Patents

Literature

68results about How to "Simple electrical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

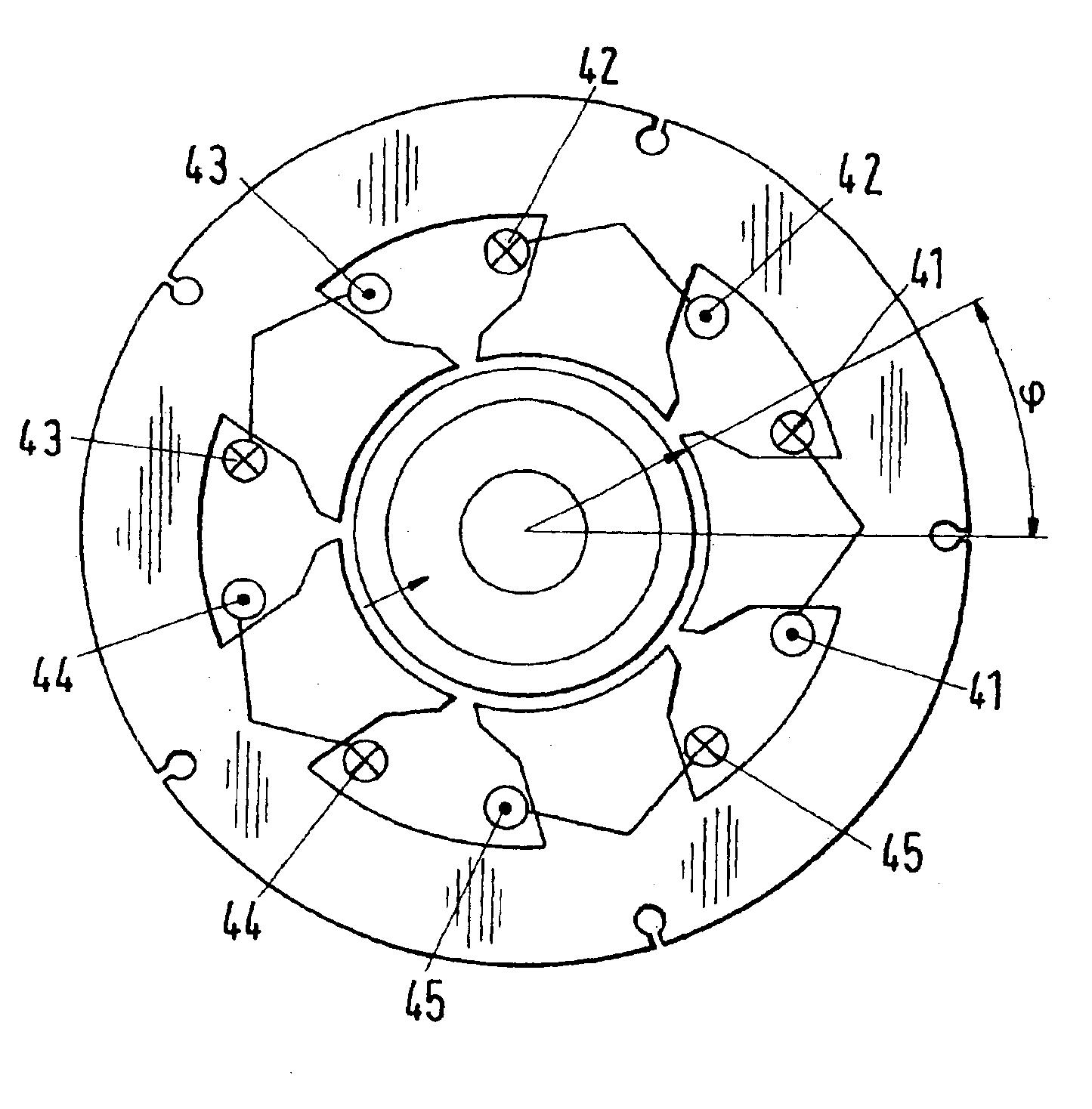

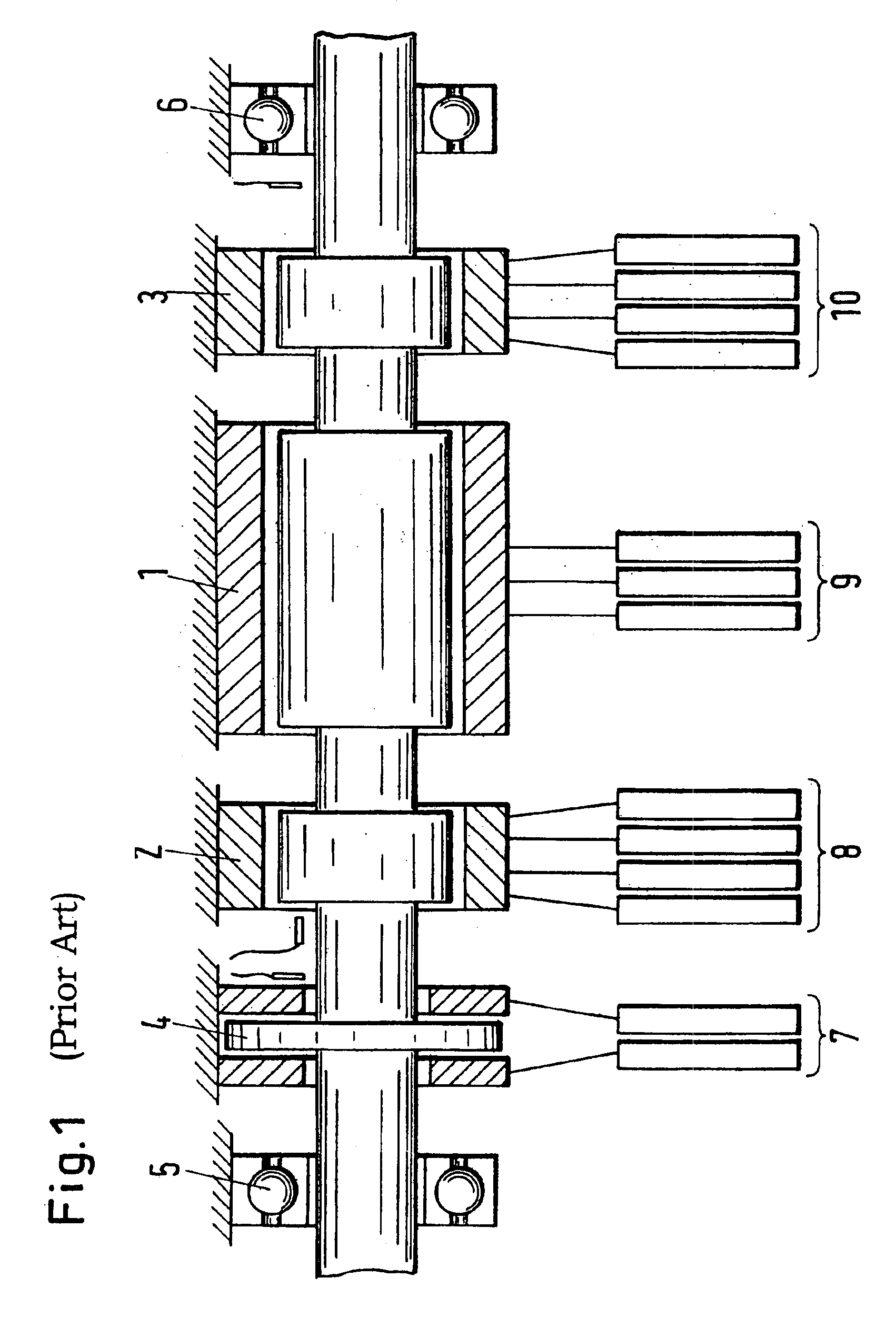

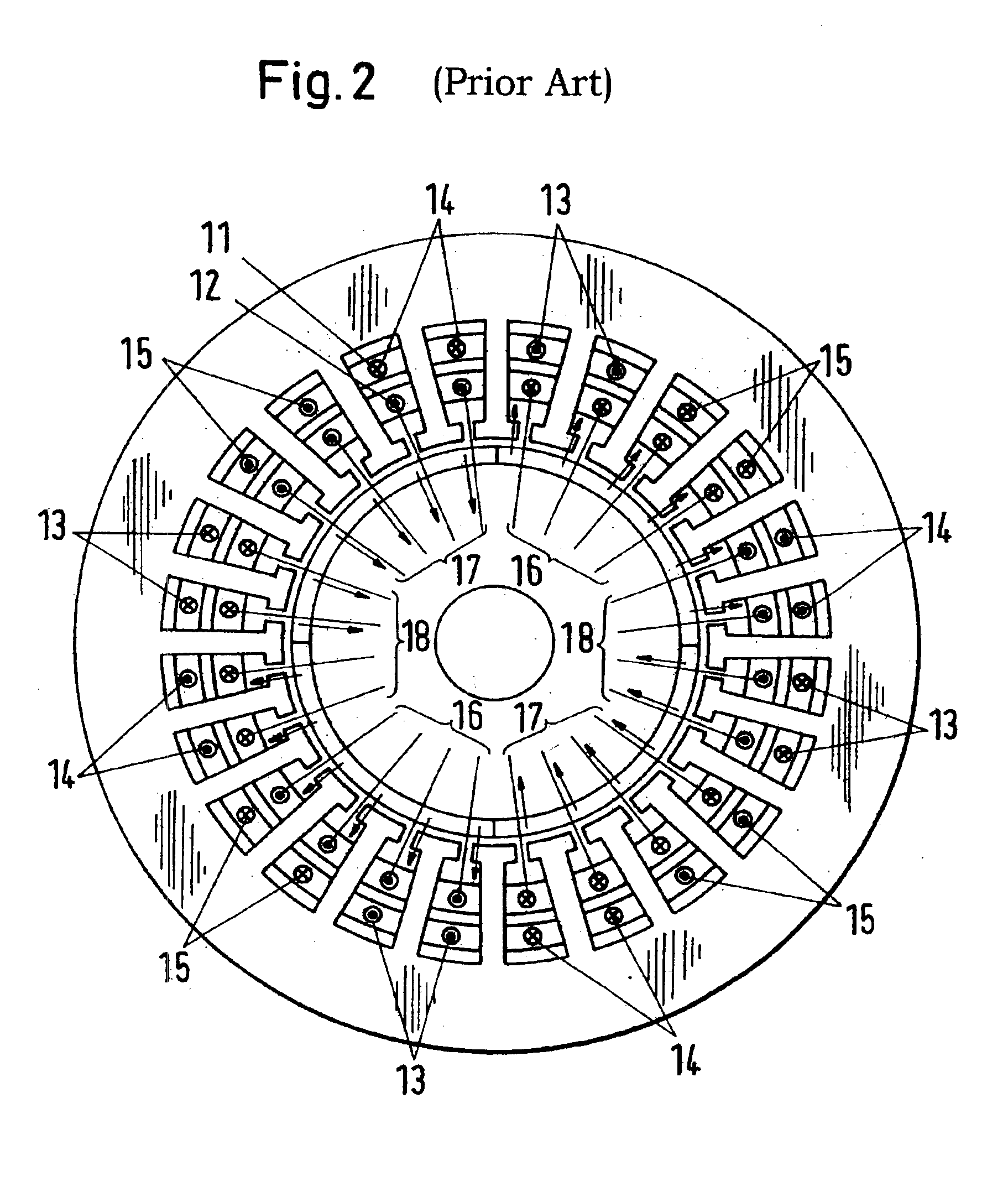

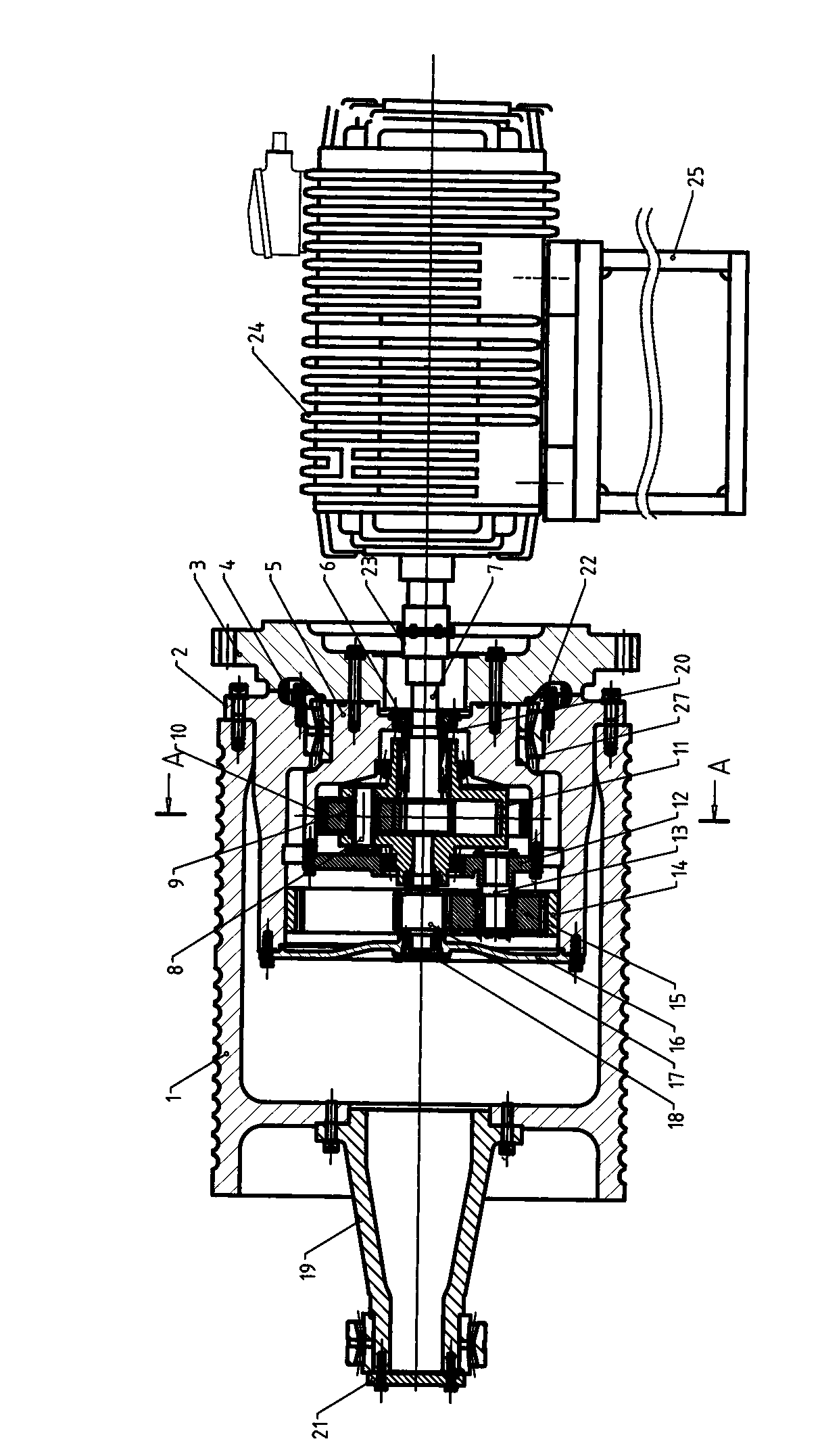

Stator field providing torque and levitation

InactiveUS6879074B2Easy constructionSimple electrical controlShaftsMechanical energy handlingMagnetomotive forceLevitation

The invention relates to an economical, non-wearing, electrical permanent magnet drive for actively controlling the rotor position in three degree of freedom. The stator windings produce superimposed fields with different pole numbers in the pole pitches by unsymmetrical magnetomotive force distributions.

