Patents

Literature

63results about How to "Improve placement quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and systems for placement and routing

ActiveUS20090254874A1Influence optimizeImprove performanceCAD circuit designSoftware simulation/interpretation/emulationElectrical resistance and conductanceCapacitance

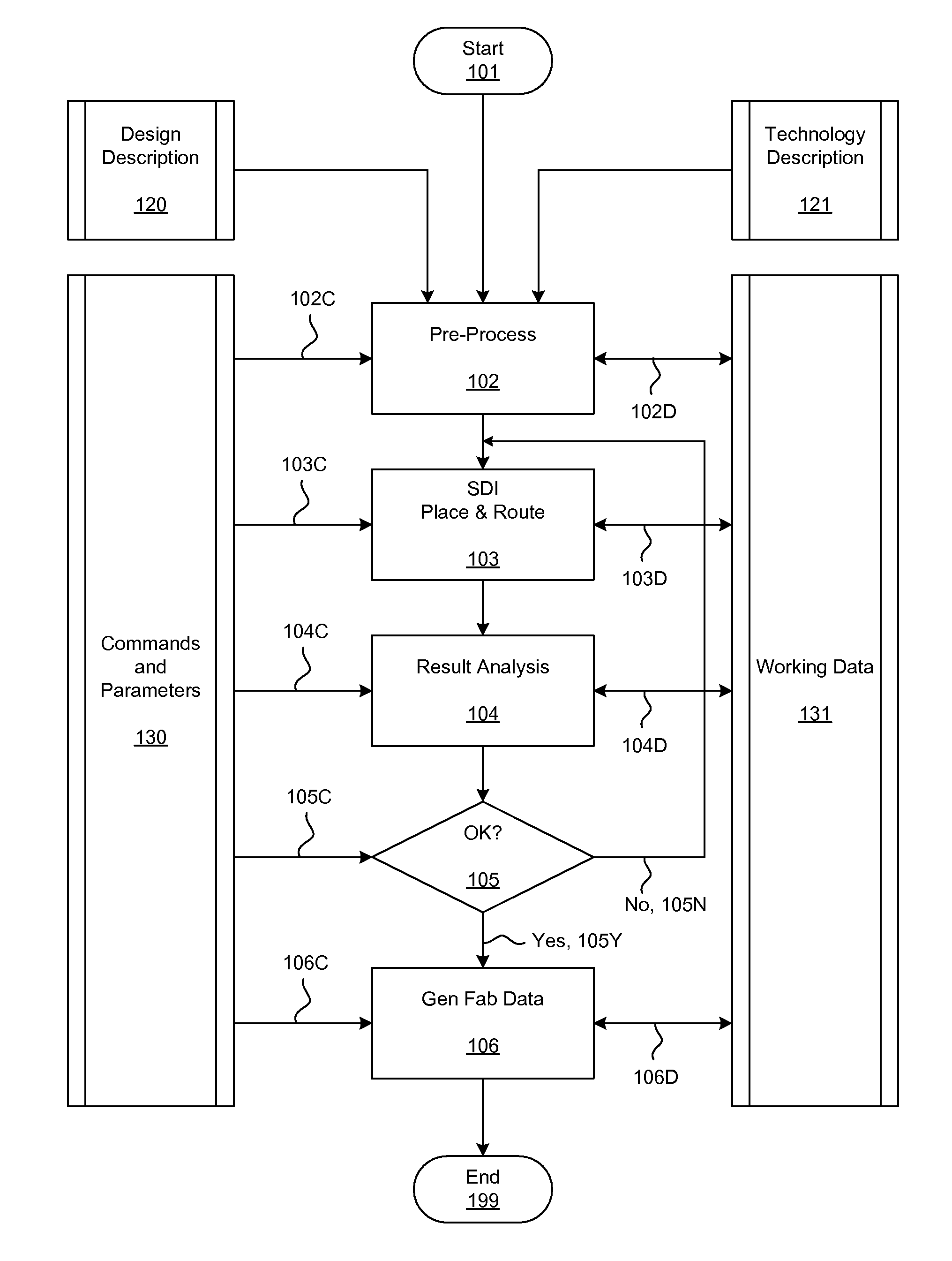

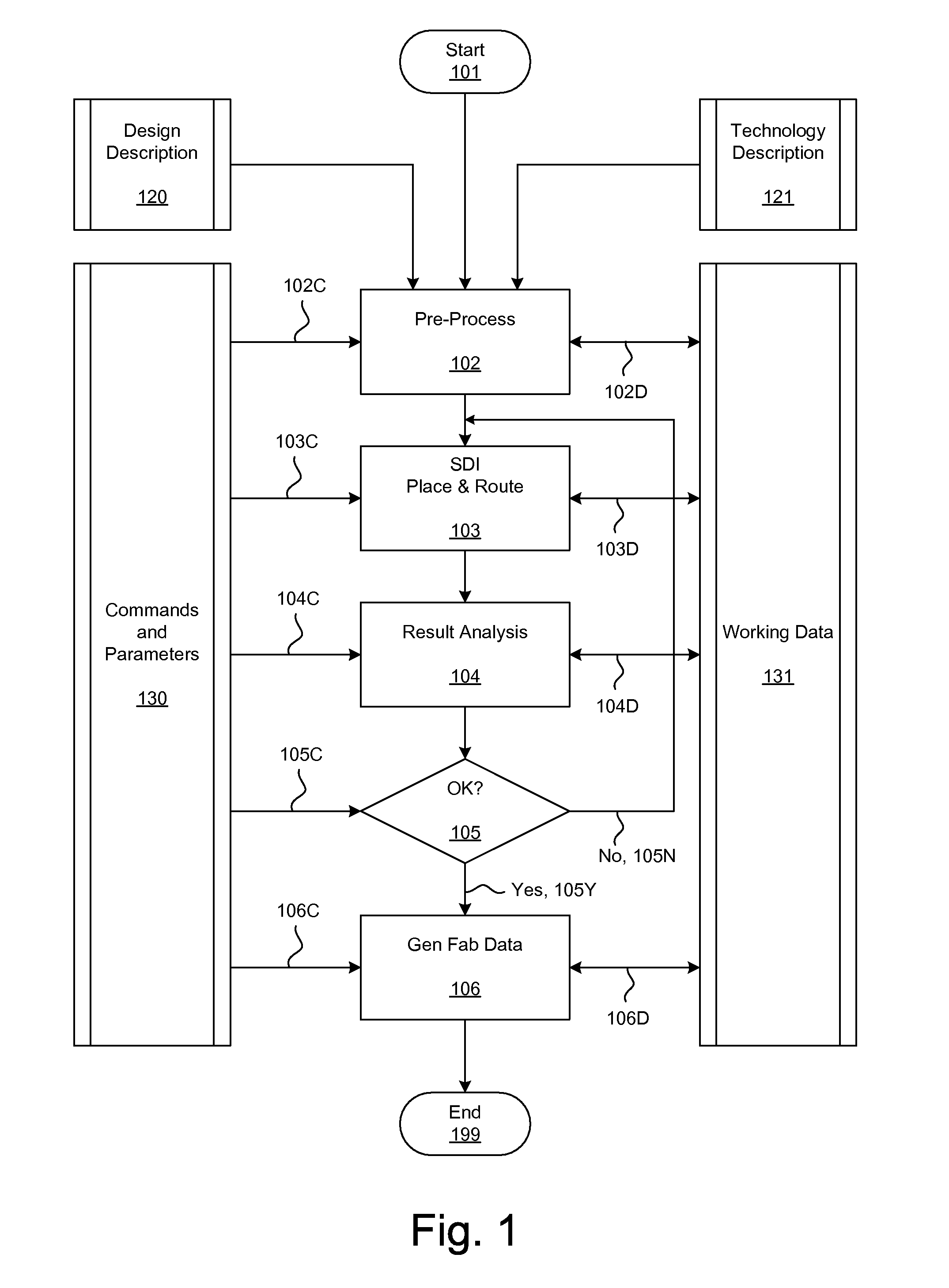

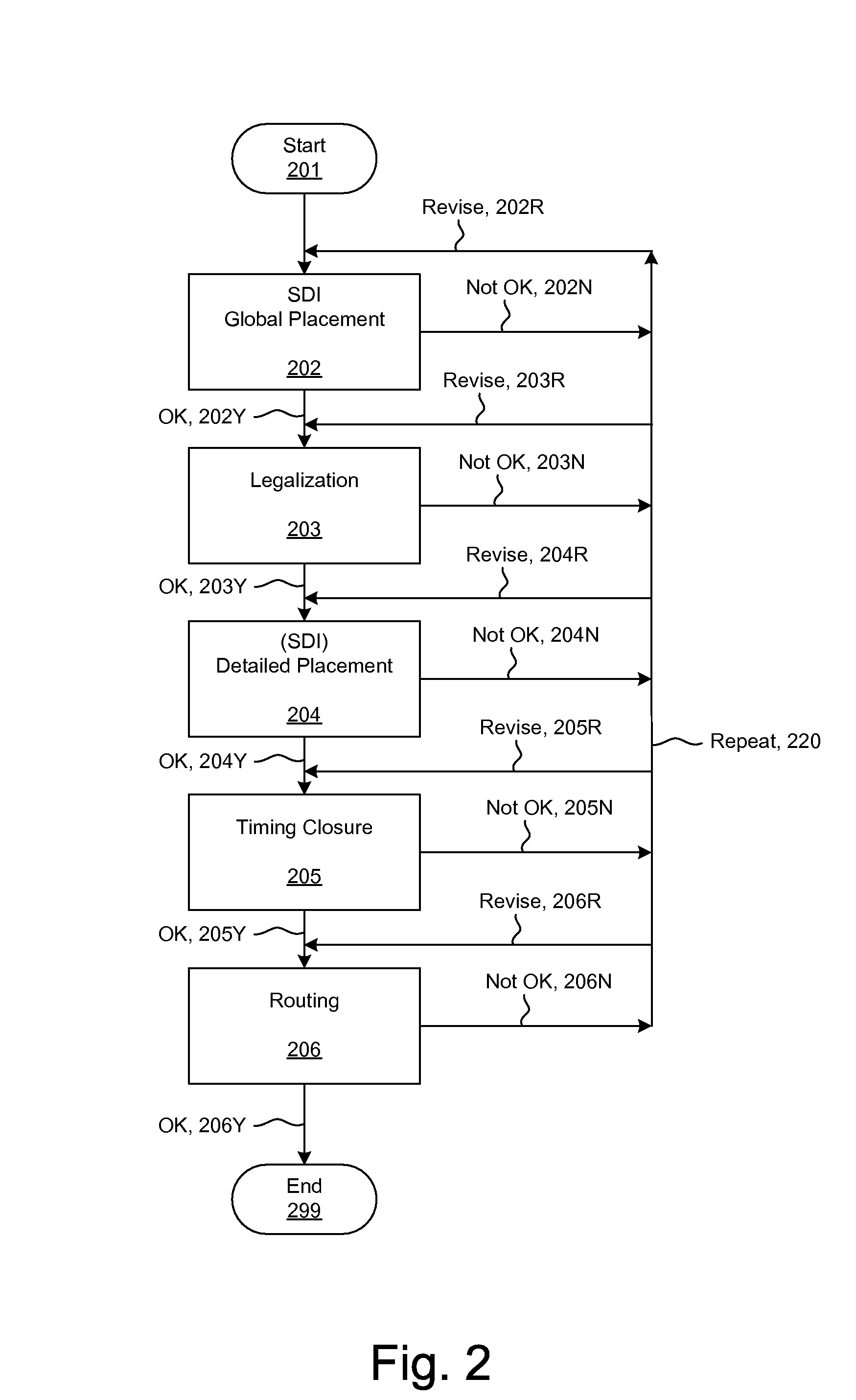

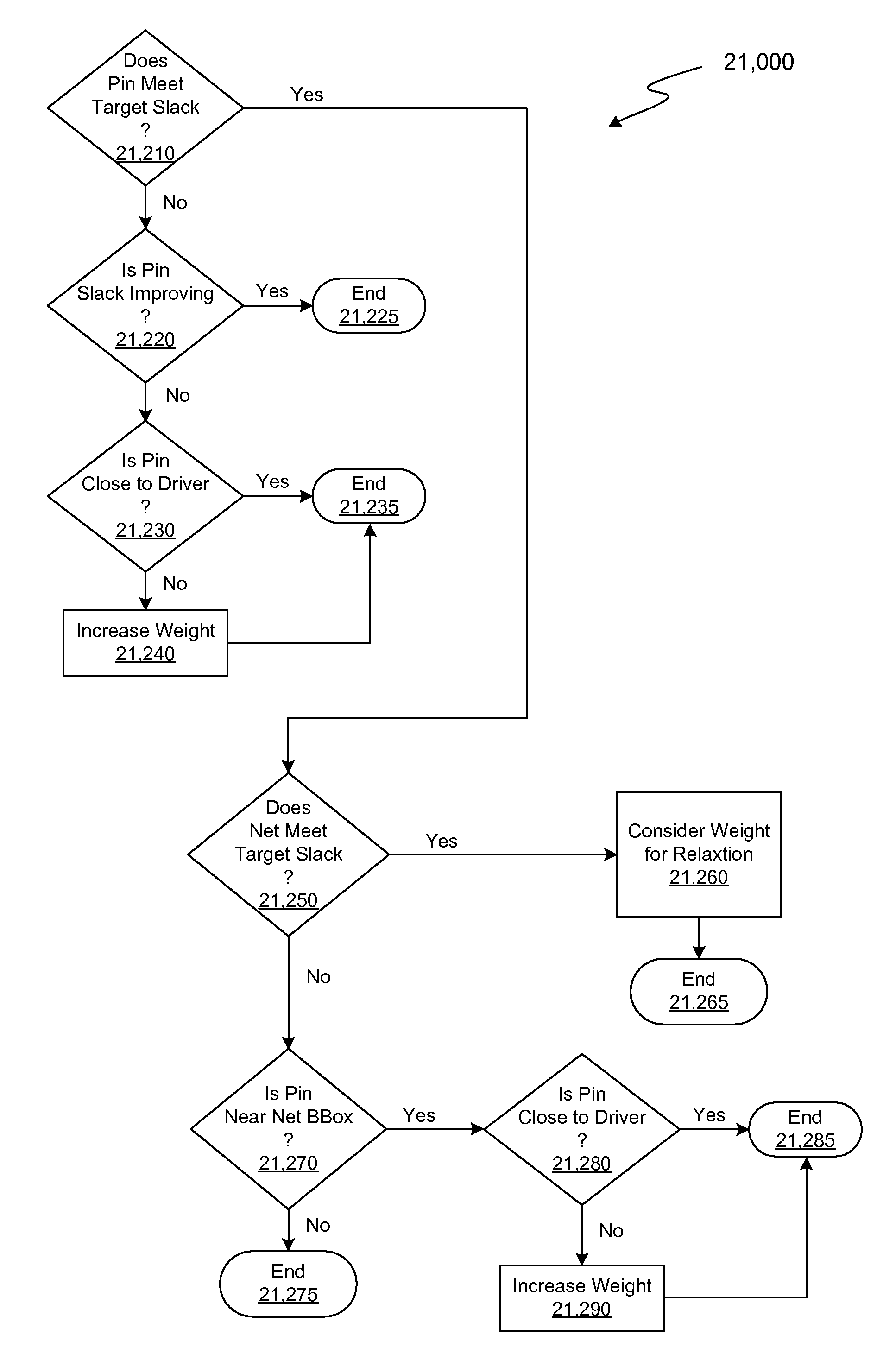

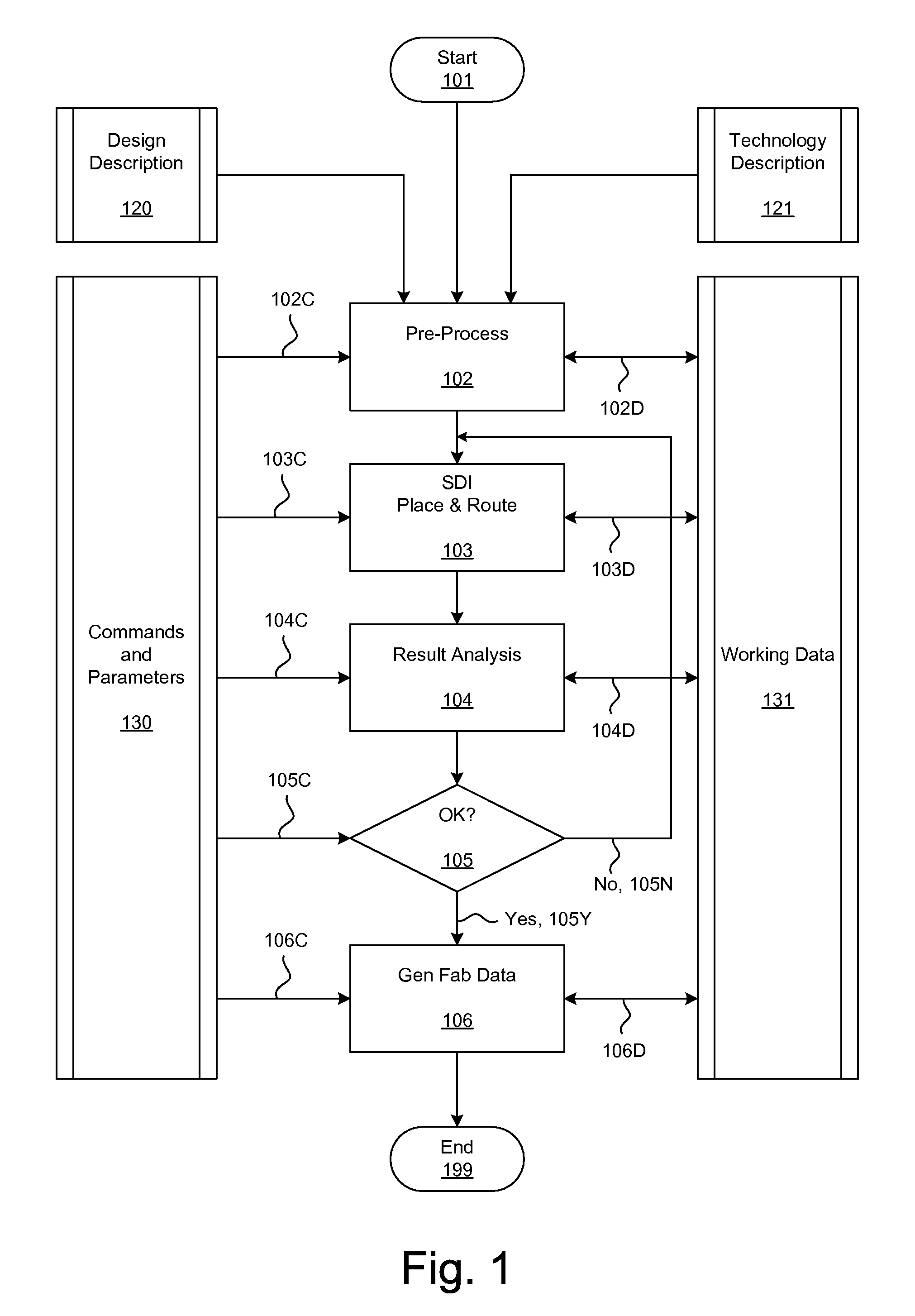

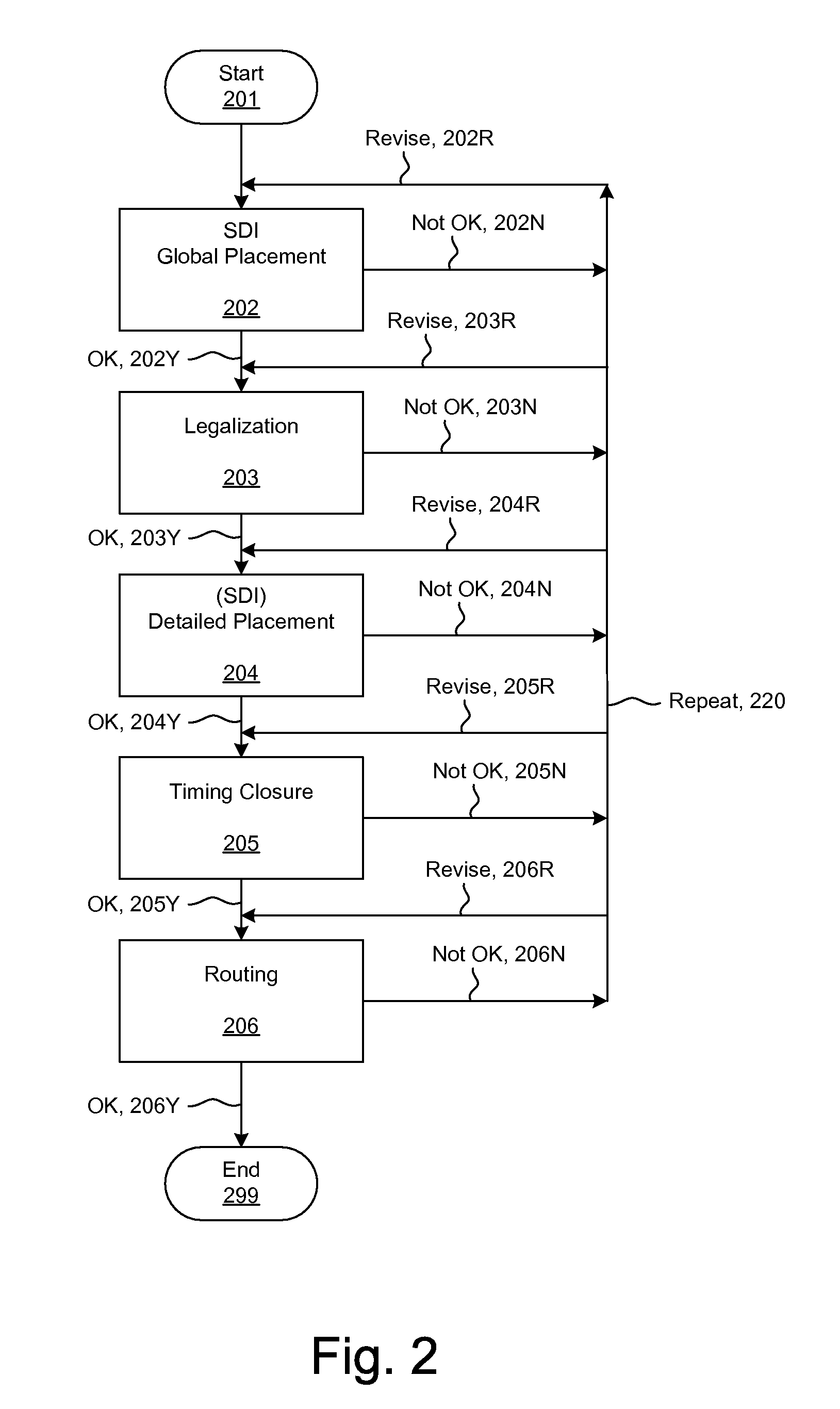

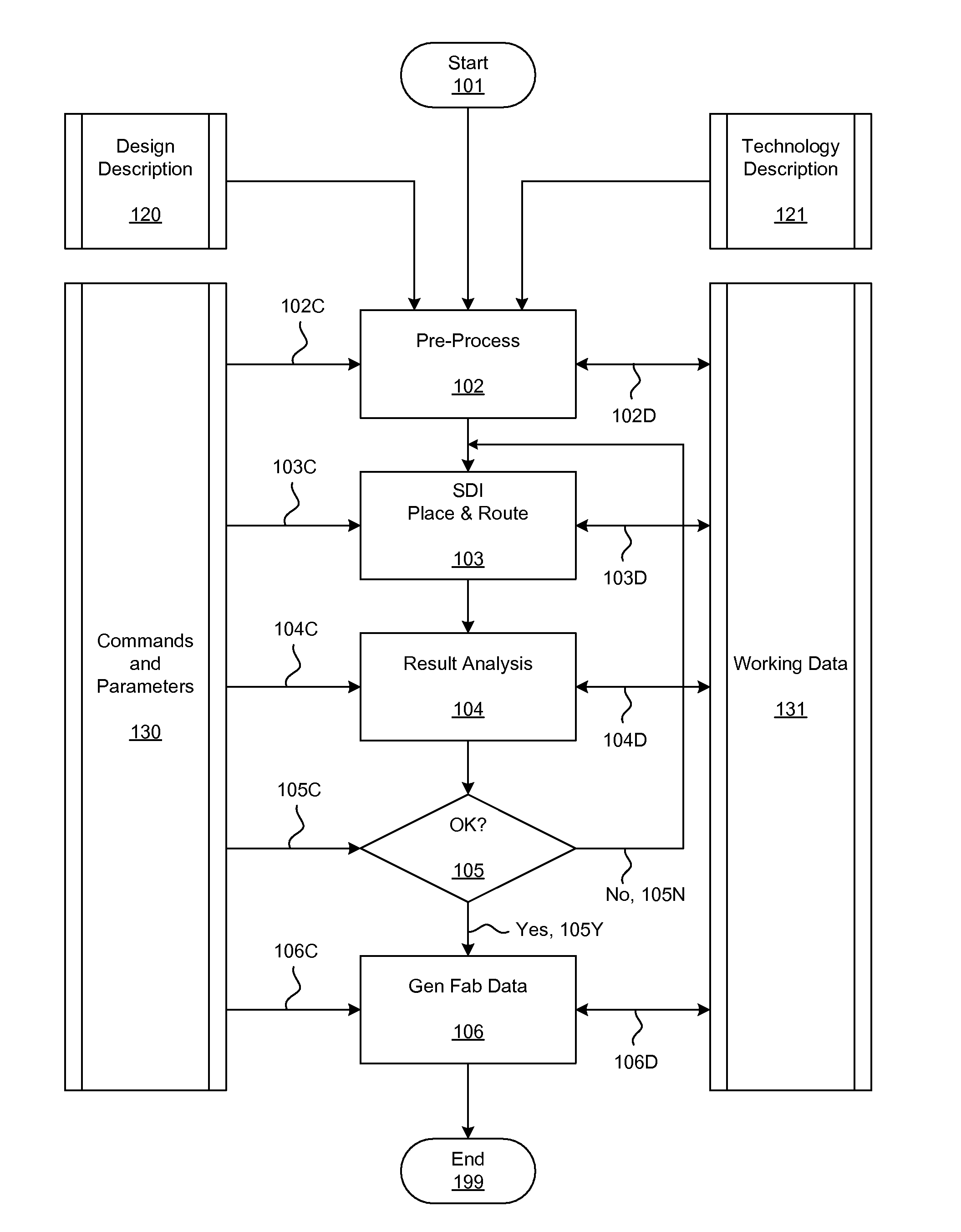

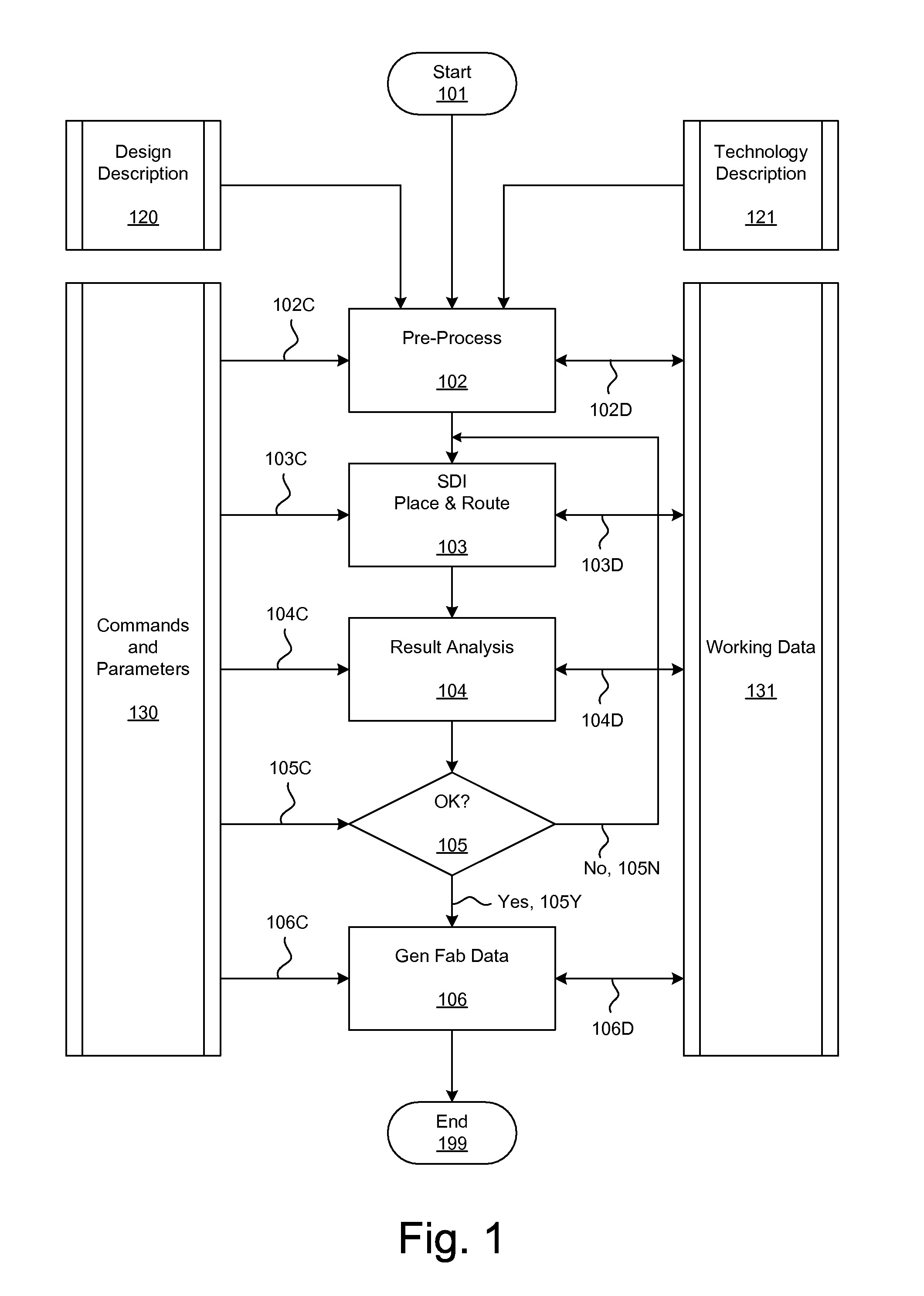

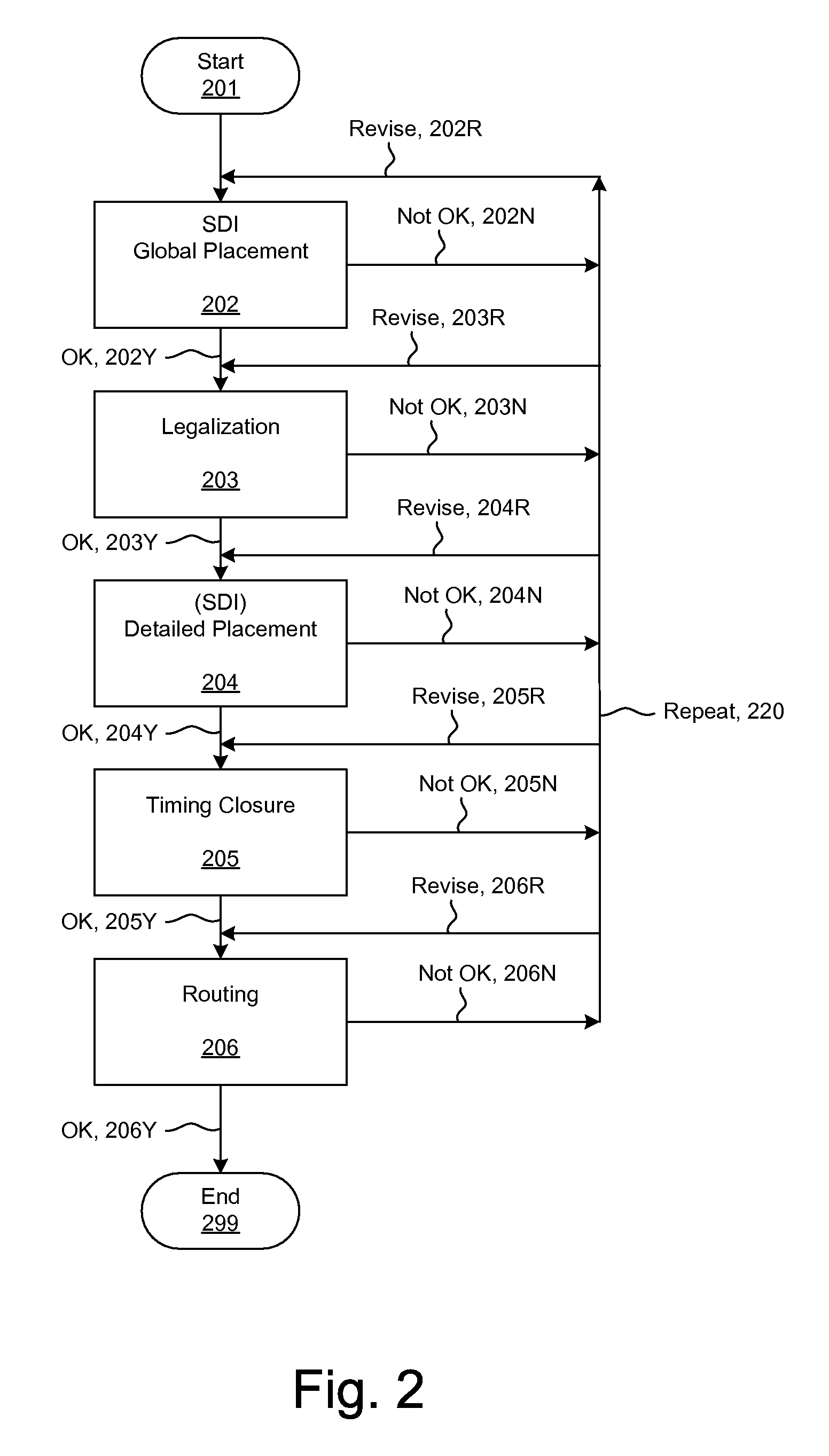

Techniques for placement of integrated circuit elements include global placement, detailed placement, timing closure, and routing. The integrated circuit is described by a netlist specifying interconnections of morphable devices. The detailed placement uses, for example, Simultaneous Dynamical Integration, wherein the morphable-devices correspond to nodes influenced by forces, including timing forces. The timing forces are derived, for example, from a timing graph; path delay; slack; and drive resistance of the elements. The timing closure uses timing-driven buffering and timing-driven resizing to reduce maximum delay and / or transition time, and / or to fix hold time. Nets having high capacitance and / or fanout, and timing critical nets are preferentially processed. Timing-driven buffering applies buffering solutions to segments of route trees, combines solutions of adjoining segments, and prunes sets of solutions. Timing-driven resizing morphably replaces selected elements with upsized versions thereof.

Owner:CALLAHAN CELLULAR L L C

Incremental Relative Slack Timing Force Model

InactiveUS20080216040A1Influence optimizeImprove performanceCAD circuit designSpecial data processing applicationsInterconnectionComputer science

Simultaneous Dynamical Integration modeling techniques are applied to global placement of elements of integrated circuits as described by netlists specifying interconnection of morphable-devices. Solutions to a system of coupled ordinary differential equations in accordance with Newtonian mechanics are approximated by numerical integration. A resultant time-evolving system of nodes moves through a continuous location space in continuous time, and is used to derive placements of the morphable-devices having one-to-one correspondences with the nodes. Nodes under the influence of net attractive forces, computed based on the interconnections between the morphable devices, tend to coalesce into well-organized topologies. Nodes are also affected by spreading forces determined by density fields that are developed based on local spatial node populations.

Owner:CALLAHAN CELLULAR L L C

Node Spreading via Artificial Density Enhancement to Reduce Routing Congestion

ActiveUS20080216039A1Influence optimizeImprove performanceCAD circuit designSpecial data processing applicationsInterconnectionRouting congestion

Simultaneous Dynamical Integration modeling techniques are applied to global placement of elements of integrated circuits as described by netlists specifying interconnection of morphable-devices. Solutions to a system of coupled ordinary differential equations in accordance with Newtonian mechanics are approximated by numerical integration. A resultant time-evolving system of nodes moves through a continuous location space in continuous time, and is used to derive placements of the morphable-devices having one-to-one correspondences with the nodes. Nodes under the influence of net attractive forces, computed based on the interconnections between the morphable devices, tend to coalesce into well-organized topologies. Nodes are also affected by spreading forces determined by density fields that are developed based on local spatial node populations.

