Longitudinal magnetic flux structure rectilinear eddy current brake

A linear eddy current braking and longitudinal magnetic flux technology, applied in asynchronous inductive clutches/brakes, electric components, electrical components, etc., can solve the problems of inability to continuously change, test loading force in one direction, etc., to improve test accuracy, eliminate The effect of fluctuation of loading force and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

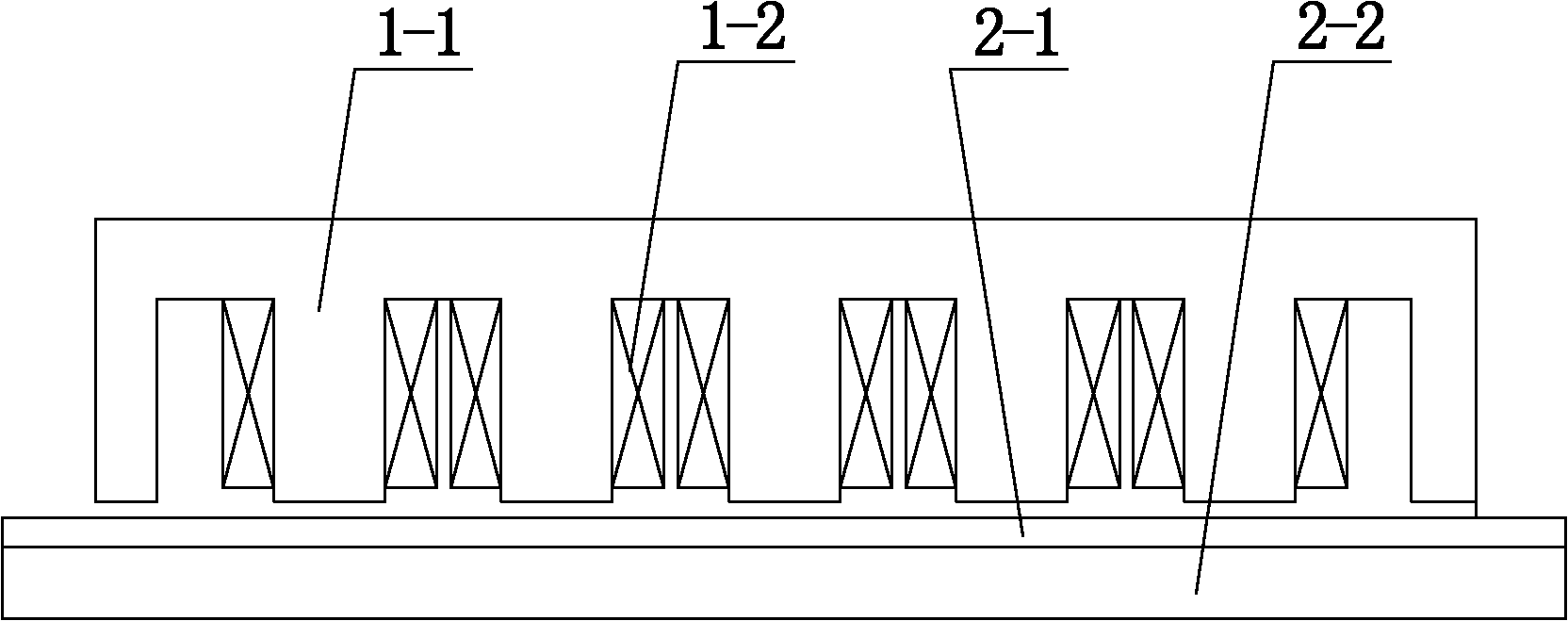

[0032] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the linear eddy current brake with longitudinal magnetic flux structure in this embodiment, the brake is a unilateral structure, consisting of a primary and a secondary, with an air gap between the primary and secondary,

[0033] The primary is composed of an armature core 1-1 and an armature winding 1-2, and a plurality of rectangular slots are evenly opened on the surface of the air gap side of the armature core 1-1, so that the armature core 1-1 forms a cogged structure , the slotting direction of the rectangular slot is perpendicular to the moving direction of the brake mover, a winding coil is wound on each tooth between two adjacent rectangular slots, and the winding direction of the winding coil wound on two adjacent teeth is opposite. The winding coils on each tooth are sequentially connected in series to form the armature winding 1-2;

[0034] The secondary is compo...