Owner:LEVITRONIX TECH +1

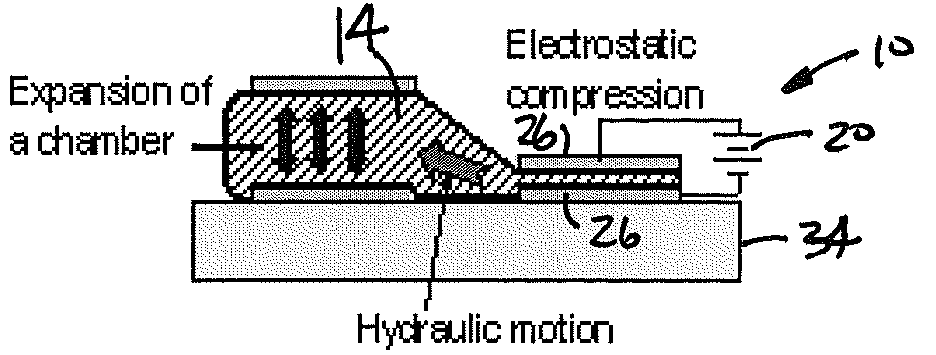

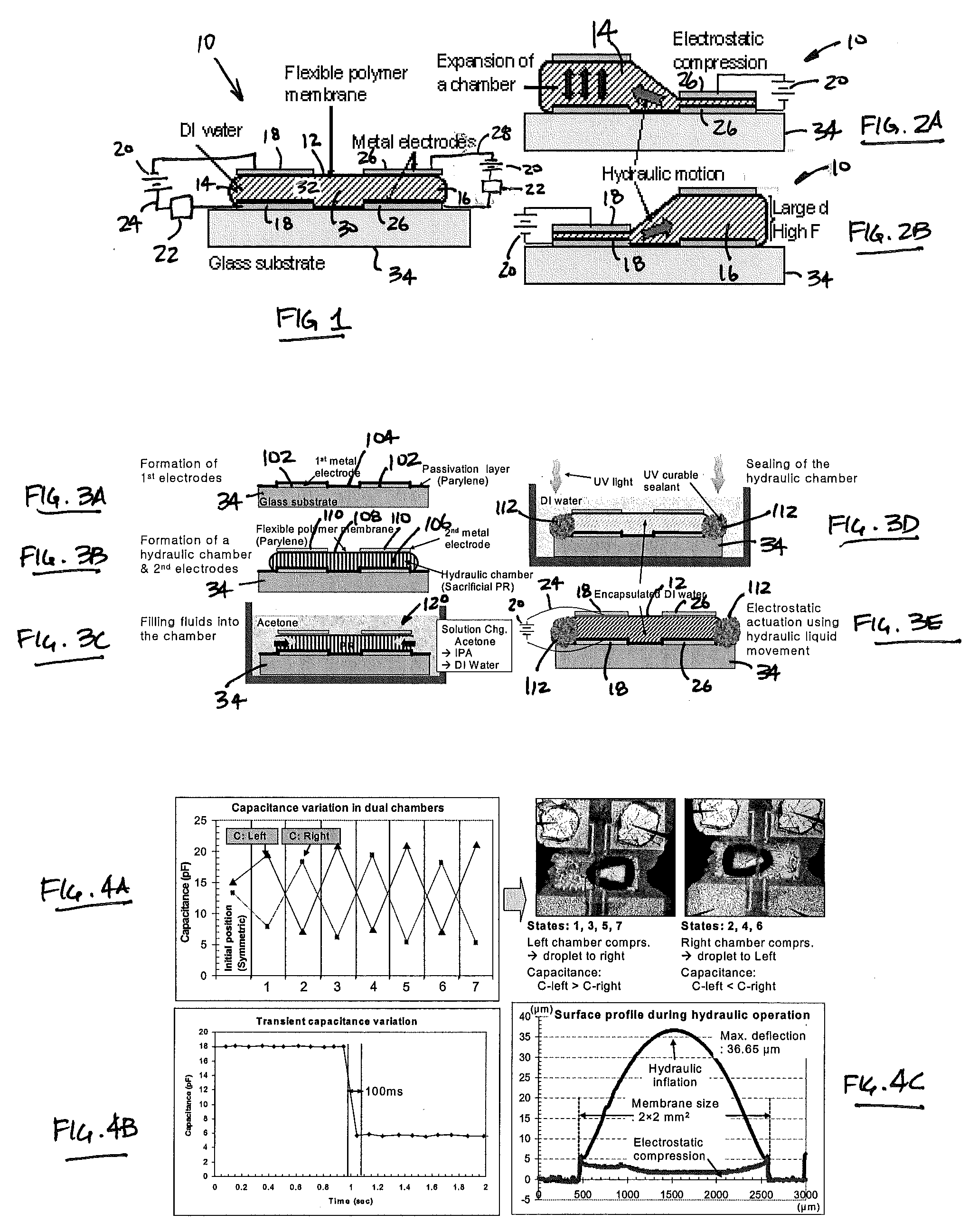

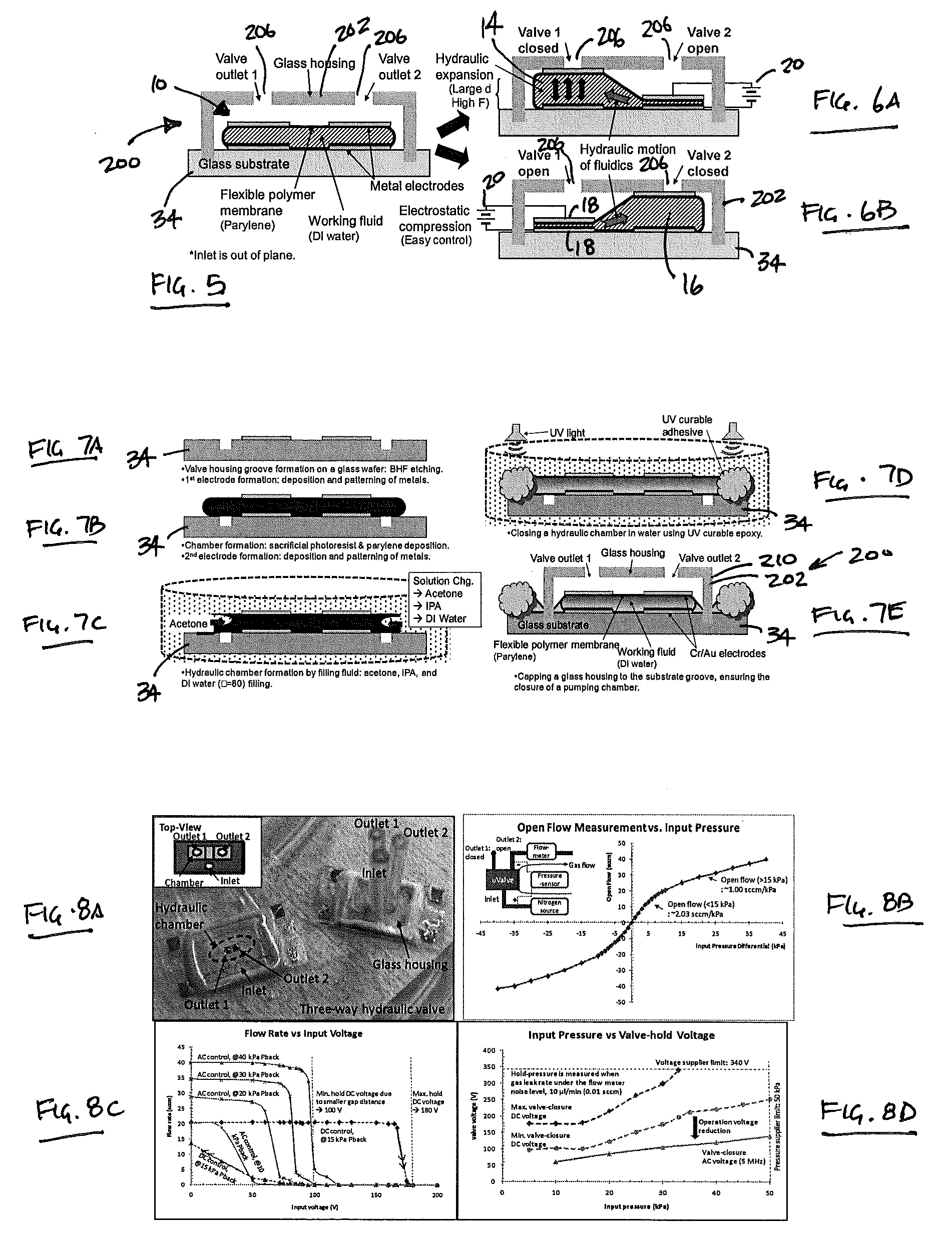

Liquid-gap electrostatic hydraulic micro actuators

InactiveUS20090115285A1Reduce voltageHigh gas conductancePiezoelectric/electrostrictive device manufacture/assemblyOperating means/releasing devices for valvesParallel plateMicro actuator

A liquid-gap electrostatic hydraulic micro actuator is provided that produces higher displacement (in and out of plane) and larger force than typical electrostatic actuators by utilizing a non-conducting liquid as its dielectric material. This new class of actuators utilizes the liquid dielectric for hydraulic amplification and force transfer. The liquid electrostatic actuator consists of two chambers each forming a parallel-plate capacitor, filled with a non-conducting incompressible liquid. One chamber is compressed by pulling down a flexible membrane using electrostatic actuation, thus forcing the liquid under it to transfer into the other chamber. Such movement causes the other chamber's membrane to expand out of plane.