Owner:CALLAHAN CELLULAR L L C

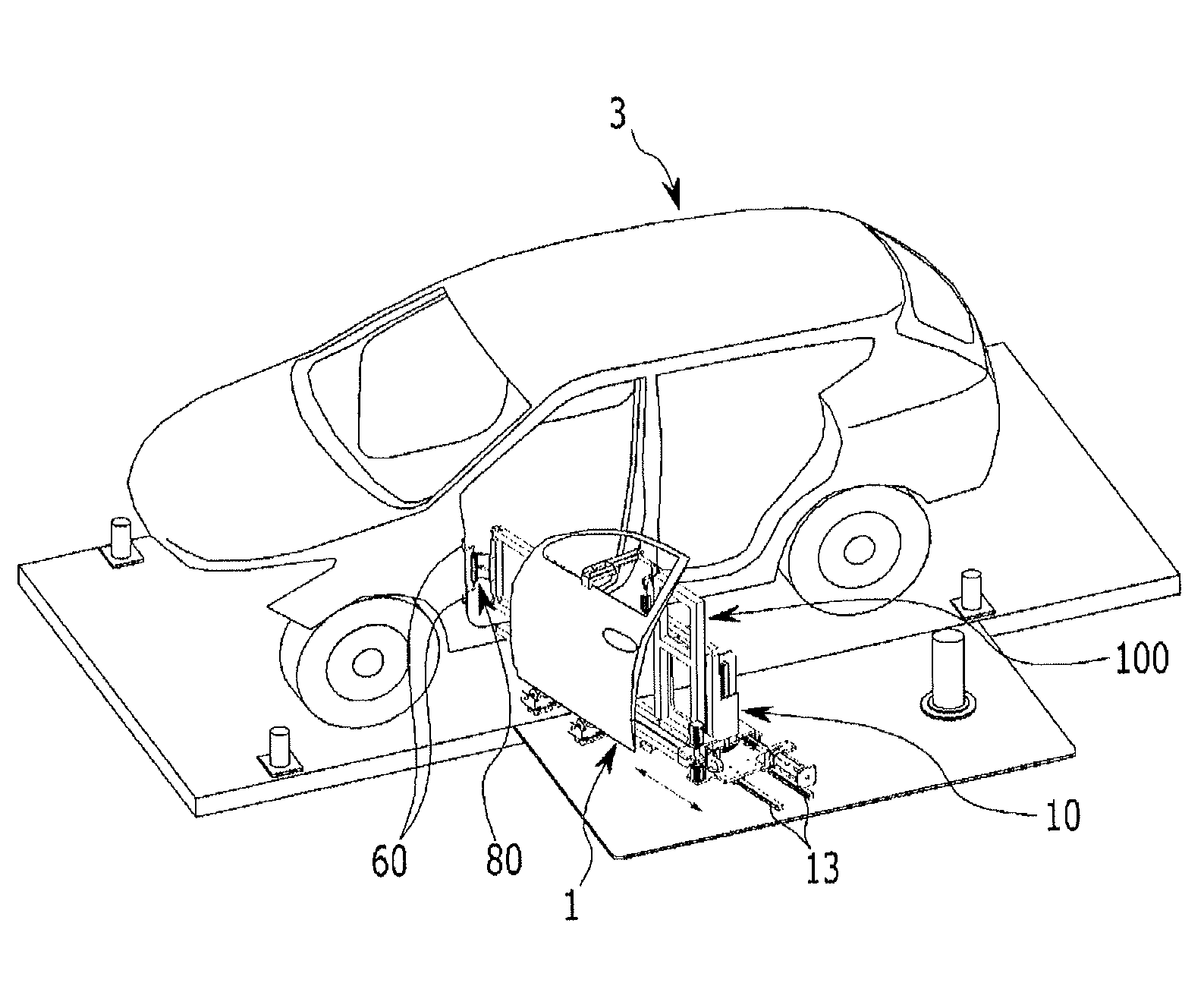

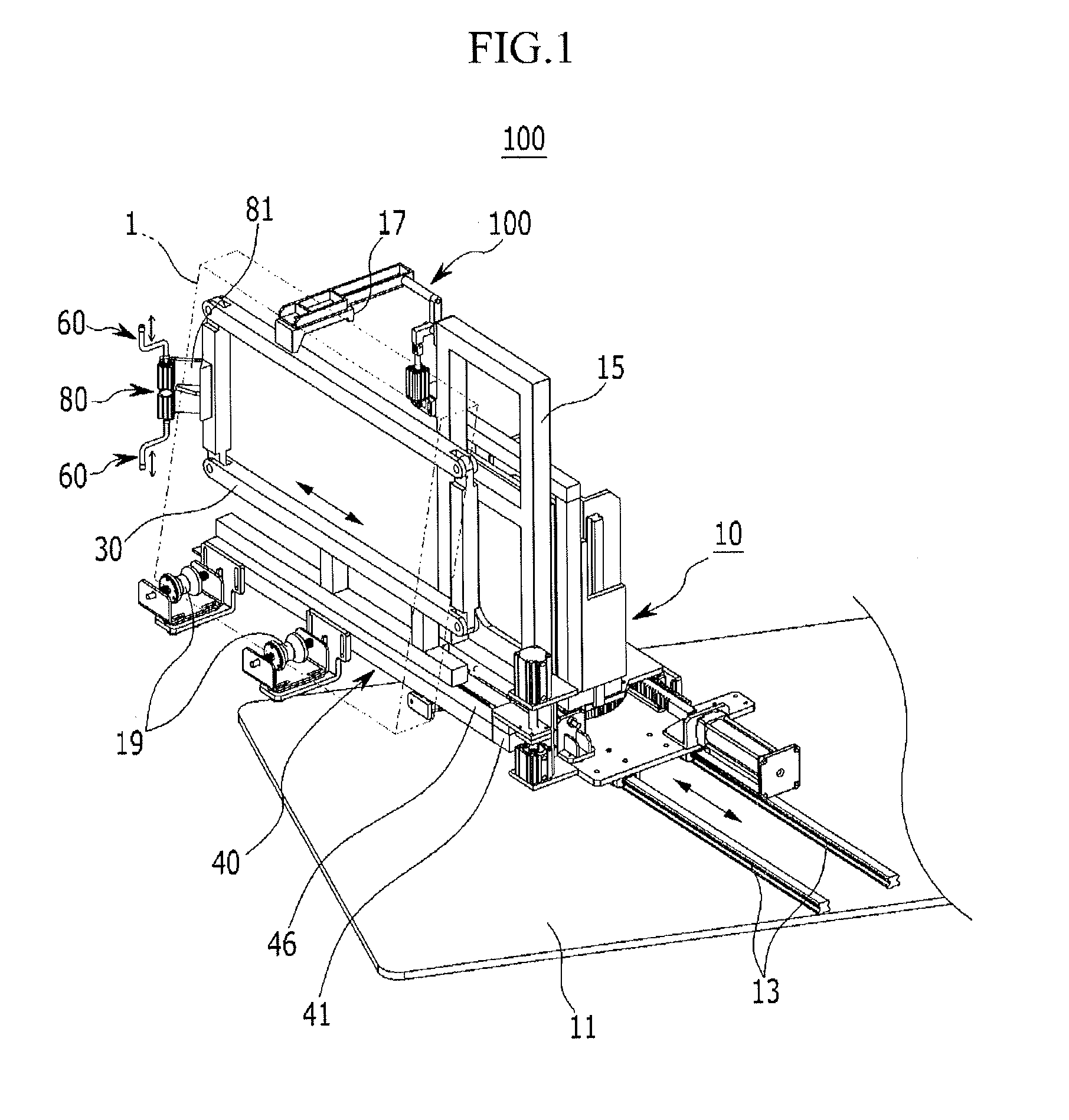

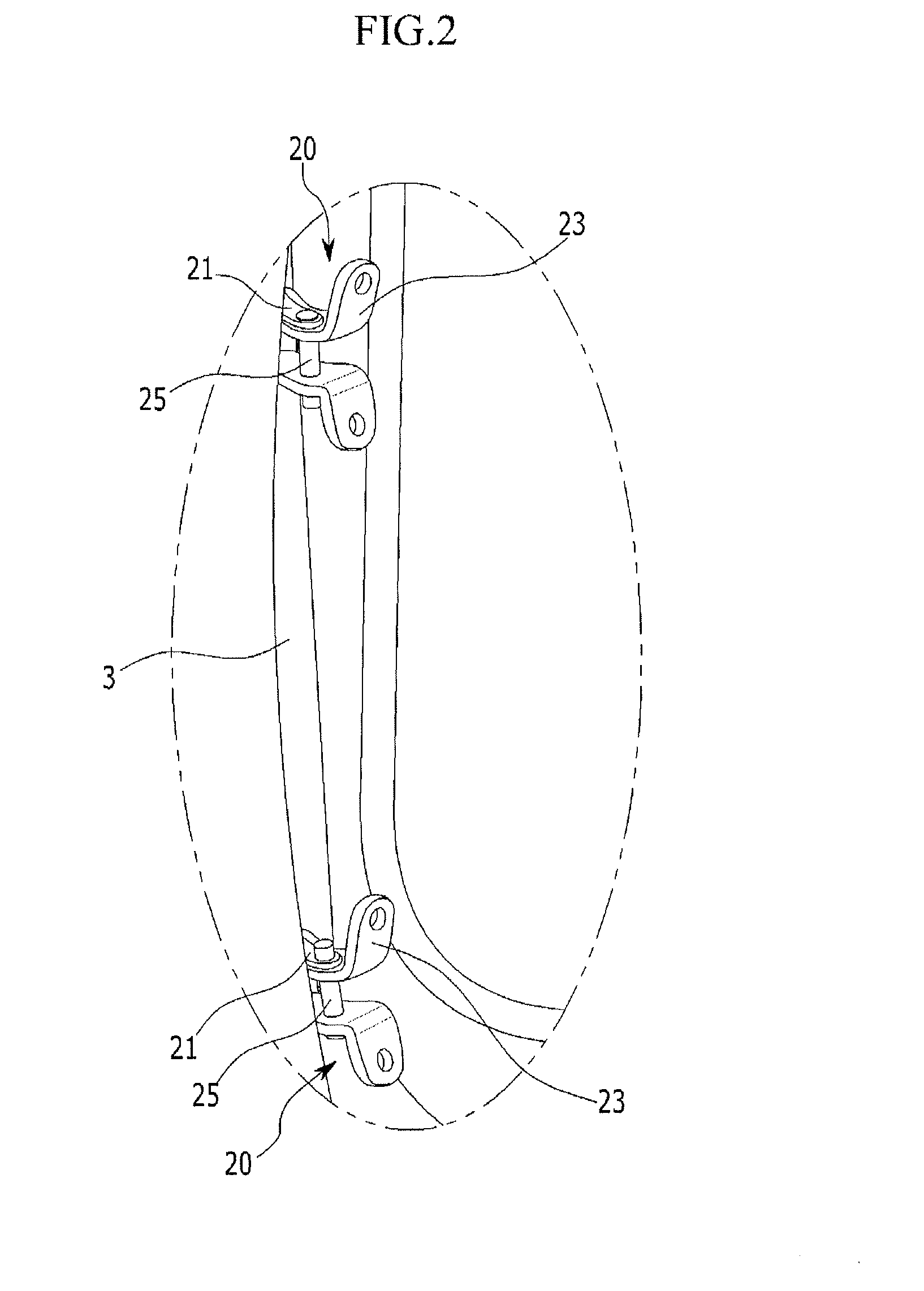

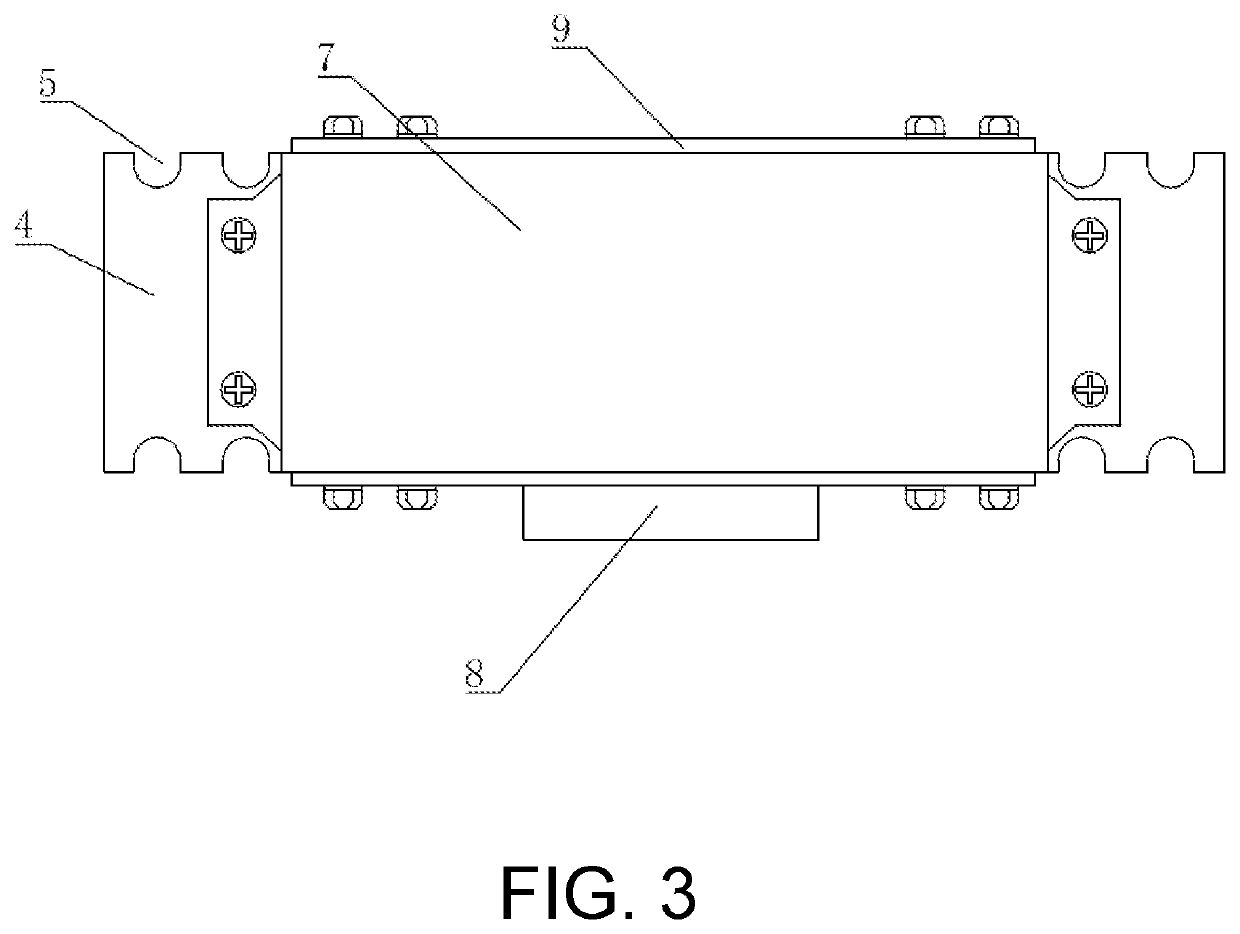

Door positioning apparatus for door mounting device of vehicle and door positioning system

InactiveUS20150013133A1Simple manufacturing processWork lessAssembly machinesWork holdersEngineeringPositioning system

