Patents

Literature

32results about How to "Exert carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

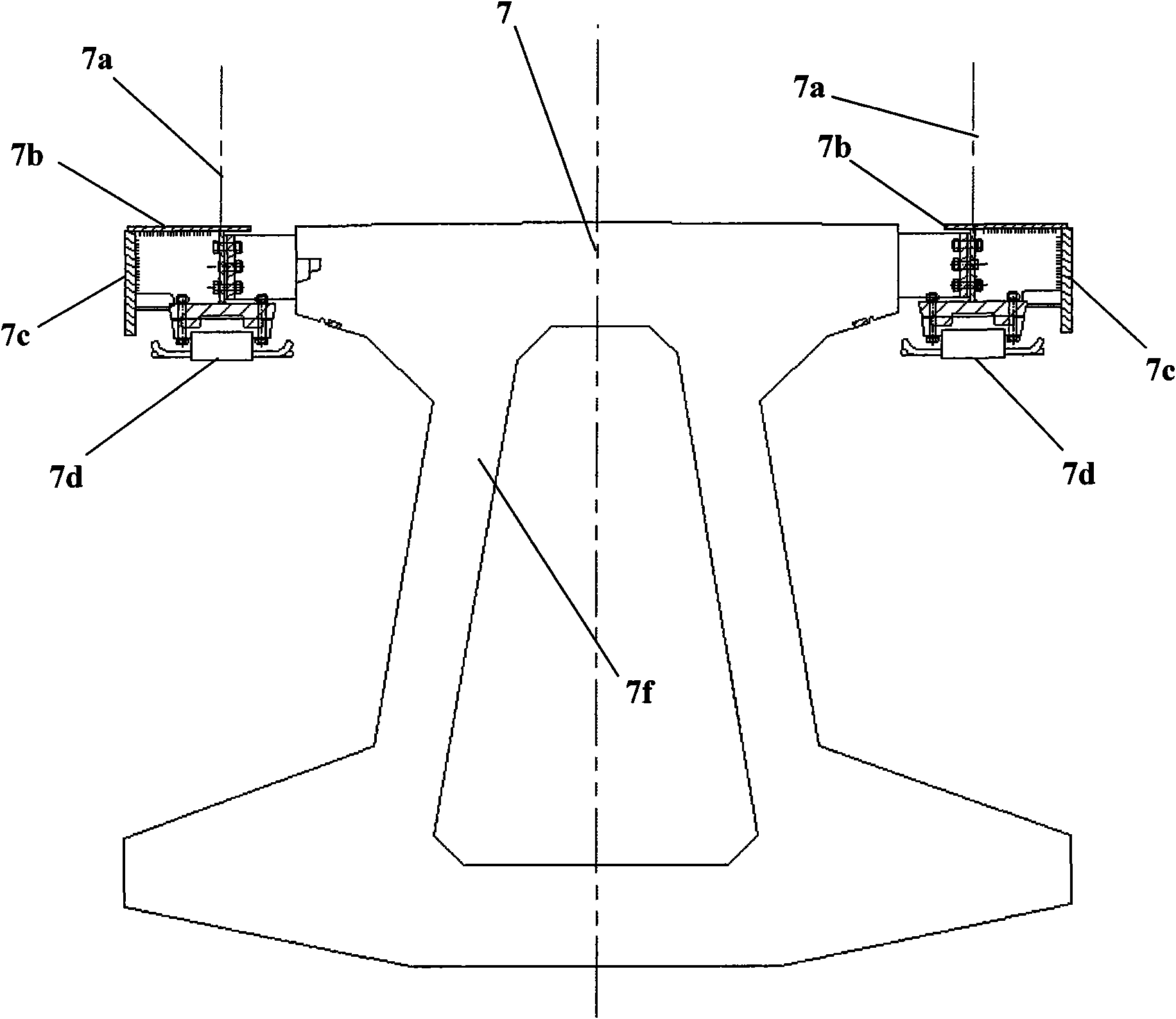

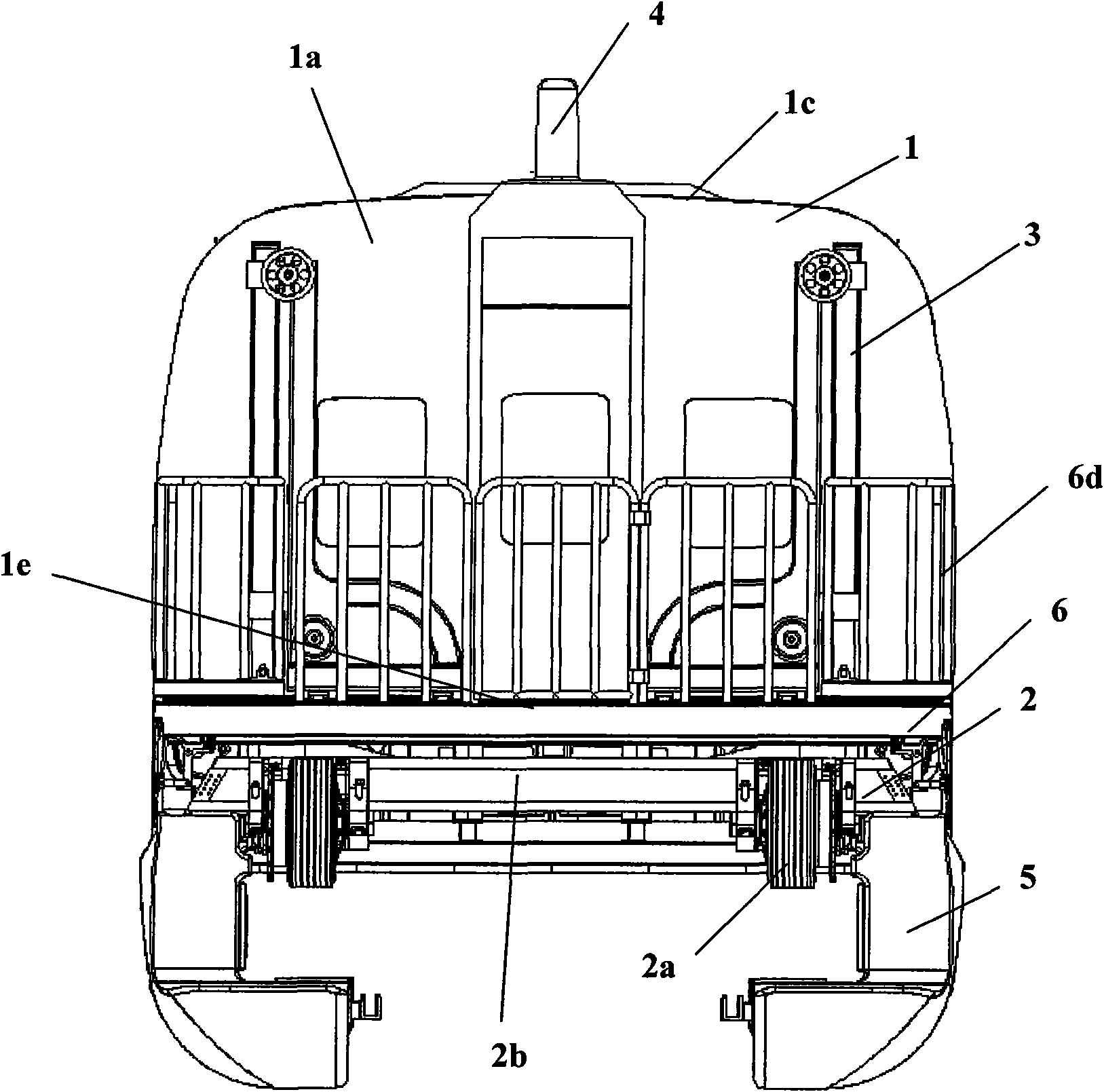

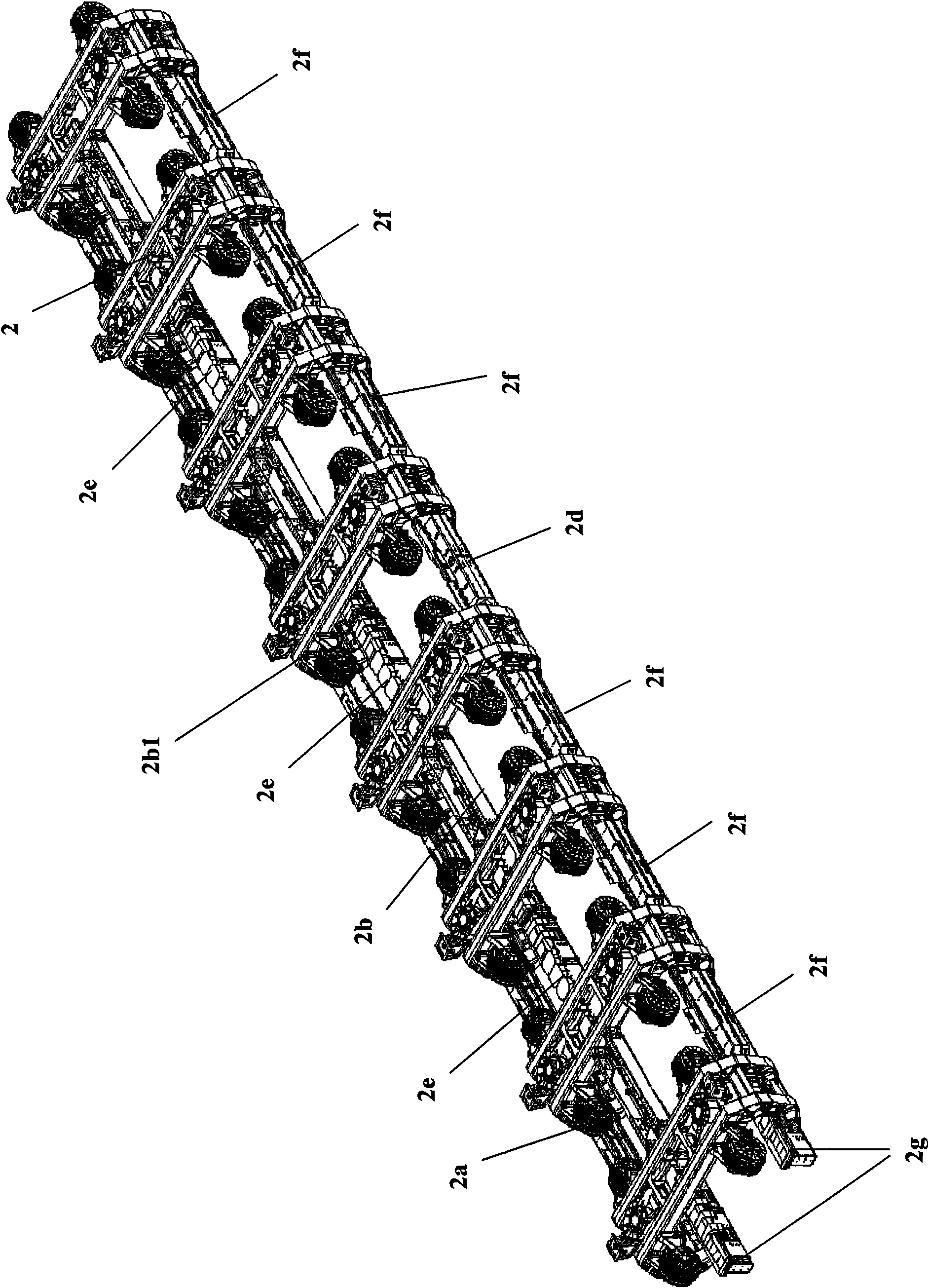

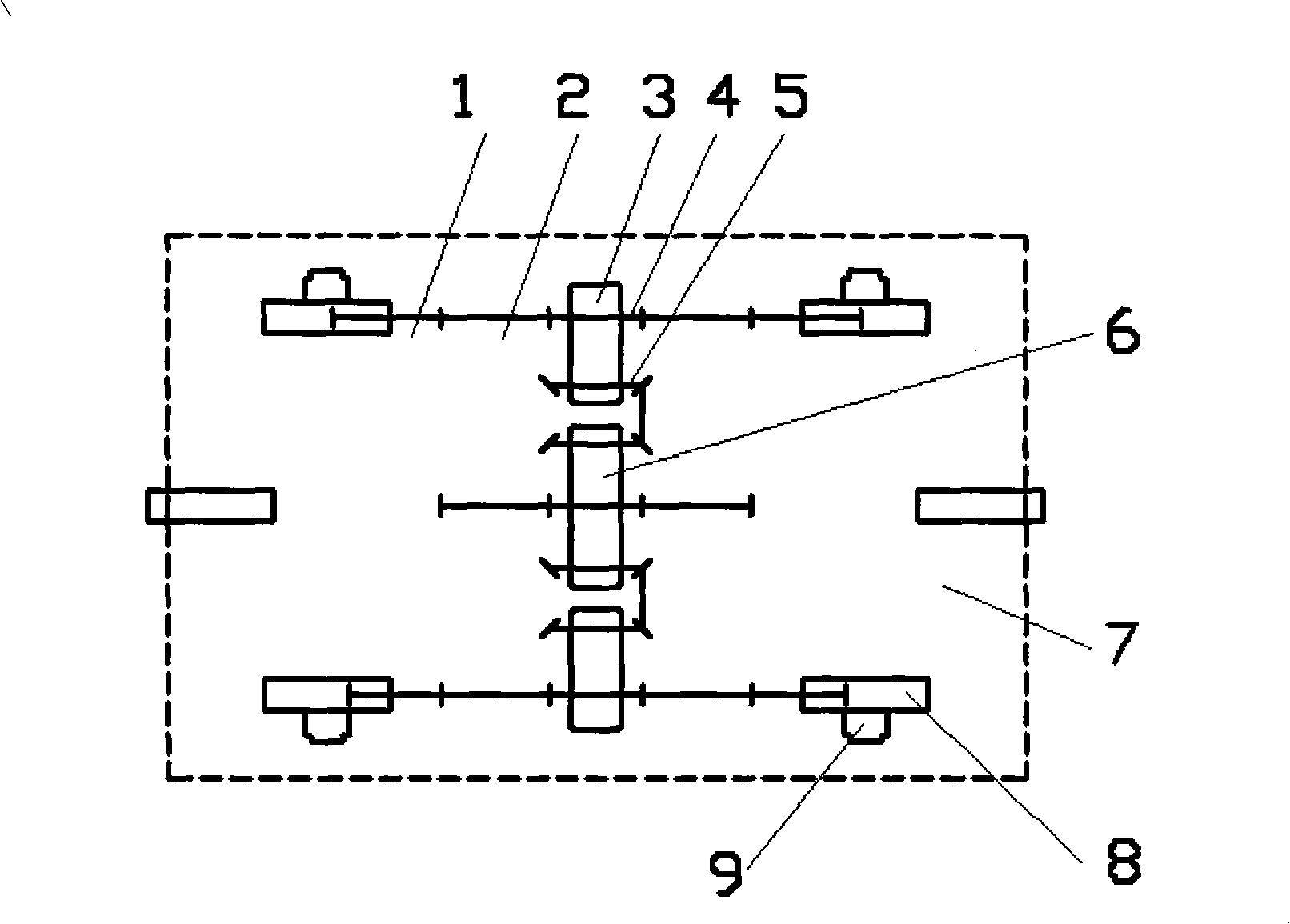

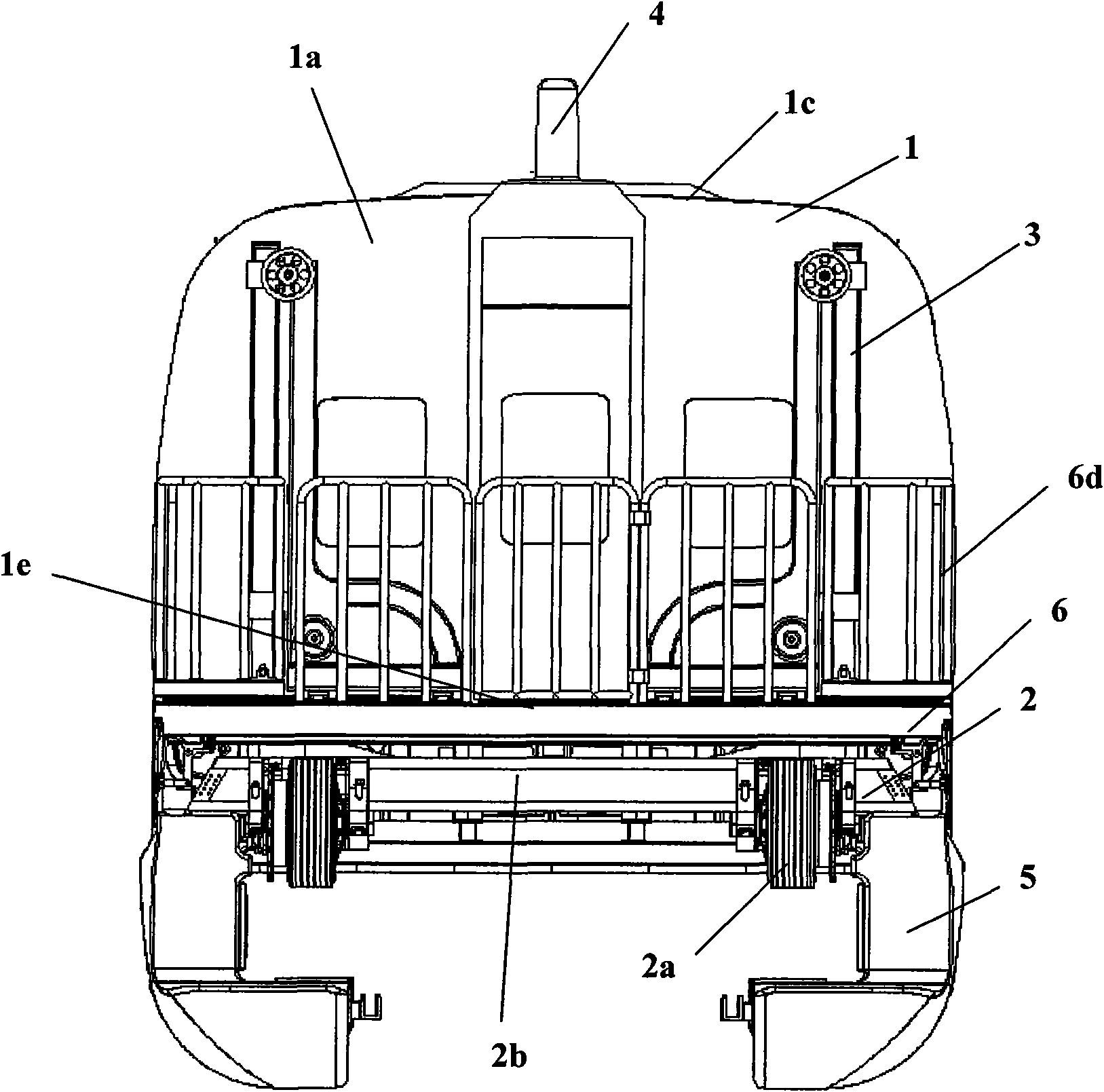

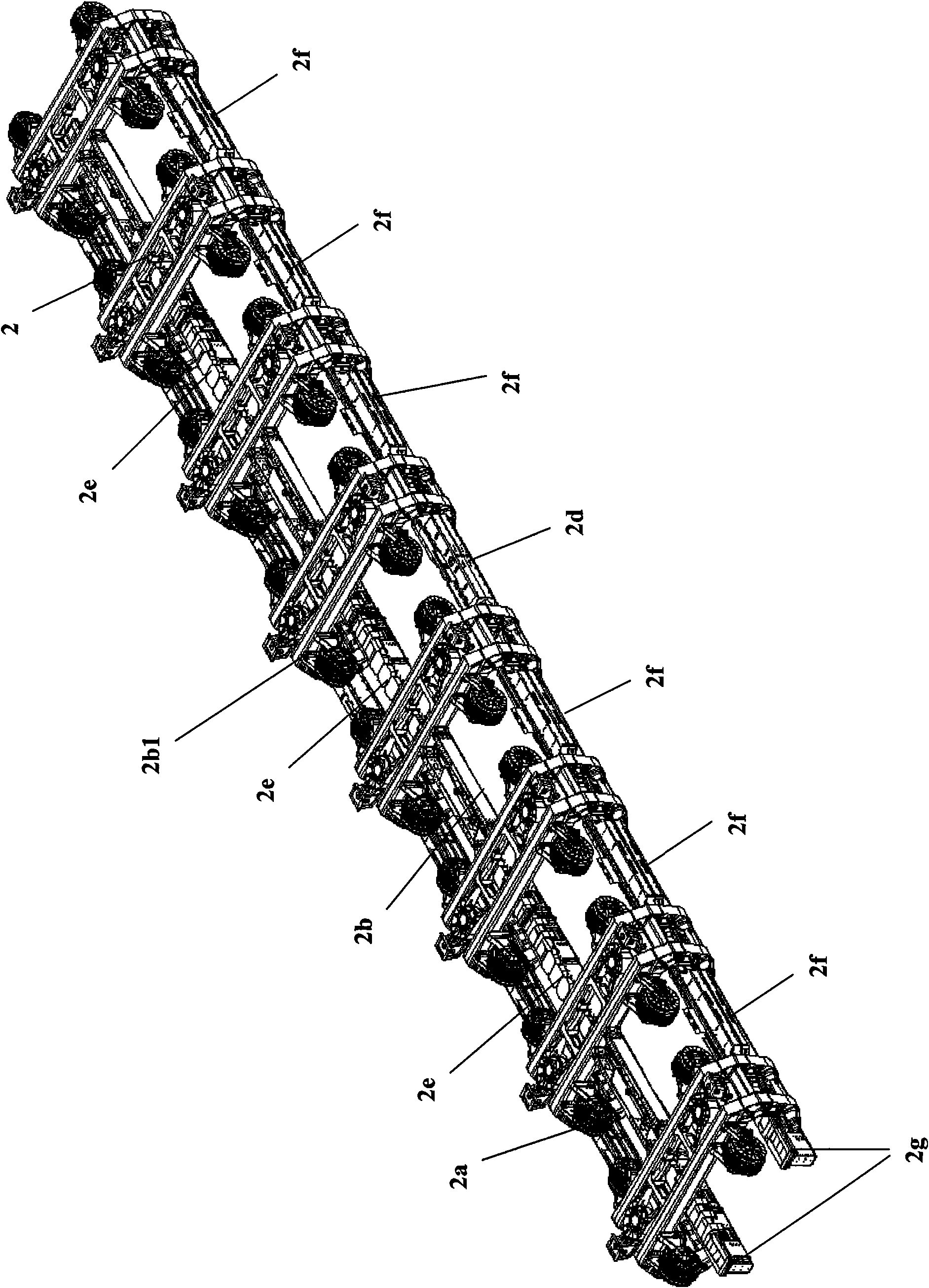

Travel structure of magnetic levitation type rail polling car

InactiveCN101624054AAchieving self-rescue abilityEfficient deliveryRailway inspection trolleysSliding/levitation railway systemsLow speedMotor drive

The invention provides a travel structure of a magnetic levitation type rail polling car, wherein the travel structure is fixedly arranged at the lower part of the bottom board of carriage of the rail polling car and comprises a plurality of floating frames which are sequentially arranged as well as a long stator linear motor traction device and an outer rotor motor driven supporting wheel device which are arranged on the floating frames; wherein the floating frames comprises a plurality of beam frames and corbel frames which are arranged at the two ends of the beam frame; the long stator linear motor traction device comprises a floating magnet module arranged on the corbel frame, a plurality of guiding magnet modules and a plurality of eddy braking magnet modules; the outer rotor motor driven supporting wheel device comprises a motor supporting wheel loading device which is arranged at the two ends of the beam frame and at the inner side of the corbel frame as well as an outer rotor motor supporting wheel arranged at the two ends of the bottom of the beam frame by the loading device. The invention can realize the compatible double traction pattern of long stator linear motor traction and outer rotor motor supporting wheel traction, so that the rail polling car can have the functions of high speed polling and low speed detection.