Owner:RGT UNIV OF MICHIGAN

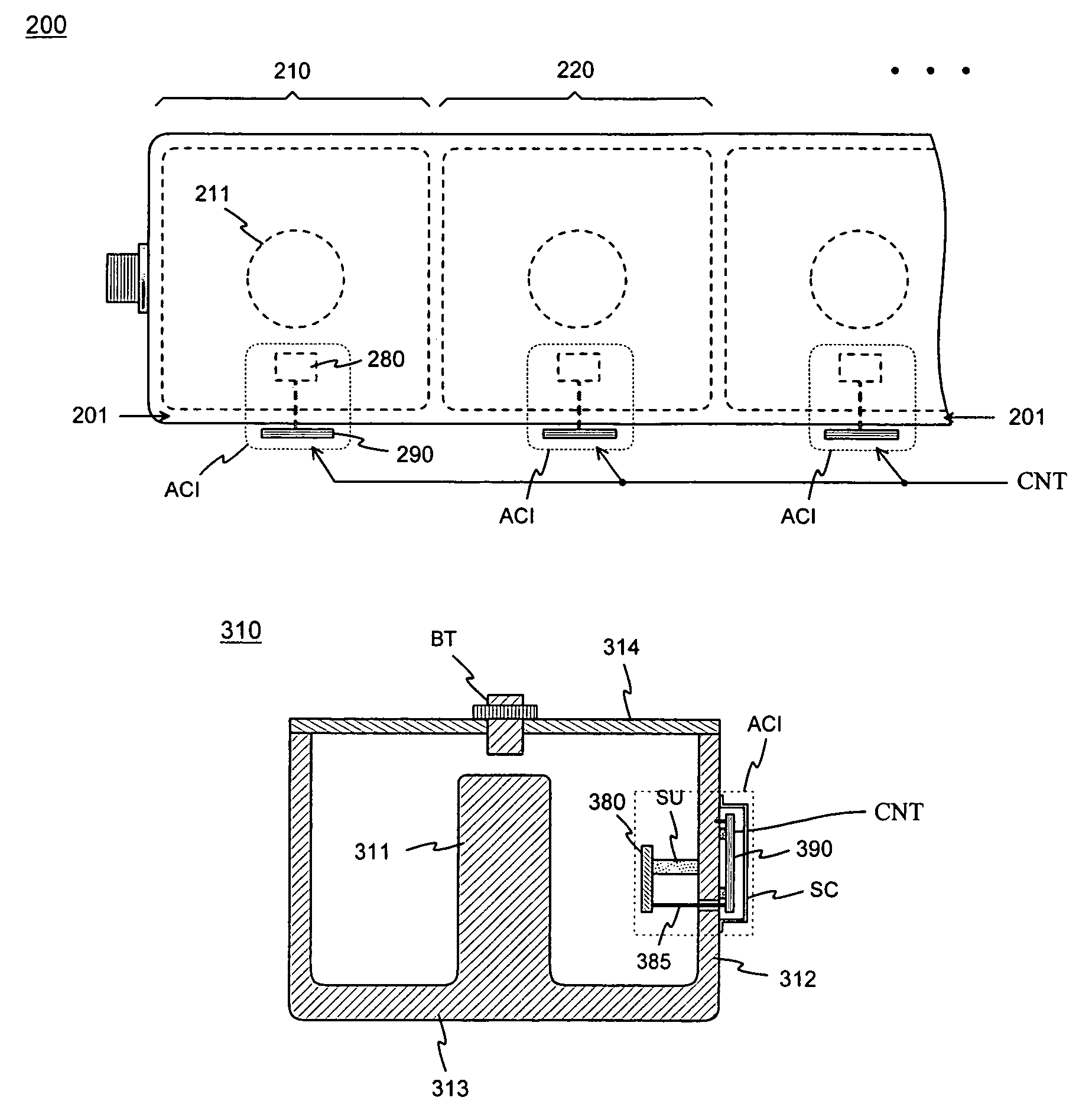

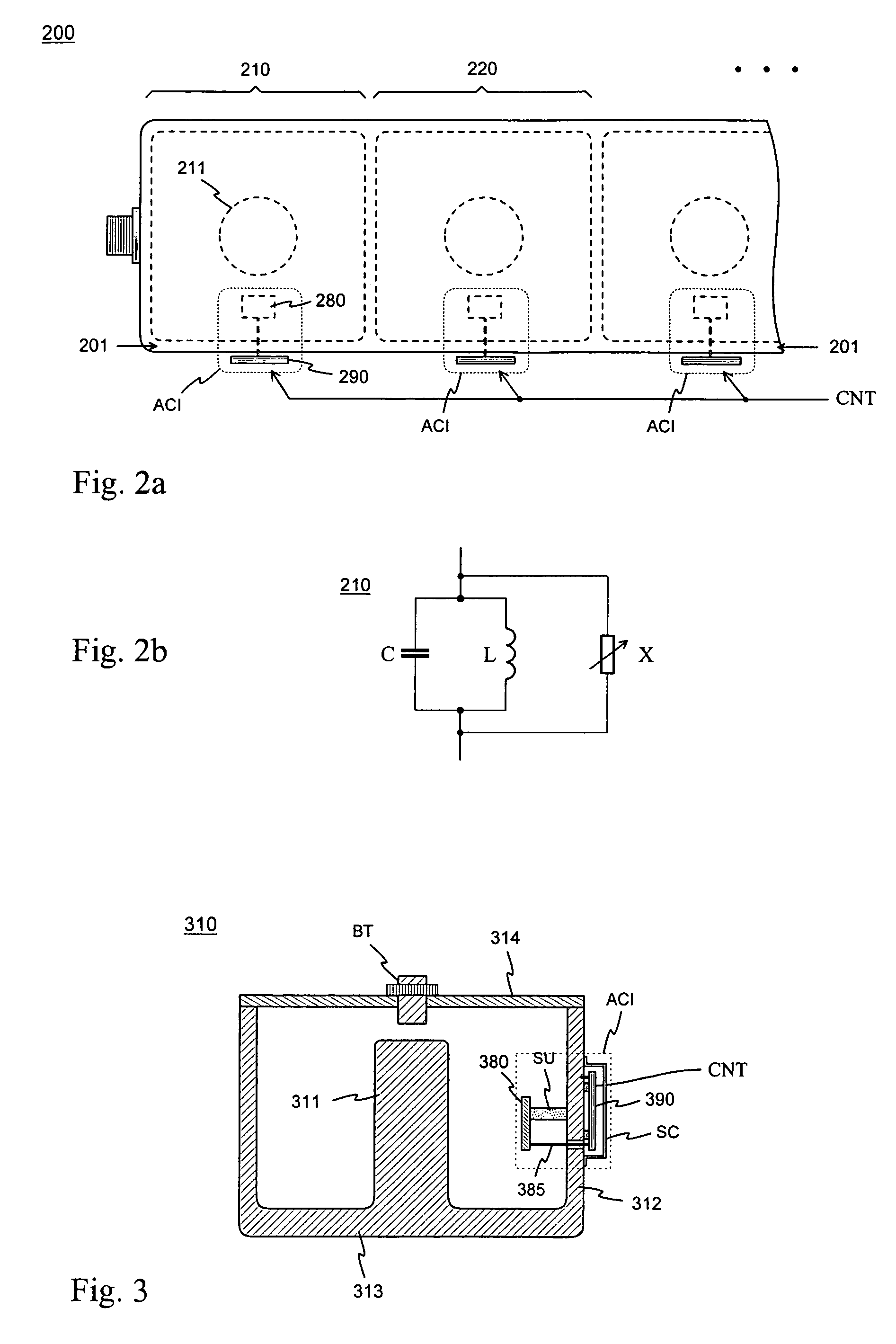

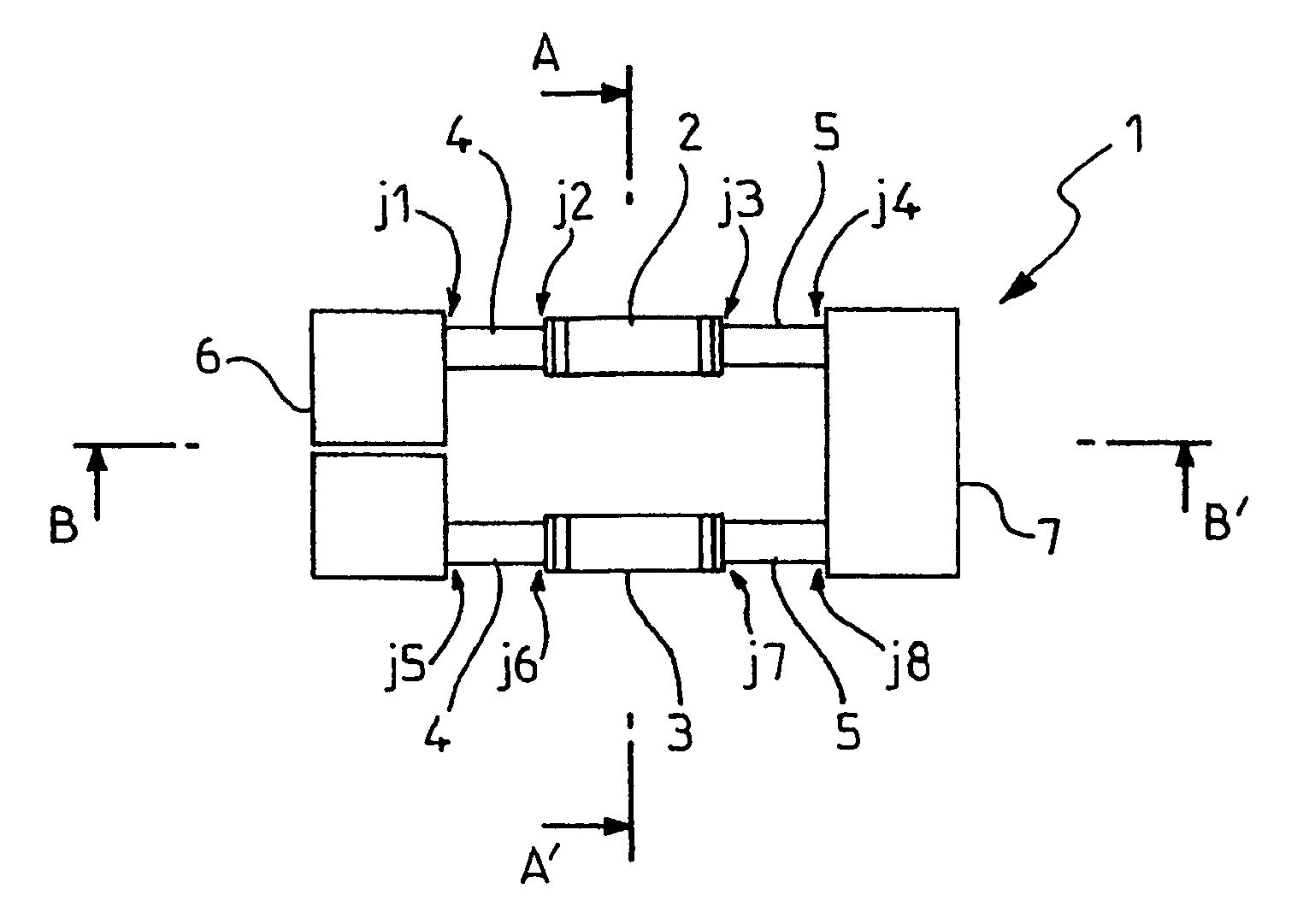

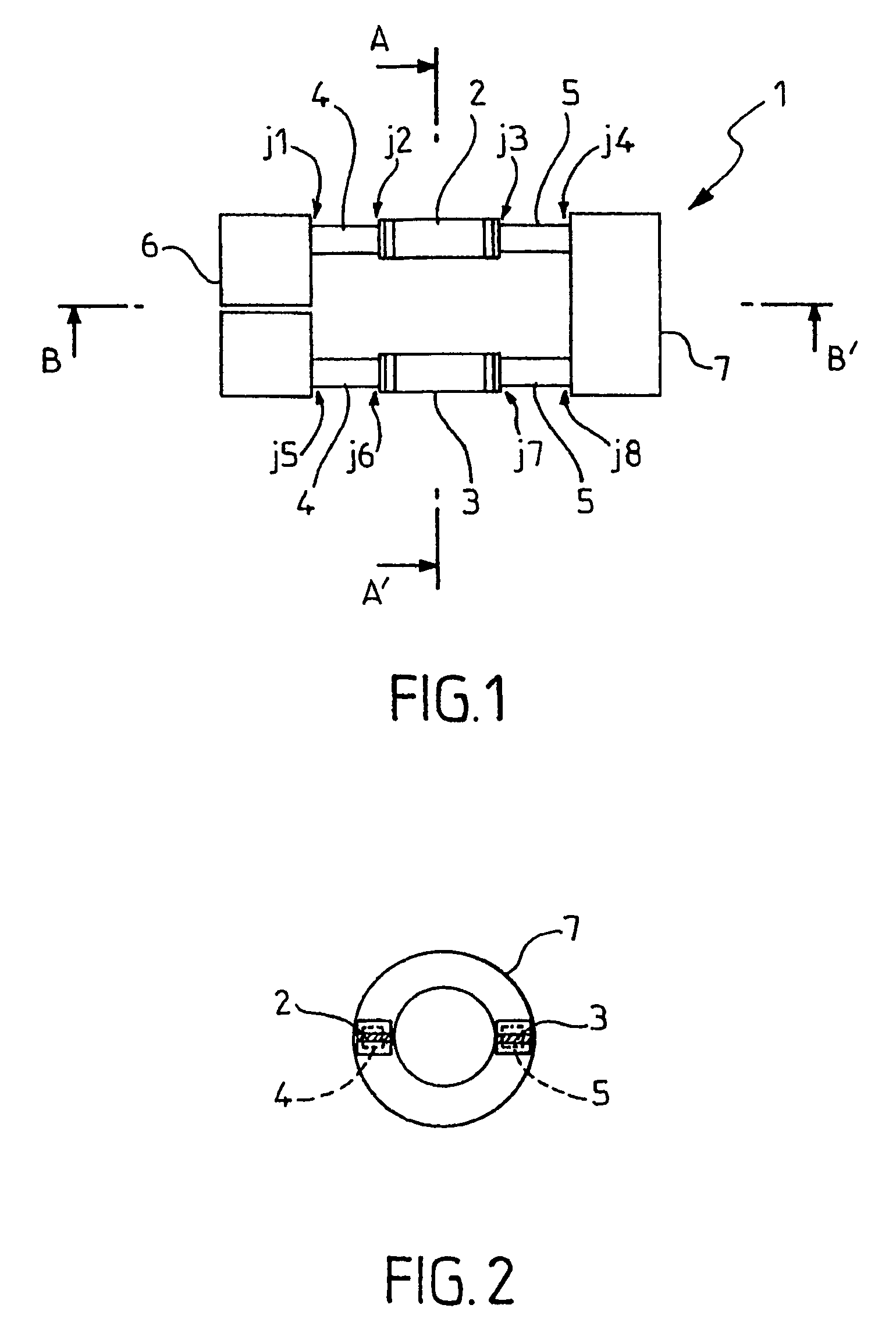

Adjustable resonator filter

InactiveUS7236069B2Easy to adjustImprove reliabilityResonatorsWaveguidesElectromagnetic couplingResonant cavity

An adjustable resonator filter (200), the operating band of which can be shifted by a one-time adjustment. The natural frequency of each resonator (210, 220) is affected, in addition to the basic tuning arrangement, by an adjustment circuit (ACI), which includes a fixed tuning element (280) in the resonator cavity and an adjusting part (290) outside the cavity. The tuning element has an electromagnetic coupling to the basic structure of the resonator. The adjustment circuit is functionally a short transmission line, which is “seen” by the resonator as a reactance of a certain value. By changing the electric length of the transmission line, the value of the reactance and the electric length and natural frequency of the whole resonator are changed. The change is implemented in the adjustment part by means of switches or a movable dielectric piece. In the resonator filter each resonator has a similar adjustment circuit, and the adjustment circuits have common control (CNT) for shifting the band of the filter. When the subband division is in use, the filters need not be separately adjusted for each subband in connection with the manufacture. No moving parts are required inside the filter housing.

