Travel structure of magnetic levitation type rail polling car

A technology of inspection vehicle and track, which is applied in the field of traveling structure of maglev track inspection vehicle, can solve problems such as inability to run at high speed, affect the transportation capacity of passenger lines, and not have high-speed inspection operation, and achieve effective traction and braking The effect of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

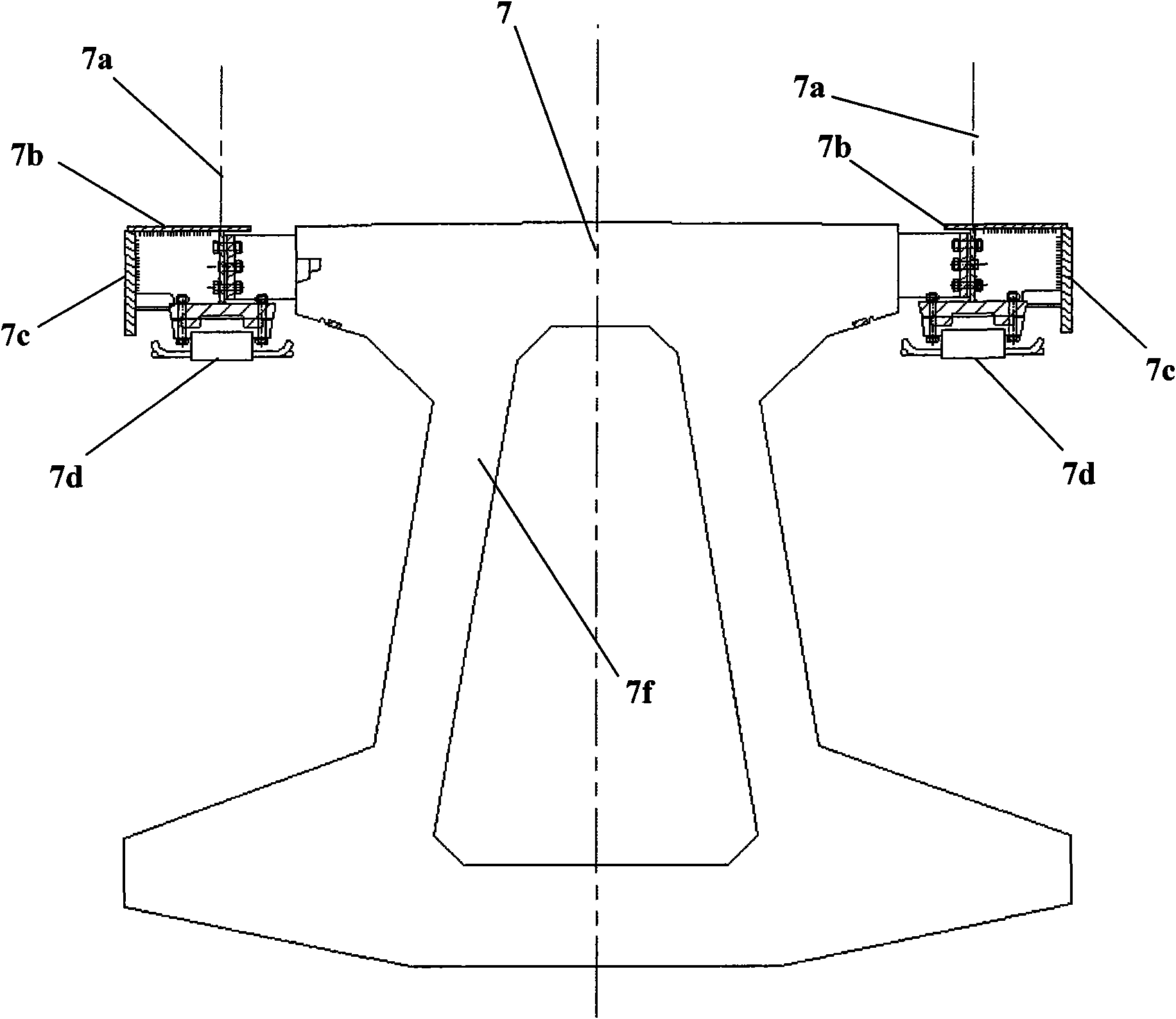

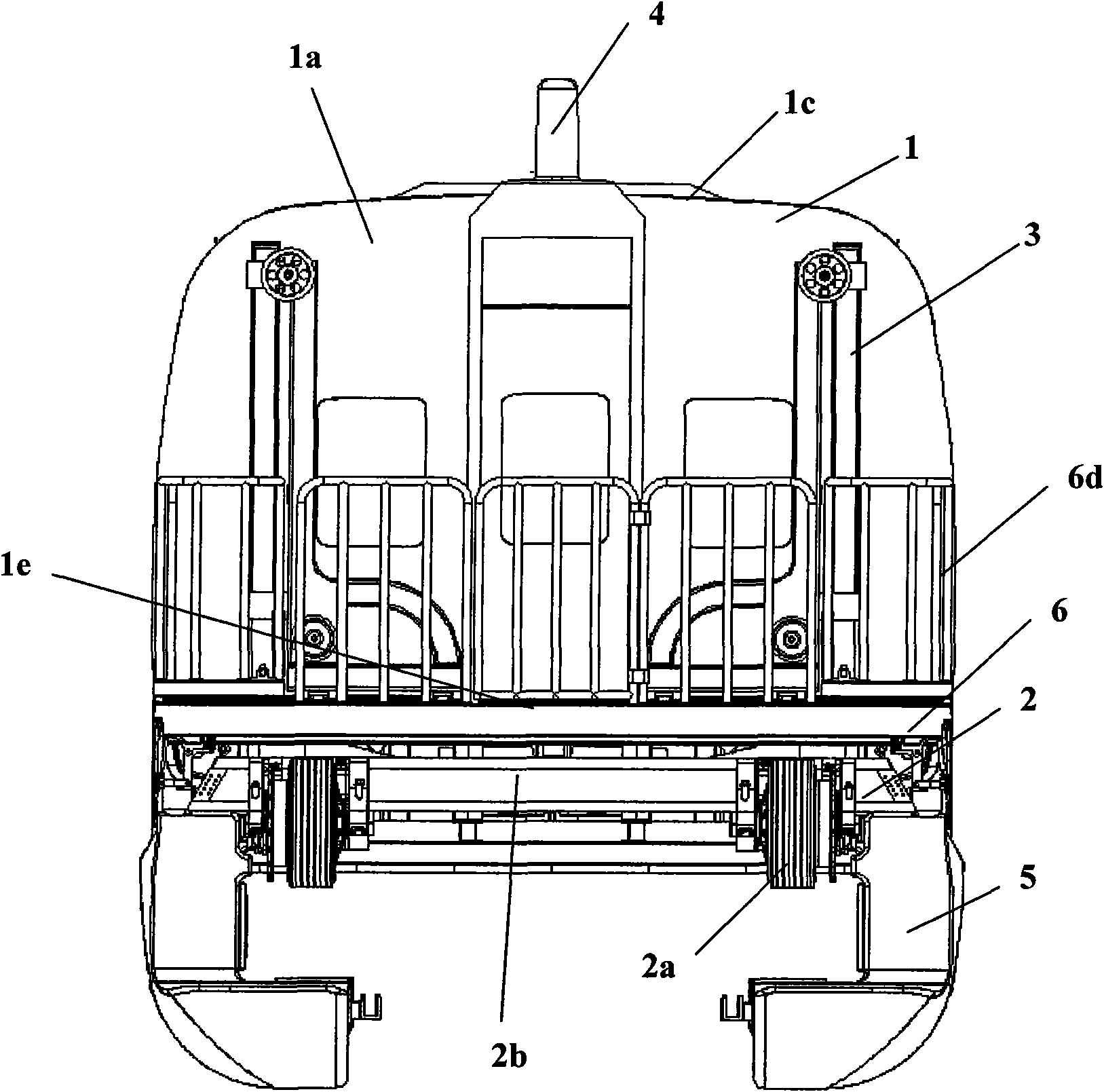