Owner:TONGJI UNIV

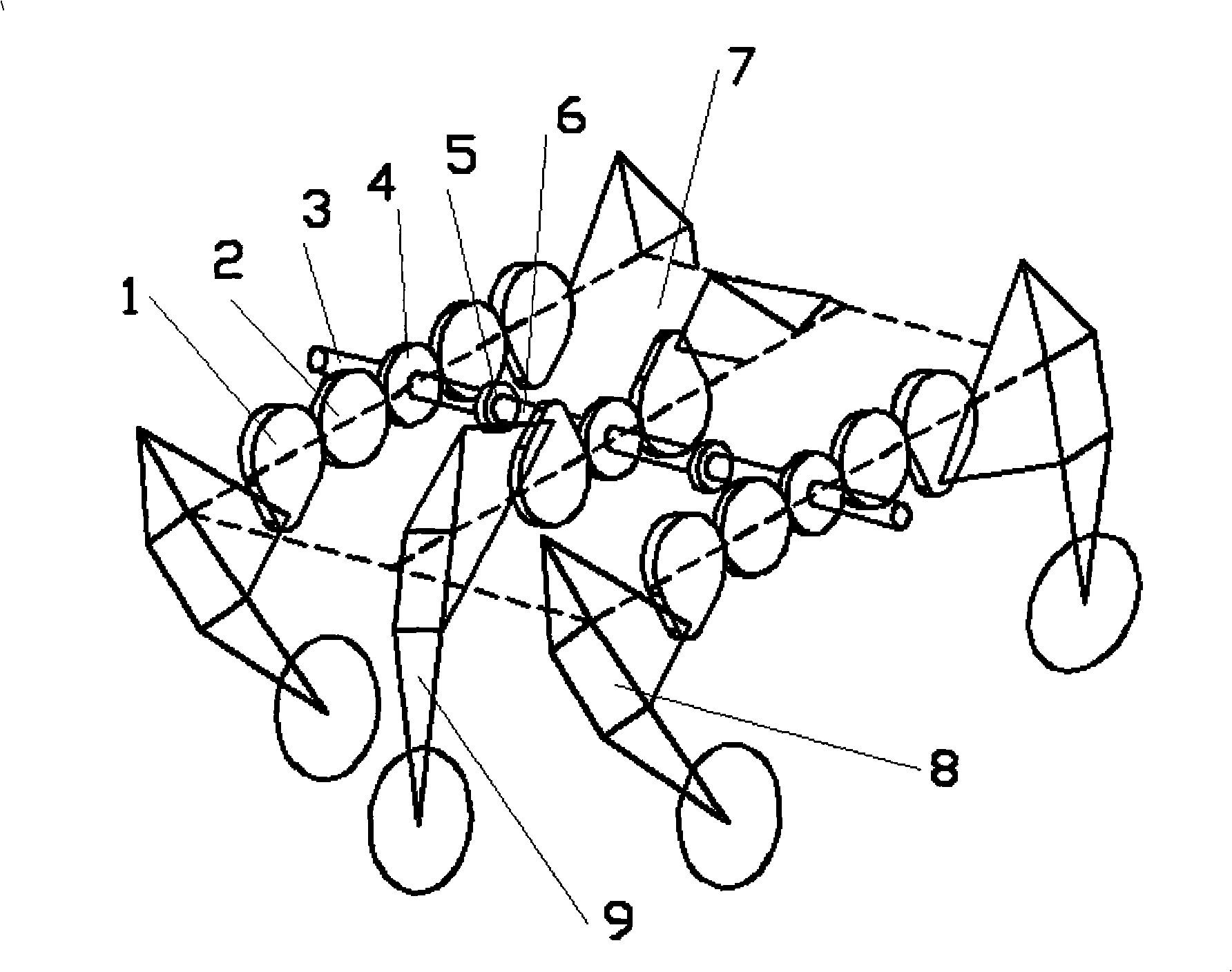

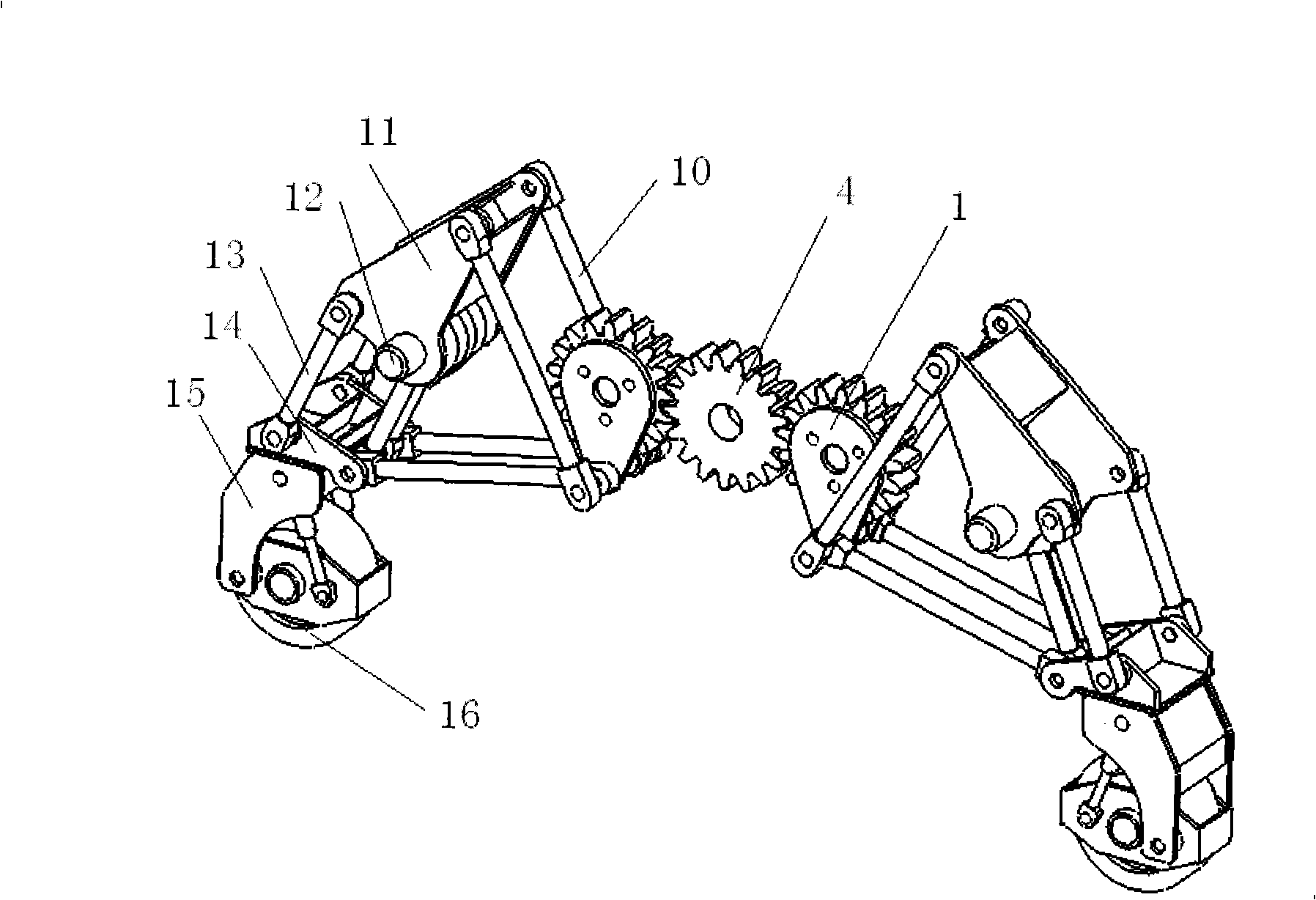

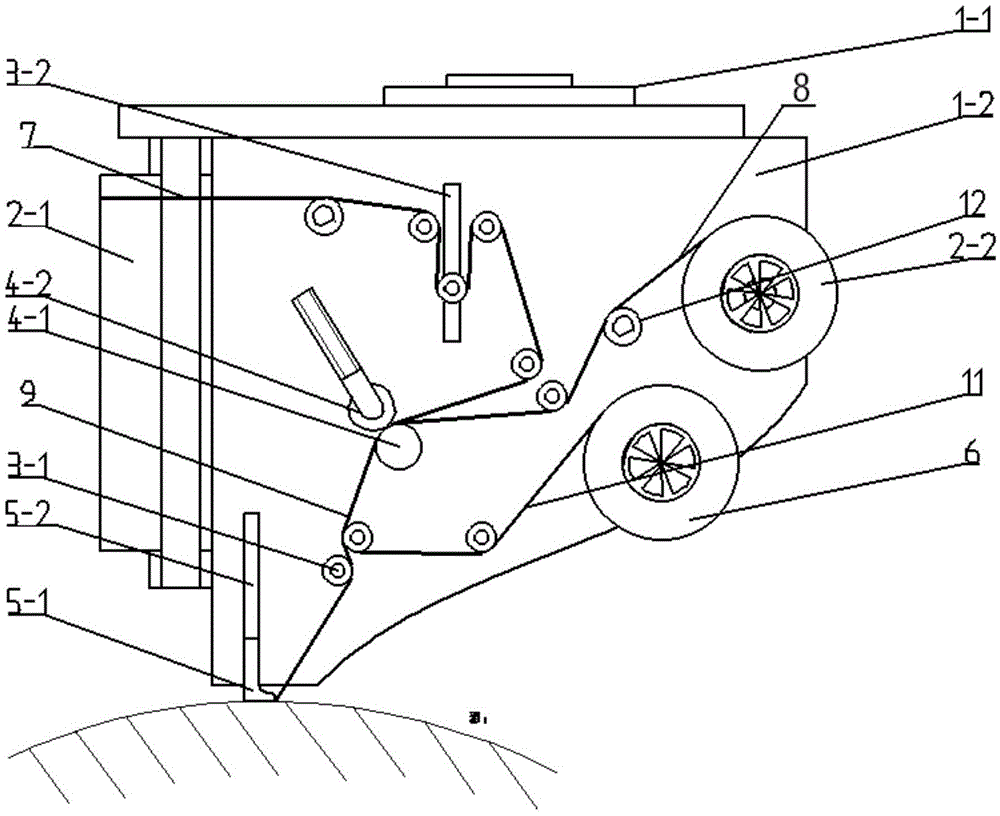

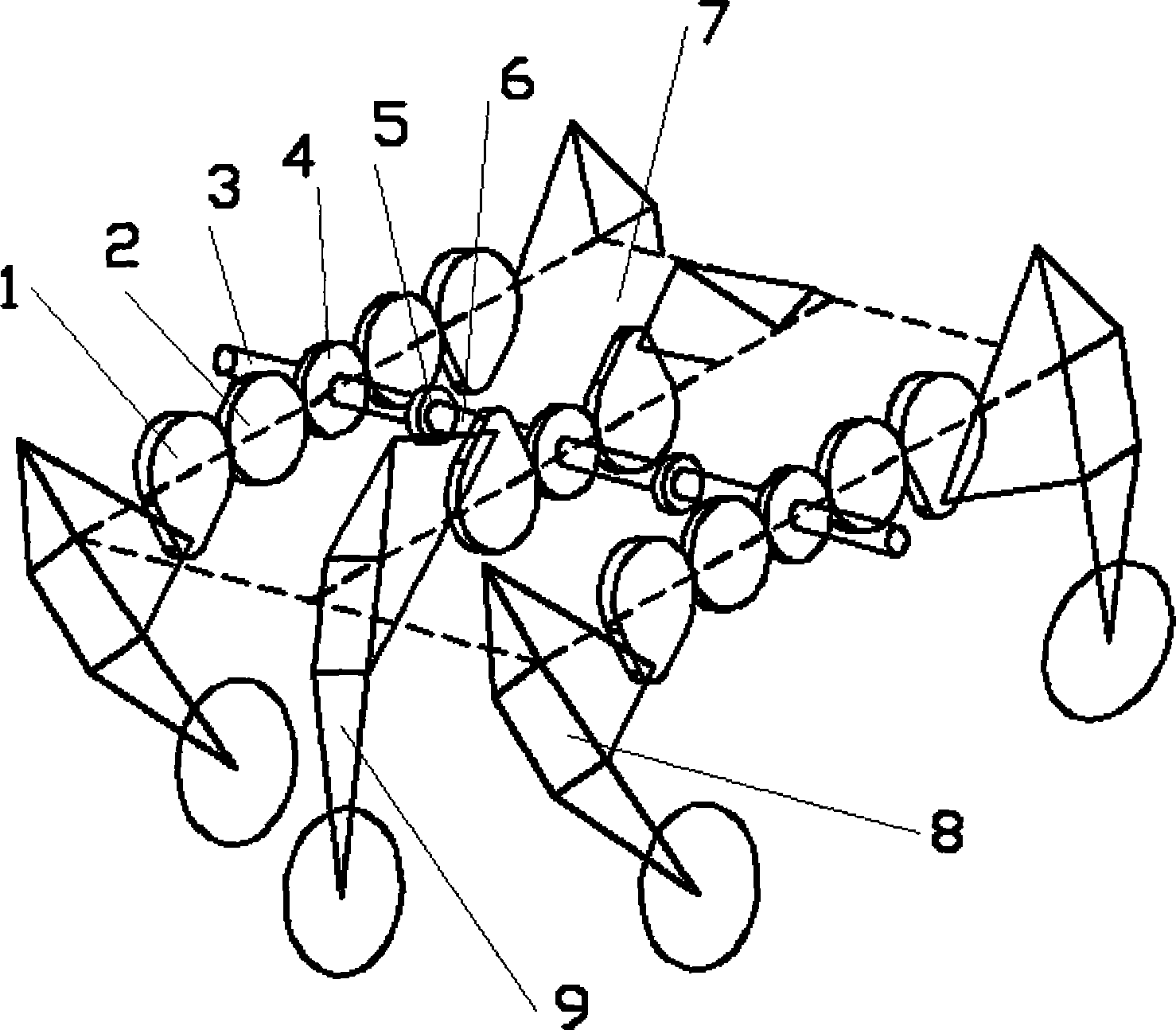

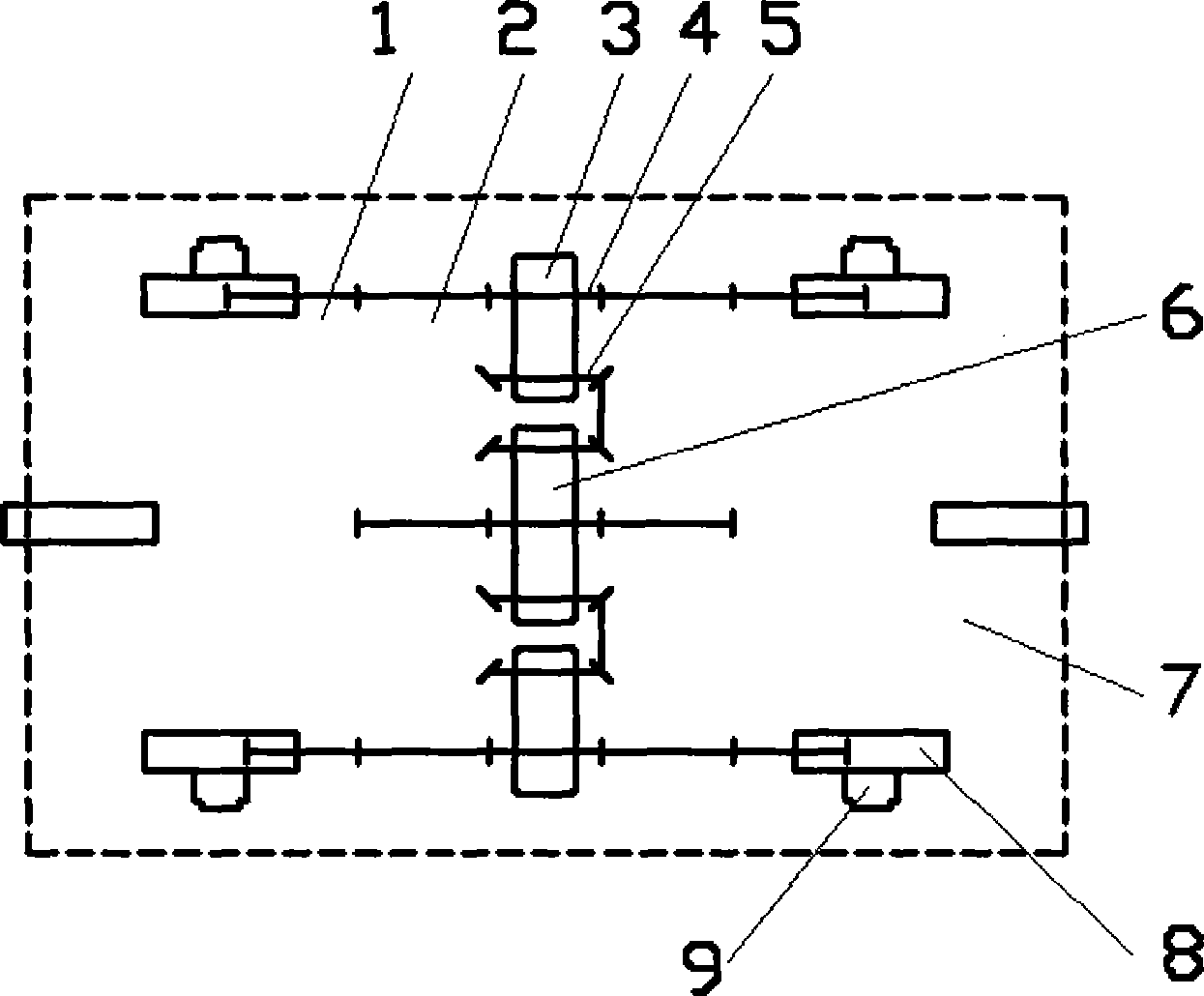

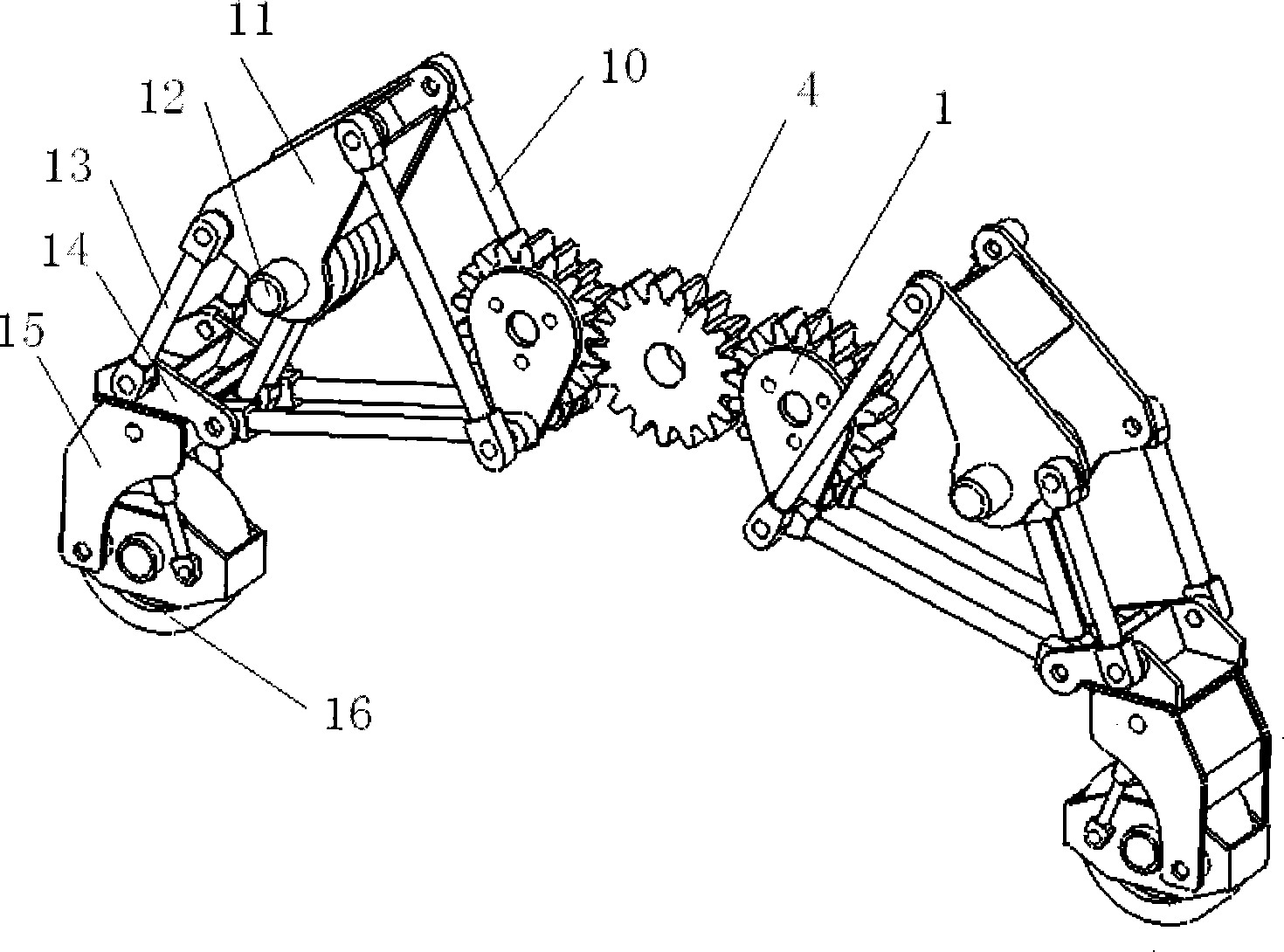

Wheeled robot with traveling system

The invention relates to a wheel type robot with a walking system, and the walking system is formed by combing foot type walking devices with a driving device and is connected with a fixing frame (7); each foot type walking device is composed of a follower gear (1), a leg type supporter and a hanging mechanism (15) provided with wheels (16). One connection point of the leg type supporter is hinged with an eccentric point of the follower gear (1), and the other connection point of the leg type supporter is hinged with the connection point of the hanging mechanism; the number of the foot type walking devices is at least two, and the hanging devices (15) of at least two foot type walking devices are provided with electric motors (19) for driving wheels (16) to rotate; the driving device is provided with a main electric motor and a main drive shaft (6) which is provided with a main drive gear (4) engaged with the follower gear (1). The wheel type robot with the walking system has the characteristics of high motion velocity, simple control and flexible turning, and has the function of foot walking, so that the robot has more adaptive capacity to the ground.

