Composite foundation treatment method and application

A treatment method and composite foundation technology, which is applied in foundation structure engineering, construction, soil protection, etc., can solve the problem that the bearing capacity of the pile body and the soil between the piles cannot be fully exerted, the permeable rigid pile needs special processing, the pile body and the pile In order to control the post-construction settlement, reduce the length of piles, and increase the distance between piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

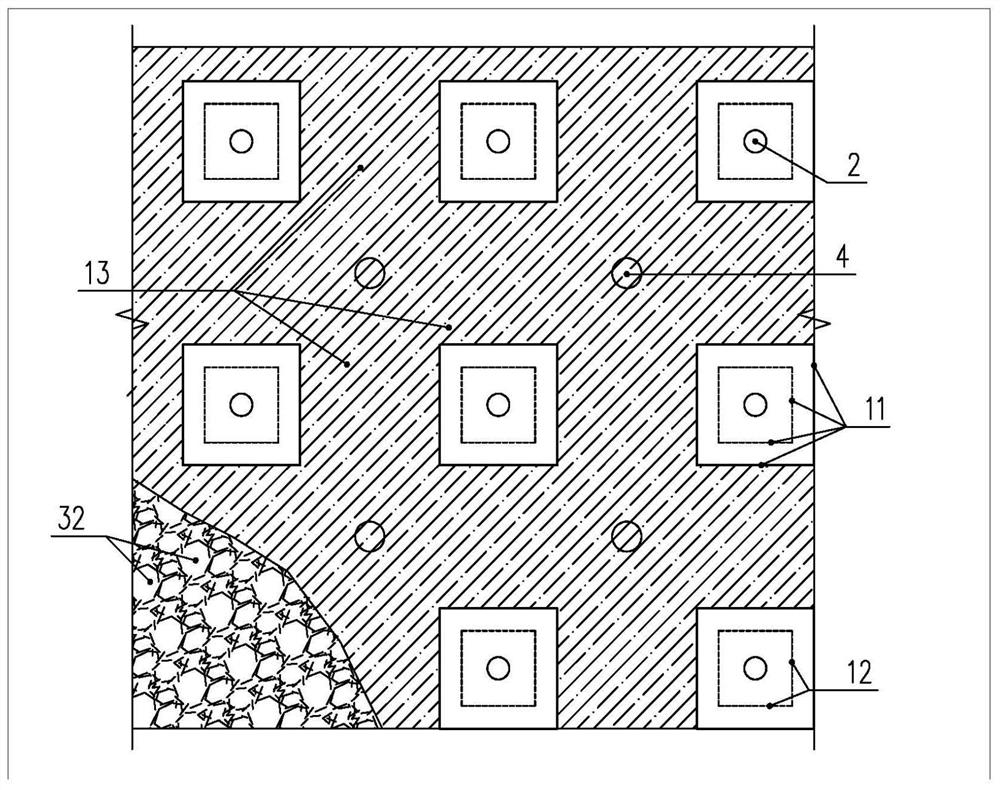

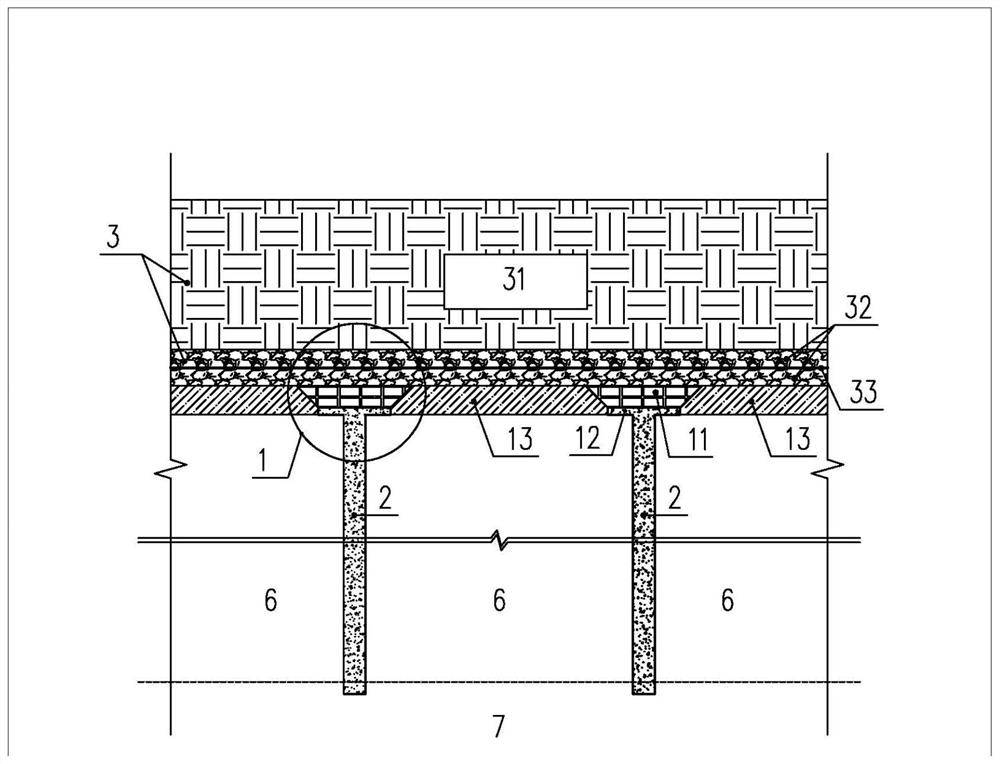

[0034] Example 1: A Composite Foundation Treatment Method

[0035] refer to figure 1 , figure 2 , Figure 4 with Figure 5 , the geological condition of the site is a relatively deep layer of soft plastic to plastic silty clay 6 overlying it, underneath it is a bearing layer 7 of plastic to hard plastic silty clay, and the groundwater level is about 1 meter below the surface. Composite foundation treatment adopts PHC pipe pile 2, and the pile body penetrates the soft plastic to plastic powdery clay layer 6 and enters the plastic to hard plastic powdery clay bearing layer 7, and no vertical drainage channel is set.

