Large deformation flexible compression device for automatic fiber placement

A technology of pressing device and automatic wire laying, which is applied in the field of fiber laying, can solve the problems of inability to compact the fiber tape and high hardness, and achieve the effects of easy control of pressing force, improvement of molding quality, and improvement of adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

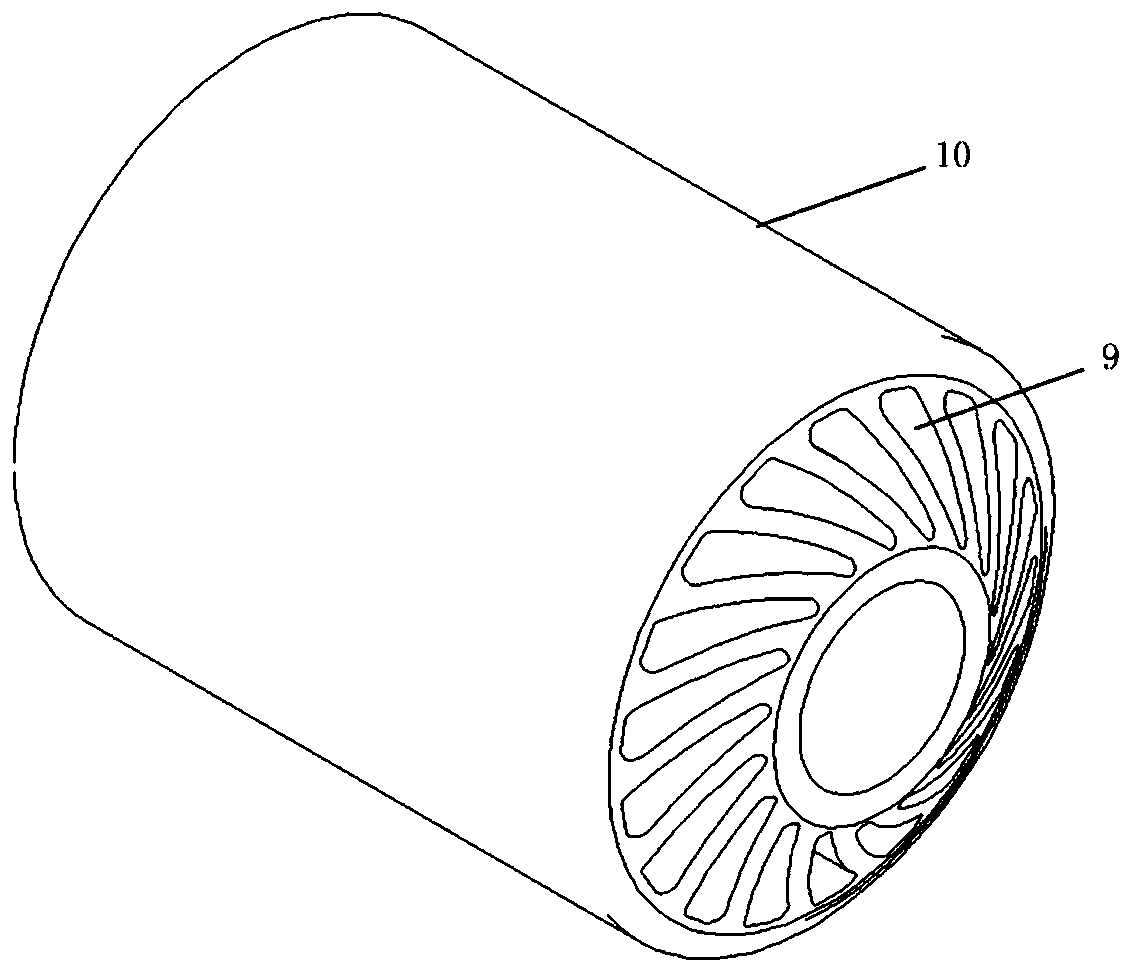

[0030] The large deformation in the present invention refers to that through a certain structural design, the deformation of the pressure roller exceeds the elastic deformation capacity of the solid body of the same material. Large amount of deflection to better adhere to curved mold surfaces.

