Automatic fiber laying system and planning method for its laying track

A laying trajectory and motion trajectory technology, which is applied in the field of automatic fiber laying system and its laying trajectory planning, can solve the problems of unstudied parameter coupling, few studies on laying pressure/position hybrid control, etc. Poor force, avoid wire/pipe entanglement and motion interference, overcome the effect of laying deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

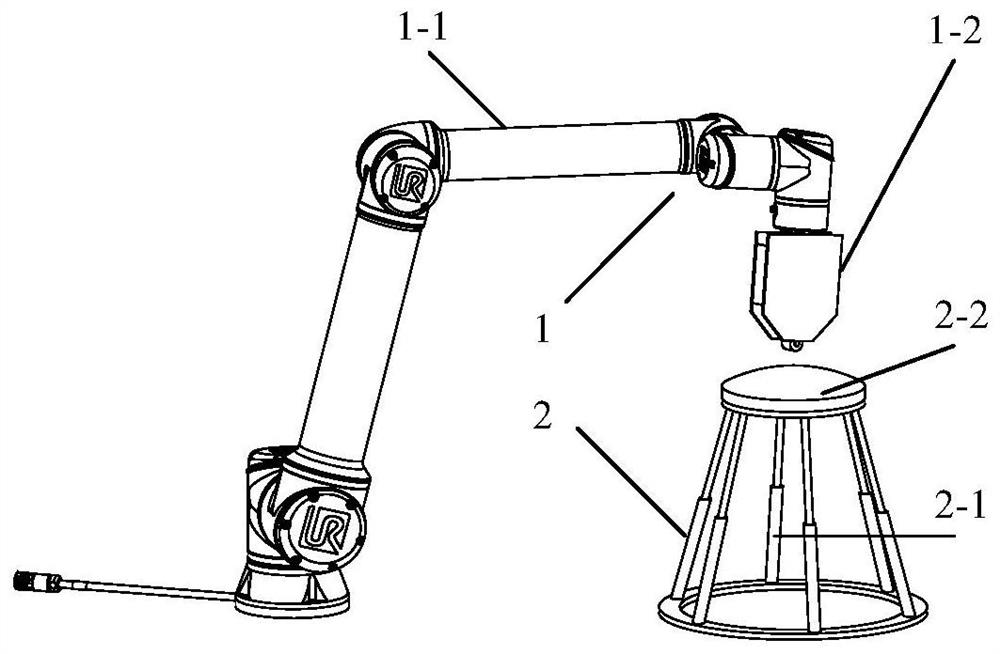

[0037] The invention provides a fiber automatic laying device, such as figure 1 As shown, it includes an automatic fiber placement device 1 based on a collaborative robot arm, a mold carrying device 2 based on a multi-degree-of-freedom motion platform, and a control subsystem for controlling the automatic fiber placement device 1 and the mold carrying platform 2 . Wherein, the automatic fiber placement device 1 includes a cooperative robot arm 1-1 and a placement head 1-2 arranged at the end of the cooperative robot arm 1-1. The mold carrying device 2 includes a multi-degree-of-freedom motion platform 2-1 and an intelligent temperature-controlled mold 2-2 arranged on the multi-degree-of-freedom motion platform 2-1, wherein the laying head 1-2 and the intelligent temperature-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com