Owner:HYUNDAI MOTOR CO LTD

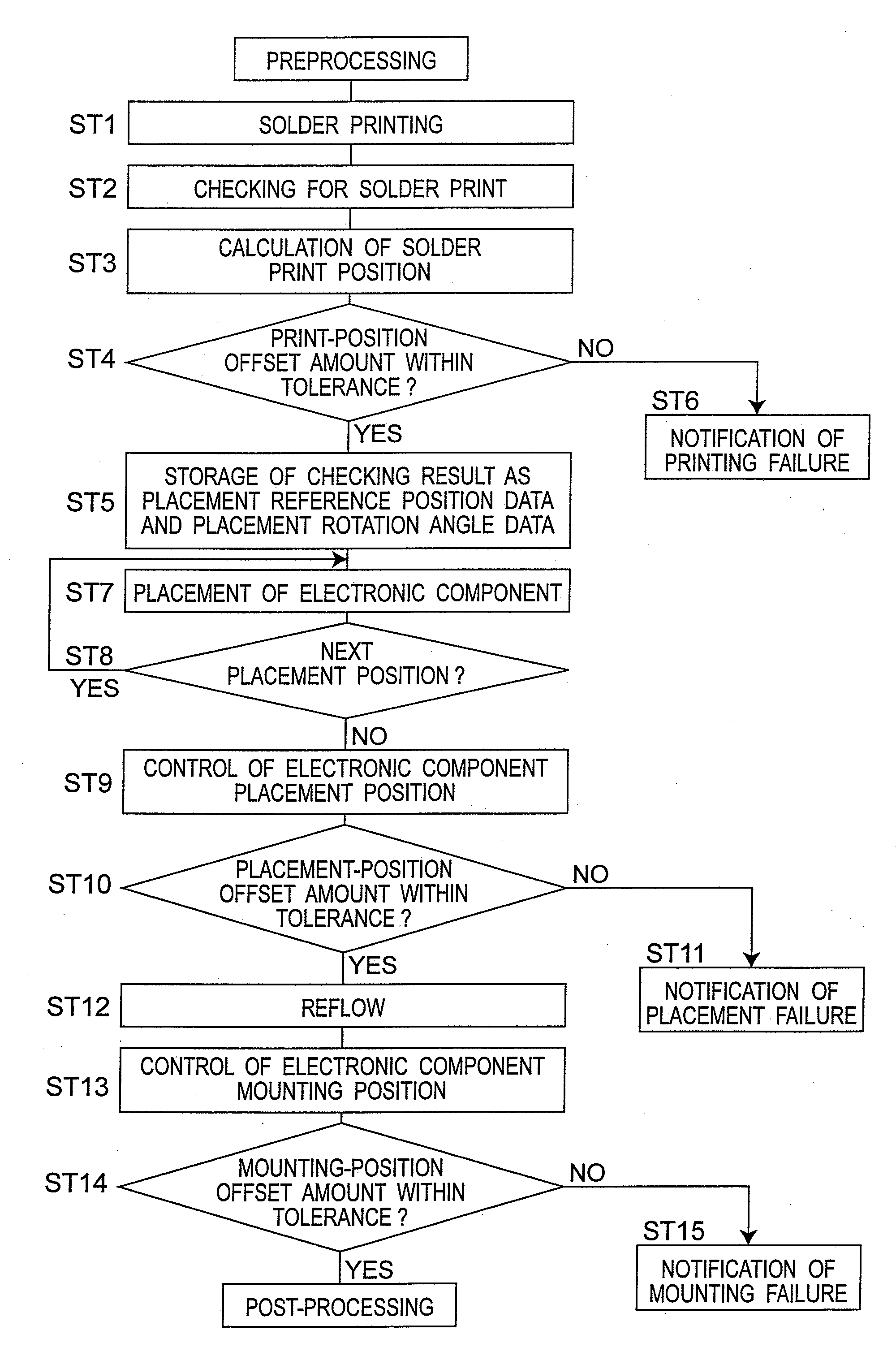

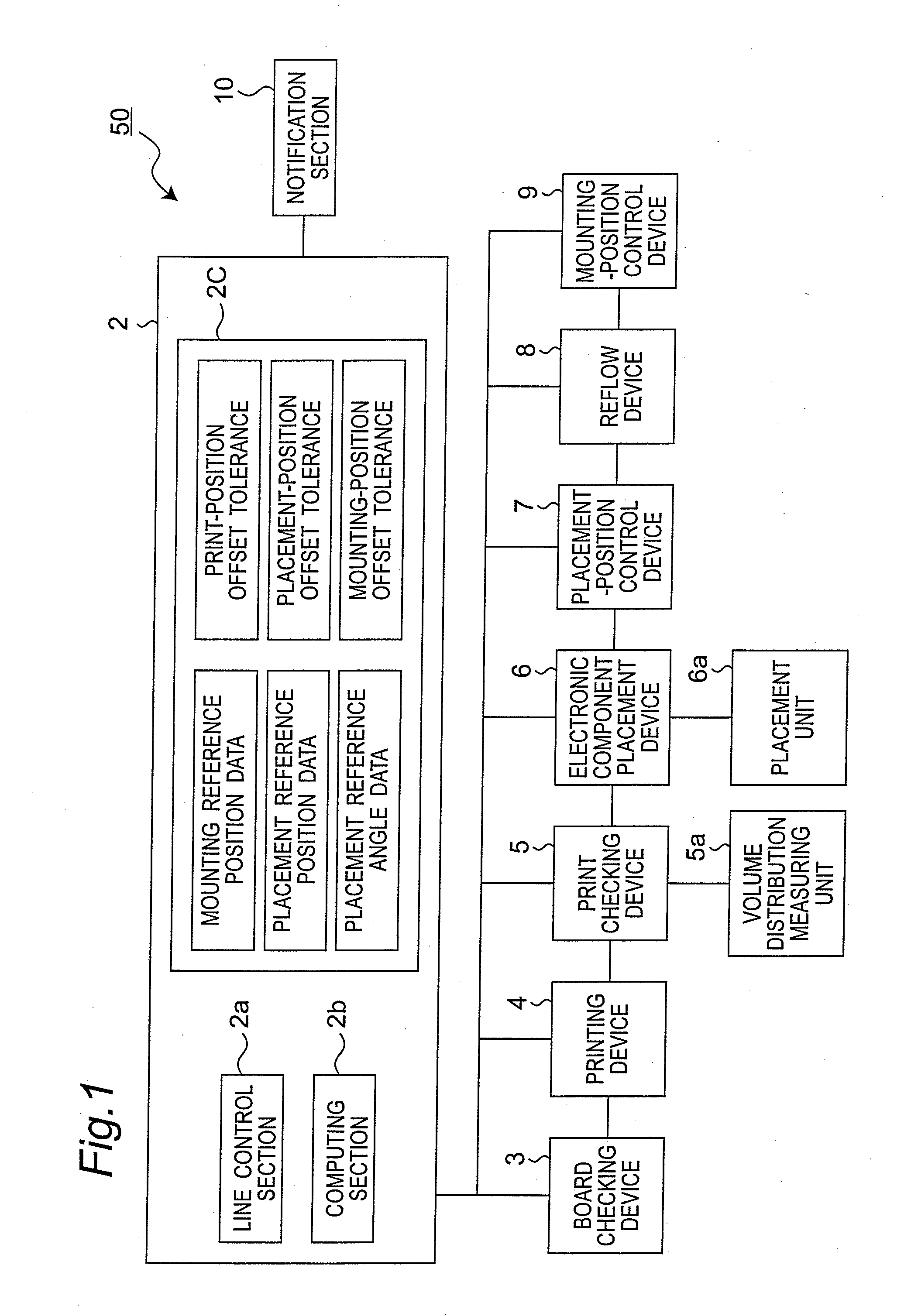

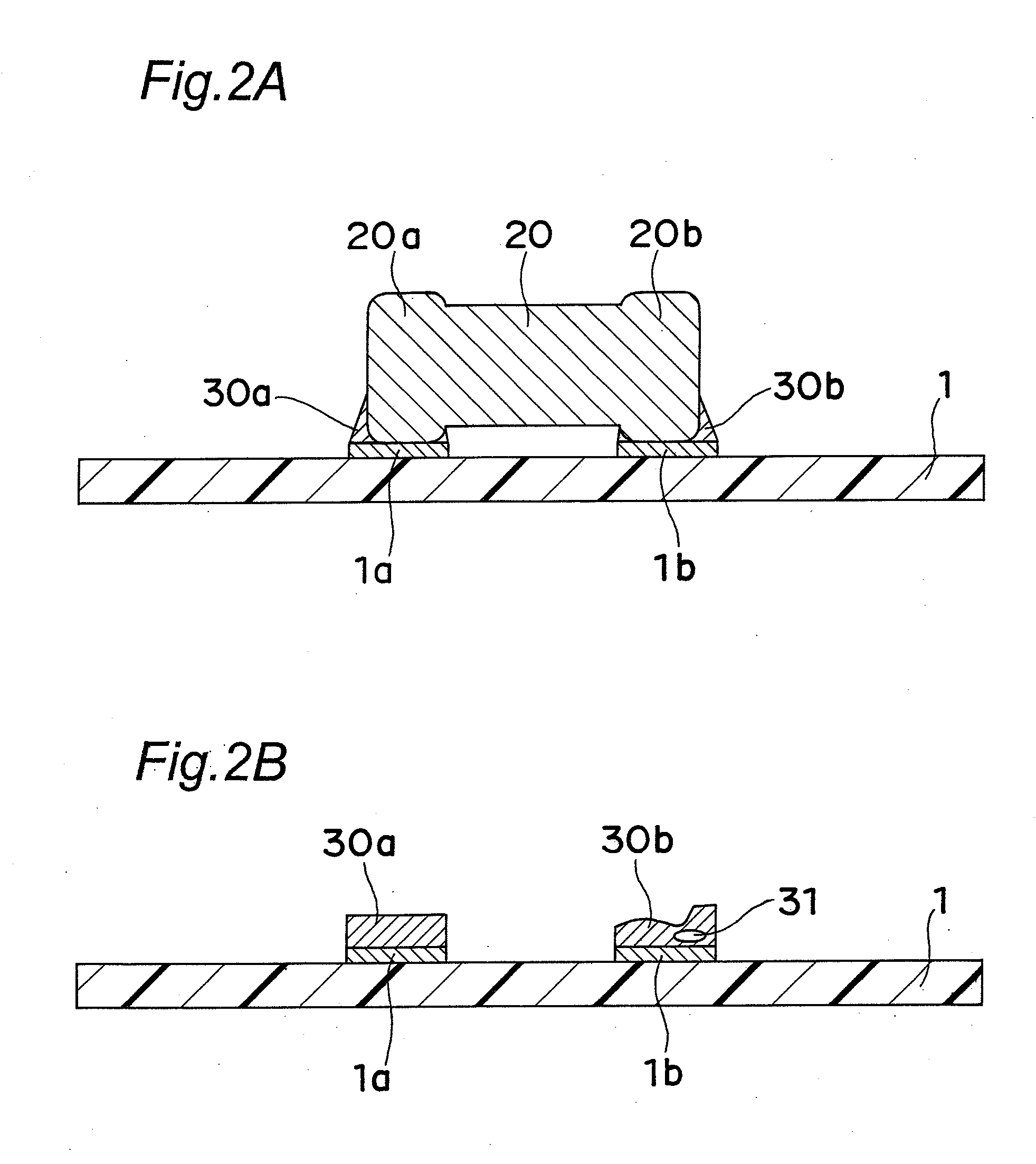

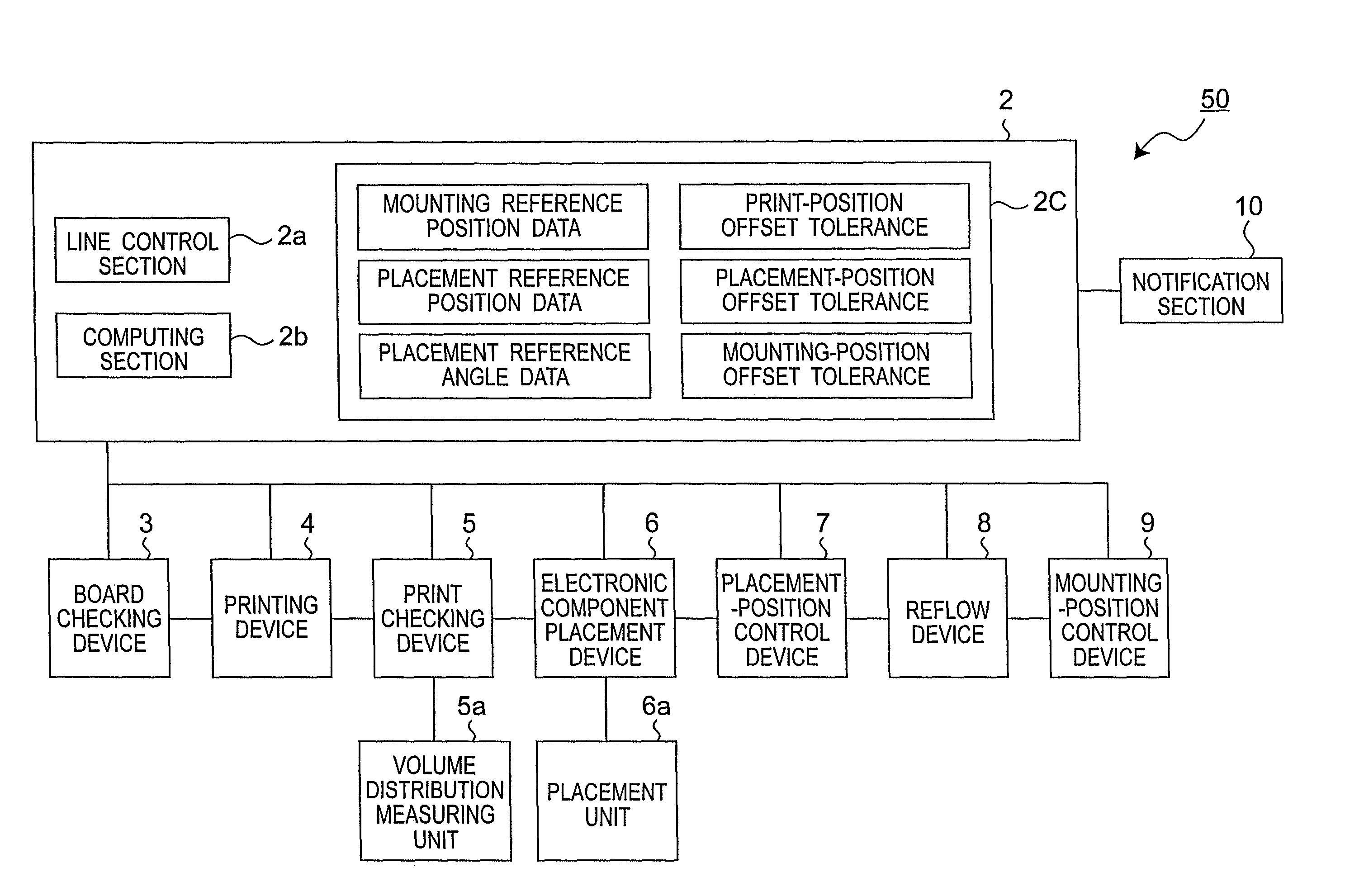

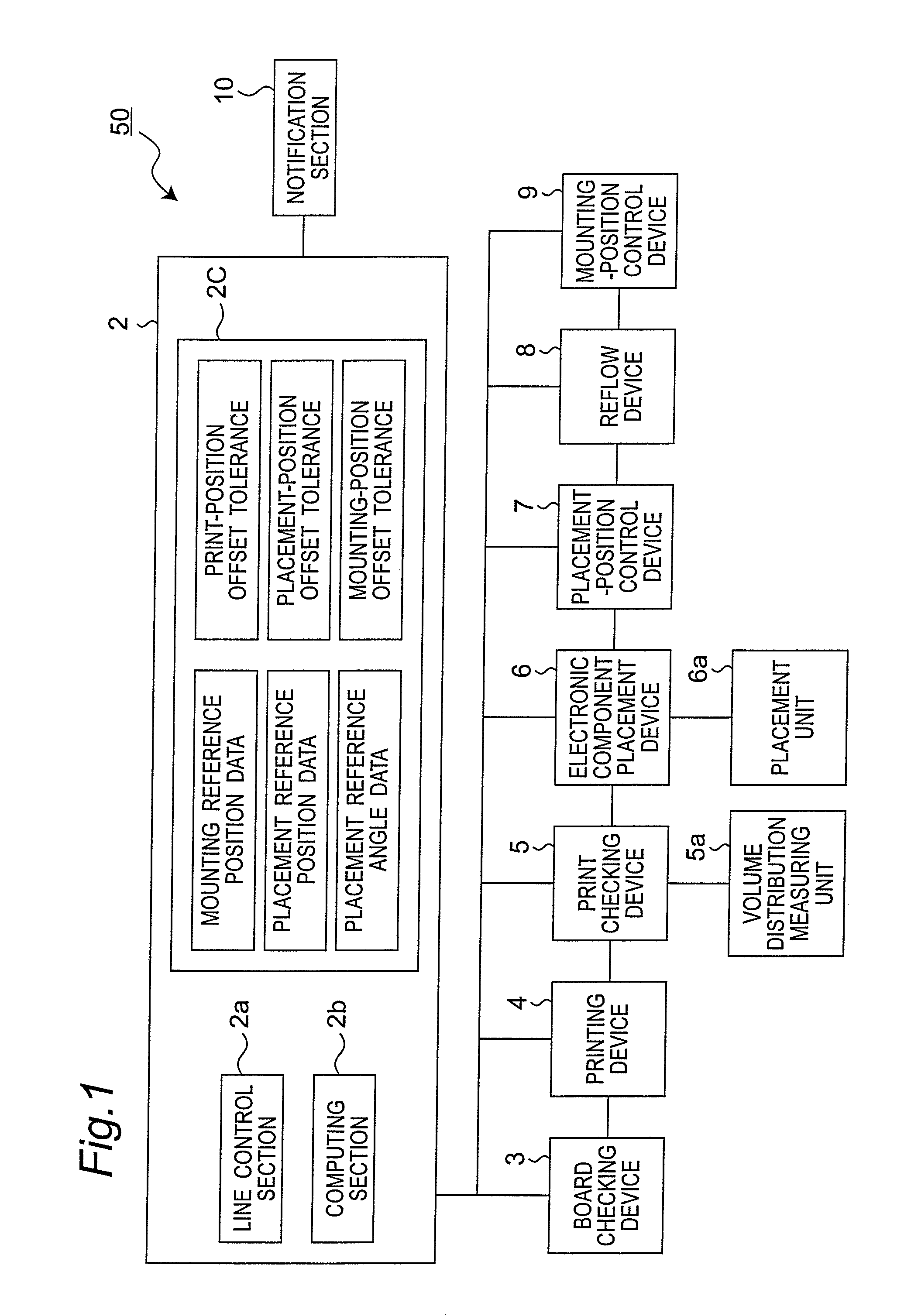

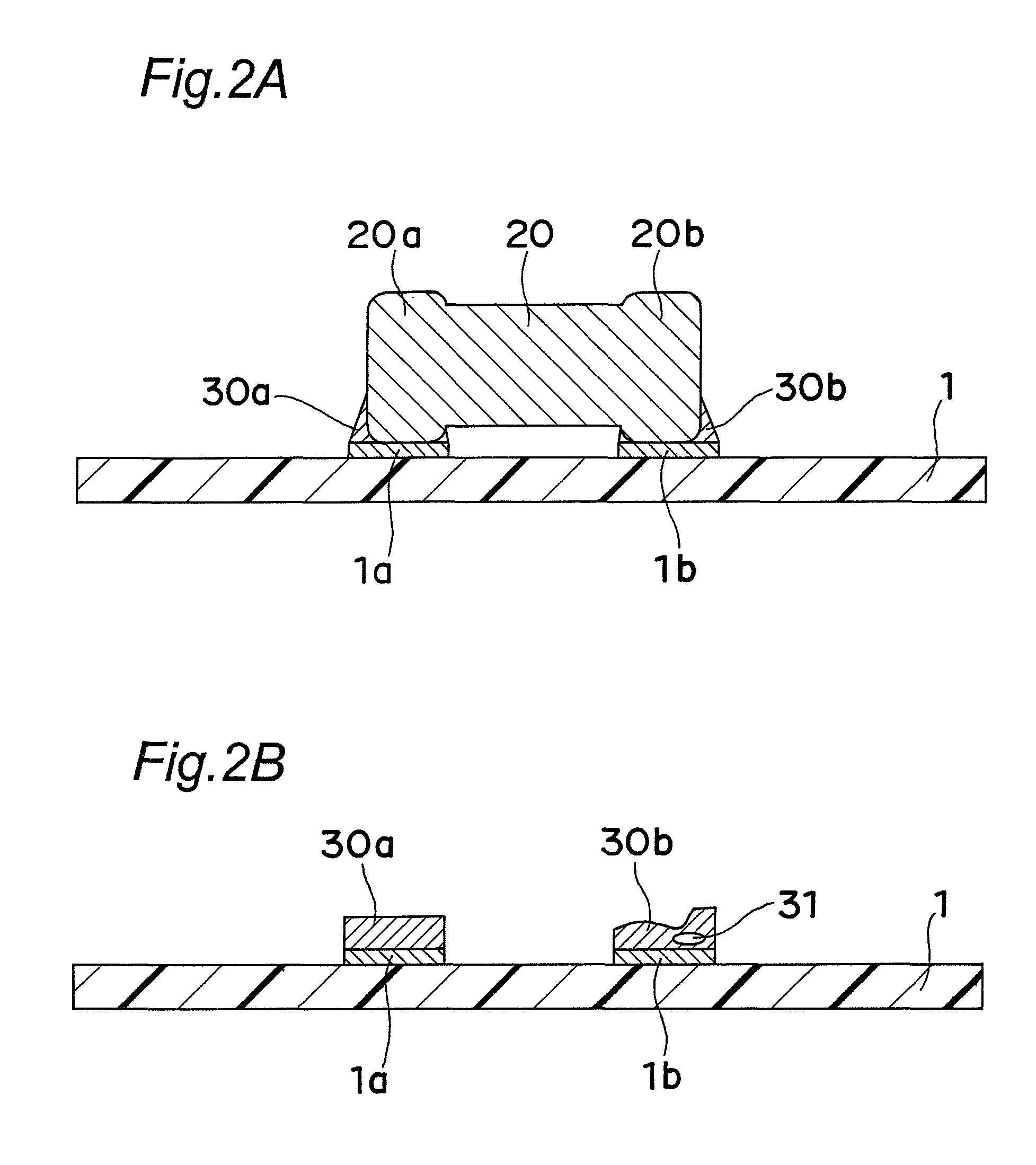

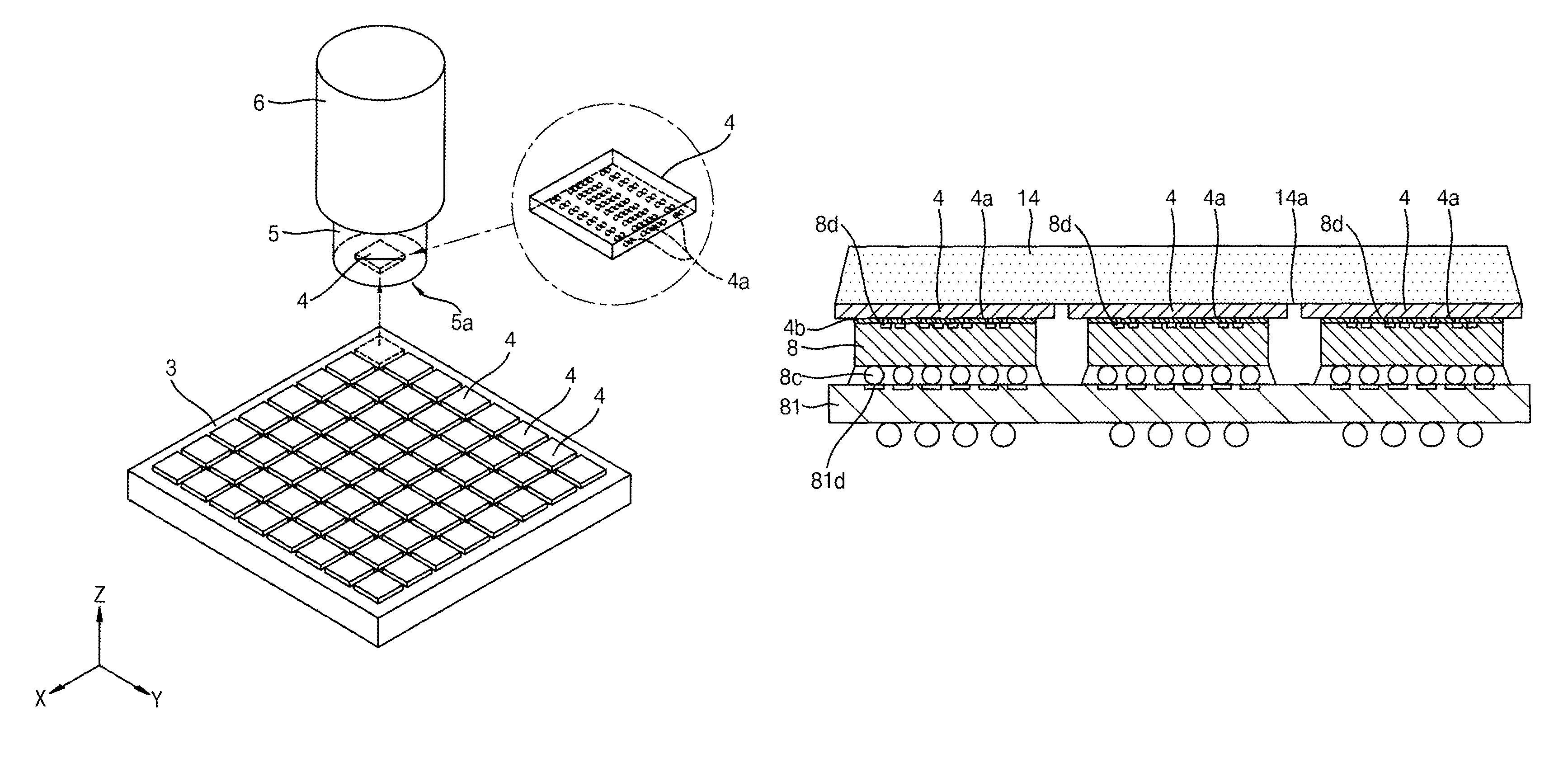

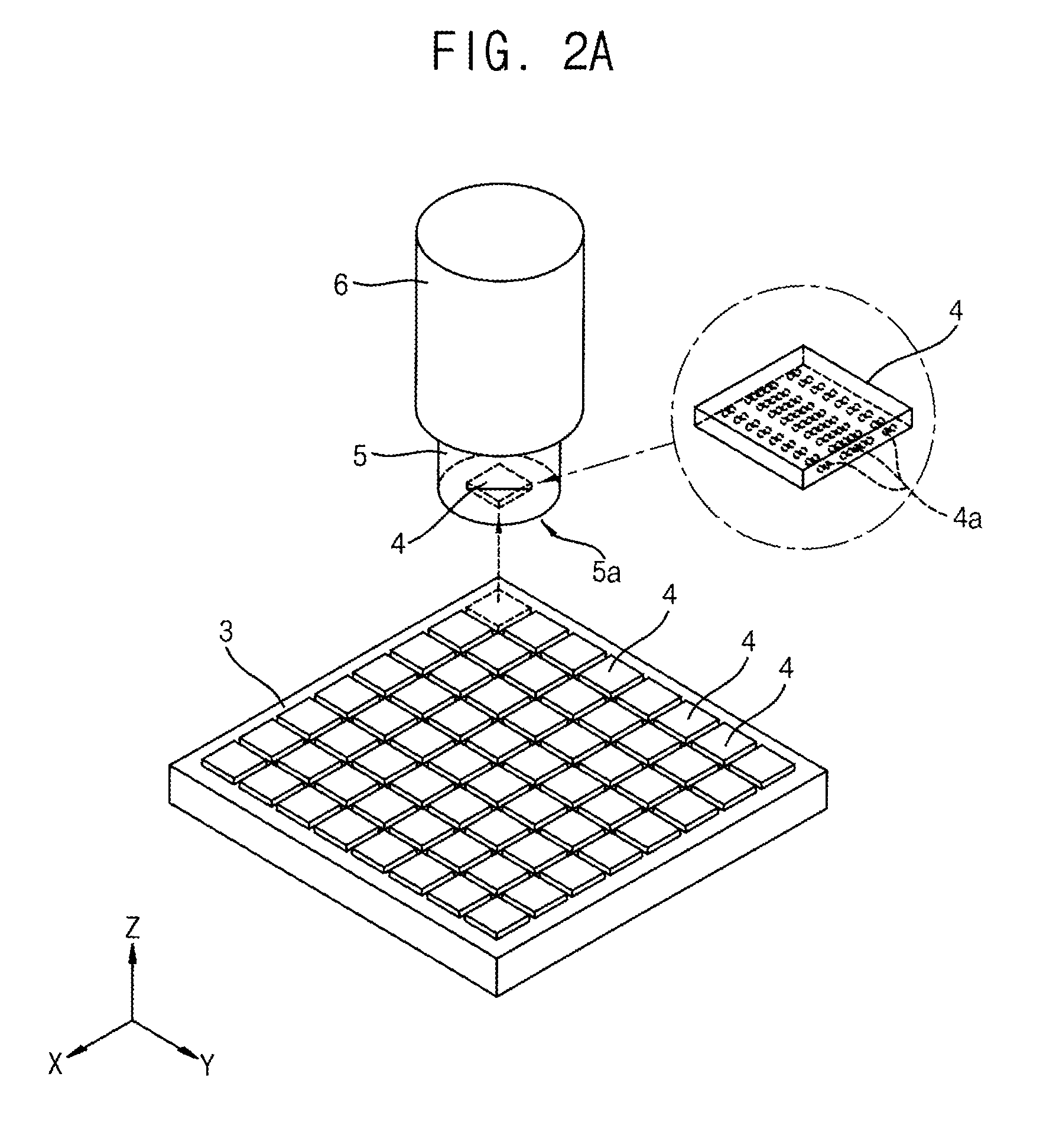

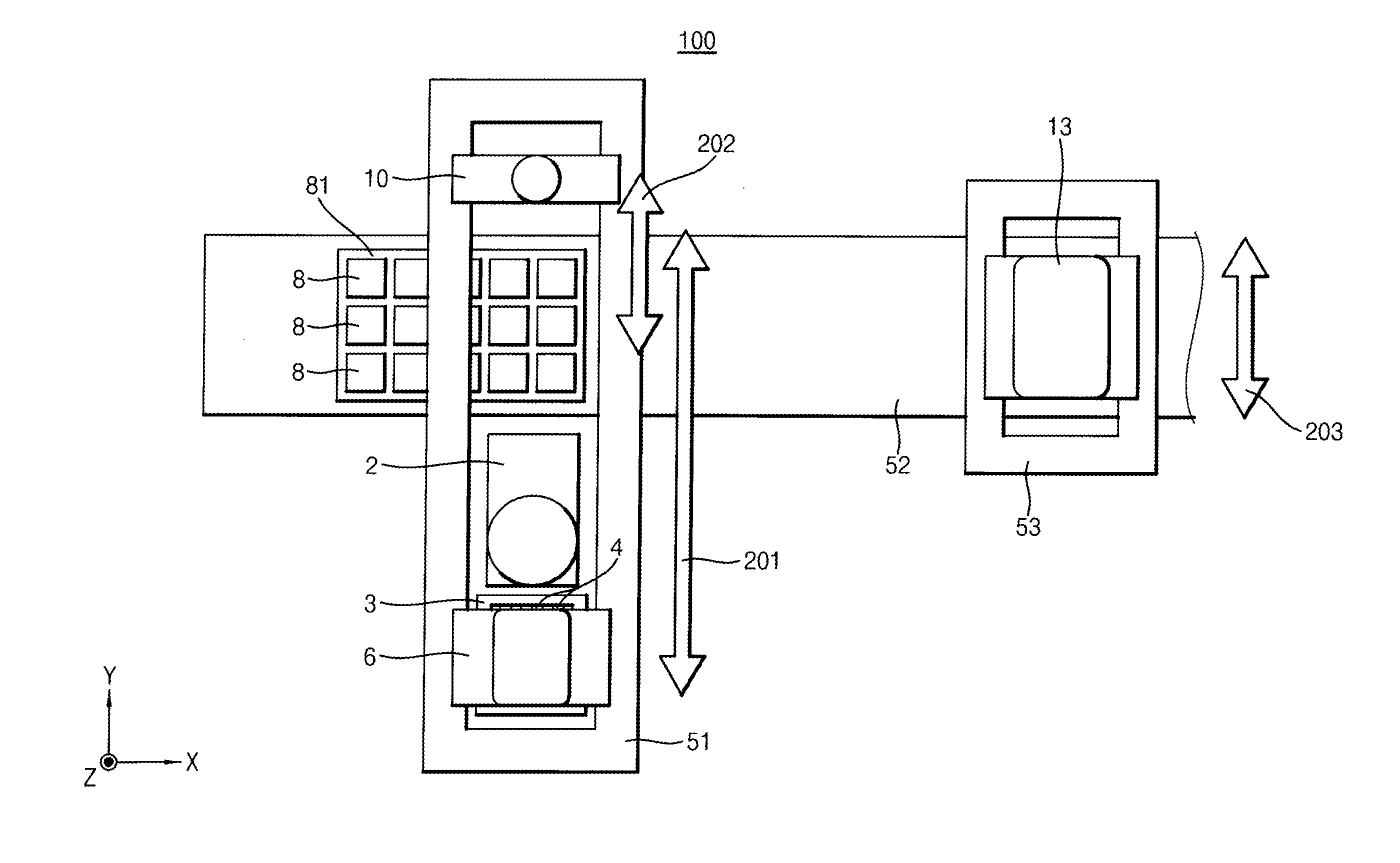

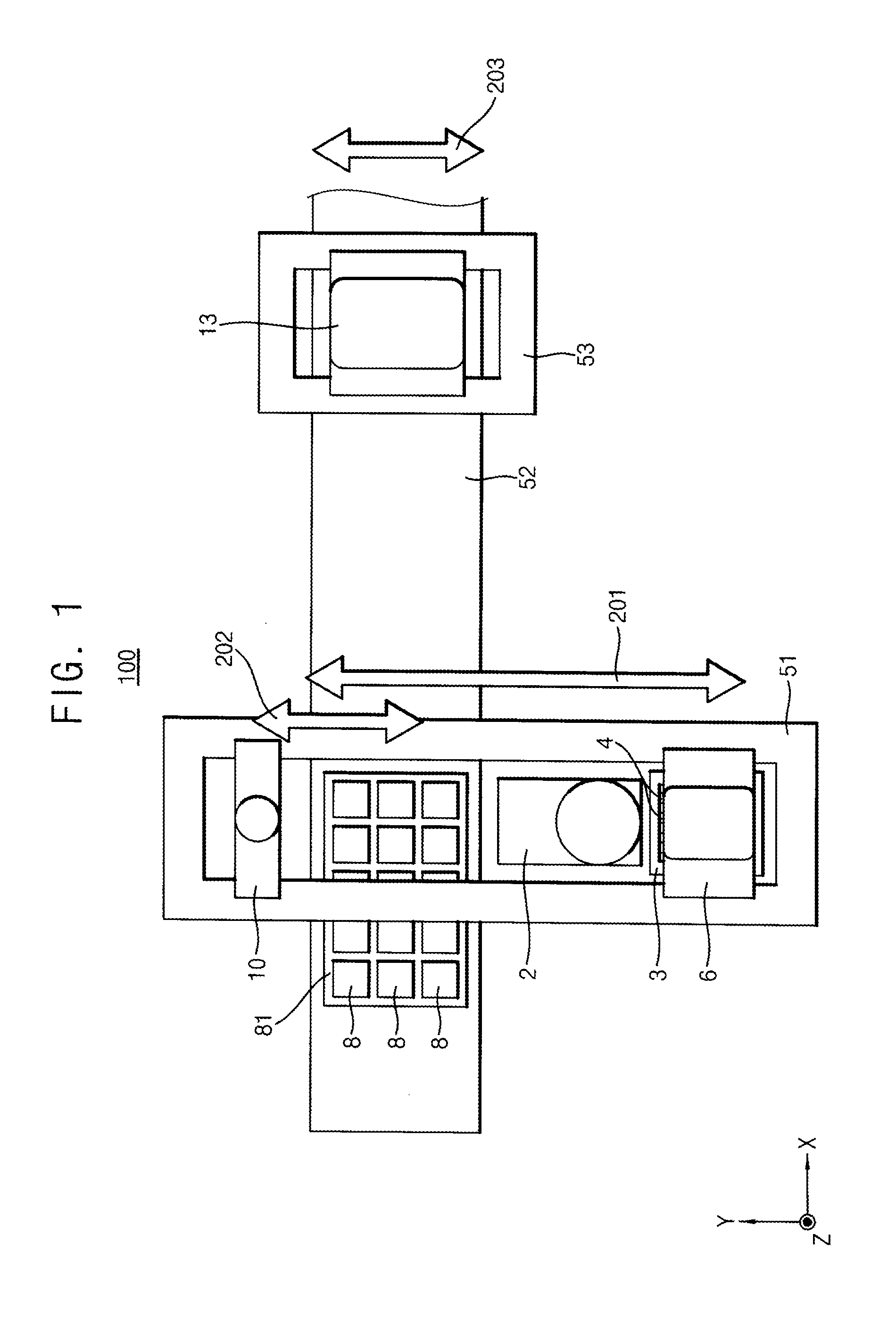

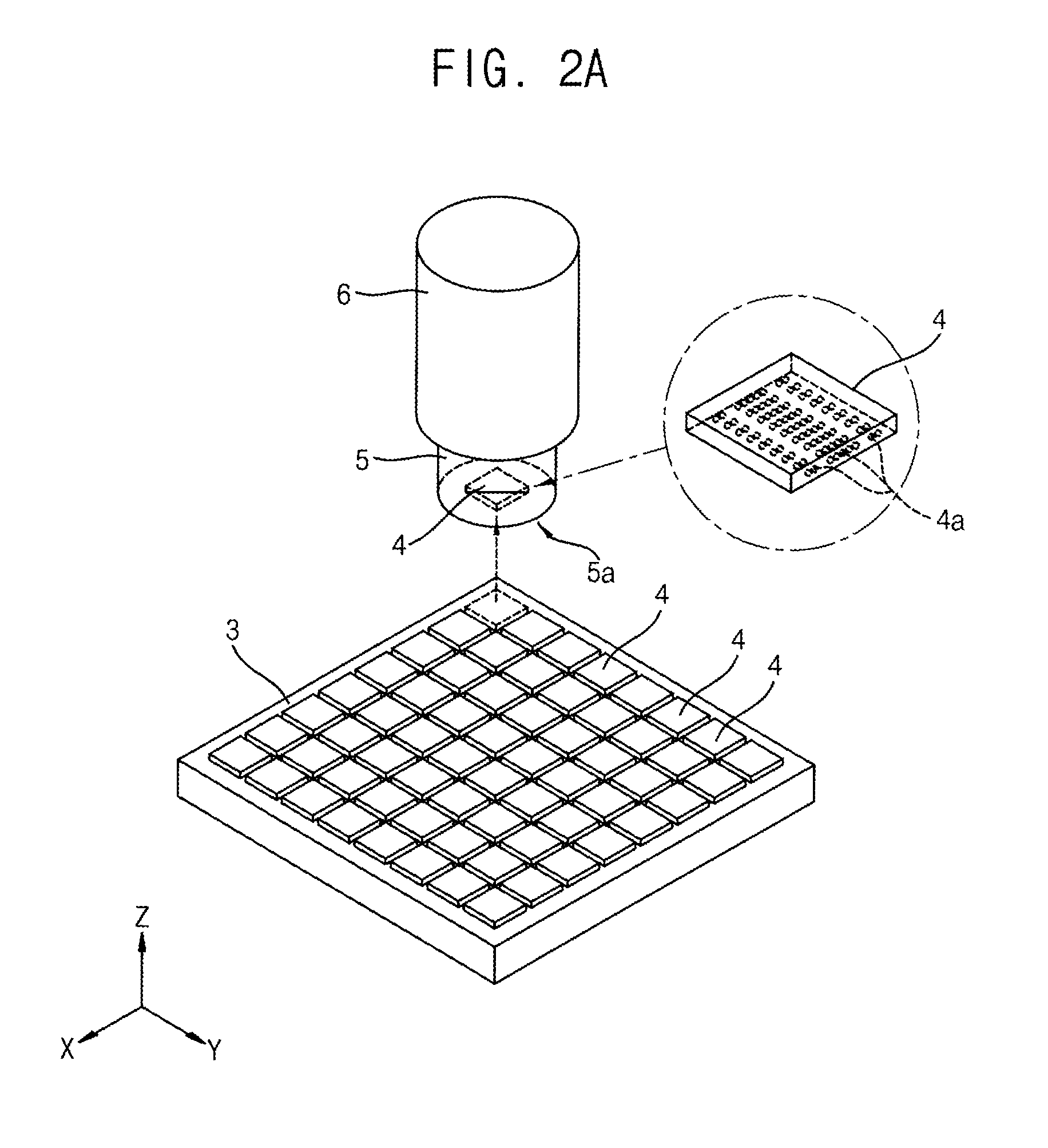

Component-mounted board production apparatus and position control method for electronic components in component-mounted board production apparatus

ActiveUS20100001042A1Improve placement qualityPrinted circuit assemblingAutomatic control devicesOn boardEngineering

The electronic component mounting line includes computing unit for calculating a print position of solder paste printed on board-side electrodes, electronic component placement device for placing an electronic component onto the board-side electrodes by referencing the print position of the solder paste, placement position control device for controlling the placement position of the electronic component by referencing the print position of the solder paste, bonding device for melting the solder paste to bond the electronic component and the board-side electrodes to each other, and mounting-position control device for controlling the mounting position of the electronic component by referencing the board-side electrode position. In this configuration, position control responsive to a displacement of the electronic component by the self alignment effect exerted by the molten solder paste is fulfilled.

Owner:PANASONIC CORP

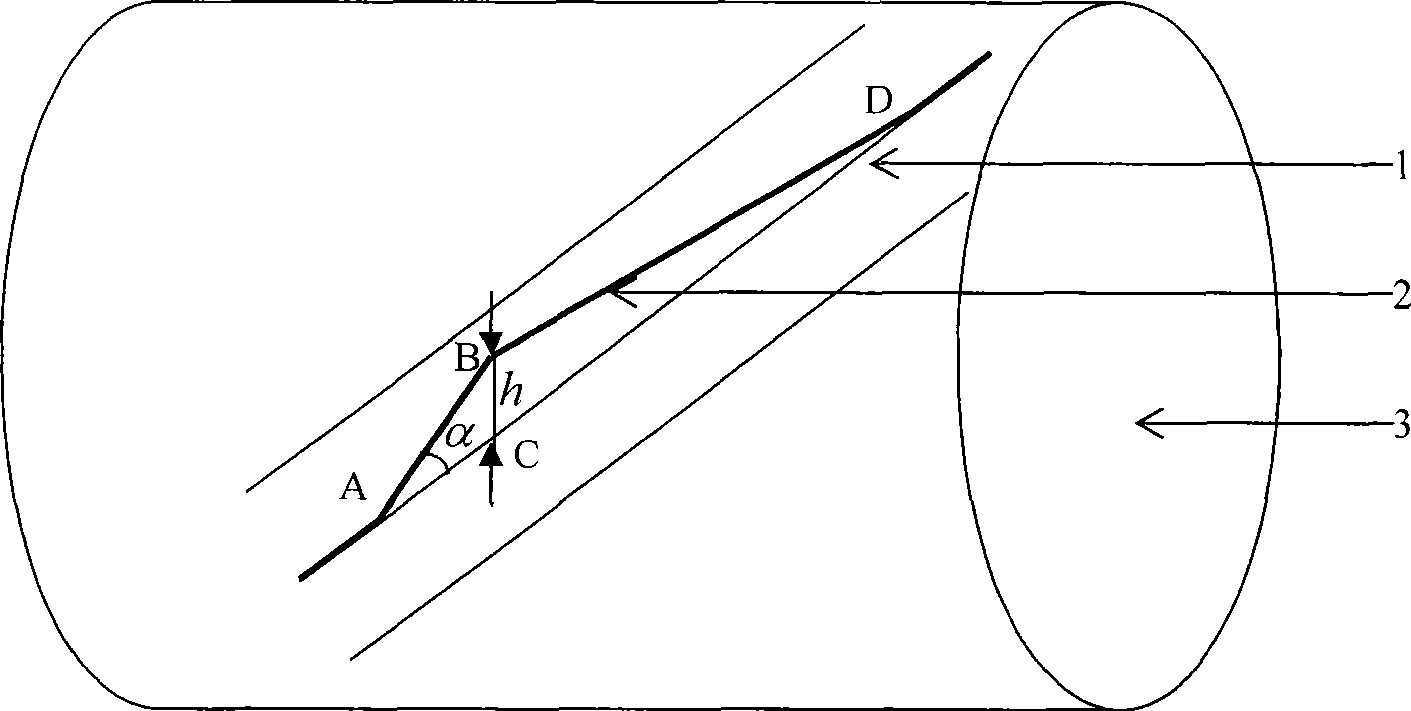

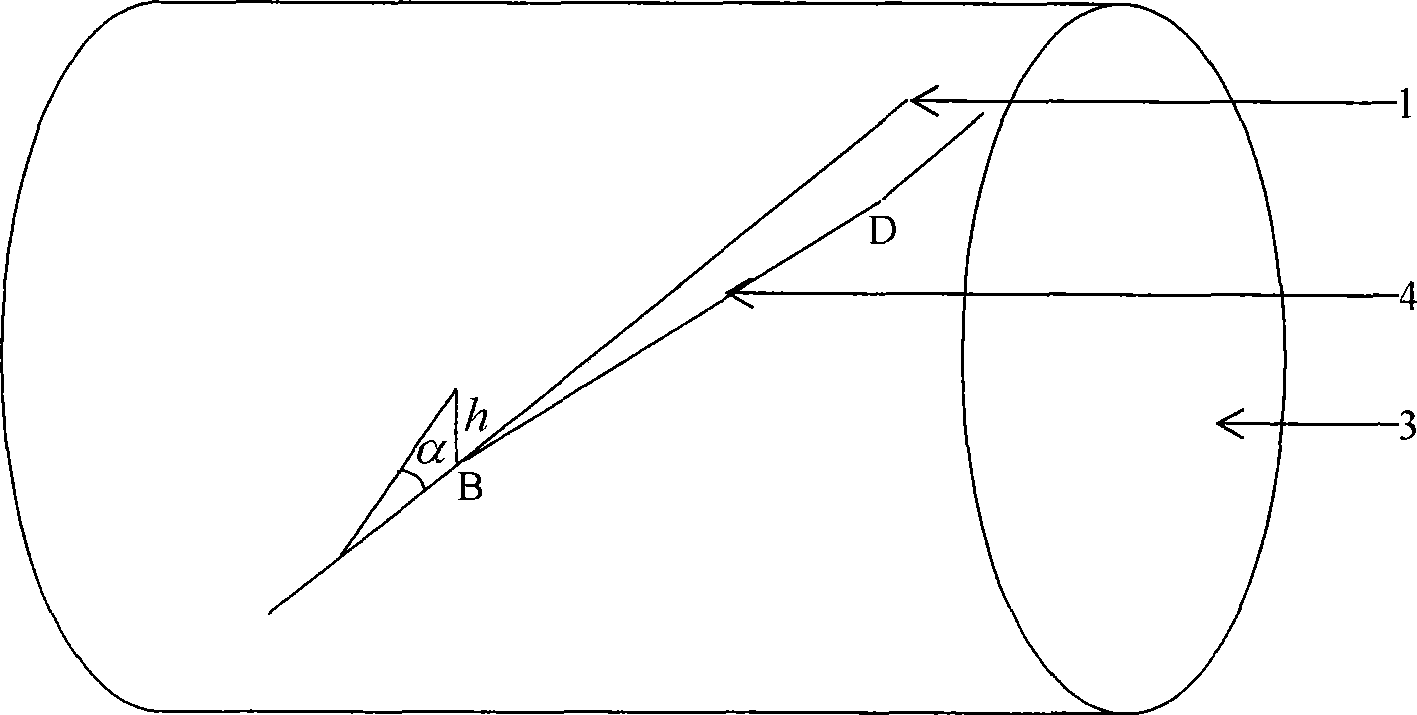

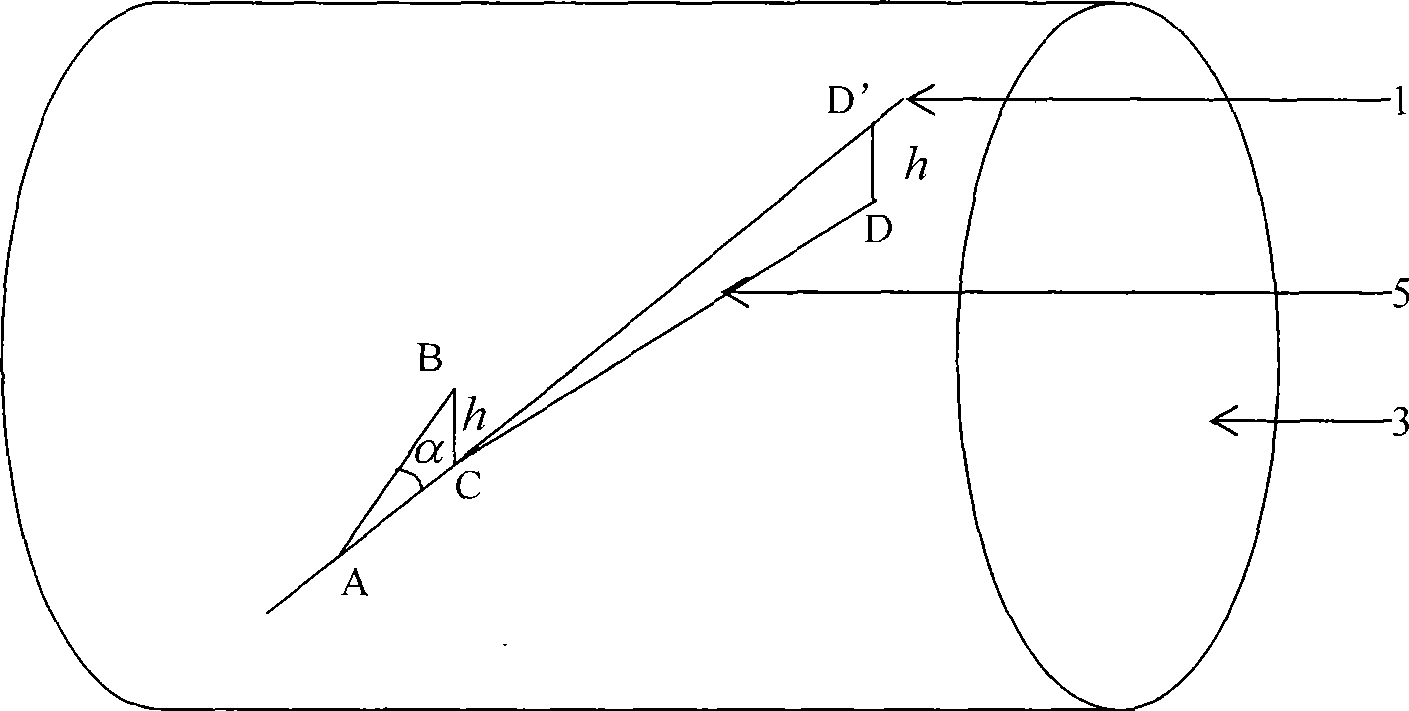

Composite material laying track micro diameter-changing self-regulating method

The invention provides a micro-reducing self-adjusting method used for a composite material laying orbit, and relates to the technical field of composite material laying moulding. The method has the characteristics as follows: error between a designed orbit and an ideal orbit is judged and calculated so as to adjust a two-step laying orbit slightly along a certain direction, namely, an orbit node with error is firstly adjusted to the ideal orbit slightly; and a reverse micro-adjustment is then carried out on a subsequent node correspondingly according to the micro-adjustment. The method can effectively eliminate error of the designed laying orbit; furthermore, the amount of calculation of the error process is not large.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

