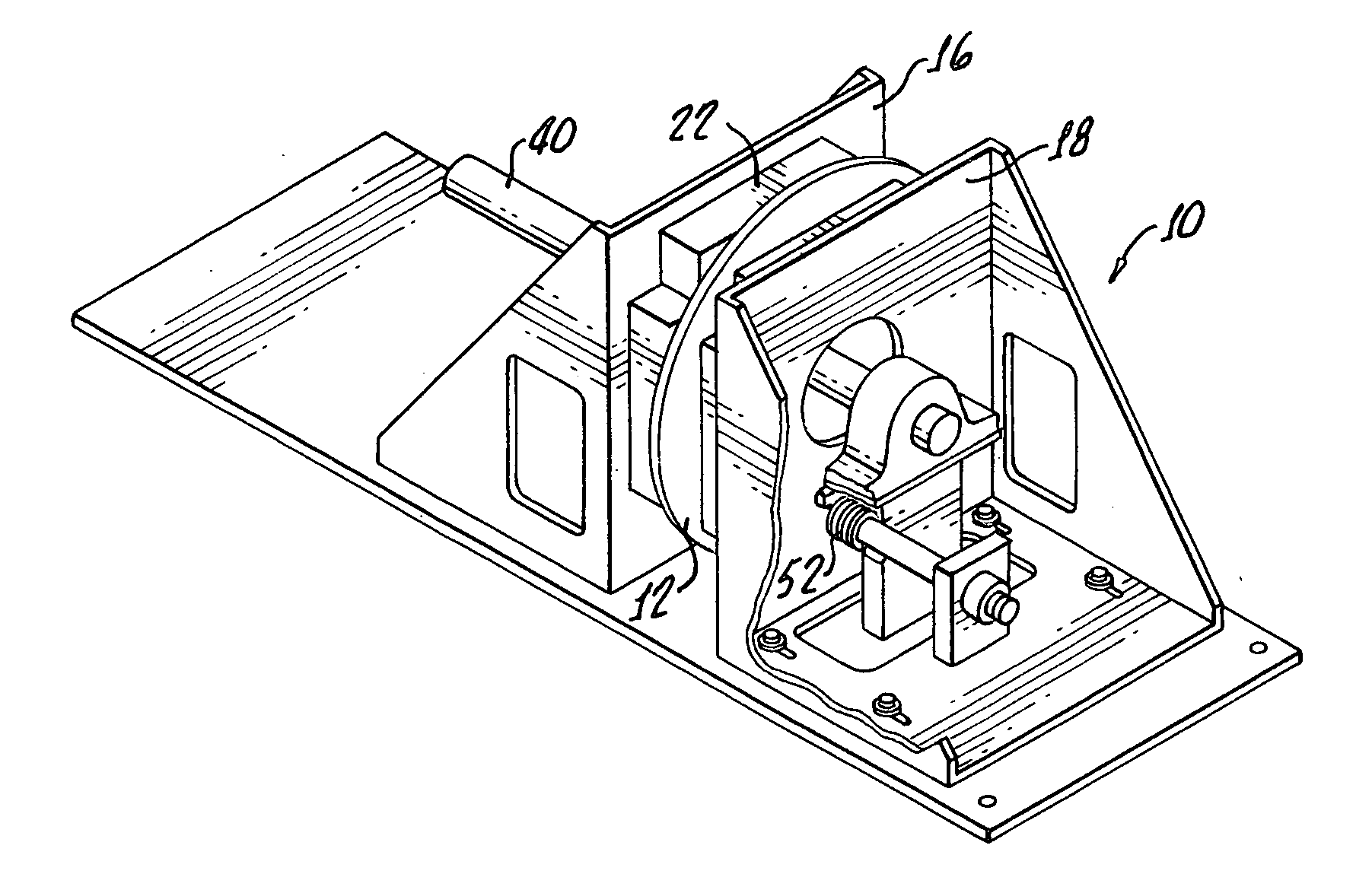

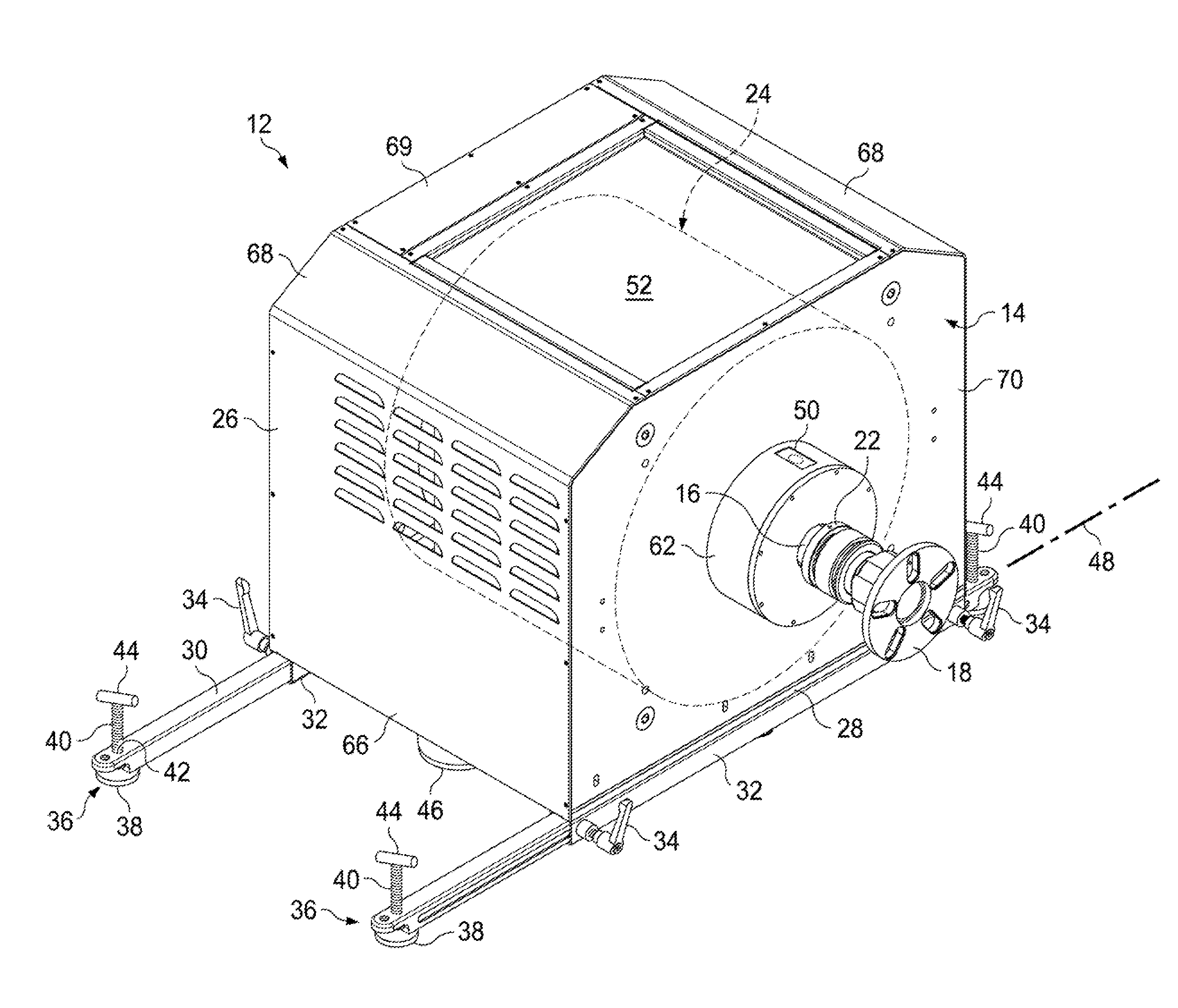

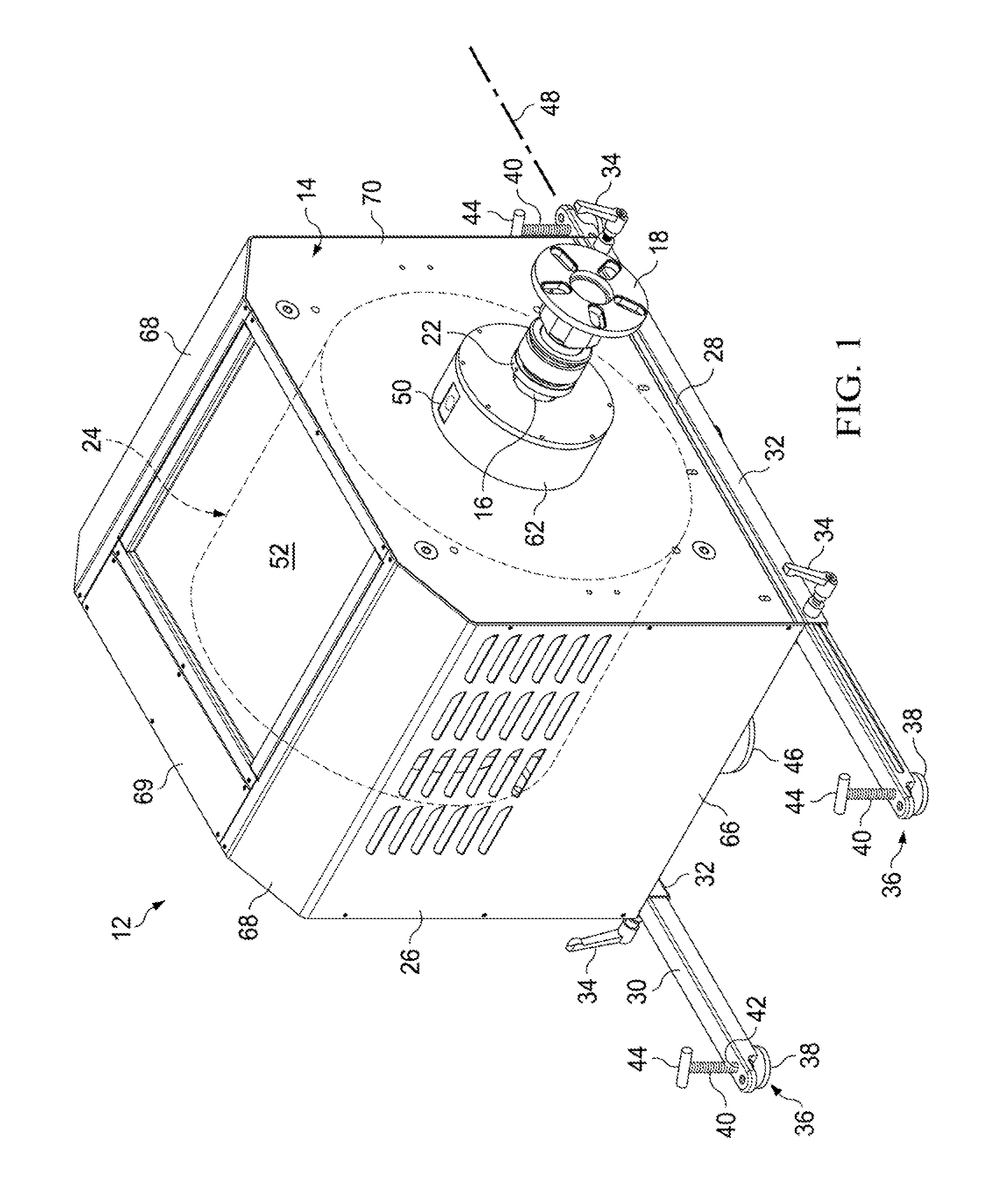

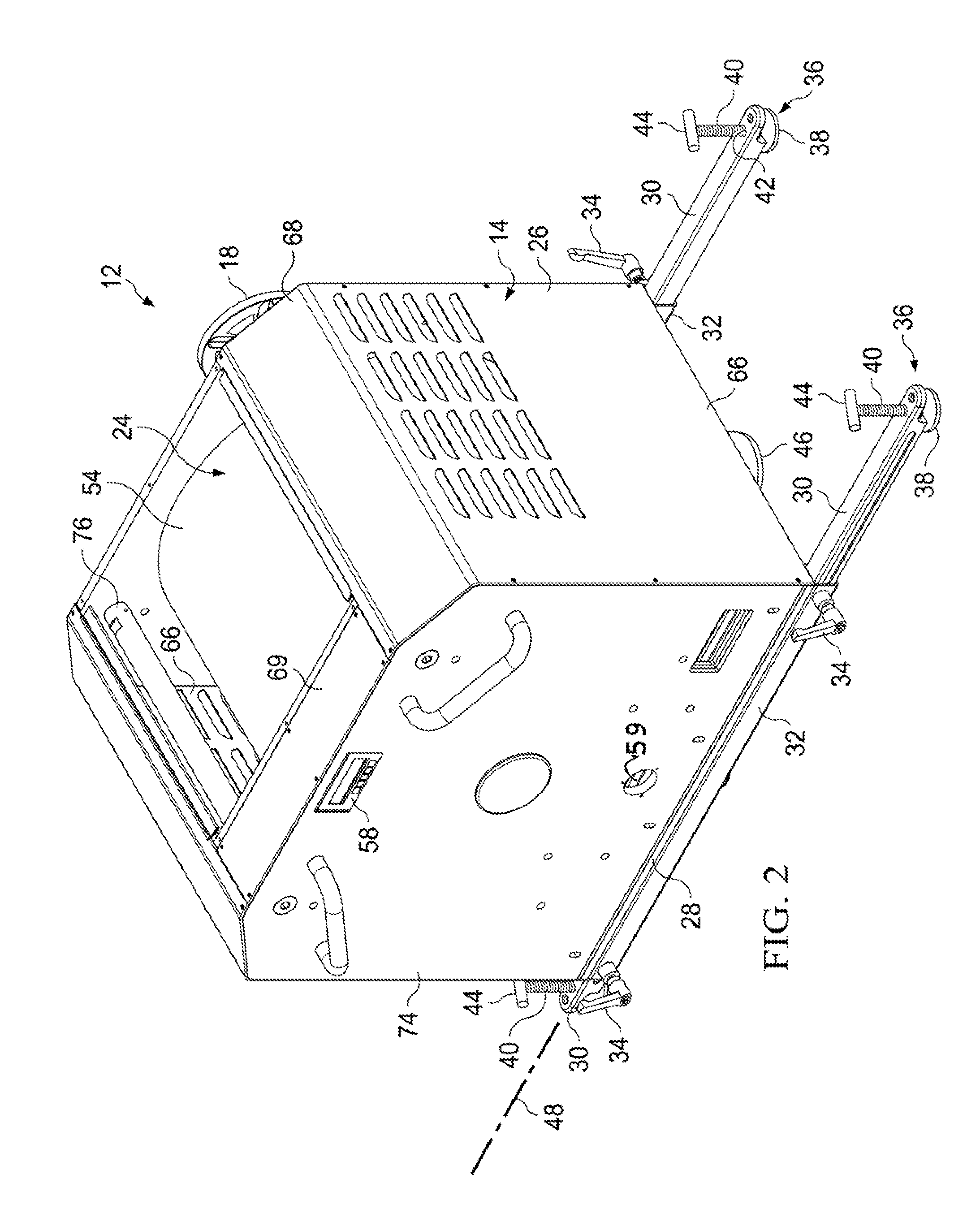

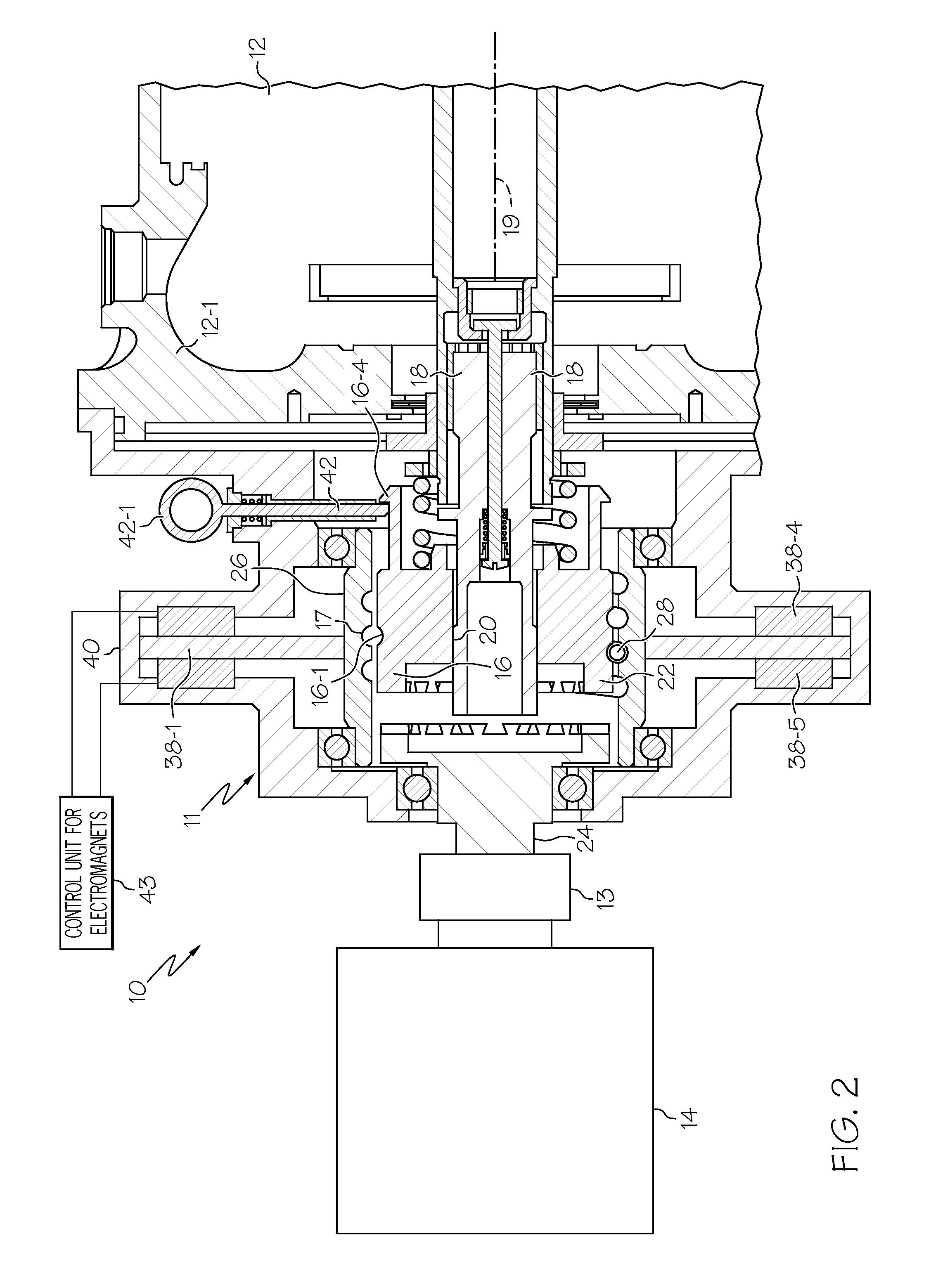

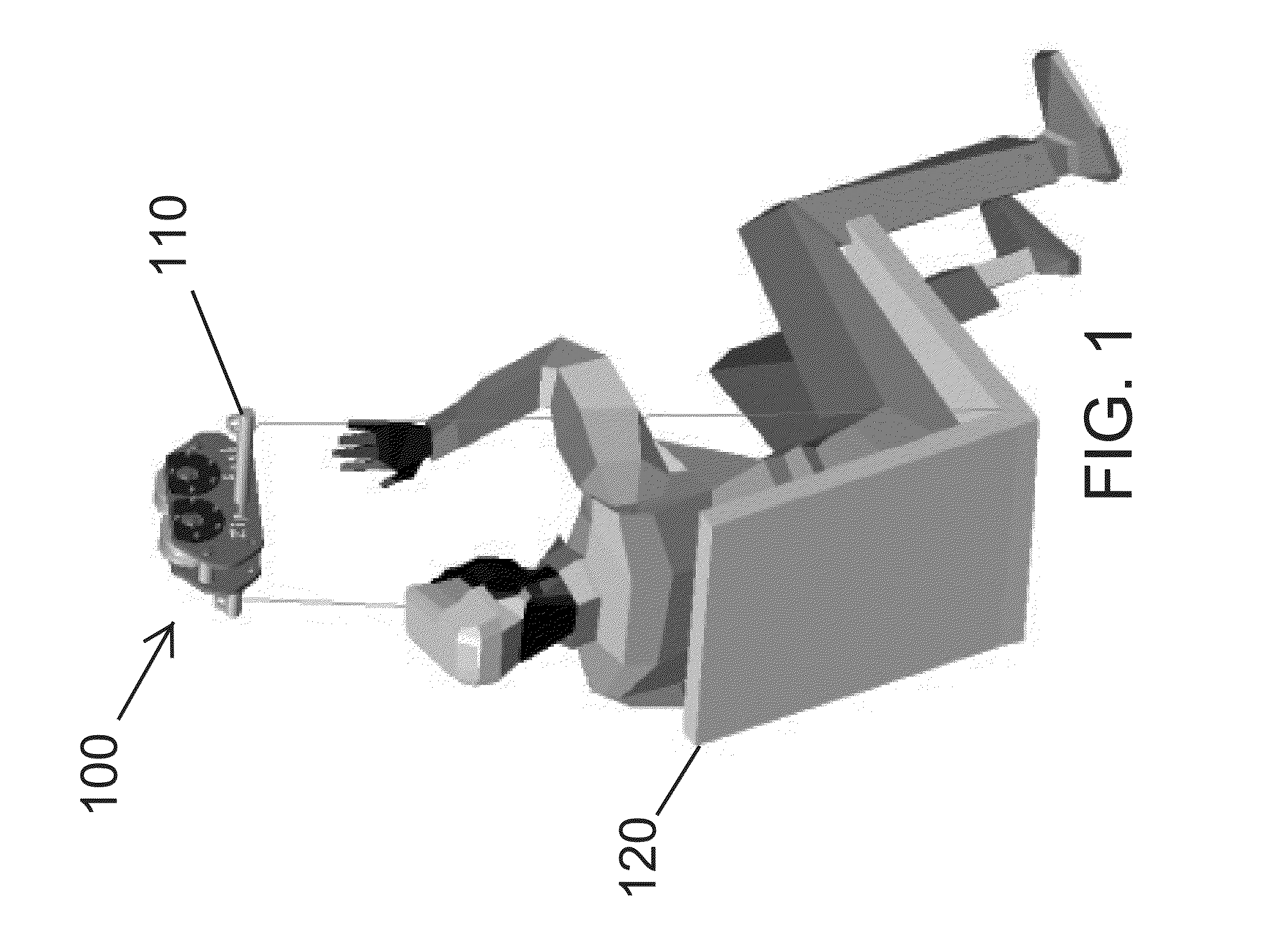

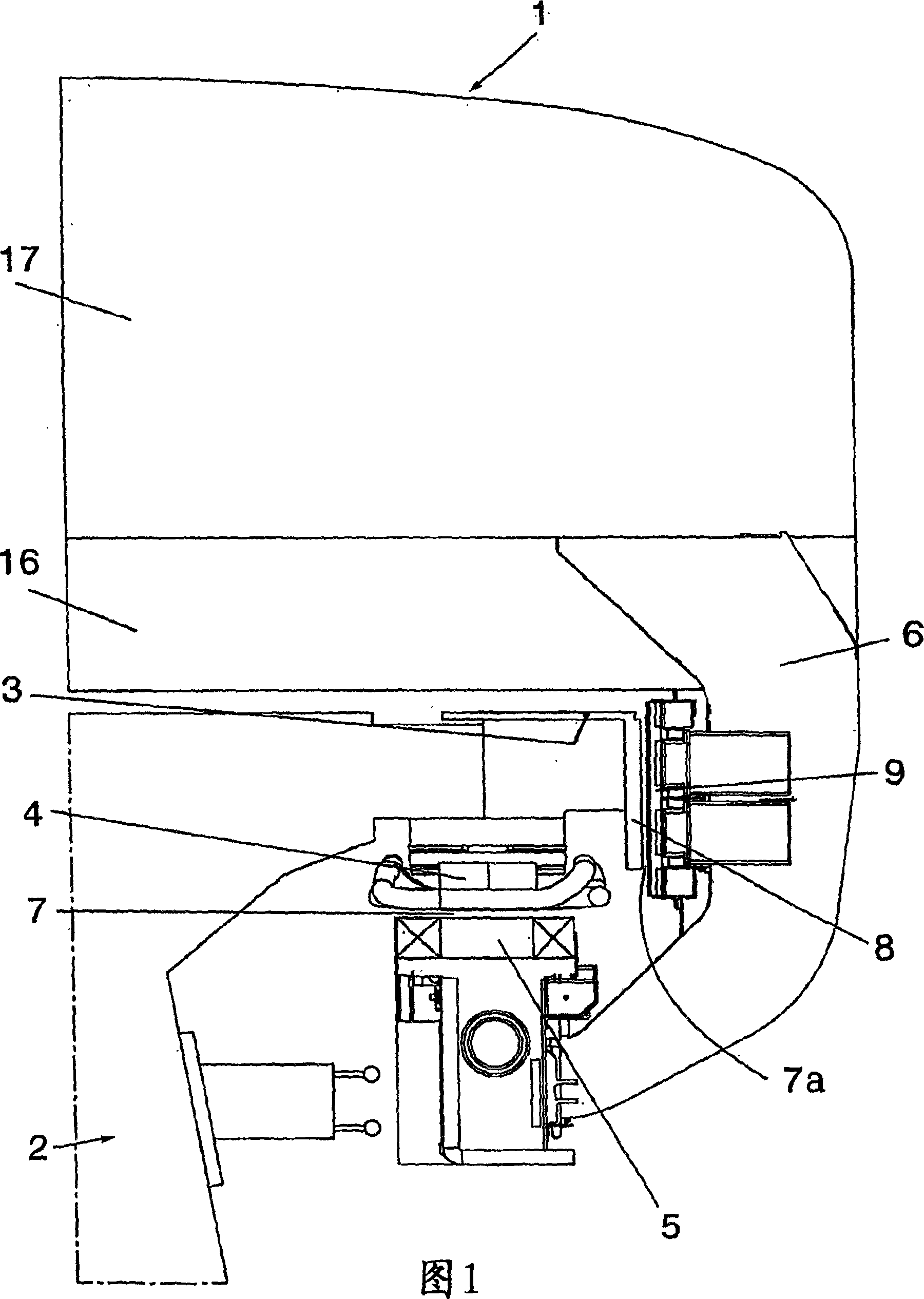

Portable on vehicle dynamometer

A portable on vehicle dynamometer (12) has a rigid frame (64), a load shaft (16), and an eddy current brake (24) with a stator (56) connected to the rigid frame (64) and a rotor (54) connected to the load shaft (16). A hub coupling (18) is secured to a first end of the load shaft (16) and connected to the drive shaft. The rigid frame (64) has two outwardly extending support arms (30) for securing in outwardly extending, fixed positions. Two roller assemblies (46) are mounted to a lower end of the rigid frame (64) for multidirectional movement of the dynamometer (12). Preferably the eddy current brake (24) comprises a cylindrically-shaped rotor drum (54) extending exteriorly around the stator (56), and the stator (56) comprises a plurality of stator coils (94) extending exteriorly around the load shaft (16), spaced apart from an interior of the rotor drum (54).

Owner:DYNOCOM INDS

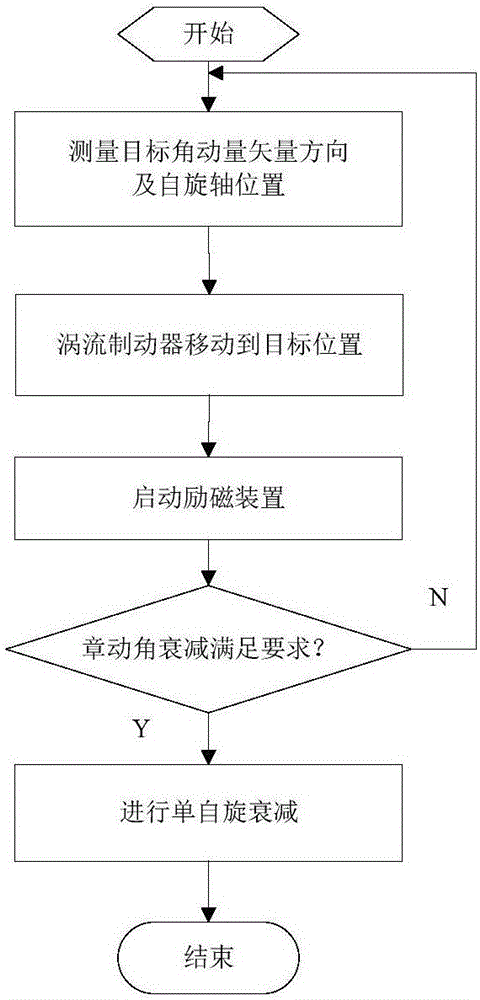

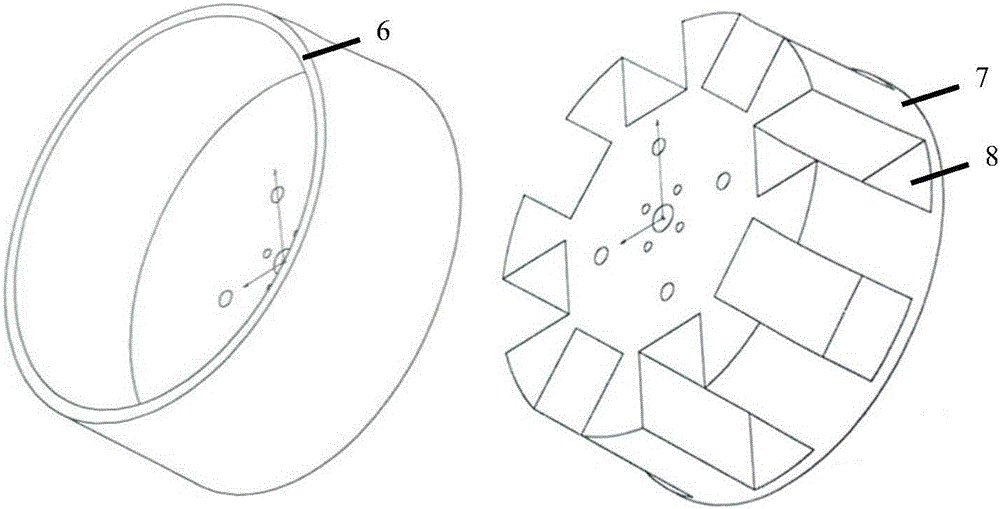

Space tumbling target de-spinning control method based on permanent magnet eddy current effect

ActiveCN106406329AMeet the attitude adjustment control requirementsIncrease the working distanceCosmonautic vehiclesCosmonautic partsNutationEngineering

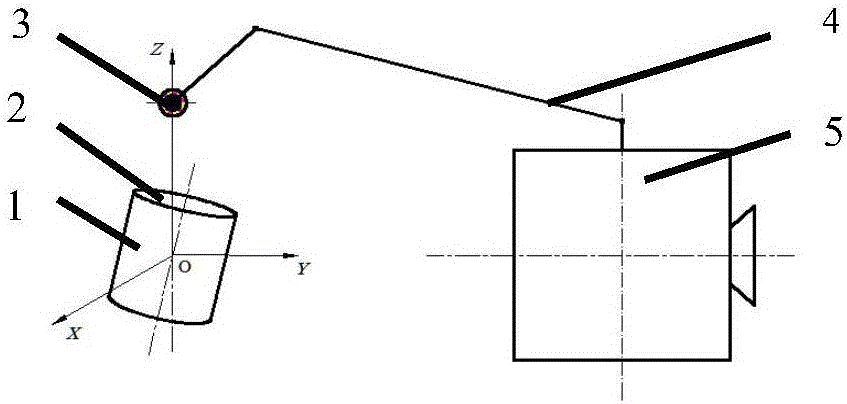

Disclosed is a space tumbling target de-spinning control method based on a permanent magnet eddy current effect. The method comprises the following steps: a service spacecraft docks in the working space of a mechanical arm, and is kept at a safety distance from a tumbling non-cooperative target; a visual inspection system carried by the service spacecraft measures the direction of a target angular momentum vector H and the direction of a spin axis position