Cooperative anchoring structure for enhancing stability of gob-side entry driving coal pillar and construction method

An anchoring structure and construction method technology, which is applied in the installation of bolts, earthwork drilling, shaft equipment, etc., can solve the problems of failing to meet the requirements of roadway safety and stability, and achieve effective protection of coal pillars, realization of coal mine safety, and reduction of roadways. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

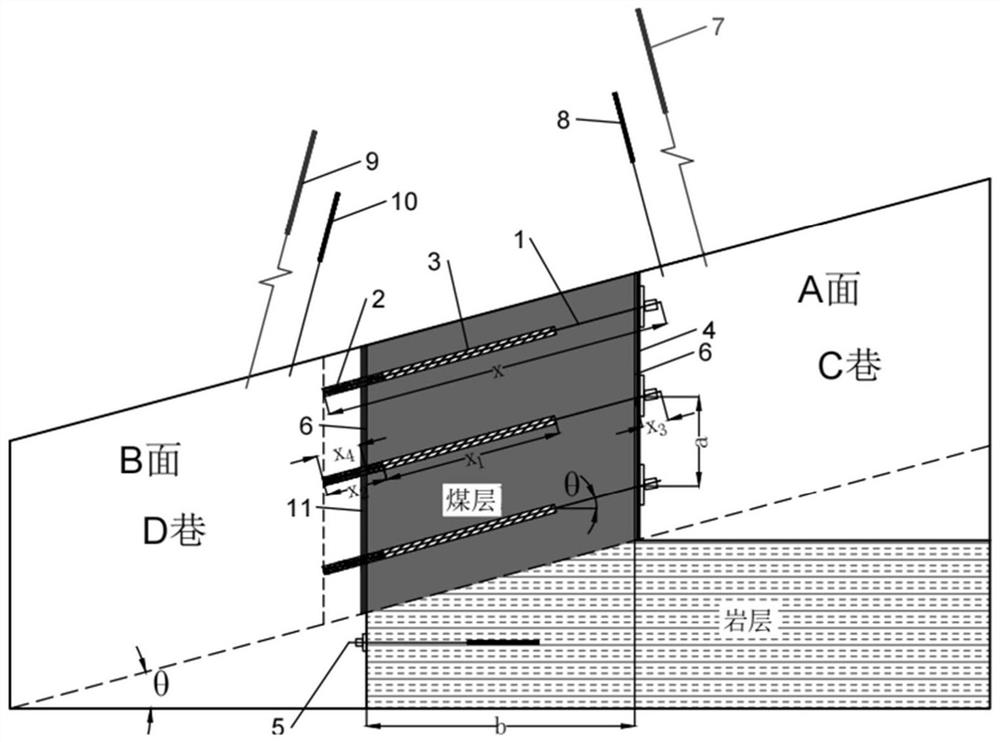

[0038] An embodiment of the present invention, such as Figure 1 to Figure 5 As shown, a construction method of a coordinated anchoring structure for enhancing the stability of a gob-gob coal pillar is disclosed, comprising the following steps:

[0039] Step 1: During the excavation of the A-side C roadway, the anchor net 6 is laid under the C roadway.

[0040] When arranging the roadway on the working face of the coal mine, when excavating the roadway on the A side and the C roadway, the roadway is driven along the roof of the coal seam. When the thickness of the coal seam is higher than 1500mm, the height of the lower part of the C roadway is consistent with the thickness of the coal seam; when the thickness of the coal seam is less than 1500mm, the excavation depth of the lower part exceeds the bottom plate to meet the normal use requirements of the roadway.

[0041] During the excavation of the roadway, the anchor mesh 6 is laid at the same time, and the anchor mesh 6 is ...

Embodiment 2

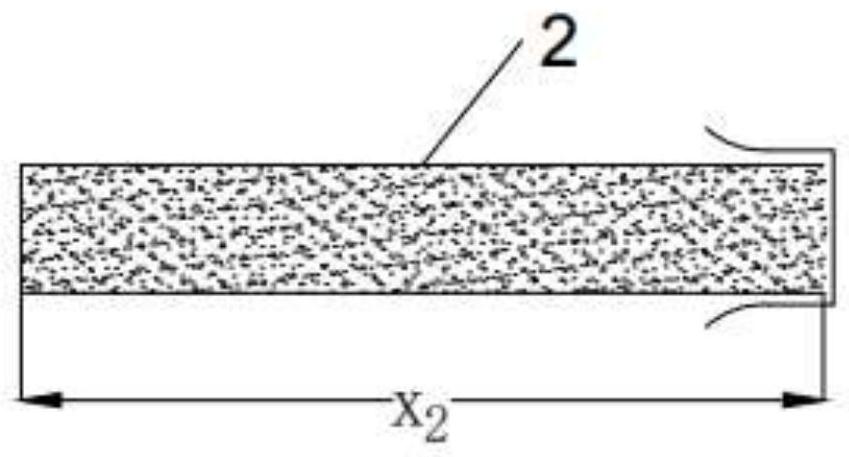

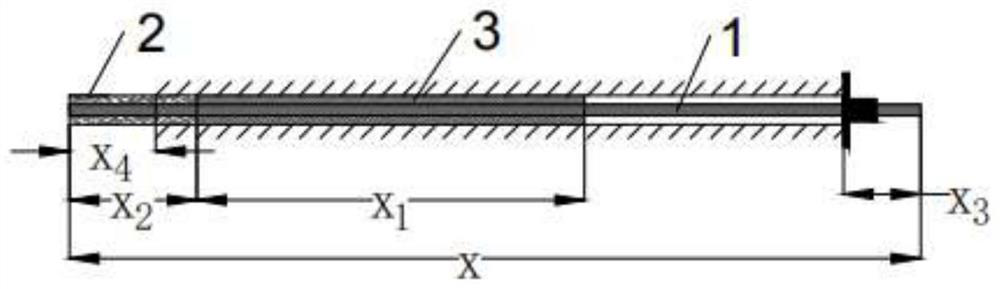

[0077] An embodiment of the present invention, such as Figure 1 to Figure 5 As shown, a coordinated anchoring structure for enhancing the stability of coal pillars in gob-side driving is disclosed, including a first anchor cable 1, a protective sleeve 2, a first steel belt 4, a second steel belt 11 and an anchor net 6. The nets 6 are laid on both sides of the coal pillar, the first anchor cables 1 are drilled and mounted on the coal pillar, and the exposed parts of the multiple first anchor cables 1 located on the same end face are connected by the first steel belt 4 in the exposed part of the lower side of the C roadway. , the exposed part of the upper part of the D roadway is interlocked by the second steel belt 11 .

[0078] In this embodiment, by interlocking and anchoring the lower side of the roadway on the A side and the upper side of the roadway on the B side, the double tension of the first anchor cable and the coordination of the pre-tightening force can be realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com