Full-sea deep-use reinforced integrated gradient braided composite pressure cylinder and preparation method thereof

A composite material and pressure cylinder technology, applied in textiles, fabrics, multi-strand fabrics, etc., can solve problems such as poor fiber elongation adaptability, microscopic fiber crack interface, pressure vessel instability and failure, and achieve simple equipment and excellent lateral performance. , the effect of reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

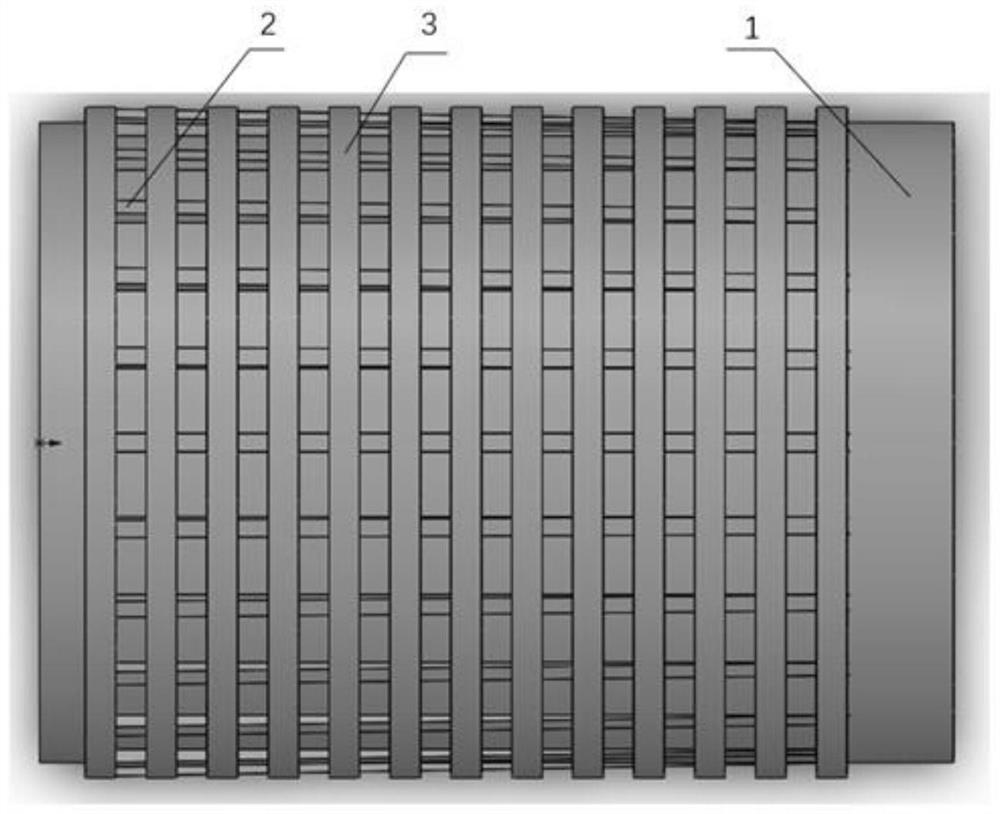

[0054] A prefabricated body of a full-sea reinforced integrated gradient braided composite pressure cylinder (such as figure 1 ) method, described method is to adopt 6 jacquard machines to carry out integrated gradient weaving simultaneously; Comprise the steps:

[0055] (1) According to the size, bearing pressure and weight / volume ratio of the pressure cylinder, the structure of the reinforced gradient woven composite pressure cylinder is designed, and the yarn arrangement and rib yarn arrangement of the pressure cylinder along the wall thickness direction are obtained. process parameters;

[0056] The size of the pressure cylinder: the length is 1000mm, the outer diameter is 400mm, the wall thickness is 50mm, and there are 18 circumferential reinforcement strips and 18 longitudinal reinforcement strips;