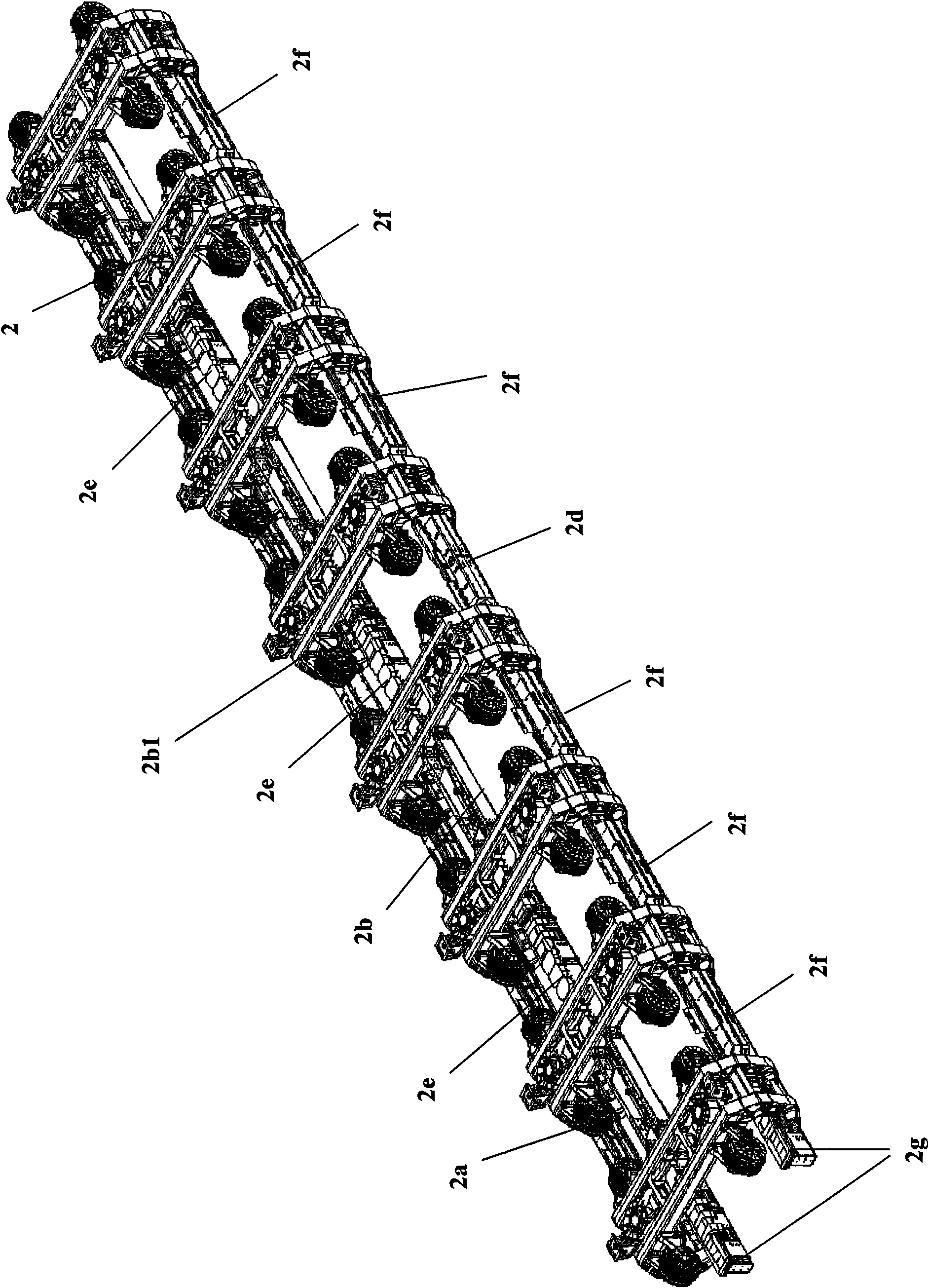

[0036] based on the following Figure 1 to Figure 6 , to describe in detail the preferred embodiments of the present invention.

[0037] Such as figure 2Shown is a cross-sectional view of a constant conduction electromagnetic levitation track inspection vehicle. As can be seen from the figure, the running structure 2 of the maglev rail inspection vehicle provided by the present invention is fixedly installed under the compartment floor 6 of the rail inspection vehicle. A compartment 1 is installed on the compartment floor 6, and a maintenance platform 1e, a lifting maintenance platform 3, a vehicle-ground communication device 4 (including a mounting bracket), a guardrail on the maintenance platform and a front railing door are arranged at both ends of the compartment 1. 6d. Both ends of the compartment 1 are also equipped with a front door 1a with a front door, and a vehicle-mounted air-conditioning system 1c is installed on the roof of the middle part. Thus, it can be sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com