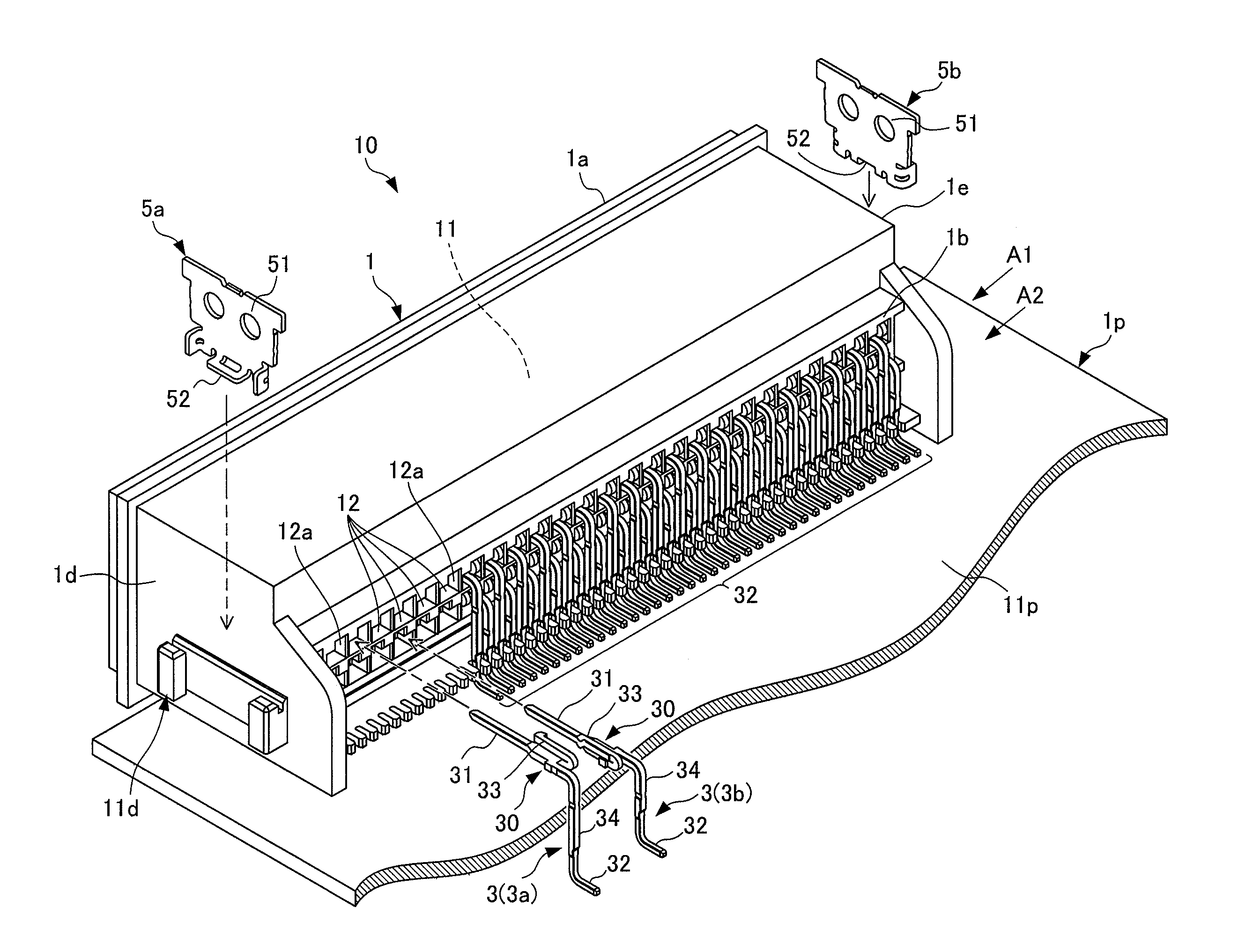

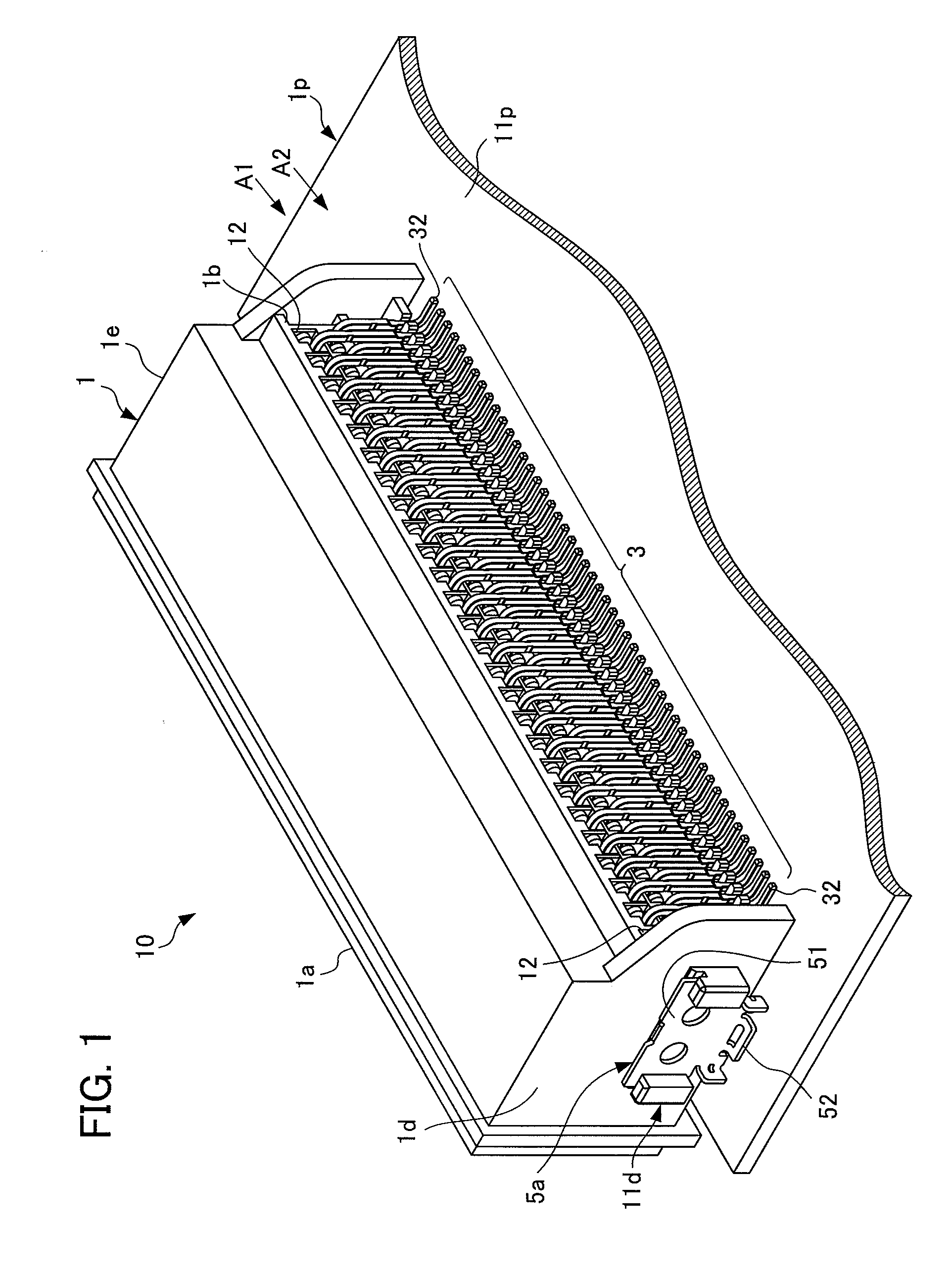

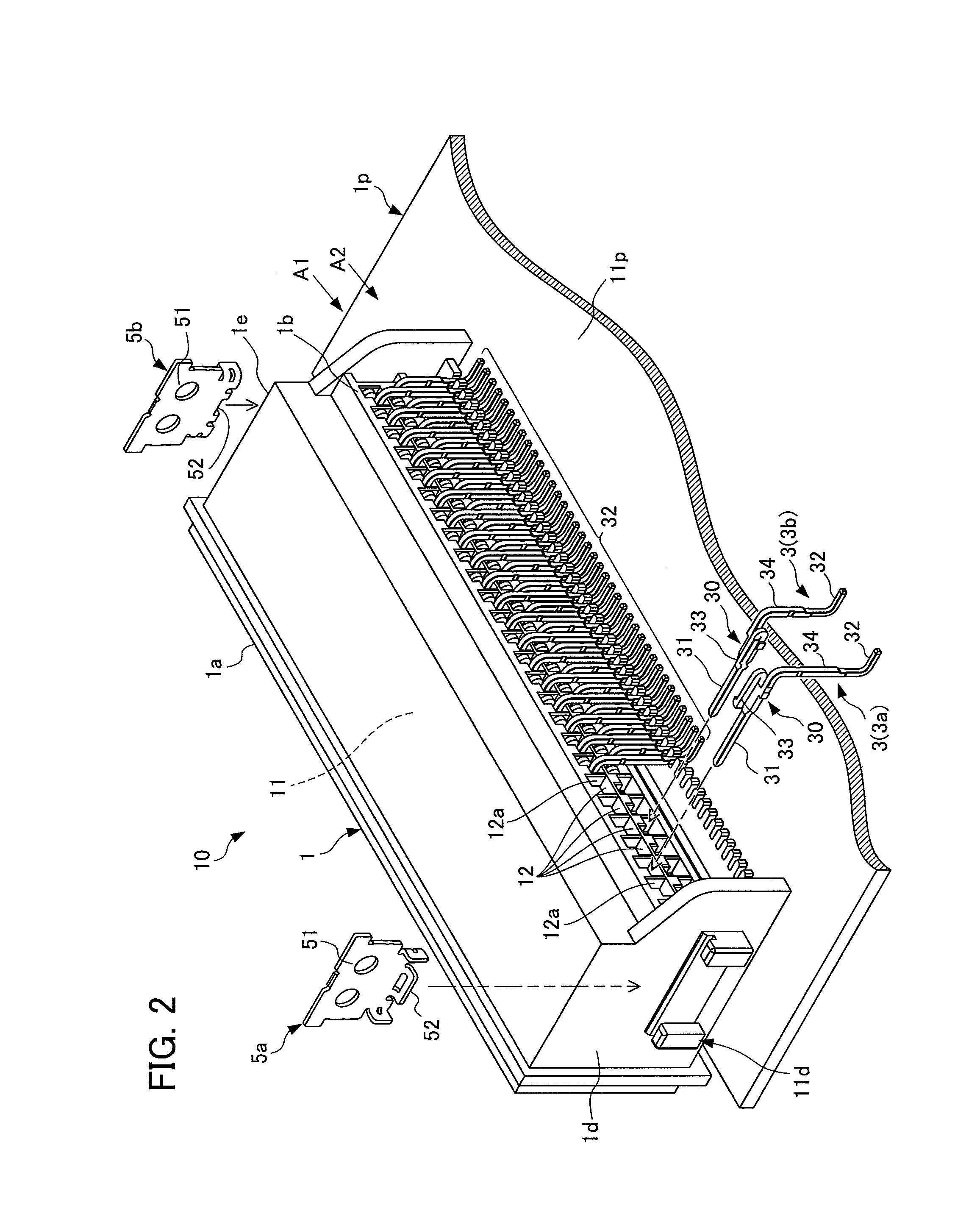

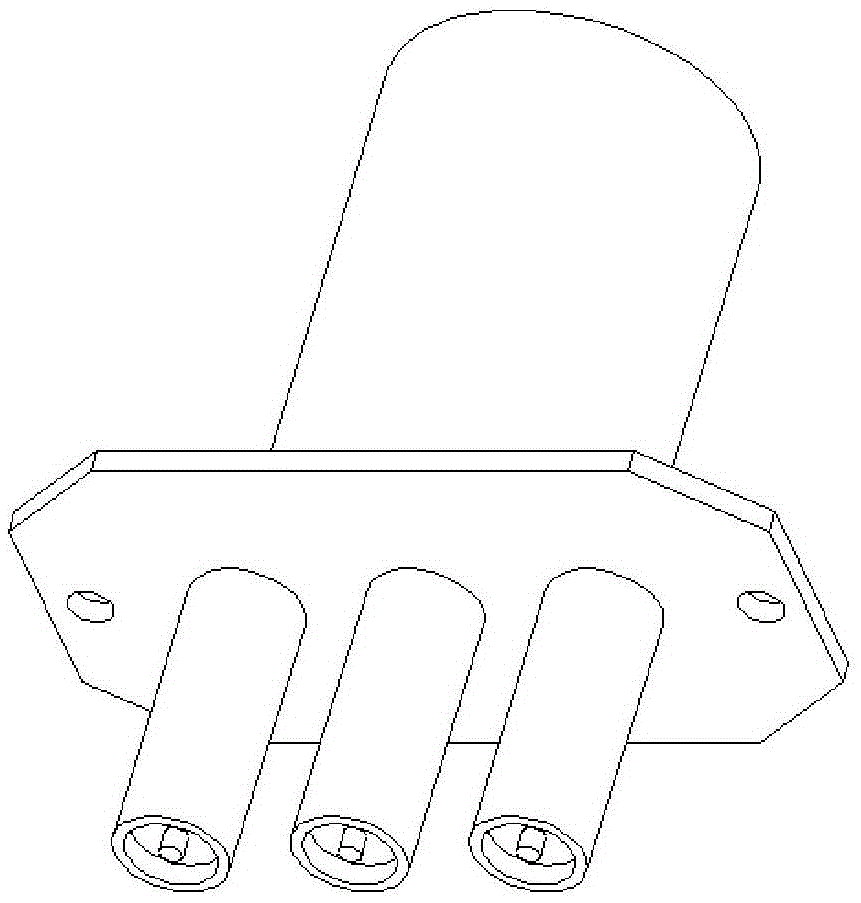

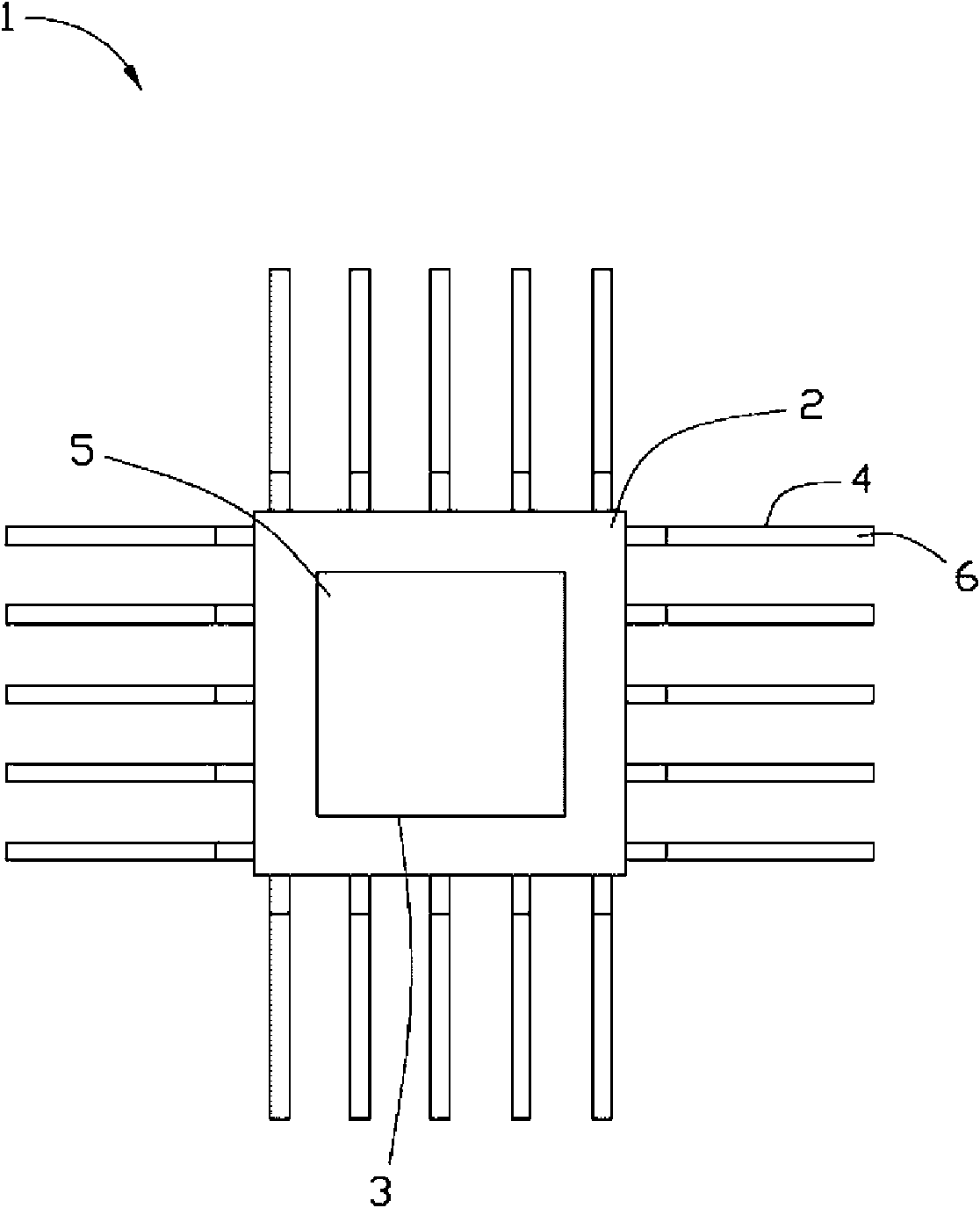

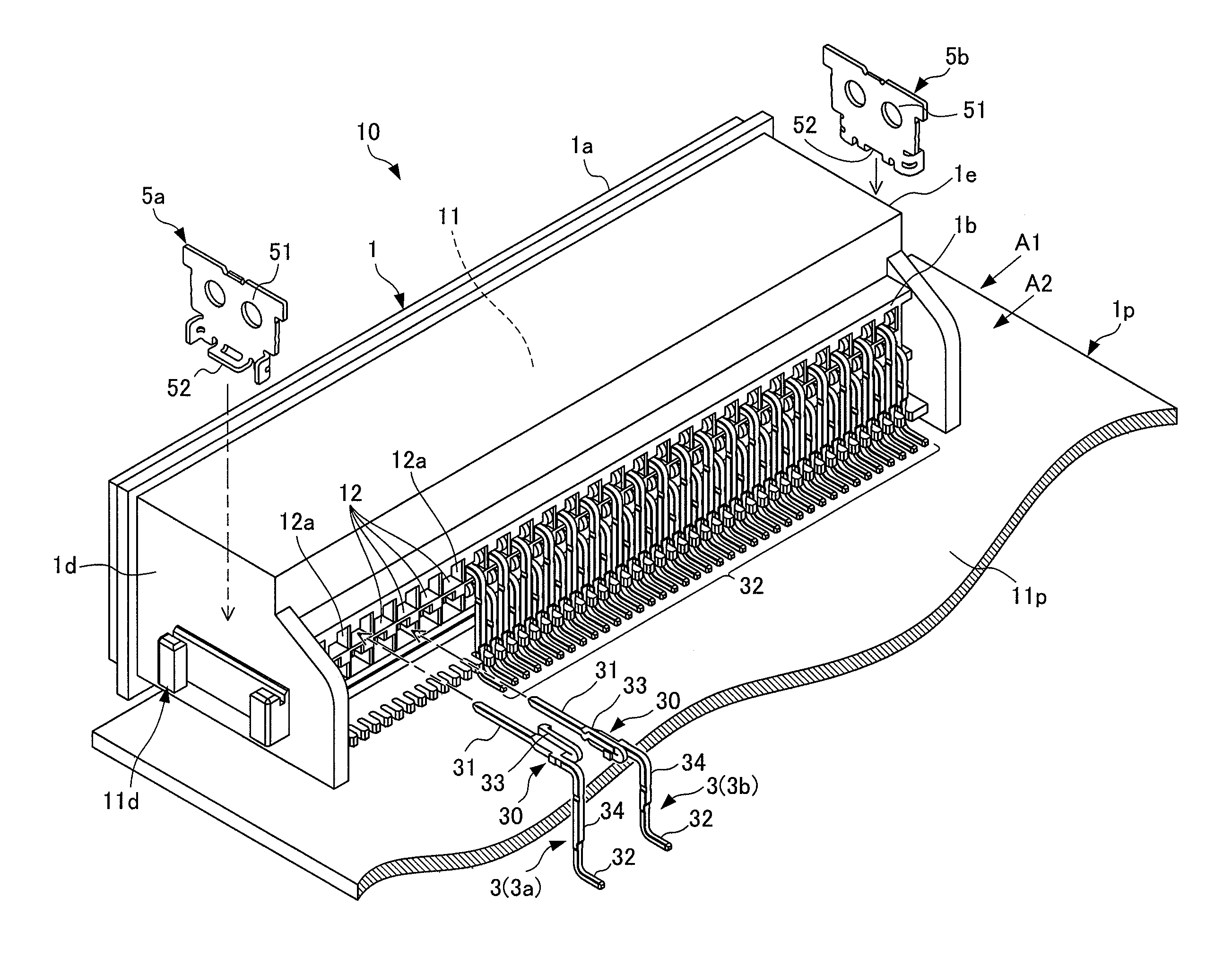

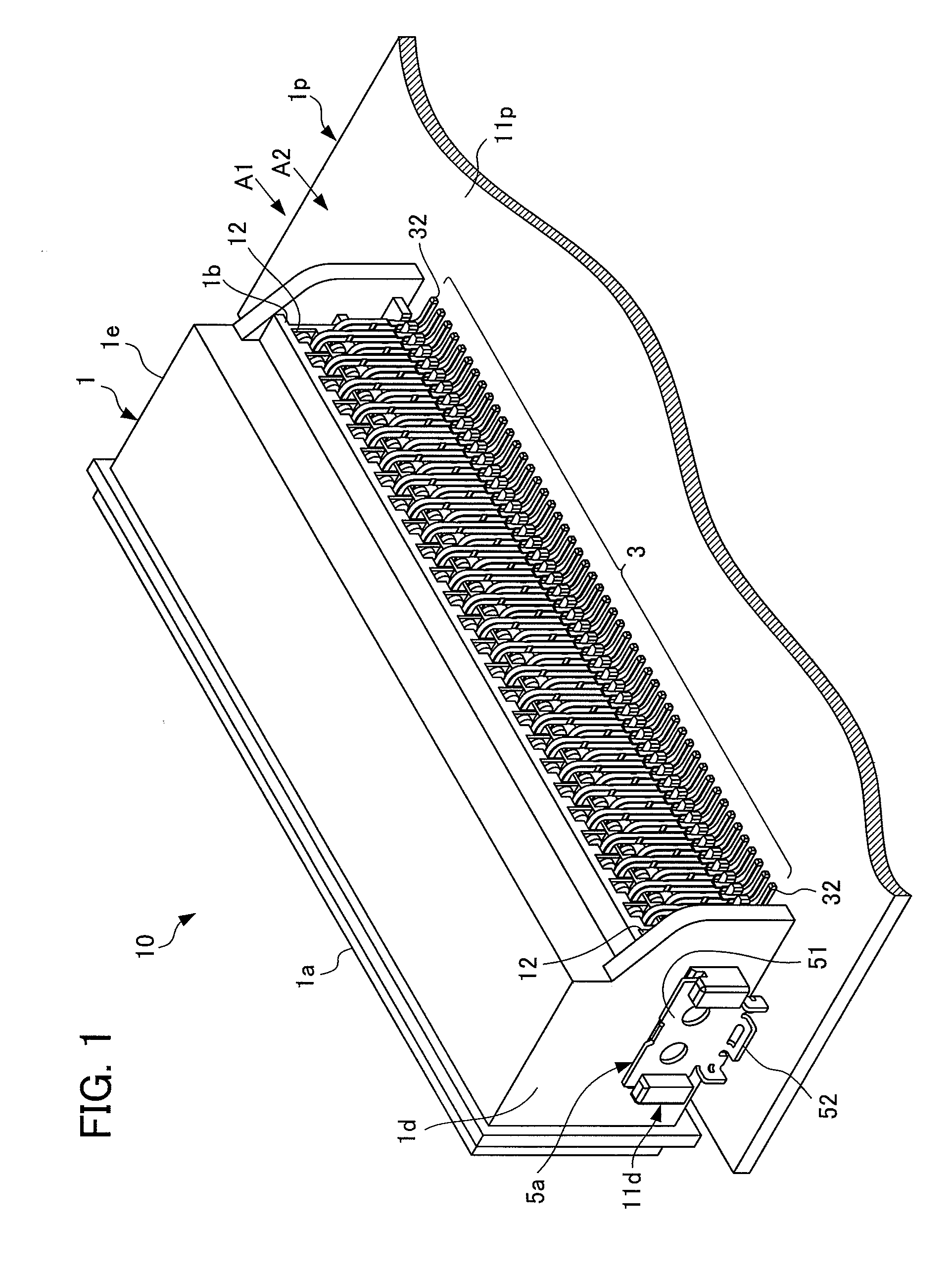

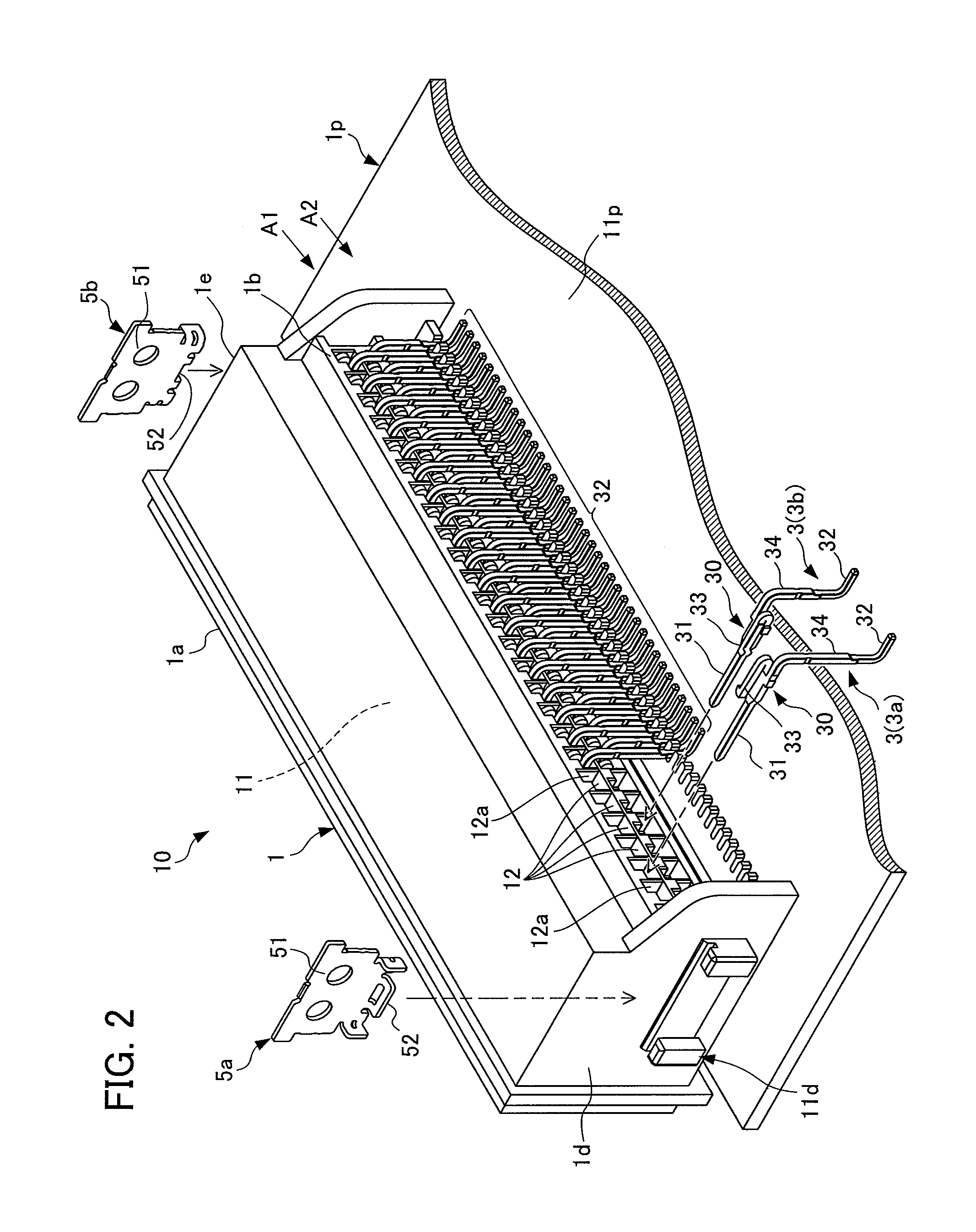

Printed circuit board connector

ActiveUS20120149228A1Improves connector mounting qualityUniform thicknessEngagement/disengagement of coupling partsEngineeringPrinted circuit board

A printed circuit board connector is equipped with a housing and plurality of contacts. The housing has an insertion chamber 11 inserted by the mating-side connector, and a plurality of contact-insertion holes inserted by the contacts. The contact has a base portion, a contact-connecting portion that connects with a mating-side contact, and a lead portion that is solder-bonded to the printed circuit board. The base portion and the housing have a contact lance and level that engage with each other so that the contact does not move in an insertion direction to the contact insertion hole or a reverse direction, and the contact lance and level swingably hold the base portion inside the contact-insertion hole so that the lead portion approaches and separates from the printed circuit board surface.

Owner:JST MFG CO LTD

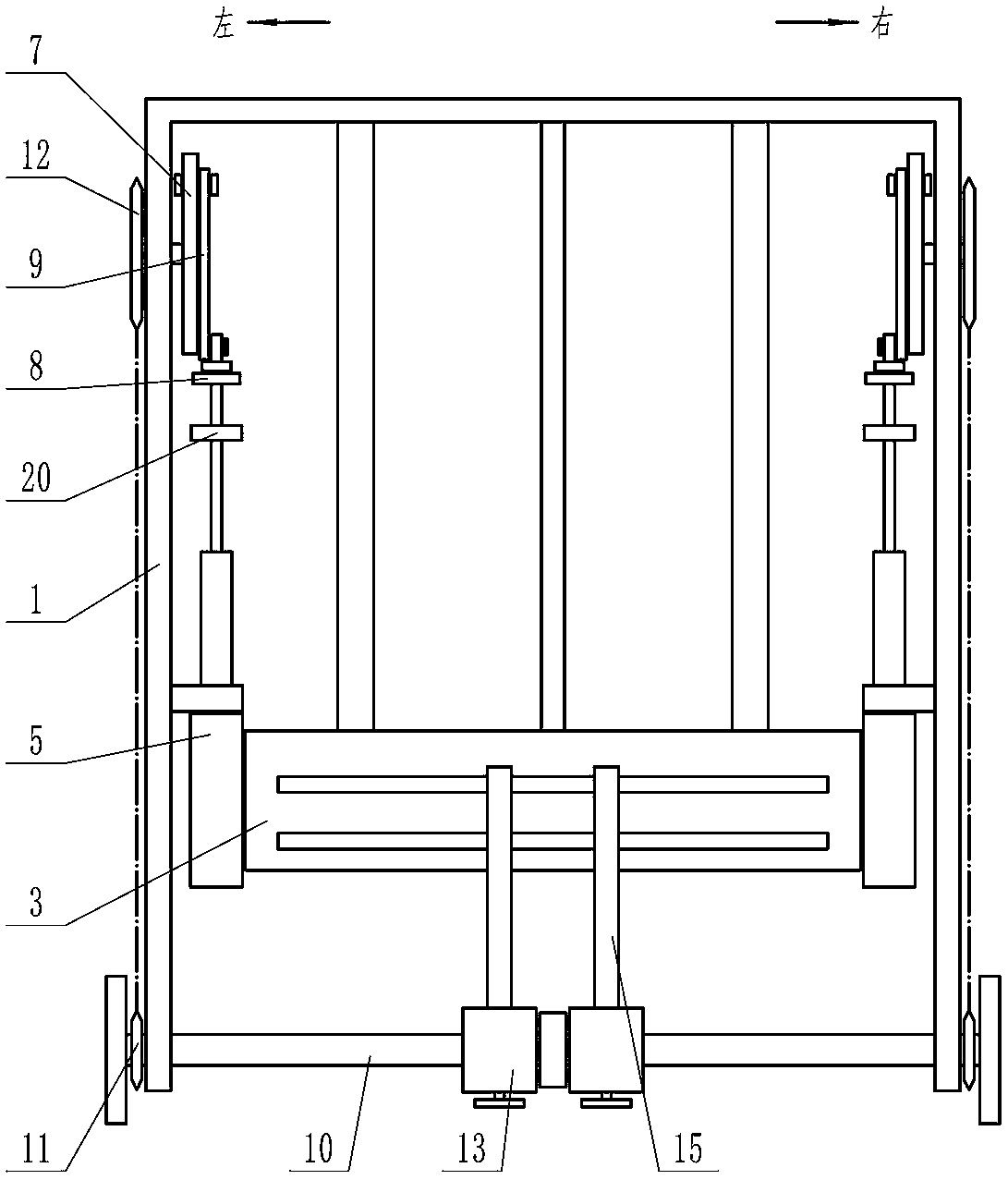

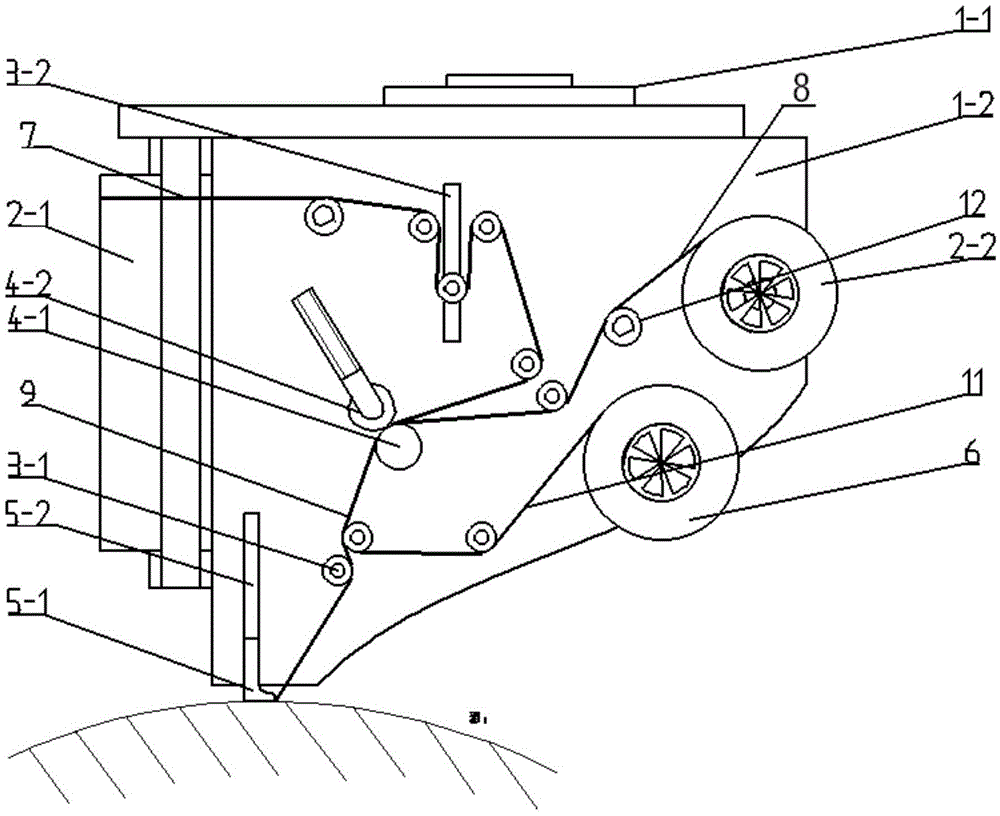

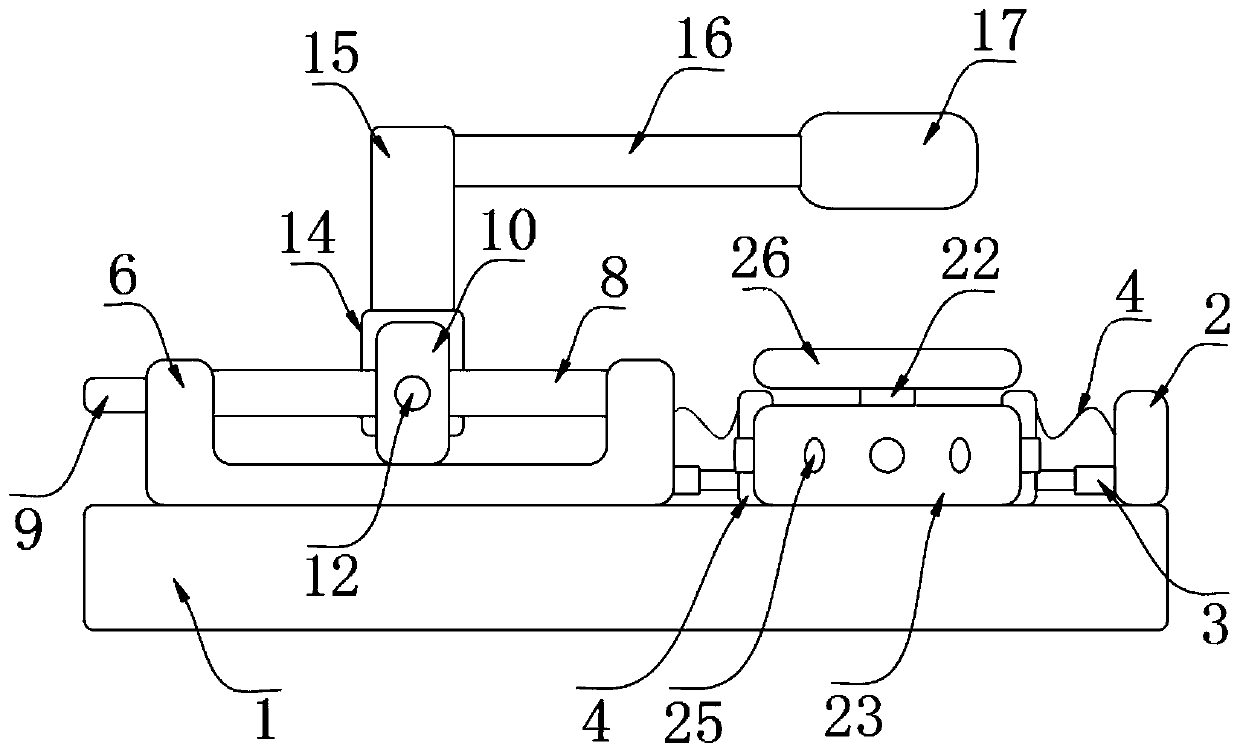

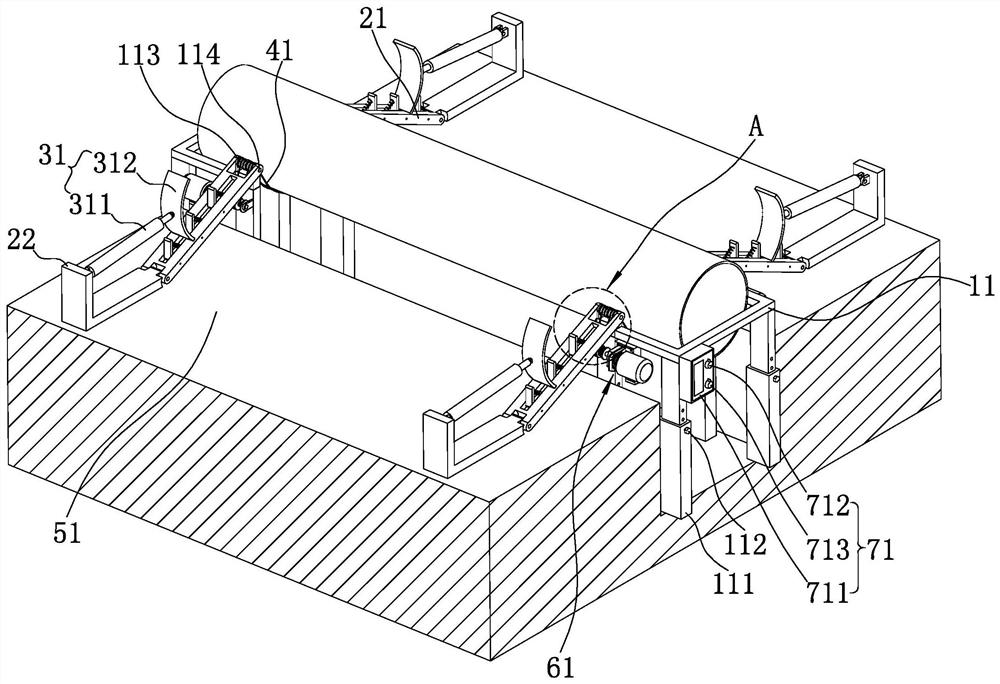

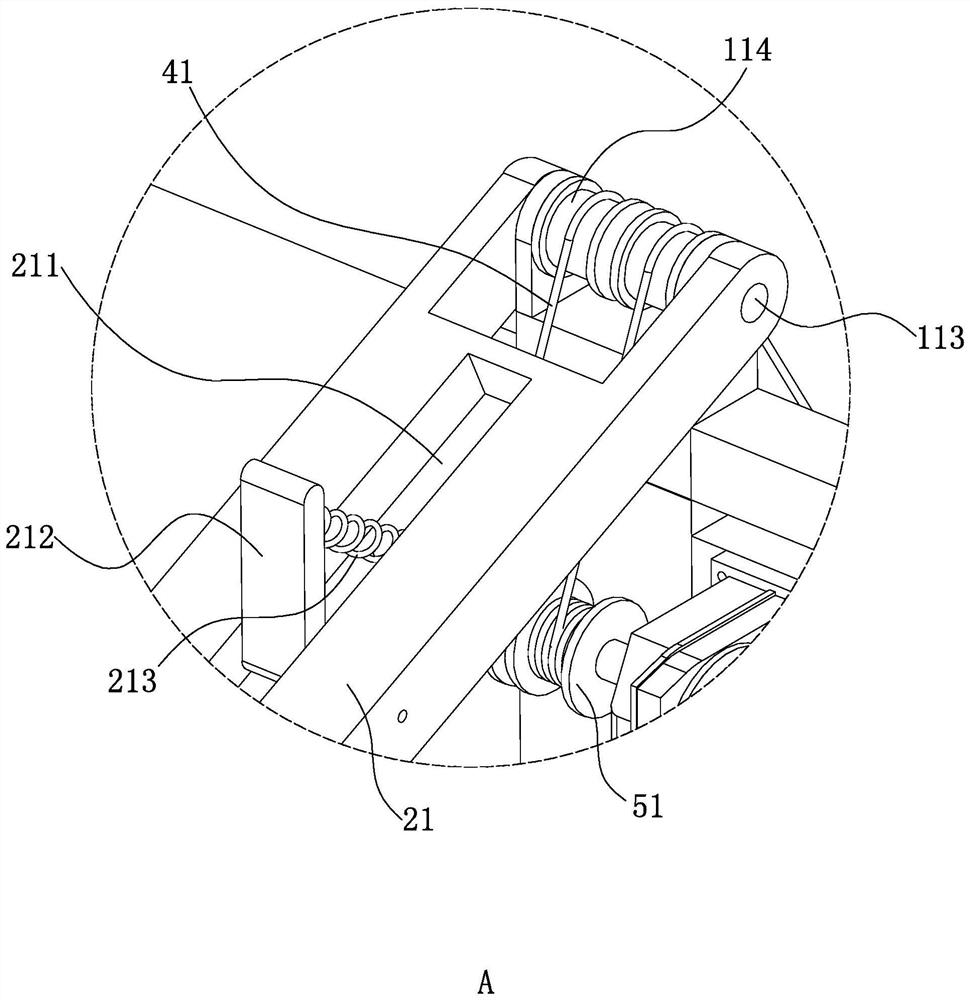

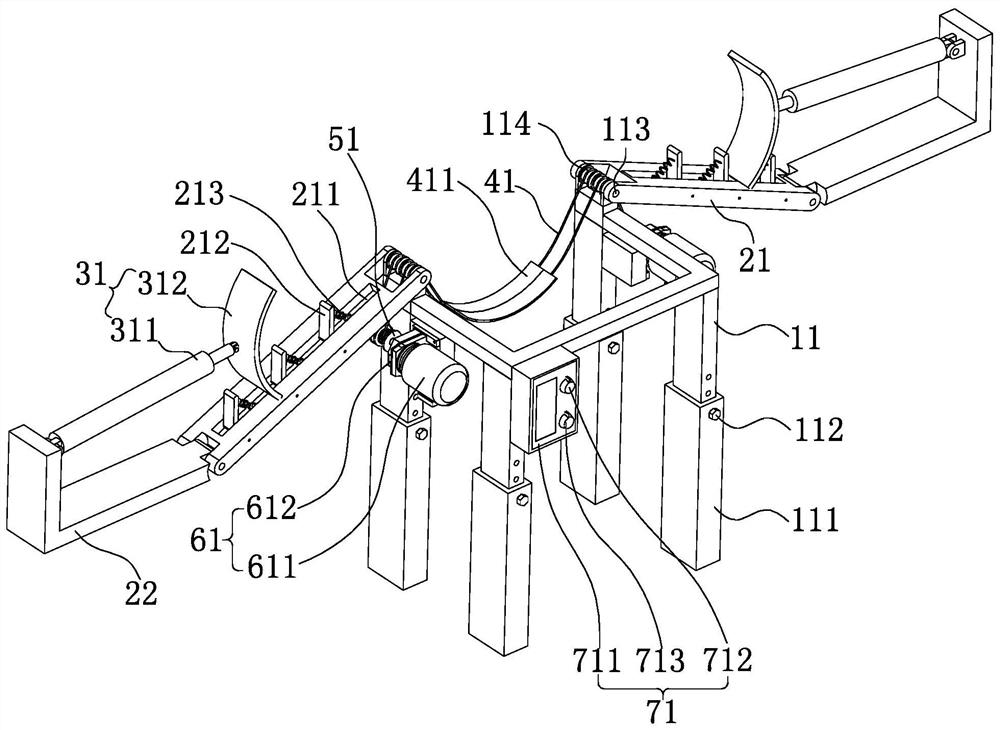

Cement road formwork placement device

ActiveCN109594453AImprove placement efficiencyEvenly placedRoads maintainenceRear quarterCircular disc

The invention provides a cement road formwork placement device. The cement road formwork placement device solves the problems that during construction, road formwork placement requires a lot of manpower, workers are prone to being scratched, placement is uneven, and the efficiency is low. According to the technical scheme, the cement road formwork placement device includes a machine frame, a flatplate is arranged in the machine frame, vertical plates are correspondingly arranged on the upper sides of the front and rear ends of the flat plate, long strip plates are arranged in the flat plate,long strip blocks are correspondingly arranged on the left and right side walls of the machine frame, a plurality of formworks are placed between the long strip plates and the long strip blocks, and grooves are formed at the ends, close to the flat plate, of the long strip blocks; and disks are arranged on the inner sides of side plates of the machine frame, connecting rods are hinged to the disks, horizontal plates are arranged at the lower ends of the disks, the disks, the connecting rods and the horizontal plates form a crank sliding block mechanism, and the horizontal plates and the long strip blocks are connected by a plurality of vertical jacking rods. The cement road formwork placement device is ingenious in structure and design, improves the efficiency of formwork placement in roadconstruction, effectively reduces manual labor amount, achieves even placement of the formworks, and improves the quality of the placement, meanwhile, the workers are prevented from being scratched,the applicability is wide, and the cement road formwork placement device is easy to promote.

