High-stress soft rock roadway supporting system with metal mesh backplane and construction method

A roadway support and construction method technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of reducing the bearing capacity of arch frames, increasing workload, damage, etc., and achieves improved overall pressure bearing capacity and strong compression resistance Ability, security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

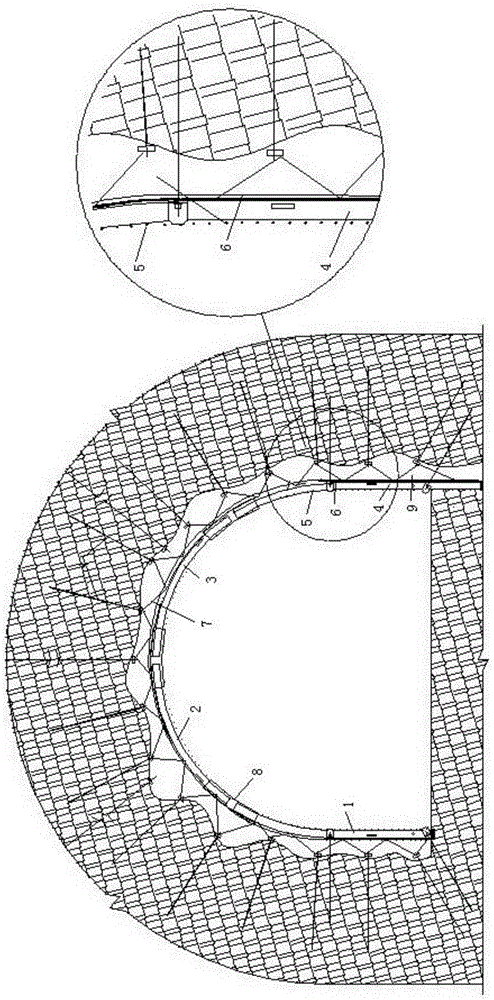

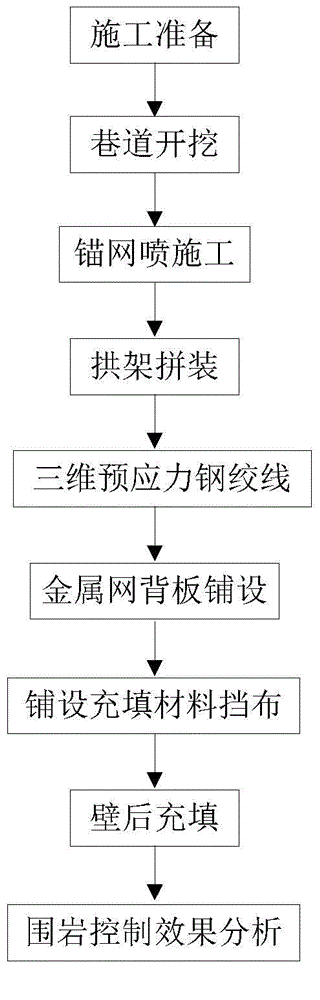

[0041] Such as Figure 1-Figure 2 As shown, the structure of the high-stress soft rock roadway support system with metal mesh backboard is as follows from inside to outside: metal mesh backboard 5, constrained concrete arch frame, filling material retaining cloth 6, wall filling material 9 and anchor Net spray support; the metal mesh back plate 5 is located under the restrained concrete arch, and the metal mesh back plate 5 is connected to the filling material dam 6; Stressed steel strands are connected.

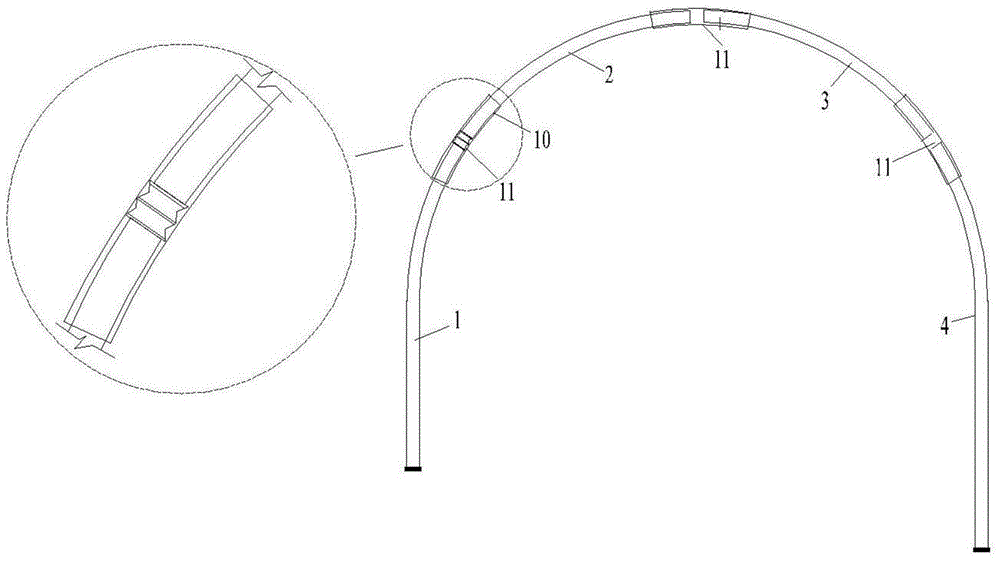

[0042] The constrained concrete arch frame includes a left arch leg 1, the upper end of the left arch leg 1 is connected with the left arch string 2 through the sleeve 10, the left arch string 2 is connected with the right arch string 3 through the sleeve 10, the lower end of the right arch string 3 is connected with the right arch leg 4 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com