Owner:WUHAN UNIV OF TECH

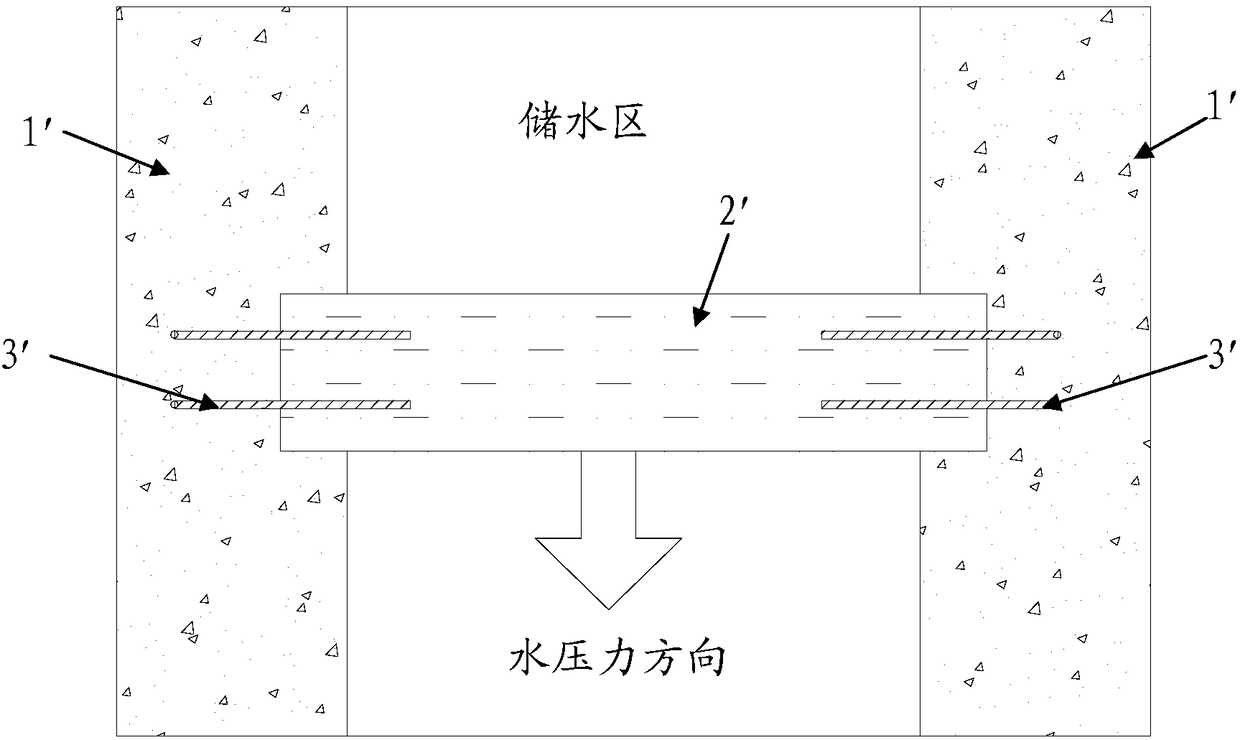

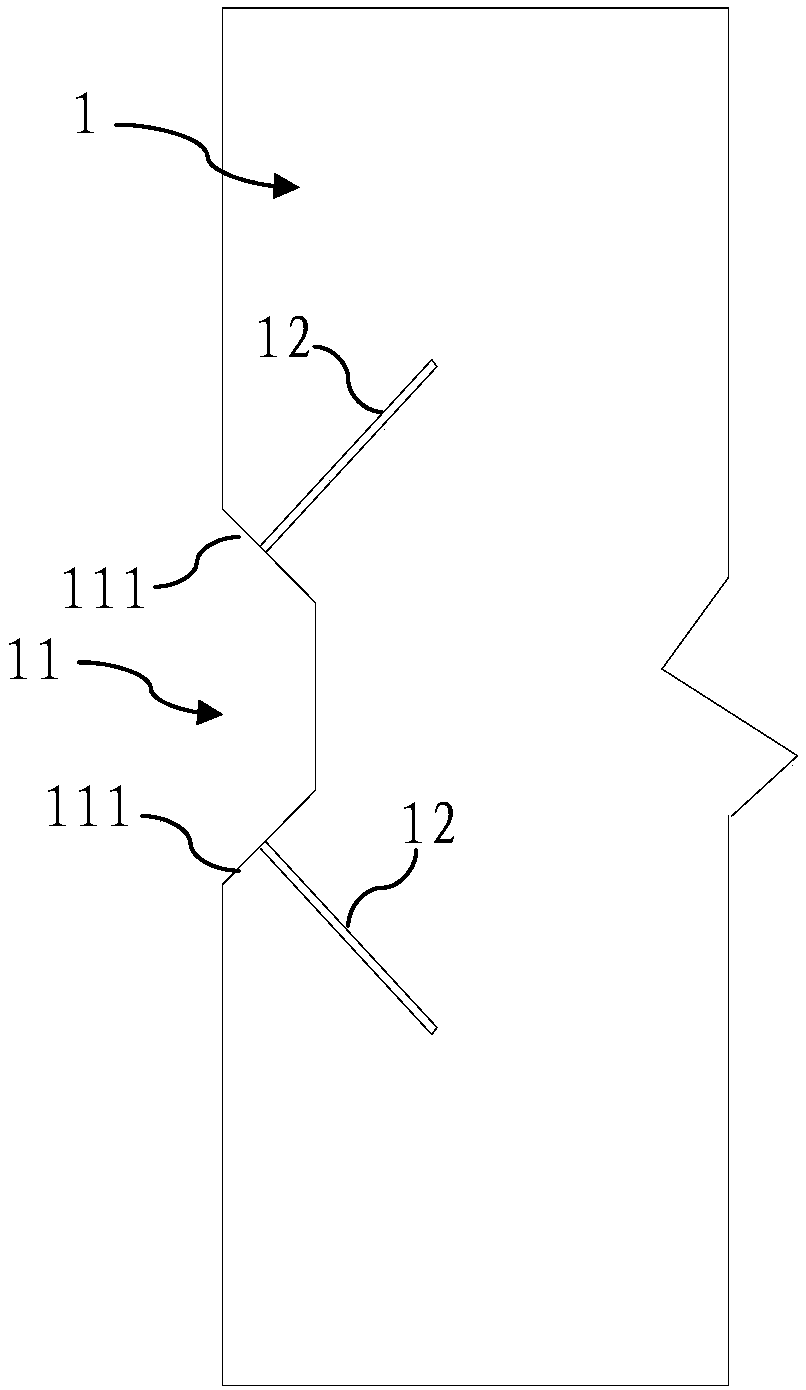

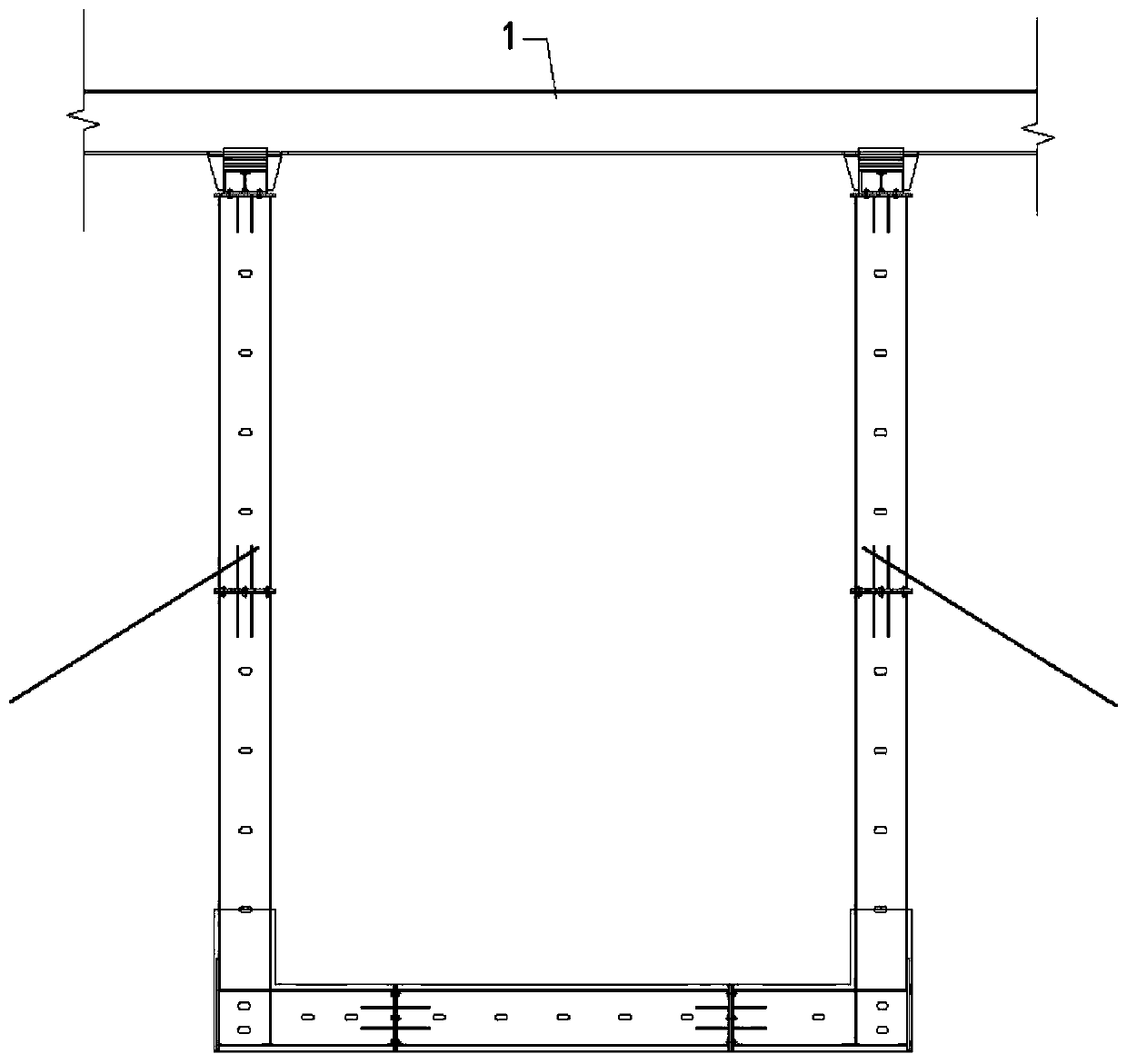

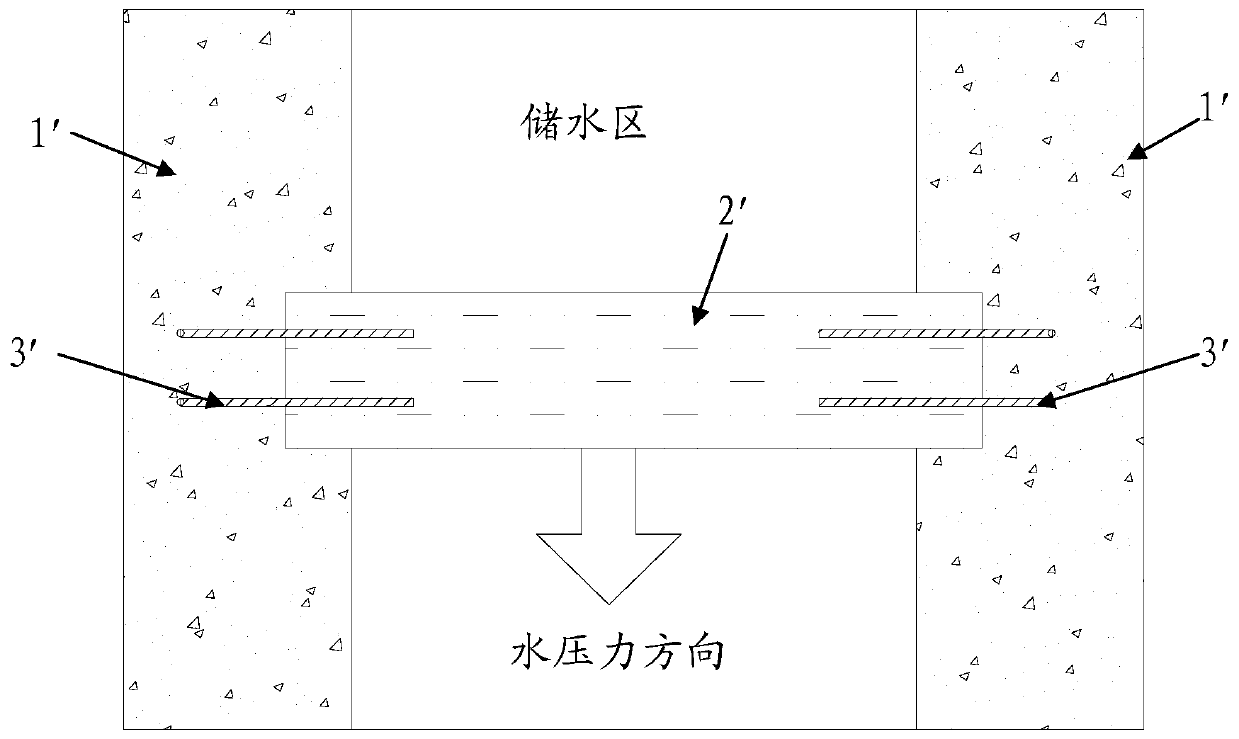

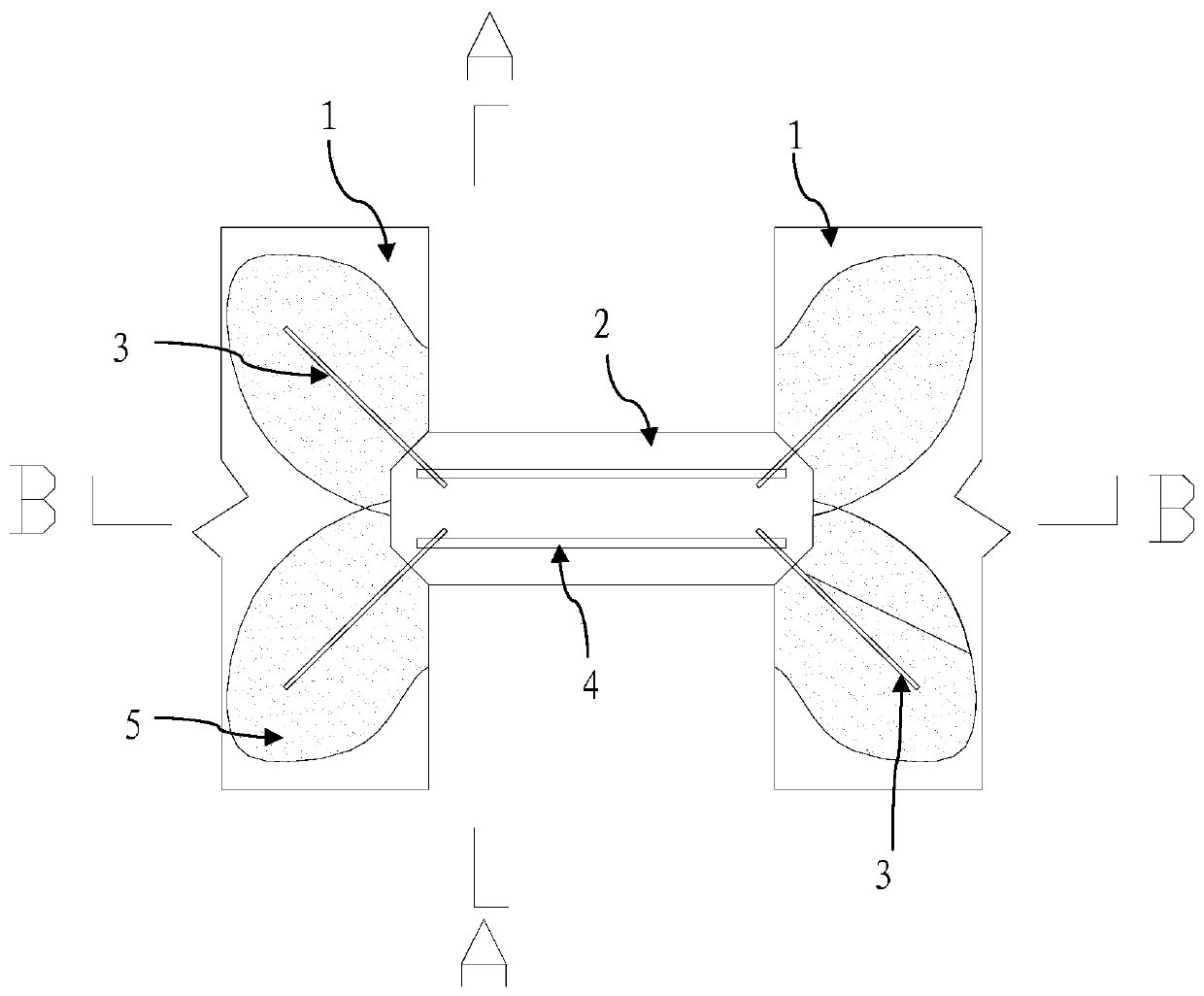

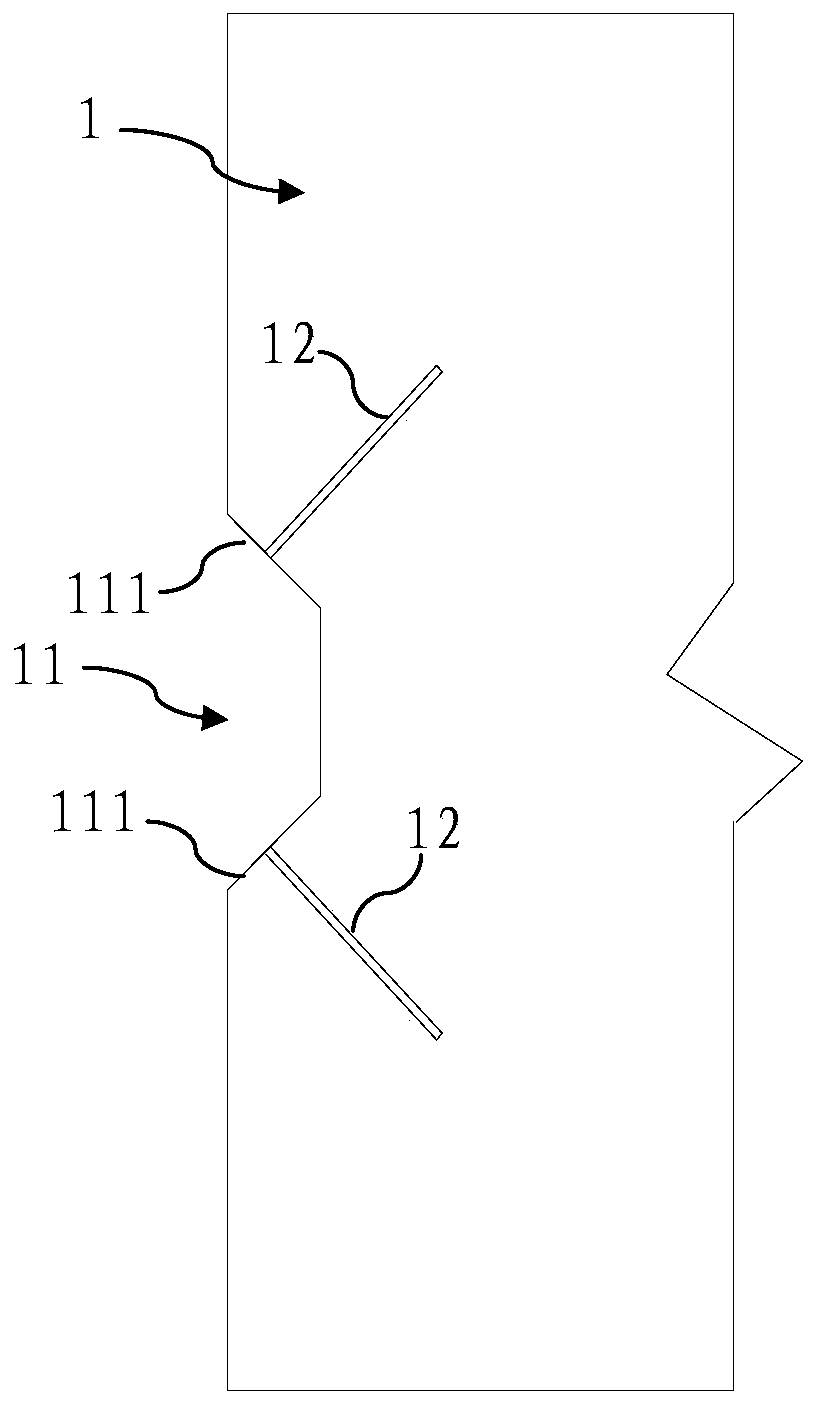

Underground reservoir artificial dam body and coal pillar dam body connecting structure and construction technology thereof

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

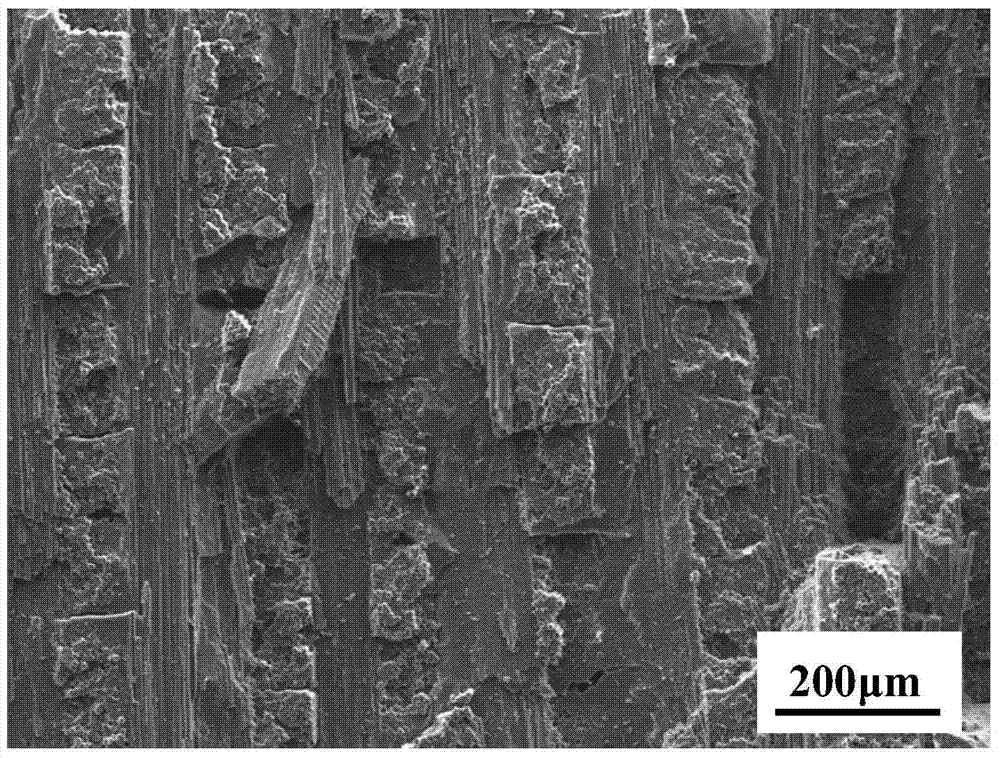

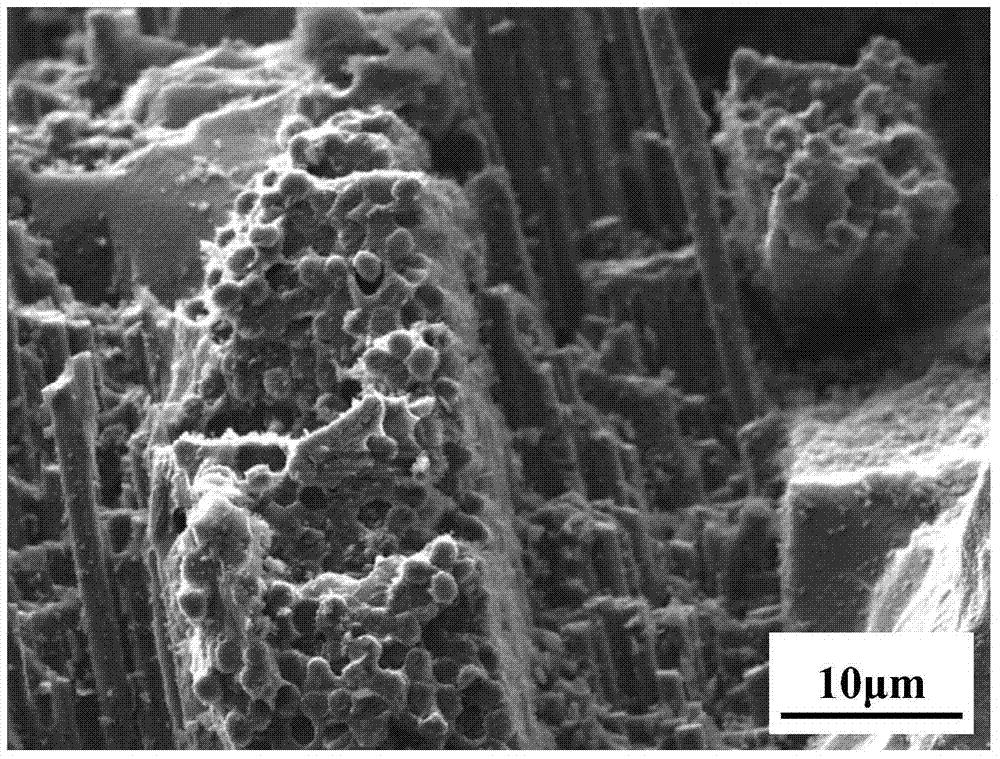

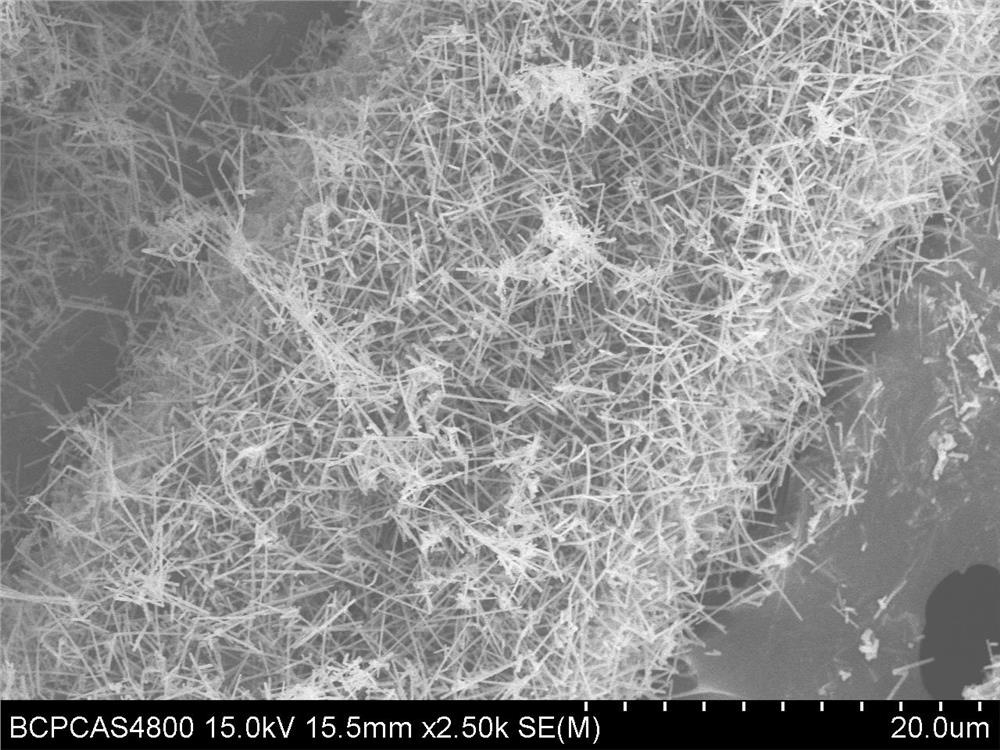

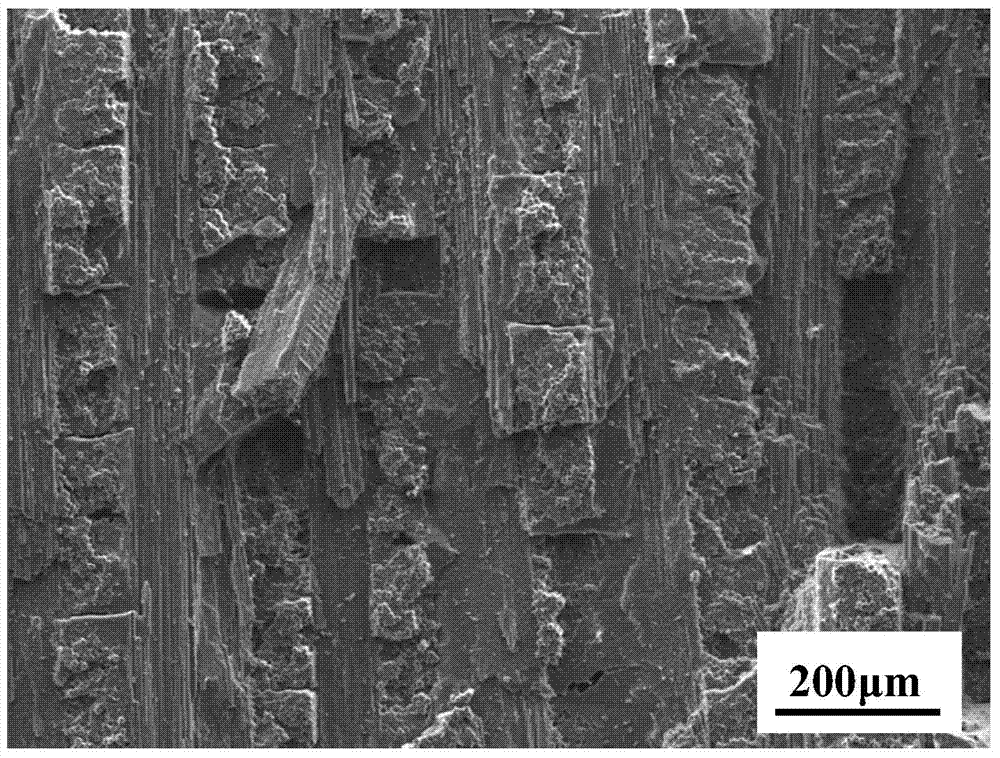

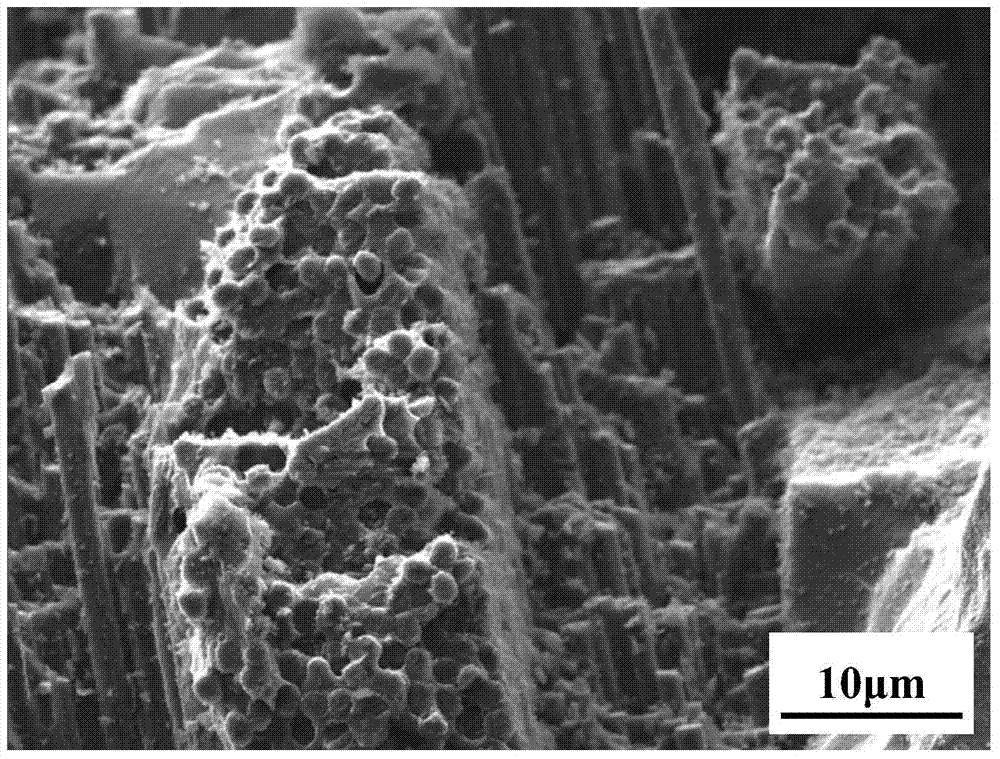

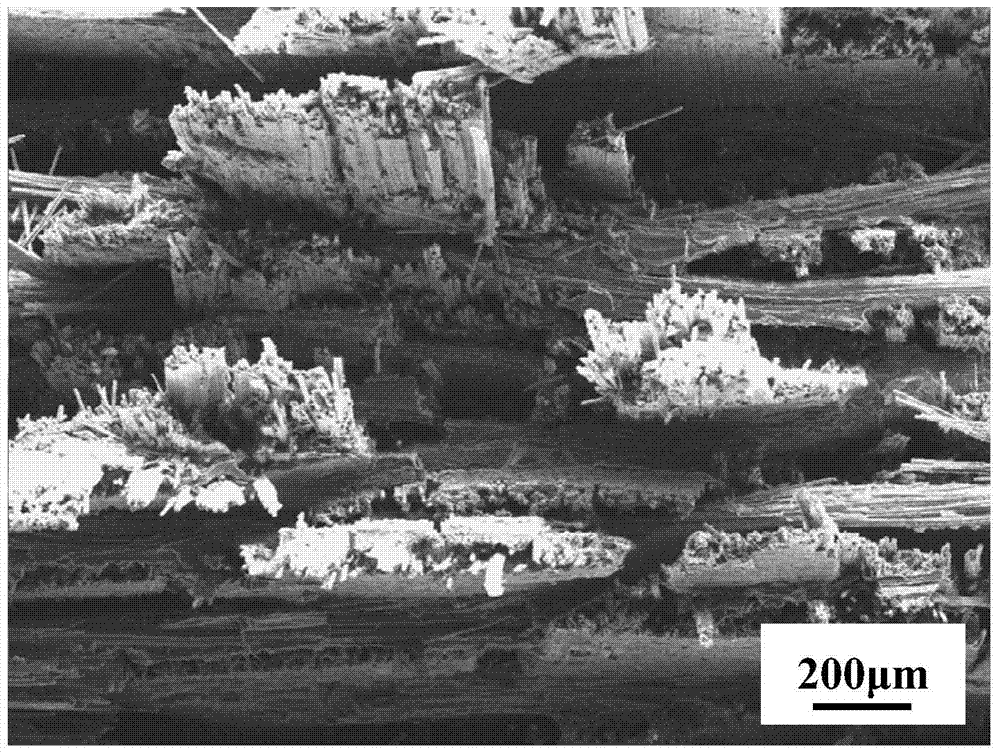

Method for improving binding strength of two-dimensional carbon/carbon composite material

The invention relates to a method for improving the binding strength of a two-dimensional carbon / carbon composite material so as to improve the tensile strength of the material in the horizontal direction, belonging to the technical field of heatproof bearing integrated carbon / carbon composite materials. The two-dimensional carbon / carbon composite material prepared by the method is moderate in binding strength of fibers and matrix interfaces, the fracture appearance is rough, multi-layered and multi-size fibers can be pulled out, the bearing and the force conduction effect of the fibers are brought into good play, the tensile property of the material is greatly improved, and the tensile strength is 137-301MPa, that is, the tensile strength is improved by more than 50% when being compared with the original tensile strength of 92MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

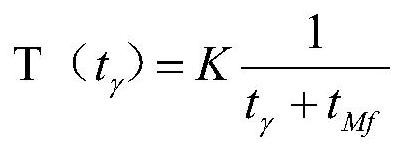

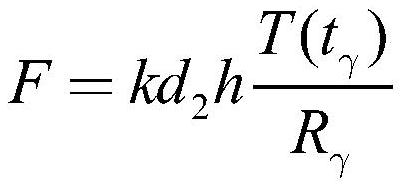

Detection method of carrier pile bearing force

ActiveCN107268690AAvoid excessive settlementImprove bindingFoundation testingSoil propertiesVertical displacement

The invention provides a detection method of carrier pile bearing force. The detection method is characterized in that a heavy hammer is used for hammering a carrier pile, the hammering energy is controlled to enable a pile body to generate vertical displacement, and the vertical bearing capacity of the pile is judged through a measured displacement numerical value and the soil property of the bearing course at the pile end. The detection method includes the particular steps that (1) a pile head of the carrier pile needing to be detected is subject to strengthening protection; (2) the heavy hammer is used above the pile head by a certain height and freely falls to hit the pile head, the hammering energy is controlled to enable the pile body to generate downward vertical displacement, and the displacement numerical value is measured and recorded; (3) hammering operation in the step (2) is repeatedly carried out, and when the total energy of multiple times of hammering reaches a set value, hammering is stopped, and the total displacement numerical value of the pile body is recorded; and (4) the carrier equivalent calculation area Ae value is judged through the total displacement numerical value and the soil property of the bearing course at the pile end, and the vertical bearing capacity of the pile is calculated according to the Ae value. The detection method has the beneficial effects of being accurate in result, efficient, rapid and low in cost.

