Permanent magnet electromagnetic composite disc type eddy current braking device

An electromagnetic compound, eddy current braking technology, applied in the direction of permanent magnet clutch/brake, electromechanical device, electric brake/clutch, etc. Improved energy transfer efficiency, reduced maintenance effort, and effects in terms of braking force regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

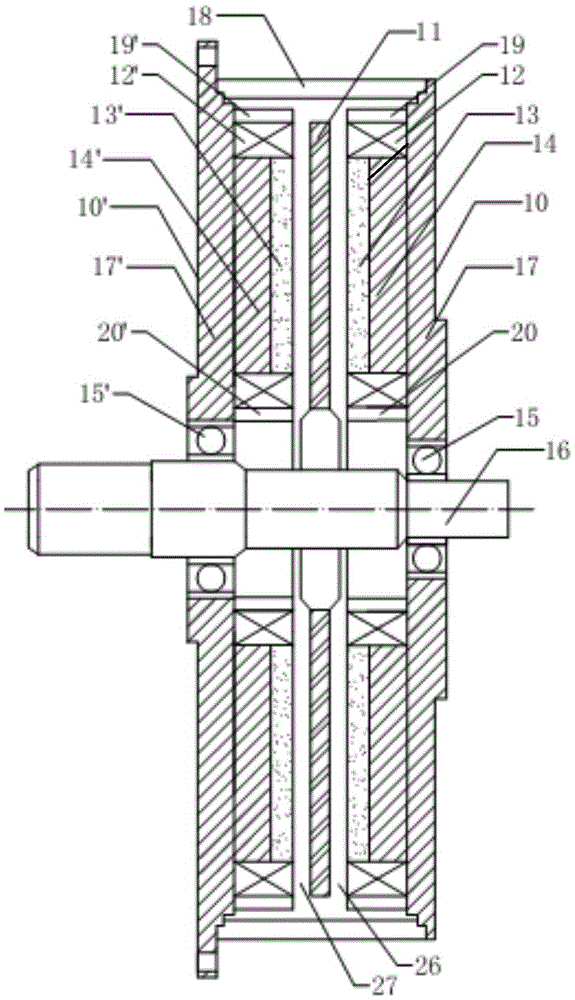

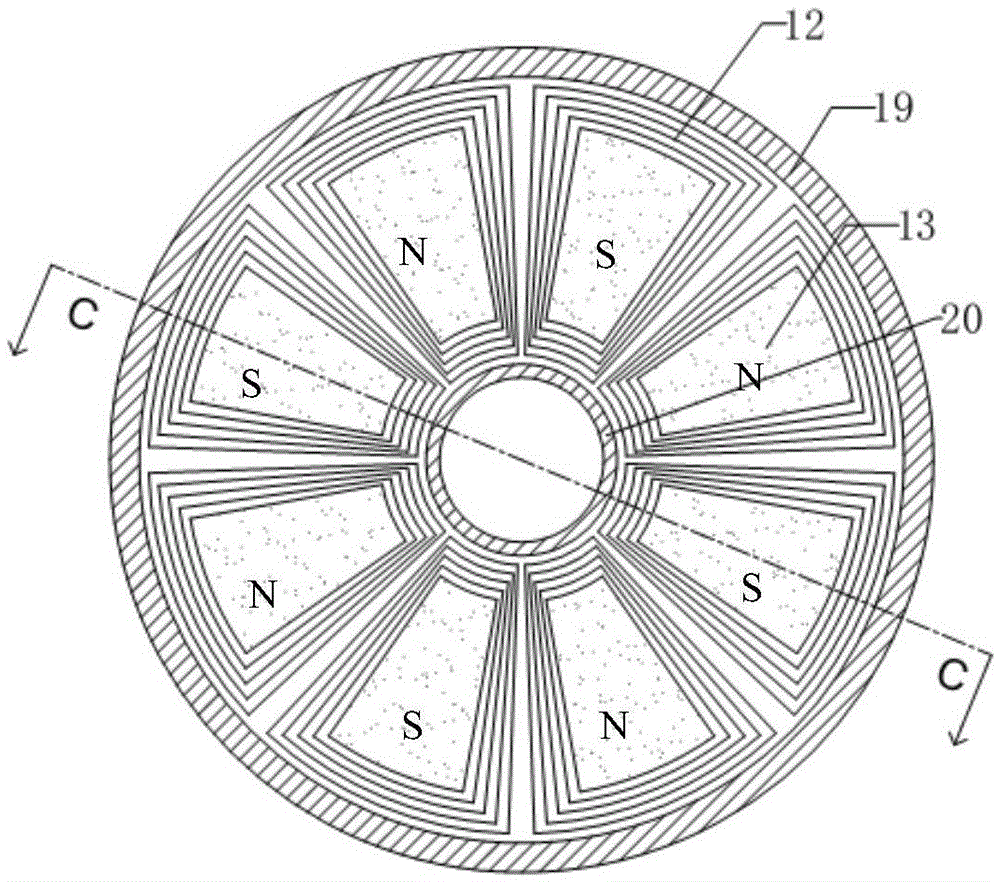

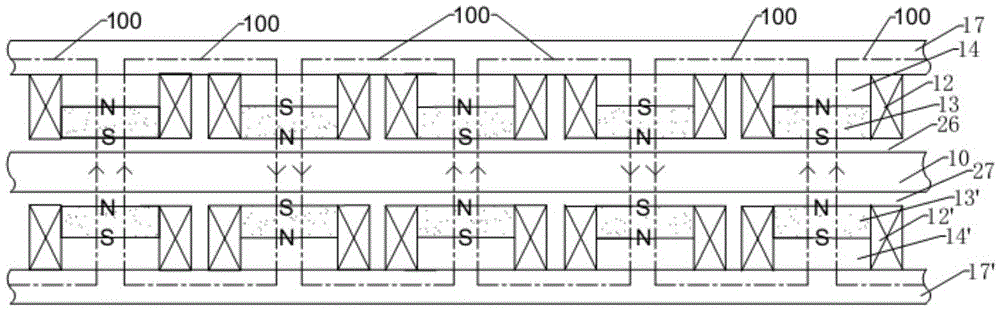

[0045] The permanent magnet electromagnetic composite disk type eddy current braking device of the present invention comprises two magnet disks 10, 10 ', one metal disk 11 and a transmission shaft. The two magnet discs 10, 10' are fixed on the stationary equipment in parallel; the body structures of the two magnet discs 10, 10' are the same, and they are placed symmetrically on both sides of the metal disc. The metal disc 11 is coaxially installed between the two magnet discs 10, 10', parallel with the two magnet discs 10, 10', and fixed on the transmission shaft. Transmission shaft is supported on two sides magnet disk 10,10' by bearing 15,15'. Each magnet disk is evenly spaced along the circumference with m compound magnetic poles compounded by permanent magnets and electromagnets, where m is an even number, and the m compound magnetic poles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com