vector Zb, and the mechanical arm drives a permanent magnet eddy current braking device at the end to an initial de-spinning position, and the docking position is 100mm from the surface of the target in the direction of the target angular momentum vector; the permanent magnet eddy current braking device is started, the direction of a vector outputting an external torque T1 is corrected according to the real-time change of attitude angle in the tumbling process of the target until the angle of nutation attenuates completely, and the rotation state of the target is changed to a single spinning motion state; the position of the permanent magnet eddy current braking device is adjusted to the side of the tumbling non-cooperative target, the permanent magnet eddy current braking device is started to output a brake torque T2 until the single spinning motion state attenuates completely; after the target is completely de-spun, an end actuator is replaced with a grasping paw, and the target is captured directly by the mechanical arm.

Owner:黑龙江省工研院资产经营管理有限公司

Application of eddy current braking system for use in a gearbox/generator mechanical disconnect

InactiveUS20090224728A1Motor/generator/converter stoppersMagnetically actuated clutchesBall screwDrive shaft

A disengagement assembly for disengaging a generator from an engine or gear box may include an inner ball screw having helical threading on an outer surface thereof and surrounding and operatively engaged to a rotating generator drive shaft to cause rotation of the inner ball screw, the inner ball screw may have interlockable teeth engaged to corresponding teeth of the gear box drive shaft. An outer ball screw may surround and may normally rotate with the inner ball screw. A helical ball track may be formed between the inner and outer ball screws. An eddy current brake may slow or stop rotation of the outer ball screw so that the inner ball screw may rotate relative to the outer ball screw and slide axially toward a lock thereby disengaging the generator from the engine.