Owner:王继忠 +1

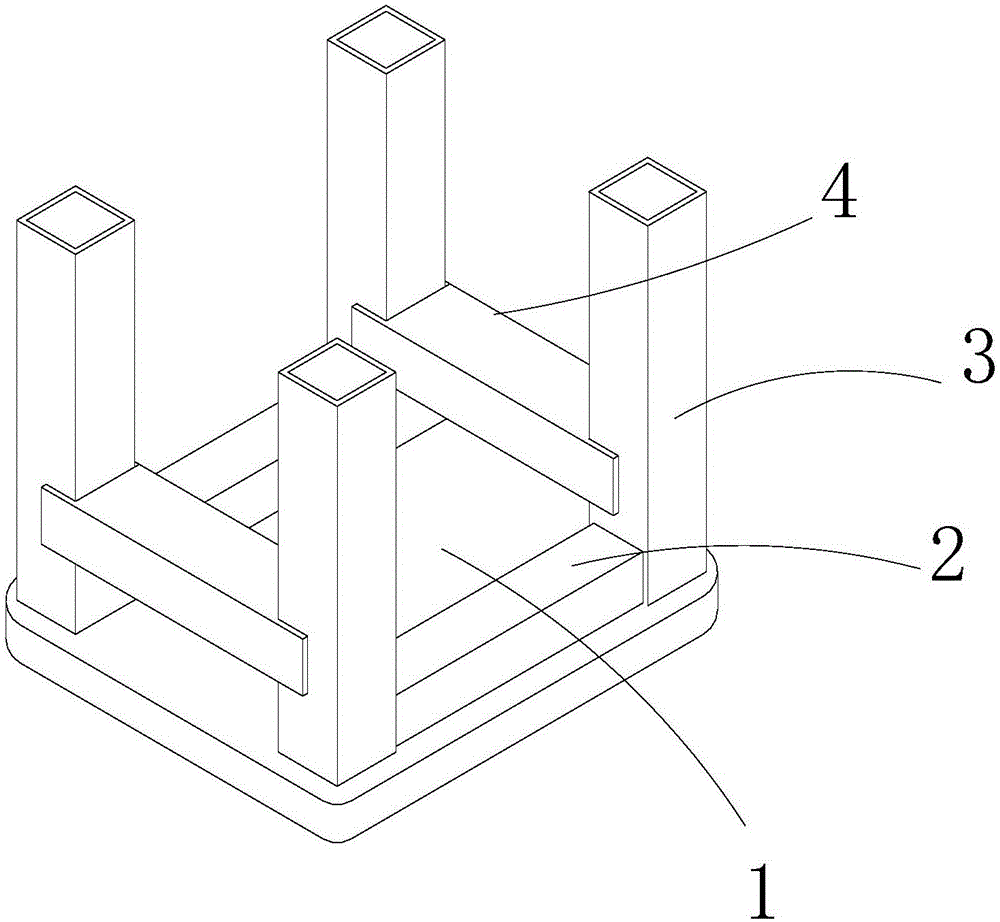

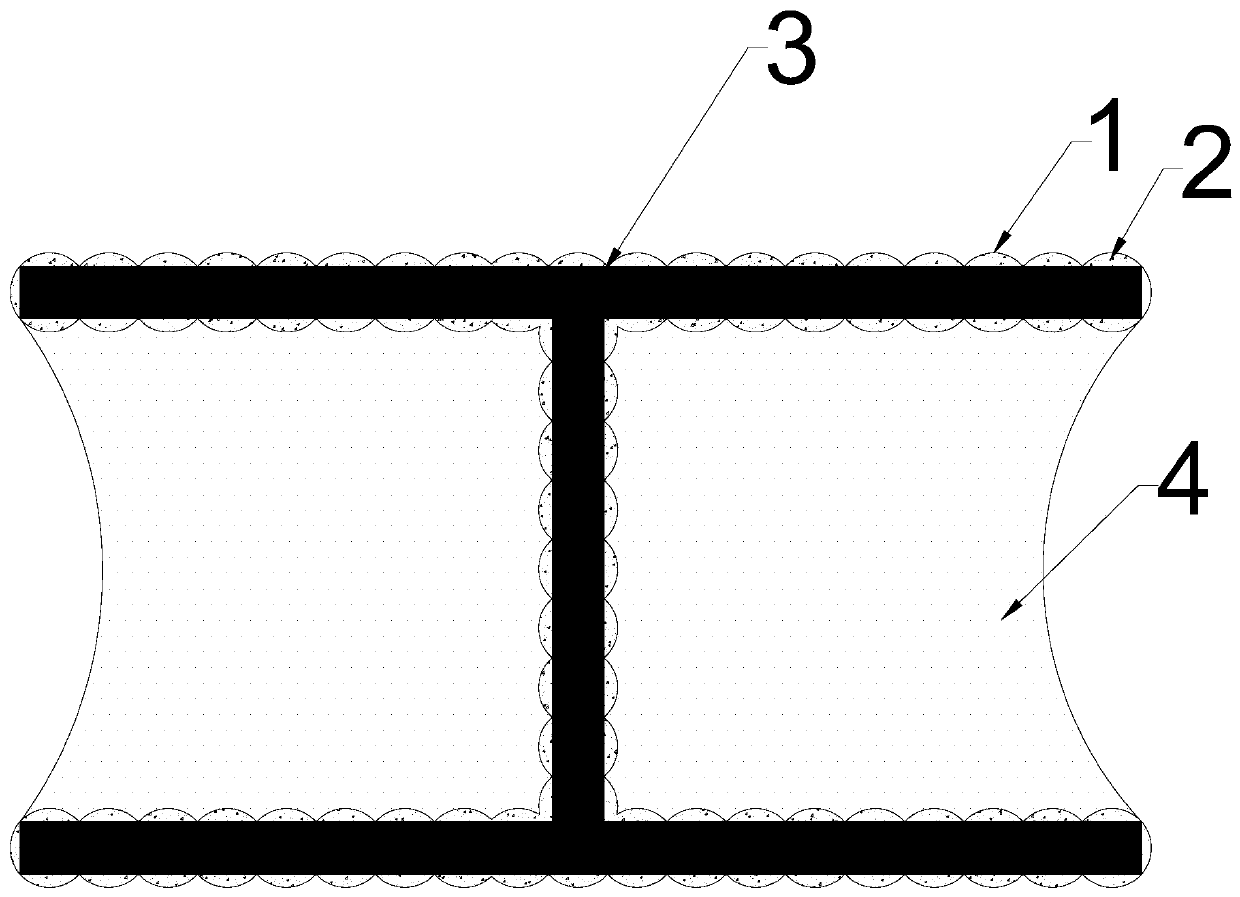

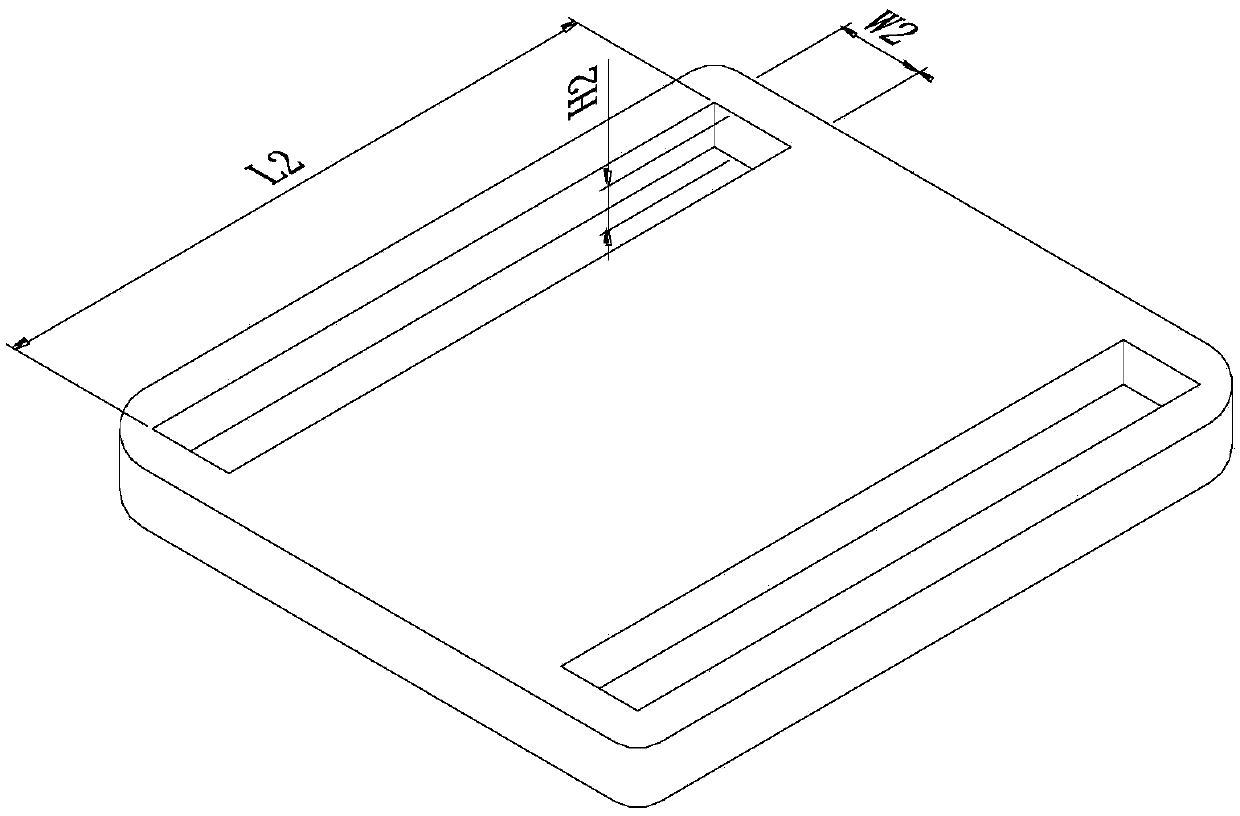

Paper tube furniture manufacturing process and small square stool manufactured through process

ActiveCN106239684AStability issues manifestExert carrying capacityWood working apparatusEngineeringFurniture manufacturing

The invention provides a paper tube furniture manufacturing process and a small square stool manufactured through the process. Paper tube furniture comprises a face plate used for bearing and containing, and 2N hollow square tube supporting legs which are arranged below the face plate and used as supports. N rectangular connection pipes are arranged on the lower surface of the face plate and are embedded in blind grooves correspondingly formed in the lower portion of the face plate. Mortises matched with the sections of the supporting legs are formed in the lower portions of the connection pipes, the pipe walls of the supporting legs are connected in the mortises in an inserted manner so that the supporting legs can be perpendicularly fixed to the connection pipes, a connection beam is fixed between every two supporting legs which are adjacent but not located below the same connection pipe, and overall damp-proof treatment is conducted. The structure is simple, the dynamic stability is good, the caliber or wall thickness of paper tubes or the strip number of the connection paper tubes can be regulated according to requirements of clients and bearing so that different use requirements can be met. Assembling is convenient, transportation is convenient, and cost is saved.

Owner:GUANGZHOU HAIFANG TECH CO LTD

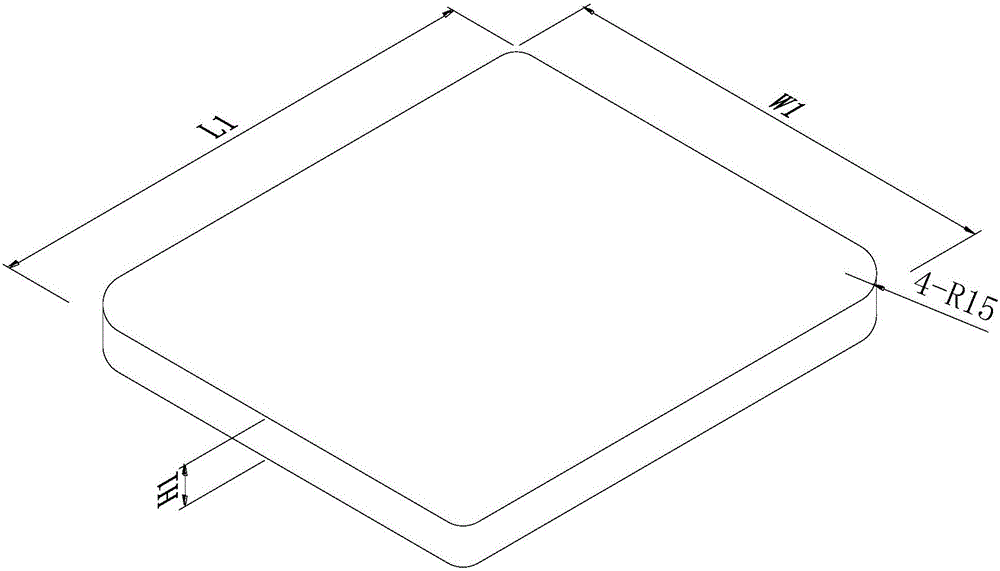

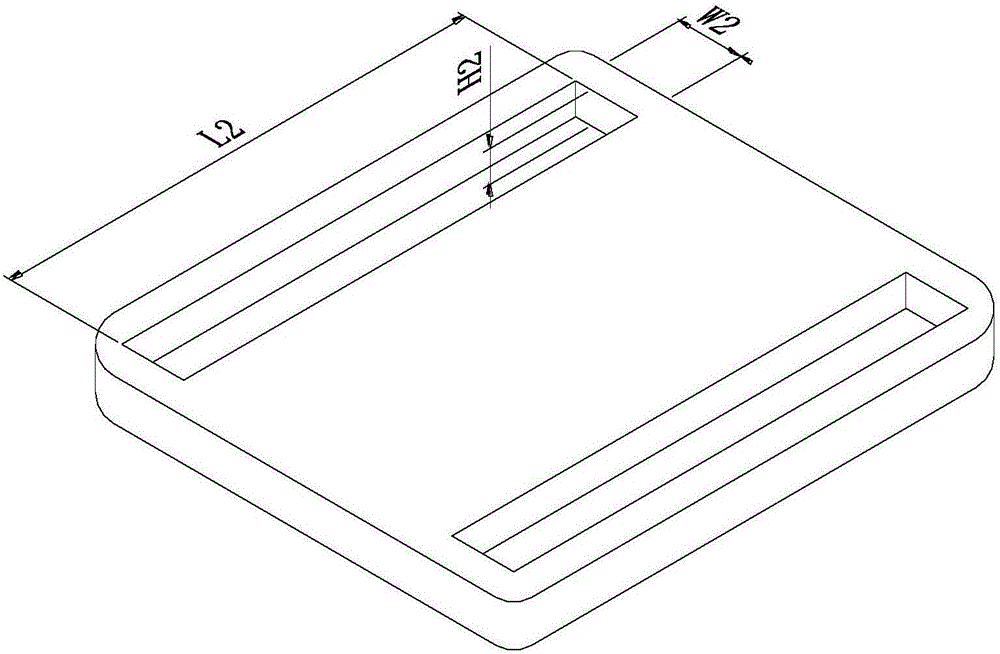

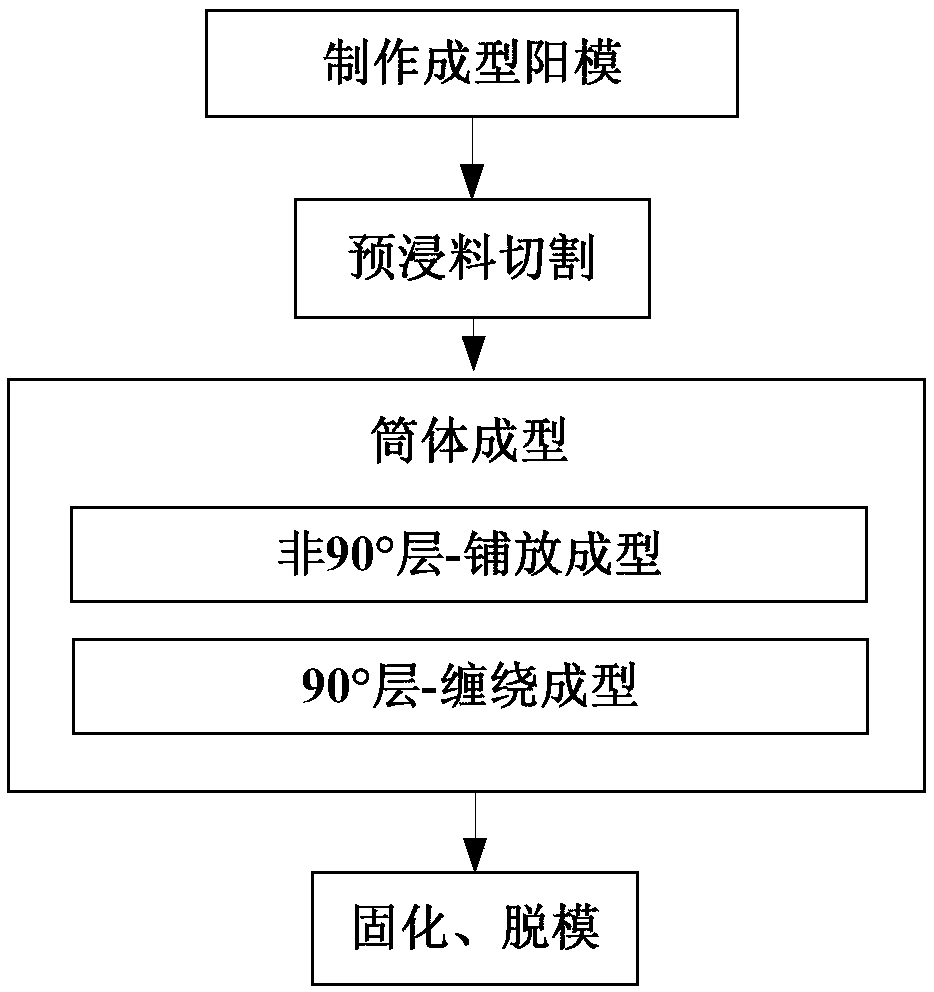

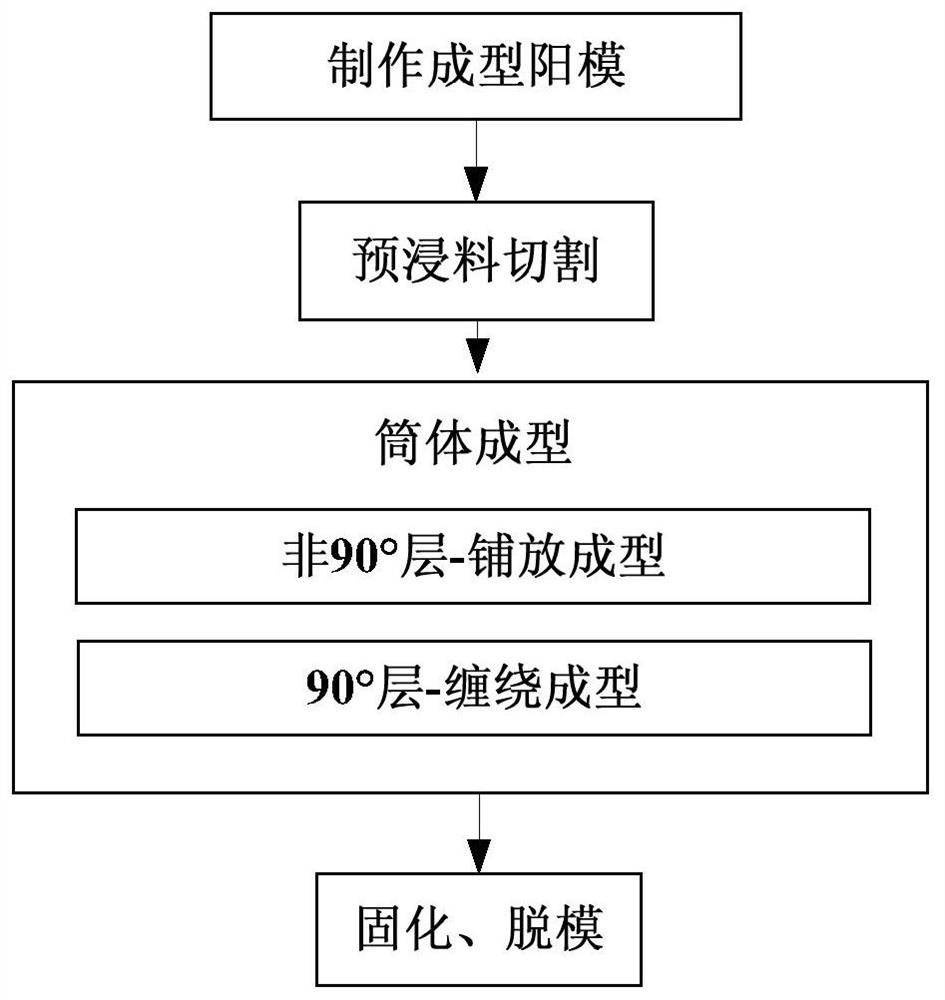

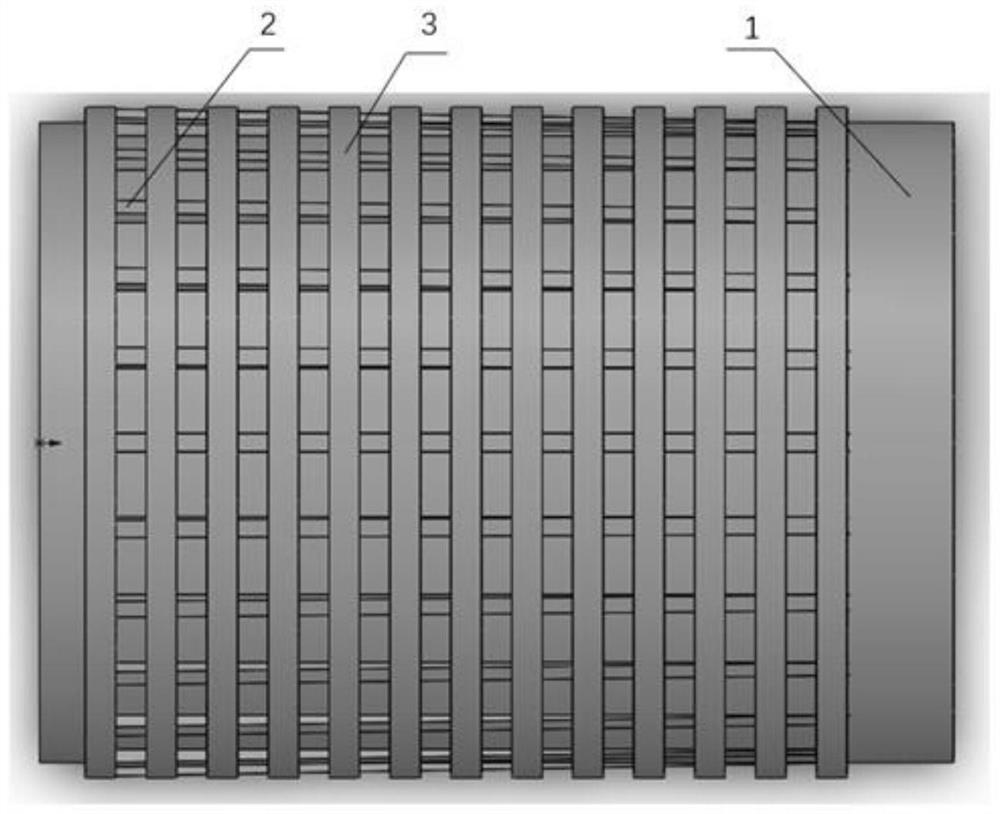

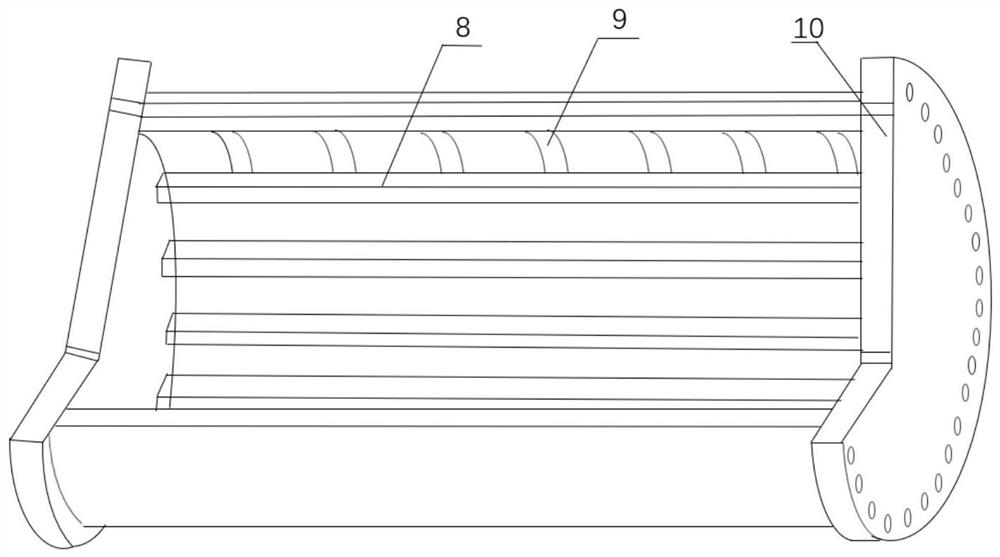

Forming method of cylindrical composite component

ActiveCN108995240AExert carrying capacityTape laying and winding process matchingPositive pressureConductor Coil

The invention relates to a forming method of a cylindrical composite component and belongs to the technical field of composite preparation technologies. Positive pressure is applied in a non-90-degree-layer automatic laying process to form forming pressure. The laying tape forming pressure and winding tension are both converted into forming pressure, coordinated control is performed according to the provided forming pressure, the winding tension and the laying tape pressure are adjusted according to requirements of the width of an actual prepreg tape, the total thickness of a laying layer, thediameter of a product and the like, so that the forming pressure is basically consistent, and the matching of the laying tape winding technology is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

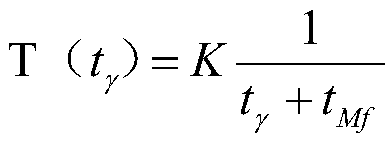

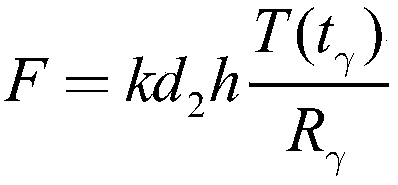

A device and method for automatic film laying of composite material preforms

The invention discloses a device and method for automatically laying a composite preformed body in a film-mounting manner. The device is characterized in that a supply system, a hot press roll system, a laying compression and pressure adjusting device and a conveying guide wheel are arranged on a rack. The method comprises the following steps: conveying fibers and resin films supplied by the supply system to the hot press roll system for pressing the fibers and the resin films into half prepreg tapes, conveying the half prepreg tapes to the laying compression and pressure adjusting device, enabling a laying arm of a robot to drive the rack for driving the laying compression and pressure adjusting device to lay the half prepreg tapes on a core mold, and adjusting the laying pressure and the laying path in real time as needed to obtain the preformed body. According to the device and the method, the fiber laying angle can be changed according to the needs of the laying path, the fiber-resin ratio of the composite preformed body can be accurately controlled, the subsequent processing processes of the preformed body and the material waste are reduced, the laying quality of the preformed body is high, the compatibility between the preformed body and other composite material forming process is good, and various preformed bodies with different fiber / resin systems can be formed.

