Novel slurry refining and concentrating system

A concentration system and slurry technology, applied in the field of sanitary napkin concentration, can solve the problems of short fibers, low fiber dry bulkiness, and poor filling properties of fluff pulp, and achieve high dry bulkiness, good absorbency, and make up for quality. The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

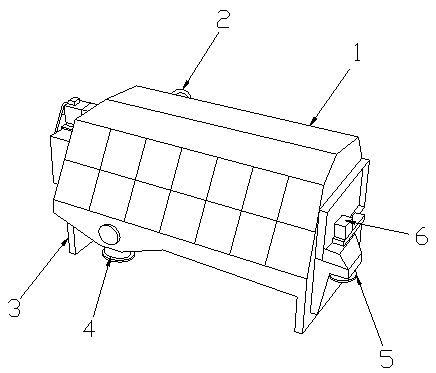

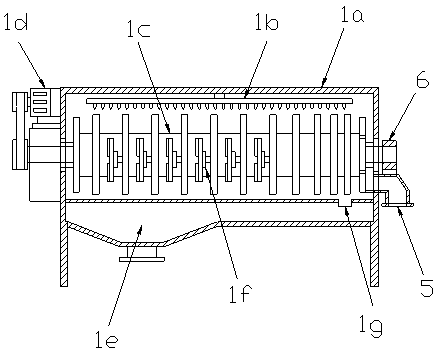

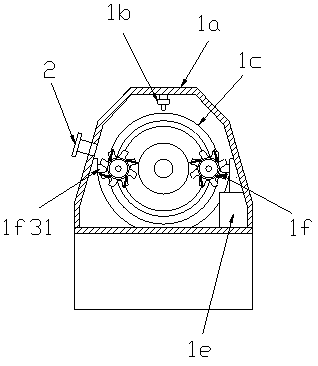

[0028] see Figure 1-Figure 7 , the present invention provides a novel slurry refining and concentrating system, the structure of which includes a slurry concentrator 1, a feed pipe 2, a support frame 3, a discharge pipe 4, a slag discharge pipe 5, and a bearing seat 6. The slurry A support frame 3 is provided under the bottom end of the thickener 1, and the slurry thickener 1 is connected to the support frame 3. The surface of the slurry thickener 1 is provided with a feed pipe 2, and the slurry thickener 1 is provided with a feed pipe 2. The machine 1 and the feed pipe 2 are welded by electric welding. The bottom of the slurry thickener 1 is provided with a discharge pipe 4. The slurry thickener 1 and the discharge pipe 4 are fixedly connected. The slurry A bearing seat 6 is installed on the right end of the concentrator 1, and a slag discharge pipe 5 is provided under the right end of the slurry concentrator 1, and the slurry concentrator 1 is connected to the slag discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com