Owner:HONEYWELL INT INC

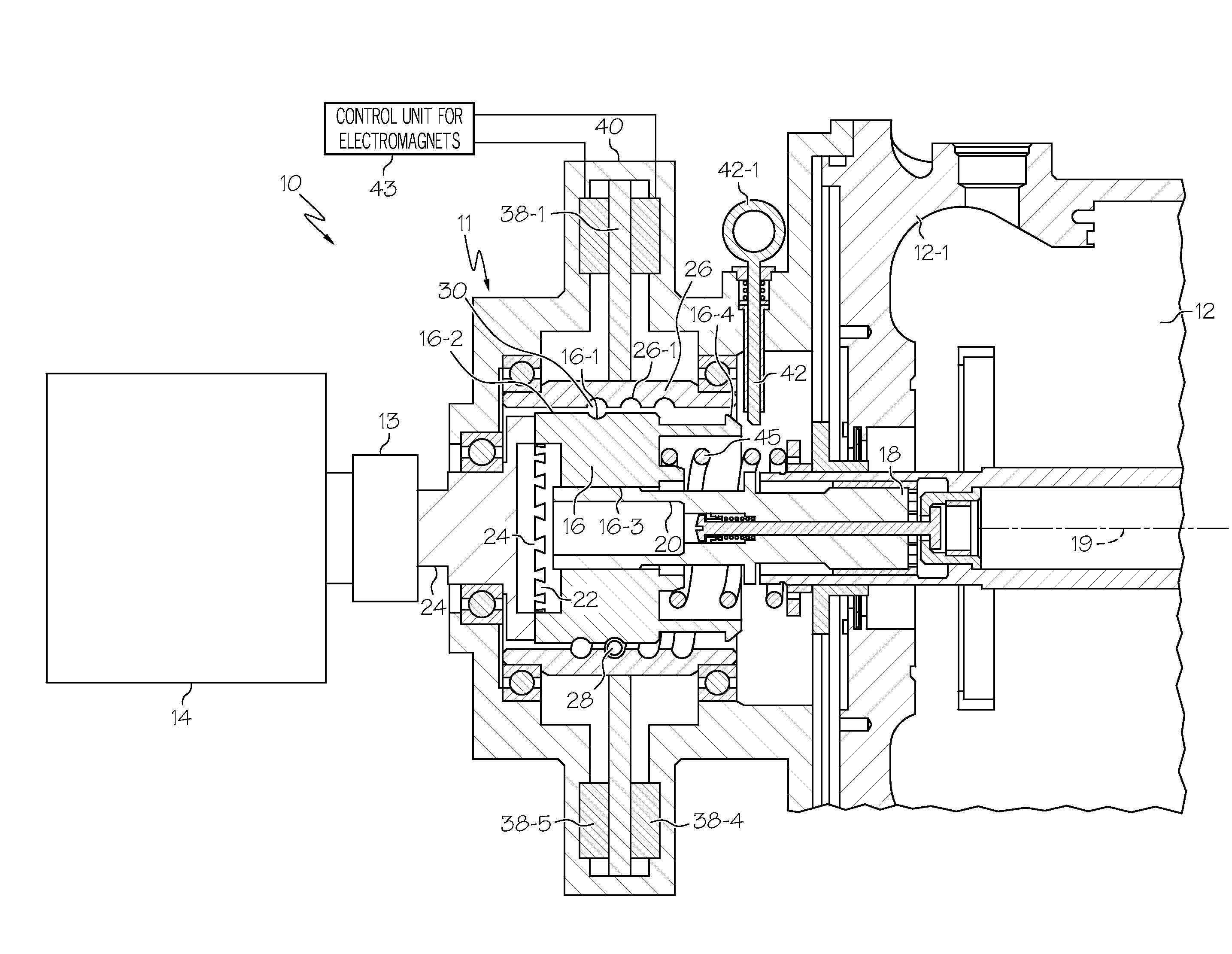

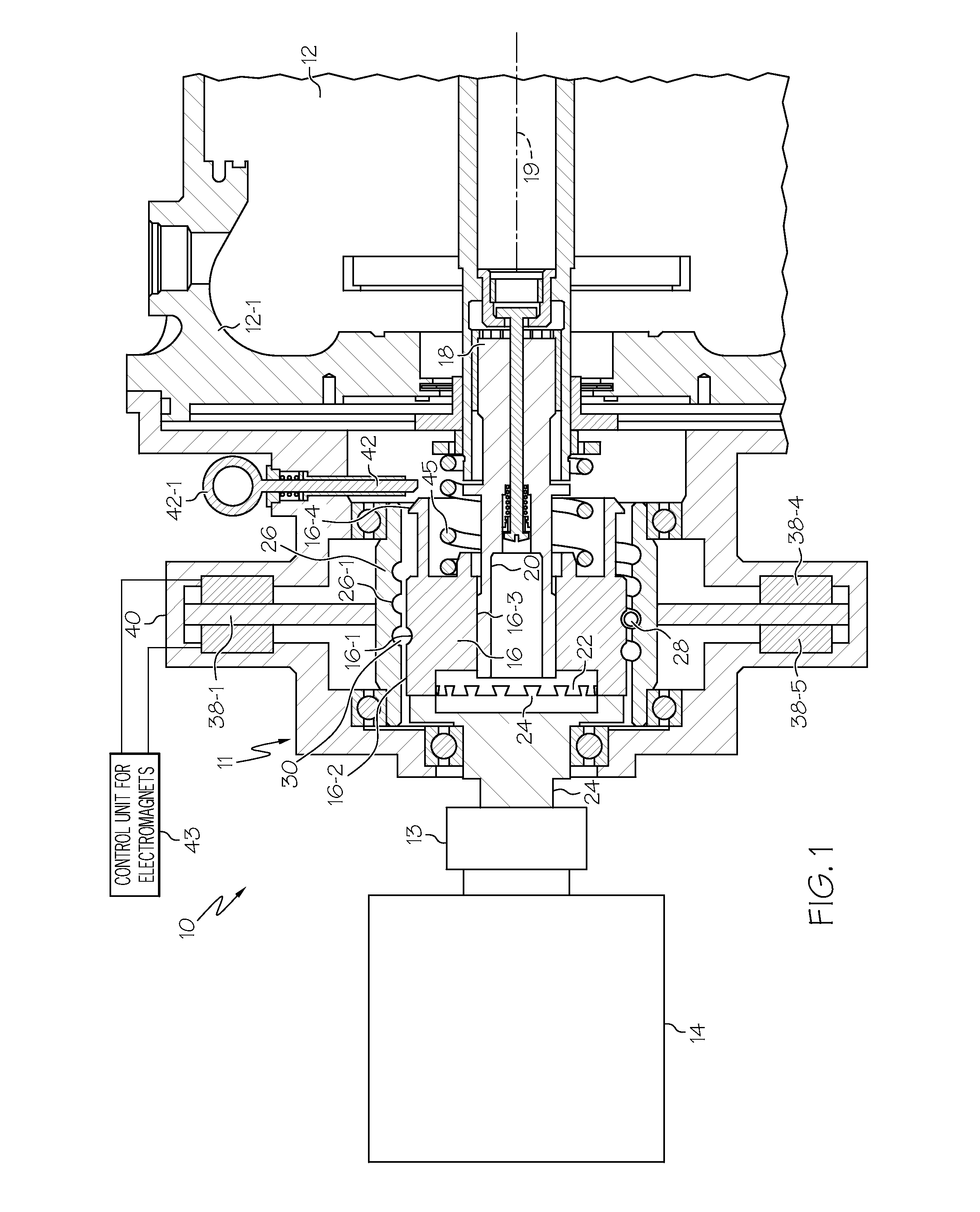

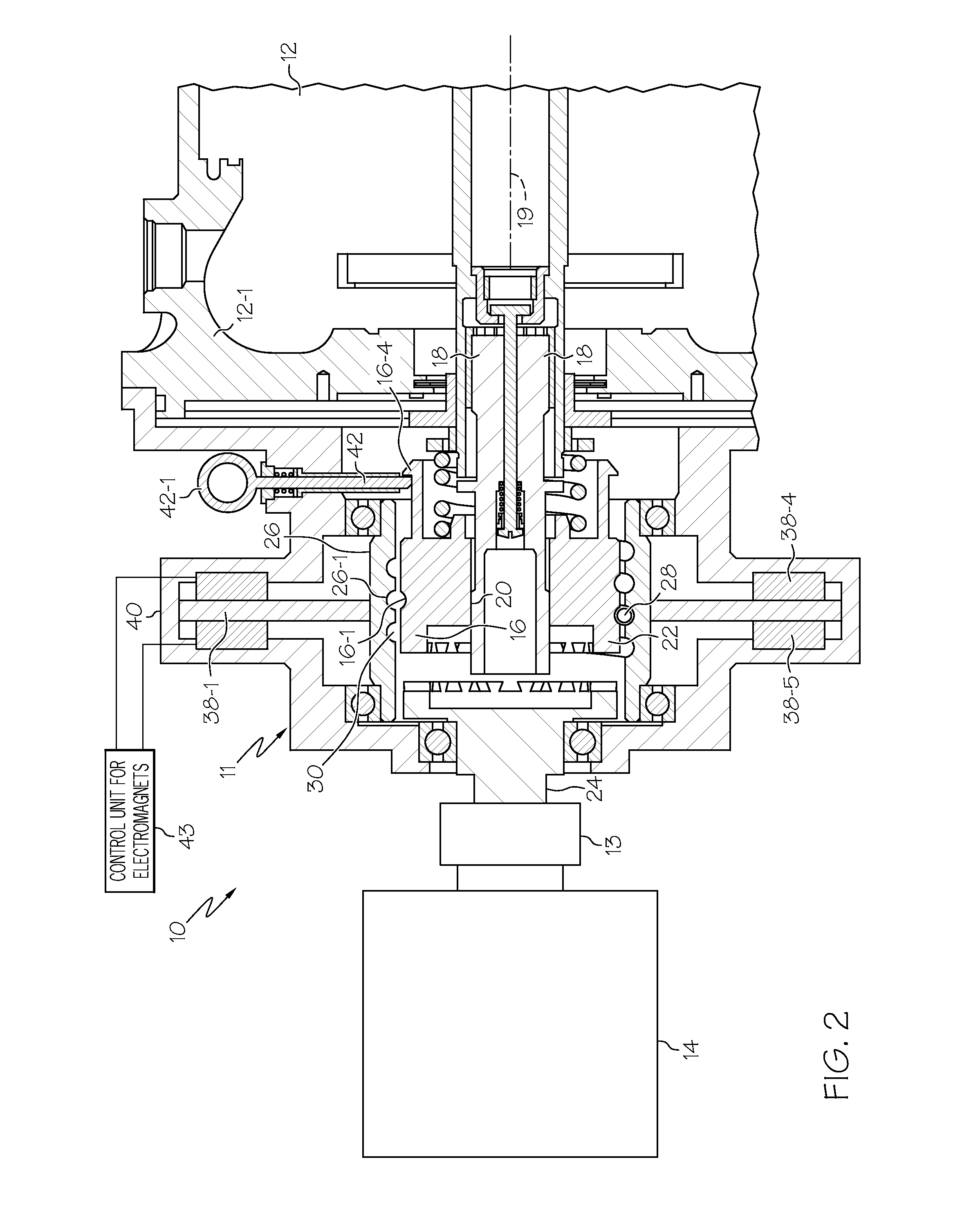

Eddy current braking device for rotary systems

ActiveUS20160052401A1Increased complexityDifficult to adjustDynamo-electric brakes/clutchesElectrodynamic brake systemsEngineeringEddy current brake

An apparatus has a first portion of a magnetic braking system with a first element disposed thereon. The first portion rotates about an axis. The position of the first element is a fixed distance from the axis. A second portion of the magnetic braking system has a second element disposed thereon. A spring biases the rotatable first portion a first distance from the second portion. Upon application of a force to one of the portions, the relative position of the rotatable first portion to the second portion is reduced to a second distance less than the first distance.

Owner:TRUBLUE

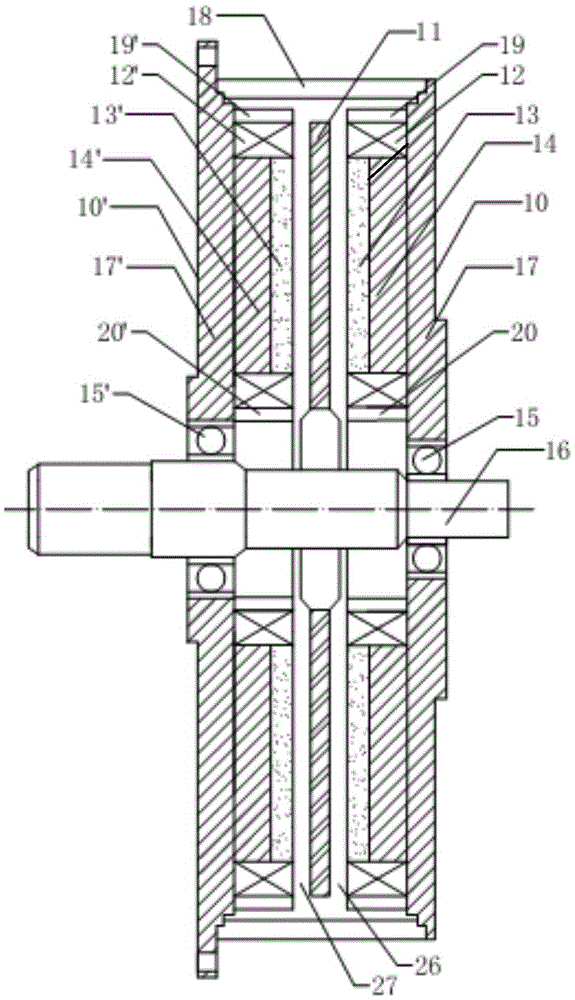

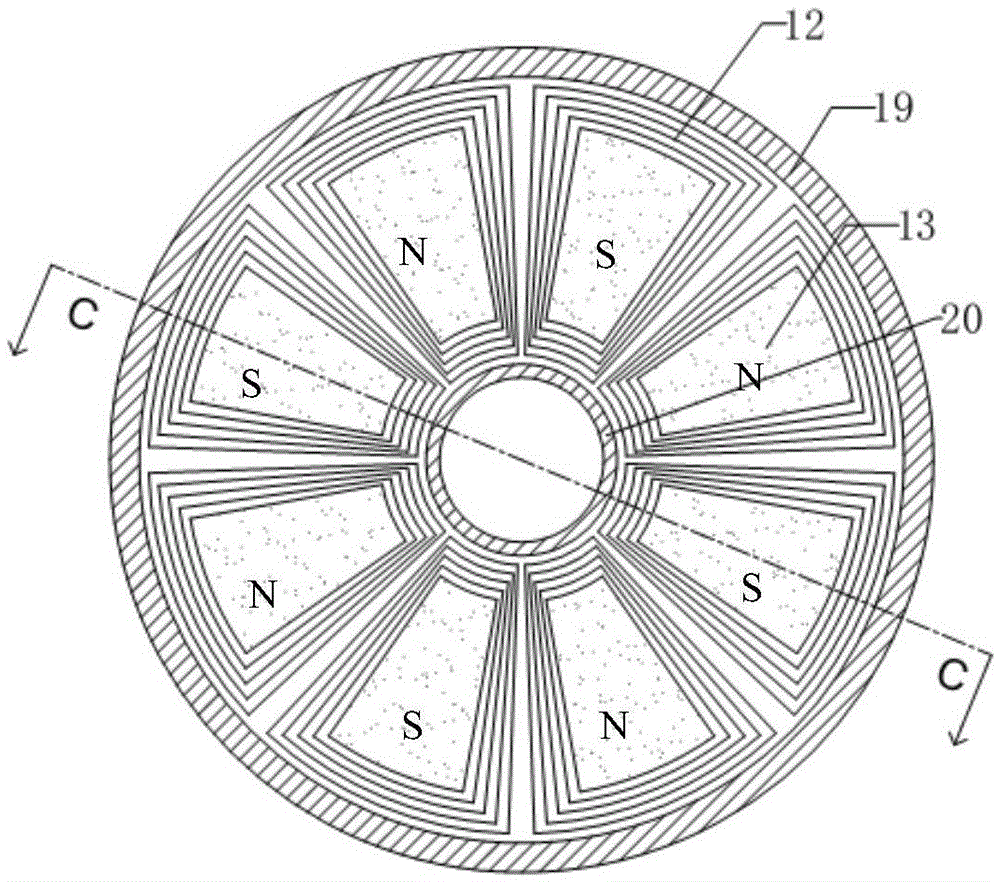

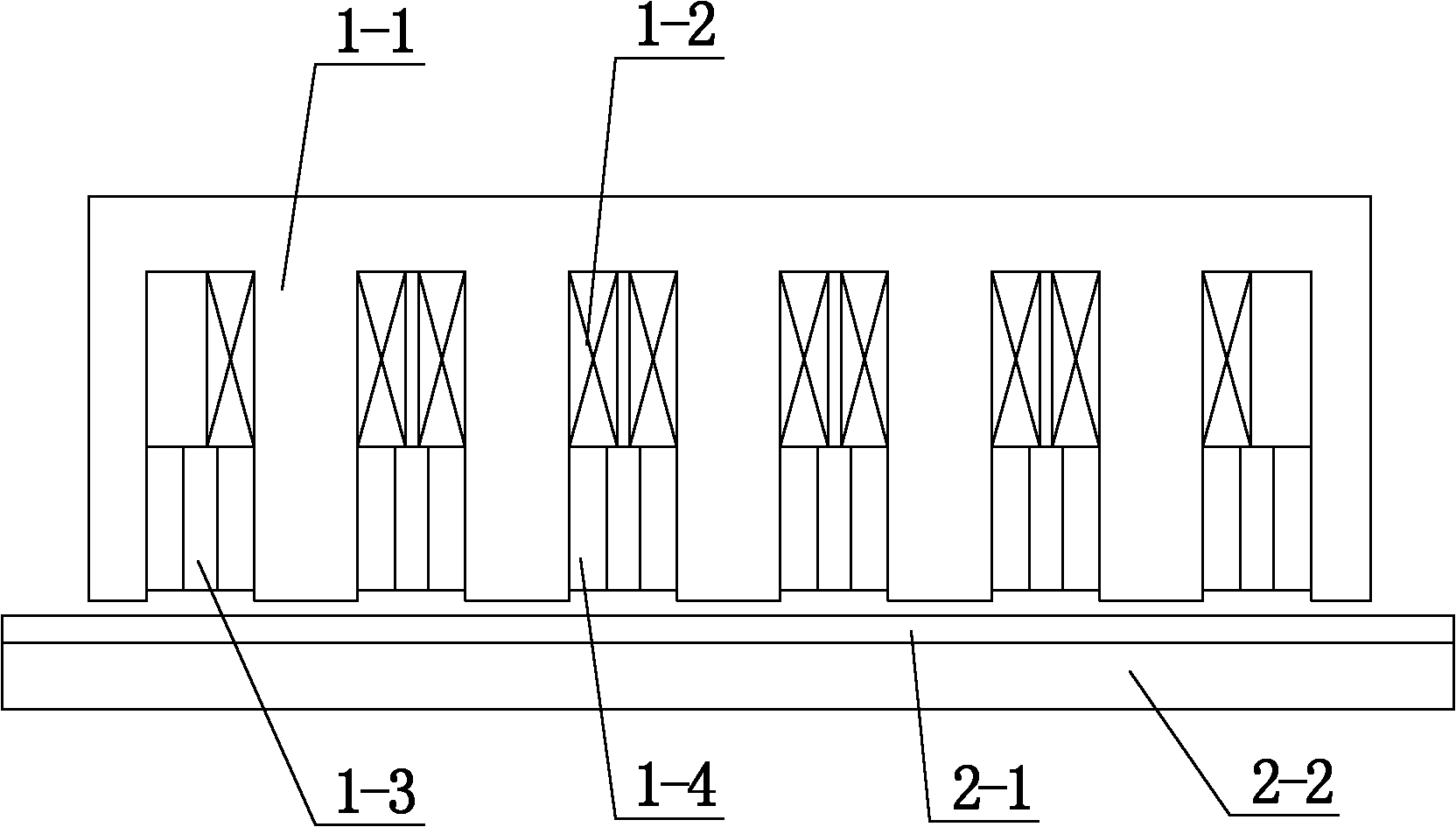

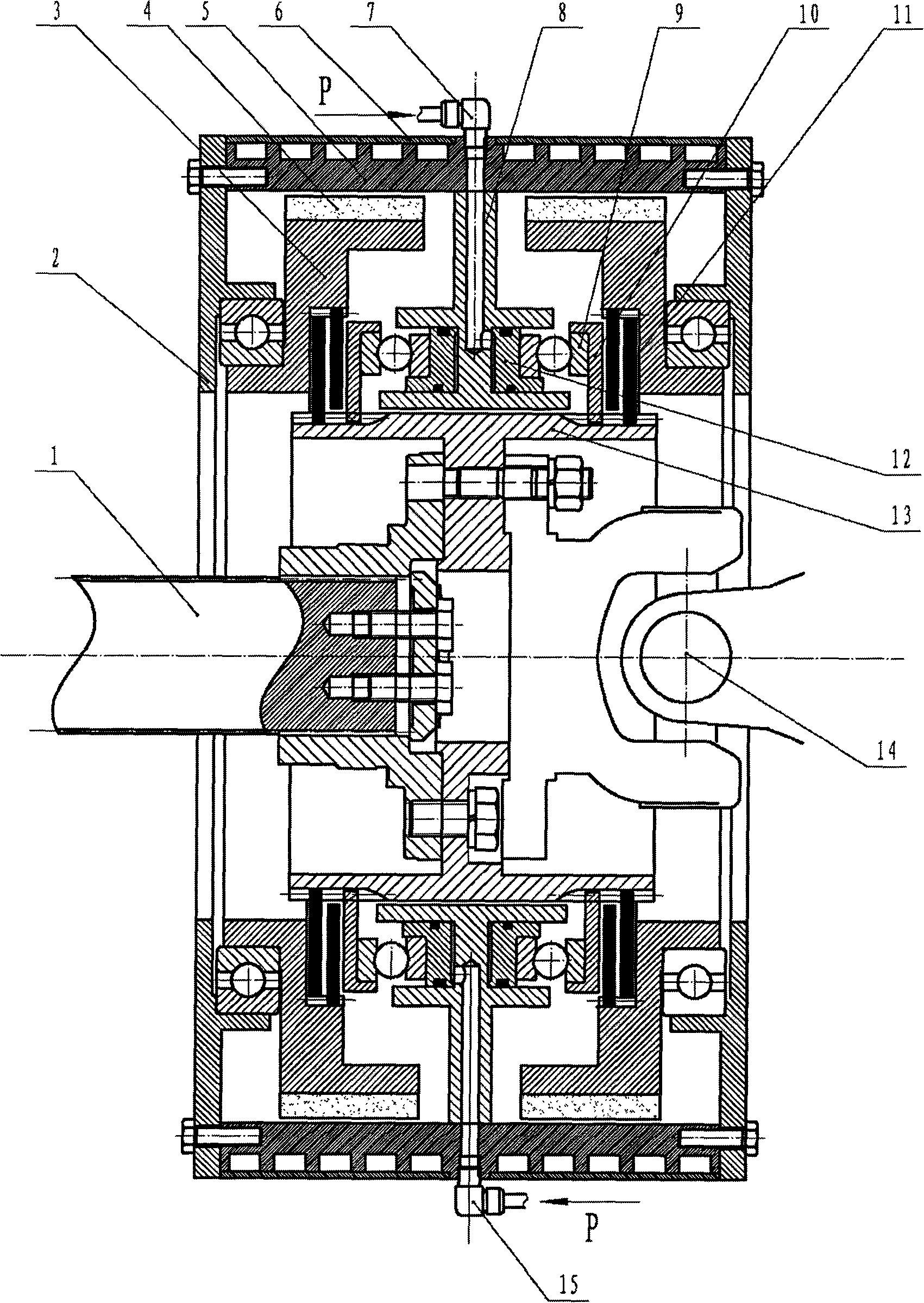

Permanent magnet electromagnetic composite disc type eddy current braking device

ActiveCN105591523AImprove energy transfer efficiencyHigh braking torque densityAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesDrive shaftMagnetic poles

Provided is a permanent magnet electromagnetic composite disc type eddy current braking device. The device comprises two magnet discs, a metal disc, and a transmission shaft, the two magnet discs are fixed on static equipment in parallel, the metal disc is fixed on the transmission shaft and arranged between the two magnet discs in parallel, the metal disc and the two magnet discs are also coaxially installed, the transmission shaft is supported on the two magnet discs via bearings, each magnet disc is provided with m composite magnetic poles formed by permanent magnets and electromagnets along the circumference (m is an even number), the m composite magnetic poles on the two magnet discs are opposite in pairs in the axis direction, and the magnetic field at the position of the metal disc between the two magnet discs is changed via the adjustment of the current and direction of electromagnet coils. When the metal disc and the magnet discs generate relative movement, eddy current is generated in the metal disc, interaction is generated, and rapid braking between the metal disc and the transmission shaft and moving bodies connected with the metal disc is realized. The braking device is applicable to rapid braking of high-speed moving bodies.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