Owner:陕西普立通复材科技有限公司

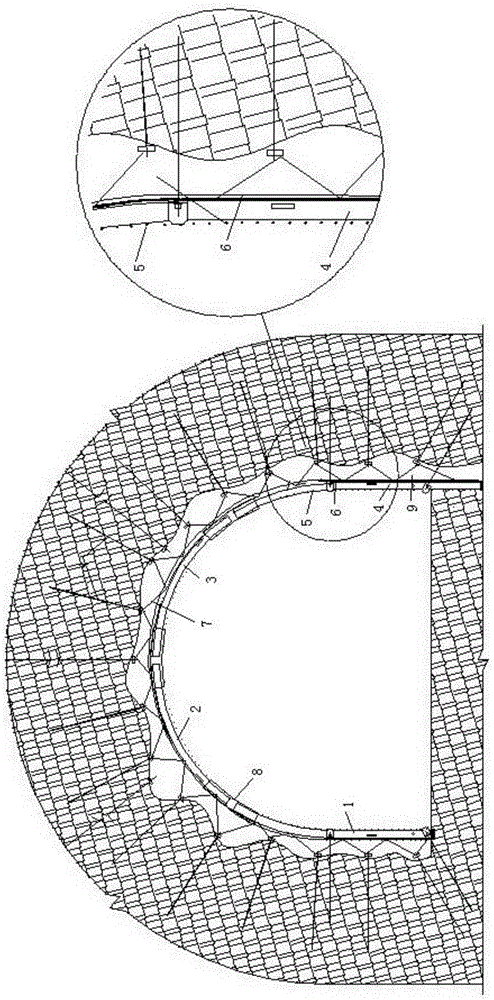

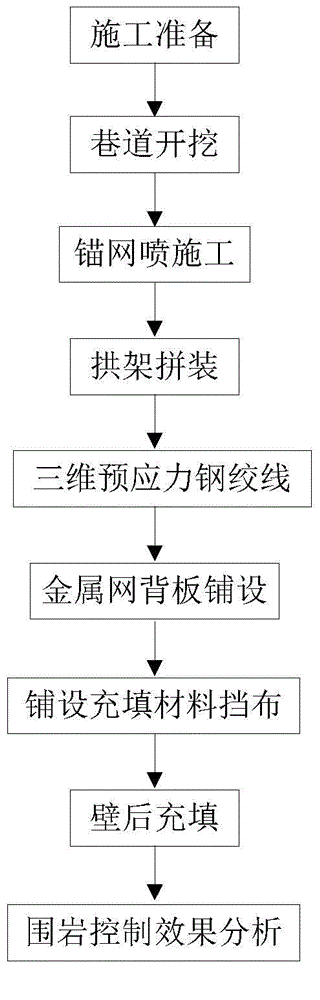

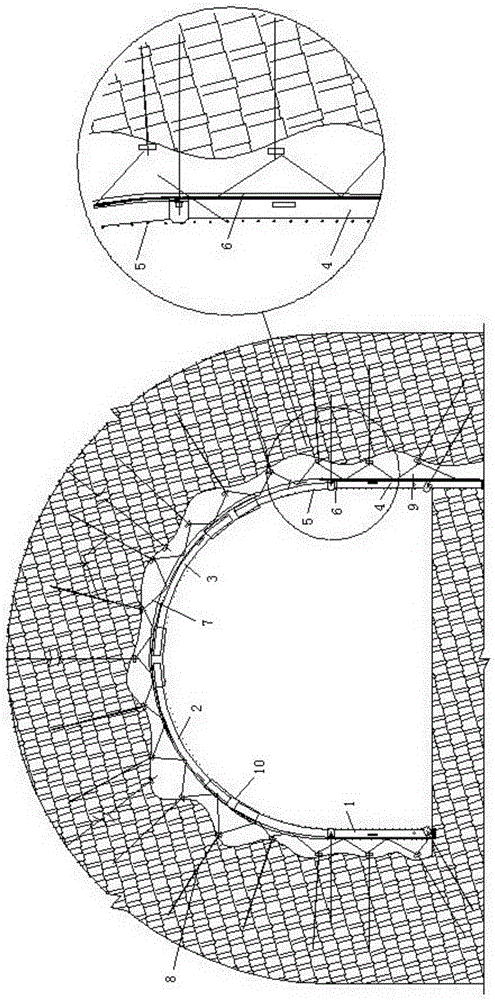

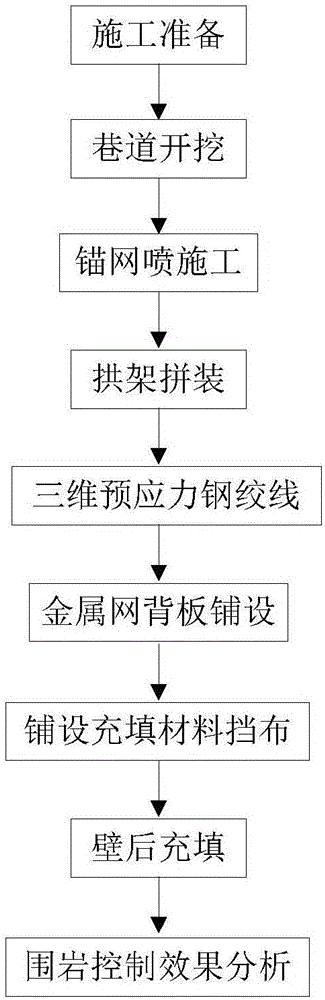

High-stress soft rock roadway supporting system with metal mesh backplane and construction method

ActiveCN104832187AFall preventionReduce laborMining devicesUnderground chambersSupporting systemFilling materials

The invention discloses a high-stress soft rock roadway supporting system with a metal mesh backplane and a construction method. The system sequentially comprises the metal mesh backplane, a confined concrete arch, a filling material blocking cloth, a backwall filling material and a bolt-mesh-spurting support from inside to outside, wherein the metal mesh backplane is located below the confined concrete arch; the metal mesh backplane is connected with the filling material blocking cloth; and the outer edge of the confined concrete arch is connected with the bolt of the bolt-mesh-spurting support via a pre-stressed steel strand. The high-stress soft rock roadway supporting system with the metal mesh backplane has the beneficial effects that the metal mesh backplane is located at the lower side of the arch, thereby reducing the material use amount of the metal mesh backplane; the position of the metal mesh backplane changes, the arch is directly contacted with the filled concrete material, force borne by the arch tends to be uniform, the force is together borne by the arch, the filling layer and the surrounding rock, the overall supporting performance of the arch is improved, the bearing ability of the arch and the self-bearing ability of the surrounding rock are used, and stability of the support is facilitated.