Owner:INTEL CORP

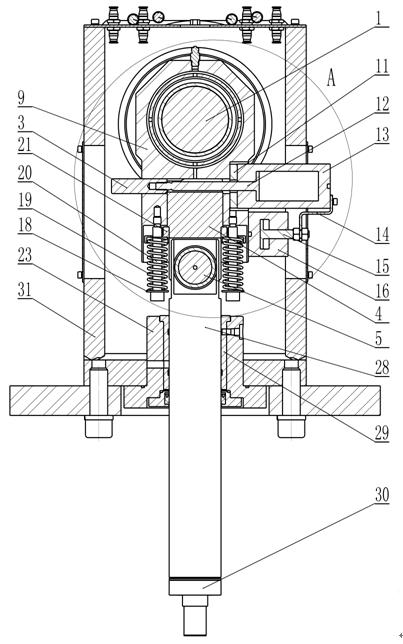

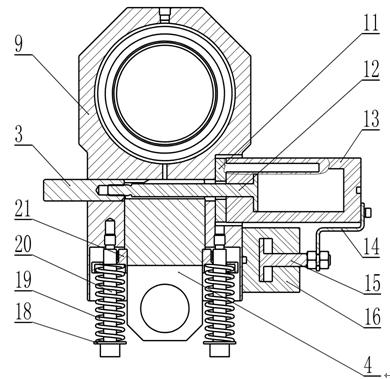

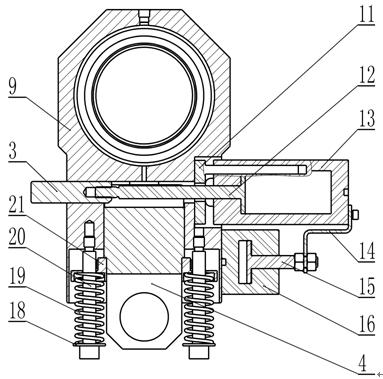

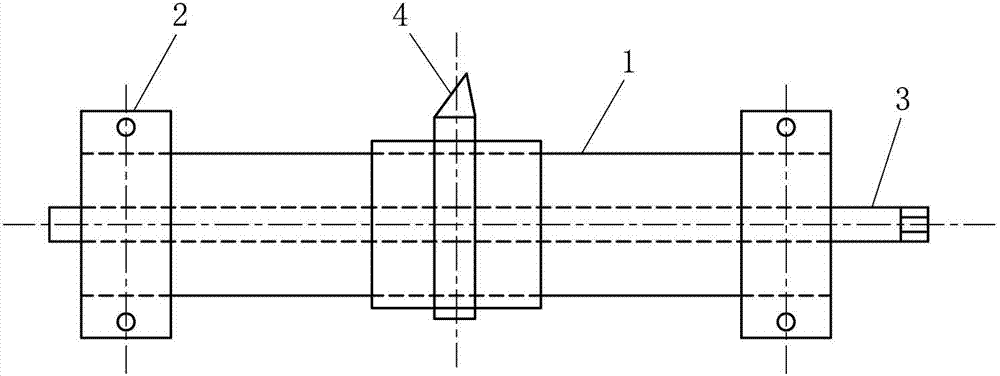

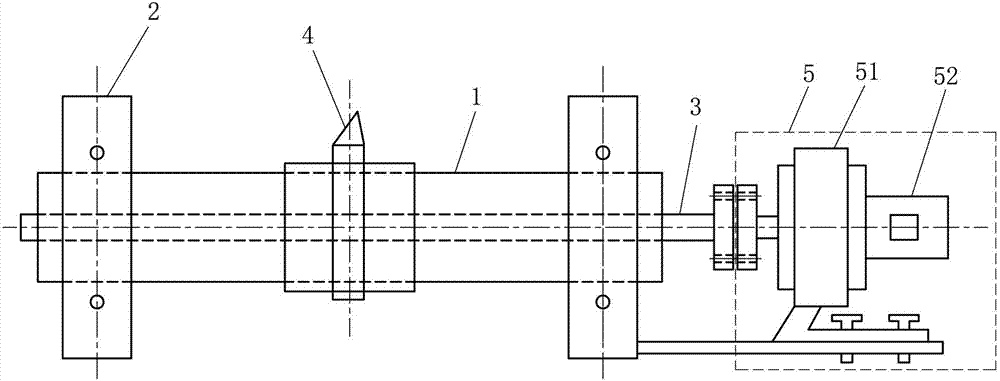

Single-action type variable length connecting rod and crank-connecting rod transmission mechanism

InactiveCN102319785AAchieve lengthEasy to adjustConnecting rodsGearingArchitectural engineeringEngineering

The invention relates to a single-action type variable length connecting rod and a crank-connecting rod transmission mechanism, the single-action type variable length connecting rod comprises an inner connecting rod and an outer connecting rod, which are nested together and in sliding fit and connection, and the single-action type variable length connecting rod is characterized in that a guide groove is formed on the outer connecting rod and a cushion block which is in sliding fit with the guide groove is arranged in the guide groove; connecting plates for articulating the inner connecting rod and the cushion block together are respectively arranged on the two sides of the inner connecting rod and the cushion block; a guide cylinder is mounted on the outer connecting rod, a guide plate ofthe guide cylinder is fixed on the outer connecting rod through a screw, a guide hole arranged on the wall of the guide cylinder is in sliding fit with a guide short shaft on the guide plate, and a piston rod of the guide cylinder is fixed with the cushion block; a short stroke cylinder is mounted below the guide cylinder which is positioned on the outer connecting rod, and the connecting plates are used for connecting a cylinder body of the guide cylinder with the piston rod of the short stroke cylinder so as to enable the regulation of the length of the connecting rod to be more convenient and faster and enable the electric control to be easier; and the length of the variable length connecting rod can be adjusted in three positions, namely the initial position, the middle position and the hitting position, so that the variable connecting rod in the structure can be applied more widely.