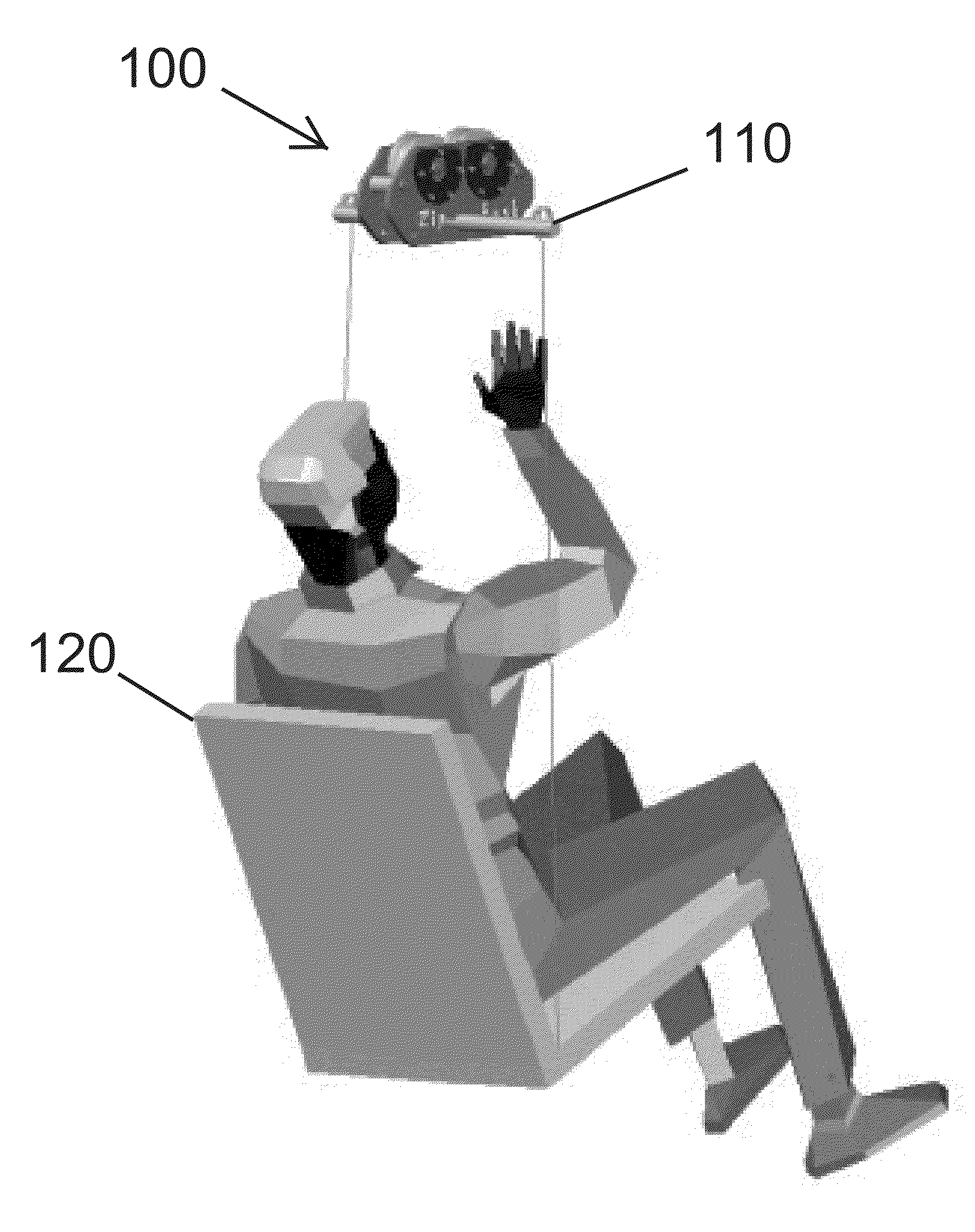

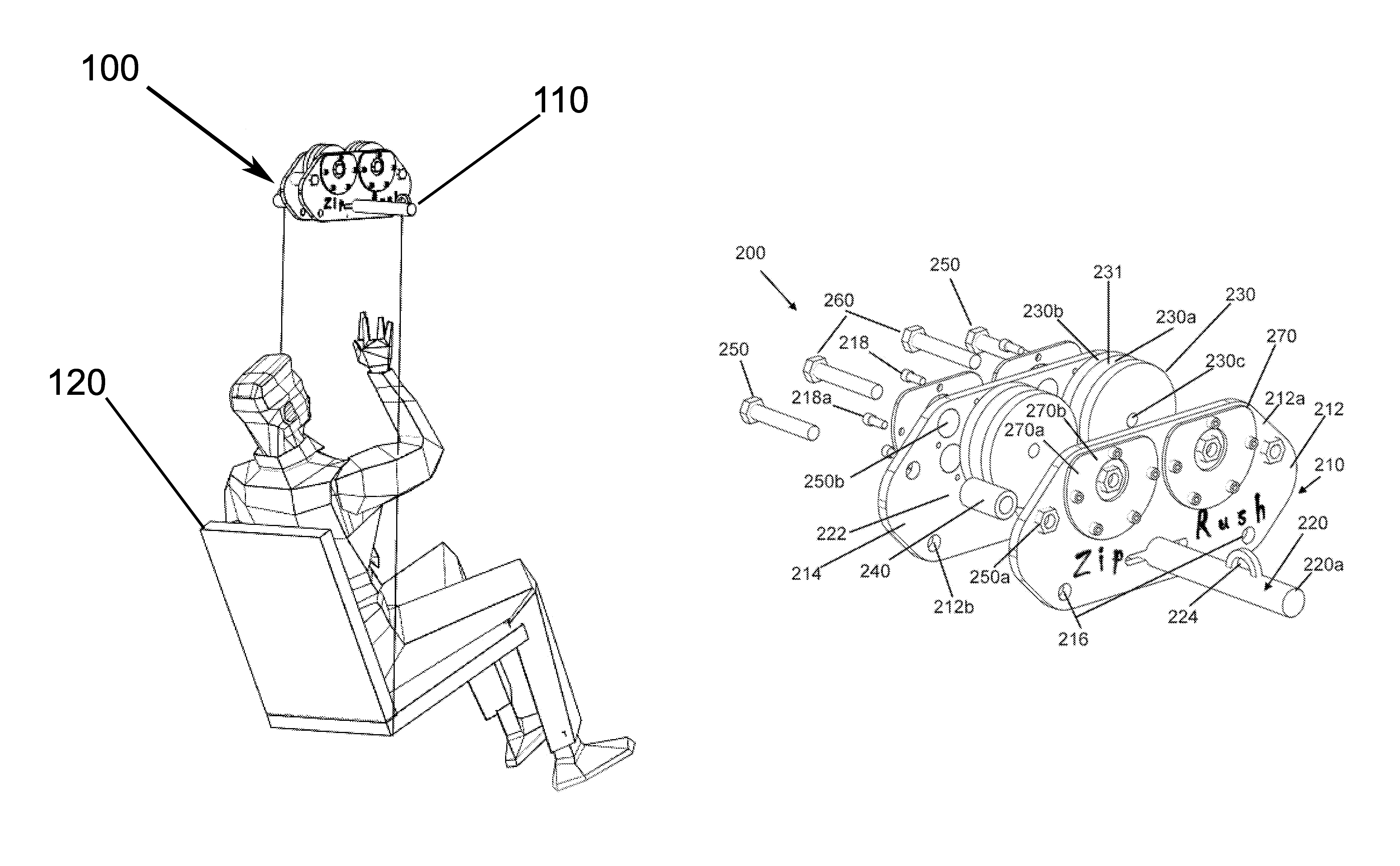

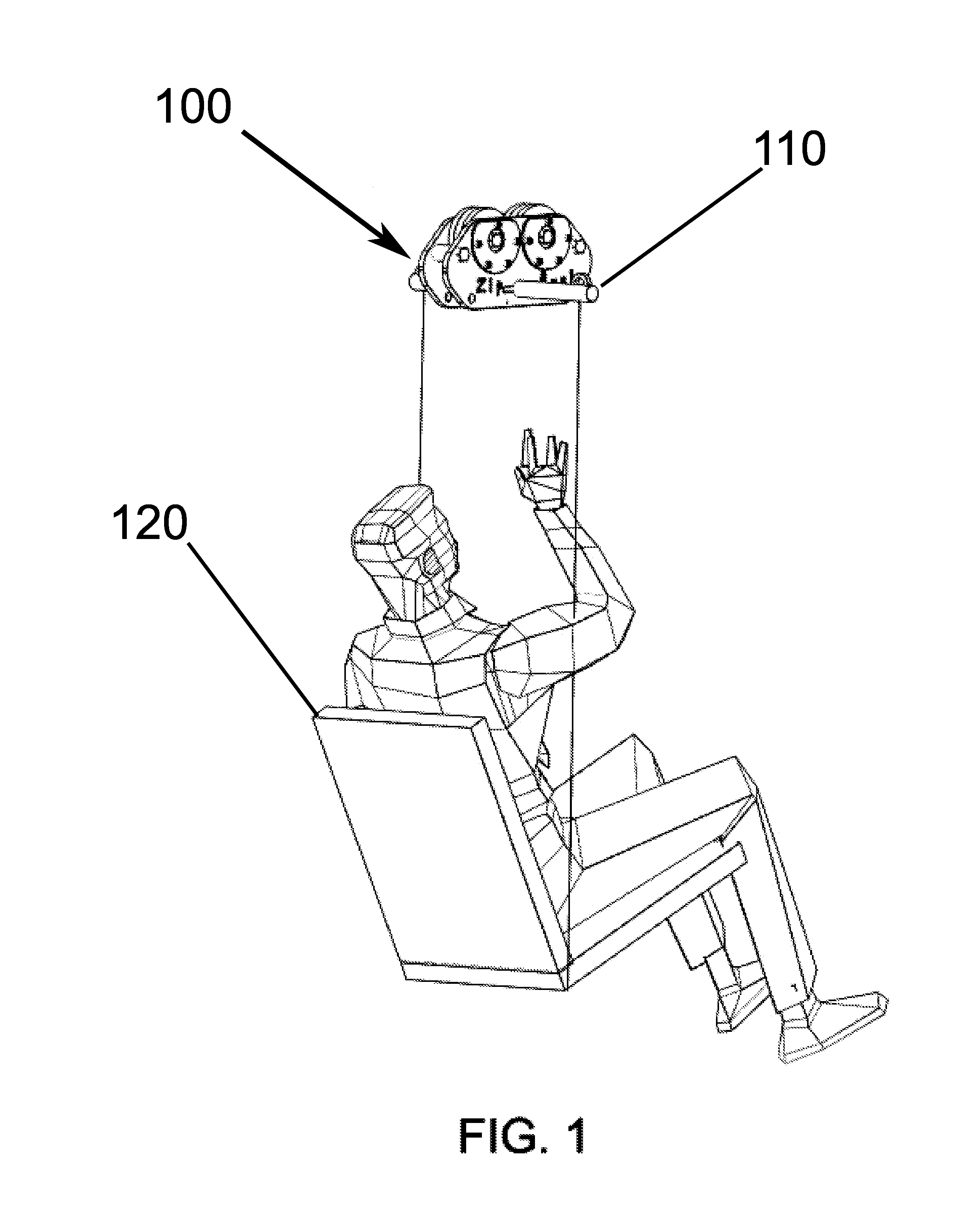

High-speed magnetic trolley

ActiveUS20130327242A1Reduce heat buildupShorten speedDynamo-electric brakes/clutchesBrakes for specific applicationsMagnetic tension forceEddy current brake

A high-speed magnetic trolley that utilizes an eddy current brake that may reduce the speed of a person in a harness traveling on a relatively steep zip line cable, making it possible to reach a landing brake at a reasonable speed and becomes easy to adjust an amount of braking force needed to reach a desired speed by taking off or adding more magnets without throwing one or more aluminum wheels out of balance. The high-speed magnetic trolley produce an eddy current that generates an opposing magnetic field, which then resists rotation of one or more aluminum wheels providing braking force.

Owner:BERNIER STEPHANE

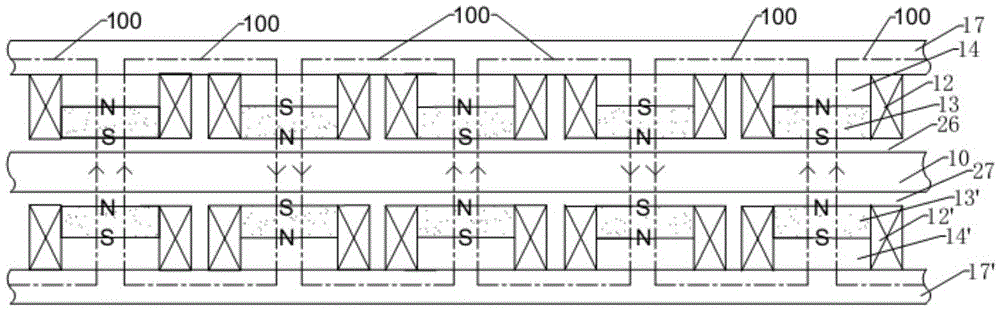

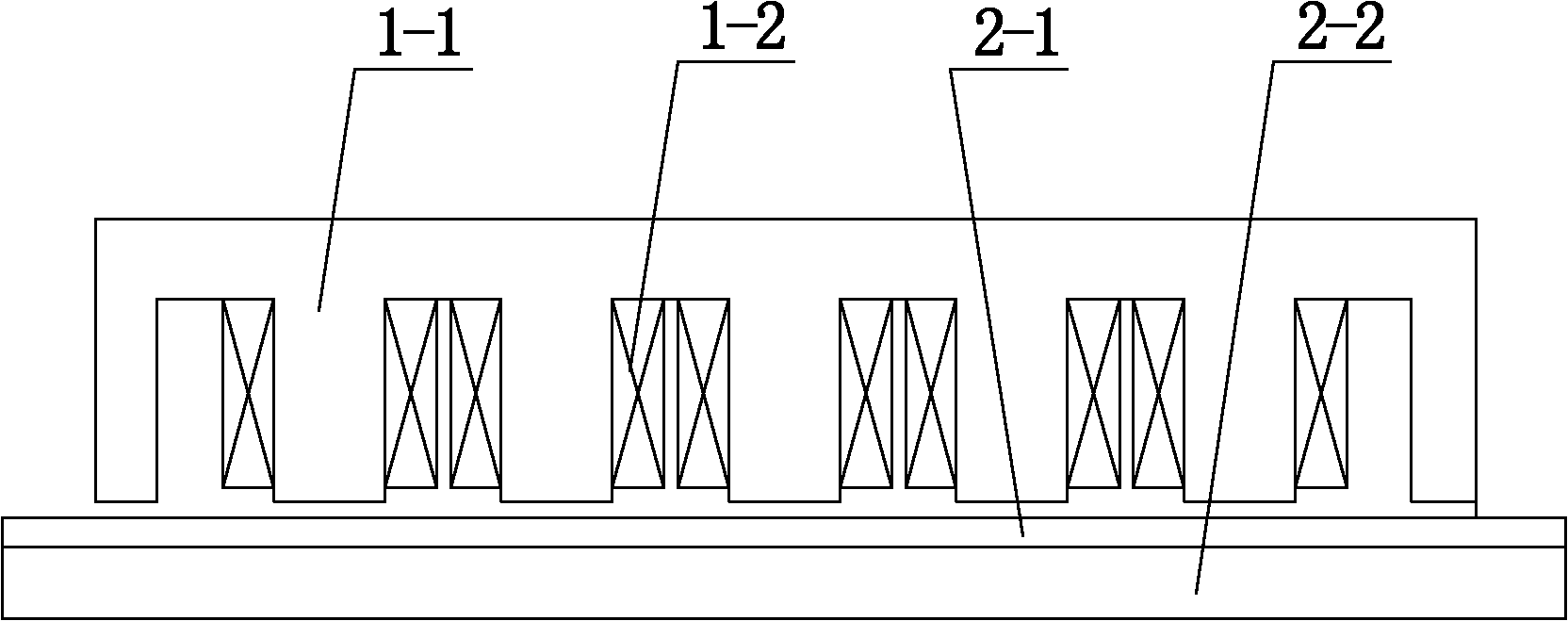

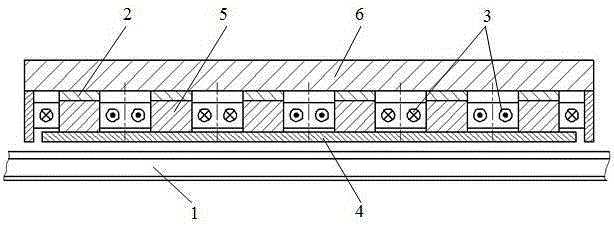

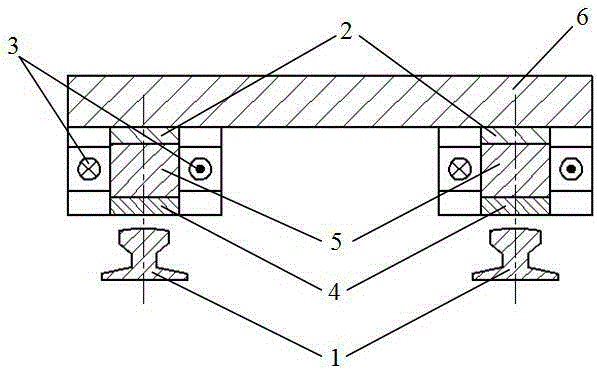

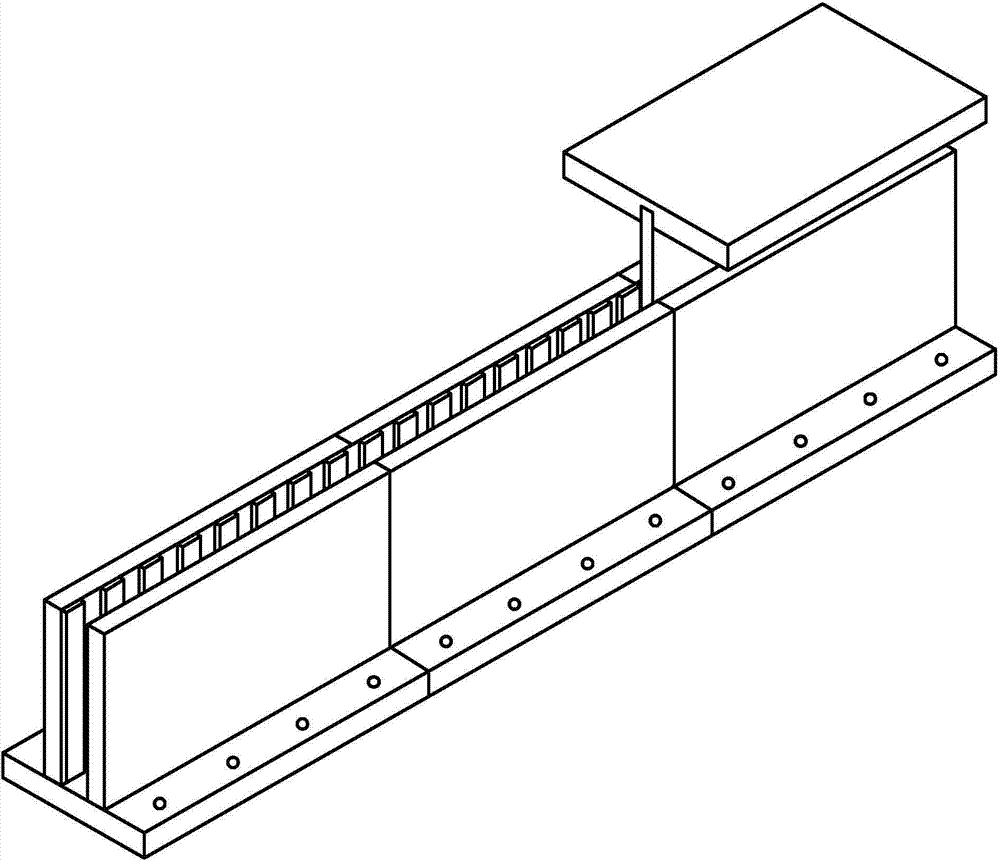

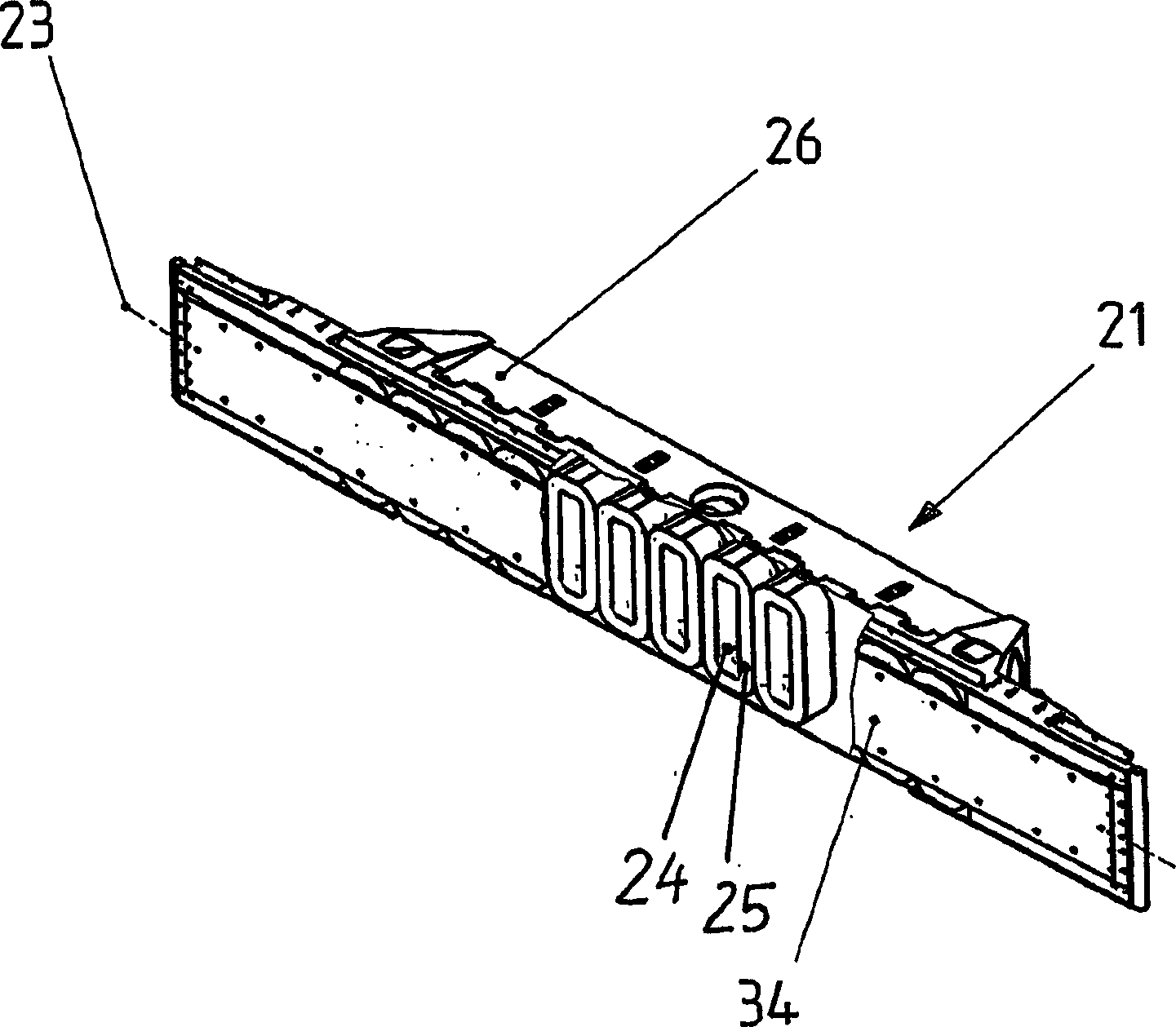

Longitudinal magnetic flux structure rectilinear eddy current brake

InactiveCN102355117ASimple structureImprove power densityAsynchronous induction clutches/brakesPropulsion systemsEngineeringConductor Coil

The invention relates to a longitudinal magnetic flux structure rectilinear eddy current brake, which belongs to the technical field of electric motors and solves the problems that a thrust loading test device of an existing linear electric motor is only capable of single-direction test and the loading force can not be changed continuously. The brake disclosed by the invention is in a unilateral structure and consists of a primary coil and a secondary coil, an air gap exists between the primary coil and the secondary coil, the primary coil consists of an armature core and an armature winding, an air gap side surface of the armature core is uniformly provided with a plurality of rectangular through slots so as to make the armature core form a toothspace structure, the slotting direction of the rectangular through slots is perpendicular to the movement direction of a rotor of the brake, a tooth between every two adjacent rectangular through slots is wound with a winding coil, the winding directions of the winding coils wound on the two adjacent teeth are opposite, and the winding coils on each tooth are sequentially connected in series to form the armature winding; and the secondary coil consists of a response plate and a magnetic conduction yoke plate, and the response plate is attached to the air gap side surface of the magnetic conduction yoke plate. The brake disclosed by the invention is suitable for the thrust loading test of the linear electric motor.