Owner:SHANDONG UNIV

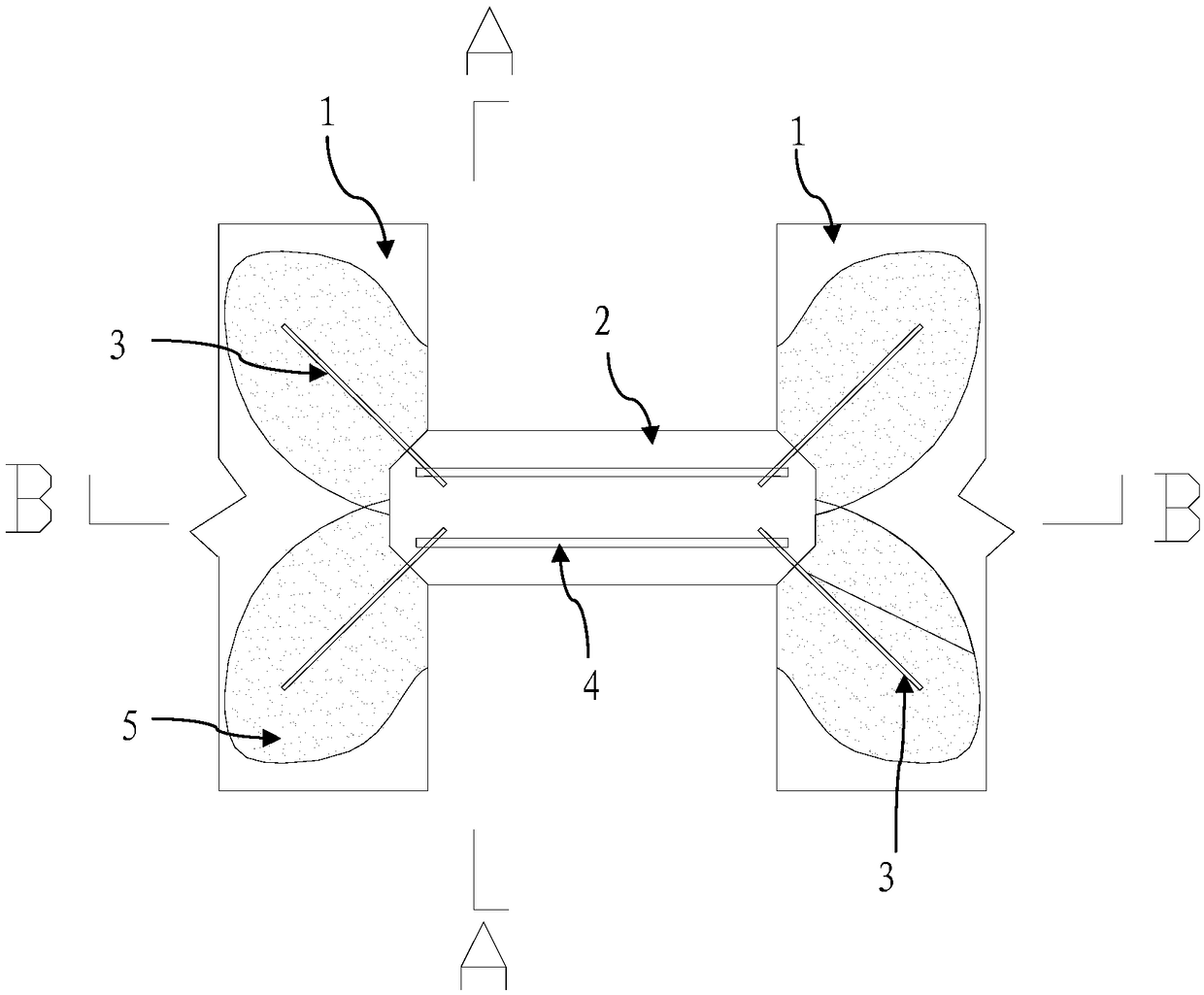

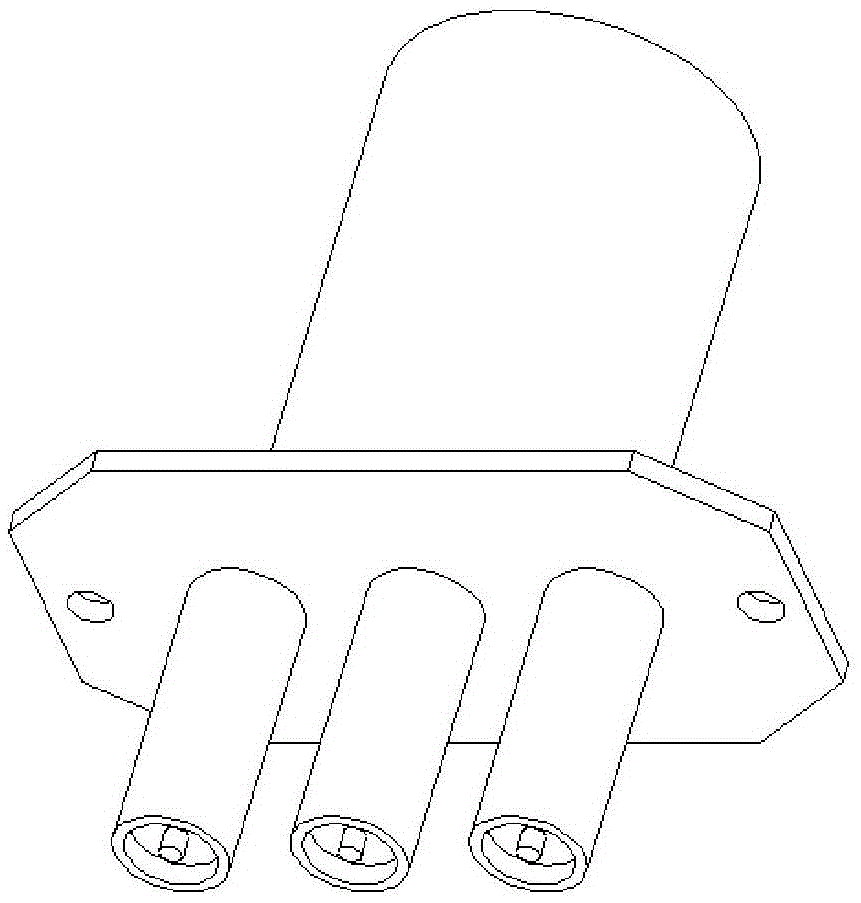

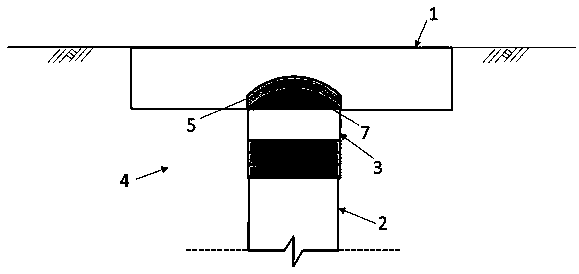

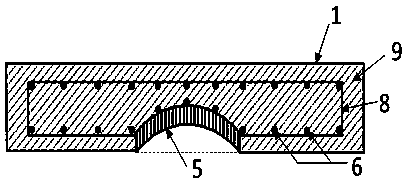

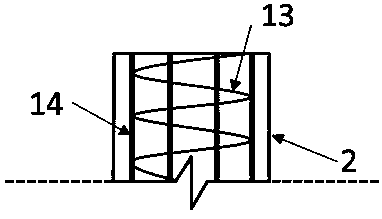

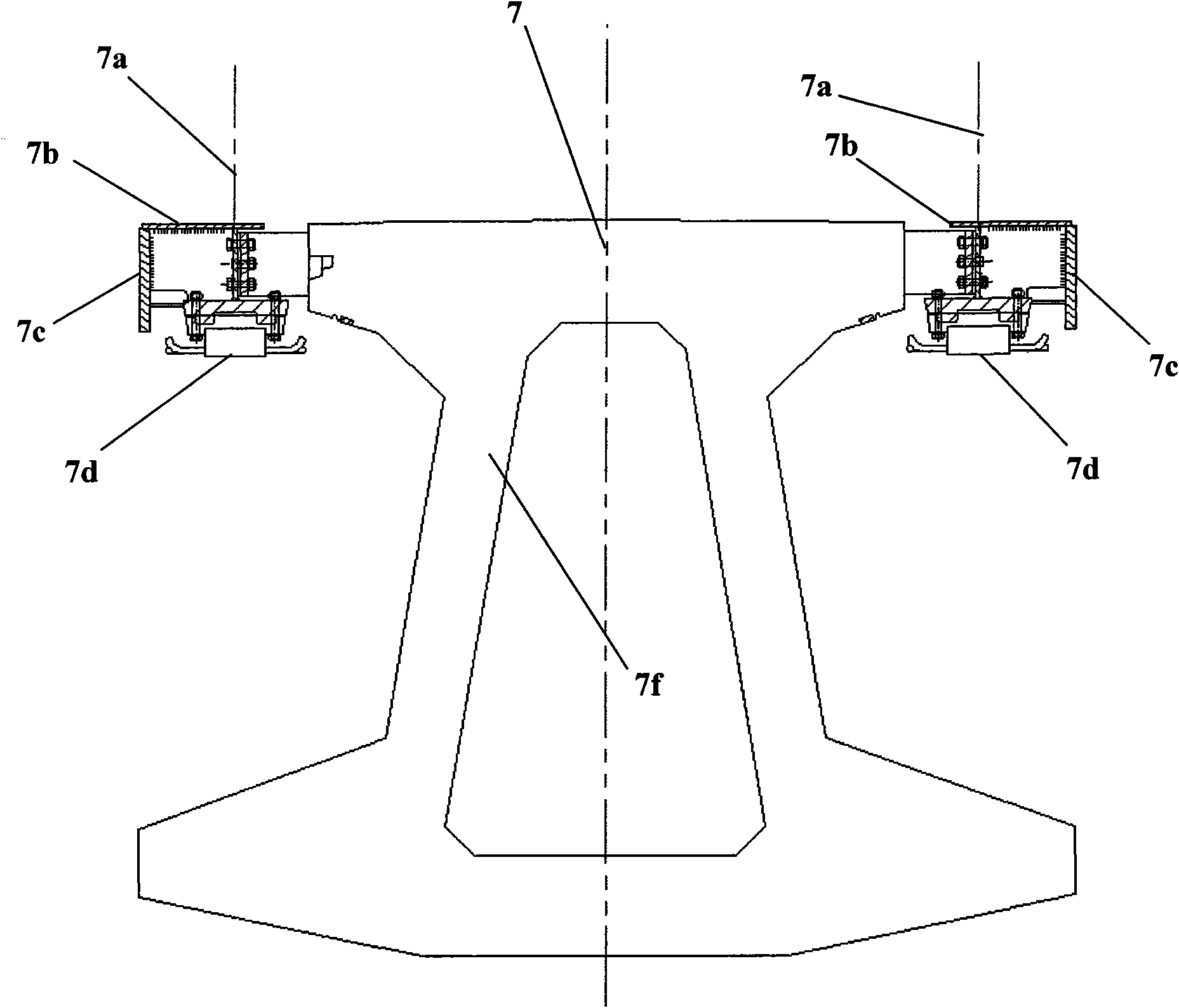

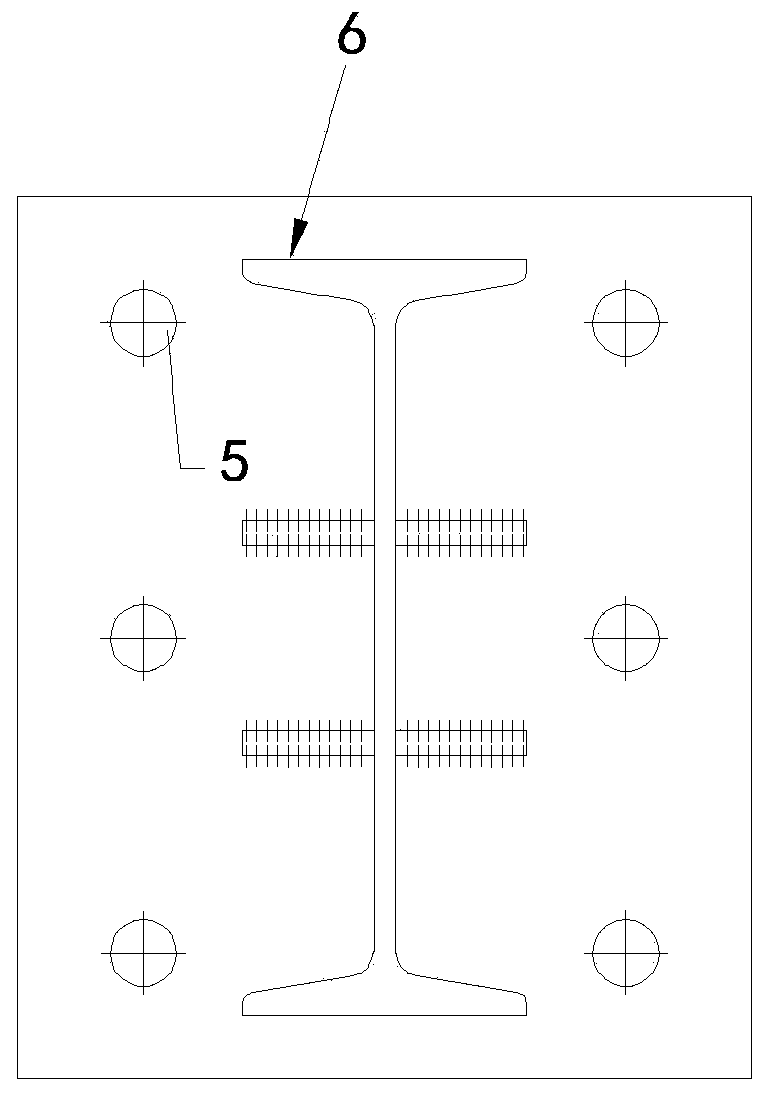

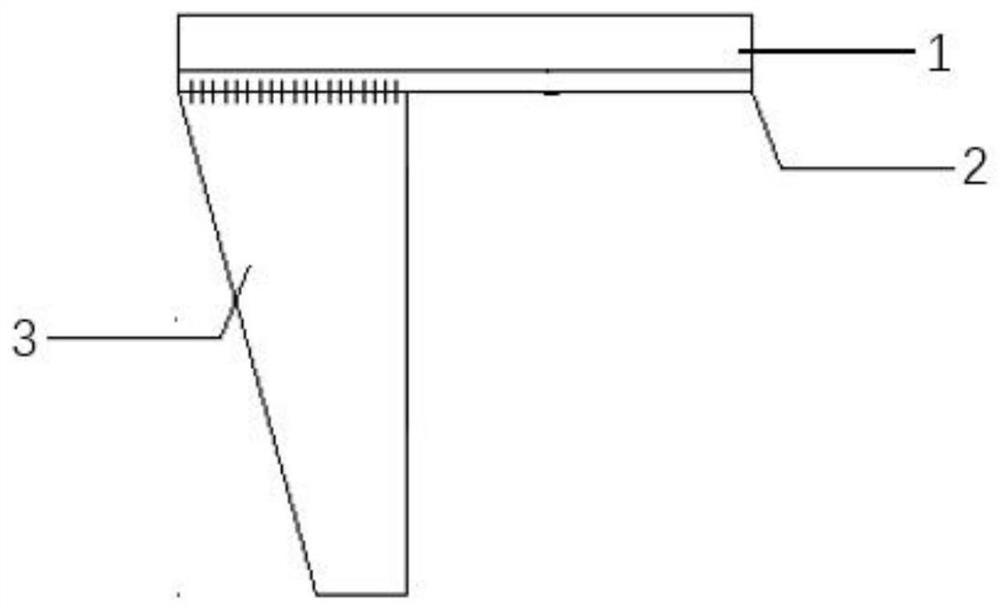

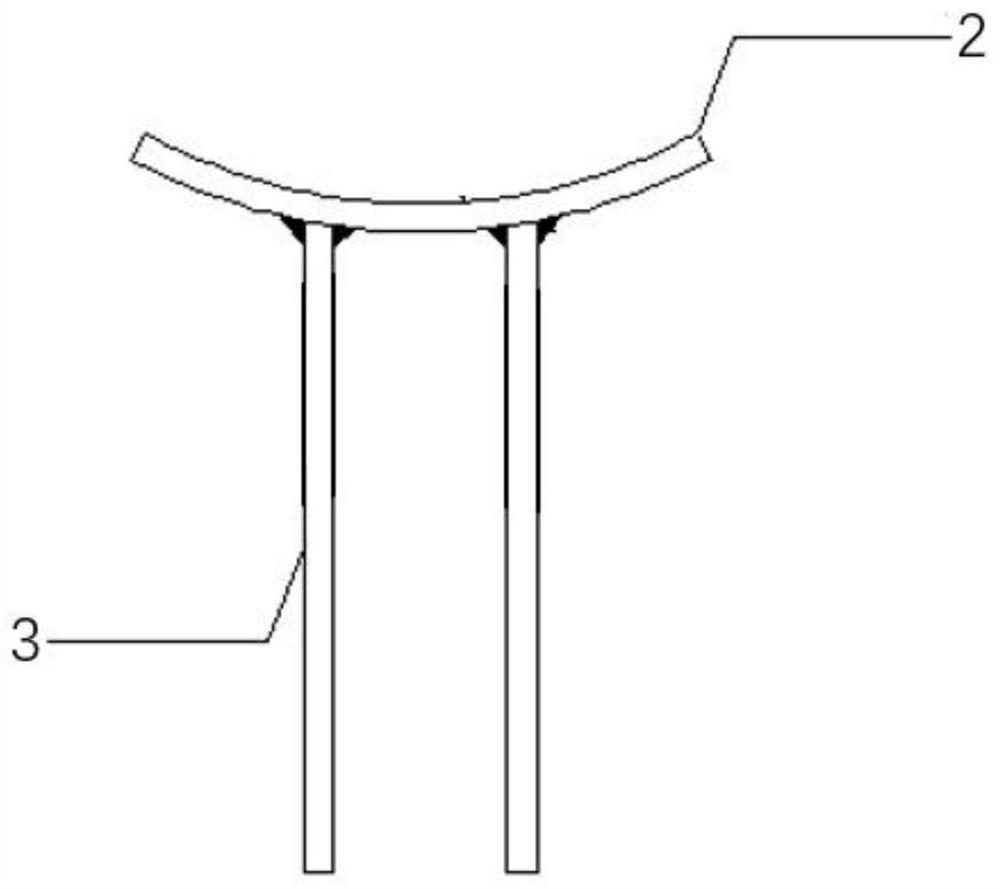

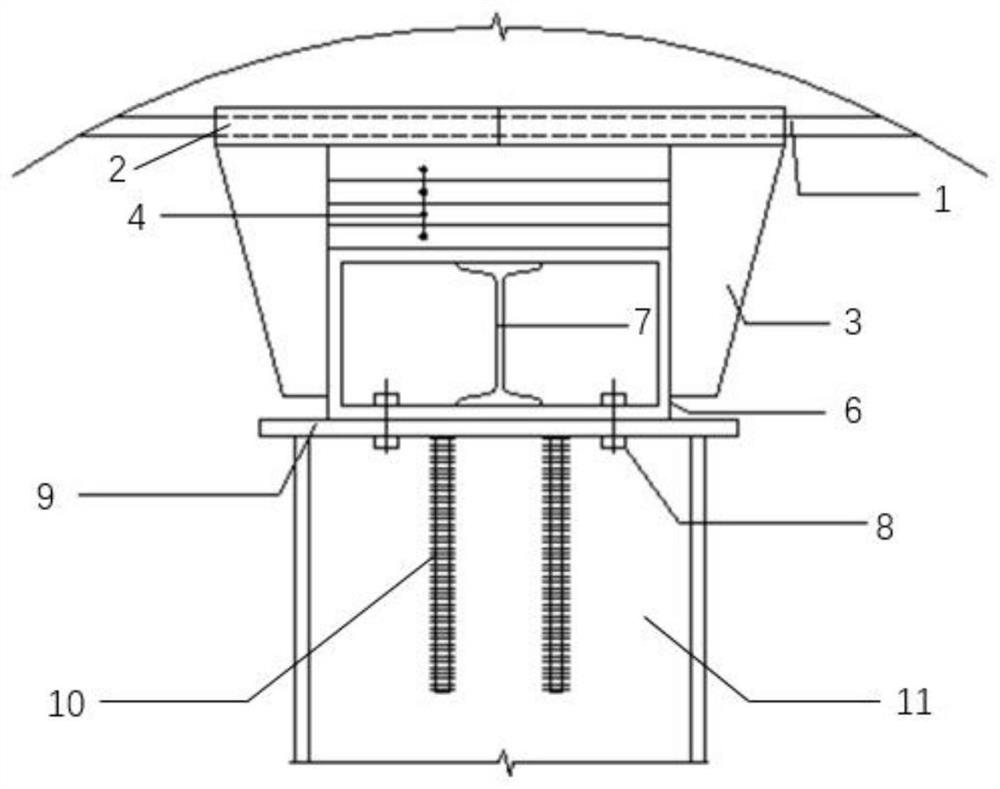

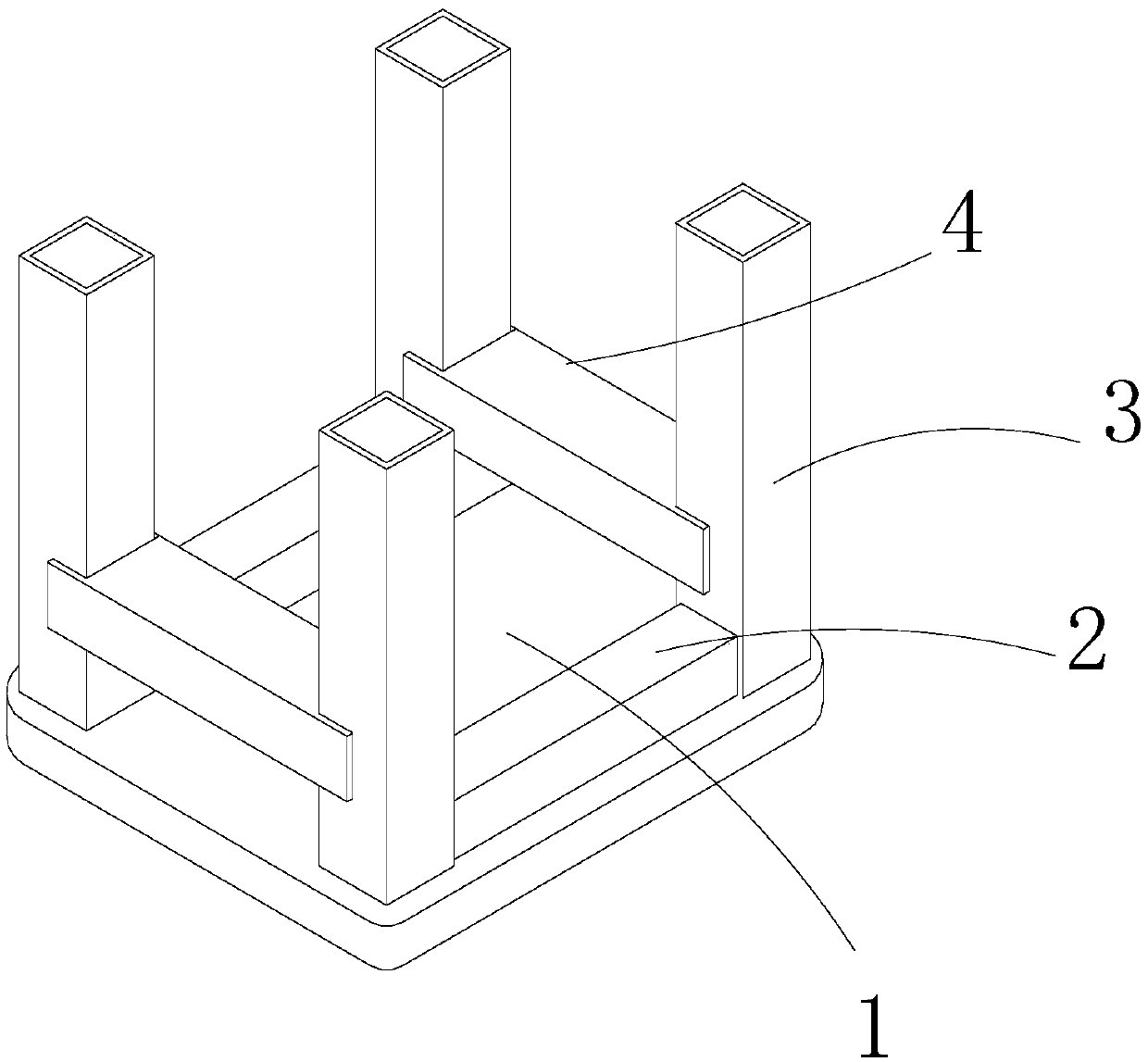

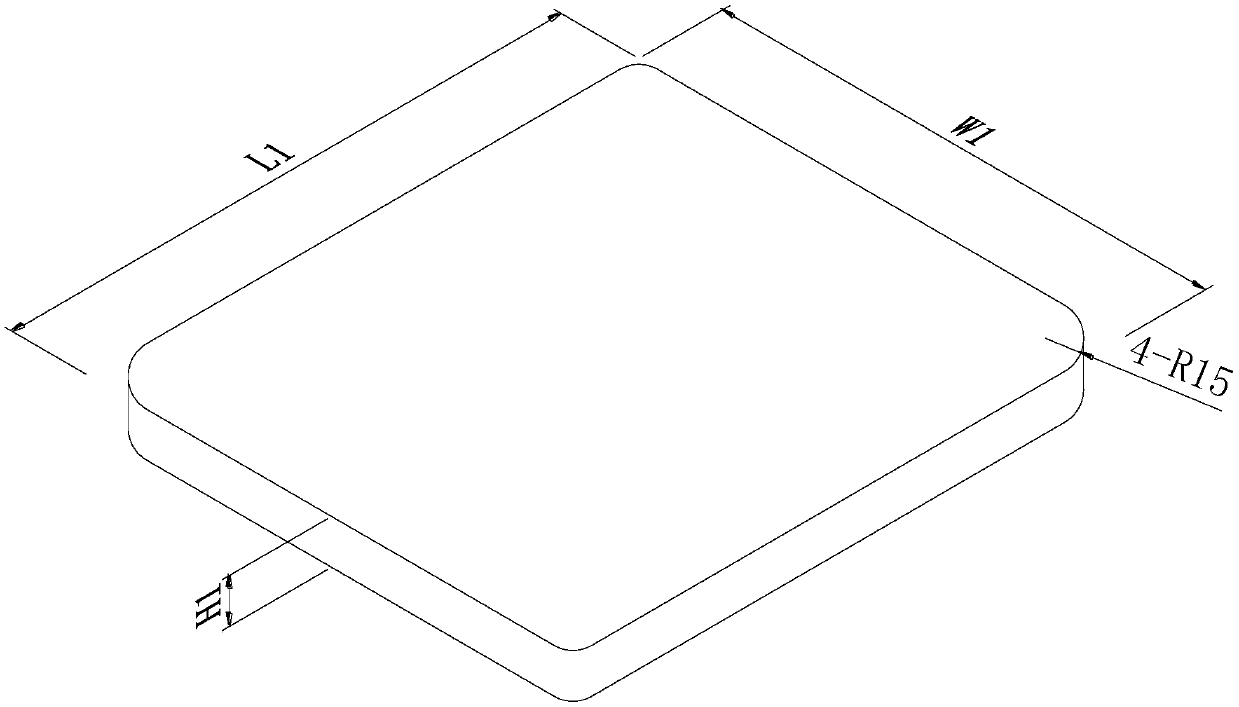

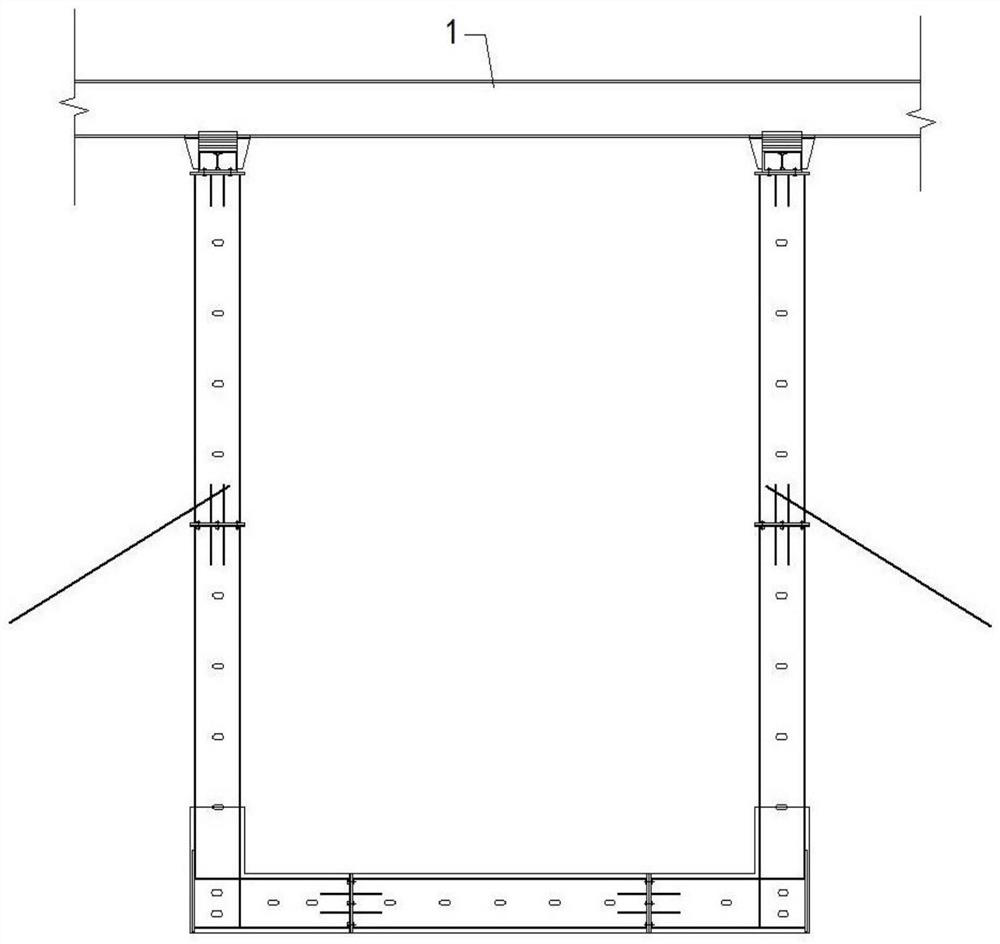

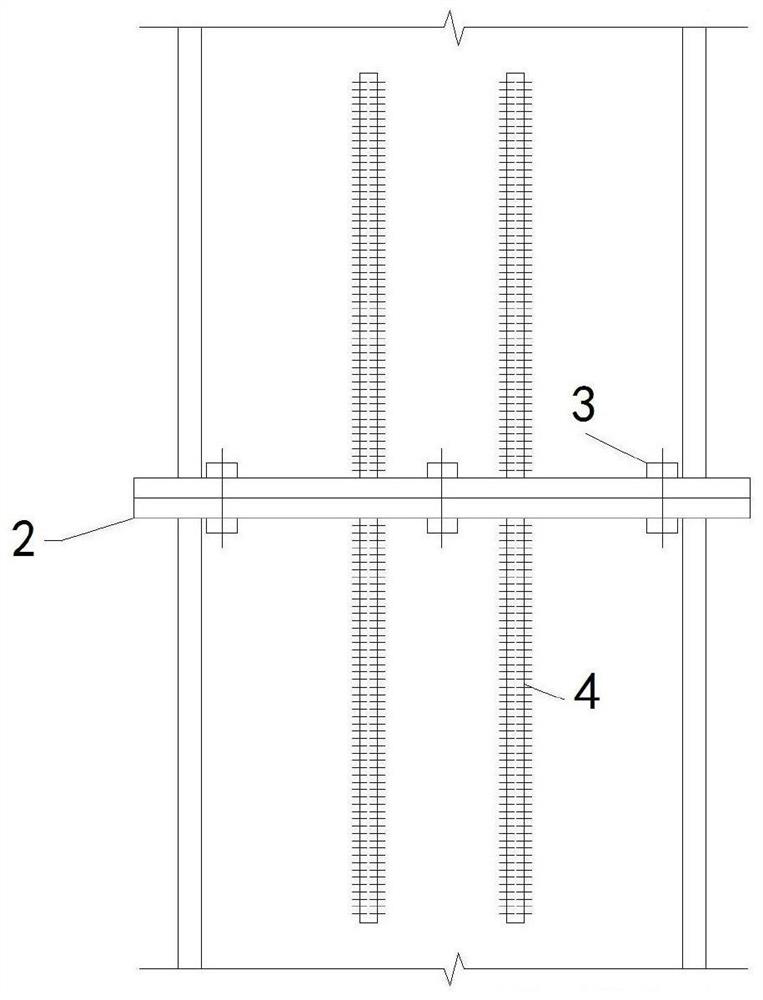

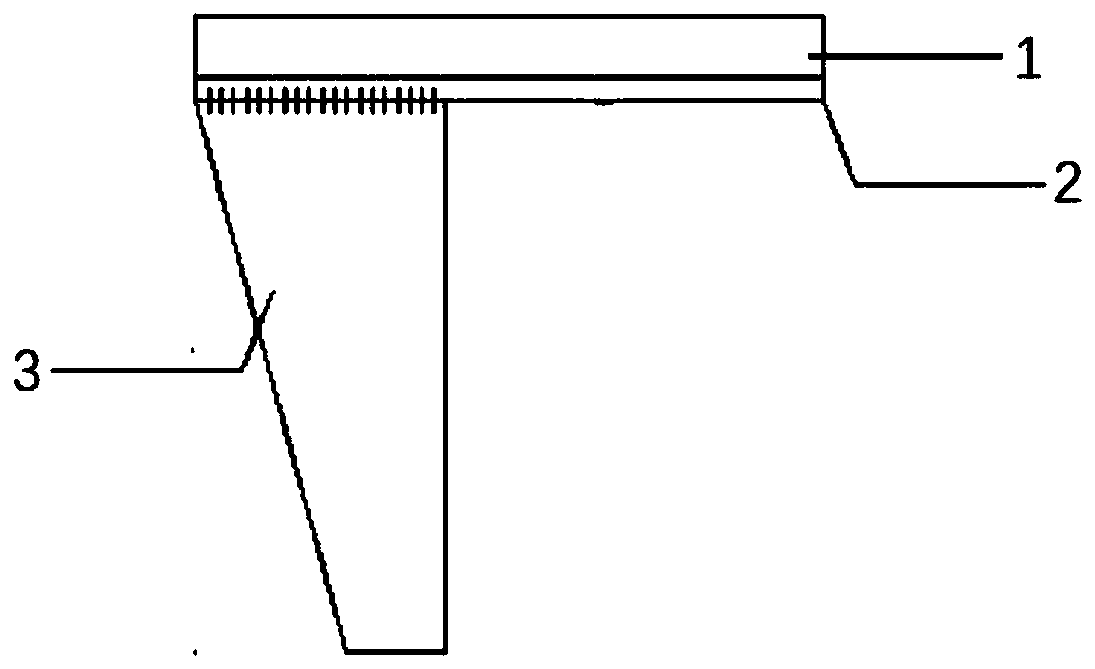

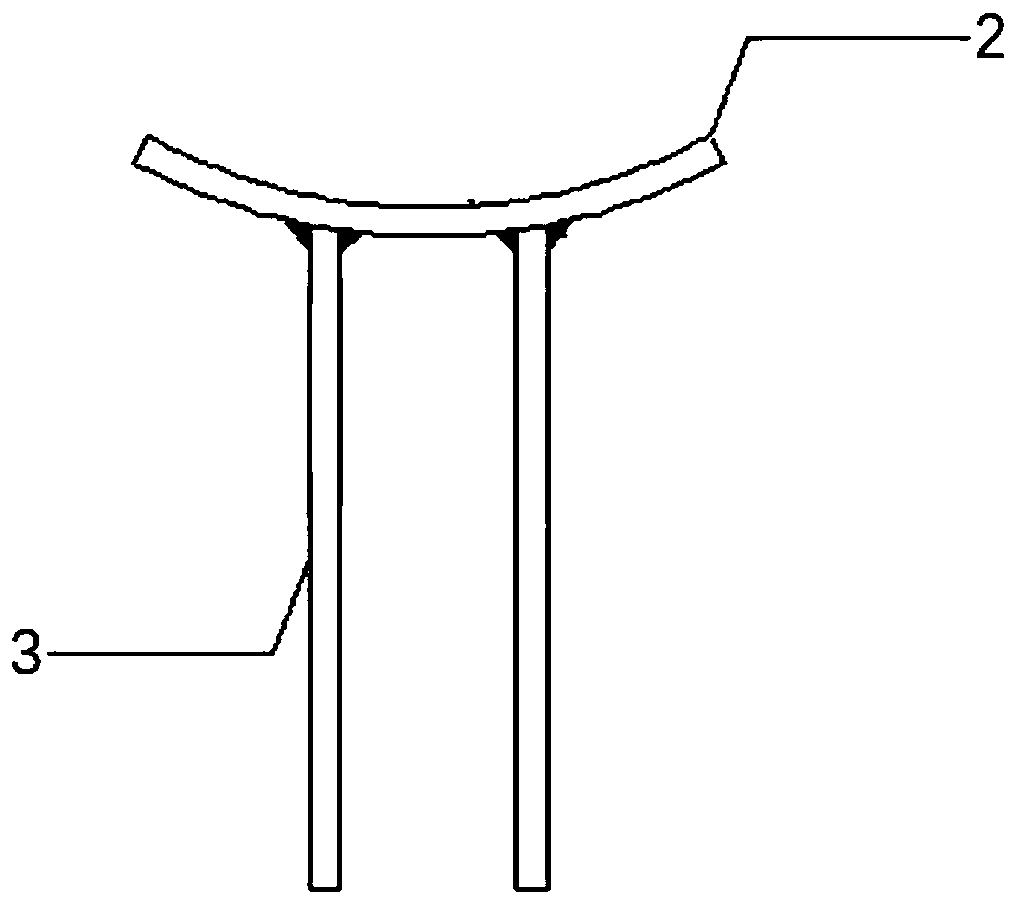

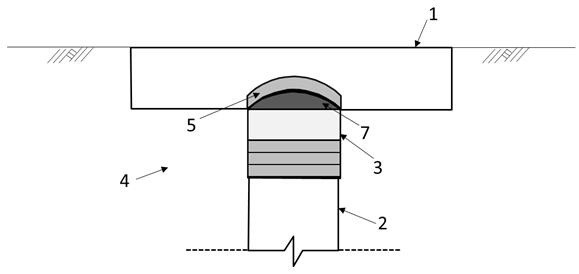

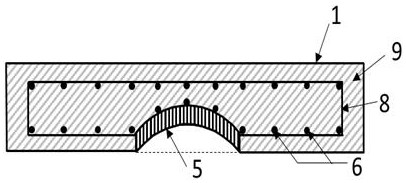

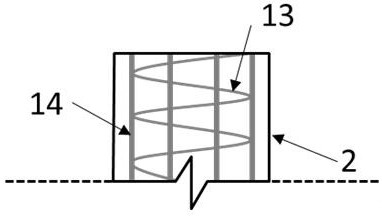

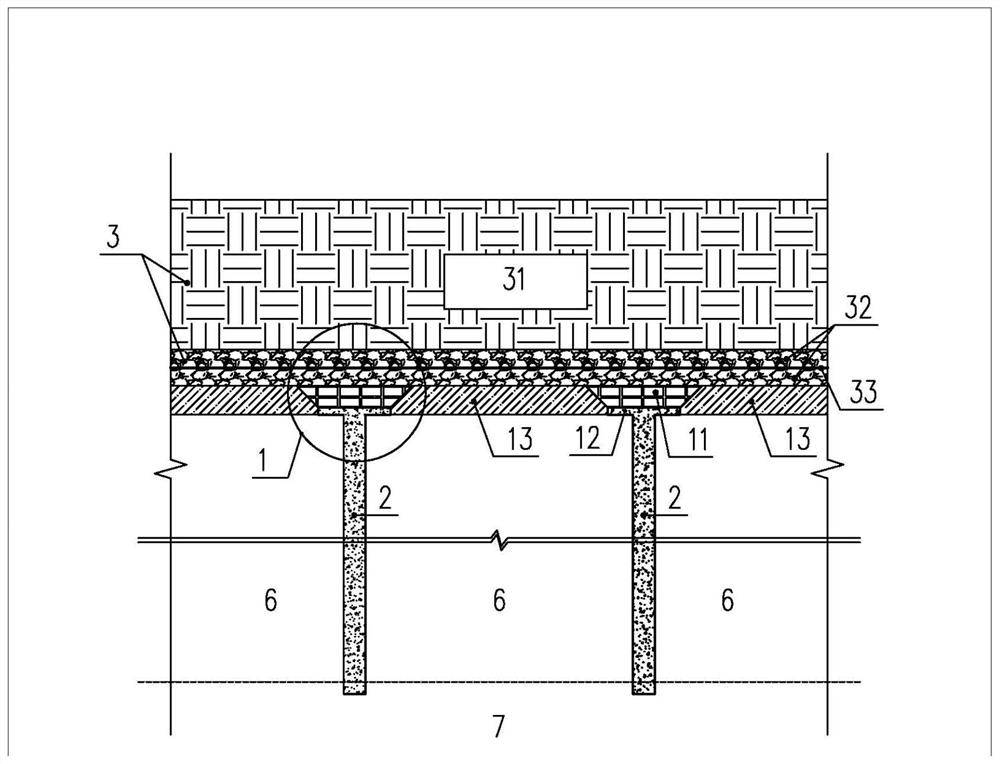

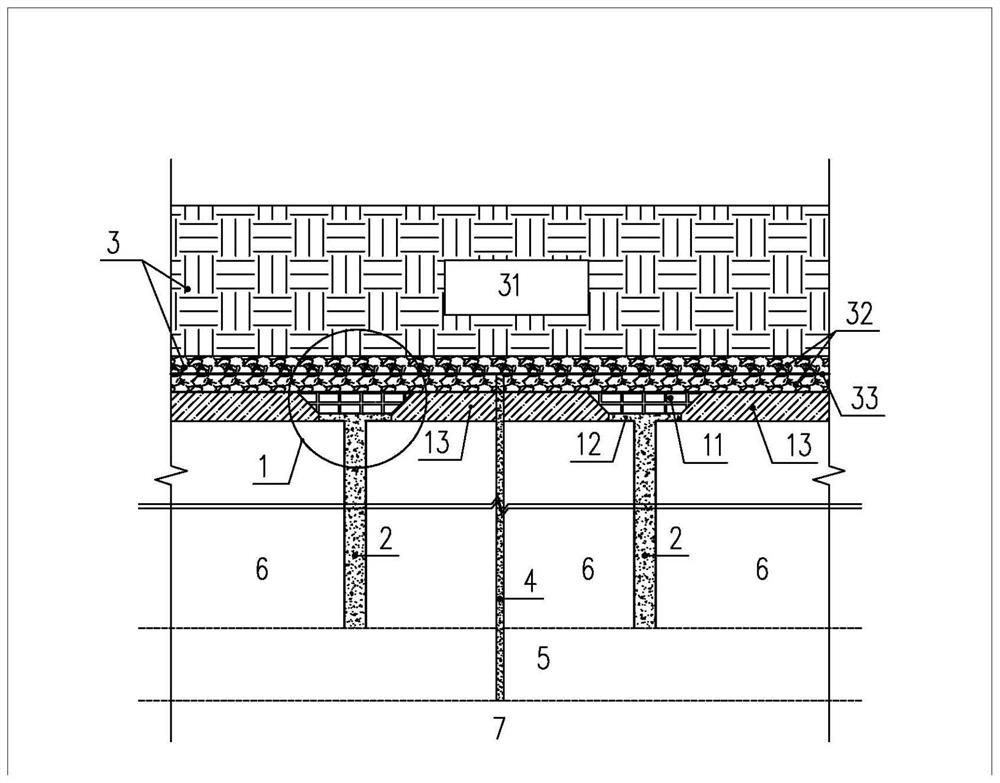

Rigid pile composite foundation fabricated pile cap and assembling method thereof

ActiveCN110004918ACollaborative working mechanism coordinationExert carrying capacityBulkheads/pilesPile capStructural engineering

The invention discloses a rigid pile composite foundation fabricated pile cap and an assembling method thereof. A pile sleeve is arranged at the top end of a rigid pile body, the end, being connectedwith a pile cap plate, of the pile top sleeve is arc, an arc gasket is arranged between the arc end of the pile top sleeve and the pile cap plate, a groove matched with the shape of the arc gasket isformed in the bottom center of the pile cap plate, the arc gasket is separately in contact with the pile top sleeve and the groove, and the arc gasket can separately slide relative to the groove and the pile top sleeve. According to the rigid pile composite foundation fabricated pile cap and the assembling method thereof, general members and materials are adopted, the structure is simple, the durability is high, the mounting is convenient, the assembly process of the pile cap is reduced, the member forming quality is improved, the cost is low, and popularization and use are facilitated.