Owner:江苏金森木业有限公司

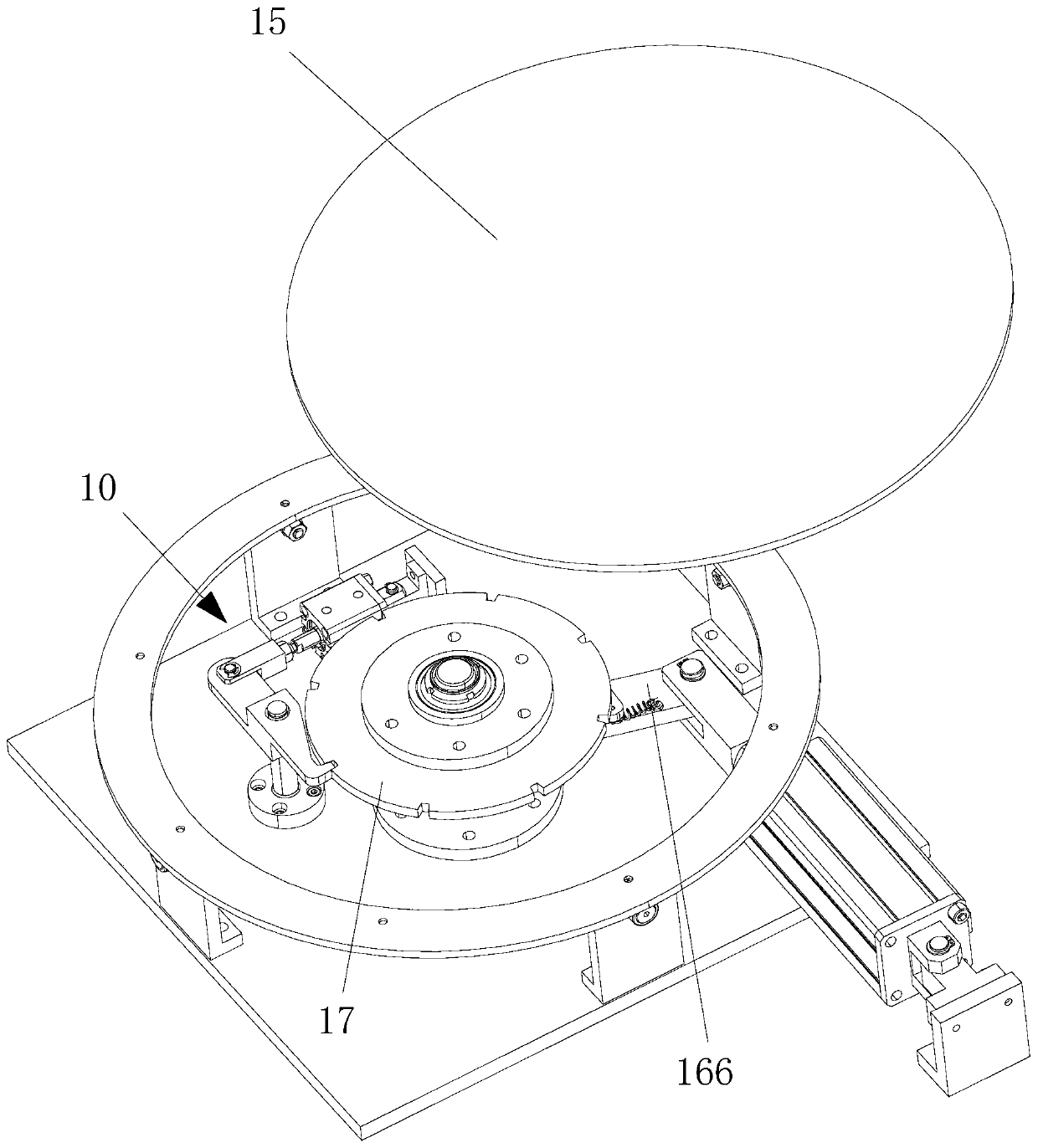

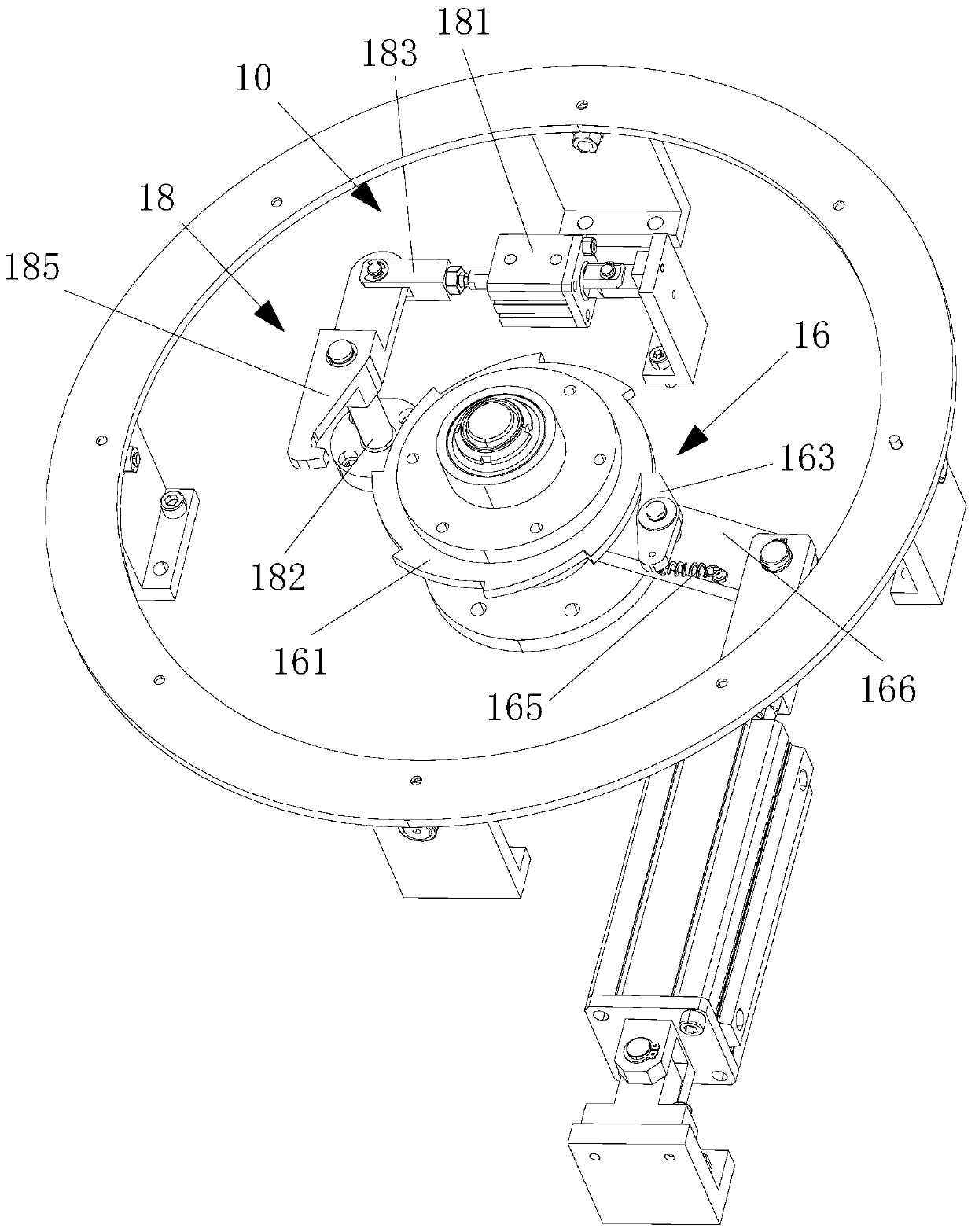

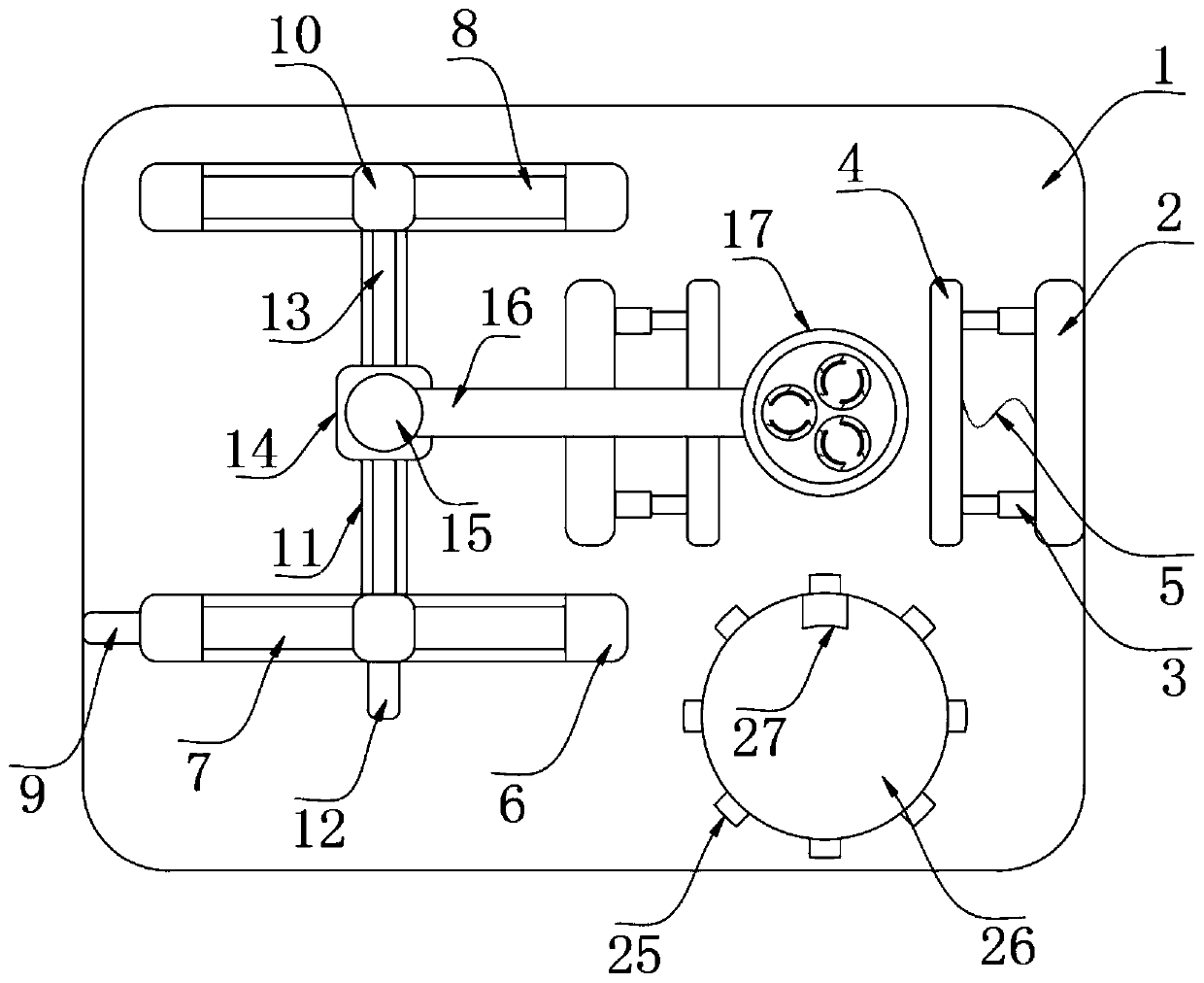

Ratchet wheel transmission type dispensing system for SMT mounting

ActiveCN111250359AAccelerated cooling and solidificationImprove adhesionPretreated surfacesCoatingsRatchetElectric machinery

The invention relates to a ratchet wheel transmission type dispensing system for SMT mounting. The ratchet wheel transmission type dispensing system for SMT mounting comprises a transmission mechanismand a plurality of dispensing mechanisms. The transmission mechanism comprises a driving motor and a circular workbench, and the circular workbench is mounted on the driving motor. The plurality of dispensing mechanisms are arranged around the periphery of the circular workbench. Each dispensing mechanism comprises a mounting beam, a lifting assembly, a dispensing assembly and a heating assembly,wherein the mounting beam is fixed on the ground and is provided with an accommodating groove, the accommodating groove is used for accommodating the periphery of the circular workbench, the liftingassembly is mounted on the mounting beam, and the dispensing assembly is mounted on the lifting assembly. The ratchet wheel transmission type dispensing system for SMT mounting can improve SMT mounting quality.

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

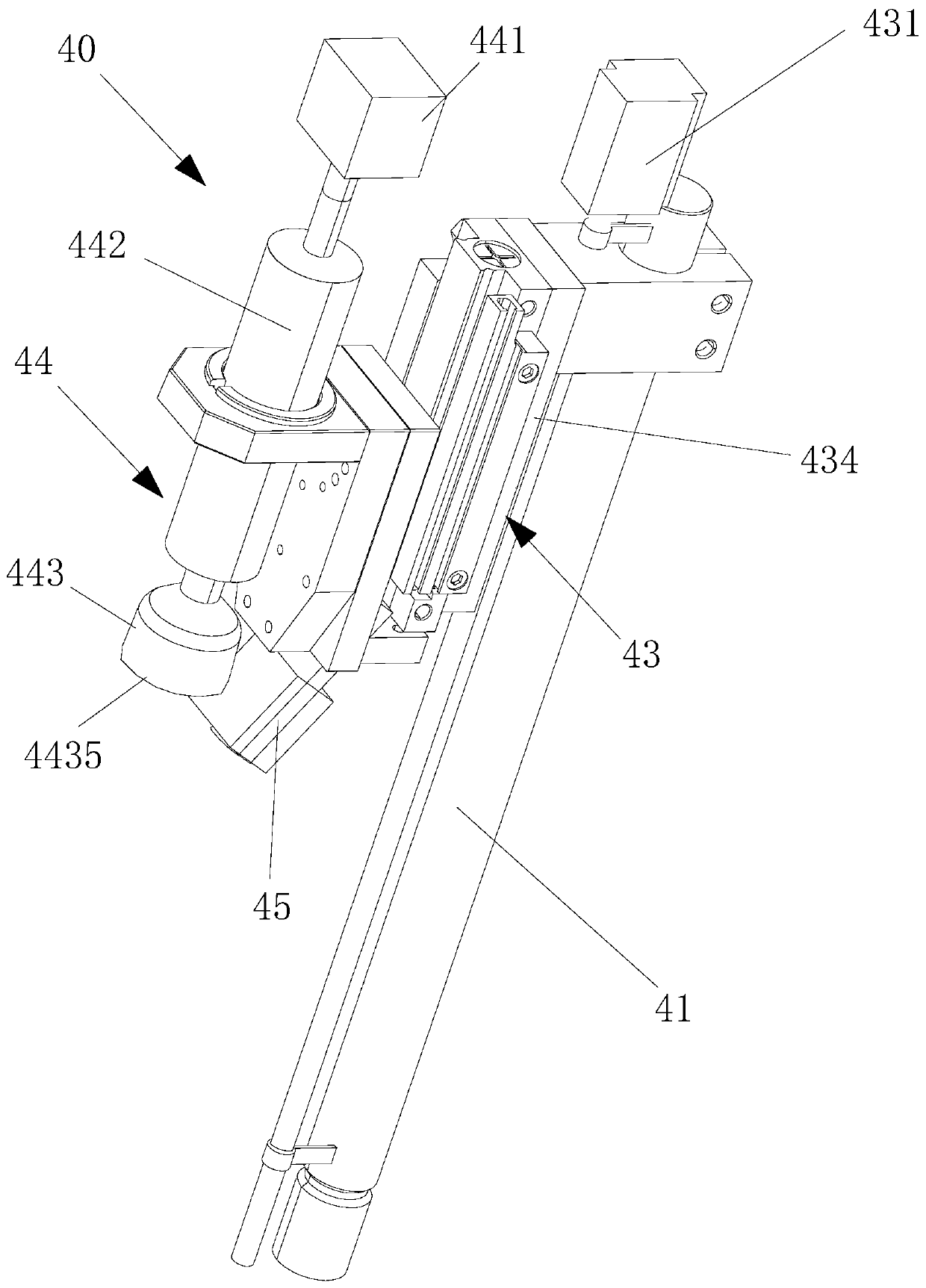

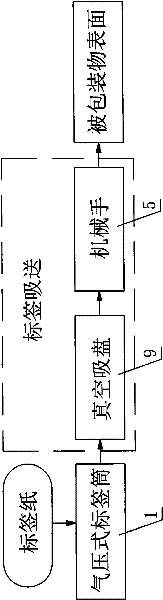

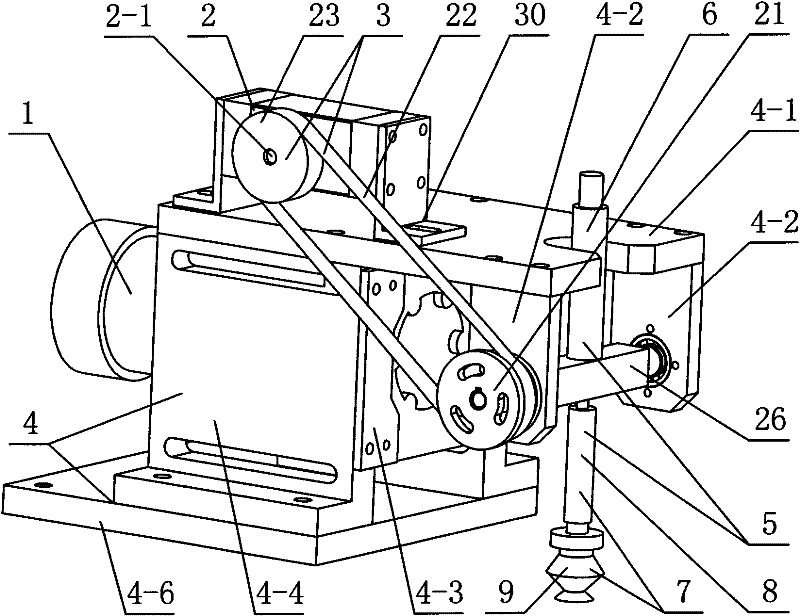

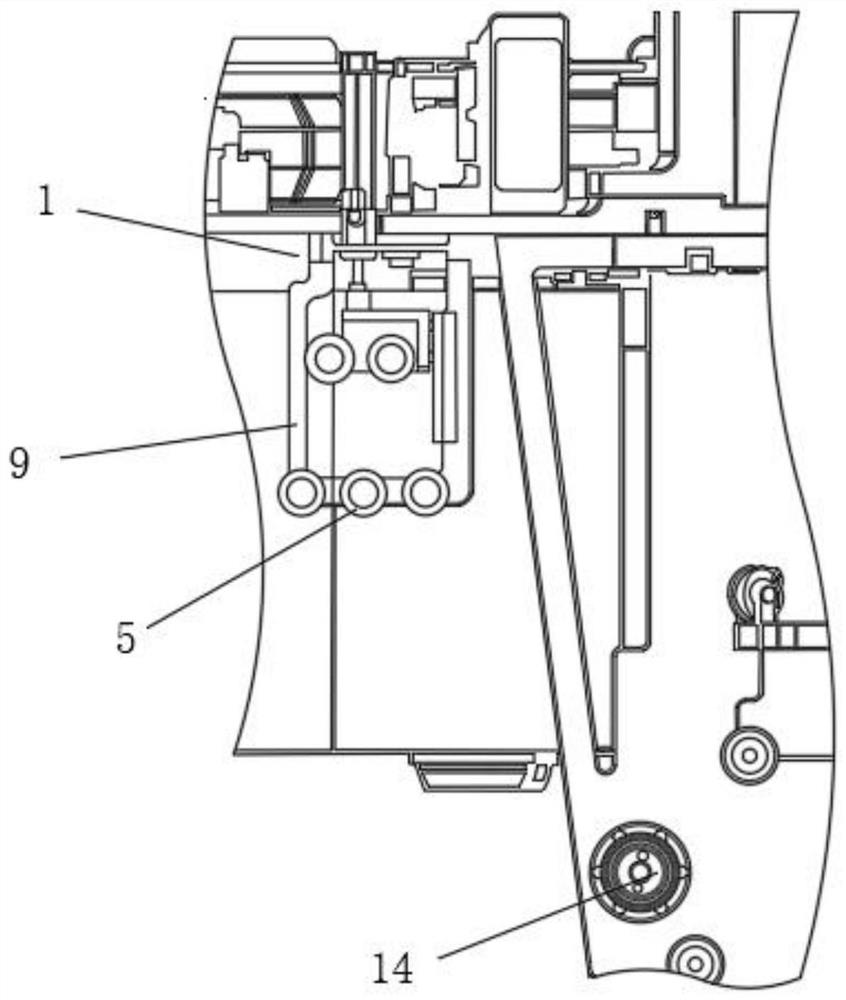

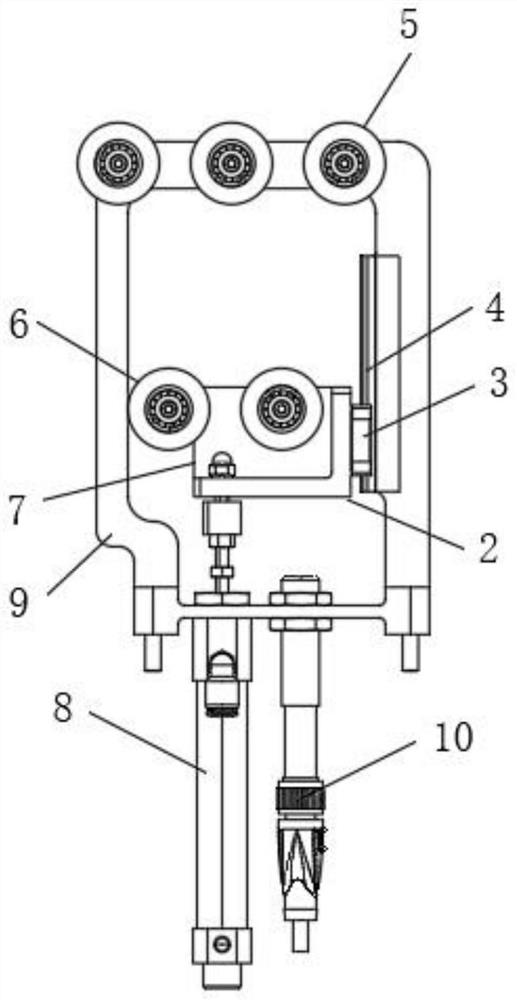

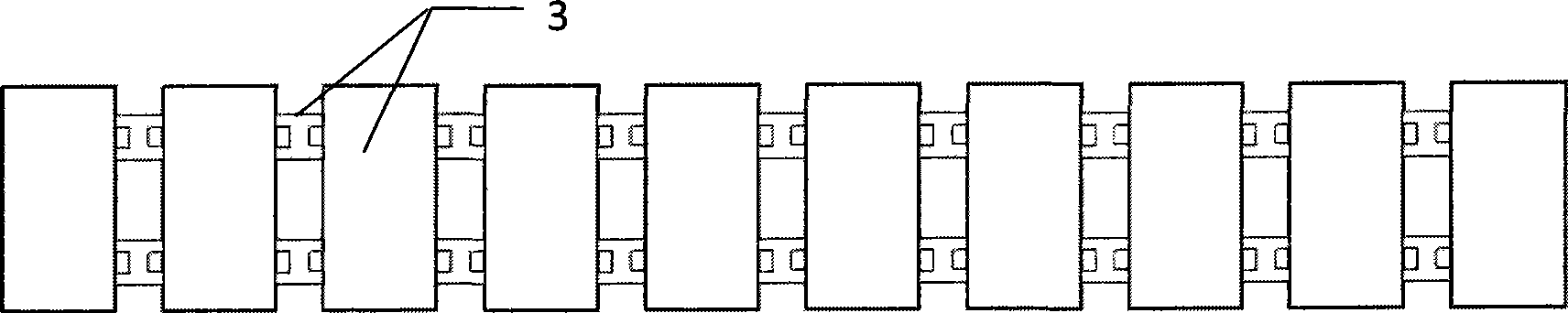

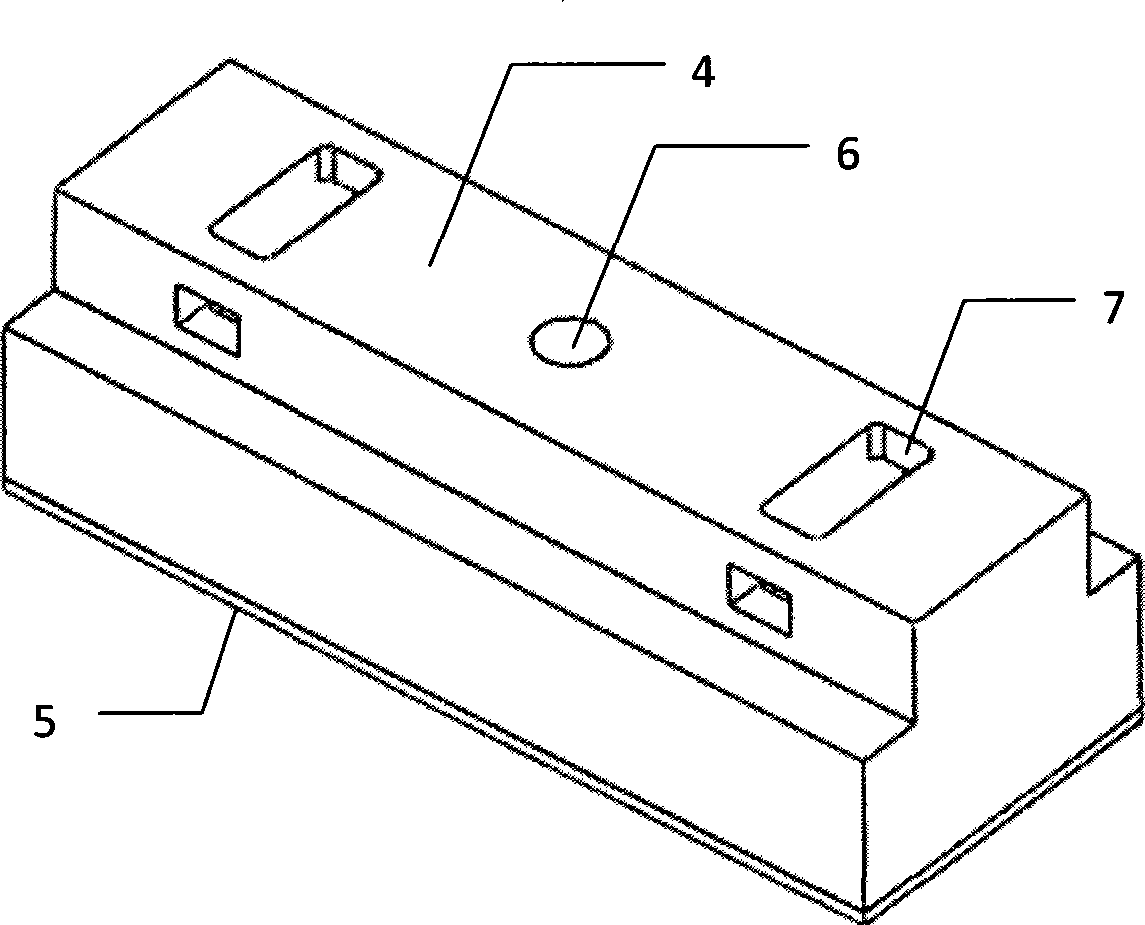

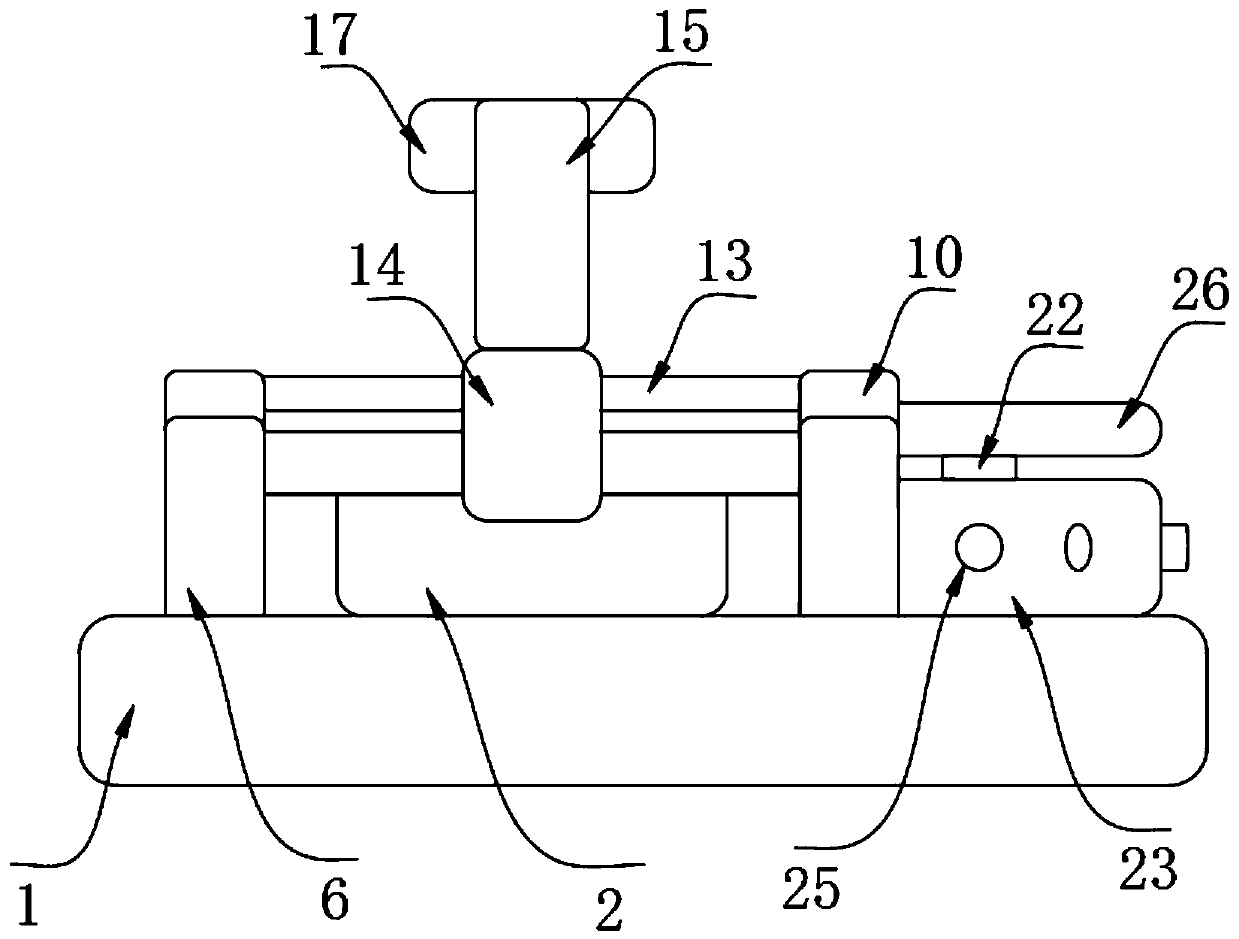

Paper label suction and conveying mechanism

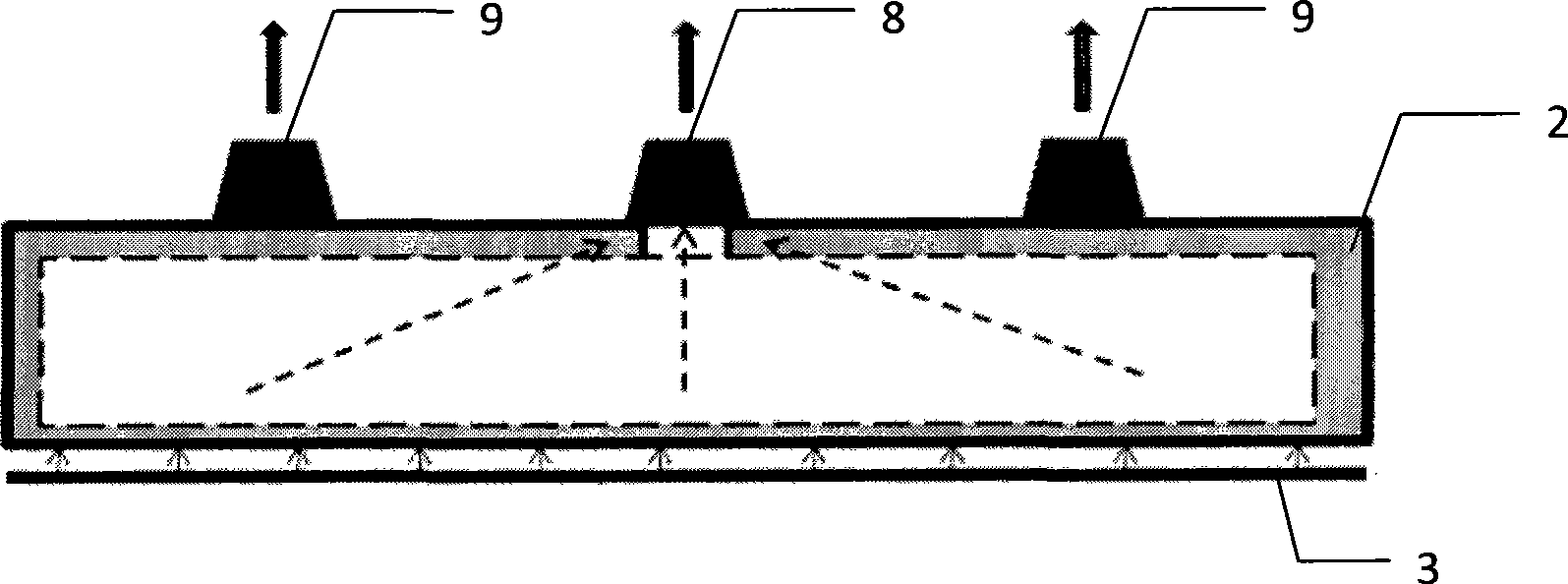

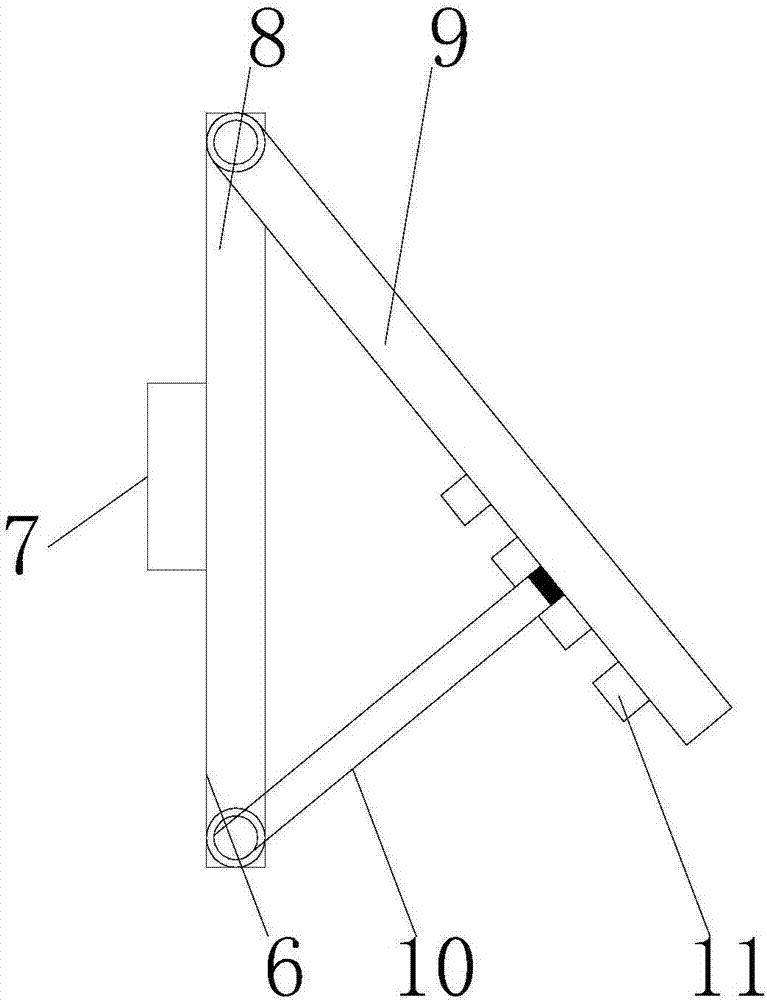

The invention particularly relates to a paper label suction and conveying mechanism. The paper label suction and conveying mechanism comprises a pneumatic label cylinder (1), a swing cylinder (2), a synchronous belt transmission device (3), a support saddle (4), a mechanical hand (5) and a rotating shaft (26), wherein a synchronous belt wheel II (23) of the synchronous belt transmission device (3) is connected with the swing cylinder (2), a synchronous belt wheel I (21) is connected with the rotating shaft (26), and the rotating shaft (26) is movably connected with the support saddle (4); and the mechanical hand (5) comprises a cylinder (6) and a vacuum paw combination (7), the vacuum paw combination (7) comprises a cylinder connecting rod (8) and a vacuum sucking disc (9), the cylinder (6) is connected with the rotating shaft (26), the cylinder connecting rod (8) is respectively connected with the cylinder (6) and the vacuum sucking disc (9), an airway hole (8-1) is formed in the cylinder connecting rod (8), and one end of the airway hole (8-1) is communicated with the vacuum sucking disc (9). The paper label suction and conveying mechanism disclosed by the invention has the advantages of high production efficiency of placing label paper, low cost, high speed and good quality.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

