Detachable U-shaped preliminary bracing method combined with canopy-method construction

An initial support, U-shaped technology, used in earth-moving drilling, wellbore lining, tunnel lining and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

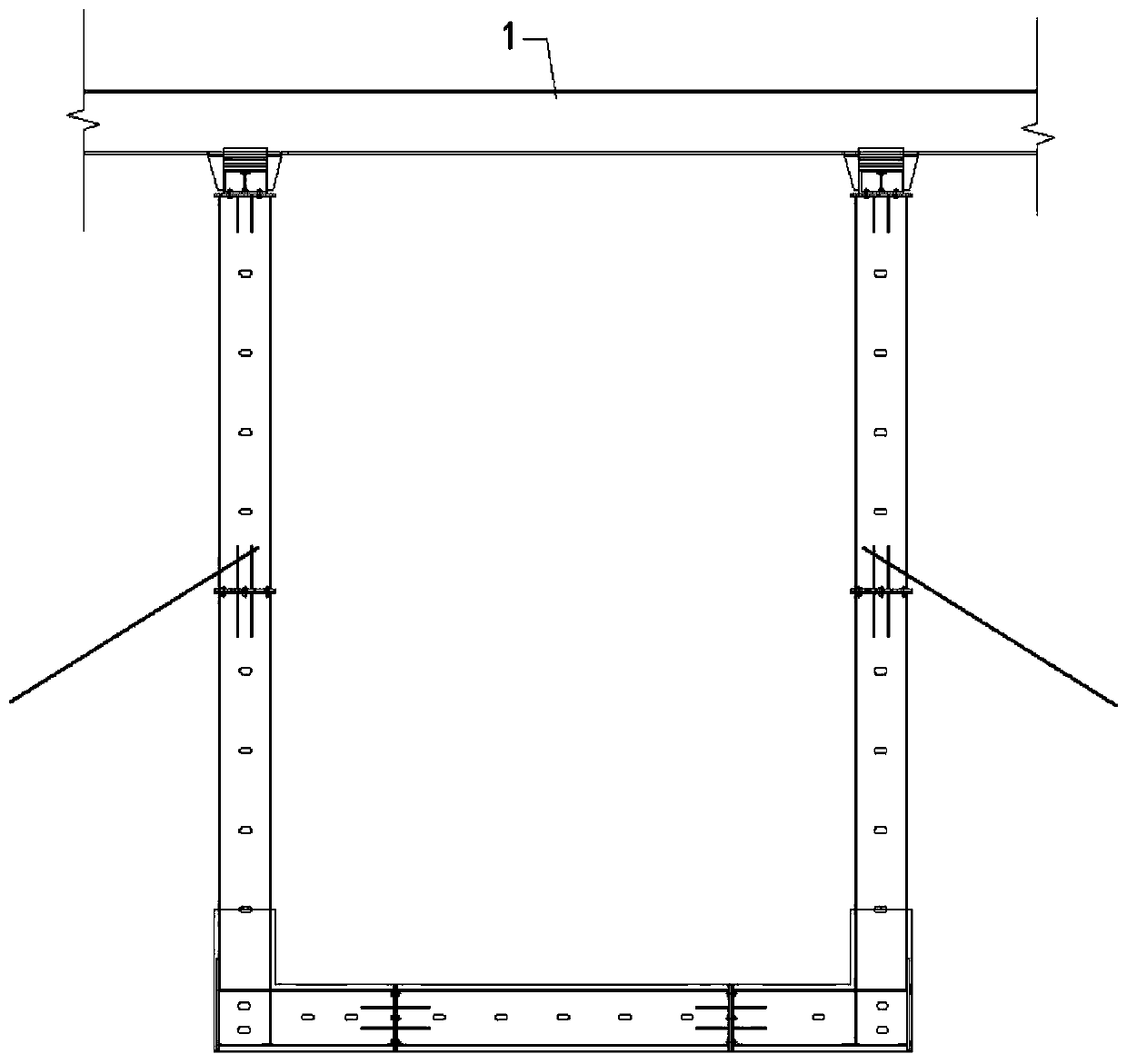

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The invention relates to a detachable U-shaped initial support structure combined with the construction of the shed cover method and its construction method.

[0027] The specific implementation method is:

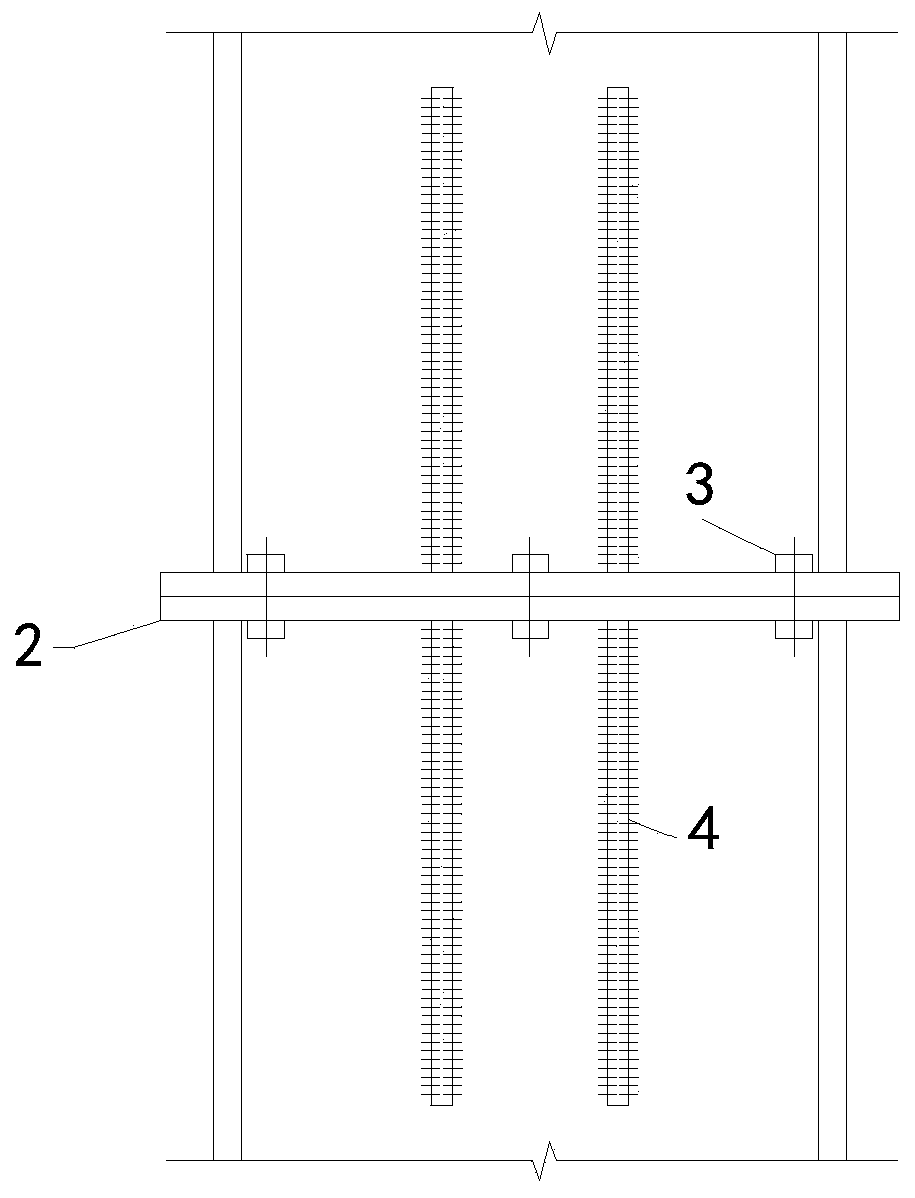

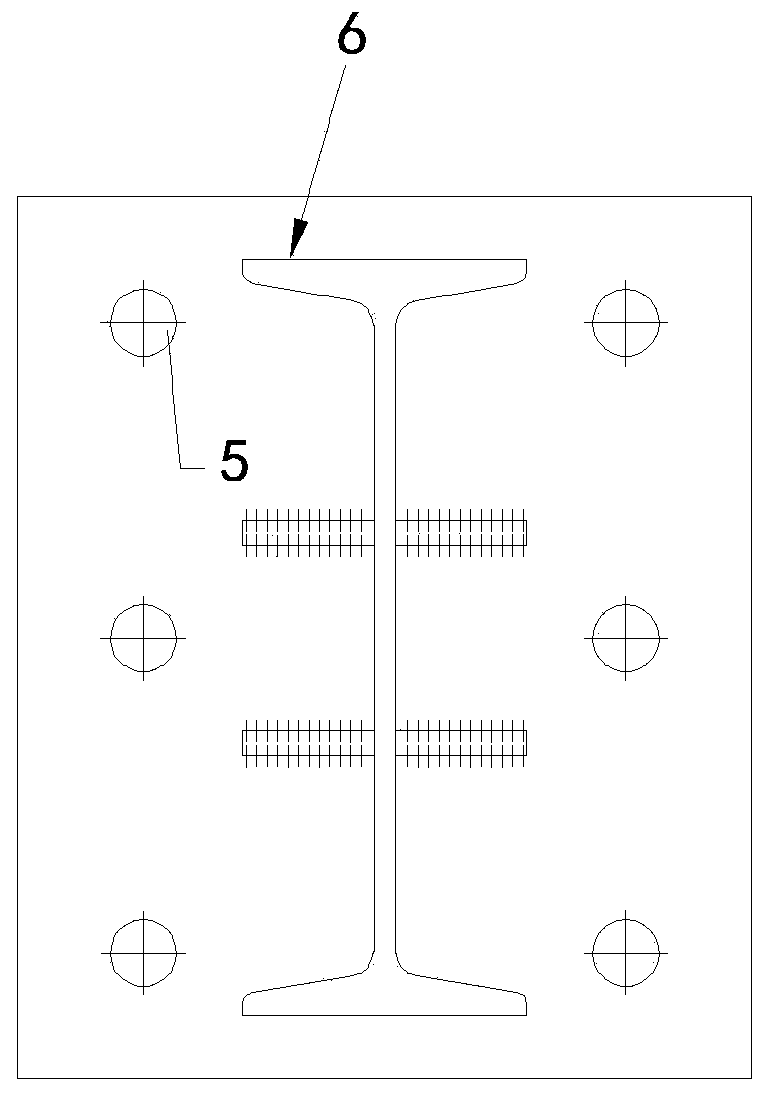

[0028] (1) Profile steel material preparation: Prepare profile steel that meets the requirements of the diagram as the material for the profile steel columns on both sides and the bottom profile, and make web holes according to the requirements of the diagram.

[0029] (2) Preparation of connection joints: weld steel plates at the connection joints (ends of section steel) according to the requirements of the diagram, and open bolt holes according to the position and size of the diagram. Prepare the stiffener version according to the requirements of the diagram, and weld it at the designated position of the joint part.

[0030] (3) Preparation of corner joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com