Owner:NANJING FORESTRY UNIV +1

Travel structure of magnetic levitation type rail polling car

InactiveCN101624054BAchieving self-rescue abilityBrake decelerationRailway inspection trolleysSliding/levitation railway systemsLow speedMotor drive

Owner:TONGJI UNIV

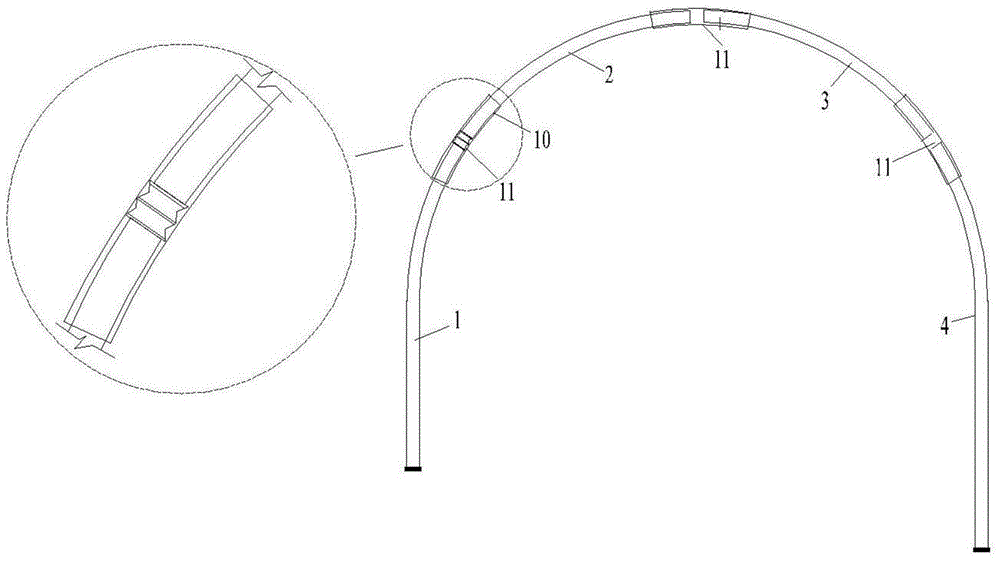

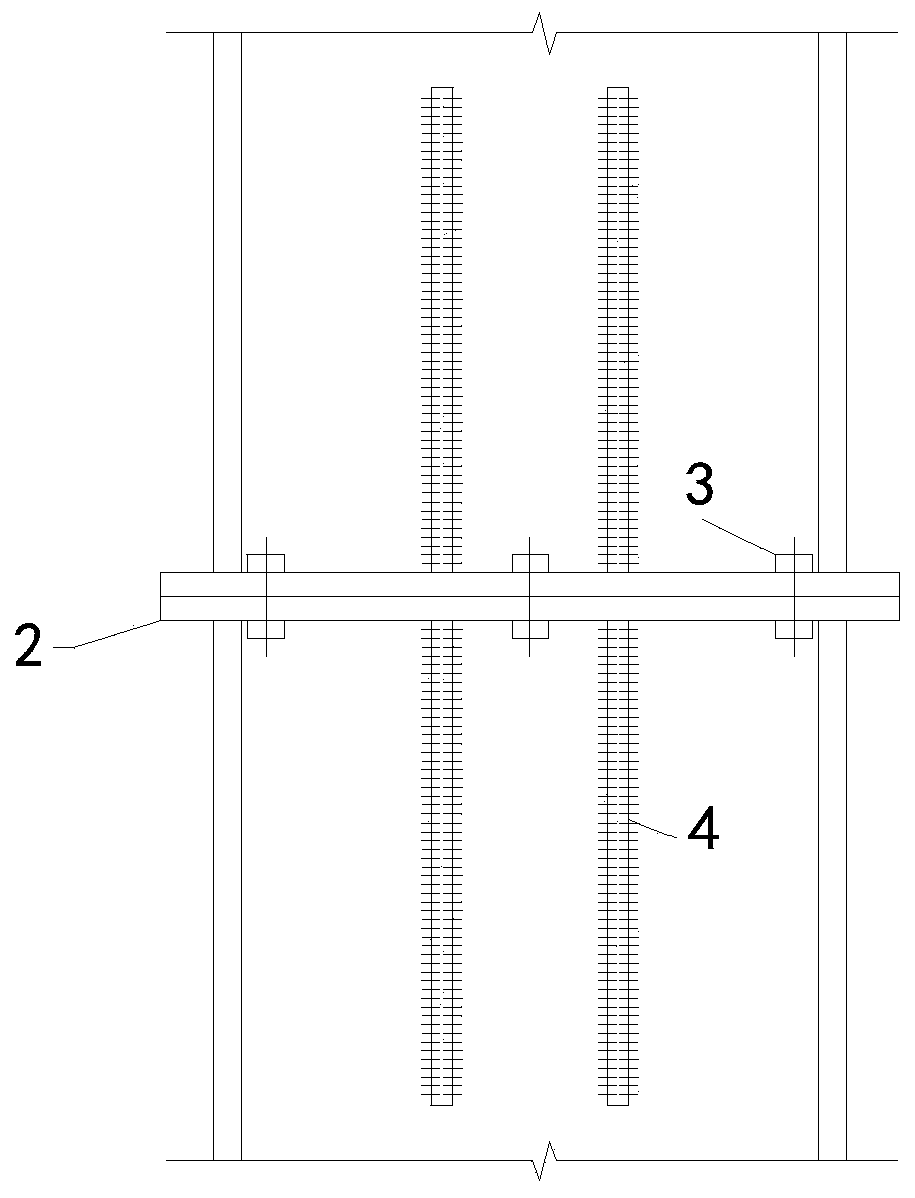

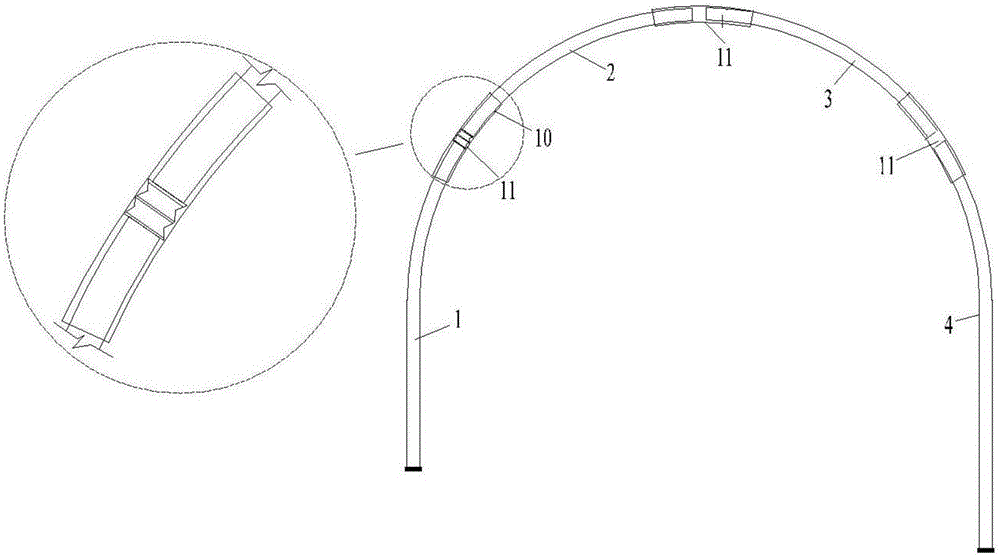

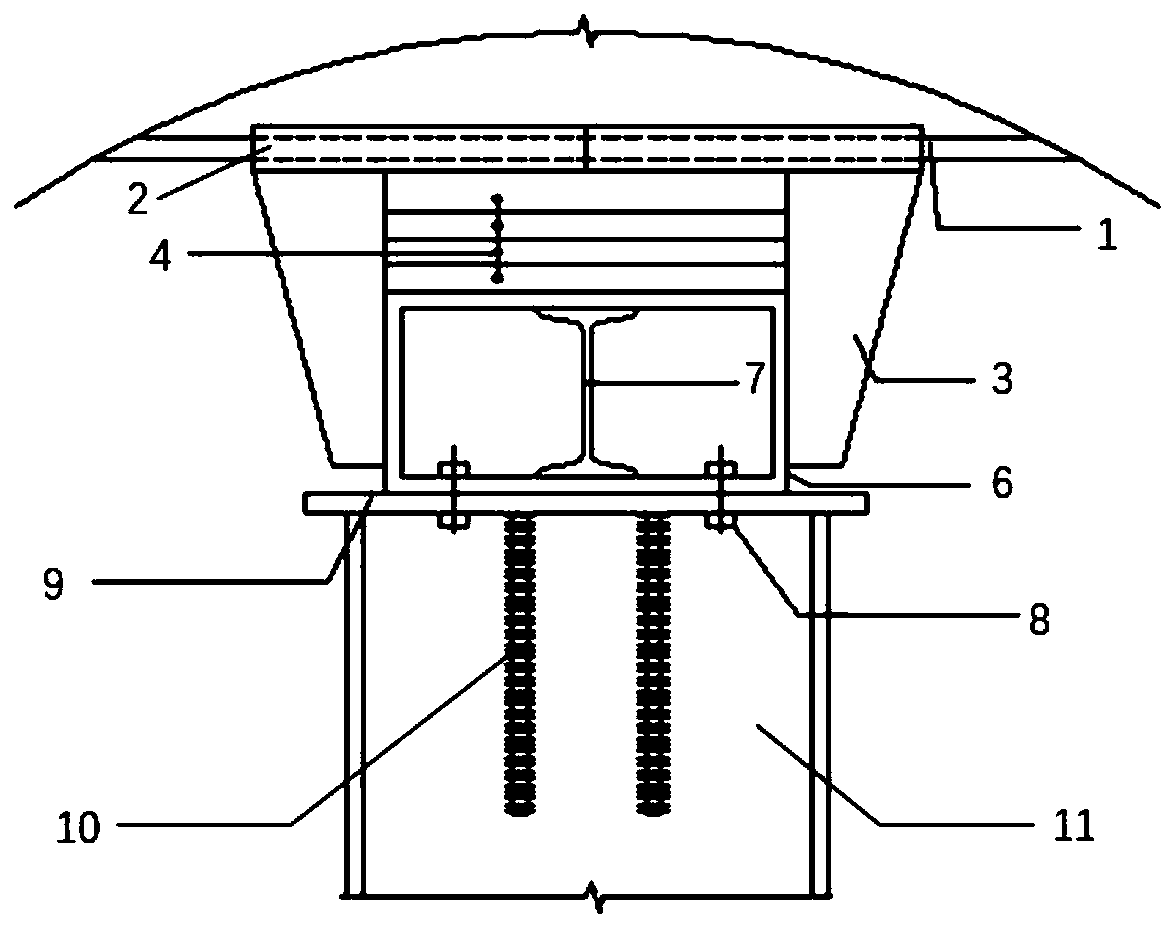

Detachable U-shaped preliminary bracing method combined with canopy-method construction

ActiveCN111379577AExert carrying capacityEnsuring the transmission of vertical forcesUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a detachable U-shaped preliminary bracing method combined with canopy-method construction. According to the method, a method that a U-shaped steel frame and a large-diameter pipe shed are connected is adopted, and the U-shaped steel frame is convenient to mount and can be detached and recycled, so that the construction period and materials are greatly saved; and meanwhile,the carrying capacity of the large-diameter pipe shed is fully exerted, a preliminary bracing is not required to be constructed at the top of a pilot tunnel, a preliminary bracing and a leading pre-bracing (the large-diameter pipe shed) constructed in the preorder form a combined bracing system, and the synergistic effect of a tunnel bracing structure system is fully shown. A new idea is providedfor Collaborative optimized design of the tunnel bracing structure system. The pipe shed and the U-shaped preliminary bracing are sequentially combined from top to bottom as follows: the large-diameter pipe shed, connecting pieces, cushion blocks, adjusting pieces, side wall profile-steel frames (pieces of profiles are connected through bolts), locking foot anchor pipes and bottom grid steel frames (grids are connected through bolts).

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

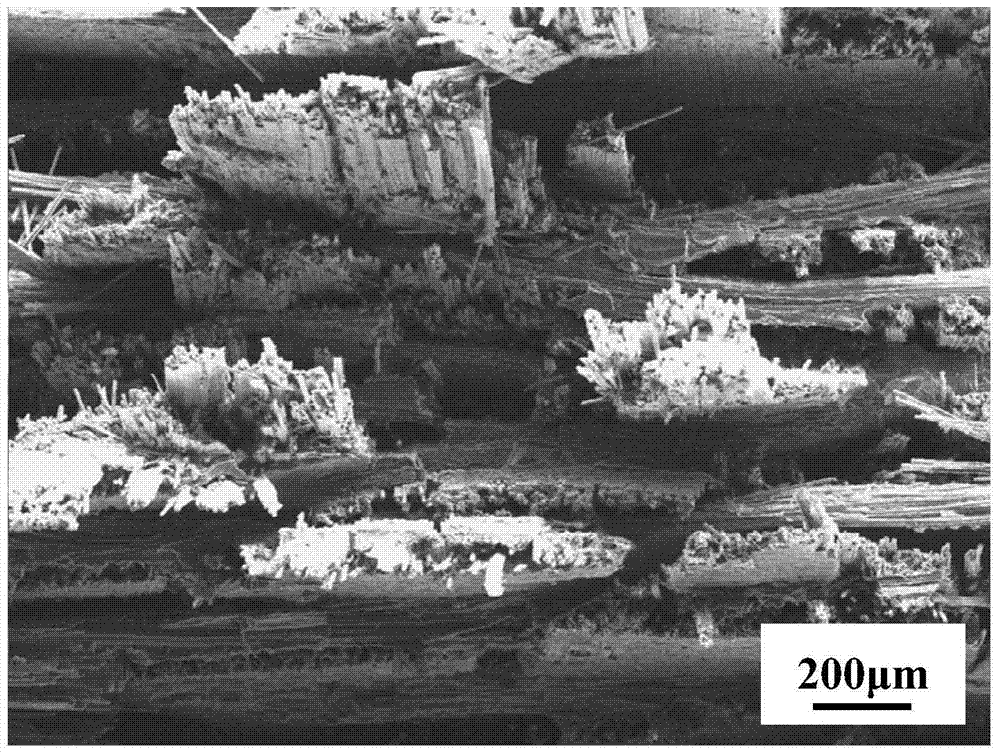

Multilayer ceramic-based composite material for aero-engine thermal structural member and preparation method thereof

The invention discloses a multilayer ceramic-based composite material for an aero-engine thermal structural member and a preparation method of the multilayer ceramic-based composite material. The preparation method comprises the following steps: preparing a fiber preform from continuous fibers; preparing a pyrolytic carbon and SiC nanowire composite interface phase on the internal fiber surface of the preform, densifying the preform with the composite interface phase by adopting a vacuum-pressure impregnation process to obtain a second-stage green body, performing matrix filling on the second-stage green body by adopting a chemical vapor infiltration process, and performing pre-oxidation to obtain a third-stage green body; introducing a pyrolytic carbon layer into the third-stage green body through a chemical vapor infiltration process, introducing carbon nanowires through a catalyst-assisted deposition method to obtain a fourth-stage green body, finally, preparing a SiC hole sealing coating on the surface of the fourth-stage green body through a melt siliconizing method, wherein the prepared ceramic-based composite material is low in porosity, has the ablation-resistant and corrosion-resistant characteristics, and excellent mechanical property can still be kept under the high-temperature aerobic condition.

Owner:湖北瑞宇空天高新技术有限公司

A high-stress soft rock roadway support system and construction method containing metal mesh backboard

ActiveCN104832187BFall preventionReduce laborMining devicesUnderground chambersSupporting systemPre stress

The invention discloses a high-stress soft rock roadway supporting system with a metal mesh backplane and a construction method. The system sequentially comprises the metal mesh backplane, a confined concrete arch, a filling material blocking cloth, a backwall filling material and a bolt-mesh-spurting support from inside to outside, wherein the metal mesh backplane is located below the confined concrete arch; the metal mesh backplane is connected with the filling material blocking cloth; and the outer edge of the confined concrete arch is connected with the bolt of the bolt-mesh-spurting support via a pre-stressed steel strand. The high-stress soft rock roadway supporting system with the metal mesh backplane has the beneficial effects that the metal mesh backplane is located at the lower side of the arch, thereby reducing the material use amount of the metal mesh backplane; the position of the metal mesh backplane changes, the arch is directly contacted with the filled concrete material, force borne by the arch tends to be uniform, the force is together borne by the arch, the filling layer and the surrounding rock, the overall supporting performance of the arch is improved, the bearing ability of the arch and the self-bearing ability of the surrounding rock are used, and stability of the support is facilitated.

Owner:SHANDONG UNIV

Connection structure and construction technology of artificial dam body and coal pillar dam body of underground reservoir

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A connection method for the initial support and large-diameter pipe shed in the construction of shed cover method

ActiveCN111379576BExert carrying capacityEnsure safetyUnderground chambersTunnel liningClassical mechanicsSteel frame

The invention discloses a method for connecting the initial support and the large-diameter pipe shed during the construction of the shed cover method, which can eliminate the need for the initial support of the top of the pilot tunnel during the construction of the shed cover method, and the initial support of the side wall It is effectively connected with the tube shed. The connection method includes setting a connecting piece at the bottom of the pipe shed in the underground excavation pilot tunnel. The connecting piece includes an arc-shaped supporting plate and a baffle, and the supporting plate and the pipe shed, and between the supporting plate and the baffle are welded and connected; the lower part of the connecting piece is a backing plate , the backing plate is a thick steel plate processed according to the design size, and the specific quantity is reasonably configured according to the distance between the pipe shed and the adjusting part; the lower part of the backing plate is the adjusting part, and the adjusting part can be I-shaped steel or square steel according to different types of steel frames; The adjusting part is connected with the initial supporting steel frame by bolts. The method of the present invention effectively exerts the bearing capacity of the large-diameter pipe shed, no initial support is required on the top of the pilot tunnel, and the pipe shed and the initial support are integrated to ensure stability in the pilot tunnel, less construction procedures, fast, simple, and economical duration and materials.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

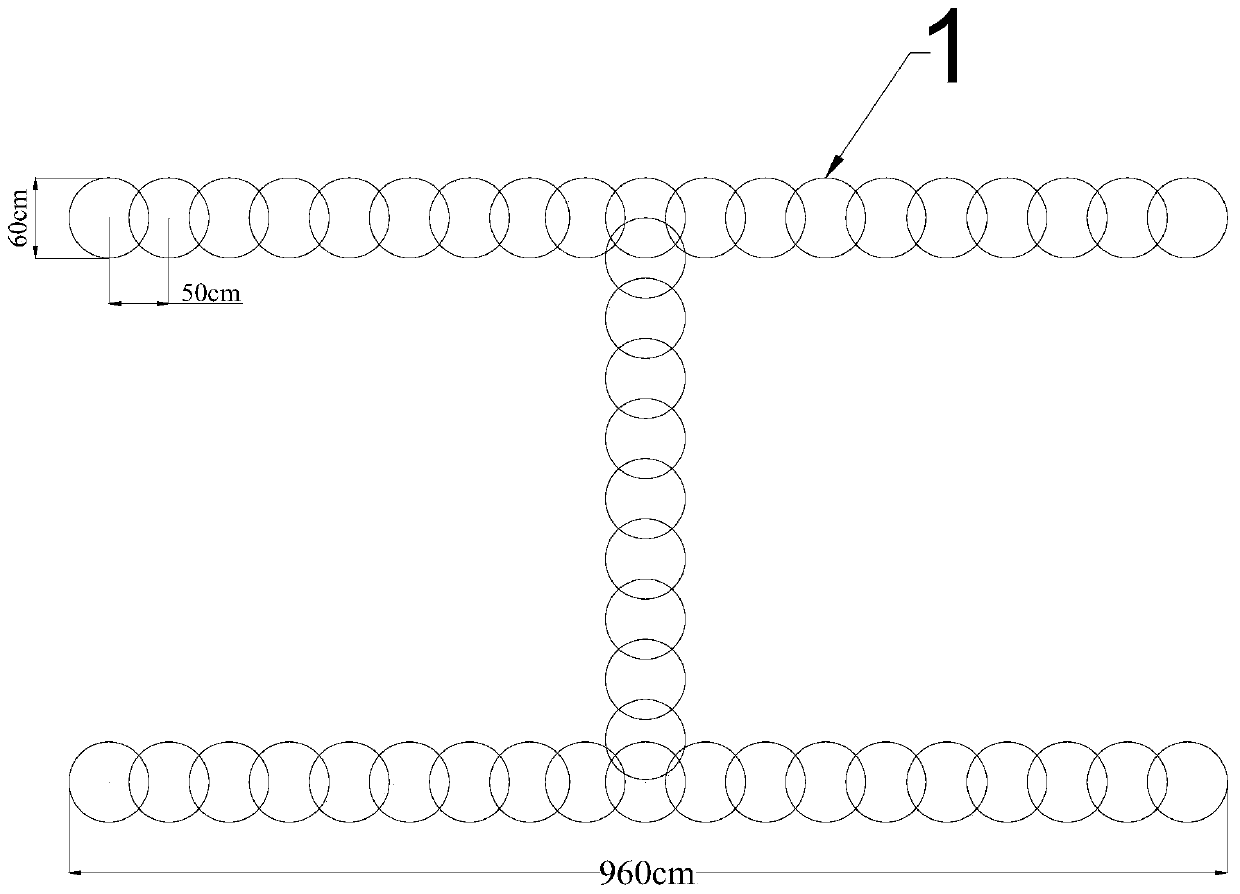

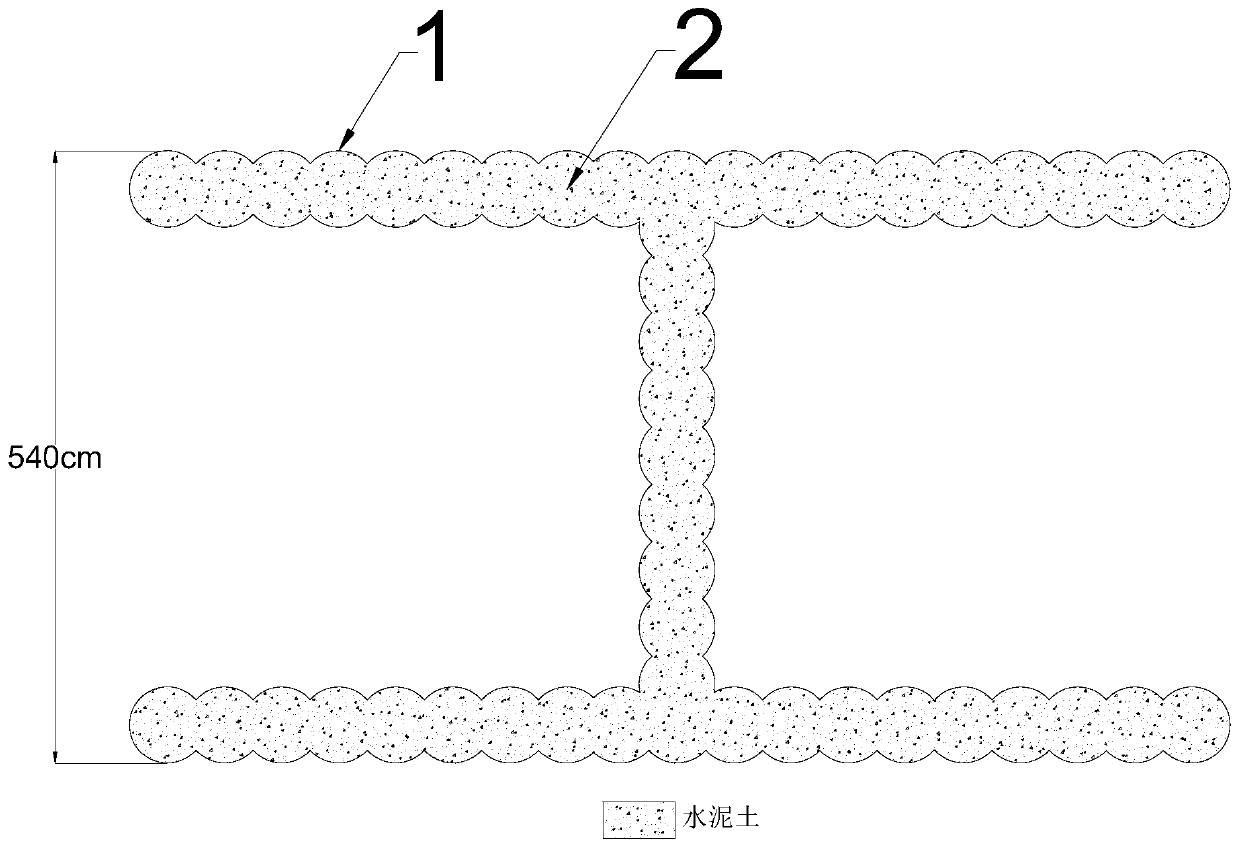

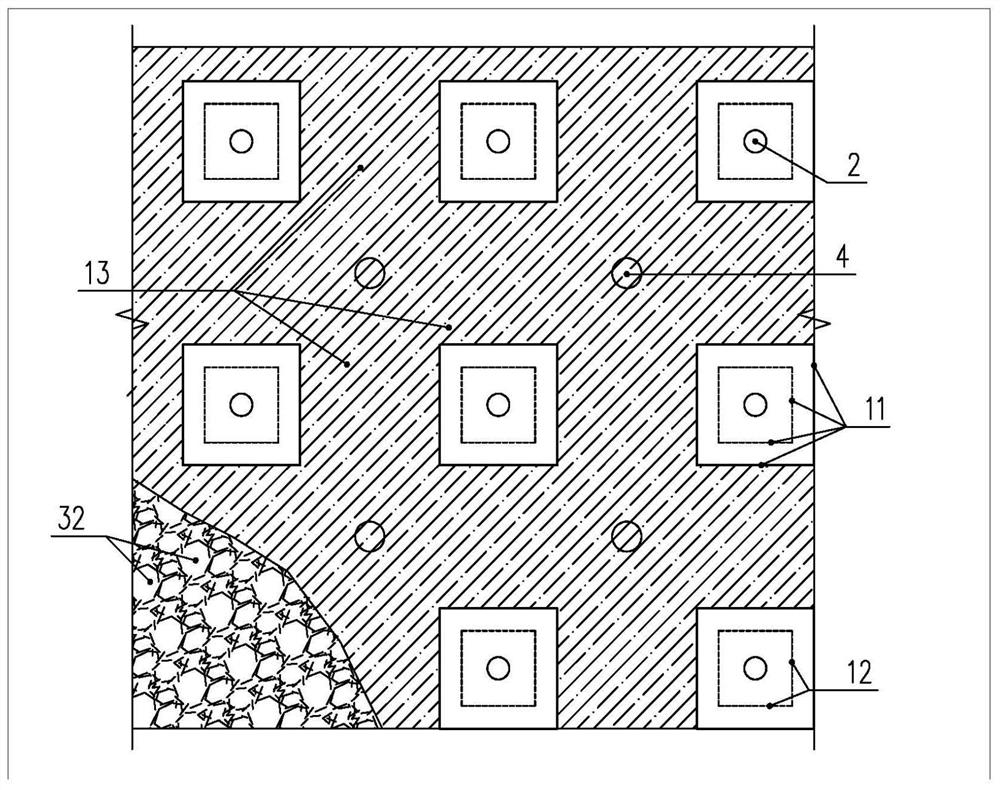

Mixed grooved inserted combined prefabricated special-shaped section composite foundation structure and construction method

PendingCN109898507AReduce post-construction settlementImprove playbackBulkheads/pilesStructure of the EarthGround plane

The invention discloses a mixed grooved inserted combined prefabricated special-shaped section composite foundation structure and a construction method, and belongs to the field of foundations. The structure includes a plurality of mixing piles, and each mixing pile is embedded into the foundation in a circular pile shape; all mixing piles are arranged on a ground plane in an H shape, every adjacent mixing piles are mutually interlocked and connected, and a continuous wall type H-shaped mixing tank is formed; a prefabricated plate is inserted vertically in each mixing pile, and the prefabricated plates in all mixing piles are continuously spliced in the direction of the H-shaped mixing tank; and in each mixing pile, the position between the two sides of the prefabricated plates and foundation soil at the edges of the mixing piles is filled with cement soil as a transition layer. According to the mixed grooved inserted combined prefabricated special-shaped section composite foundation structure and the construction method, the principle is simple and reliable, construction operation is easy and convenient, applicable working conditions are wide, and the influence by site construction conditions is small; and according to a composite foundation, compared with conventional foundations, under the condition of using concrete mortar with the same volume, the bearing capacity is greatly improved, and the good application prospects are achieved.

Owner:ZHEJIANG UNIV

The craft of making paper tube furniture and the small square stool made by this craft

ActiveCN106239684BStability issues manifestExert carrying capacityWood working apparatusStructural engineeringIndustrial engineering

The invention provides a paper tube furniture manufacturing process and a small square stool manufactured through the process. Paper tube furniture comprises a face plate used for bearing and containing, and 2N hollow square tube supporting legs which are arranged below the face plate and used as supports. N rectangular connection pipes are arranged on the lower surface of the face plate and are embedded in blind grooves correspondingly formed in the lower portion of the face plate. Mortises matched with the sections of the supporting legs are formed in the lower portions of the connection pipes, the pipe walls of the supporting legs are connected in the mortises in an inserted manner so that the supporting legs can be perpendicularly fixed to the connection pipes, a connection beam is fixed between every two supporting legs which are adjacent but not located below the same connection pipe, and overall damp-proof treatment is conducted. The structure is simple, the dynamic stability is good, the caliber or wall thickness of paper tubes or the strip number of the connection paper tubes can be regulated according to requirements of clients and bearing so that different use requirements can be met. Assembling is convenient, transportation is convenient, and cost is saved.

