Method for improving binding strength of two-dimensional carbon/carbon composite material

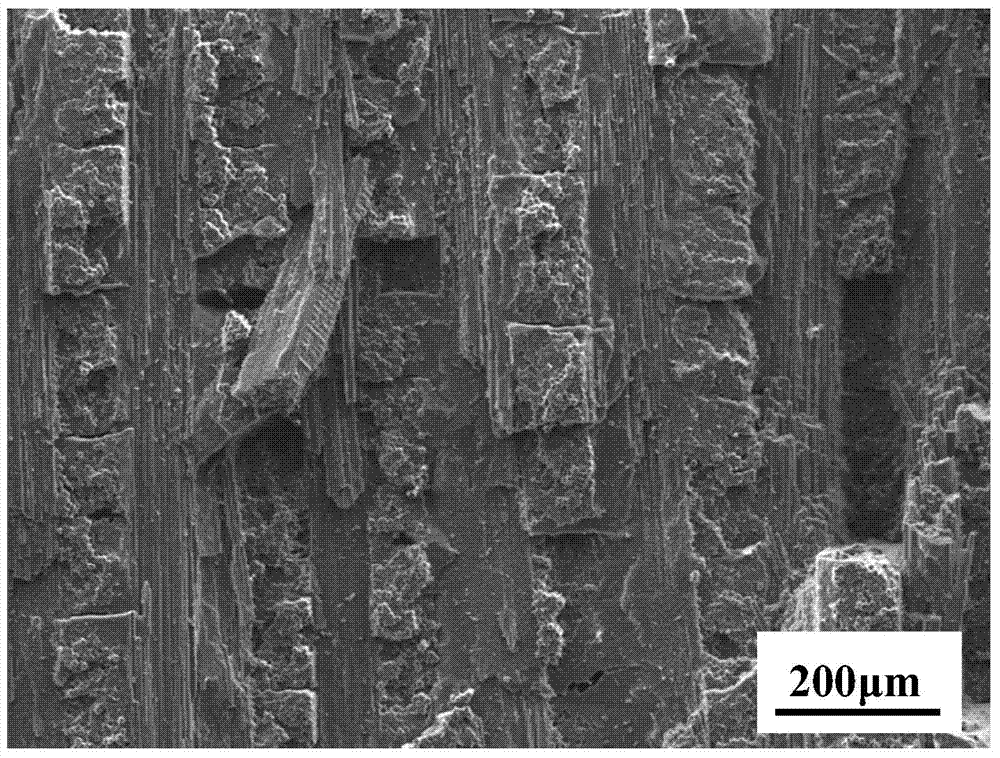

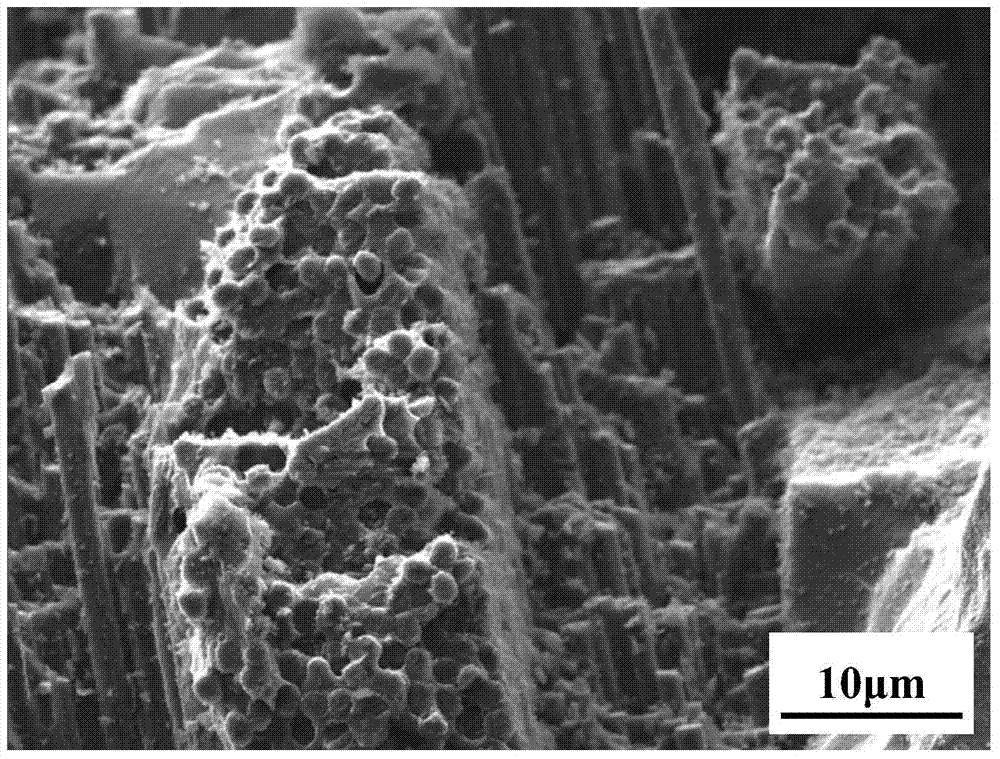

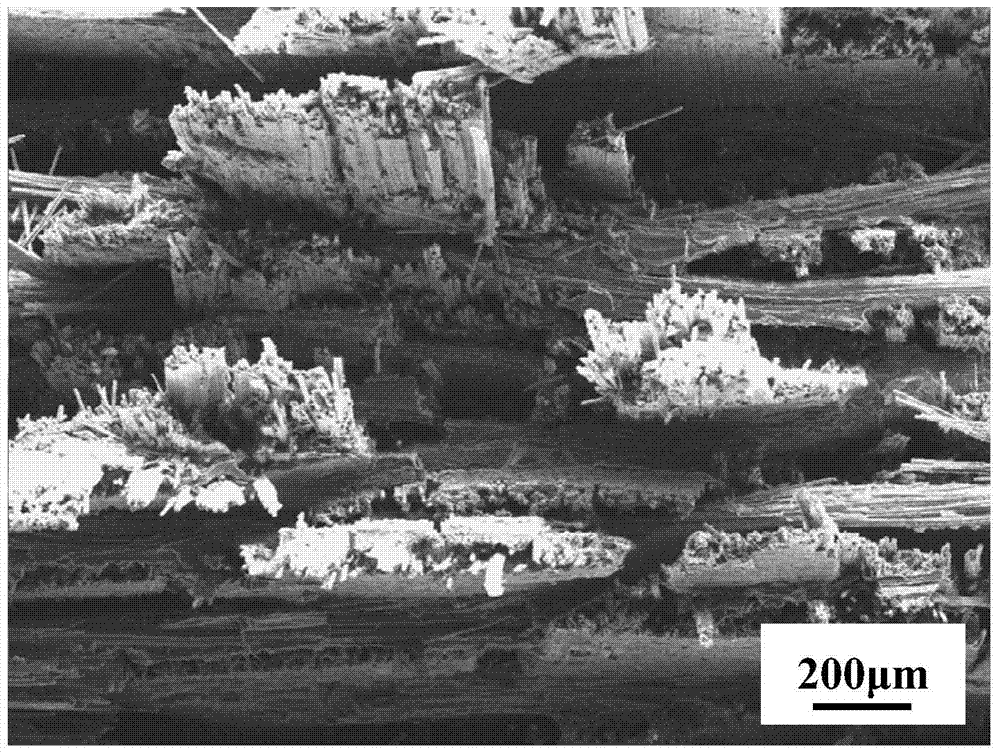

A technology of interface bonding strength and carbon composite material, which is applied in the field of improving the interface bonding strength of two-dimensional carbon/carbon composite materials, can solve problems such as excessive interface bonding, and achieve improved tensile properties, moderate bonding strength, and rough fracture morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weave 5Kg carbon fiber into four pieces of satin carbon cloth;

[0035] 2) Mix the carbon black filler and the phenolic resin solution in a mass ratio of 1:9 to obtain a phenolic resin solution, and impregnate the carbon cloth obtained in step 1) into the phenolic resin solution to make a prepreg, and cut it into 200mm ×200mm cloth;

[0036] 3) Lay the cloth pieces obtained in 2) at 0° and 90° to form a green body with a thickness of 20mm;

[0037] 4) Heat the ply body obtained in 3) on the platform of the hot press to 90°C, hold the temperature for 30 minutes and start to pressurize to 5MPa, keep the pressure for 2 hours, then continue to heat up to 180°C, keep the temperature and hold the pressure 4h, obtain the two-dimensional carbon / carbon composite material process sample;

[0038] 5) Put the two-dimensional composite material process sample obtained in 4) into a carbonization furnace and raise the temperature to 850°C under the protection of an argon atmosphe...

Embodiment 2

[0046] 1) Weave 5Kg carbon fiber into eight pieces of satin carbon cloth;