Owner:JINAN CASTING FORGING MACHINERY INST

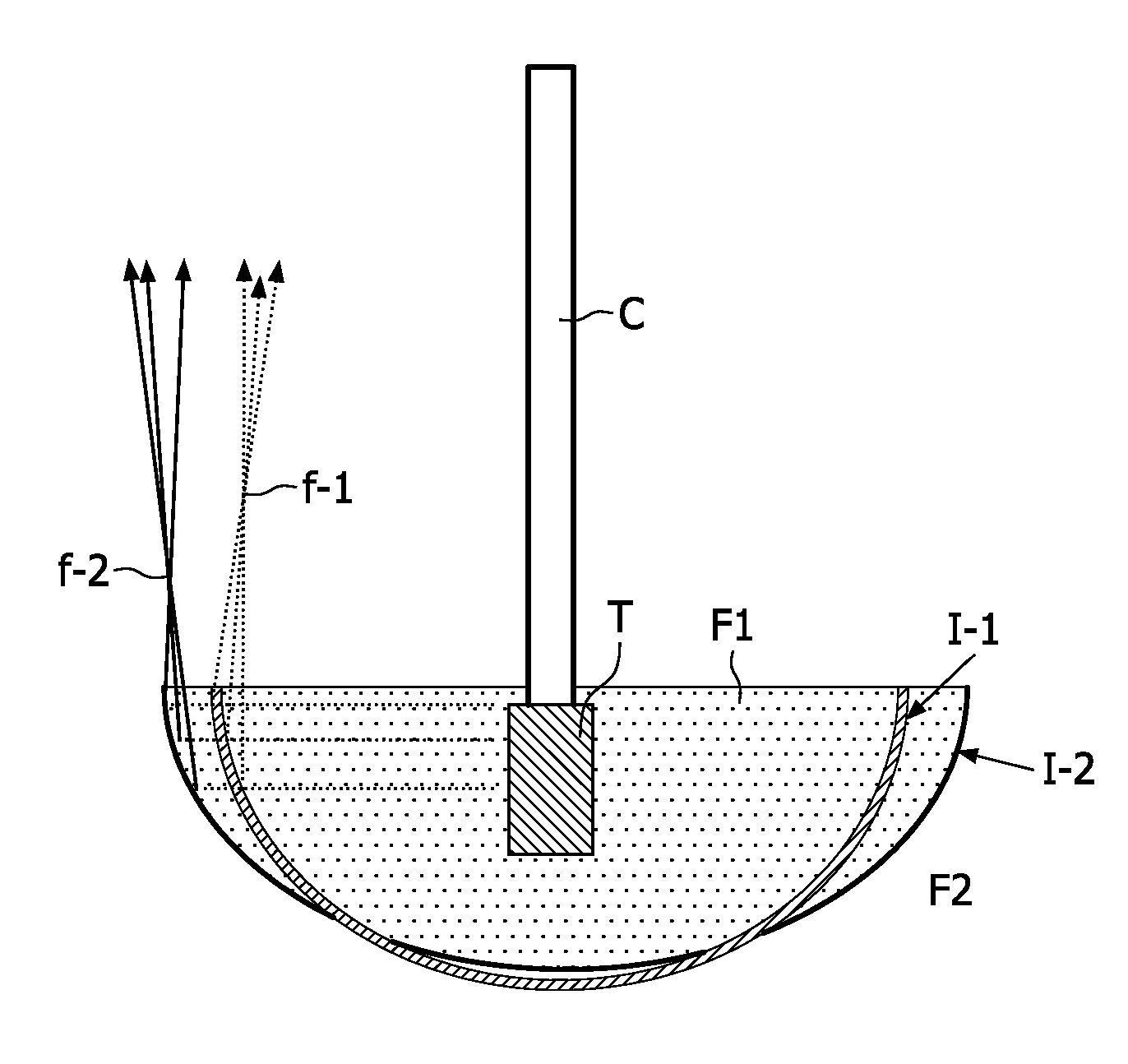

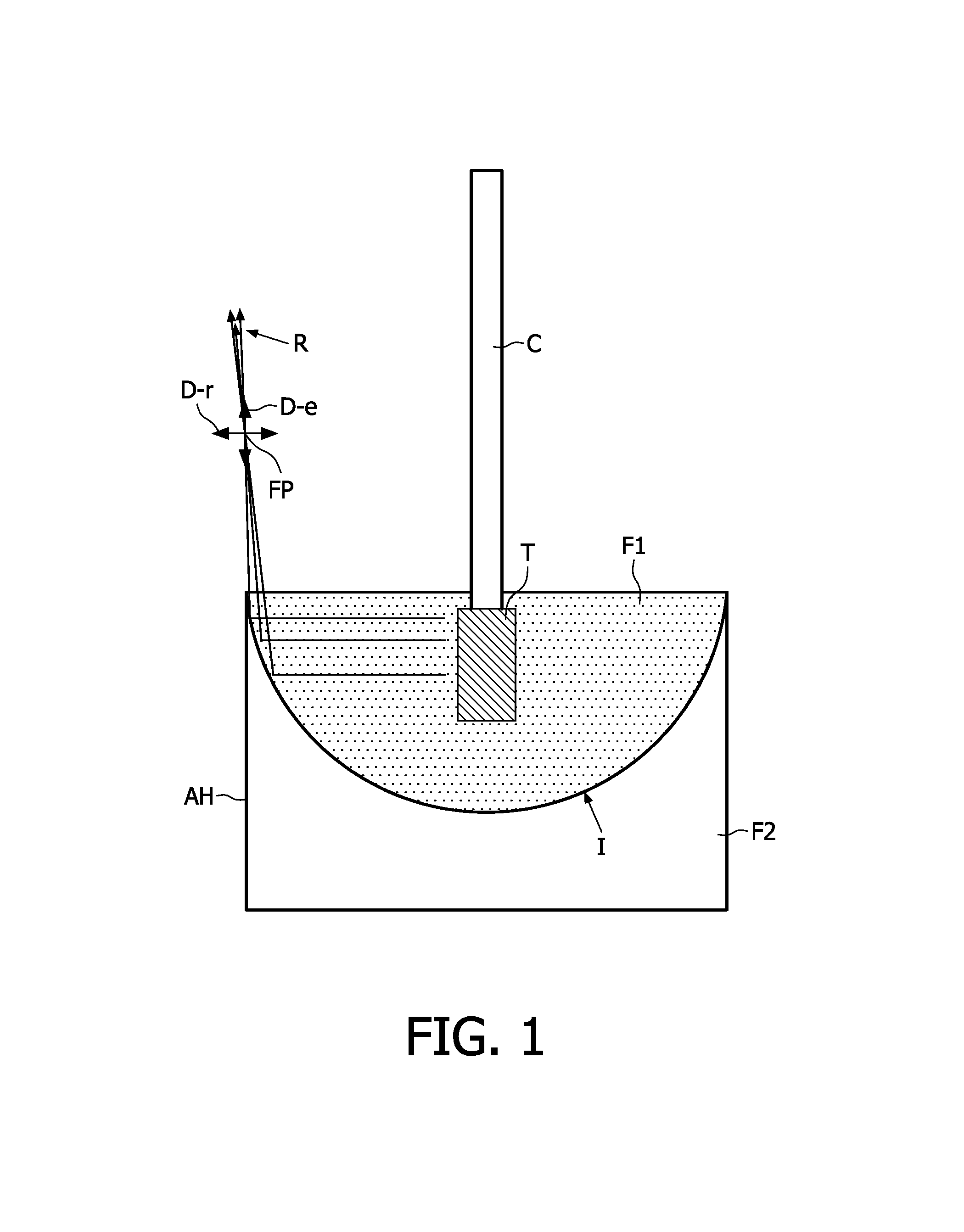

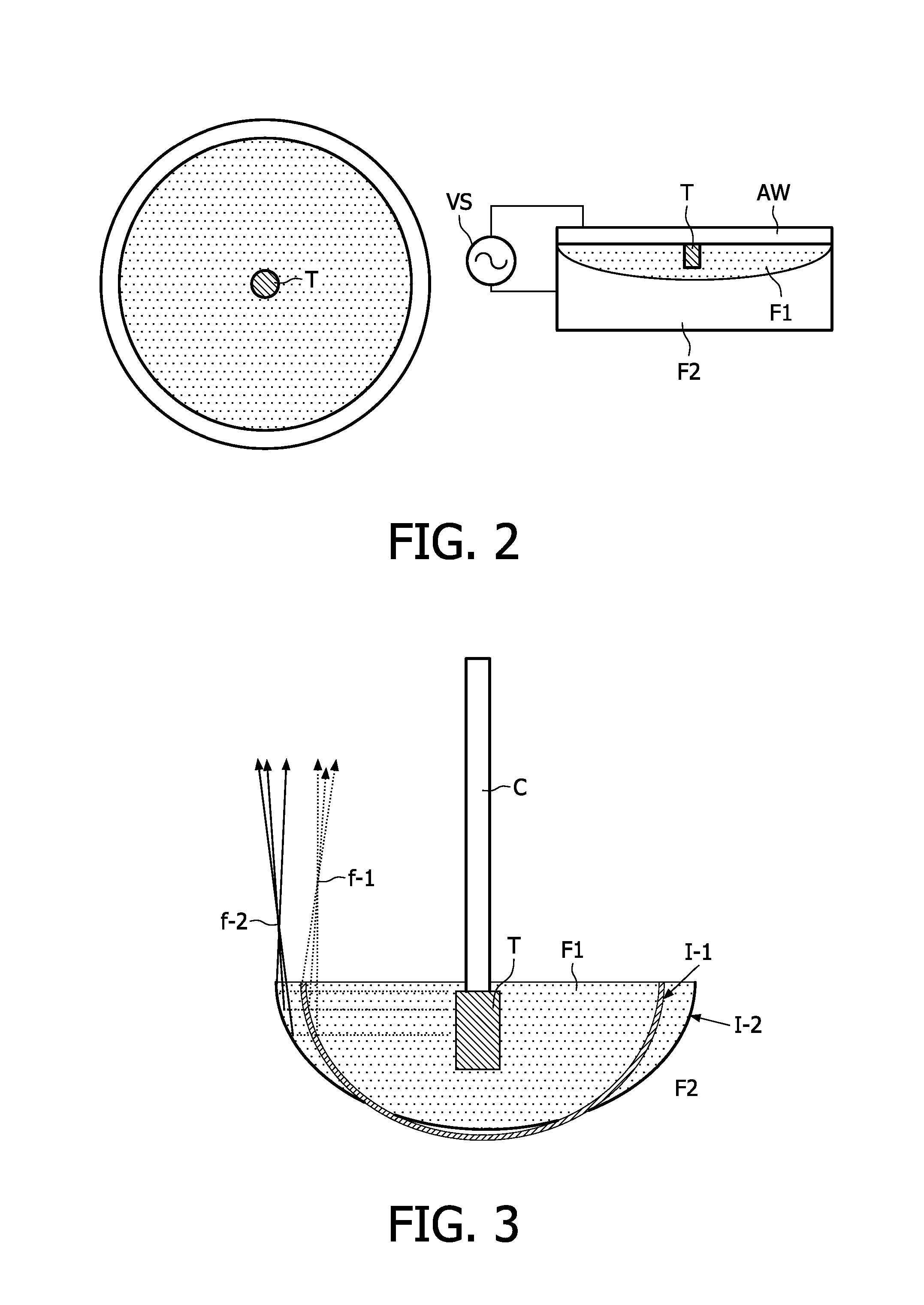

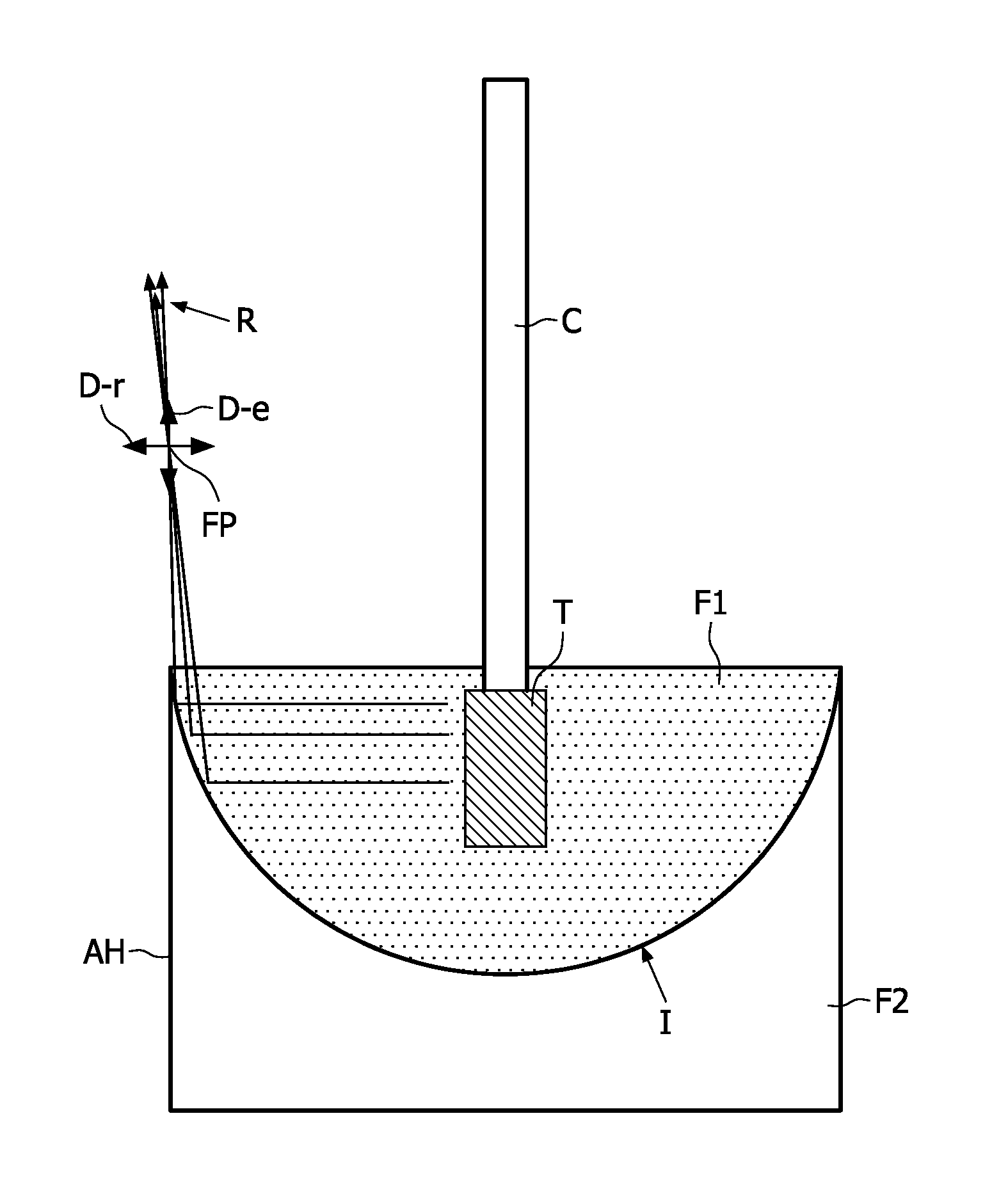

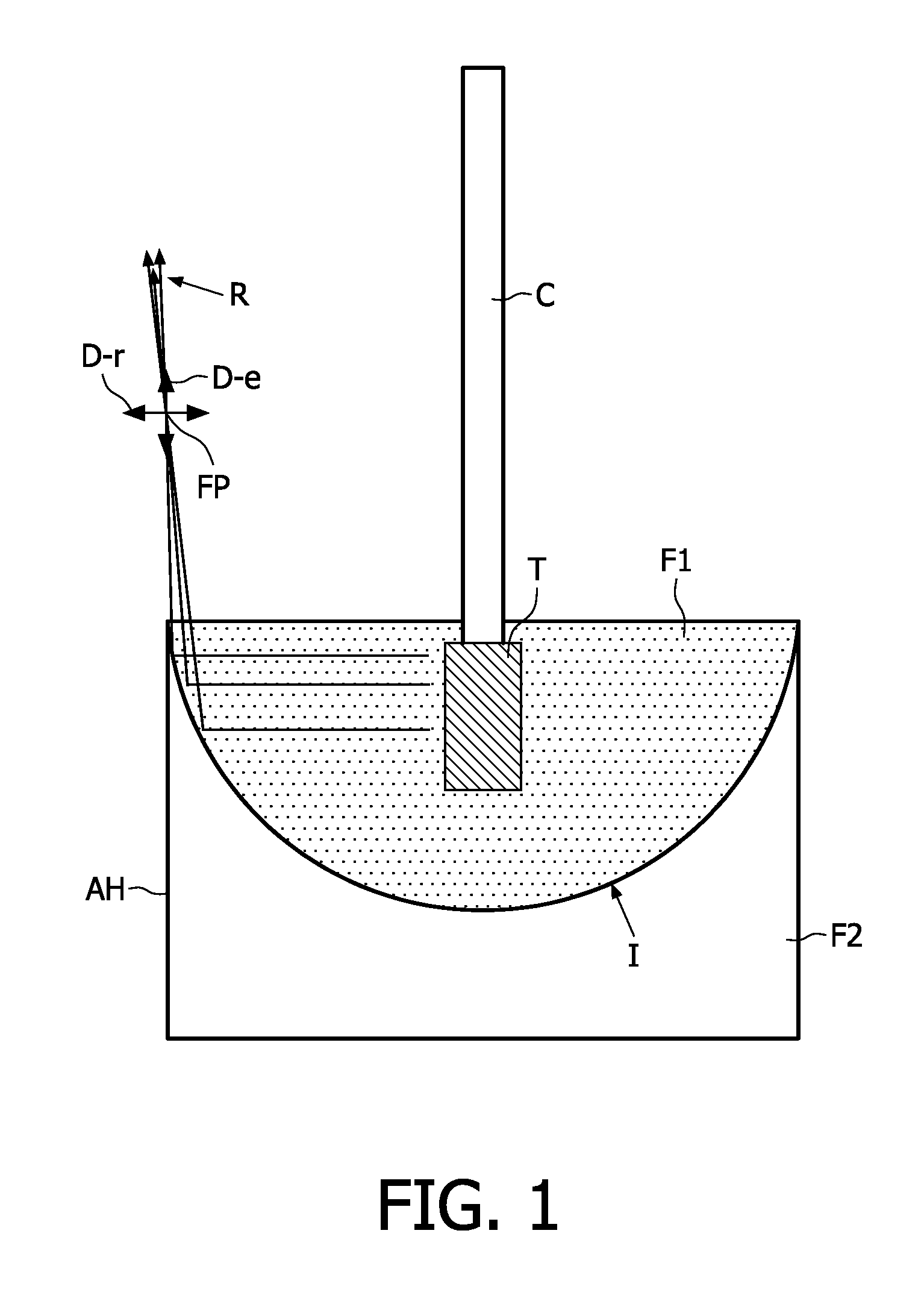

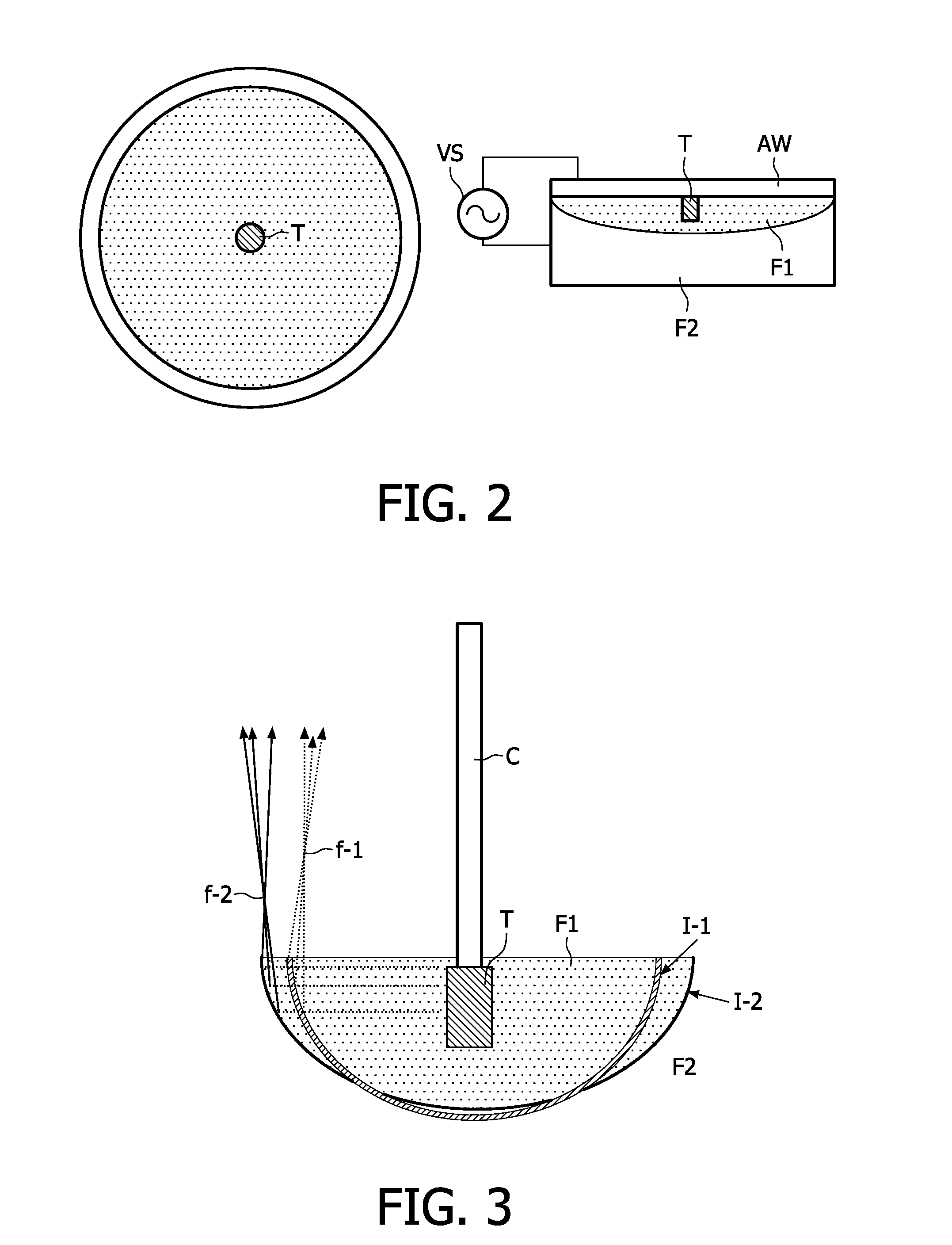

Ultrasonic assembly with adjustable fluid lens

InactiveUS8475442B2Simple and economical to useProcess controlUltrasound therapyChiropractic devicesUltrasonic sensorTransducer

An ultrasonic assembly suited for attachment to a catheter, e.g. for medical treatment. The ultrasonic assembly includes an adjustable ultrasonic focus mechanism arranged in connection with the ultrasonic transducer to adjust focus of ultrasonic waves generated by the transducer. The ultrasonic focus mechanism includes a fluid focus lens with at least two fluids separated by an interface such that ultrasonic waves are substantially reflected at the interface. At least two electrodes are arranged in connection with the fluid focus lens so as to allow adjustment of the interface shape, e.g. a curvature of the interface, when a voltage is applied to the electrodes. In preferred embodiments the electrodes are arranged so as to allow adjustment of the fluid focus lens in an elevation direction as well as in a radial direction. In simple embodiments with rotational symmetric geometry with the transducer positioned in the center of the fluid focus lens, ultrasonic waves can be focused in an annular ring. This is e.g. suitable for ablative or coagulative necrotic treatment of human tissue, e.g. for atrial fibrillation treatment. In some embodiments, the assembly has a number of separate individually adjustable fluid focus lens compartments allowing a more detailed control of the ultrasonic focus pattern.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