specific Embodiment approach 2

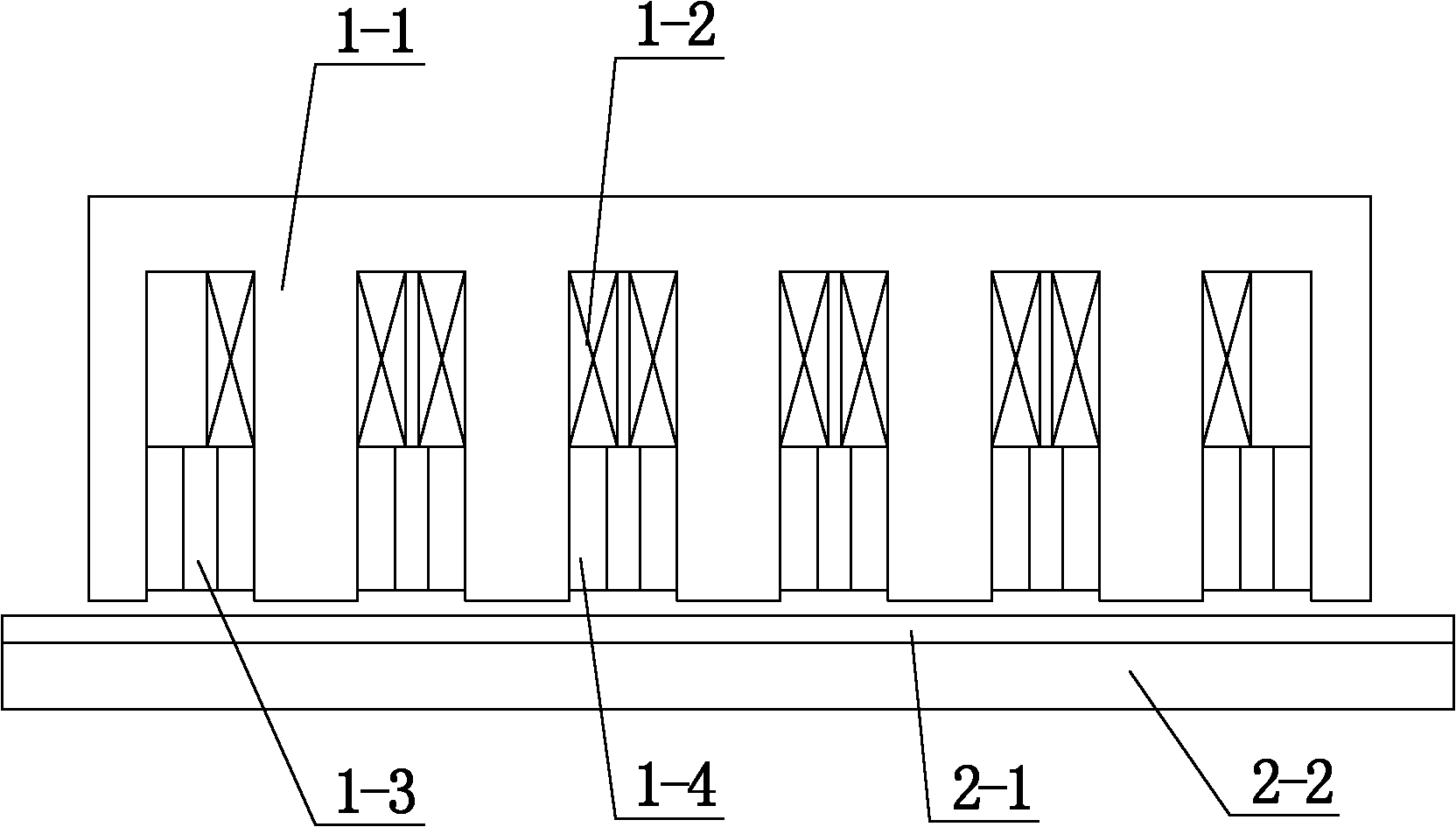

[0036] Specific implementation mode two: the following combination figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. The primary stage in this embodiment also includes a plurality of permanent magnets 1-3 and a plurality of magnetic yokes 1-4. The permanent magnets 1-3 are flat ,

[0037] A permanent magnet 1-3 is set in the center of each rectangular channel near the air gap side, and a magnetic guide yoke 1-4 is respectively embedded between each permanent magnet 1-3 and the two side walls of the rectangular channel where it is located. To fix the permanent magnet 1-3;

[0038] The magnetization direction of the permanent magnets 1-3 is parallel to the moving direction of the brake mover, and the magnetization directions of the adjacent permanent magnets 1-3 are opposite.