Owner:HARBIN INST OF TECH

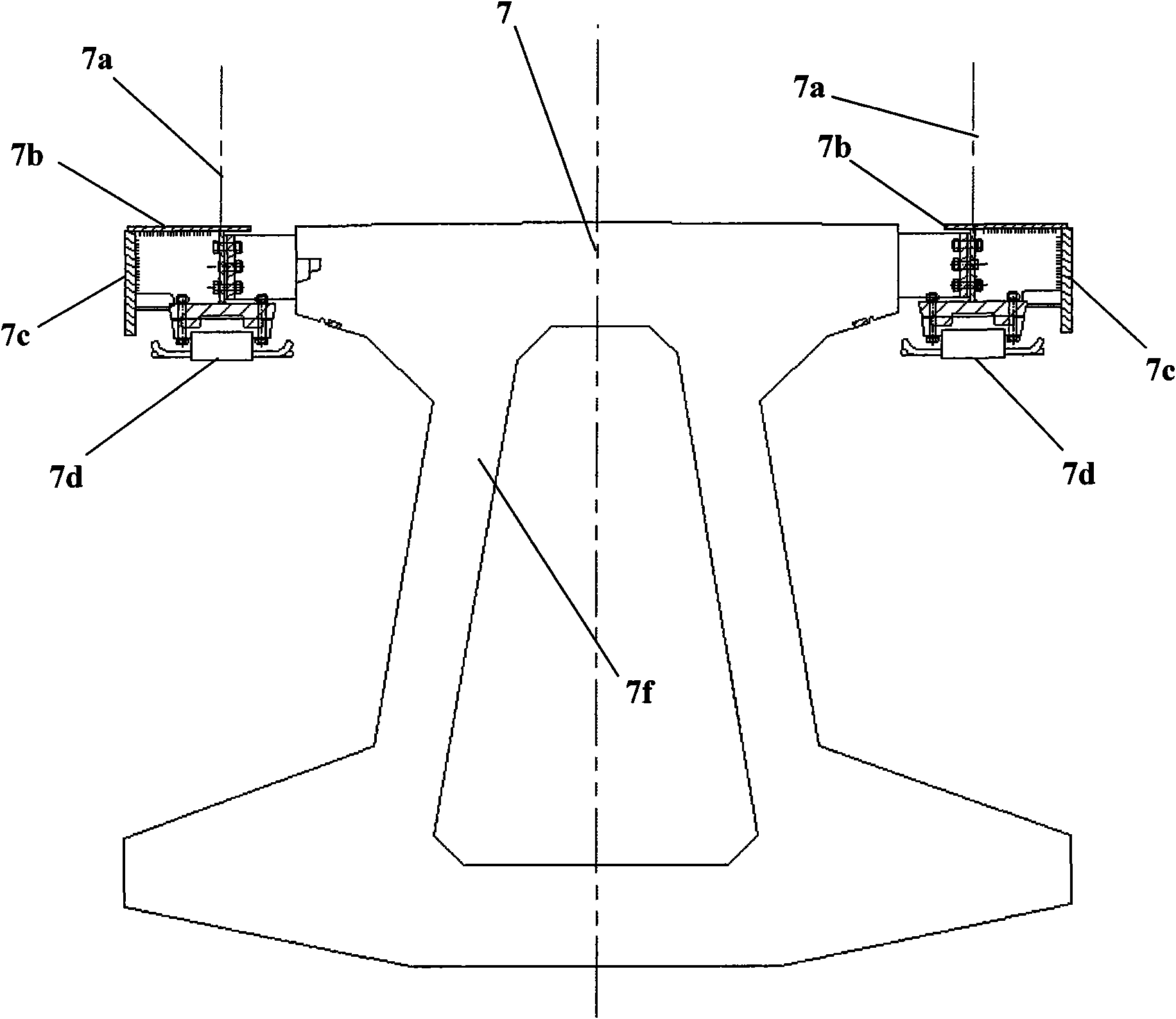

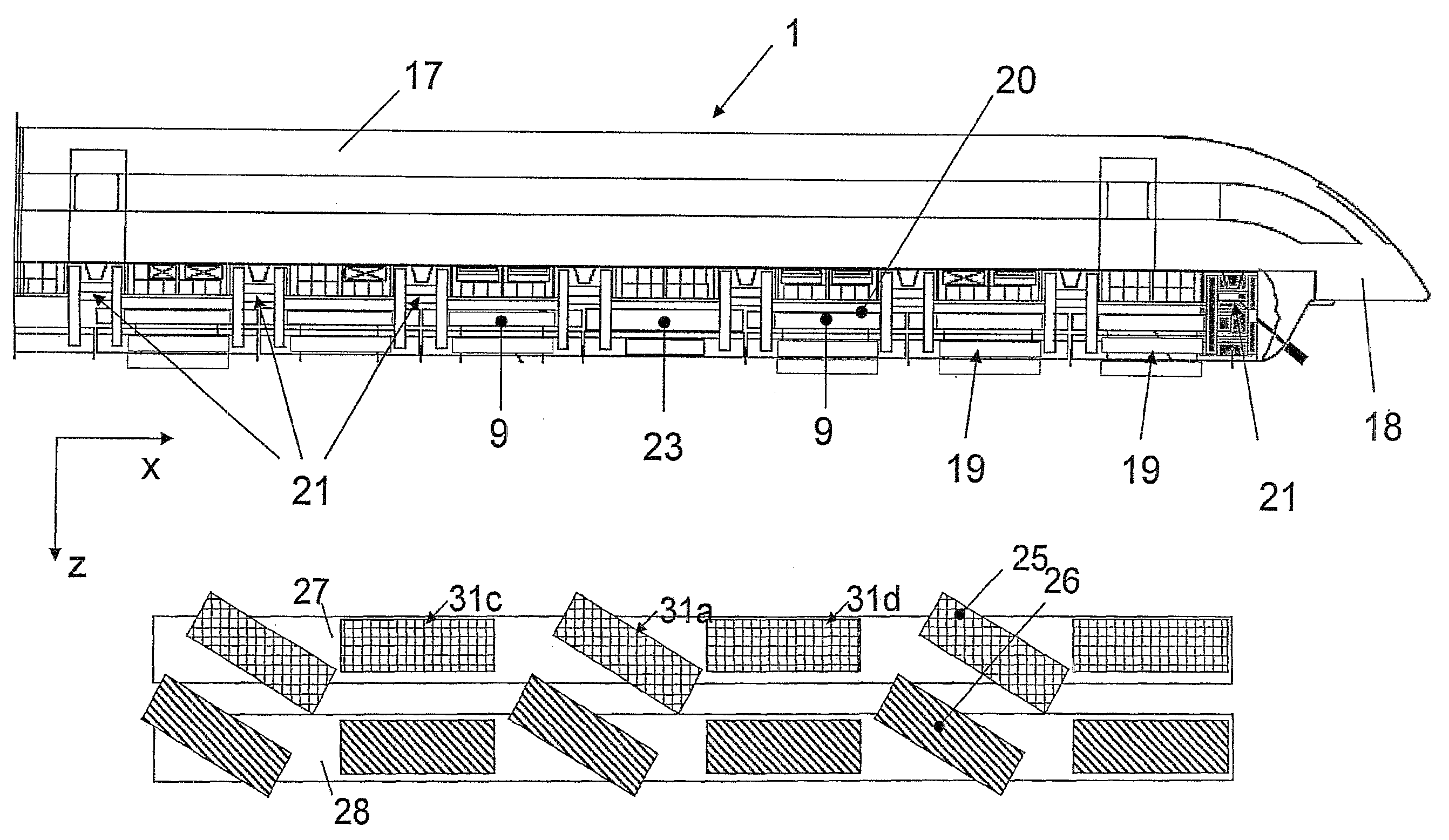

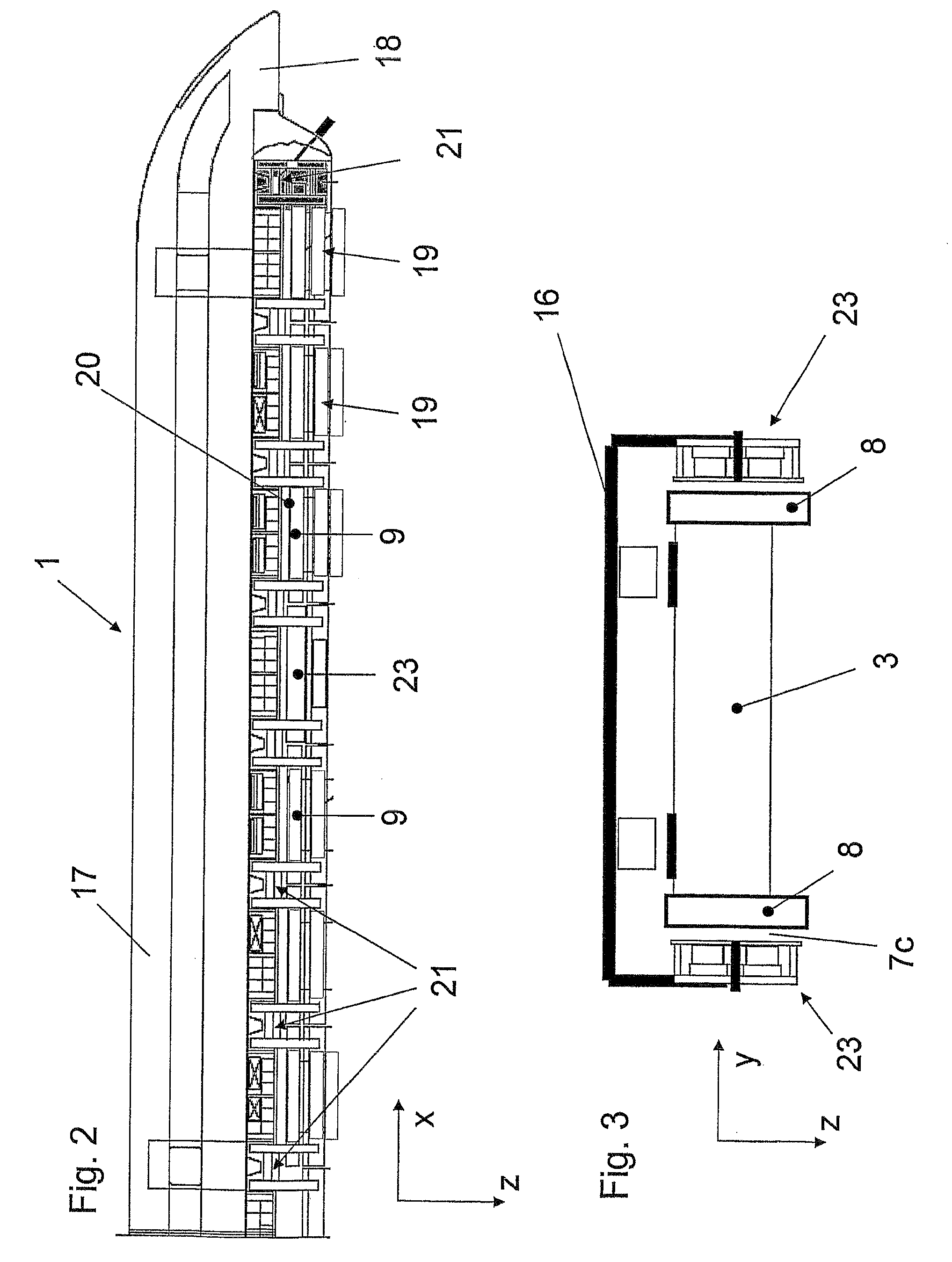

Vehicle having an eddy current brake for a rail-borne transportation system, and a transportation system which is operated therewith, in particular a magnetic levitation train

ActiveUS8281723B2Minimal energy requirementWeaken energyElectrodynamic brake systemsRailway vehiclesTransit systemMagnetic poles

A vehicle for a rail-borne transportation system includes an eddy current brake that contains a large number of magnetic poles and a mechanism for activating the magnetic poles for braking. The magnetic poles are formed by movably supported permanent magnets, and the activation mechanism switches the permanent magnets from an inactive position into an active position.

