Multilayer ceramic-based composite material for aero-engine thermal structural member and preparation method thereof

An aero-engine, multilayer ceramic technology, applied in the field of materials, can solve the problems of erosion, performance attenuation, mechanical property damage of composite materials, etc., and achieve the effect of reducing porosity, improving mechanical behavior, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a method for preparing a multilayer ceramic matrix composite material for thermal structural parts of an aero-engine, comprising the following steps:

[0044] Step 1: Using continuous fibers as the toughening phase to prepare a fiber preform, the structure of the preform is any one of ply stitching, three-dimensional braided structure, 2.5D and other structures, the continuous fiber is silicon carbide fiber, and the The fiber volume fraction in the preform is 30-45%; step 2: use chemical vapor deposition to deposit on the surface of the fiber in the fiber preform to obtain a composite interface of pyrolytic carbon and SiC nanowires to obtain a primary body; step 3: use vacuum - Pressurized impregnation process to quickly densify the product obtained in step 2 to obtain a secondary green body; step 4: use chemical vapor infiltration process to fill the secondary green body with matrix, and perform pre-oxidation to obtain a third-grade green body; st...

Embodiment 1

[0051] The invention provides a method for preparing a multilayer ceramic matrix composite material for thermal structural parts of an aero-engine, comprising the following steps:

[0052] Step 1: using continuous fibers as the toughening phase to prepare a fiber preform, the structure of the preform is ply stitching, the continuous fibers are silicon carbide fibers, and the fiber volume fraction in the preform is 45%;

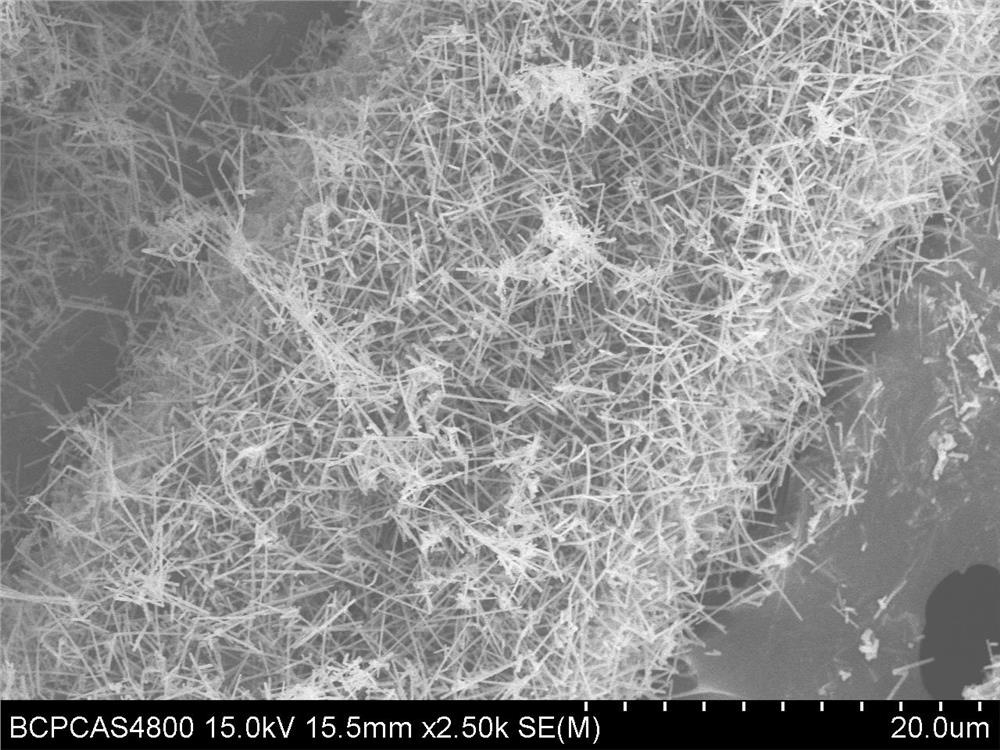

[0053] Step 2: Deposit the surface of the fiber in the fiber preform by chemical vapor deposition to obtain a composite interface of pyrolytic carbon and SiC nanowires to obtain a primary green body; the preparation method of the pyrolytic carbon interface is to place the preform in pyrolysis In the carbon deposition equipment, propane is used as the deposition gas, nitrogen is used as the dilution gas, the deposition temperature is 700°C, the deposition time is 5h, and the deposition pressure is 1200Pa, wherein the propane flow rate is 50g / h, and the nitrogen ...

Embodiment 2

[0060] The invention provides a method for preparing a multilayer ceramic matrix composite material for thermal structural parts of an aero-engine, comprising the following steps:

[0061] Step 1: using continuous fibers as the toughening phase to prepare a fiber preform, the preform structure is a three-dimensional braided structure, the continuous fibers are silicon carbide fibers, and the fiber volume fraction in the preform is 40%;

[0062] Step 2: Deposit the surface of the fiber in the fiber preform by chemical vapor deposition to obtain a composite interface of pyrolytic carbon and SiC nanowires to obtain a primary green body; the preparation method of the pyrolytic carbon interface is to place the preform in pyrolysis In the carbon deposition equipment, propane is used as the deposition gas, nitrogen is used as the dilution gas, the deposition temperature is 800 ° C, the deposition time is 3.5 h, and the deposition pressure is 1200 Pa, wherein the propane flow rate is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com