[0036] Specifically include the following steps: leveling the construction site to the bottom of the reinforced concrete pile cap 12, using the static pressure method to construct the PHC pipe pile 2; constructing the elastic pile cap system 1, including: the reinforced concrete pile cap 12 is connected with the PHC through reserved steel bars or steel parts T...

Embodiment 2

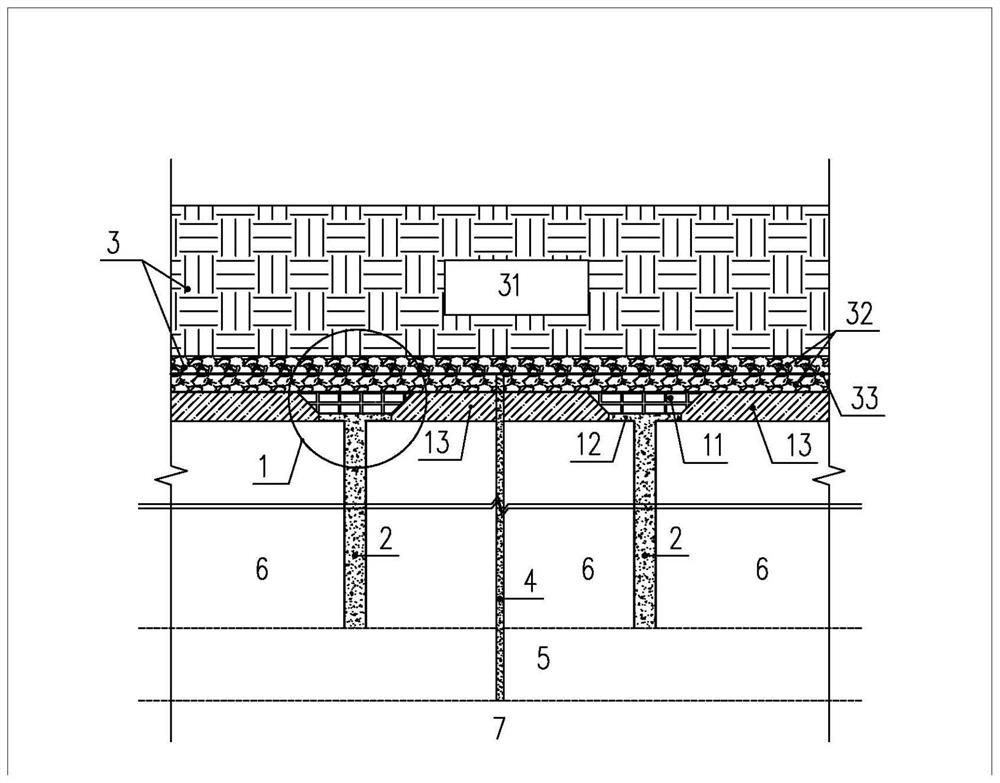

[0038] Embodiment 2: A composite foundation treatment method, applied to a composite foundation with a consolidated drainage system.

[0039] refer tofigure 1 , image 3 , Figure 4 with Figure 5 , the geological condition of the site is a relatively deep layer of soft plastic to plastic silty clay 6 overlying it, underneath it is a bearing layer 7 of plastic to hard plastic silty clay, and the groundwater level is about 1 meter below the surface. Composite foundation treatment adopts PHC pipe pile 2, the pile body does not penetrate through the soft plastic ~ plastic powdery clay layer 6, the remaining part of the underlying layer 5, the vertical drainage channel 4 uses plastic drainage boards, and the drainage board penetrates through soft plastic ~ plastic powder The clay layer 6 reaches the top of the plastic-hard plastic silty clay bearing layer 7.

[0040] Specifically include the following steps: leveling the construction site to a pile top elevation of 50 cm or mor...

Embodiment 3

[0042] Example 3: A composite foundation treatment method without vertical drainage system

[0043] refer to figure 1 , figure 2 , Figure 4 with Figure 5 The geological condition of the site is that there is a relatively thick plain fill layer 6 overlying it, the bedrock 7 below it, and the groundwater is stagnant water in the upper layer and fissure water in the bedrock. The composite foundation treatment adopts bored cast-in-situ piles 2, and the pile body penetrates the plain fill layer 6 and enters the bedrock 7, and vertical drainage channels are not provided.

[0044] It specifically includes the following steps: leveling the construction site; using the rotary drilling drill to follow up the sleeve to form a hole, pouring concrete to form a pile 2, and pulling out the sleeve after the concrete pouring is completed; the construction of the pile body is completed, and after the design strength requirement is reached, the pile top is enlarged The head soil is excava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com