Owner:THYSSENKRUPP TRANSRAPID

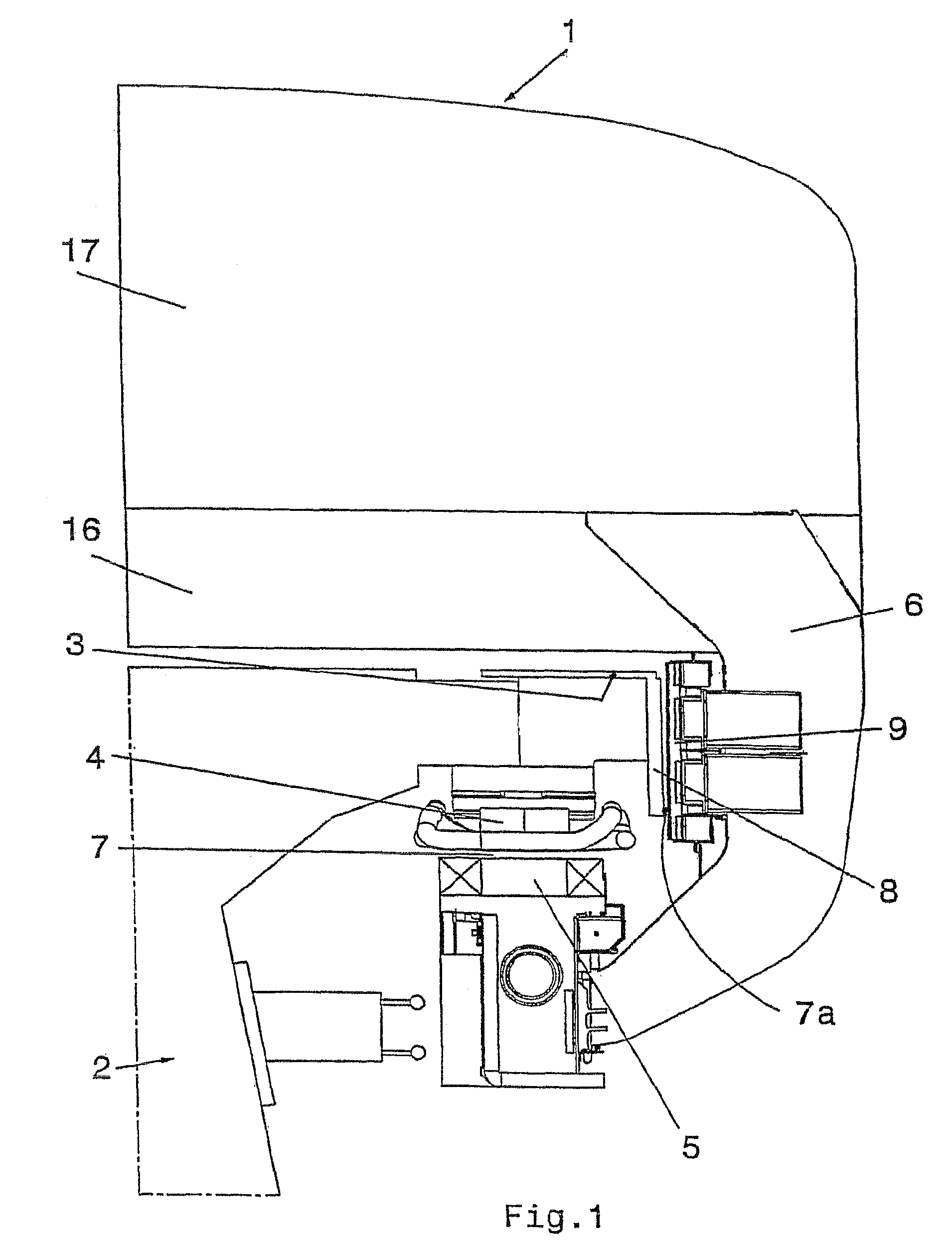

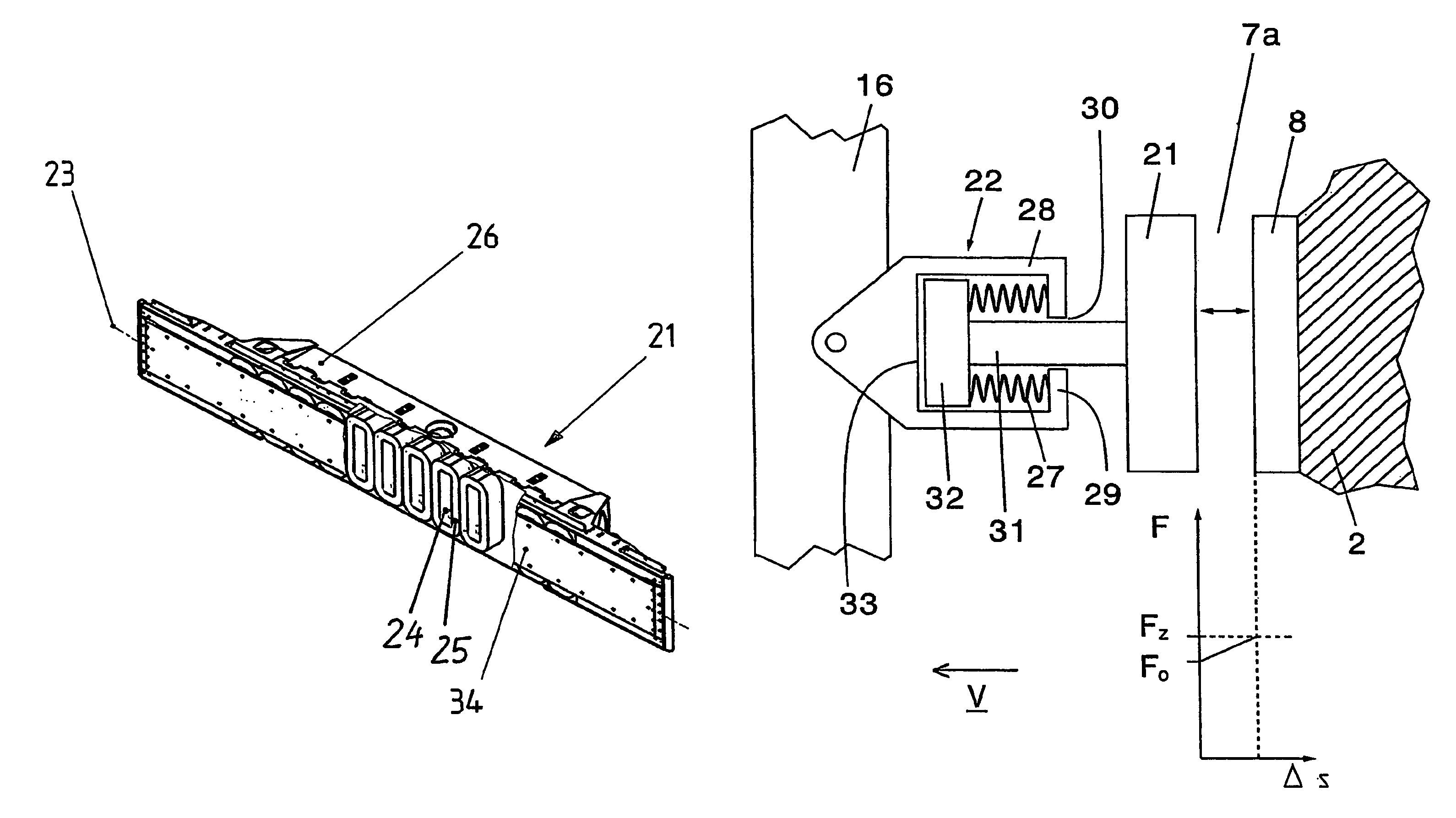

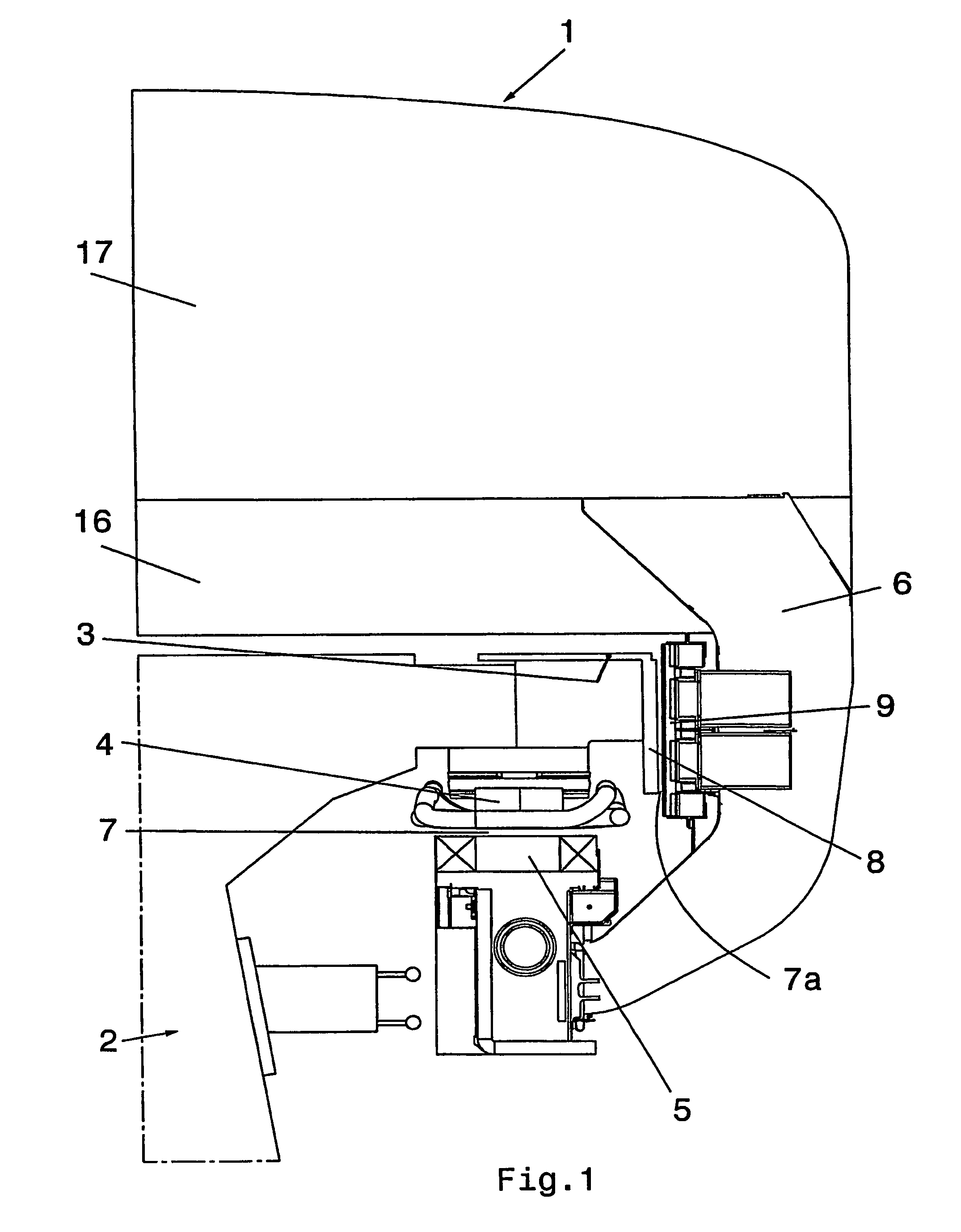

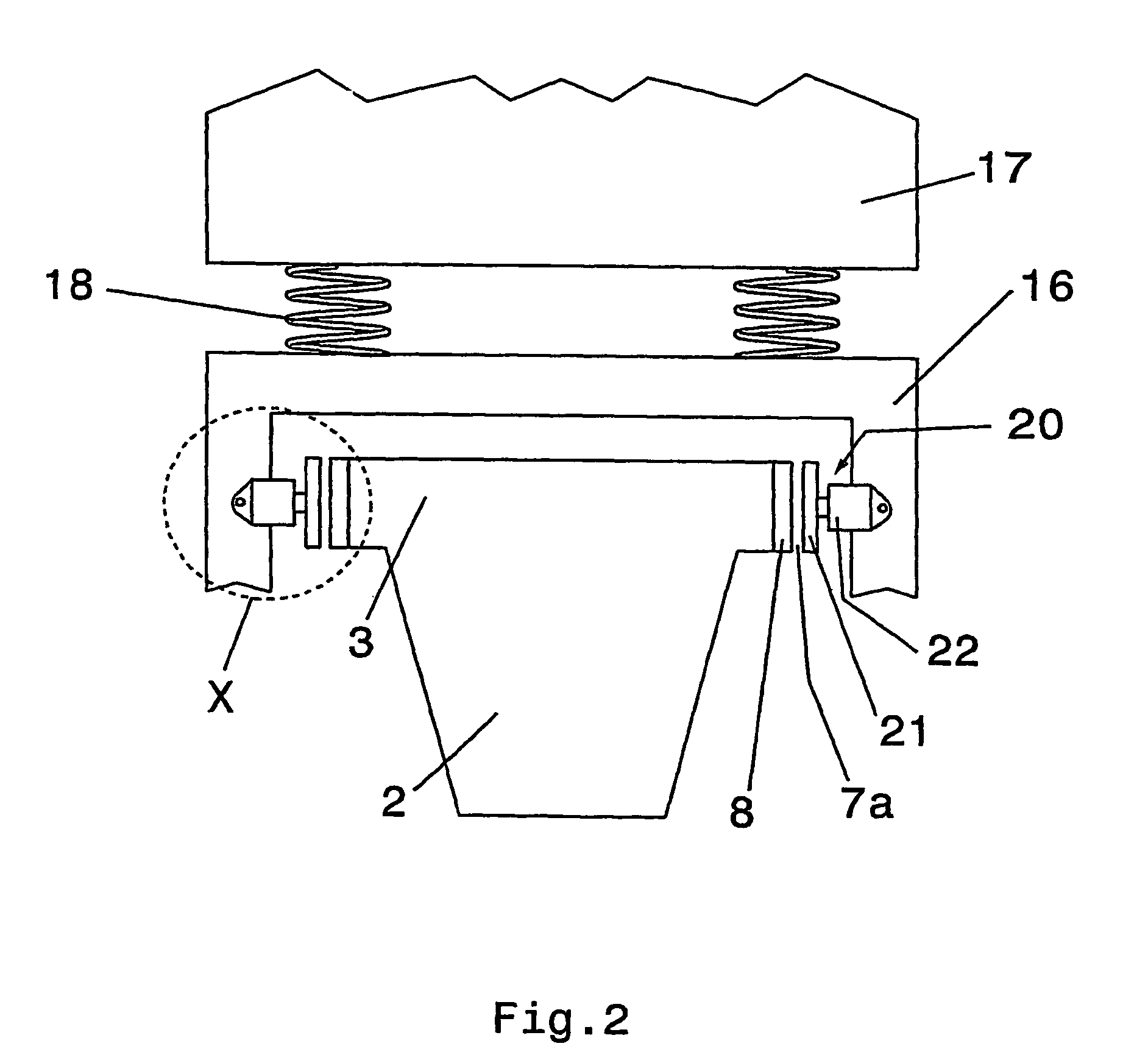

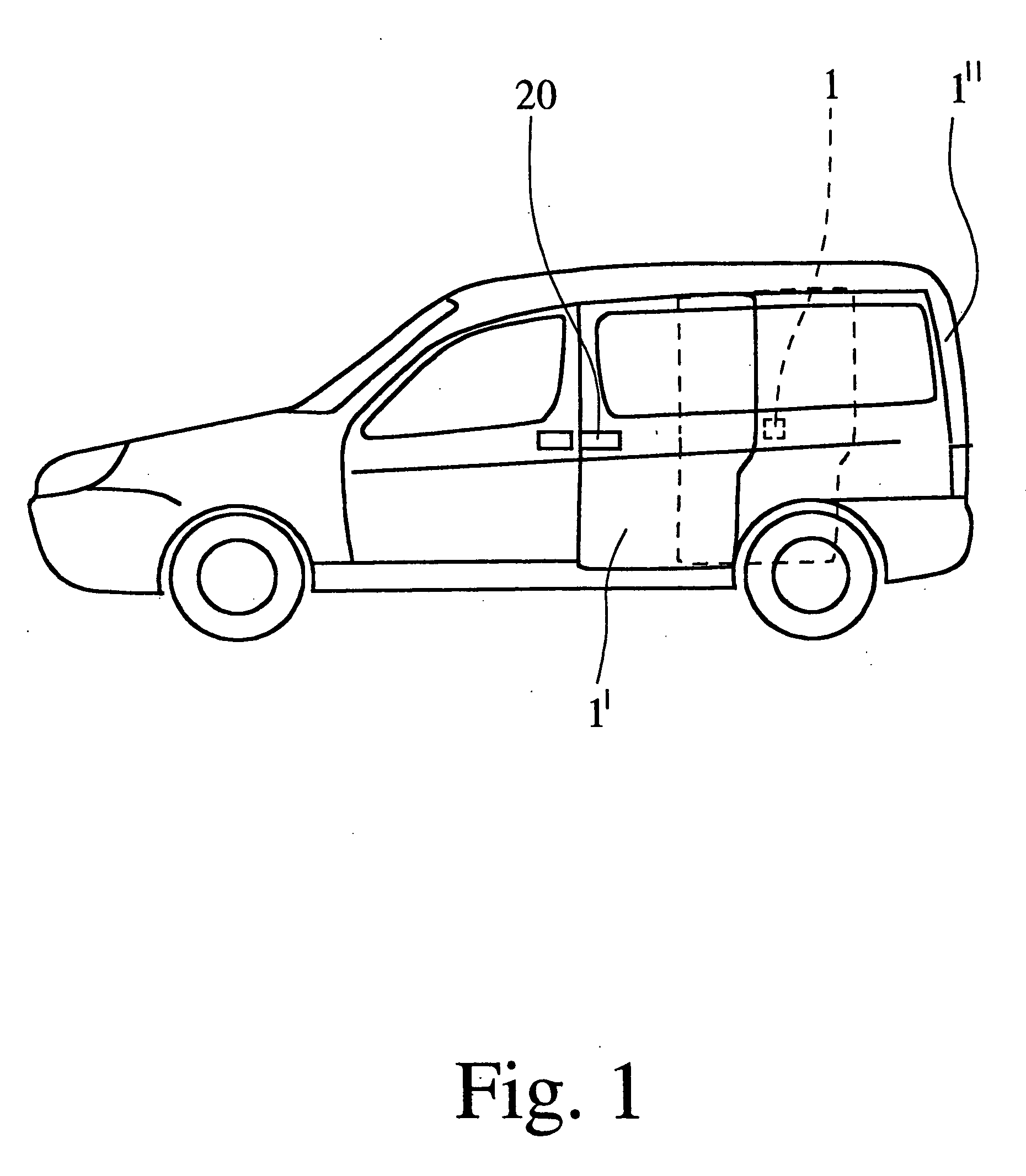

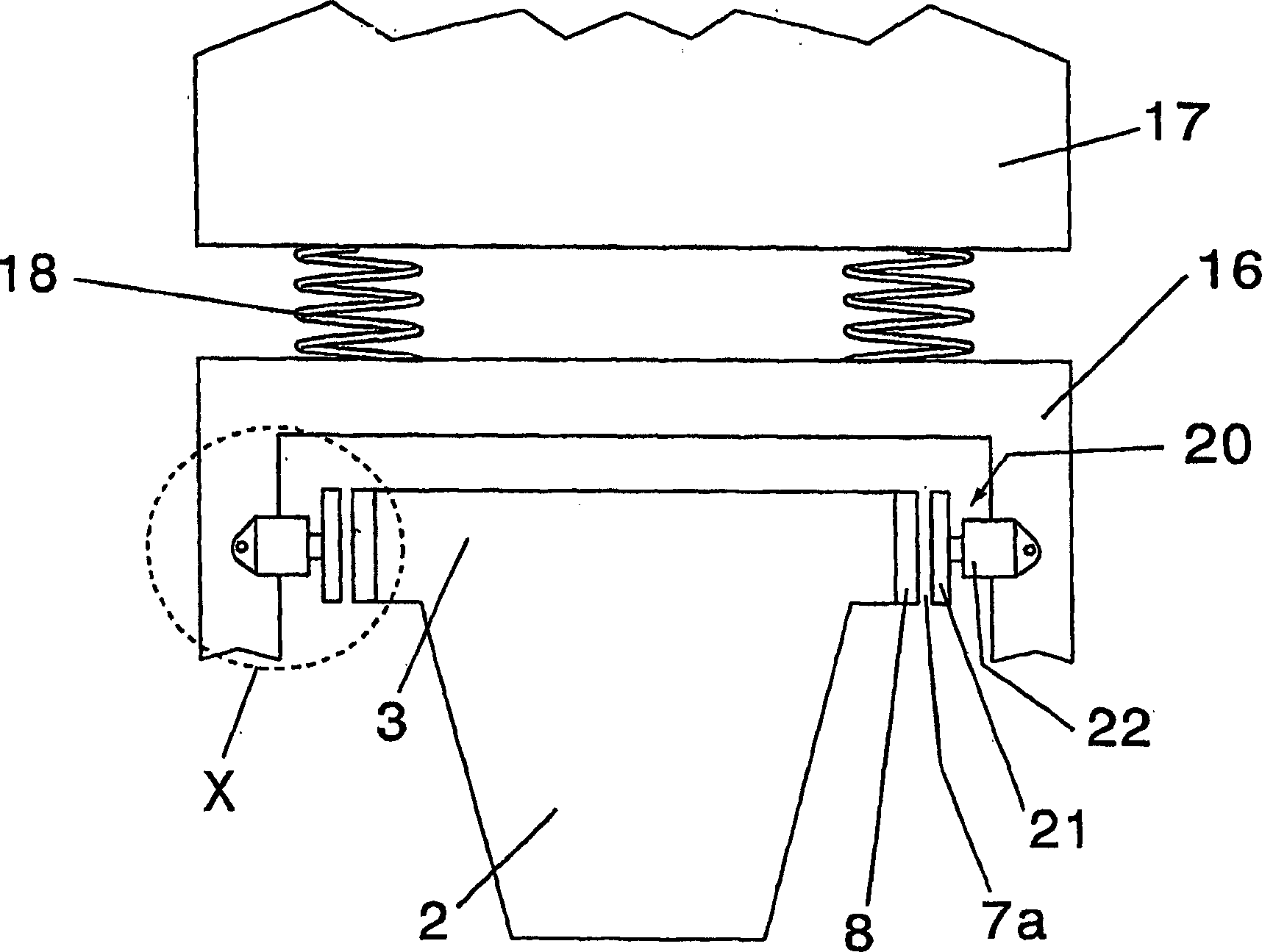

Magnetic levitation train provided with an eddy-current brake

ActiveUS8250990B2Reduce frictionImprove braking effectElectrodynamic brake systemsBrake actuating mechanismsNormal forceEddy current brake

A magnetic levitation railway having an eddy-current brake (20) cooperates with a reaction rail (8) of the driveway (2). The eddy-current brake (20) has at least one brake magnet (21) which is movably mounted to the vehicle (1) and transversely to the reaction rail (8) and which is made to abut the reaction rail (8) if a normal force, for example, fixed by means of springs (27) is exceeded.

Owner:THYSSENKRUPP TRANSRAPID

Drive arrangement for a motor vehicle door or hatch which can be moved by a motor

ActiveUS20050277512A1Reduce braking forceImprove securityConstruction fastening devicesToothed gearingsDrive shaftGear wheel

A drive arrangement for a motor vehicle door or hatch which can be moved by a motor with a planet gear and a brake device with a brake. The brake device has a brake drive which is separate from the drive which drives the drive shaft and the brake is able to be moved at least from one of two positions into the other of the two positions by the brake drive. The brake can be an arc-shaped clip pivotally supported by a pivot axle with an inner periphery which is matched to an outer periphery of an element of the planet gear. The brake can be combined with the brake drive as an eddy current brake or can be operated by a further gearing or use of a permanent magnet with which an electromagnet is able to interact.

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

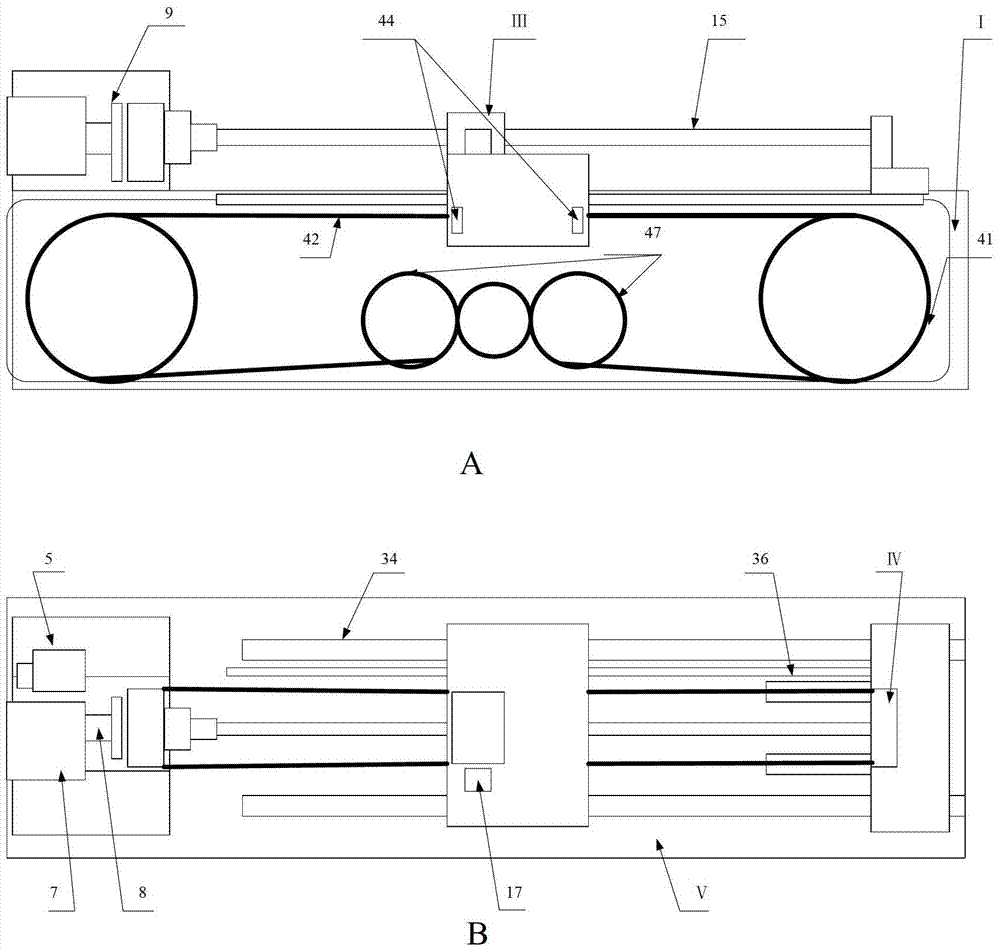

Ball screw assembly precision retaining ability testing device

ActiveCN103115770AGuaranteed CompatibilityGuaranteed stabilityMachine gearing/transmission testingValue passingCoupling

The invention discloses a ball screw assembly precision retaining ability testing device. A motor and a gearbox are arranged on a head frame supporting plate. An output shaft of the gearbox is connected with a dynamic torque sensor. The dynamic torque sensor is connected with the tested ball screw assembly through a coupling. A circular magnetic grid is arranged on the coupling. The circular magnetic grid is connected with the tested ball screw assembly. The head portion and tail portion of the tested ball screw assembly are fixed in a supporting mode through a head frame and a tail frame. An eddy current brake is connected with the gearbox and is connected with a load component. The load component comprises two duplex pulley blocks, two duplex coiling blocks and three gears. Steel wire ropes on the coiling blocks transmit damping to the nut of the tested ball screw assembly through a nut supporting board. The supporting board is fixedly connected with the matched nut of the screw assembly. Four sliding blocks are arranged on the lower sides of the two sides of the supporting board and enable the supporting board to slide on a guild rail fixed on a bed body. A tail frame supporting board is arranged on a flat-V guide rail of the tail portion of the bed body. In work, the eddy current brake provides load, through adjusting the current value passing through eddy current brake, simulation of the ball screw assembly working condition can be achieved.