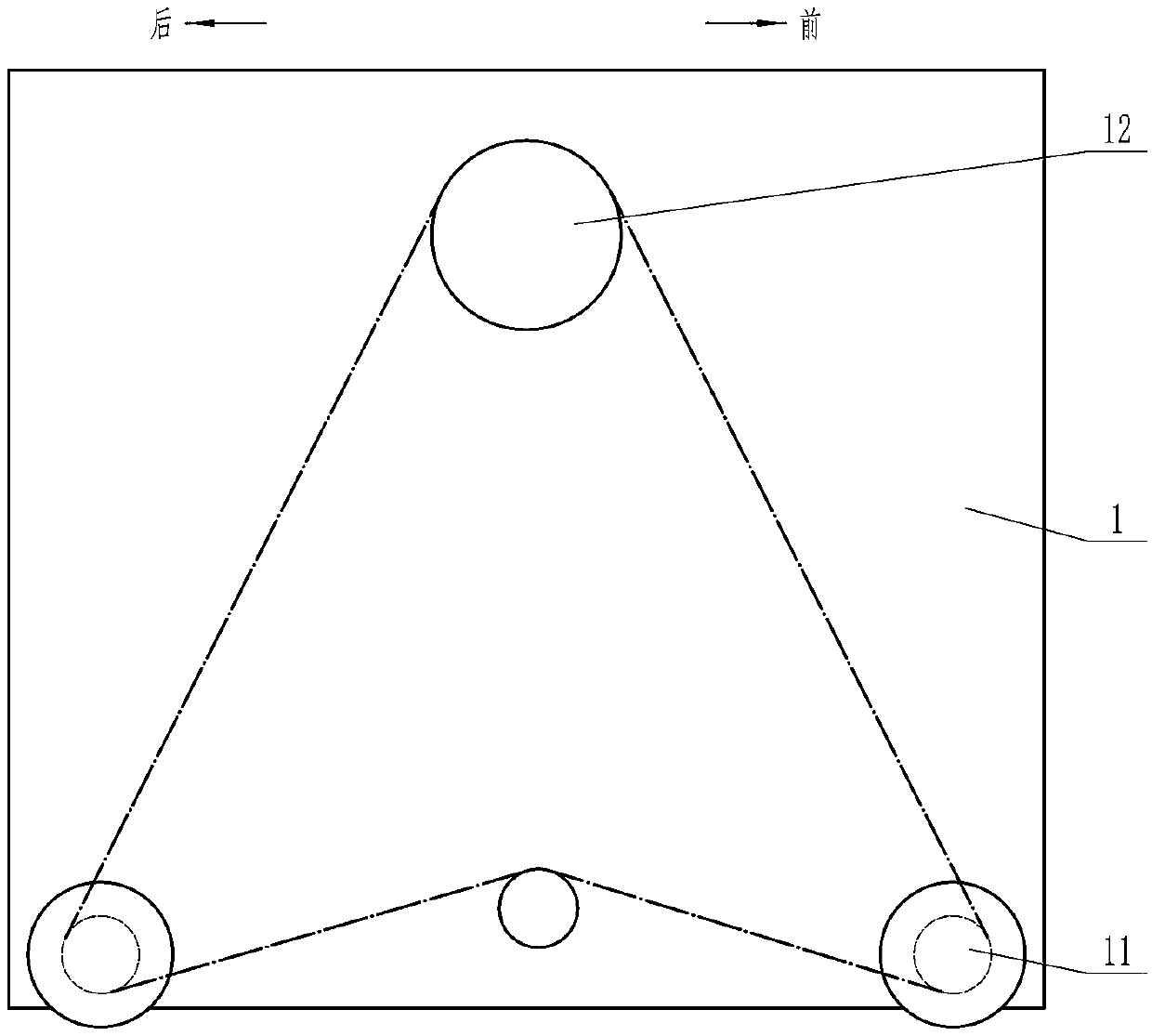

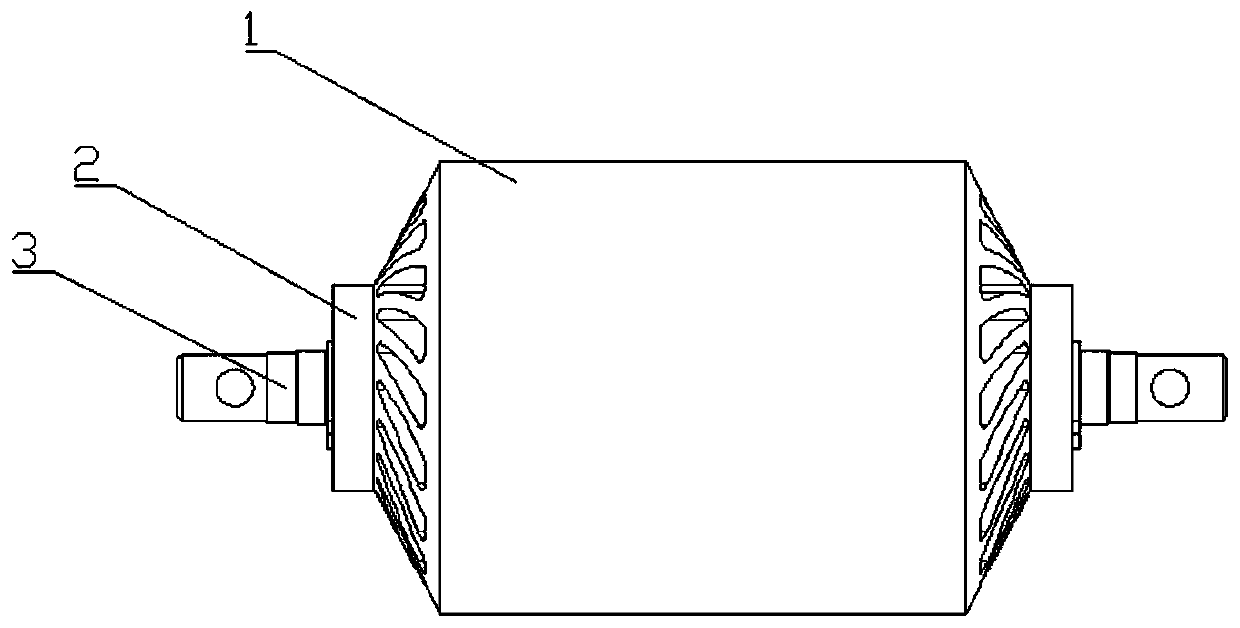

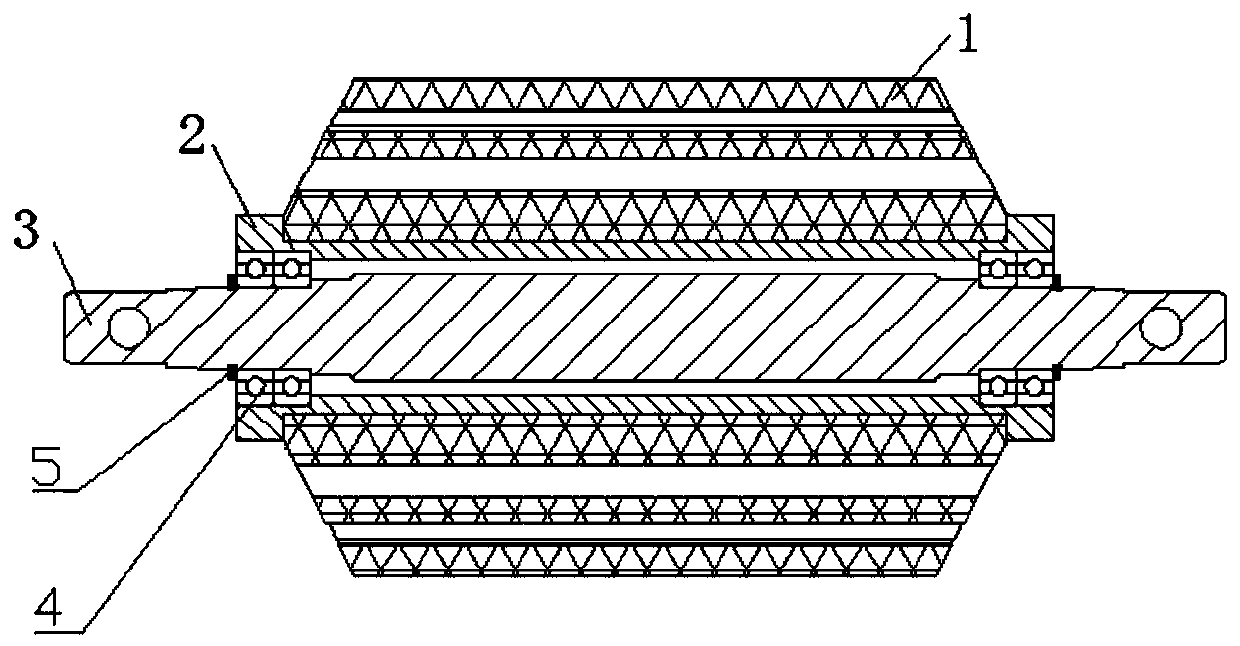

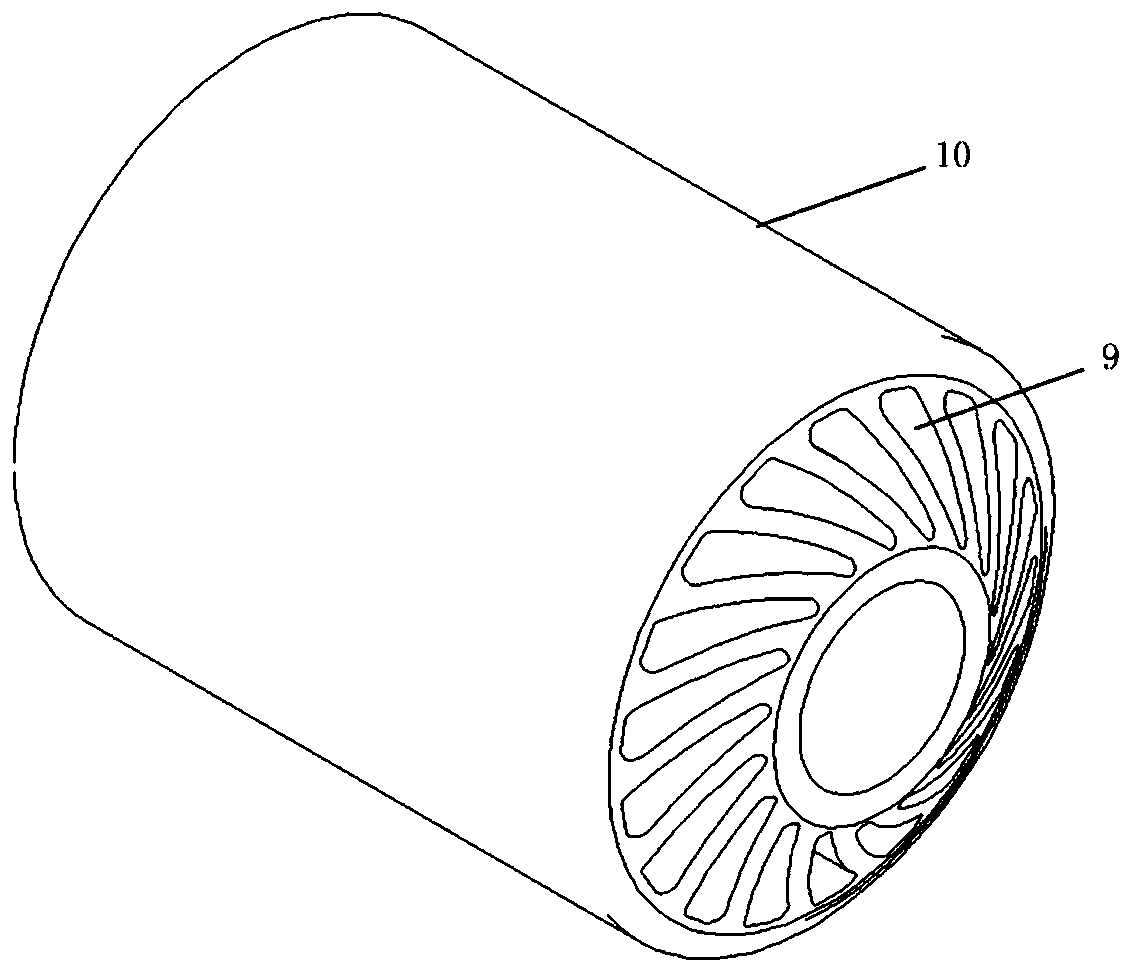

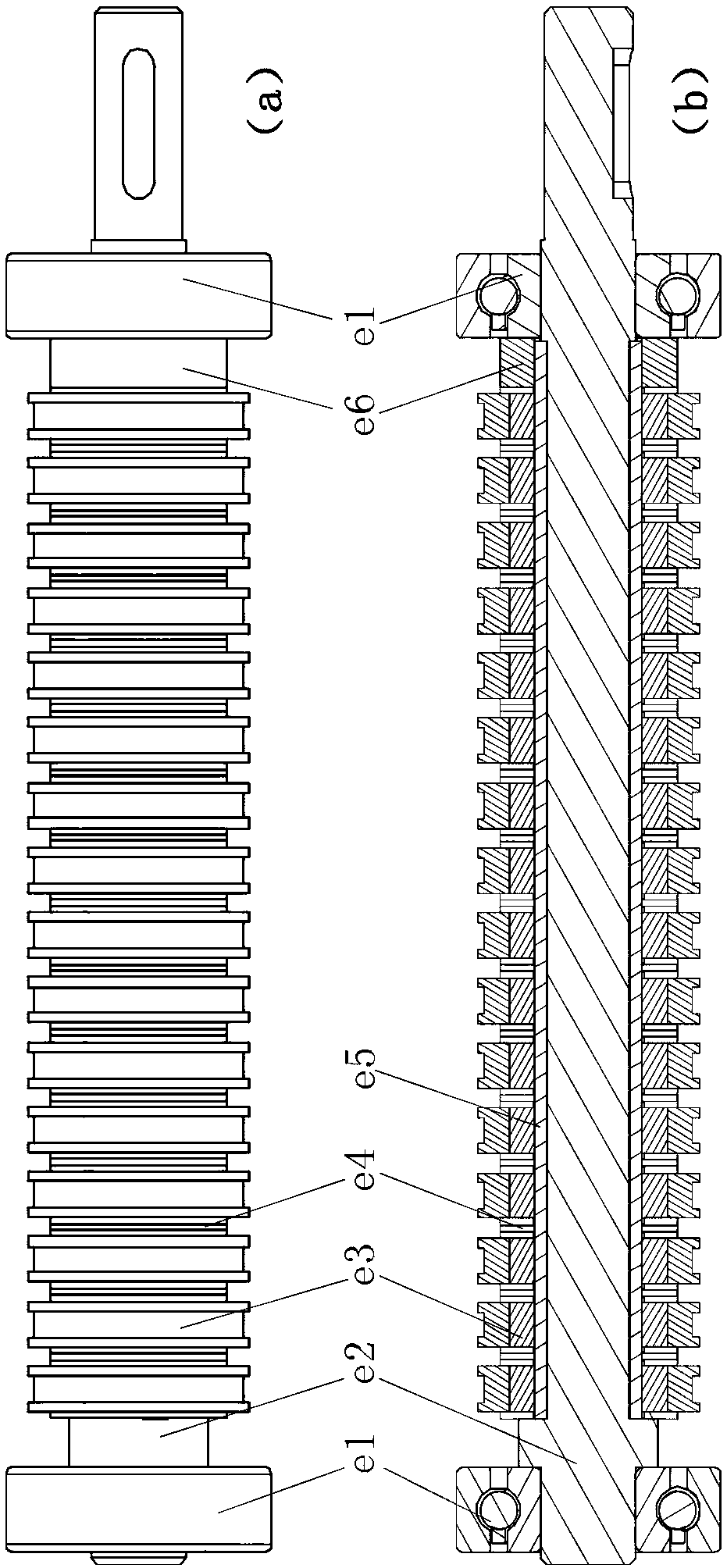

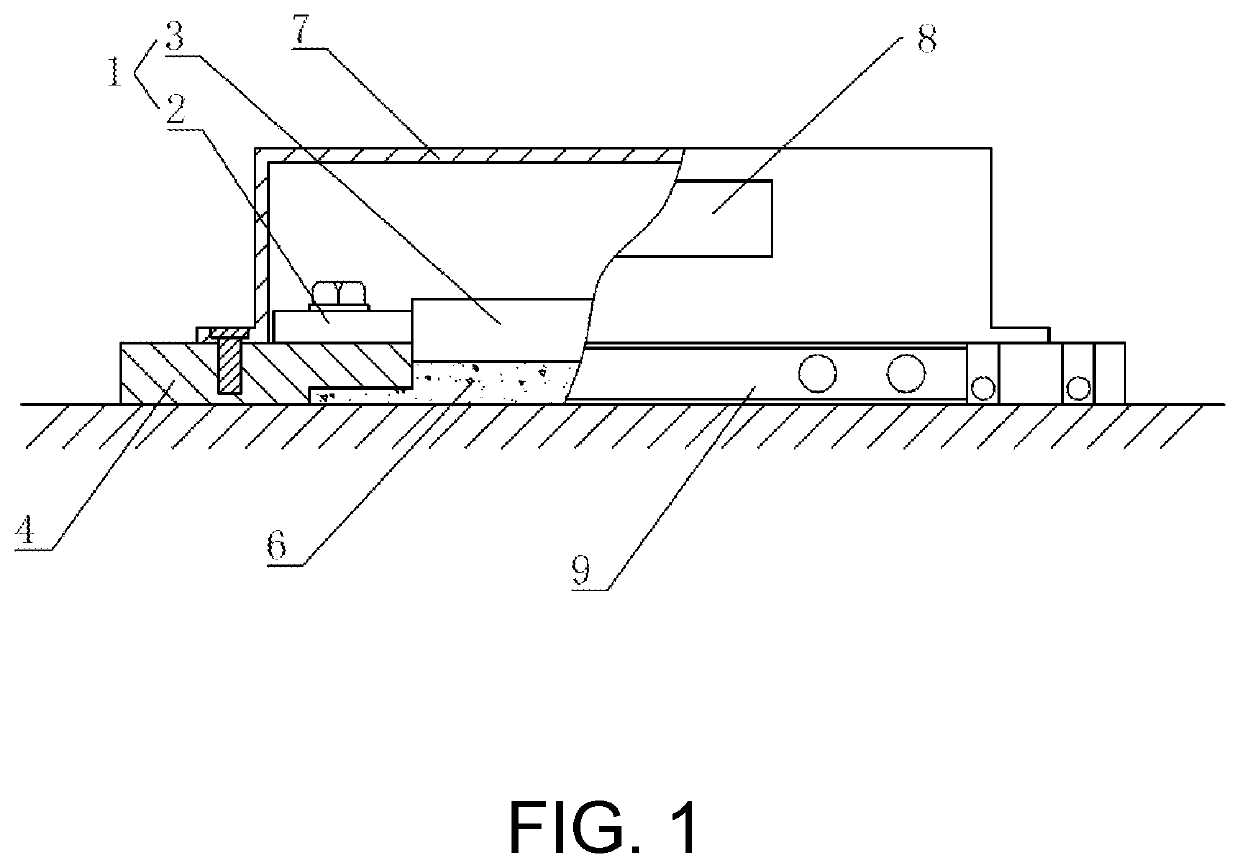

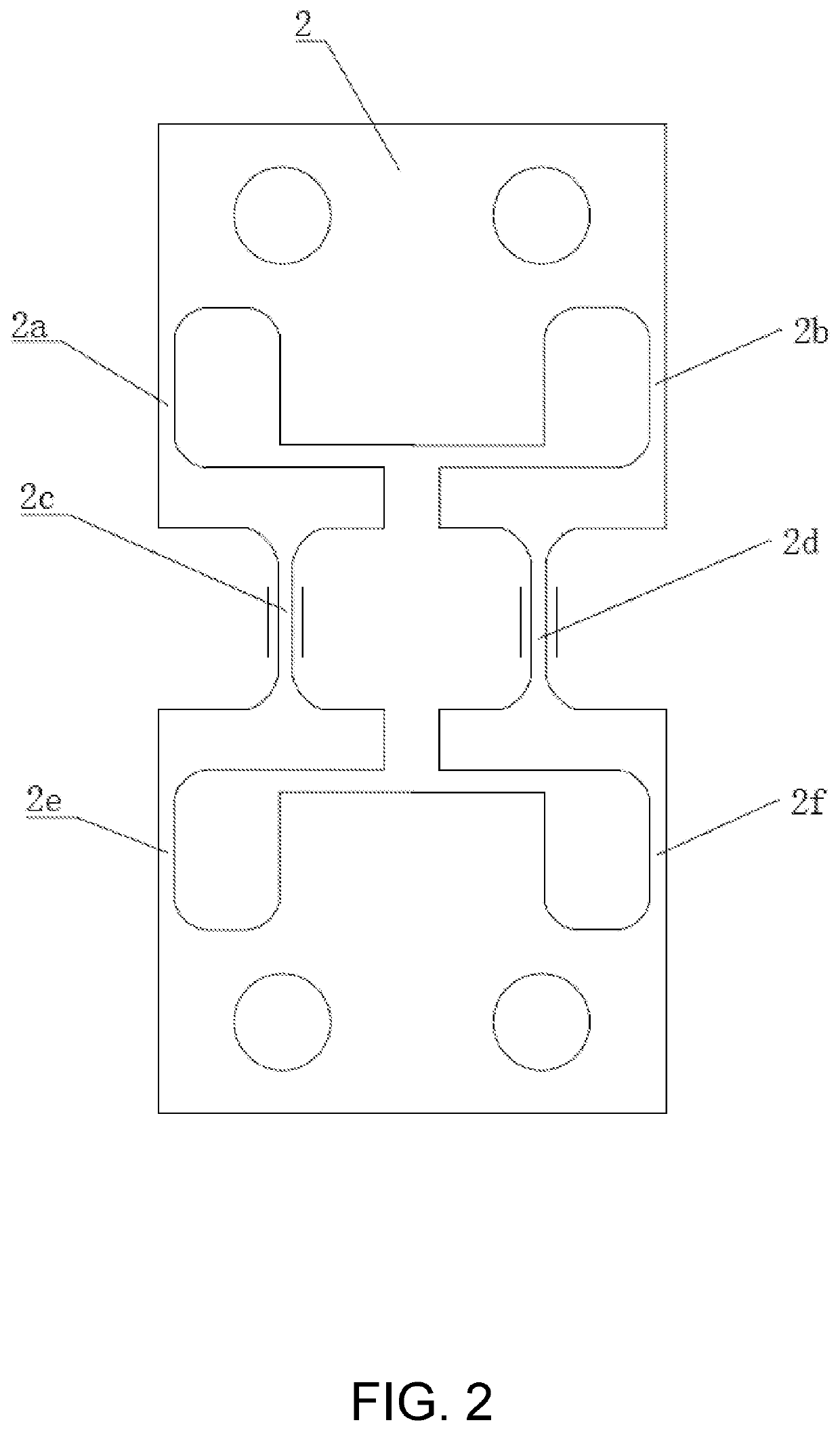

Large deformation flexible compression device for automatic fiber placement

A large deformation flexible compression device for automatic fiber placement comprises a compression roller gum cover, a compression roller and a compression roller shaft, wherein the compression roller gum cover sleeves the compression roller, the compression roller is installed on the compression roller shaft, the compression roller can freely rotate so as to drive the compression roller gum cover to rotate around the compression roller shaft, and two ends of the compression roller gum cover are provided with hollow structures. In the filter placement and shaping process, a fiber band is sent out from a fire placement head channel, guided by a guiding comb to an interval between the compression roller and a mold, and finally compressed on the surface of the mold through the compressionroller. When the mold is low in intensity and cannot bear large compression force, the hollow type large deformation flexible compression roller provides a good deformation space, and the compressionforce is easy to control; and when the mold is large in curvature, the large deformation compression roller can fit the surface of the mold well under the circumstance that the compression force is not increased, and fiber filaments are enabled to completely fit the mold. The large deformation flexible compression device for the automatic fiber placement can improve adaptability of the fiber prepreg placement to the mold, can perform the placement of various structures, and improves shaping quality of parts.