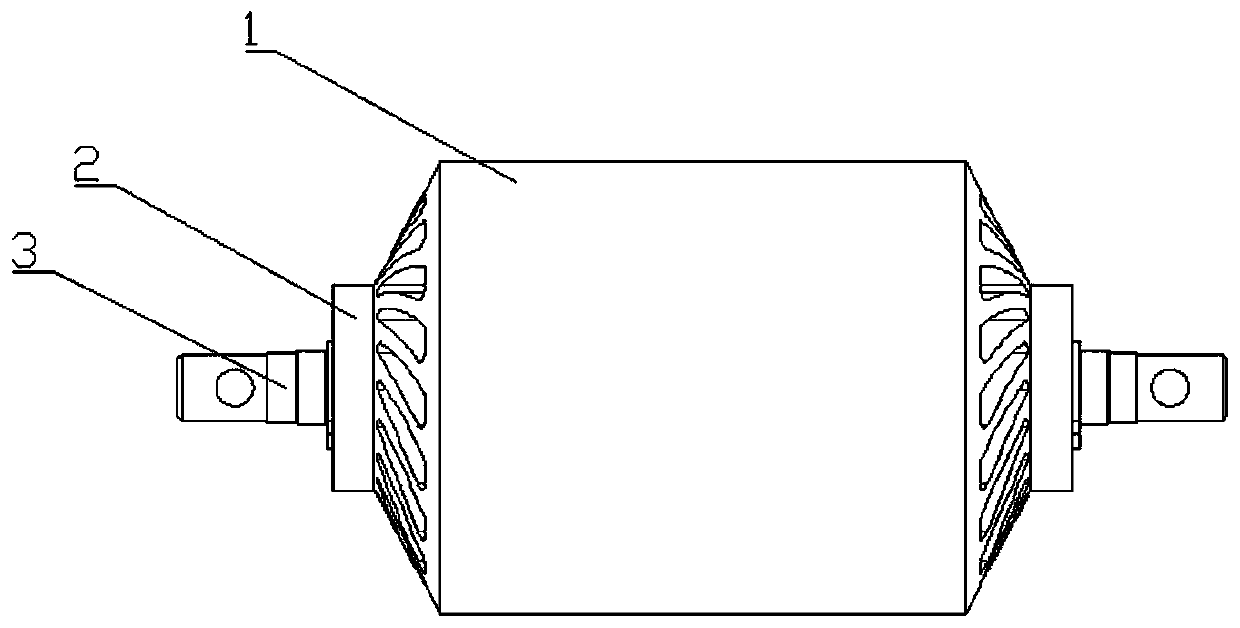

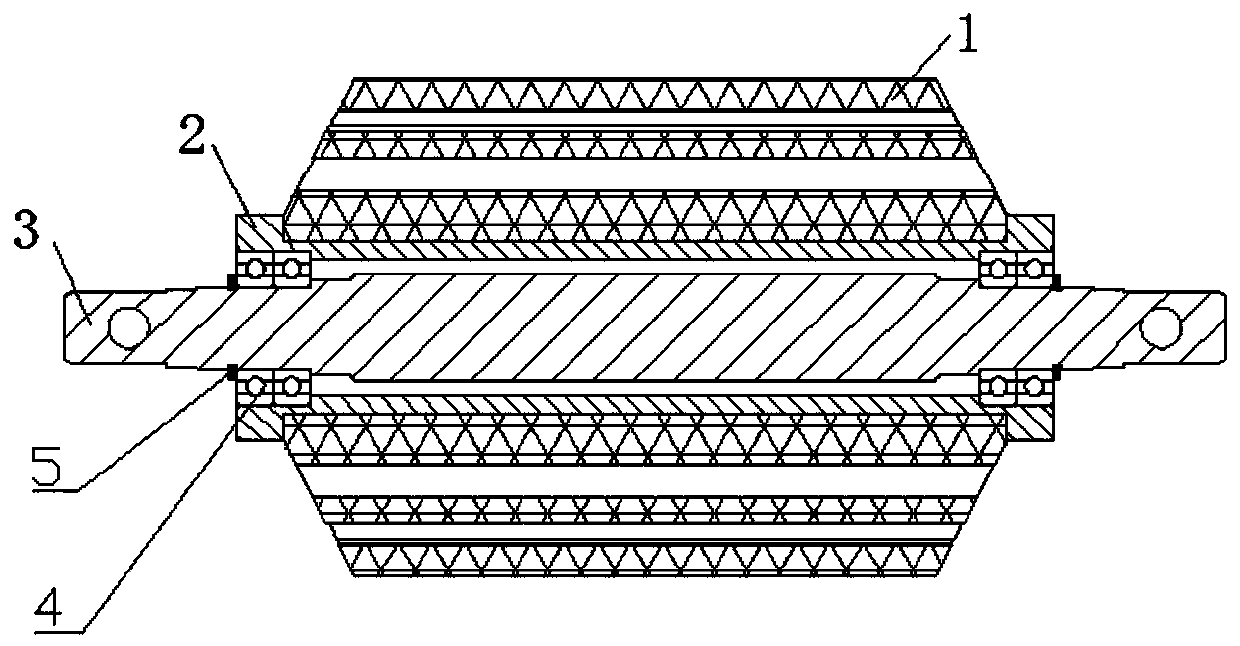

[0031] Such as figure 1 , figure 2 and image 3 As shown, a large-deformation flexible compacting device for automatic silk laying of the present invention mainly includes pressure roller rubber sleeve 1, pressure roller 2, pressure roller shaft 3, bearing 4, elastic retaining ring 5 and other components. The pressure roller shaft 3 is processed by alloy steel, the pressure roller rubber sleeve 1 is set on the pressure roller 2, the pressure roller 2 is installed on the pressure roller shaft 3 through the bearing 4, and the bearing 4 is fixed on the pressure roller shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com