Owner:NANJING UNIV OF SCI & TECH

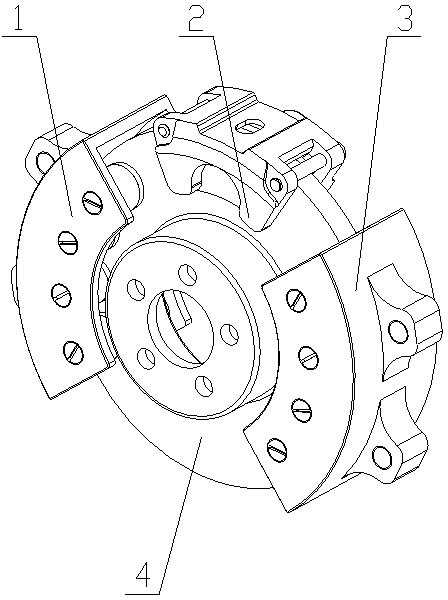

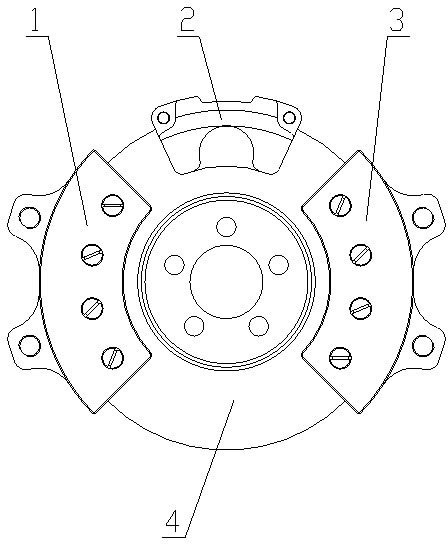

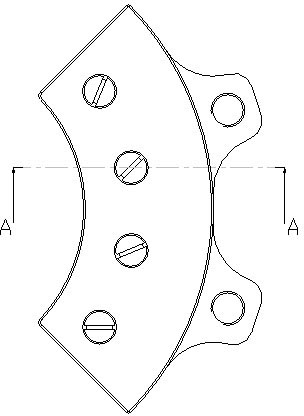

Eddy current and friction brake device for vehicles

InactiveCN102678789AImprove securityImprove stabilityAxially engaging brakesAsynchronous induction clutches/brakesLow speedIn vehicle

The invention discloses an eddy current and friction brake device for vehicles. The eddy current and friction brake device comprises a brake disc, a brake caliper, a first annular sector eddy current retarder and a second annular sector eddy current retarder. The brake caliper holds the upper portion of the brake disc. The first annular sector eddy current retarder and the second annular sector eddy current retarder symmetrically hold two sides of the brake disc relative to the brake caliper. Each annular sector eddy current retarder is formed by two rows of electromagnets on two inner annular sector faces of an annular sector frame. The eddy current retarders and the friction brake are integrated according to the principle of advantage complementing, eddy current brake is used when the vehicle runs at high speed, and the brake caliper is used for friction brake when the vehicle runs at low speed. By the eddy current and friction brake device for vehicles, safety, economy, stability, comfort level and efficiency in vehicle braking are improved. The eddy current and friction brake device for vehicles is compact and simple in structure, convenient to mount and easy to maintain.

Owner:ZHEJIANG UNIV

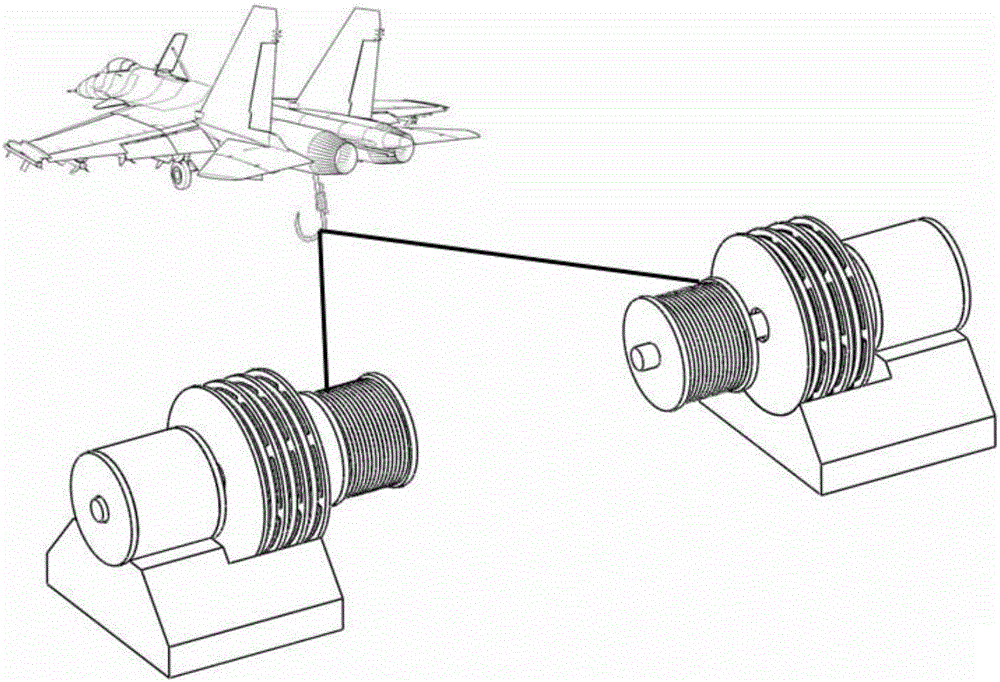

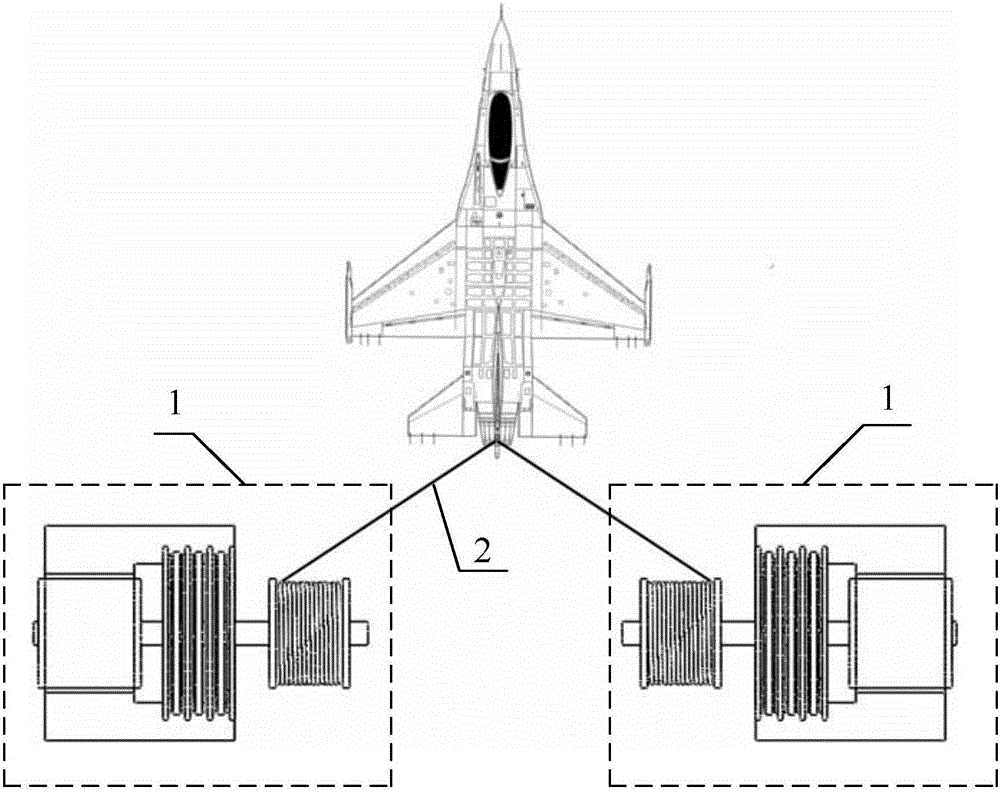

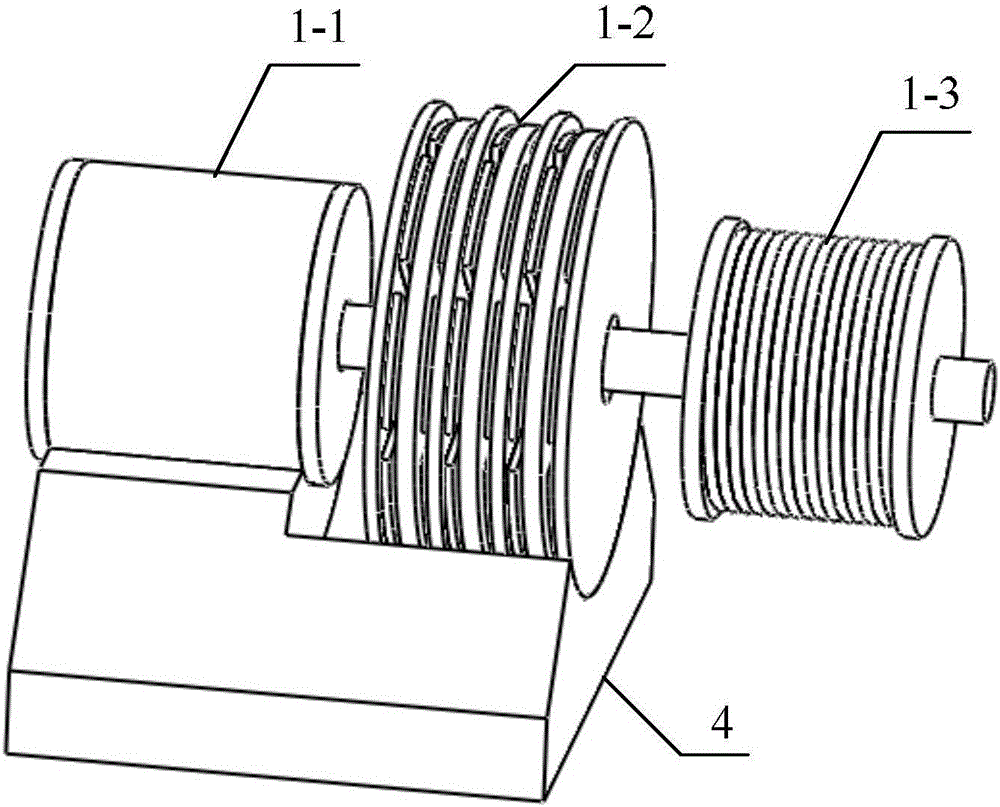

Electromagnetic arresting device for deck landing or landing of aircraft

The invention discloses an electromagnetic arresting device for deck landing or landing of an aircraft and relates to an electromagnetic arresting system. The problems that an existing landing assisting and arresting system is large in weight and size, complicated in structure, low in reliability and the like are solved. The device comprises two rotary electromagnetic arresters of the same structure, and an arresting cable. Each rotary electromagnetic arrester comprises a rotary motor, a rotary eddy current retarder brake, an arresting cable drum and a motor driven controller, wherein the rotary motor, the rotary eddy current retarder brake and the arresting cable drum share one rotary shaft. The two rotary electromagnetic arresters are arranged symmetric with an aircraft landing runway as the center, and the two ends of the arresting cable are wound on the two arresting cable drums correspondingly. The electromagnetic arresting device adapts to deck landing or landing of a carrier aircraft.

Owner:HARBIN INST OF TECH

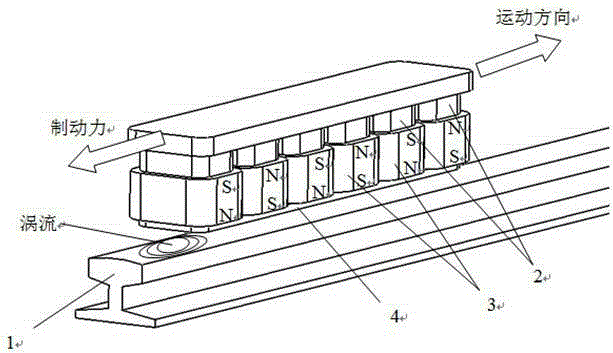

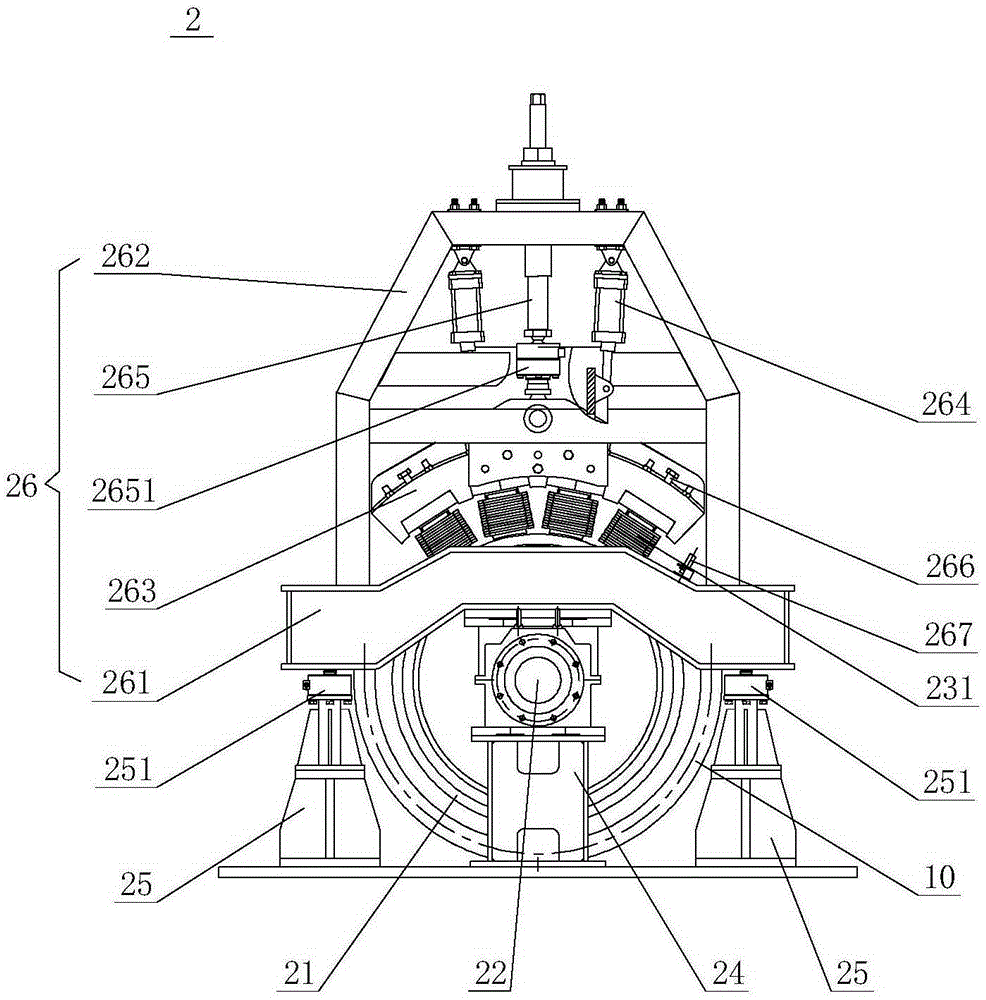

Hybrid braking excitation structure for maglev train

InactiveCN105305776AReduce feverRealize energy savingElectrodynamic brake systemsElectric machinesHeat managementExcitation current

The invention discloses a hybrid braking excitation structure for a maglev train. Magnetic poles formed by electromagnets and permanent magnets are arranged along the rail direction and are installed on the bottom of the maglev train right over rails. Each magnetic pole comprises a core, an armature coil, and a permanent magnet. The cores are arranged at intervals along the rail direction. The horizontal periphery of each core is wrapped in the armature coil provided with exciting current. The top of each core is equipped with the corresponding permanent magnet such that the magnetic poles are formed. The top of the permanent magnets are equipped with a magnet yoke along the rail direction. The bottoms of the cores are equipped with a wearing plate. By means of the adjustment of exciting current in an exciting coil, a dynamic maglev train braking process is achieved. By means of reverse excitation, a braking system is simply repositioned. The magnetic force of the permanent magnets enhances eddy current braking control and friction braking effects. The hybrid braking excitation structure reduces the heating of the system, achieves an energy-saving effect and heat management of the system, and is provided with a braking operation mode with safe fault guidance.

Owner:ZHEJIANG UNIV

High-speed magnetic trolley

ActiveUS9242659B2Reduce heat buildupShorten speedBrakes for specific applicationsBraking action transmissionMagnetic tension forceEddy current brake

A high-speed magnetic trolley that utilizes an eddy current brake that may reduce the speed of a person in a harness traveling on a relatively steep zip line cable, making it possible to reach a landing brake at a reasonable speed and becomes easy to adjust an amount of braking force needed to reach a desired speed by taking off or adding more magnets without throwing one or more aluminum wheels out of balance. The high-speed magnetic trolley produce an eddy current that generates an opposing magnetic field, which then resists rotation of one or more aluminum wheels providing braking force.

