Method for connecting initial support and large-diameter pipe shed during shed cover method construction

A technology of primary support and connection method, which is applied in the direction of earthwork drilling, wellbore lining, tunnel lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

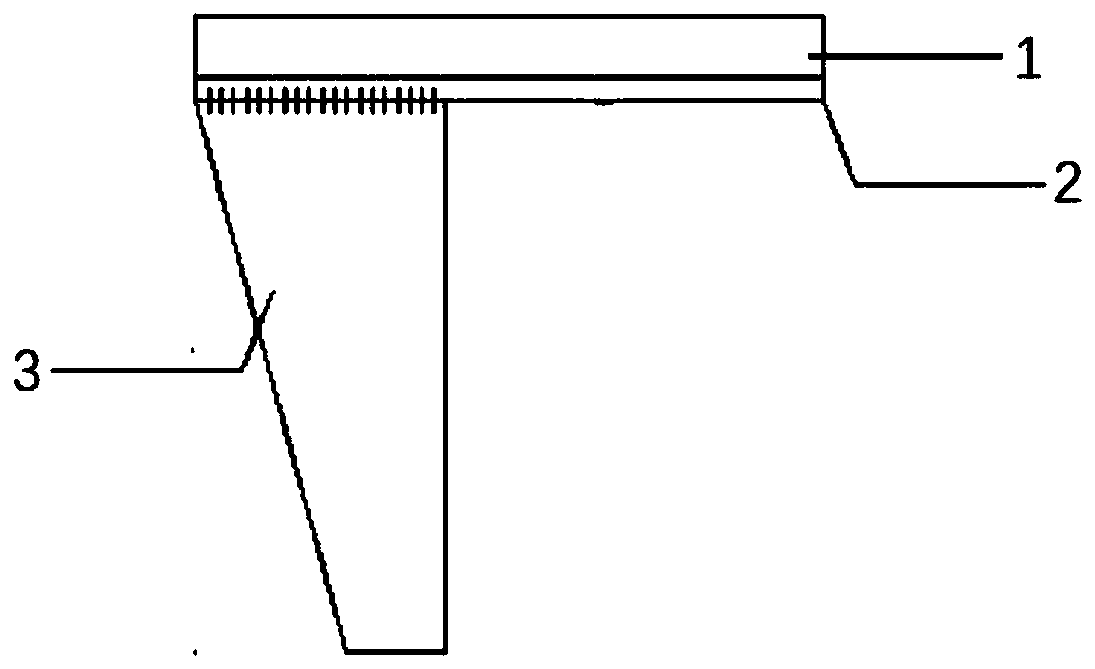

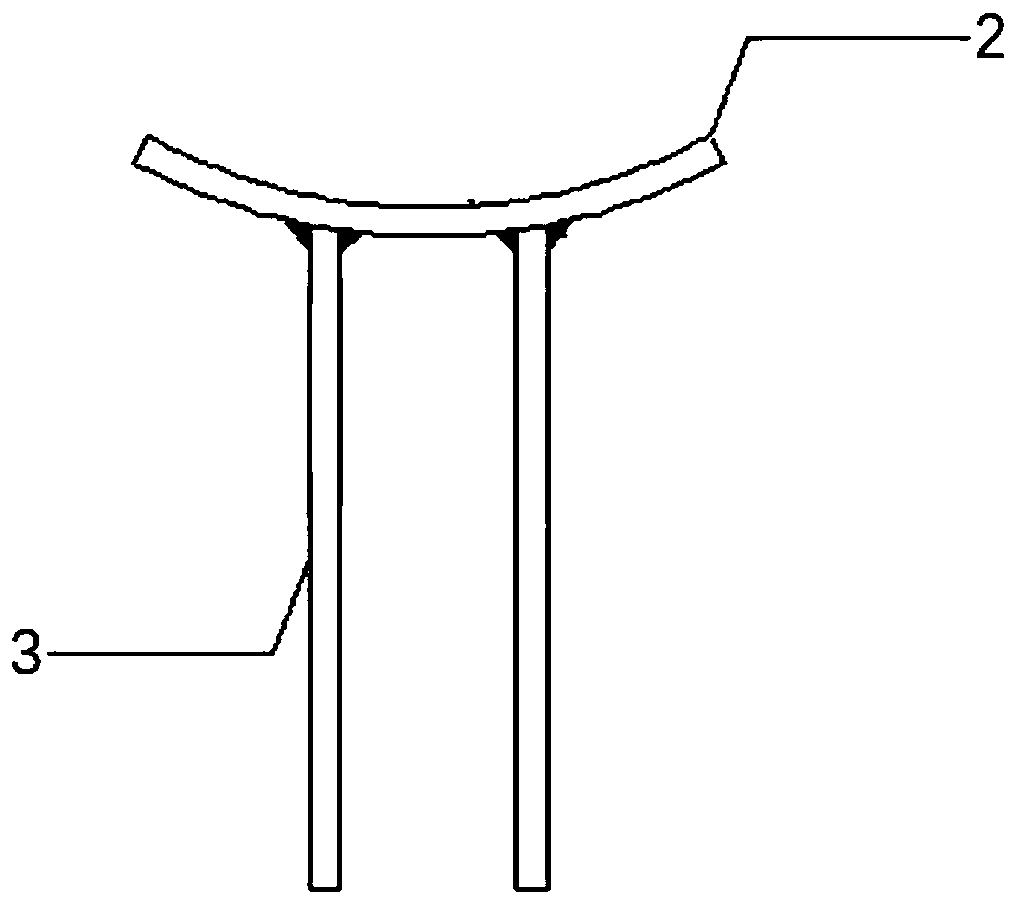

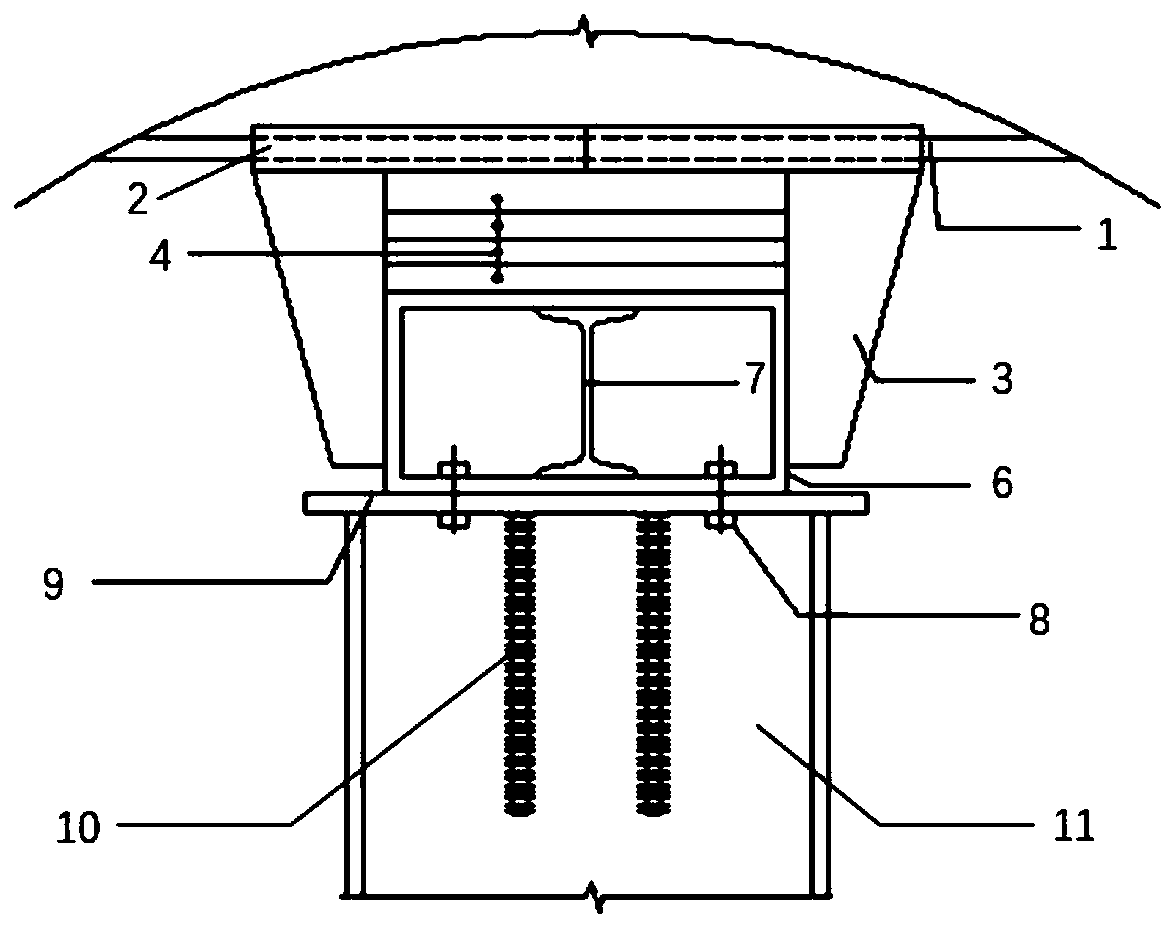

[0032] A method for connecting the initial support of the construction of the shed cover method and the large-diameter pipe shed, characterized in that the connecting parts include a large pipe shed (1), an arc-shaped supporting plate (2), a baffle plate (3), a pad Plate (4), adjustment piece (5), primary support steel frame (6), steel mesh sheet (7), locking foot anchor pipe (8), longitudinal connecting rib (9); carry out large-diameter pipe shed (1) The construction of the pipe shed after the completion of the construction forms a shed cover system; the excavation of the pilot tunnel is carried out. plate (3), and lay reinforcement mesh (7) along the side wall of the pilot tunnel, set up steel arches (6) on both sides, set up locking foot anchor pipes (8), install longitudinal connecting ribs (9); install adjustment parts (5), and fill the gap between the adjustment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com