Eddy current and friction brake device for vehicles

A braking device, eddy current technology, applied in asynchronous inductive clutch/brake, brake type, axial upward brake, etc., can solve the problems of small braking torque, friction brake wear, etc., to improve braking efficiency, easy to use. Maintenance, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

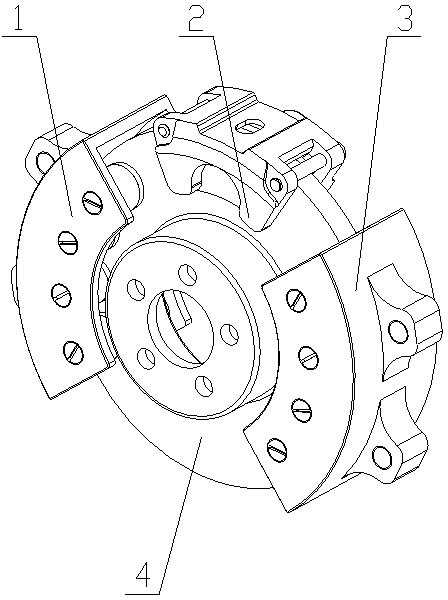

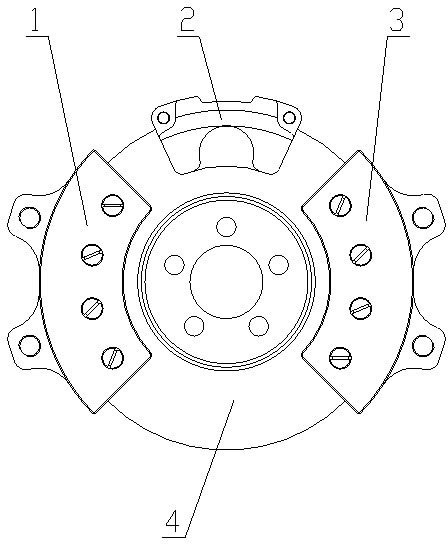

[0017] Such as figure 1 , 2 As shown, the present invention is applied to an eddy current and friction integrated braking device for vehicles, which includes a brake disc 4, a brake caliper 2, a first fan annular eddy current retarder 1 and a second fan annular electric retarder 1 with the same structure. Vortex retarder 3. The brake caliper 2 is clamped on the upper part of the brake disc 4 , and the first sector annular eddy current retarder 1 and the second sector annular eddy current retarder 3 are symmetrically clamped on both sides of the brake disc 4 relative to the brake caliper 2 .

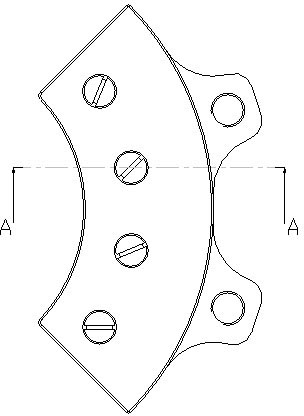

[0018] Such as image 3 , 4 , 5, the first fan annular eddy current retarder 1 and the second fan annular eddy current retarder 3 are all composed of a fan ring frame 7 and two columns installed on two fan ring surfaces inside the fan ring frame 7 Composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com