Owner:BERNIER STEPHANE

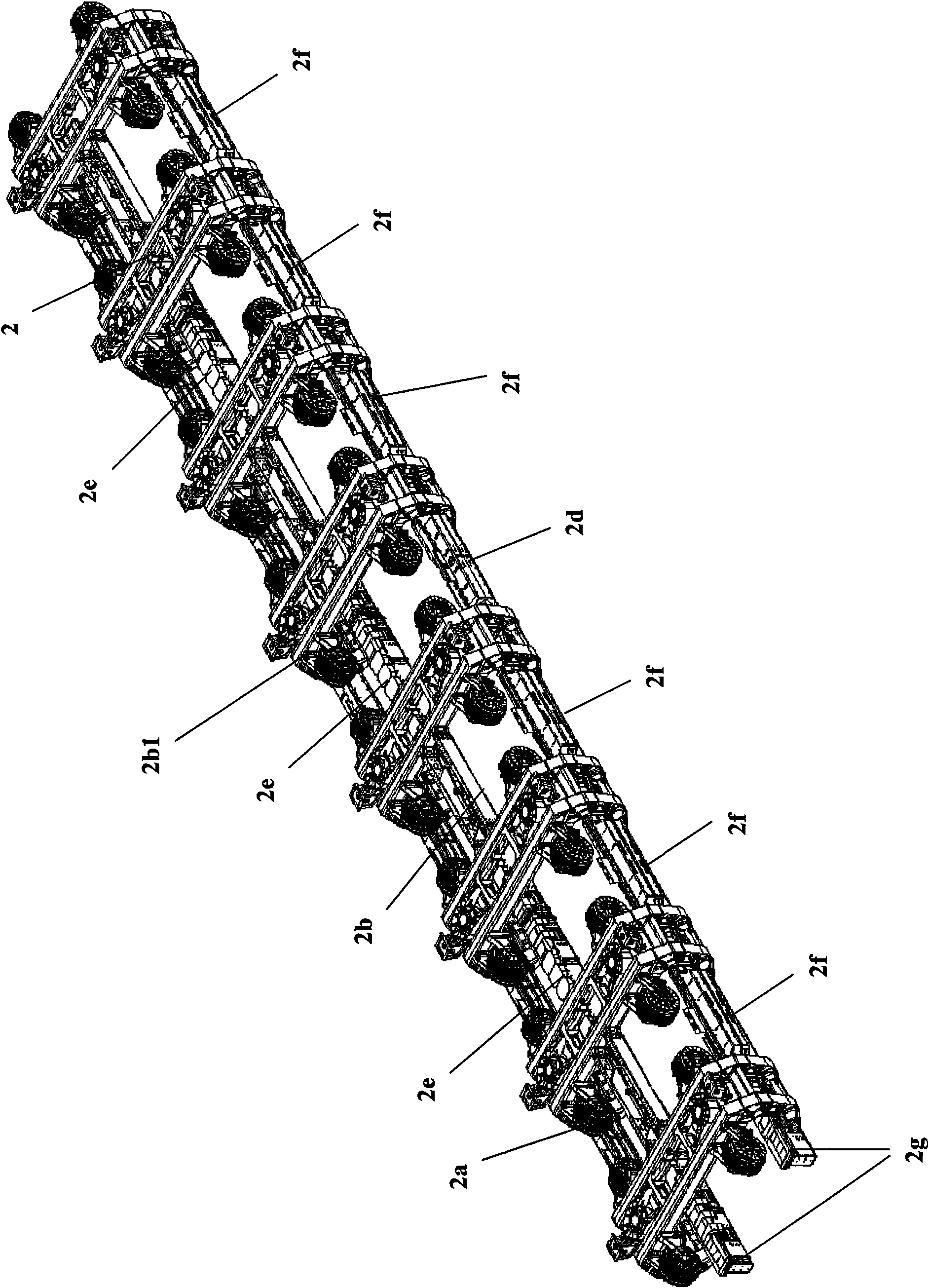

Long-stroke permanent magnet linear eddy current brake

ActiveCN104753311AIncrease braking force densityHigh braking force outputPermanent-magnet clutches/brakesPrimary permanentLow speed

The invention relates to a long-stroke permanent magnet linear eddy current brake, belongs to the technical field of motors and aims at solving the problems of an existing permanent magnet linear eddy current brake that a size of the magnetic field cannot be adjusted, and a high speed and a lower speed cannot be considered for the same time for the braking force characteristic. The long-stroke permanent magnet linear eddy current brake comprises a primary level part and a secondary level part between which an air gap is formed; the primary level part comprises a primary substrate and primary permanent magnets, wherein the primary substrate is of a flat plate type; the surface of the air gap side of the primary substrate is provided with the strip-shaped primary permanent magnets uniformly along a rotor movement direction; the magnetizing direction of each primary permanent magnet is parallel to the primary substrate and vertical to the rotor movement direction, and the magnetizing directions of the every two adjacent primary permanent magnets are opposite; the secondary level part comprises a secondary conductor plate which is a composite metal plate. The long-stroke permanent magnet linear eddy current brake serves as an eddy current brake.

Owner:HARBIN INST OF TECH

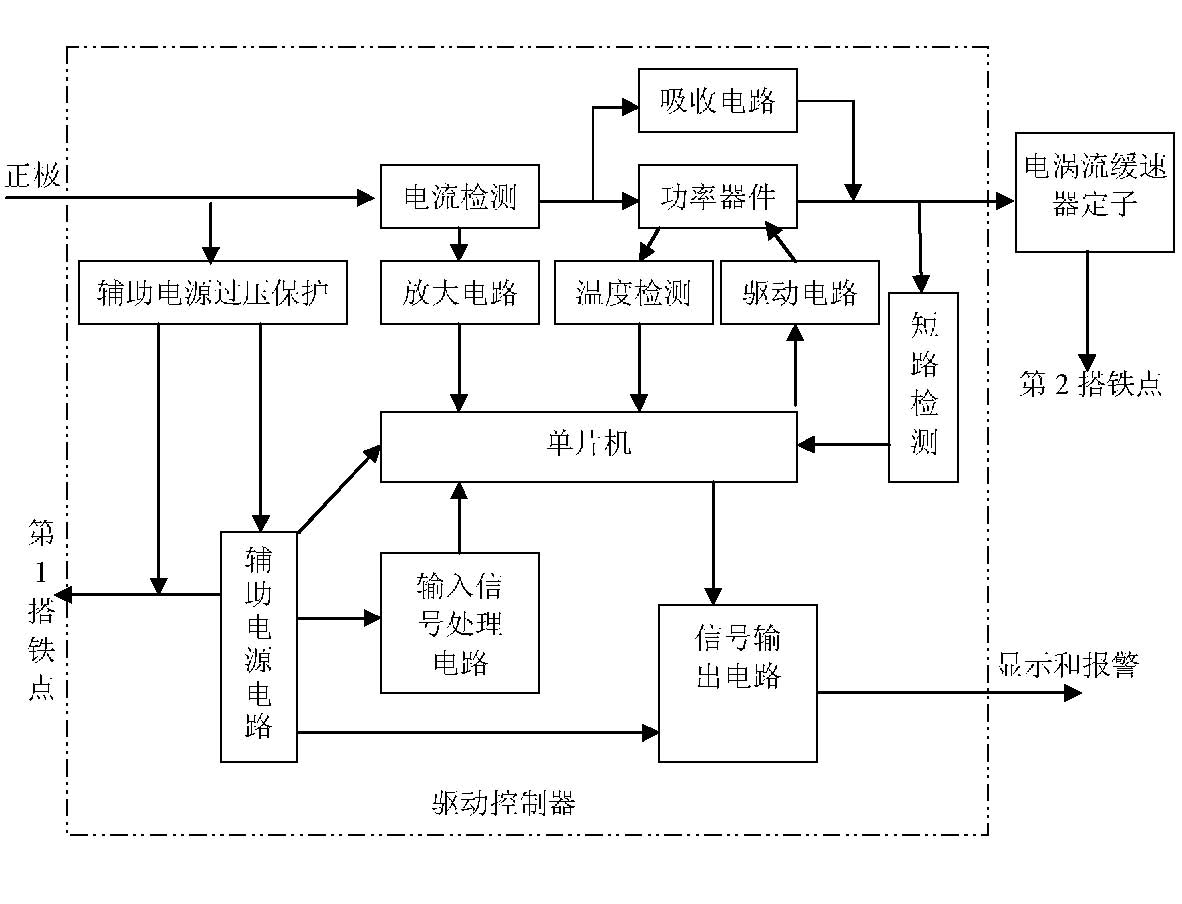

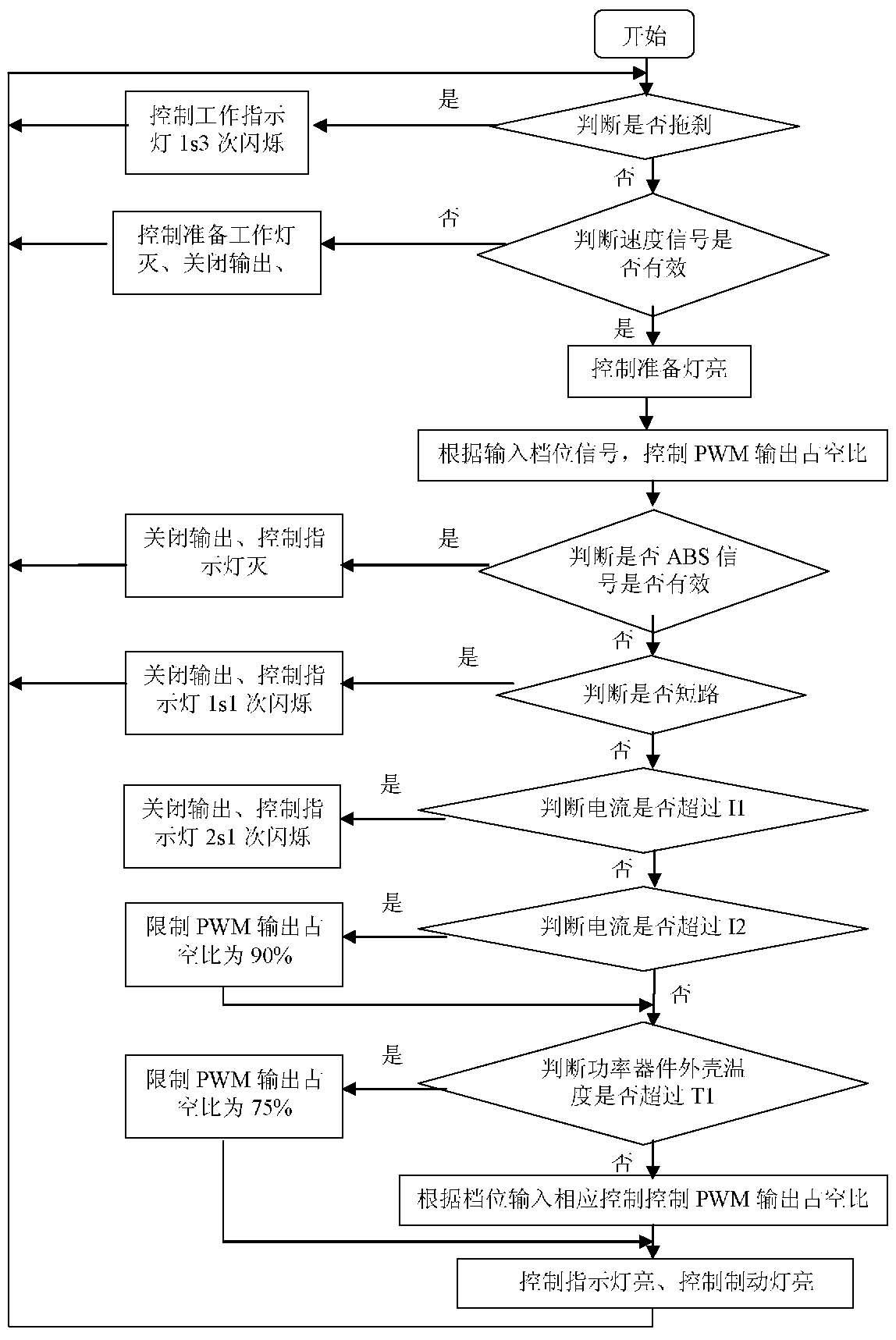

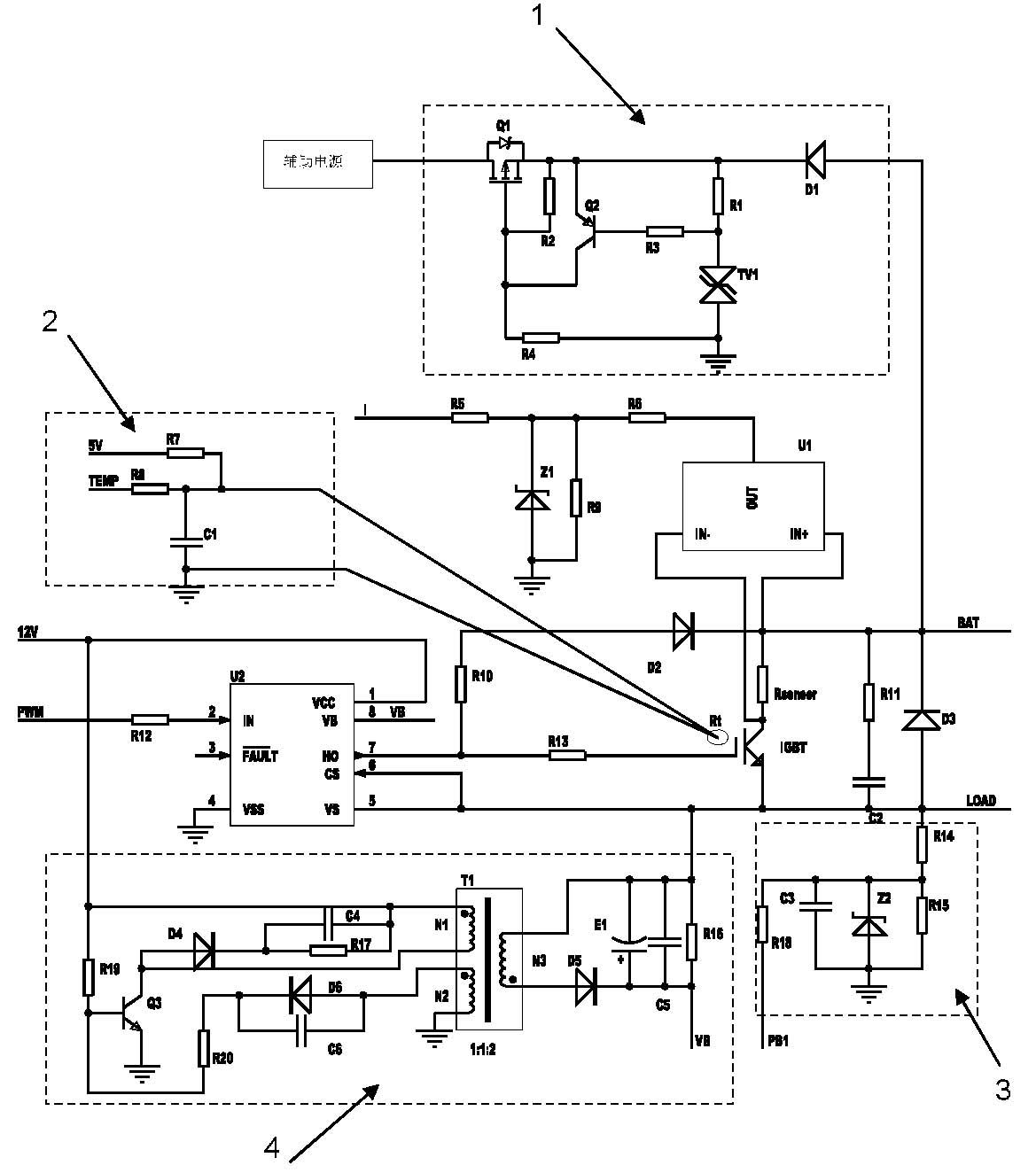

Driving controller of electric eddy current brake and control method thereof

InactiveCN101867336AAvoid failureAvoid short circuitElectrodynamic brake systemsElectric machinesDriver circuitElectricity

The invention relates to a driving controller of an electric eddy current brake and a control method thereof, wherein the controller comprises a control unit, a driving circuit and an insulated gate bipolar transistor IGBT with large current and high pressure resistance electrically connected in sequence, and a rectification unit, a transformer T1 and a power input thereof connected with an IGBT output grid electrode in sequence. The control method comprises the steps that the control unit controls the pulse width thereof according to the input gear to modulate the duty ratio of the PWM output under the condition of normal circuit detection, or else turns off the output or restricts the duty ratio of the PWM output; the driving circuit receives the PWM output and drives the IGBT output according to the PWM output. The driving controller of the electric eddy current brake and the control method thereof has the high pressure resistance of 300V, and basically avoids the over-voltage failure used on cars, the controller can not be failed under various abnormal conditions combining a detection and protection circuit, thereby greatly enhancing the reliability, and solving the industrial problem of poor reliability of electronic control mode in the electric eddy current brake industry.

Owner:深圳市大为创新科技股份有限公司

Magnetic levitation train mounted with vortex brake

ActiveCN1842431AReduce wearReduce tearingElectrodynamic brake systemsRailway vehiclesEngineeringPerpendicular direction

The invention relates to a magnetic levitation railway provided with an eddy-current brake (20) interacting with a reaction rail (8) of a travel way (2). Said invention is characterised in that said eddy-current brake (20) comprises at least one brake magnet which is movably mounted on a vehicle (16) in a perpendicular direction with respect to the reaction rail (8) and is applied thereto when a normal force exceeds a value determined, for example by a springs (27).

Owner:THYSSENKRUPP TRANSRAPID

High-speed train eddy current brake performance test device and method

ActiveCN105181361AIncrease heating capacityImprove heat transfer effectRailway vehicle testingTest efficiencyElectric machine

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Liquid cooling permanent magnet speed inhibitor capable of stage division

InactiveCN101359865AAchieve scalable controlEasy to switchAsynchronous induction clutches/brakesMagnetic sourceEngineering

The invention provides a gradable liquid cooling permanent-magnet retarder, and the retarder utilizes permanent magnets as eddy current brake magnetic sources, and carries out the auxiliary braking to an automobile vehicle through the reverse eddy current braking force produced by rotating non-contacting rotors or stators. The retarder comprises the stators, the rotors and a control mechanism. The stators include bearing end caps and stator drums, the rotors comprise a plurality of permanent magnets and magnet cages, and the rotors are connected with the stators through two rolling bearings, so the rotors can be rotationally positioned in the stators. The control mechanism is positioned in the rotors for controlling the transmission connection of spacer flanges and the rotors. Two sets of rotors of the permanent-magnet retarder are positioned at both sides of the control mechanism, and can work independently, thereby realizing the gradable control to the permanent-magnet retarder; the permanent magnets and the magnet cages serve as rotors, and the outer parts thereof have no rotating part; the control mechanism is easy to realize the switching of braking state of the permanent-magnet retarder; the permanent-magnet retarder has no magnetic leakage moment when in non-braking; and the retarder has advantages of compact overall structure and small volume and light weight.

Owner:BEIJING UNIV OF TECH

Application of eddy current braking system for use in a gearbox/generator mechanical disconnect

InactiveUS7896147B2Motor/generator/converter stoppersMagnetically actuated clutchesDrive shaftBall screw

A disengagement assembly for disengaging a generator from an engine or gear box may include an inner ball screw having helical threading on an outer surface thereof and surrounding and operatively engaged to a rotating generator drive shaft to cause rotation of the inner ball screw, the inner ball screw may have interlockable teeth engaged to corresponding teeth of the gear box drive shaft. An outer ball screw may surround and may normally rotate with the inner ball screw. A helical ball track may be formed between the inner and outer ball screws. An eddy current brake may slow or stop rotation of the outer ball screw so that the inner ball screw may rotate relative to the outer ball screw and slide axially toward a lock thereby disengaging the generator from the engine.

Owner:HONEYWELL INT INC

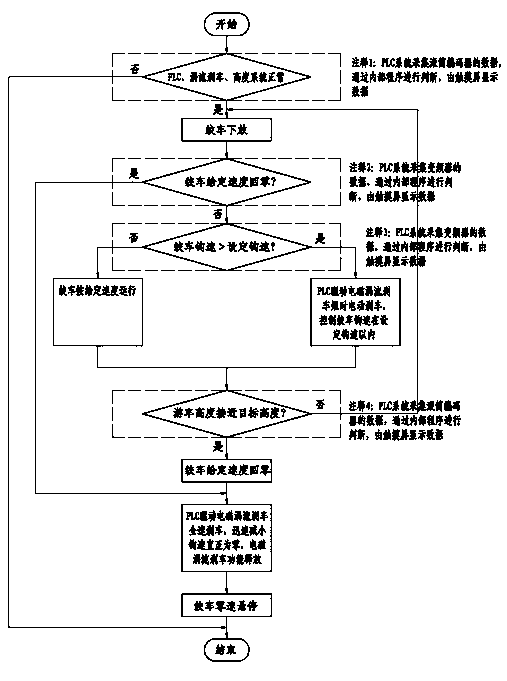

Efficient, intelligent and safe petroleum drilling winch system and control method thereof

ActiveCN103523689AImprove power utilizationImprove drilling efficiencyWinding mechanismsControl mannerFrequency conversion

The invention particularly relates to an efficient, intelligent and safe petroleum drilling winch system and a control method of the drilling winch system. According to the trinity system of the winch structure, the frequency conversion alternating current control mode, the electromagnetic eddy current brake structure and the control mode, the problems that a frequency conversion drilling machine is low in drilling efficiency, poor in down-pass safety and high in system failure rate are solved, wherein the problems trouble users for a long time. According to the technical scheme, the drilling winch system comprises a winch structure part and a winch control part. A winch structure comprises an electromagnetic turbine brake, a disk type brake, a drum shaft assembly and a double gear gearbox. The double gear gearbox is connected with alternating current frequency conversion motors through a clutch and connected with the drum shaft assembly through a clutch, the drum shaft assembly is connected with the electromagnetic turbine brake through a spline, and the disk type brake is connected between the drum shaft assembly and the electromagnetic turbine brake through the spline.

Owner:BOMAY ELECTRIC IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com