Owner:XI AN JIAOTONG UNIV

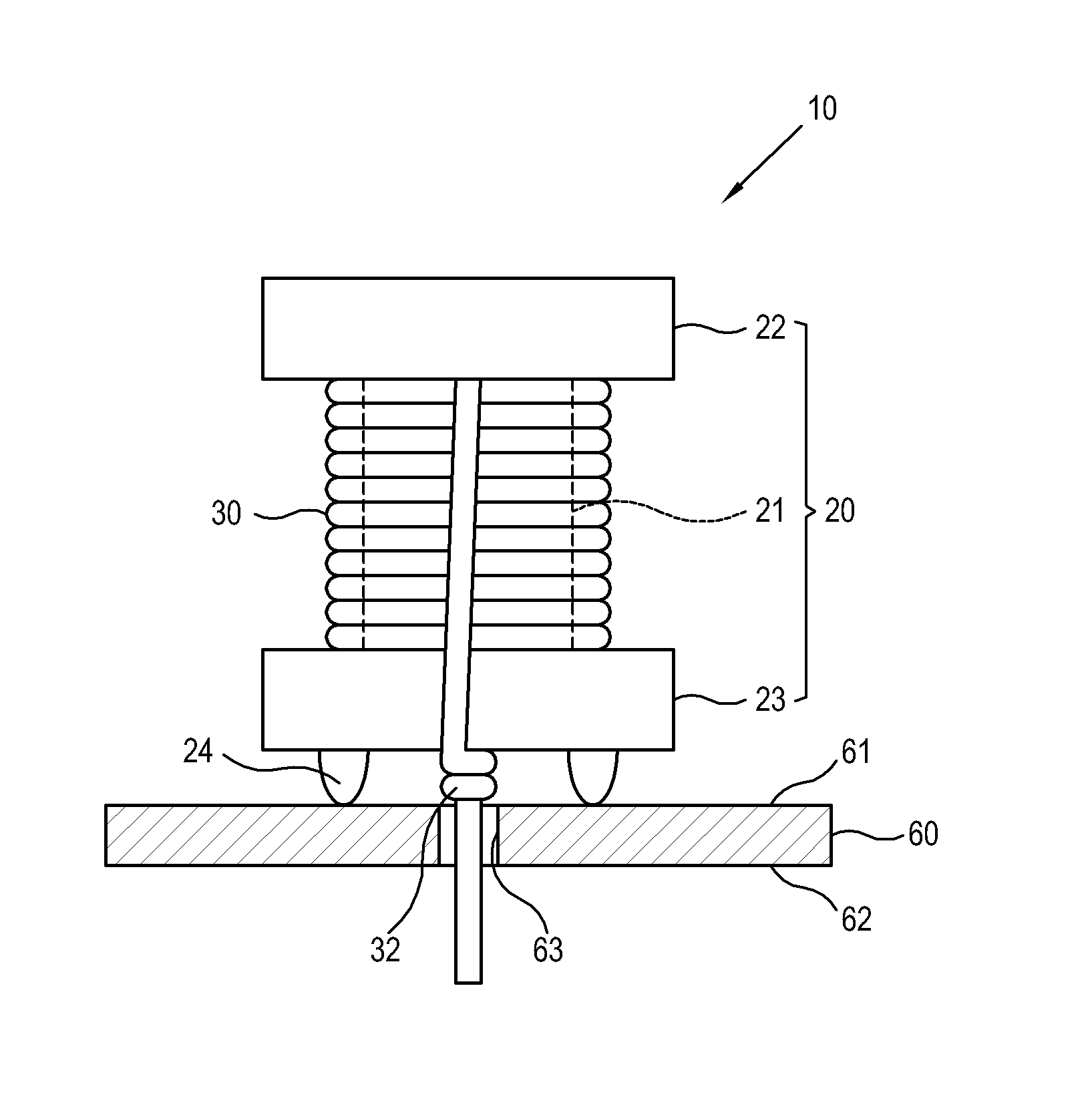

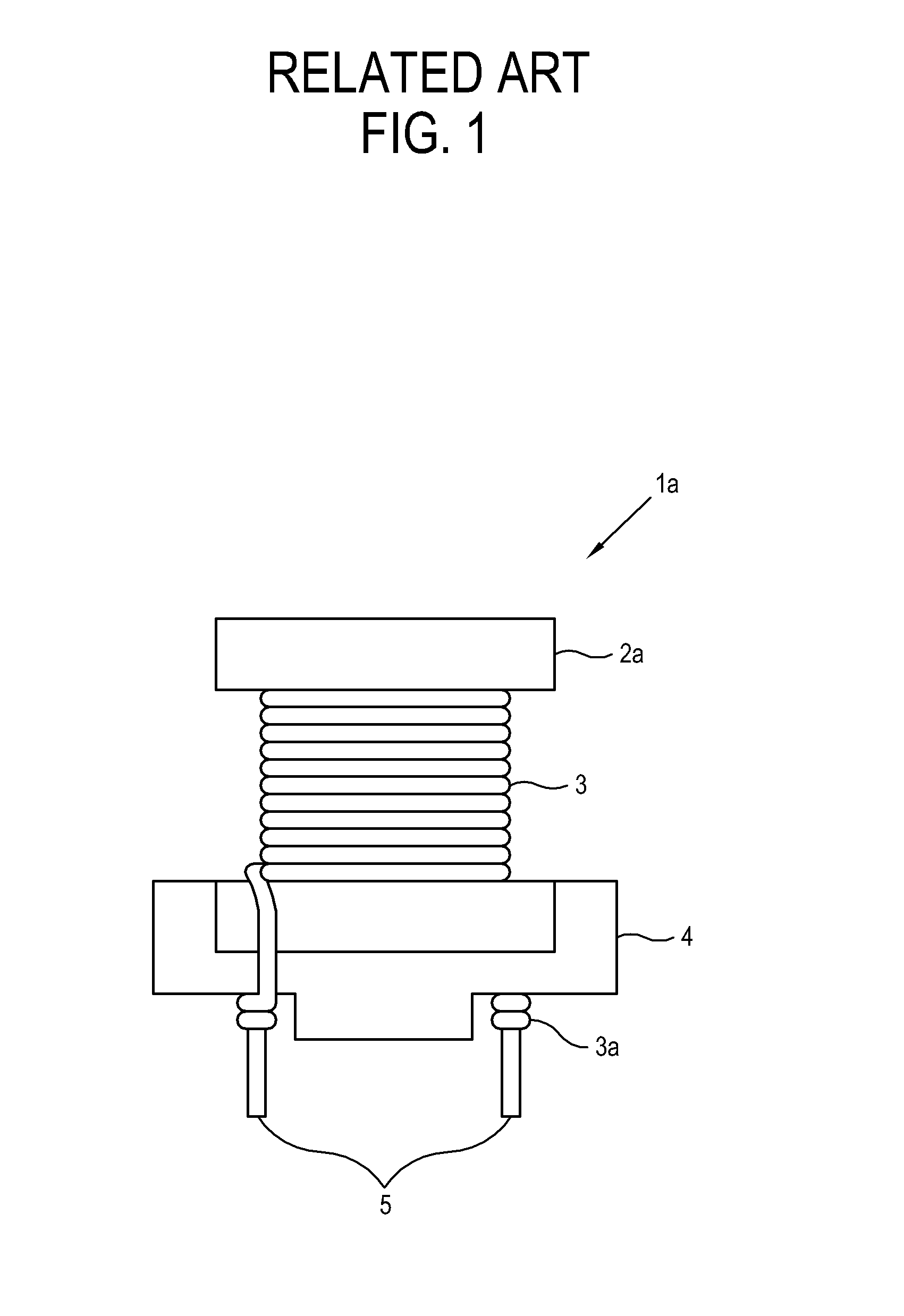

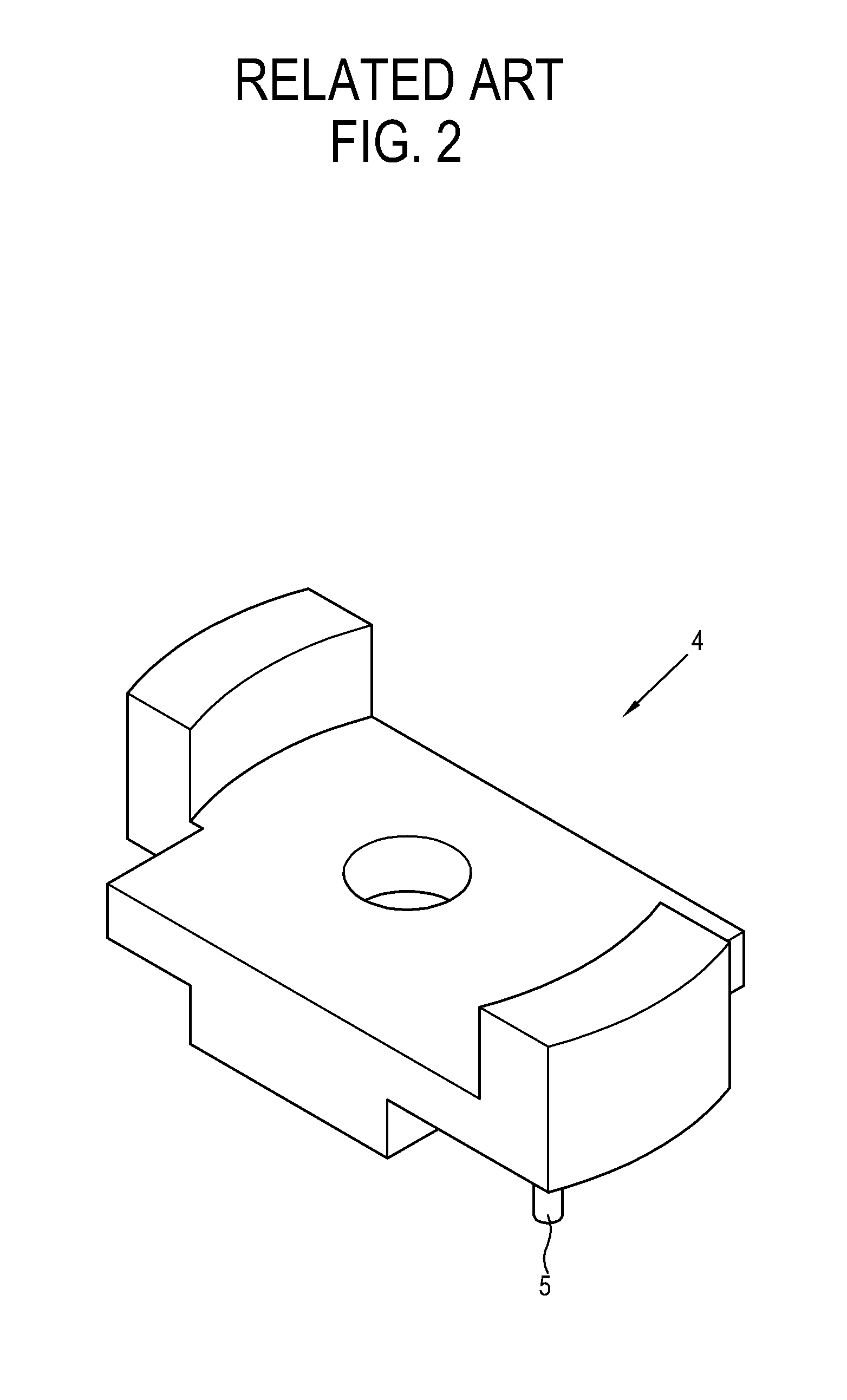

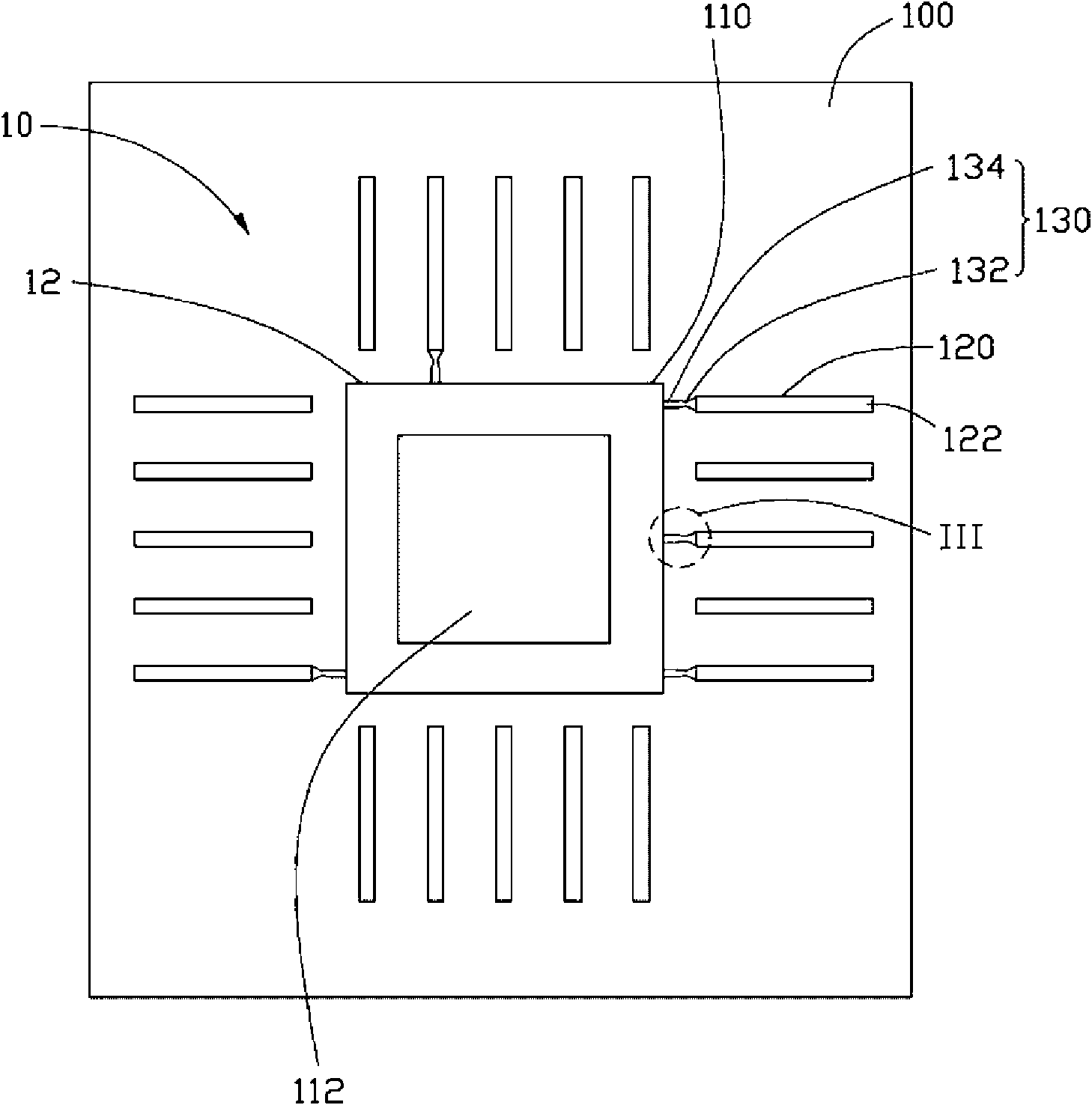

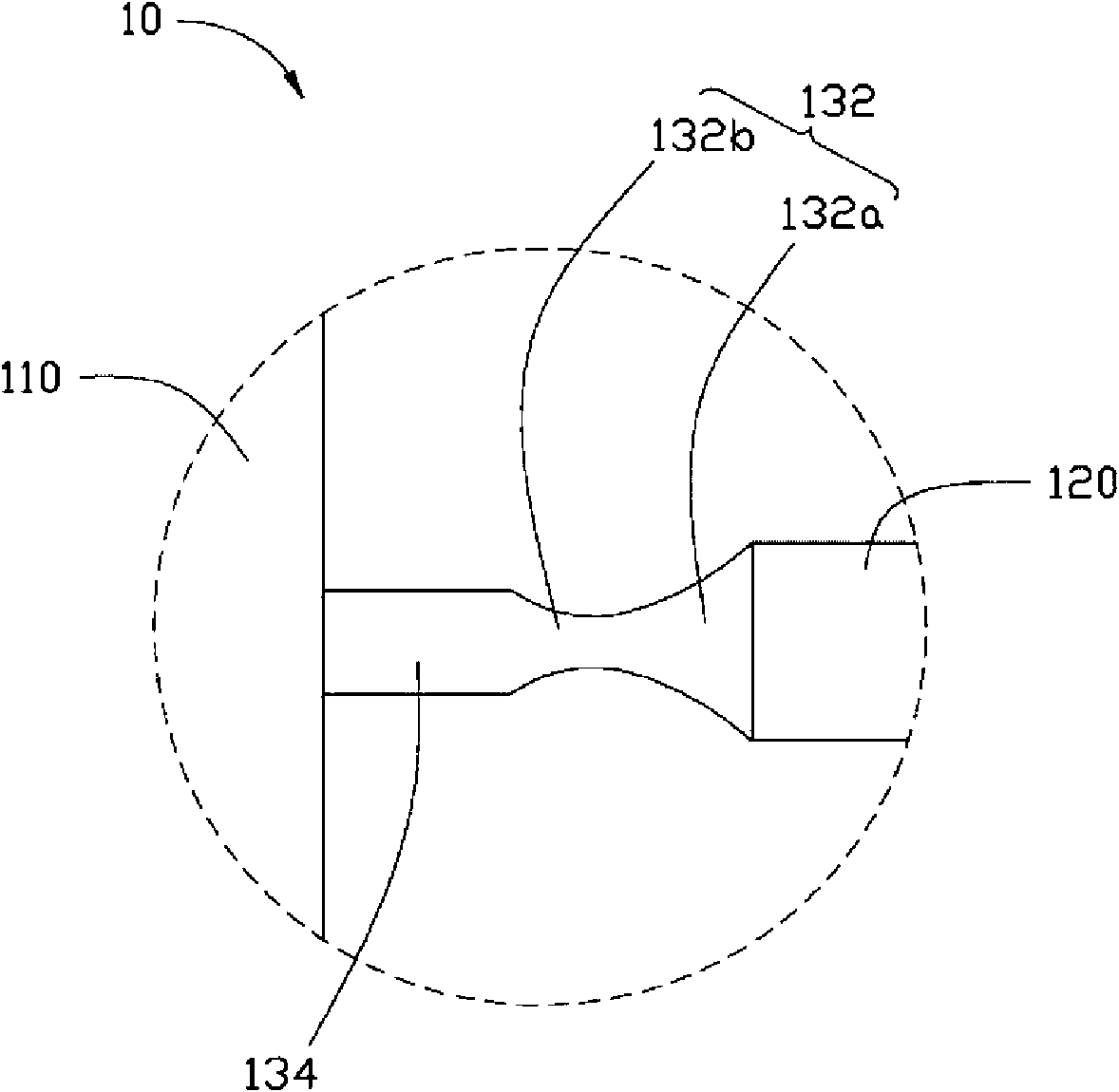

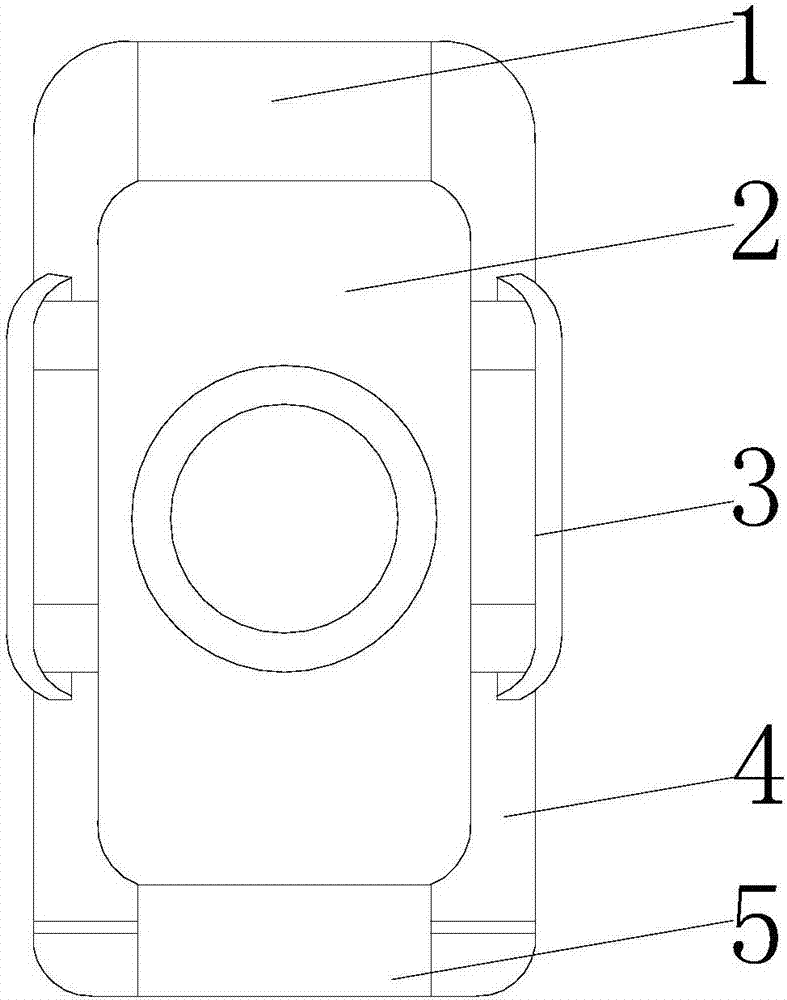

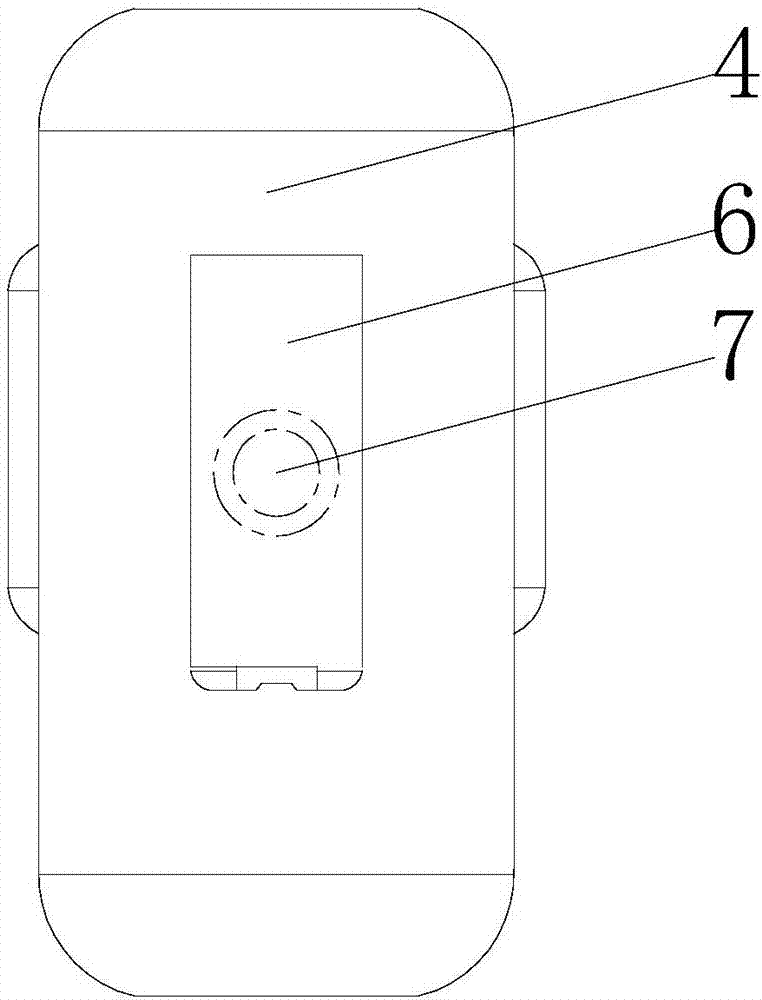

Inductor and display apparatus including the same

ActiveUS20140354526A1Mount quality of be improveImprove placement qualityStatic indicating devicesTransformers/inductances coils/windings/connectionsInductorPrinted circuit board

An inductor configured to be mounted on a printed circuit board is provided. The inductor may include a drum core including a cylindrical body and first and second flanges extending from opposite ends of the cylindrical body, a coil wound around the cylindrical body, a plurality of pins on which opposite ends of the coil are wound, wherein each of the plurality of pins has one end fixed to the second flange and another end configured to be fixed to the printed circuit board, and at least one projection which protrudes from the second flange and is configured to support the inductor to stand vertically on the printed circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD

Component-mounted board production apparatus and position control method for electronic components in component-mounted board production apparatus

ActiveUS8328074B2Improve placement qualityPrinted circuit assemblingAutomatic control devicesOn boardEngineering

The electronic component mounting line includes a computing unit for calculating a print position of solder paste printed on board-side electrodes, an electronic component placement device for placing an electronic component onto the board-side electrodes by referencing the print position of the solder paste, a placement position control device for controlling the placement position of the electronic component by referencing the print position of the solder paste, a bonding device for melting the solder paste to bond the electronic component and the board-side electrodes to each other, and a mounting-position control device for controlling the mounting position of the electronic component by referencing the board-side electrode position. In this configuration, position control responsive to displacement of the electronic component by the self alignment effect exerted by the molten solder paste is fulfilled.

Owner:PANASONIC CORP

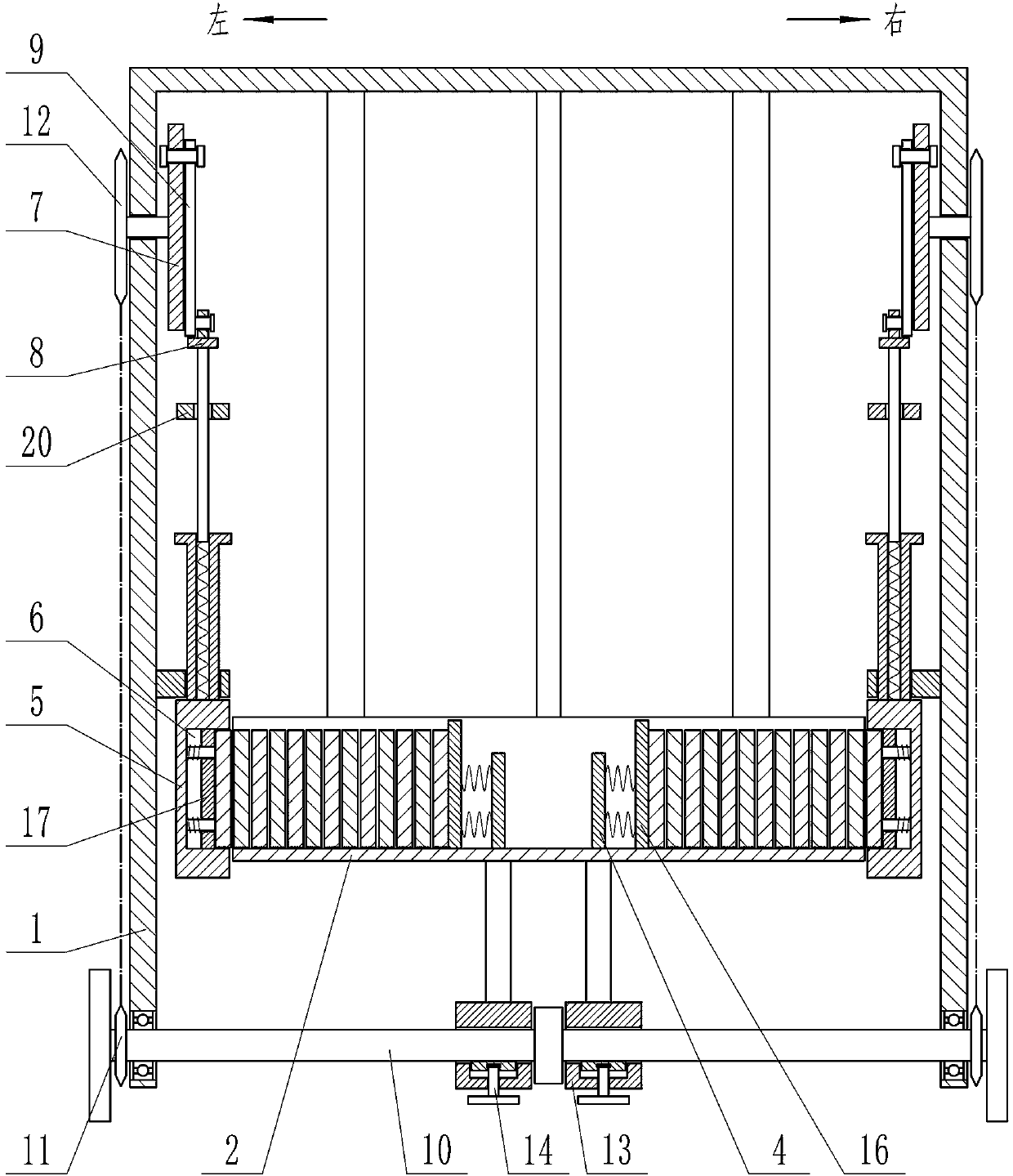

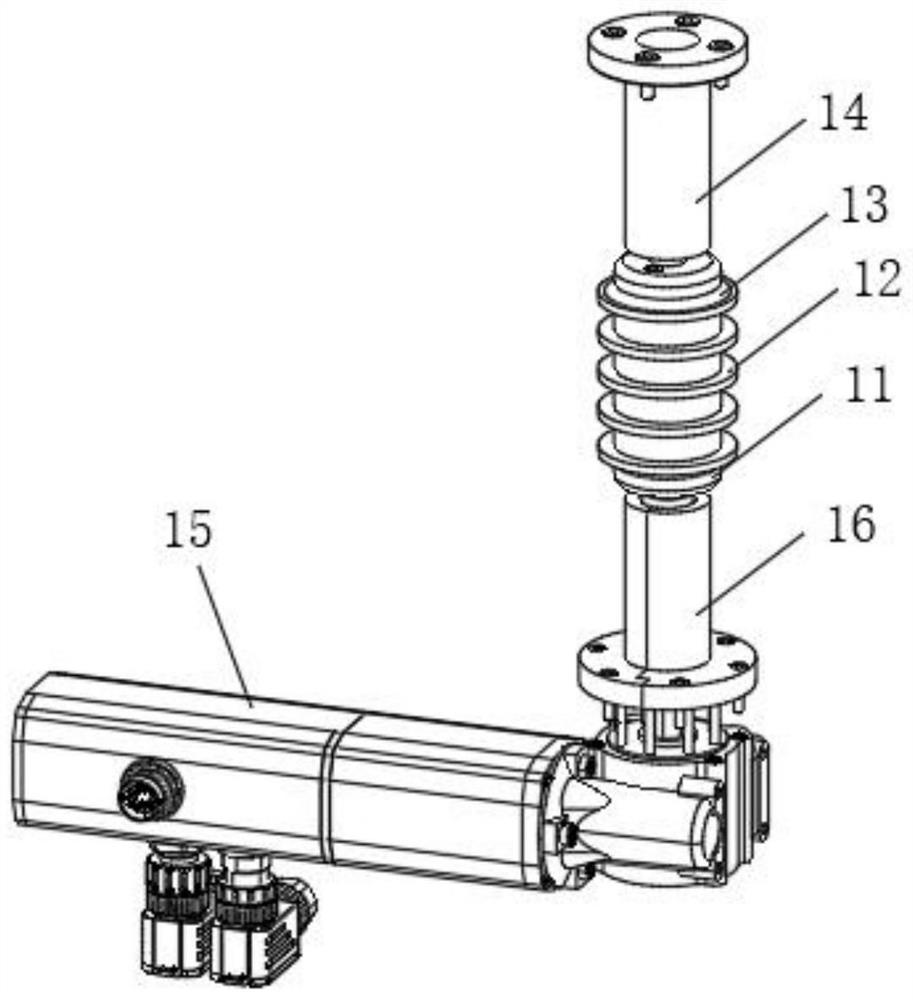

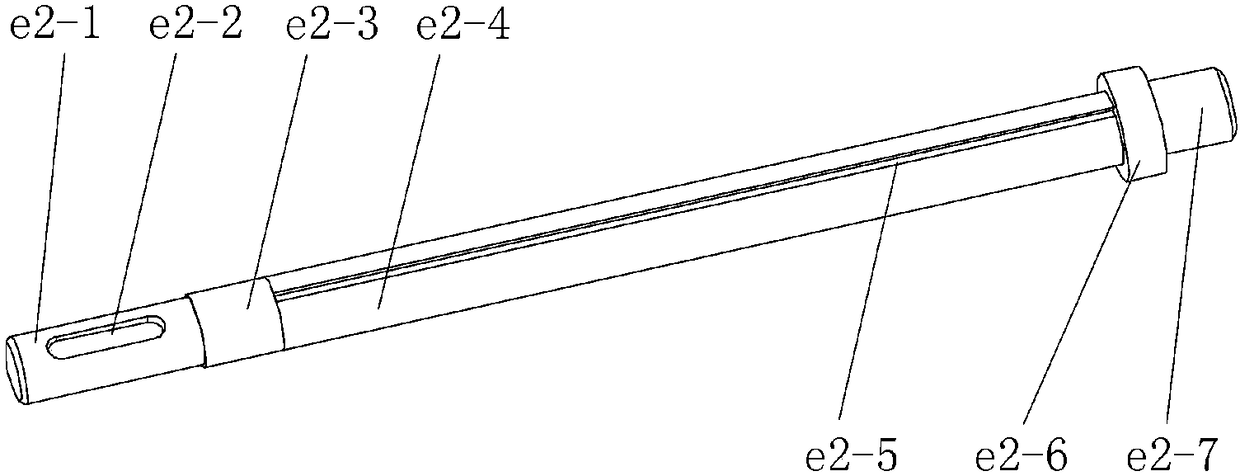

Sectional control system for extremely low tension of tows in tow placement equipment

PendingCN114671301AStable tensionImprove practicalityFilament handlingControl systemClassical mechanics

The invention provides a sectional type control system for extremely low tension of tows in tow placement equipment. The sectional type control system comprises an equipment main body; the tension regulation and control mechanism is arranged on the equipment main body; and the tension reducing mechanism is arranged on the equipment main body and is connected with the tension regulating and controlling mechanism through the tows. According to the sectional type control system for the extremely low tension of the tows in the tow placement equipment, the tension of the prepreg tows is stably controlled in an extremely low interval through two-stage control adjustment of the tension adjusting and controlling mechanism and the tension reducing mechanism, the situation that the laying tension is too large and not uniform along with speed changes in the movement process of a tow placement head is avoided, and the laying quality is improved. The tension of the tow is always stable when the tow reaches the compression roller to be laid after passing through the shearing function module, the re-conveying function module and the like, so that laid parts are stable in structure and more stable in mechanical property, the laying quality is improved, the whole device is simple in structure and convenient to operate, and the practicability of the whole sectional type control system is improved.

Owner:合肥通晟智能装备有限公司

Method for pasting battery string on space solar battery substrate surface

InactiveCN101436624AAvoid problemsEliminate deformationFinal product manufactureSemiconductor devicesScreen printingEngineering

The invention relates to a method for mounting a cell string on the surface of a spatial solar cell substrate in the technical field of spatial solar power supply. The method adopts a mounting mechanism consisting of a negative pressure gripping and pressurizing frock and a frock clamp to realize the gripping of the cell string; screen printing technology is adopted to coat glue on the surface of the cell string; and after the mounting is completed, the cell string is pressurized through the negative pressure gripping and pressurizing frock to realize parallel operation of glue coating and pressurization of the cell string. The method can effectively solve the problems of glue spilling, denaturalization of the cell string and mounted bubbles in the process of mounting the cell string and realize automatic mounting.

Owner:SHANGHAI JIAO TONG UNIV

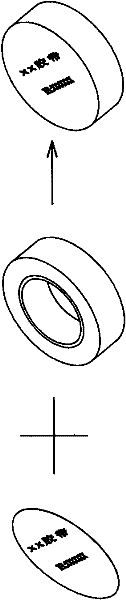

Unpowered unreeling machine, cell top surface protecting film tearing device, film adhering device and film adhering method

PendingCN108054421AUnwinding structure is simpleSimple electrical controlAssembling battery machinesFinal product manufactureElectrical controlMagnetic powder

The invention discloses an unpowered unreeling machine, a cell top surface protecting film tearing device, a film adhering device and a film adhering method. The unpowered unreeling machine comprisesan unreeling shaft for placing a reeled material; the unreeling shaft is rotatably arranged on a support frame through a bearing; the unreeling shaft is connected with a limiter which limits rotationof the unreeling shaft; when the tensile force applied to the reeled material is smaller than the torque limited value of the limiter, the unreeling shaft does not rotate; and when the tensile force applied to the reeled material is greater than torque limitation of the limiter, the unreeling shaft rotates. According to the unpowered unreeling machine, the degree of freedom of rotation of the unreeling shaft is limited by the limiter, therefore, the problem that follow-up processing is affected by unreeling of the reeled material due to the rotation inertia of the unreeling shaft or the tensile force when the unreeling shaft does not work can be avoided, and thus, a foundation is laid for development and utilization of the cell top surface film adhering equipment; and moreover, an unreeling mode is optimized into magnetic powder brake unreeling from traditional motor unreeling, the unreeling structure is simple, and electrical control of unreeling is greatly simplified.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

A device and method for automatic film laying of composite material preforms

The invention discloses a device and method for automatically laying a composite preformed body in a film-mounting manner. The device is characterized in that a supply system, a hot press roll system, a laying compression and pressure adjusting device and a conveying guide wheel are arranged on a rack. The method comprises the following steps: conveying fibers and resin films supplied by the supply system to the hot press roll system for pressing the fibers and the resin films into half prepreg tapes, conveying the half prepreg tapes to the laying compression and pressure adjusting device, enabling a laying arm of a robot to drive the rack for driving the laying compression and pressure adjusting device to lay the half prepreg tapes on a core mold, and adjusting the laying pressure and the laying path in real time as needed to obtain the preformed body. According to the device and the method, the fiber laying angle can be changed according to the needs of the laying path, the fiber-resin ratio of the composite preformed body can be accurately controlled, the subsequent processing processes of the preformed body and the material waste are reduced, the laying quality of the preformed body is high, the compatibility between the preformed body and other composite material forming process is good, and various preformed bodies with different fiber / resin systems can be formed.

Owner:陕西普立通复材科技有限公司

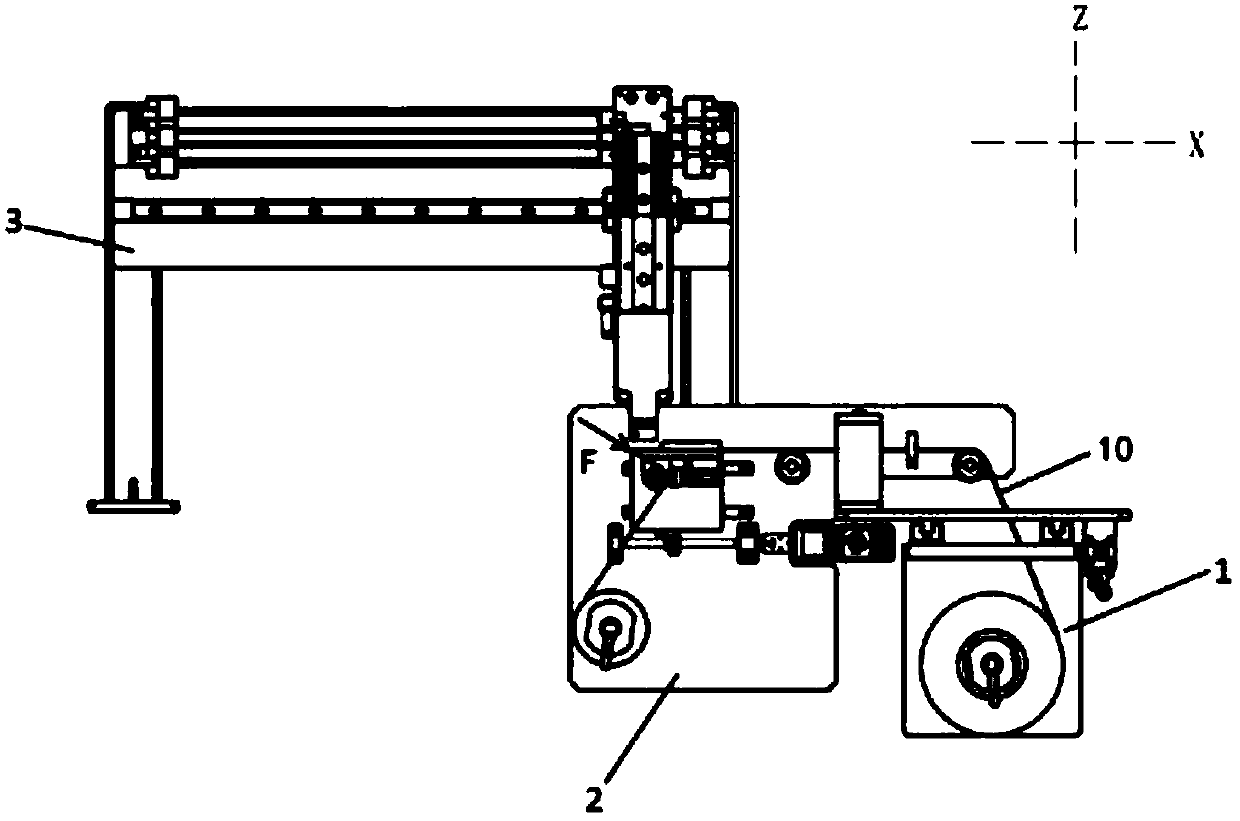

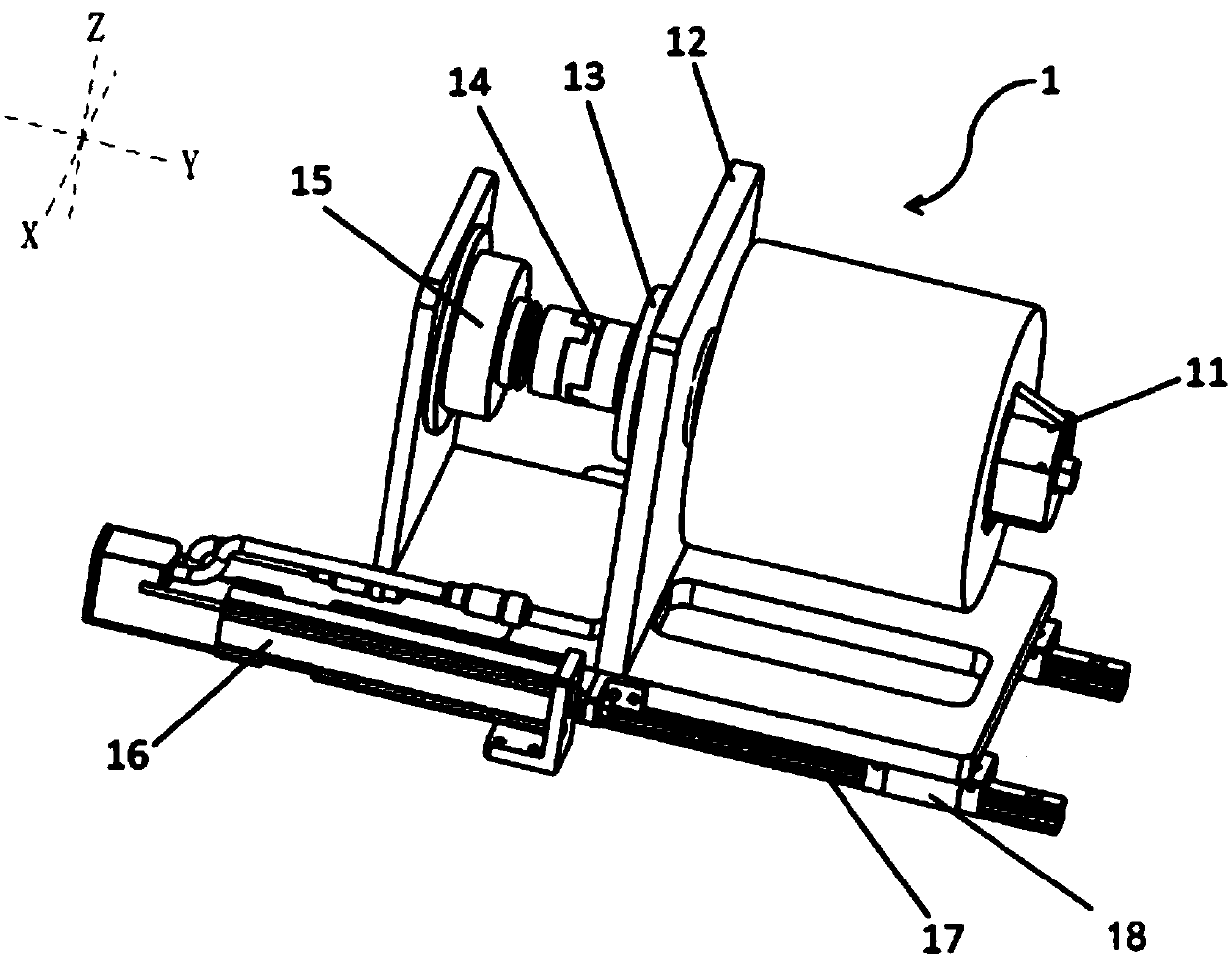

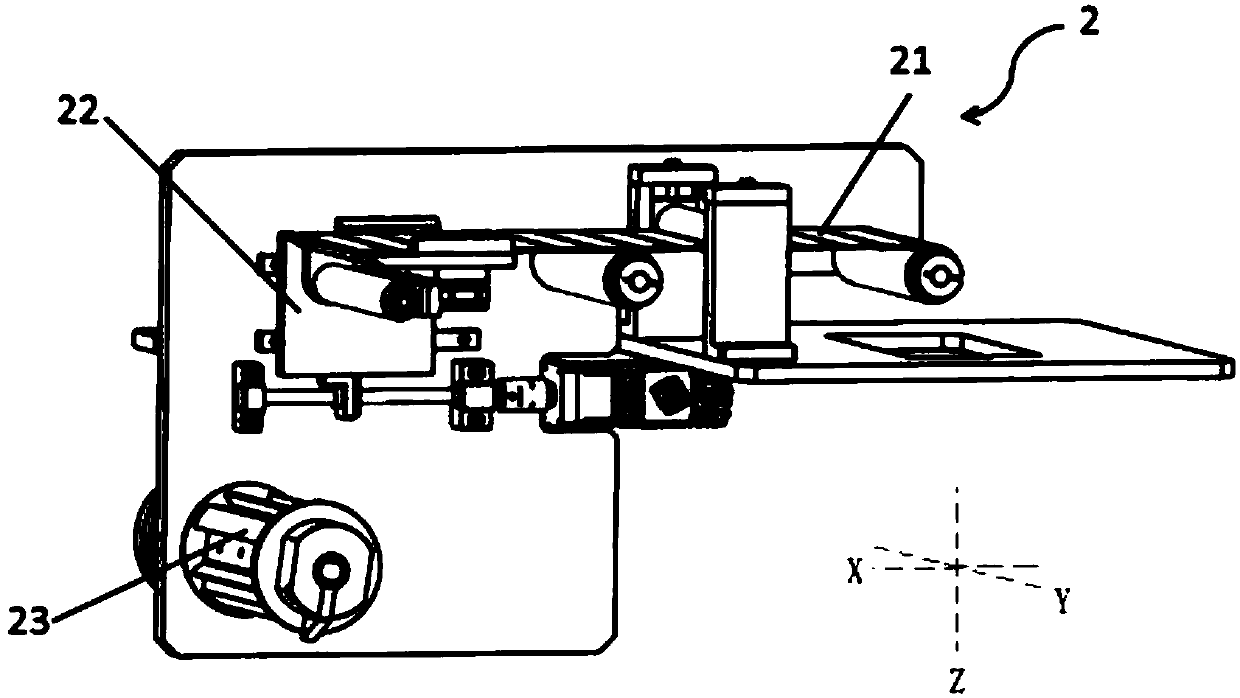

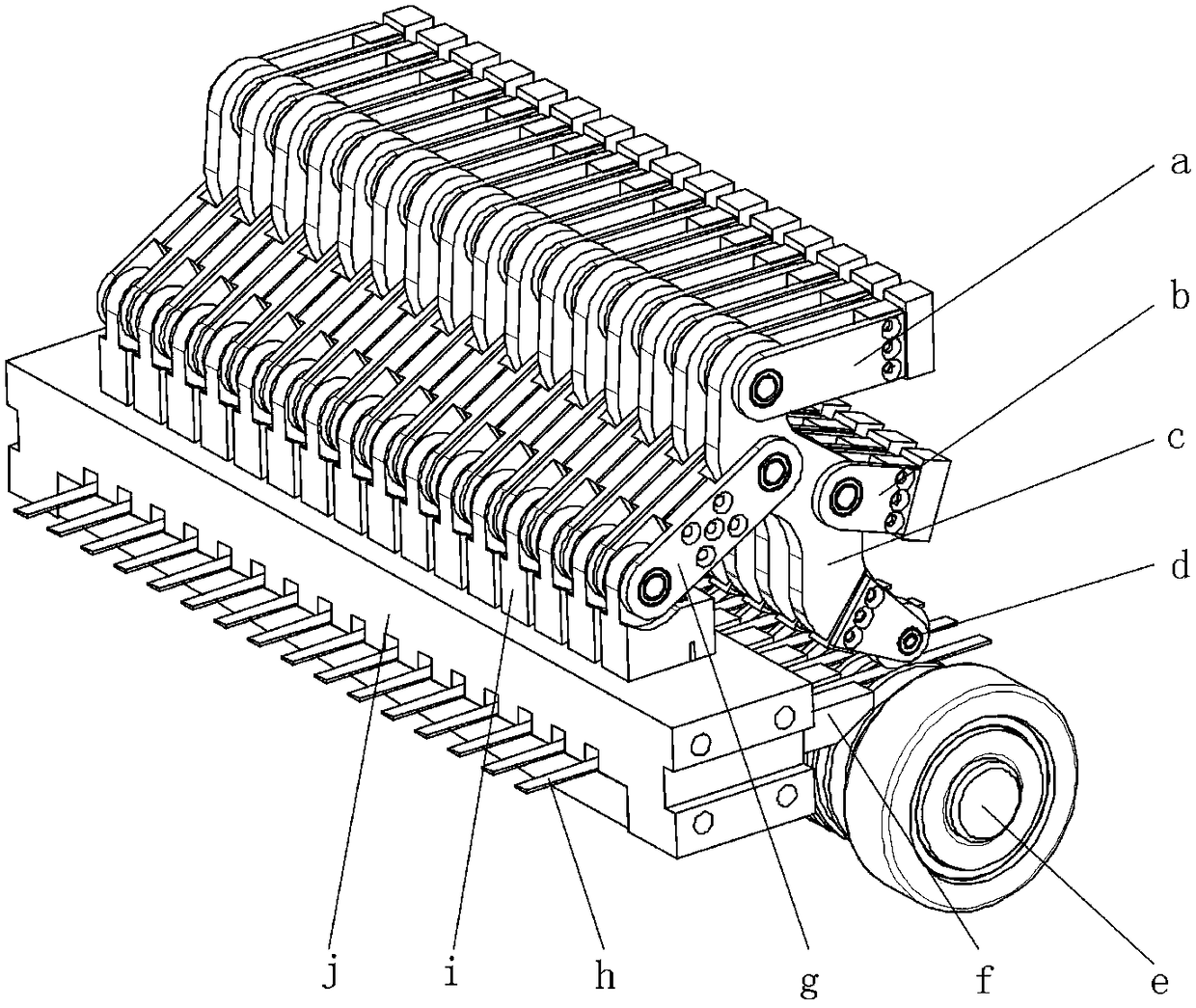

Single-driving composite material fiber placement head integral device and reconveying wheel shaft system thereof

The invention belongs to the technical field of composite material automatic placement forming, and particularly provides a single-driving composite material fiber placement head integral device and areconveying wheel shaft system thereof. The problem that an existing single-driving composite material fiber placement head integral device is poor in placement quality in the corner placement or variable curvature curved surface placement process is solved. The reconveying wheel shaft system comprises a transmission shaft and a plurality of unidirectional wheel devices; each unidirectional wheeldevice comprises an inner ring coaxially fixed to the transmission shaft, and an outer ring matched with a reconveying wheel device; the outer rings are coaxially connected with the inner rings; andconnection between the outer rings and the inner rings are arranged to enable the outer ring to freely rotate relative to the inner rings unidirectionally. The single-driving composite material fiberplacement head integral device provided with the reconveying wheel shaft system can allow that the placement path lengths of multiple fiber beams and the placement speed of the multiple fiber beams are different, the placement tension stability of each fiber beam is kept, and the placement quality is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Processing method of manual chip mounter

ActiveCN111432622AEasy to moveStable positionElectrical componentsSurface mountingProcess engineering

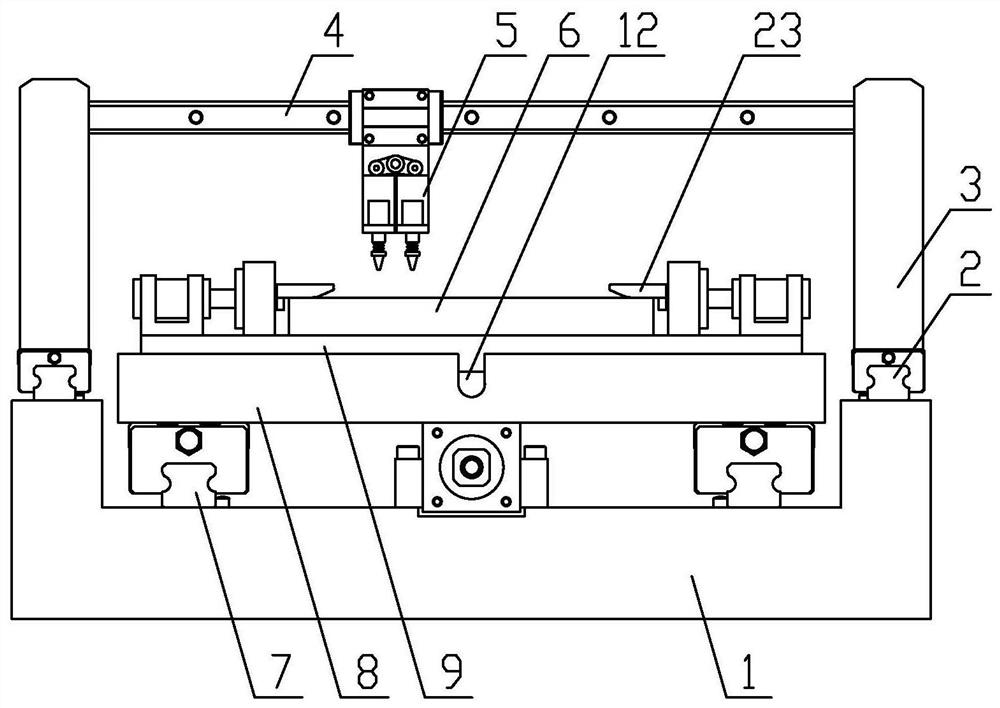

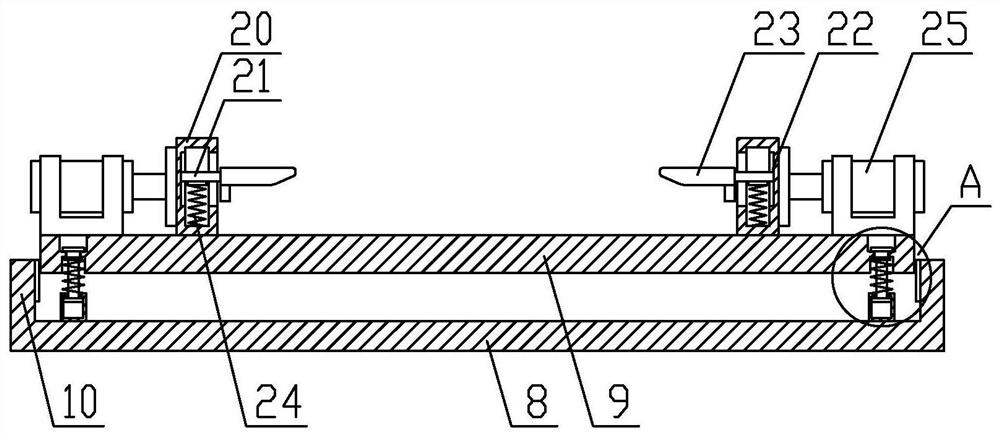

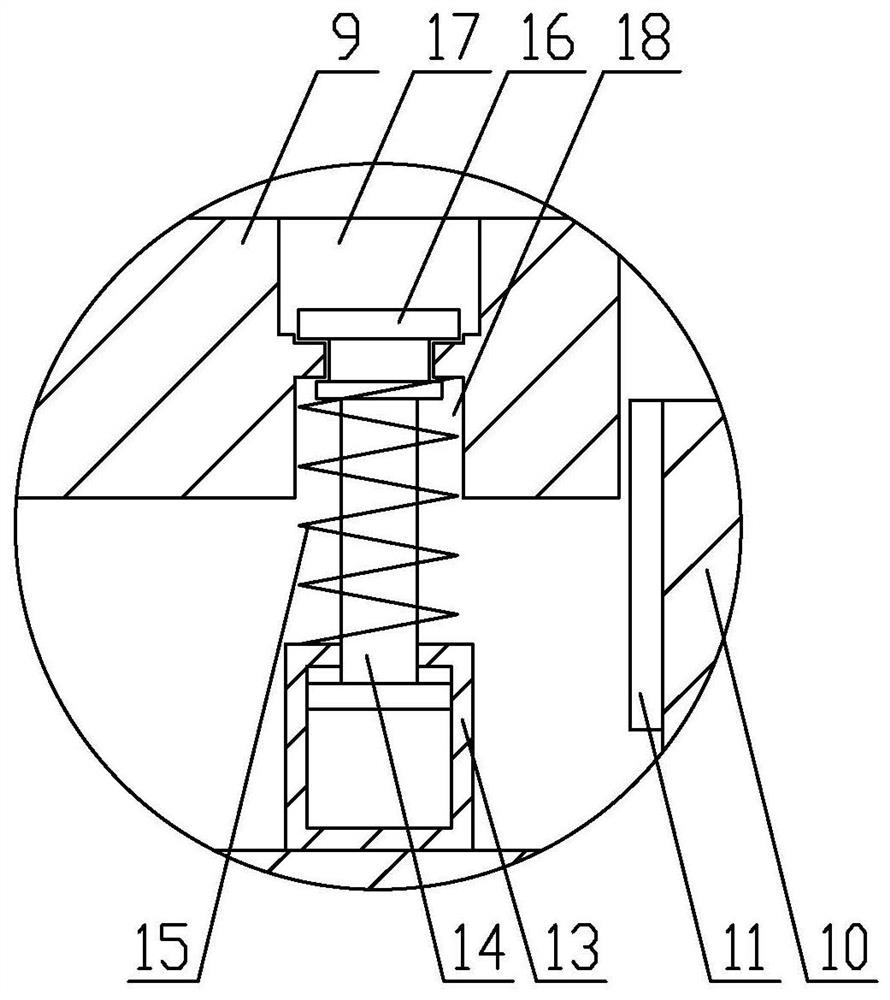

The invention discloses a processing method of a manual chip mounter. The processing method mainly comprises the following processing steps: preparing and fixing a material, taking the material and adjusting the position, pasting and re-taking the material, and disassembling a product. Machining equipment used in the machining process of the manual chip mounter comprises a machining table, a positioning and clamping mechanism and a displacement device, wherein the positioning and clamping mechanism comprises two sets of symmetrically-arranged clamping devices, and each clamping device comprises a fixing frame fixed to the upper end of the machining table. The method has the advantages that the method is simple; the baffle plays a good role in shielding the surface-mounted components whichdo not need to be taken and used. According to the surface mount device, the influence of dust on the surface mount device is effectively avoided, so that the surface mount quality is improved; the adjustment of different pneumatic suction pen positions can be realized only by rotating the rotating plate; the different surface mount devices do not need to be frequently disassembled, assembled andreplaced by arranging the plurality of pneumatic suction pens; the operation time is saved; and the processing efficiency is improved.