[0047] 2) Mix the carbon black filler with the phenolic resin solution at a mass ratio of 1:9 to obtain a phenolic resin solution, and impregnate the carbon cloth obtained in step 1) into the phenolic resin solution to make a prepreg, and mix the ) impregnated with the obtained phenolic resin containing filler to make a prepreg, and cut it into 200mm×200mm cloth pieces;

[0048] 3) Lay the cloth pieces obtained in 2) at 0° and 90° to form a green body with a thickness of 20mm;

[0049] 4) Heat the ply body obtained in 3) on the platform of the hot press to 90°C, hold the temperature for 30 minutes and start to pressurize to 5MPa, keep the pressure for 2 hours, then continue to heat up to 180°C, keep the temperature and hold the pressure 4h, obtain the two-dimensional carbon / carbon composite material process sample;

[0050] 5) Put the two-dimensional composite material process sample obtained in 4) i...

Embodiment 3

[0058] 1) Weave 5Kg carbon fiber into four pieces of satin-weave carbon cloth, pretreatment temperature of carbon cloth is 850℃, keep warm for 1h;

[0059] 2) Mix the carbon black filler with the phenolic resin solution at a mass ratio of 1:9 to obtain a phenolic resin solution, and impregnate the carbon cloth obtained in step 1) into the phenolic resin solution to make a prepreg, and mix the ) impregnated with the obtained phenolic resin containing filler to make a prepreg, and cut it into 200mm×200mm cloth pieces;

[0060] 3) Lay the cloth pieces obtained in 2) at 0° and 90° to form a 40mm thick green body;

[0061] 4) Heat the ply body obtained in 3) on the platform of the hot press to 90°C, hold the temperature for 30 minutes and start to pressurize to 5MPa, keep the pressure for 2 hours, then continue to heat up to 180°C, keep the temperature and hold the pressure 4h, obtain the two-dimensional carbon / carbon composite material process sample;

[0062] 5) Put the two-dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com