Owner:GUANGZHOU HAIFANG TECH CO LTD

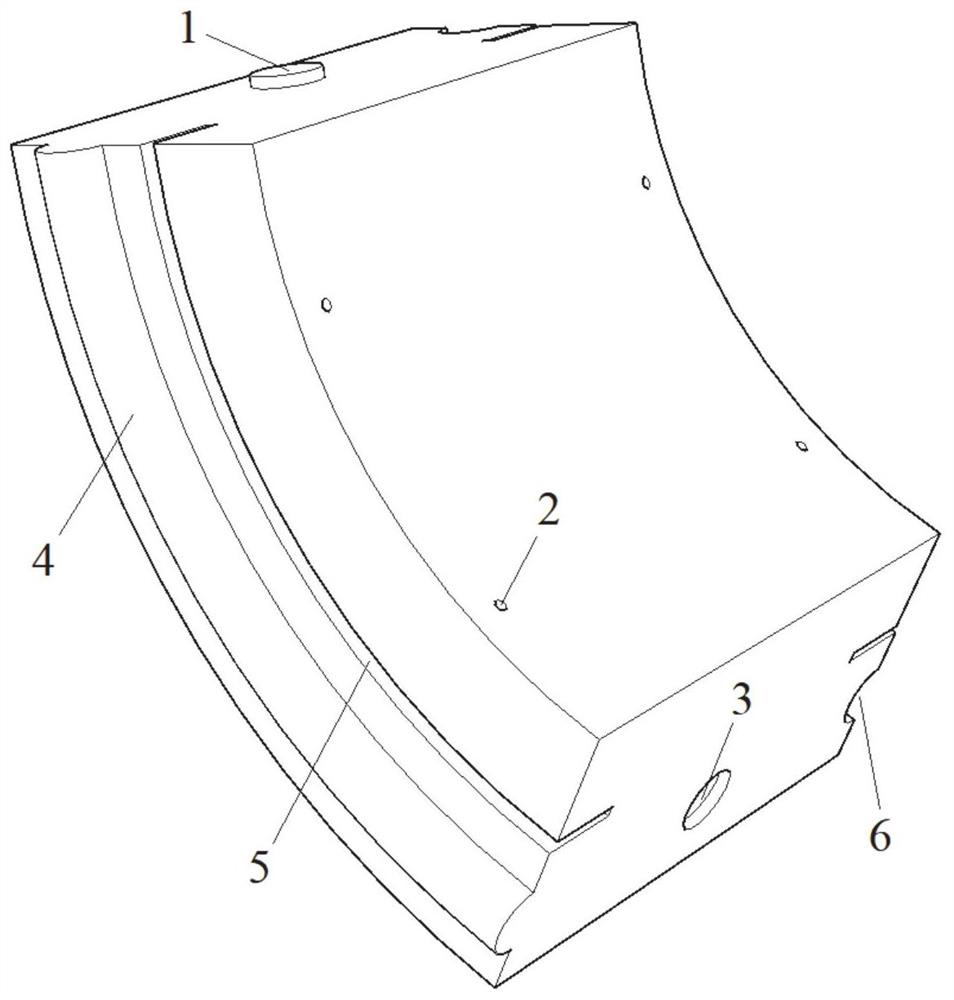

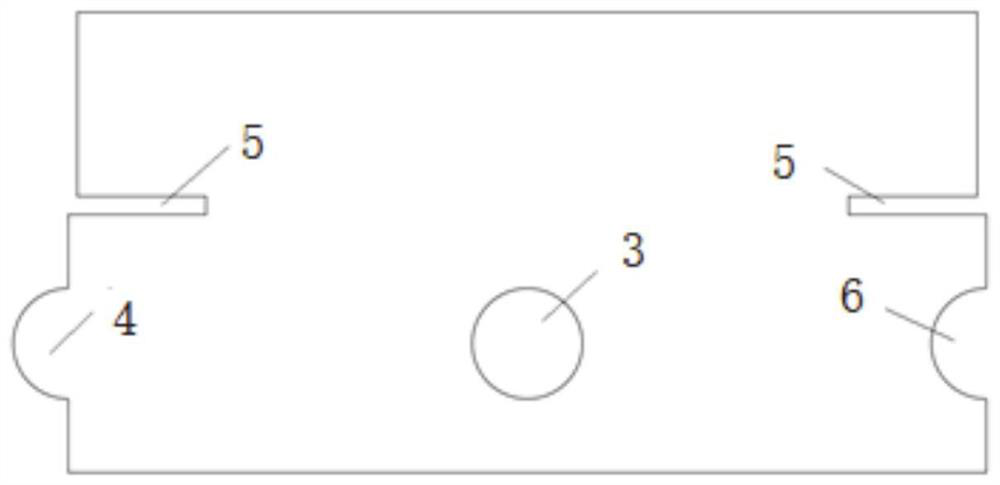

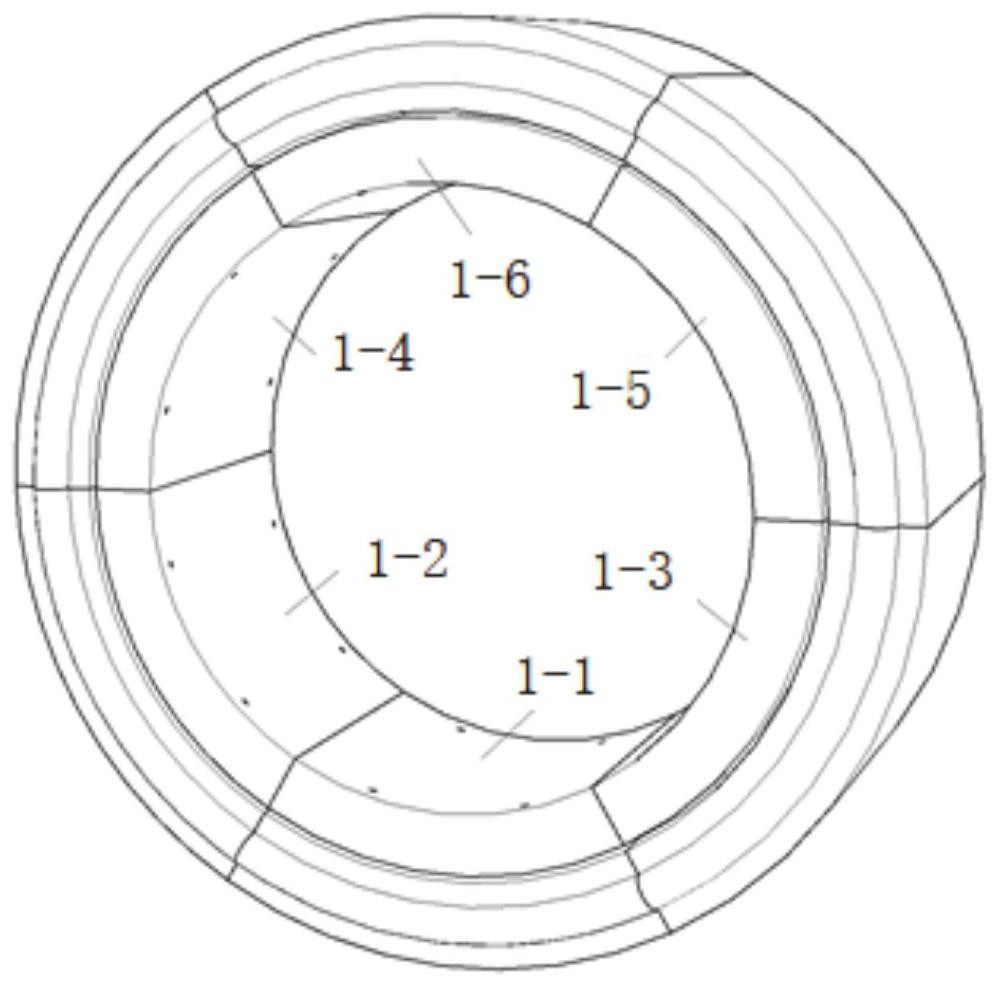

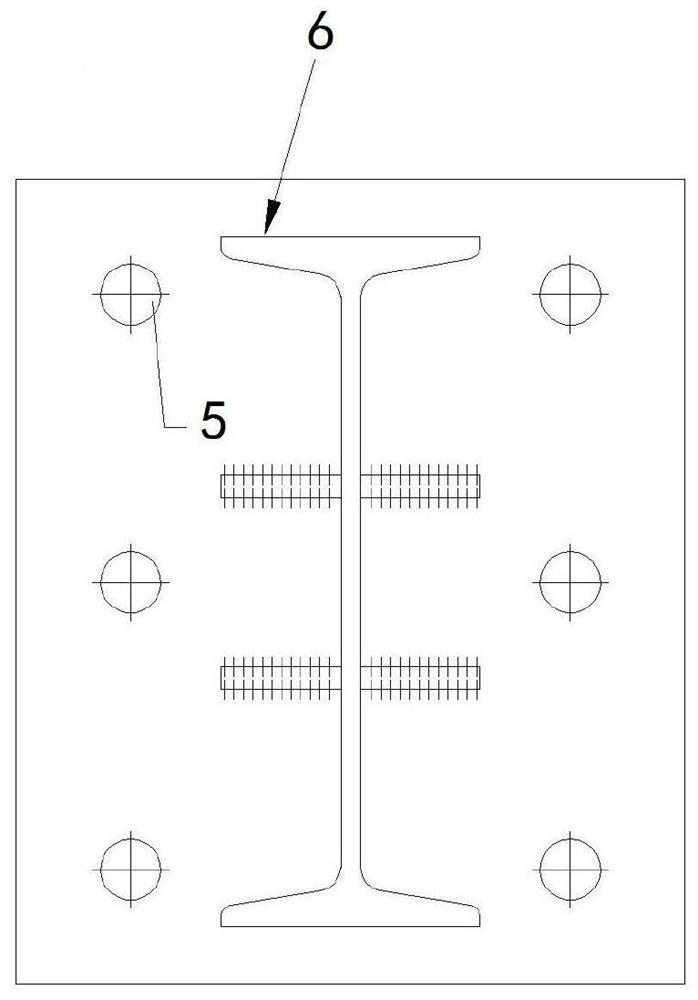

Shield segment, segment ring, tunnel segment lining, and tunnel

ActiveCN112727498AImprove carrying capacityEasy to implementUnderground chambersTunnel liningSupport systemSupporting system

The invention discloses a shield segment, a segment ring, a tunnel segment lining, and a tunnel. The shield segment comprises a segment body; an axial protrusion and a first caulking which are used for axial connection are arranged on a first side face of the segment body; an axial groove and a second caulking which are used for axial connection are arranged on a second side face of the segment body; in the annular direction of the segment body, a positioning protrusion used for annular positioning is arranged on the first annular face, and a positioning groove used for annular positioning is formed in the second annular face; an annular I-shaped steel support is inserted between every two adjacent segment rings; inner wing plates of the I-shaped steel supports are located at the inner sides of the inner rings of every two adjacent segment rings; outer wing plates of the I-shaped steel supports are inserted into caulking seams of the adjacent segment rings respectively; and bolts penetrate through the inner wing plates, the segment body and the outer wing plates. According to the shield segment, the segment ring, the tunnel segment lining, and the tunnel, compared with a traditional segment connecting mode, the axial and annular connection of the segments is jointly borne by the I-shaped steel supports and the segments, so that the connecting effect between the segments is strengthened, and meanwhile the integrity of a supporting system is improved.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

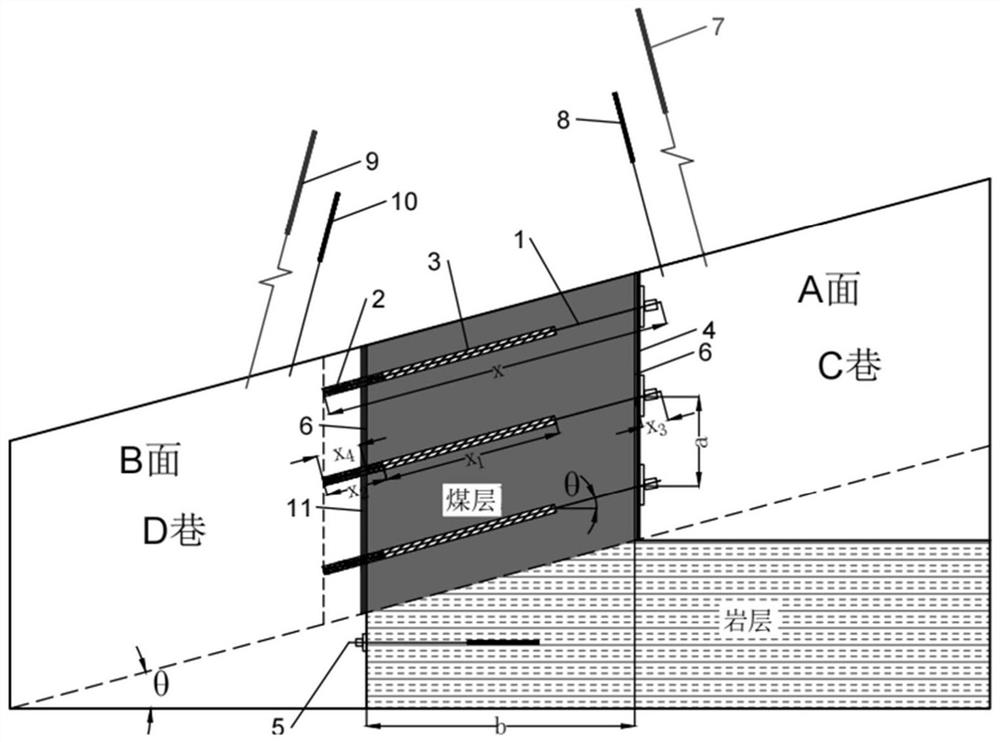

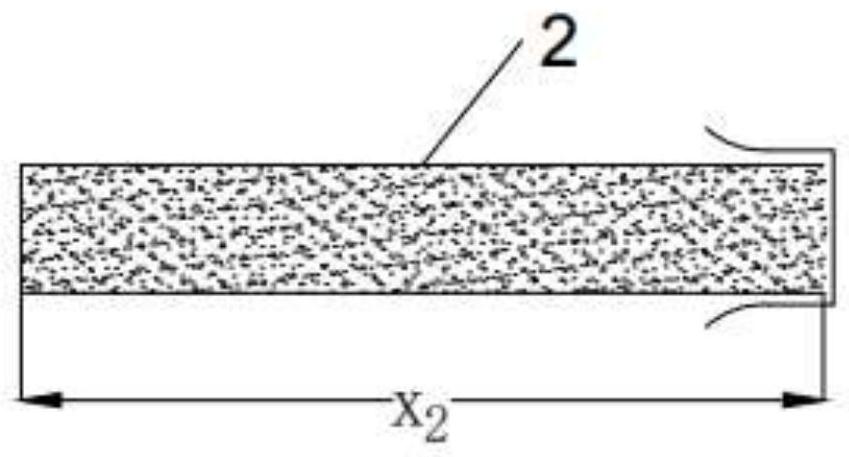

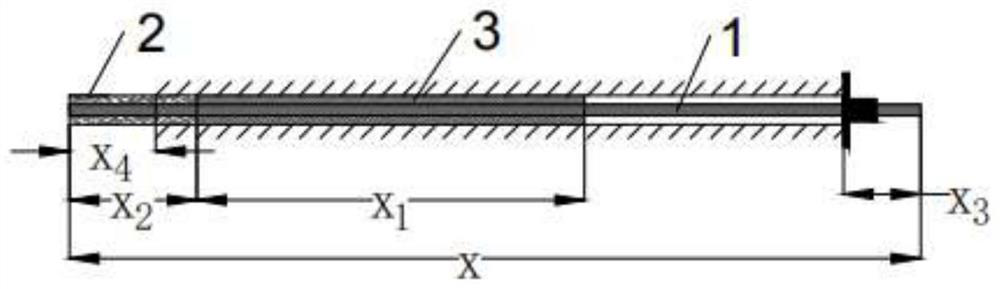

Cooperative anchoring structure for enhancing stability of gob-side entry driving coal pillar and construction method

PendingCN114704267AHigh strengthImprove carrying capacityUnderground chambersTunnel liningArchitectural engineeringCoal pillar

The invention relates to a collaborative anchoring structure for enhancing the stability of a gob-side entry driving coal pillar and a construction method, belongs to the technical field of gob-side entry driving coal pillar retaining mining, and solves the problem that an existing anchoring structure cannot meet the safety and stability requirements of a roadway. The construction method of the collaborative anchoring structure for enhancing the stability of the gob-side entry driving coal pillar comprises the steps that after an anchor net on the lower side of a roadway is laid, a first anchor cable is drilled; after drilling of a row of first anchor cables in the height direction of the lower side of the C roadway is completed, a first steel belt is used for interlocking the multiple first anchor cables in the row; in the tunneling process of the B face D roadway, the first anchor cable is installed to be located at the exposed end of the upper side of the D roadway. According to the collaborative anchoring structure for enhancing the stability of the gob-side entry driving coal pillar and the construction method, interlocking anchoring is carried out on the lower side of the roadway C on the A face and the upper side of the roadway D on the B face, two-time tensioning of the first anchor cable and cooperation of the first anchor cable and the second anchor rod on the pre-tightening force are achieved, and the strength and the bearing capacity of the coal pillar can be obviously enhanced.

Owner:CHINA UNIV OF MINING & TECH

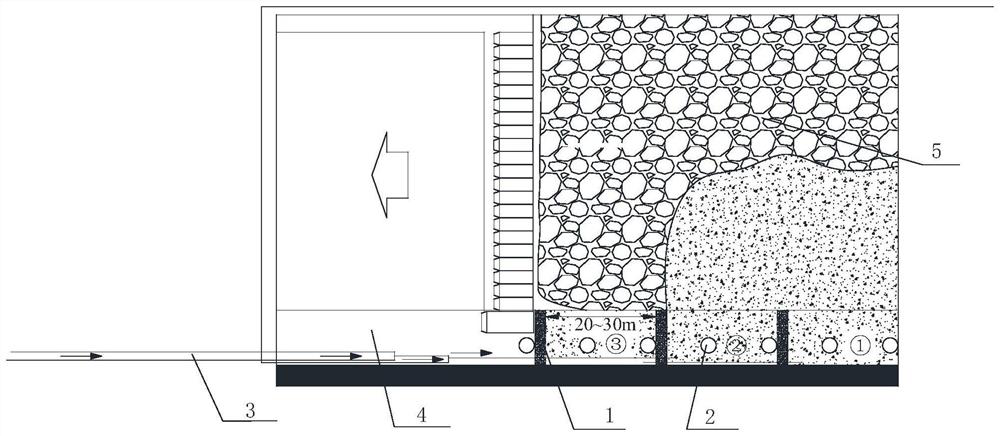

Roadway self-stabilizing and goaf filling method in coal-pillar-free mining

PendingCN114776372AExert carrying capacityAvoid affecting normal recoveryMaterial fill-upProps/chocksCoal pillarStoping

The invention discloses a roadway self-stabilization and goaf filling method in coal pillar-free mining, in the filling method, two bearing devices of grout stopping walls and pier studs are respectively designed, three cycles are used as a stage, namely three grout stopping walls are designed in advance, two pier studs are arranged in each grout stopping wall, and the interval between the grout stopping walls is 20-30 m. The grout stop wall can prevent goaf filling grout from overflowing to a working face to affect normal stoping. The pier columns support the roadway top plate, enable the roadway to be kept in a complete state and have filling space, and the pier columns are used at intervals, so that the bearing effect of the filling body in the roadway is exerted, and the filling cost is reduced.

Owner:BOXIA MINING TECH LTD +1

A method for forming a composite material tubular member

ActiveCN108995240BExert carrying capacityTape laying and winding process matchingMaterials preparationTotal thickness

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A kind of detection method of bearing capacity of carrier pile

ActiveCN107268690BAvoid excessive settlementImprove bindingFoundation testingVertical displacementTotal energy

Owner:王继忠 +1

A detachable U-shape primary support method combined with shed cover method construction

ActiveCN111379577BExert carrying capacityEnsuring the transmission of vertical forcesUnderground chambersTunnel liningSupporting systemPilot hole

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Method for improving binding strength of two-dimensional carbon/carbon composite material

The invention relates to a method for improving the binding strength of a two-dimensional carbon / carbon composite material so as to improve the tensile strength of the material in the horizontal direction, belonging to the technical field of heatproof bearing integrated carbon / carbon composite materials. The two-dimensional carbon / carbon composite material prepared by the method is moderate in binding strength of fibers and matrix interfaces, the fracture appearance is rough, multi-layered and multi-size fibers can be pulled out, the bearing and the force conduction effect of the fibers are brought into good play, the tensile property of the material is greatly improved, and the tensile strength is 137-301MPa, that is, the tensile strength is improved by more than 50% when being compared with the original tensile strength of 92MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

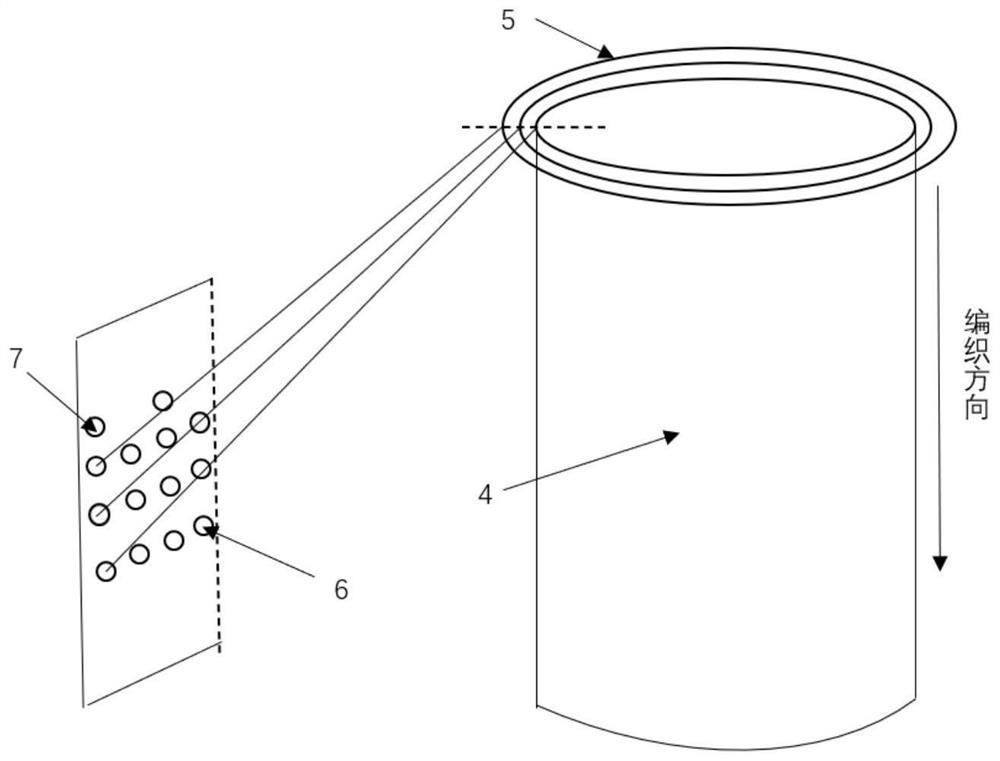

Full-sea deep-use reinforced integrated gradient braided composite pressure cylinder and preparation method thereof

ActiveCN113981586BImprove performanceReasonable mechanical structureMulti-ply fabricsCarbon fibersResin matrix

The invention discloses a reinforced integrated gradient braided composite material pressure cylinder for deep sea use and a preparation method thereof, and belongs to the field of equipment materials. The present invention selects high-strength and high-modulus carbon fibers, adopts the three-dimensional gradient weaving technology to prepare the reinforced gradient weaving preform, then selects the high-strength and high-toughness hydrophobic resin matrix, and uses the resin transfer molding technology to realize the pressure cylinder of the carbon fiber reinforced gradient weaving composite material. Prepared for low weight / volume ratio, ultra-high compressive strength and stability. The full-sea reinforced pressure cylinder prepared by the invention has the advantages of good overall performance, reasonable mechanical structure, excellent lateral performance and high stability, the critical buckling load is above 110MPa, the water pressure resistance is above 120MPa, and the bulk density ratio is 0.6 g / cm 3 Hereinafter, the transverse modulus is 9800 MPa or more, and the transverse compressive load ratio is 980 MPa or more.

Owner:JIANGNAN UNIV

Method for connecting initial support and large-diameter pipe shed during shed cover method construction

ActiveCN111379576AExert carrying capacityEnsure safetyUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a method for connecting an initial support and a large-diameter pipe shed during shed cover method construction. According to the method, the initial support of a side wall andthe pipe shed can be effectively connected together without providing an initial support on the top of a pilot tunnel during shed cover method construction. The connecting method comprises the following steps of arranging a connecting piece at the position, in the underground excavation pilot tunnel, of the bottom of the pipe shed, wherein the connecting piece comprises an arc-shaped supporting plate and a baffle, and the supporting plate is separately connected with the pipe shed and the baffle in a welded manner; a backing plate is arranged at the lower part of the connecting piece, and thebacking plate is a thick steel plate machined according to a design size, and the specific number is reasonably configured according to the distance between the pipe shed and an adjusting piece; theadjusting piece is arranged at the lower part of the backing plate, I-shaped steel or square steel can be selected as the adjusting piece according to different types of steel frames, and the adjusting piece is connected with the steel frame of the initial support through a bolt. According to the method, the bearing capacity of the large-diameter pipe shed is effectively exerted, the top of the pilot tunnel does not need to be provided with the initial support, the pipe shed and the initial support are formed into a whole, the stability in the pilot tunnel is ensured, the construction processes are few, quickness and simpleness are realized, the construction period is shortened, and material is saved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

A rigid pile composite foundation assembled pile cap and its assembling method

ActiveCN110004918BCollaborative working mechanism coordinationExert carrying capacityBulkheads/pilesPile capArchitectural engineering

The invention discloses a rigid pile composite foundation fabricated pile cap and an assembling method thereof. A pile sleeve is arranged at the top end of a rigid pile body, the end, being connectedwith a pile cap plate, of the pile top sleeve is arc, an arc gasket is arranged between the arc end of the pile top sleeve and the pile cap plate, a groove matched with the shape of the arc gasket isformed in the bottom center of the pile cap plate, the arc gasket is separately in contact with the pile top sleeve and the groove, and the arc gasket can separately slide relative to the groove and the pile top sleeve. According to the rigid pile composite foundation fabricated pile cap and the assembling method thereof, general members and materials are adopted, the structure is simple, the durability is high, the mounting is convenient, the assembly process of the pile cap is reduced, the member forming quality is improved, the cost is low, and popularization and use are facilitated.

Owner:NANJING FORESTRY UNIV +1

Composite foundation treatment method and application

The invention relates to a composite foundation treatment method and application. The composite foundation treatment method comprises an elastic pile cap system, a pile body, a load system and a preferable consolidation drainage system. The elastic pile cap system comprises reinforced concrete pile caps, expanded head geotechnical bags on the pile caps and leveling layer soil between the pile caps. The reinforced concrete pile caps are cast-in-place or prefabricated and is square; and the expanded head geotechnical bags on the pile caps are closed geotechnical bag bodies, and particle fillers are filled in the geotechnical bag bodies. The load system refers to embankment filling and gravel reinforced cushion layer filling load, and a gravel reinforced cushion layer is arranged on the top of leveling layer soil between the expanded head geotechnical bags and the pile caps. The consolidation drainage system comprises a horizontal drainage system and a vertical drainage system; the gravel cushion layer under the embankment is utilized by the horizontal drainage system; and the vertical drainage system refers to the vertical drainage channel arranged in the soil between the piles.

Owner:杨燕伟

Wheeled robot with traveling system

The invention relates to a wheel type robot with a walking system, and the walking system is formed by combing foot type walking devices with a driving device and is connected with a fixing frame (7); each foot type walking device is composed of a follower gear (1), a leg type supporter and a hanging mechanism (15) provided with wheels (16). One connection point of the leg type supporter is hinged with an eccentric point of the follower gear (1), and the other connection point of the leg type supporter is hinged with the connection point of the hanging mechanism; the number of the foot type walking devices is at least two, and the hanging devices (15) of at least two foot type walking devices are provided with electric motors (19) for driving wheels (16) to rotate; the driving device is provided with a main electric motor and a main drive shaft (6) which is provided with a main drive gear (4) engaged with the follower gear (1). The wheel type robot with the walking system has the characteristics of high motion velocity, simple control and flexible turning, and has the function of foot walking, so that the robot has more adaptive capacity to the ground.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com