Owner:苏州帕兰提尼智能科技股份有限公司

Surface mount structure and circuit board with same

ActiveCN102056405ABlock flowImprove placement qualityElectrical connection printed elementsPrinted circuit non-printed electric components associationWire widthCurrent limiting

The invention provides a surface mount structure used for fixedly mounting an electronic element with a pin and a welding chassis onto a circuit board. The surface mount structure comprises a pad formed on the circuit board, wherein the pad comprises a first pad welded with the bottom surface of the pin, a second pad welded with the bottom surface of the welding chassis and a connecting wire for connecting the first pad and the second pad. The structure is characterized in that the area of the surface of the second pad, which is opposite to the bottom surface of the welding chassis, is larger than the area of the surface of the first pad, which is opposite to the bottom surface of the pin; the space between the first pad and the second pad is smaller than 0.3mm; the connecting wire comprises a current-limiting part and a non-current-limiting part; the current-limiting part is connected with the first pad, and the non-current-limiting part is connected with the second pad; and the partial or overall wire width of the current-limiting part is smaller than the wire width of the non-current-limiting part.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

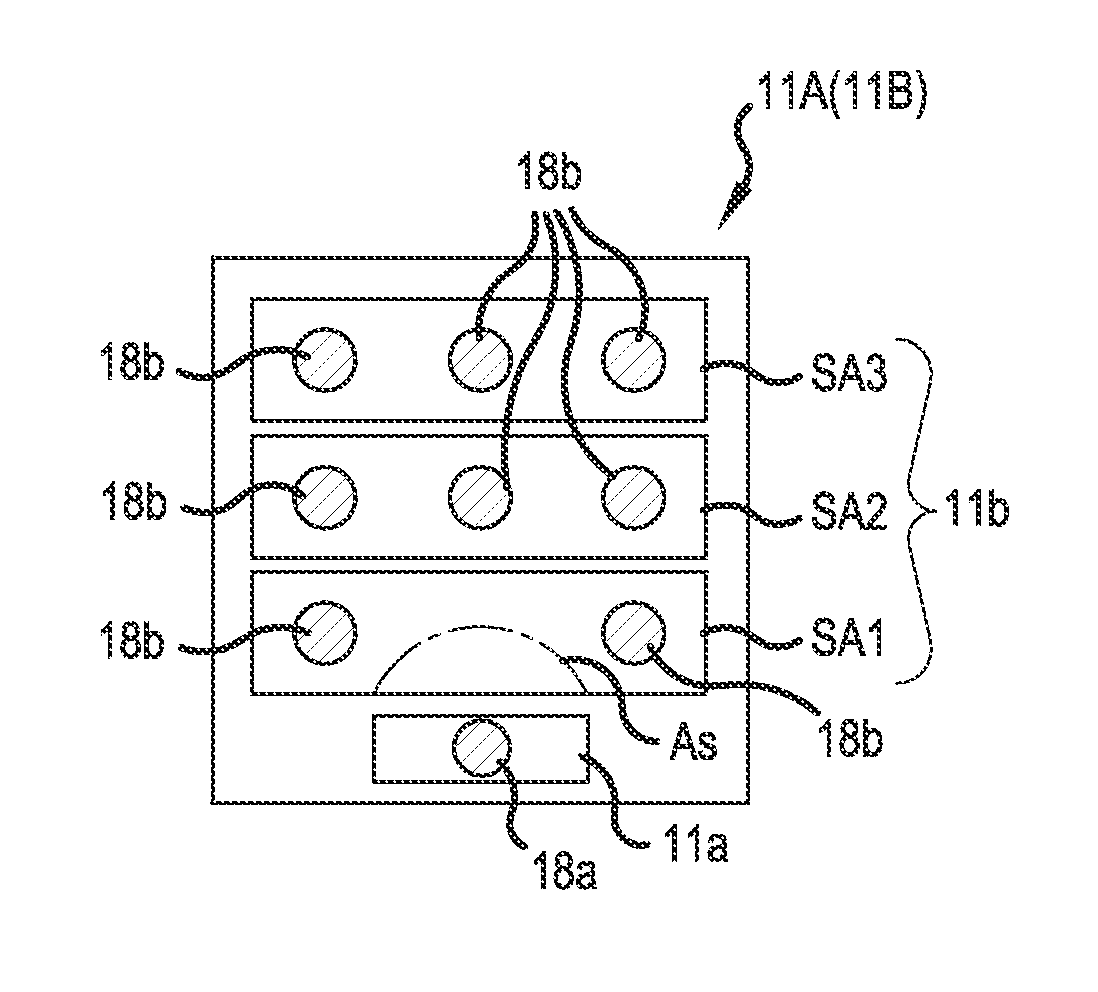

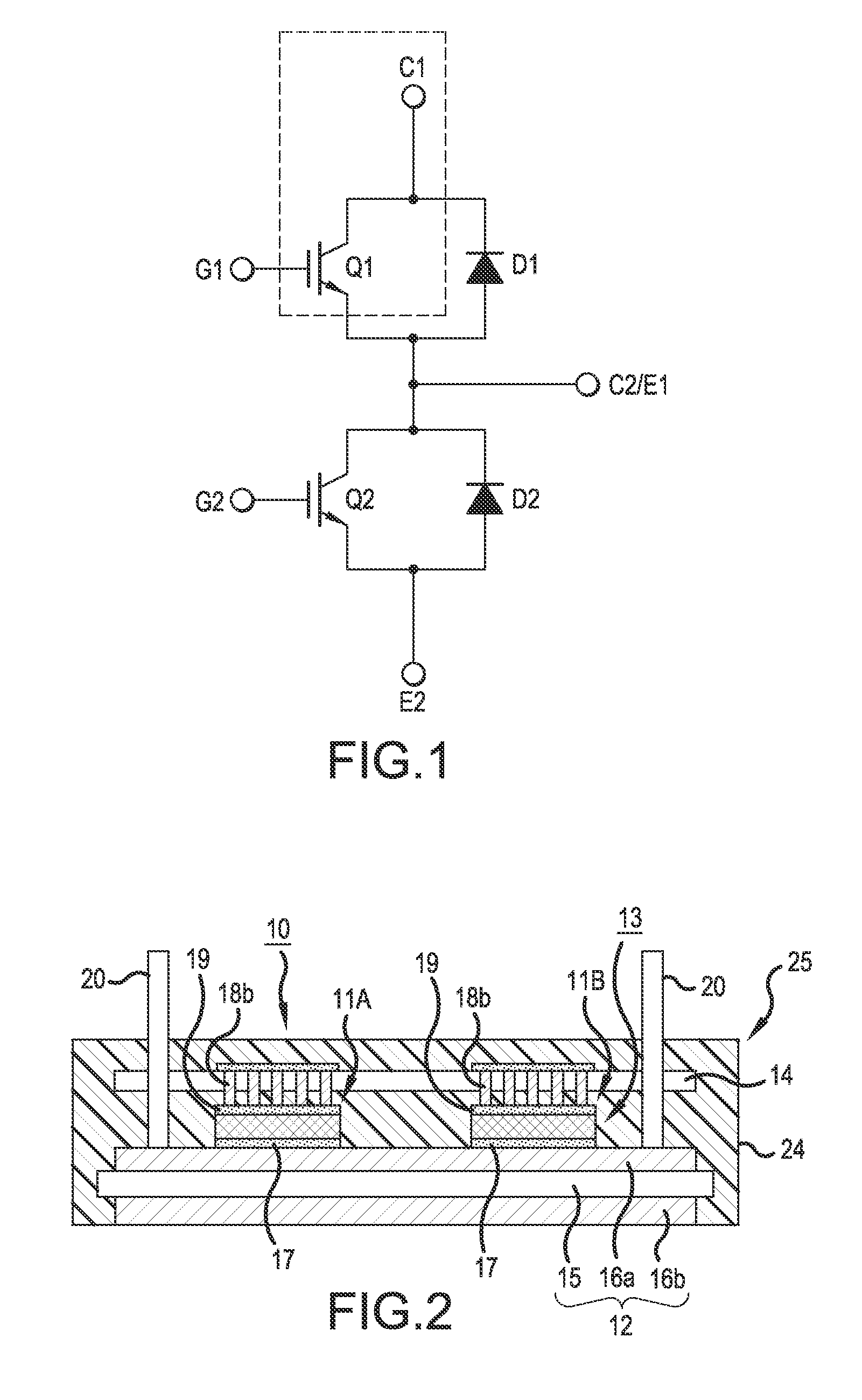

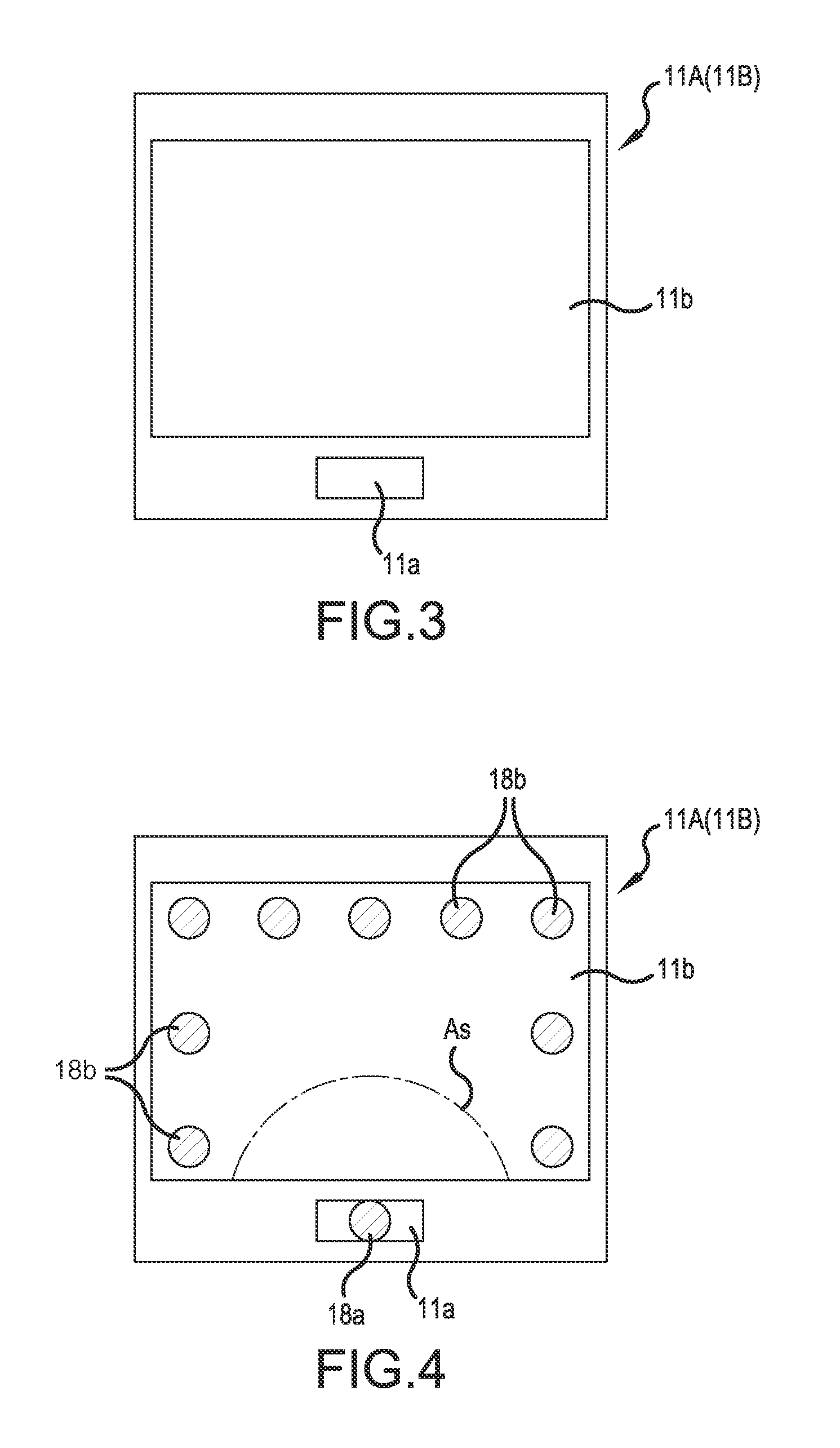

Semiconductor device

ActiveUS9418916B2Improve placement qualityIncrease volumeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrode

A semiconductor device including a semiconductor chip, a first electrode pad and second electrode pad included on one surface of the semiconductor chip, a first conductive post joined by a joining material to the first electrode pad, a plurality of second conductive posts joined by a joining material to the second electrode pad, and a printed substrate, disposed opposing the one surface of the semiconductor chip, on which is formed an electrical circuit to which the first conductive post and second conductive posts are connected. The second conductive posts on the side near the first conductive post are arrayed avoiding a short-circuit prevention region at a distance such that the joining material of the first conductive post and the joining material of the second conductive posts do not link.

Owner:FUJI ELECTRIC CO LTD

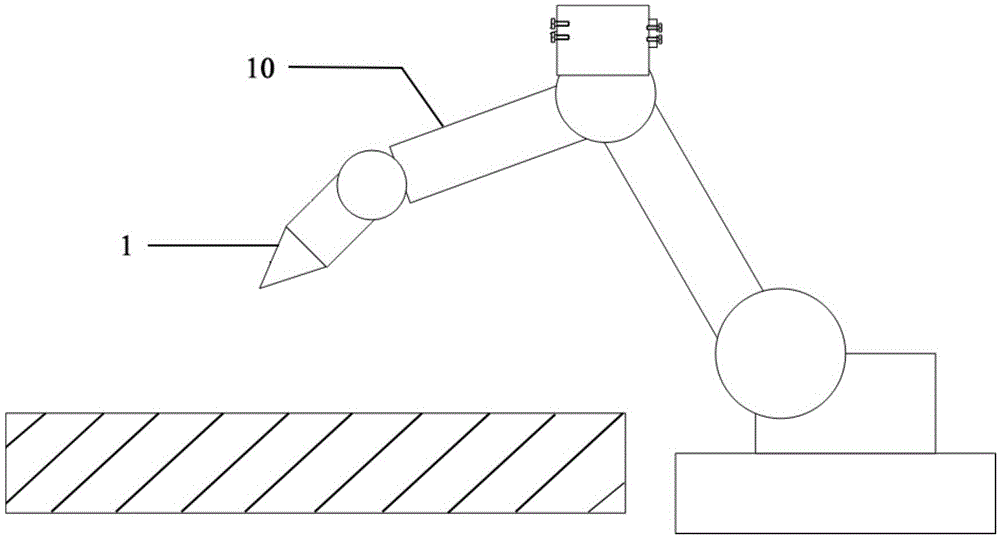

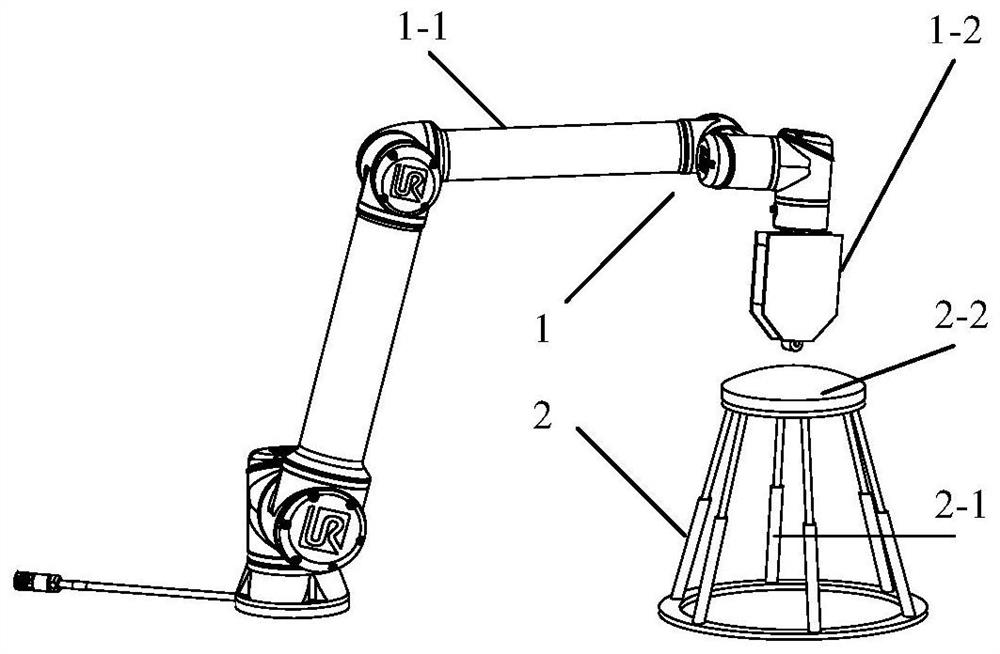

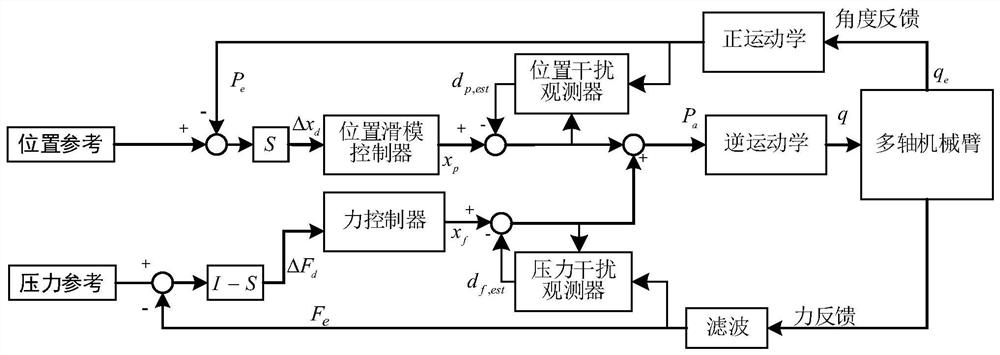

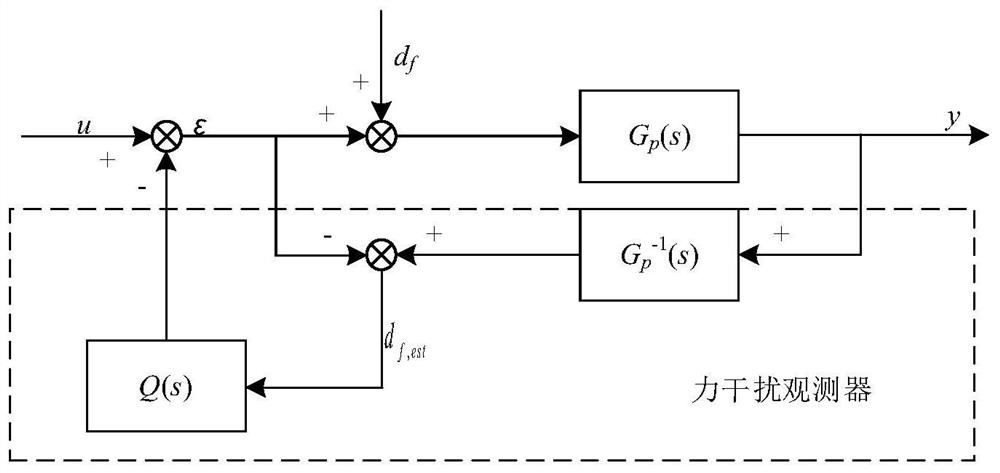

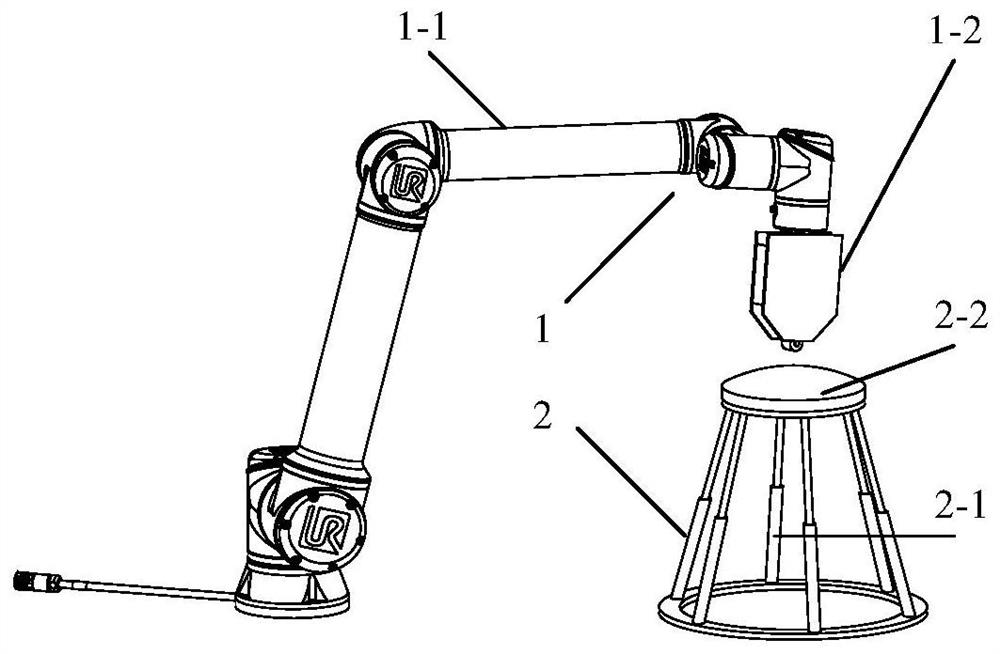

Automatic fiber laying system and planning method of laying track thereof

The invention discloses an automatic fiber laying system, the system comprises an automatic fiber laying device, a mold bearing device arranged corresponding to the automatic fiber laying device and acontrol subsystem, wherein the control subsystem comprises a compression roller pressure and laying track hybrid control module and a laying tension and speed decoupling control module which are usedfor controlling the automatic fiber laying device, and a temperature fuzzy self-adaptive control module for controlling the temperature of the mold bearing device. The invention further provides a planning method of the laying track of the automatic fiber laying device. According to the automatic fiber laying system and the planning method, precise control over laying process parameters can be achieved, so that laying quality is improved; and the laying track enables a cooperative mechanical arm to avoid singular poses, meanwhile, the joint stress condition of the cooperative mechanical arm is improved, interference is avoided, and the movement efficiency and safety are improved.

Owner:WUHAN UNIV

Attached resistance strain sensor assembly and mounting process thereof

ActiveUS20200363272A1Detection precision is highImprove securityForce measurementElectrical/magnetic solid deformation measurementElectrical resistance and conductanceInsulation layer

The invention discloses an attached resistance strain sensor assembly includes a sensor body, wherein substrates are respectively mounted at two ends of a lower end face of the sensor body, a heat insulation layer is provided between two of the substrates, the heat insulation layer covers the lower end face of the sensor body, an outer cover is covered above the sensor body, two ends of the outer cover are respectively mounted on the two substrates, and a wiring terminal is provided at one side of the outer cover. The sensor assembly can be mounted to a structural member by electric welding, so that the influence of high temperature on the performance of an elastic part in the sensor body during welding is reduced, the output value of the sensor is still in an expected range, and a more accurate load measurement value can be obtained.

Owner:HU TIANXU

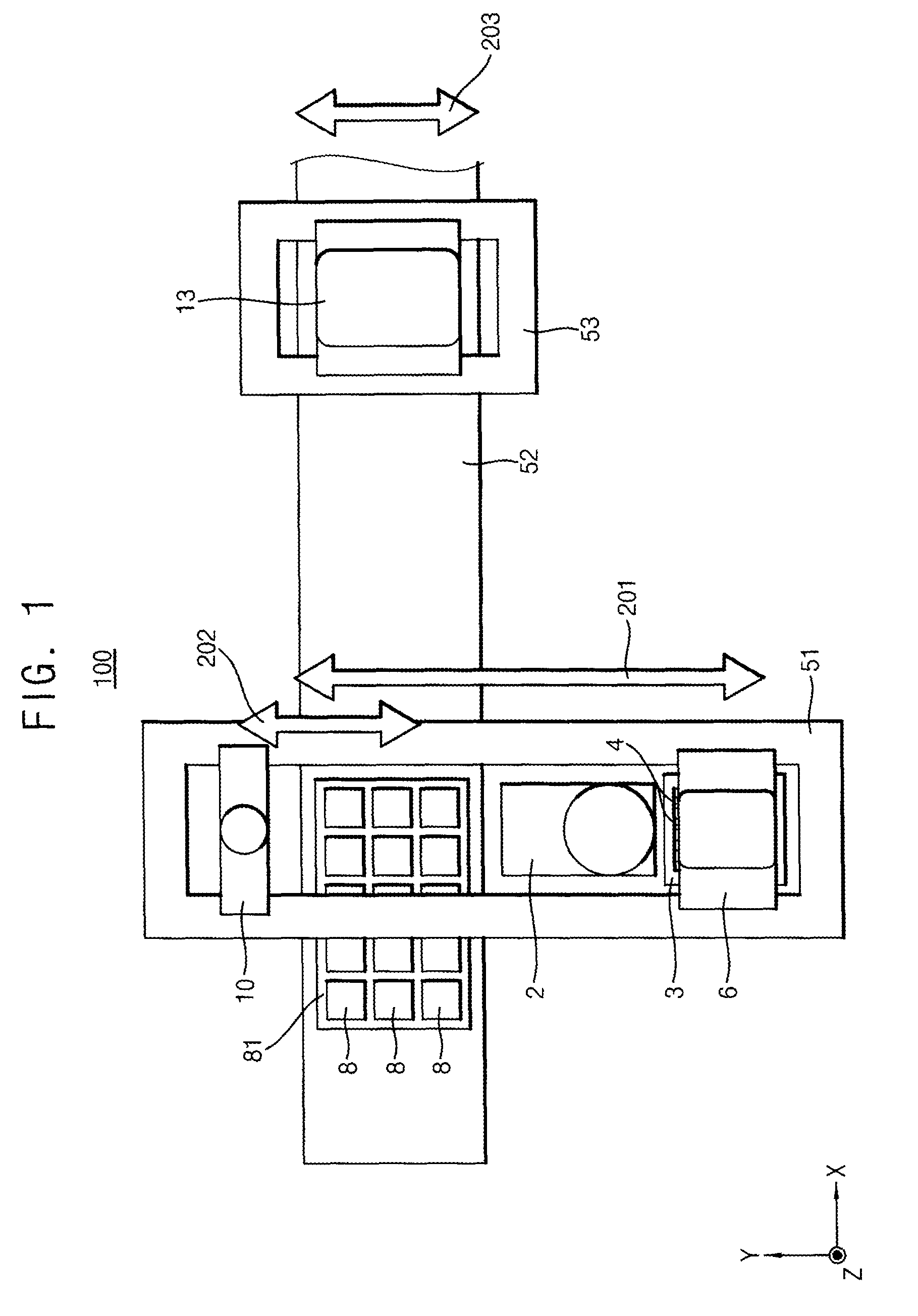

Mounting apparatus and mounting method for flip chip bonding semiconductor chips using two-step pressing process

ActiveUS9209051B2Quality improvementImprove placement qualitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipFlip chip

In one embodiment the mounting apparatus mounts an upper chip on a lower chip, and thermally presses the upper chip with the lower chip. The mounting apparatus includes a first movement part for mounting the upper chip on the lower chip and preliminarily bonding by thermal pressing, and a second movement part for mainly bonding the plurality of upper chips preliminarily bonded with the plurality of lower chips for a longer time. The second movement part thermally presses the upper chips preliminarily bonded on the lower chip in a state that the upper chips are adsorbed on an adsorption surface parallel to a loading surface of the lower chip on which the upper chips are loaded.

Owner:SAMSUNG ELECTRONICS CO LTD

Pipeline placing device for pipeline construction

ActiveCN112431961APromote shakingQuality improvementPipe laying and repairLifting framesArchitectural engineeringStructural engineering

The invention relates to a pipeline placing device for pipeline construction, and belongs to the technical field of pipeline construction. The pipeline placing device comprises two hoisting main frames arranged at intervals, feeding plates obliquely and downwards arranged on one sides of the tops of the hoisting main frames, storage plates connected with the end, away from the hoisting main frames, of the feeding plates, pipe pushing assemblies arranged on the storage plates and used for pushing a pipeline, pipe hoisting ropes arranged on the hoisting main frames, rope winding cylinders symmetrically arranged on the two sides of the hoisting main frames, driving assemblies symmetrically arranged on the two sides of the hoisting main frames in a hoisting mode and used for driving the rope winding cylinders to rotate and a control box installed on the hoisting main frames. The control box is correspondingly and electrically connected with the pipe pushing assembly and the driving assembly. The pipeline can be placed more conveniently and quickly, time is shortened, labor is saved, and the effect of improving the pipeline installation quality is achieved.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Printed circuit board connector

ActiveUS8465315B2Improve placement qualityUniform thicknessEngagement/disengagement of coupling partsPrinted circuit board

A printed circuit board connector is equipped with a housing and plurality of contacts. The housing has an insertion chamber 11 inserted by the mating-side connector, and a plurality of contact-insertion holes inserted by the contacts. The contact has a base portion, a contact-connecting portion that connects with a mating-side contact, and a lead portion that is solder-bonded to the printed circuit board. The base portion and the housing have a contact lance and level that engage with each other so that the contact does not move in an insertion direction to the contact insertion hole or a reverse direction, and the contact lance and level swingably hold the base portion inside the contact-insertion hole so that the lead portion approaches and separates from the printed circuit board surface.

Owner:JST MFG CO LTD

Multifunctional silicone earphone line, earphone storage box and mobile phone bracket

The invention discloses a silicone multi-function earphone cable, an earphone storage box and a mobile phone bracket, including a storage box A, a baffle, a silicone frame body, a storage box B and a supporting mechanism. The two ends of the silicone frame body are symmetrically installed with storage boxes A and The storage box B, the storage box A includes a flip cover, a box body and a wire roller, the flip cover and the box body are connected by hinges, and a wire roller is arranged at the middle position in the placement groove of the box body, and the wire roller There is an earphone groove in the placement groove on one side of the roller, and a plug sleeve is installed on the other side of the wire roller. Baffles are symmetrically arranged on both sides of the silicone frame body, and a middle position behind the silicone frame body is provided with A supporting mechanism, the supporting structure includes a mounting plate, a support plate and a positioning plate, the mounting plate is mounted on a rotating shaft, and one end of the mounting plate is rotationally connected to one end of the supporting plate through a rotating shaft. The invention has the advantages of novel structure, convenient use and rich functions.

Owner:天津书发志勤环保科技有限公司

A placement machine

ActiveCN109526143BAvoid shakingAvoid damagePrinted circuit assemblingCircuit board tools positioningEngineeringMachine

The invention provides a placement machine, comprising a placement machine body, first guide rails are provided on both sides of the placement machine body, moving columns are slidably installed on the two first guide rails, and a moving column is fixed between the two moving columns. The second guide rail is slidingly connected with the mounting head; the conveying slide rail is arranged under the mounting head, and the conveying platform is slidably installed on the conveying slide rail, and the carrying platform is detachably connected to the conveying platform through a shock absorbing mechanism; The shock mechanism includes a cylinder, a push rod and a damping spring. The upper end of the push rod is provided with a block; the bearing table is provided with a first installation groove and a second installation groove matching the shape of the upper end of the push rod. The clamping block passes through the second installation groove and snaps into the first installation groove; the two sides of the carrying platform are provided with a fixing mechanism, and the fixing mechanism includes a fixing seat, a pull plate, a fixing plate and a tension spring; Shock, which effectively slows down the vibration generated during the mounting process, reduces the damage caused by the vibration, and improves the mounting quality.

Owner:江苏盐湖电子科技有限公司

Mounting apparatus and mounting method

ActiveUS20140154838A1Reduce misalignmentQuality improvementSemiconductor/solid-state device detailsSolid-state devicesThermal compressionEngineering

In one embodiment the mounting apparatus mounts an upper chip on a lower chip, and thermally presses the upper chip with the lower chip. The mounting apparatus includes a first movement part for mounting the upper chip on the lower chip and preliminarily bonding by thermal pressing, and a second movement part for mainly bonding the plurality of upper chips preliminarily bonded with the plurality of lower chips for a longer time. The second movement part thermally presses the upper chips preliminarily bonded on the lower chip in a state that the upper chips are adsorbed on an adsorption surface parallel to a loading surface of the lower chip on which the upper chips are loaded.

Owner:SAMSUNG ELECTRONICS CO LTD

Automatic fiber laying system and planning method for its laying track

The invention discloses an automatic fiber placement system, which includes an automatic fiber placement device, a mold bearing device corresponding to the fiber automatic placement device, and a control subsystem. The control subsystem includes a fiber automatic placement device Controlled press roller pressure-laying track mixing control module and laying tension-speed decoupling control module and temperature fuzzy adaptive control module controlling the temperature of the mold carrying device; the present invention also provides the above-mentioned fiber automatic laying The planning method of the laying track of the laying device. The present invention can realize the precise control of the laying process parameters, thereby improving the laying quality. The laying track of the present invention can make the collaborative manipulator avoid singular poses, and at the same time improve the stress on the joints of the cooperative manipulator, avoid interference, and improve movement efficiency and safety.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com