[0039] In this embodiment, each rectangular through slot is divided into two sections along the tooth height direction of the armature core 1-1, the section n...

specific Embodiment approach 3

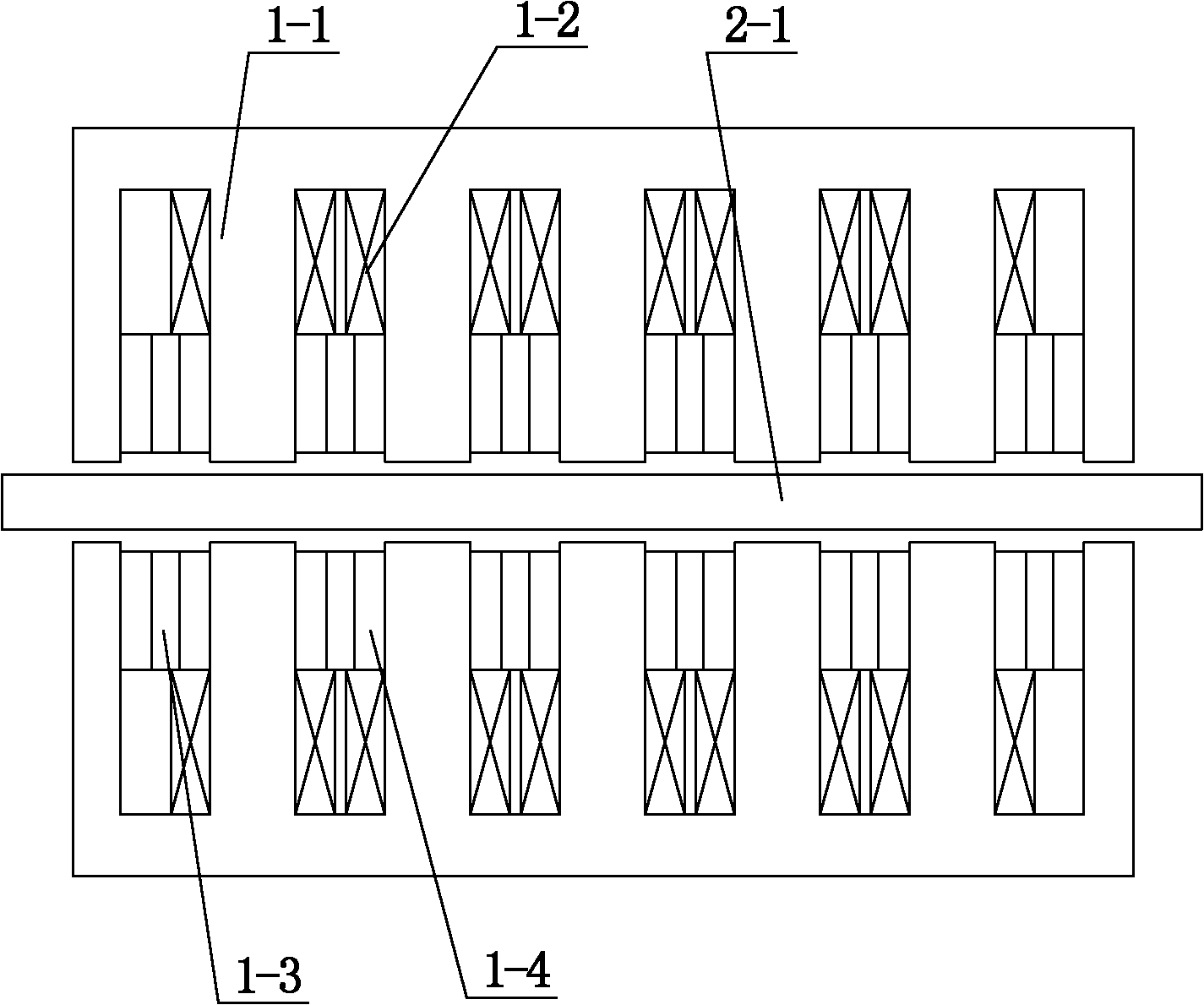

[0041] Specific implementation mode three: the following combination image 3 Describe this embodiment, the linear eddy current brake with longitudinal magnetic flux structure in this embodiment, the brake is a double-sided structure, composed of two primary and one secondary, the two primary are arranged on both sides of the secondary in mirror image symmetry, one There are two parallel air gaps between the secondary and the two primary;

[0042] The primary is composed of an armature core 1-1, an armature winding 1-2, a plurality of permanent magnets 1-3 and a plurality of magnetic yokes 1-4; A plurality of rectangular through slots make the armature core 1-1 form a cogged structure, the slotting direction of the rectangular through slots is perpendicular to the moving direction of the brake mover, and a winding is wound on each tooth between two adjacent rectangular through slots Coil, the winding direction of the winding coils wound on two adjacent teeth is opposite, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com