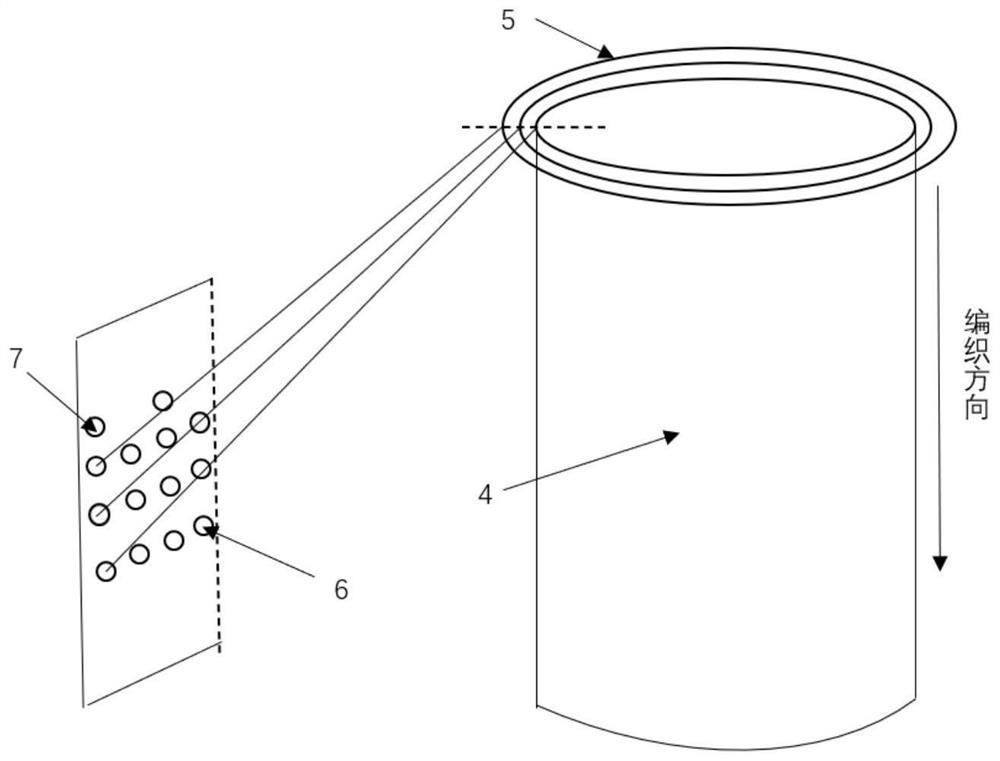

[0057] Use 6 jacquard looms on the periphery of the quartz sand core mold 1, such as figure 2 , along the direction of the pressure cylinder, on the warp yarn annular tr...

Embodiment 2

[0082] A method for preparing a reinforced pressure cylinder for full-sea deep use, comprising the following steps:

[0083] (1) Preparation of modified epoxy resin:

[0084] Stir 80 parts of 4080e epoxy resin and 30 parts of diallyl bisphenol A at 100°C, after dissolving, cool down to 70°C, add 40 parts of CYDF170 epoxy resin, add 3 parts of 5nm nano-ceramic powder, 5 parts Alumina, stir evenly to obtain modified 4080e epoxy resin; wherein, the number of parts is by mass;

[0085] (2) Preparation of resin solution:

[0086] The modified 4080e epoxy resin, bisphenol A epoxy resin, epoxy resin curing agent (diaminodiphenyl sulfone DDS, purchased from Suzhou Yinsheng Chemical Co., Ltd.) and T-403 curing agent are in a mass ratio of 4:2:2 : 1. Mix evenly to obtain resin solution;

[0087] (3) Compounding:

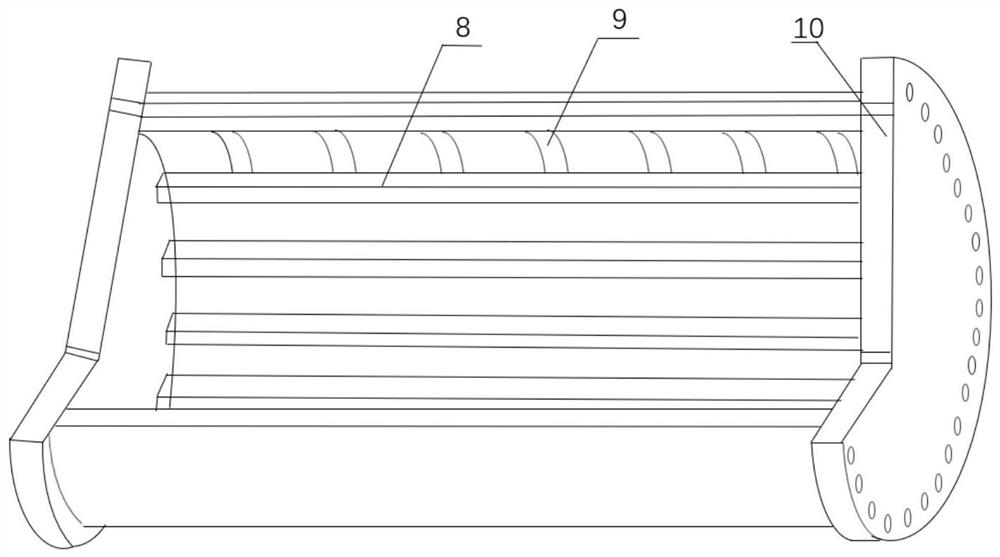

[0088] The pressure cylinder preform obtained in Example 1 is put into a composite mold (such as image 3), the composite mold has a longitudinal rib filling port 8 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com