A device and method for automatic film laying of composite material preforms

A preform and composite material technology, applied in the field of resin-based composite material manufacturing, can solve the problems of expensive equipment, limited freedom of composite material design, service life and other problems, and achieve the effect of high laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

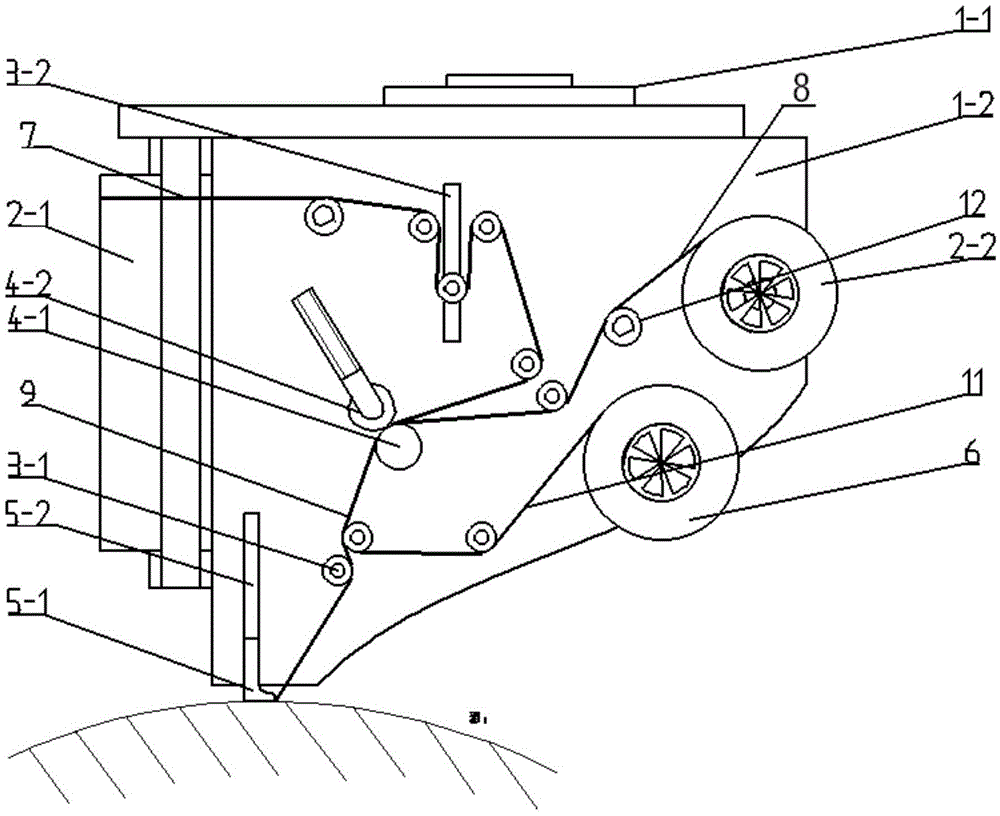

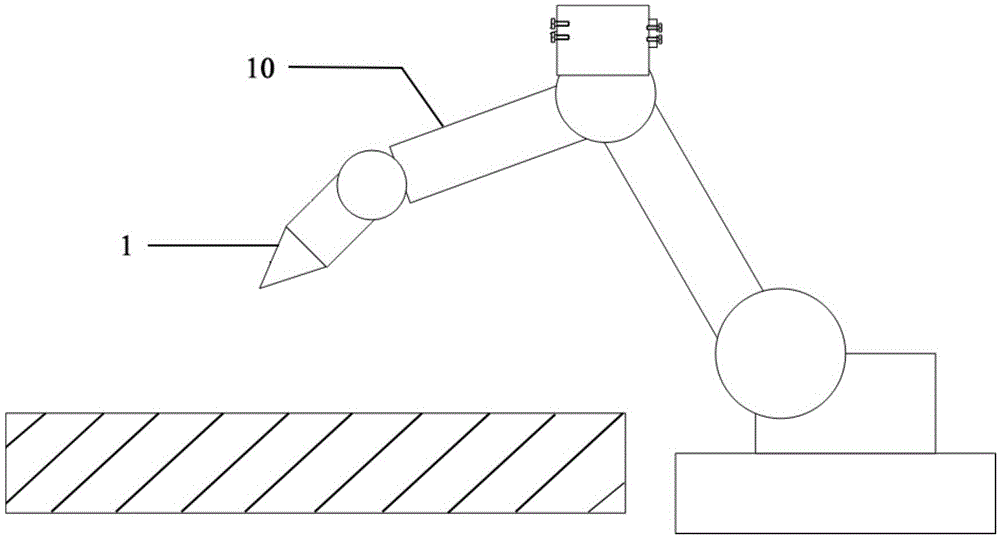

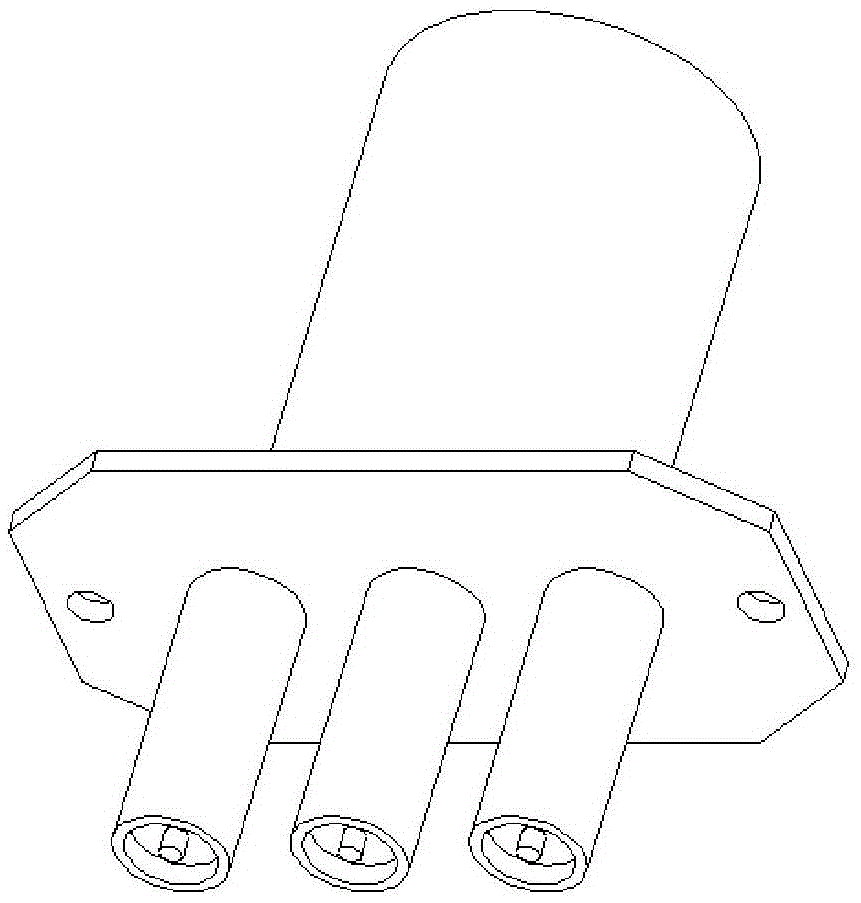

[0050] T700 carbon fiber with a fiber number of 24k and a width of 8mm, a thickness of 0.1mm, and an area density of 200g / m 2 E51 bisphenol A epoxy resin film is supplied by the supply system, through tension control (0.1N) and conveyed into the hot pressing roller system, heat and pressure (0.5MPa, 130°C) to fuse the above dry carbon fiber with the resin film, Become a semi-preg tape with high viscosity. After the hot pressing is completed, the release paper of the semi-preg tape is recovered by the release paper recovery roller, and the semi-preg tape is then transported to the laying compaction and pressure adjustment device , by pressing and laying (0.3MPa) semi-preg tape to lay carbon fiber on the surface of the mandrel. During the laying process, the laying angle of the indenter can be controlled by the robot laying arm to realize the laying of the semi-preg tape under a variable laying angle. The laid-up preforms can be subsequently cured by vacuum assisted resin trans...

Embodiment 2

[0052] The number of filaments is 3k, the width is 10mm, and the surface density is 200g / m 2 The untwisted roving glass fiber cloth with a width of 10mm and a thickness of 0.1mm isal density of 300g / m 2 The resin film blended with E44 bisphenol A epoxy resin and cyanate ester is supplied by the supply system, and enters into the hot pressing roller system through tension control (20N) and transportation, and heats and presses (1MPa, 80°C) to make the above dry The fiber and the resin film are fused to become a semi-preg tape with high viscosity. After the hot pressing is completed, the release paper of the semi-preg tape is recovered by the release paper recovery roller, and the semi-preg tape is then transported to the laying press. Close to the pressure adjustment device, lay the fiber on the surface of the mandrel by pressing and laying (0.7MPa) semi-preg tape. During the laying process, the laying compaction and pressure adjustment device can be used to control the laying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com