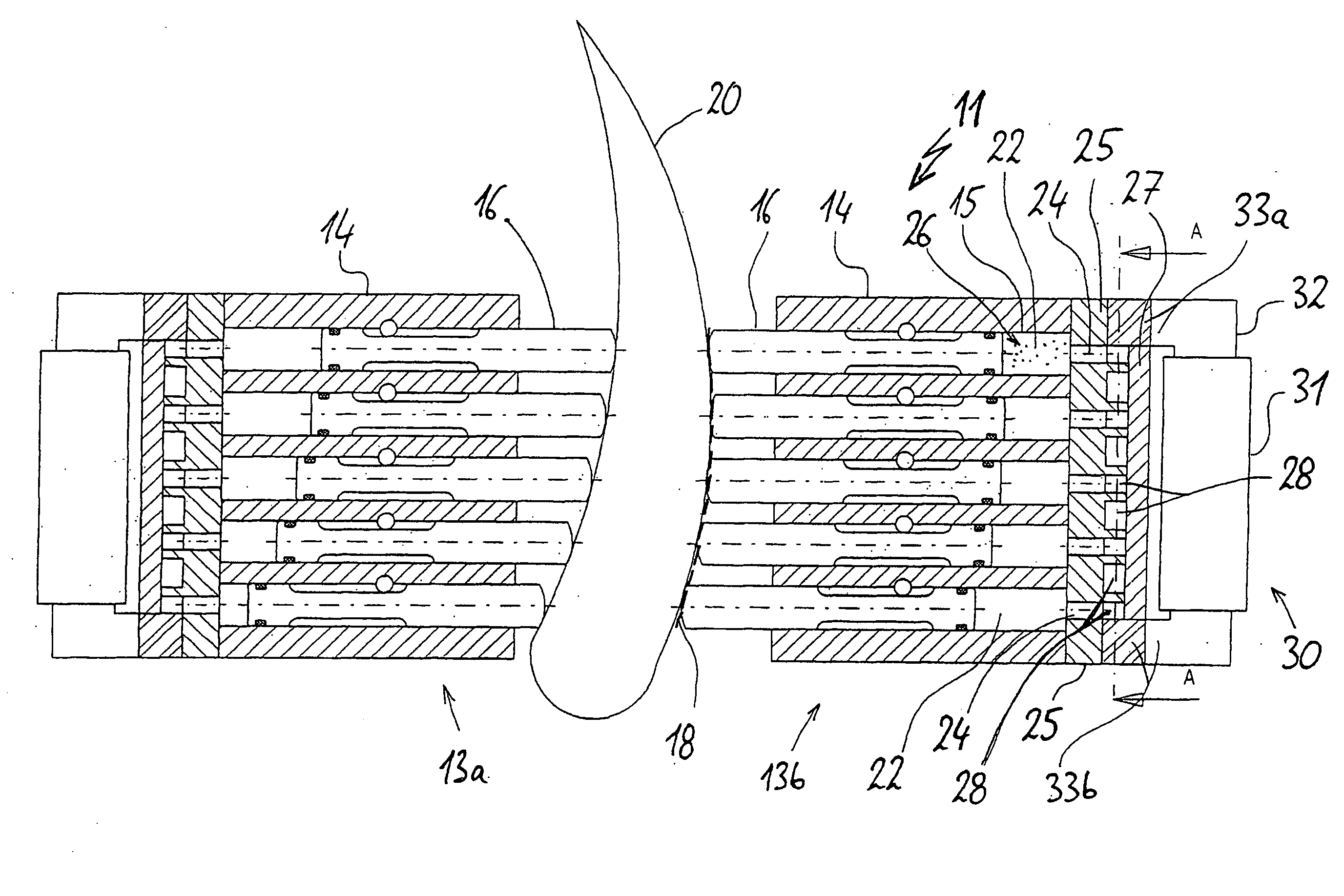

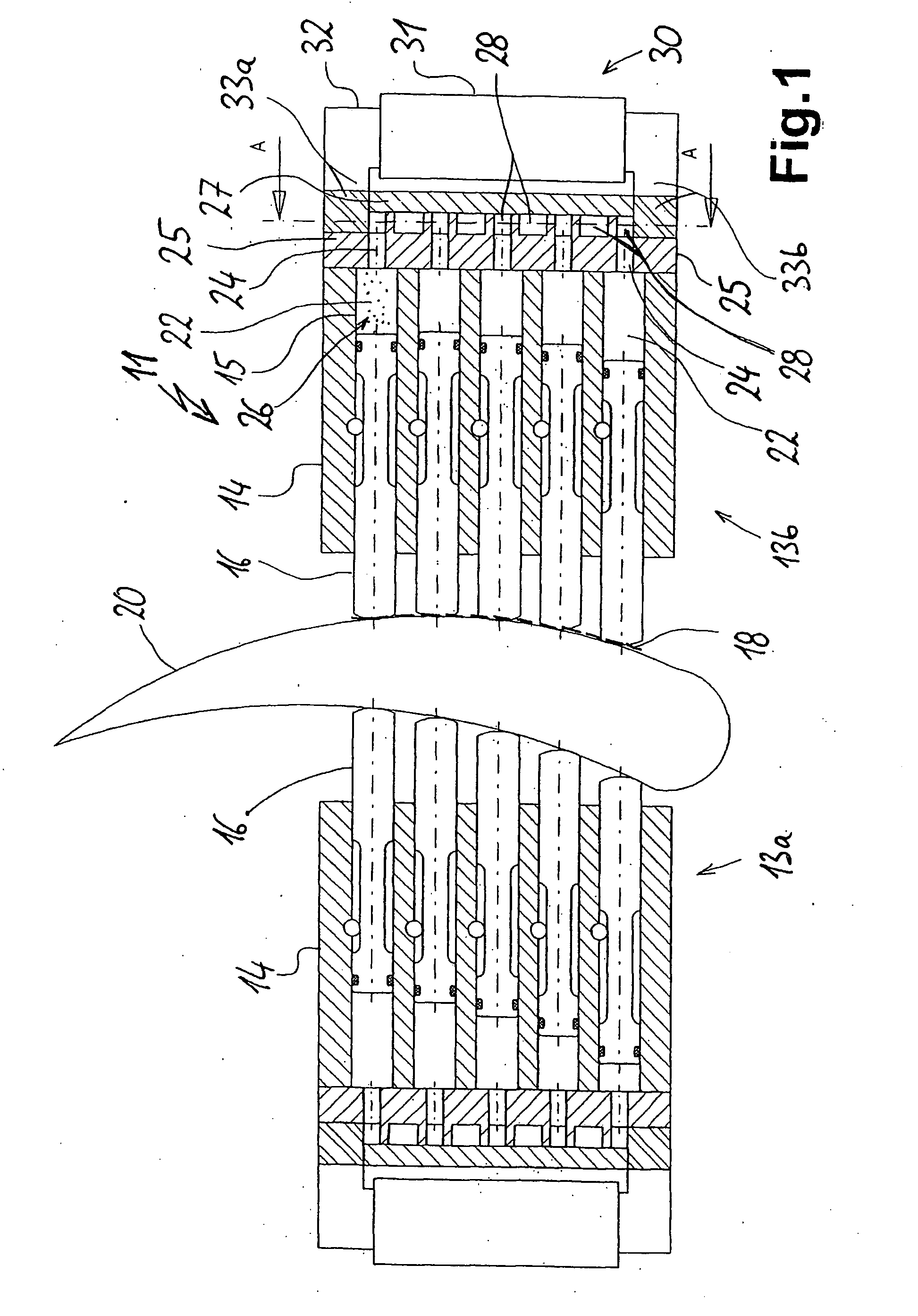

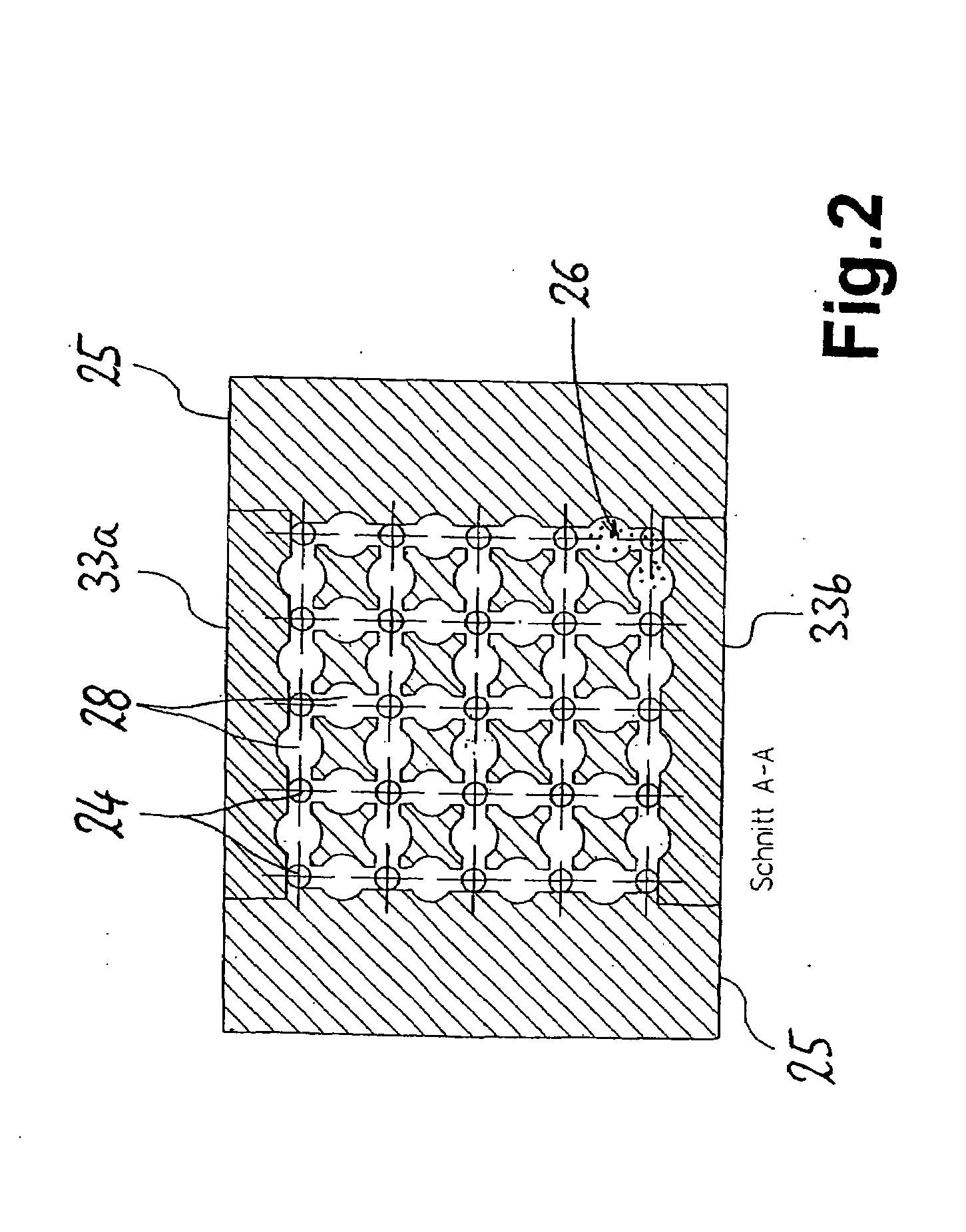

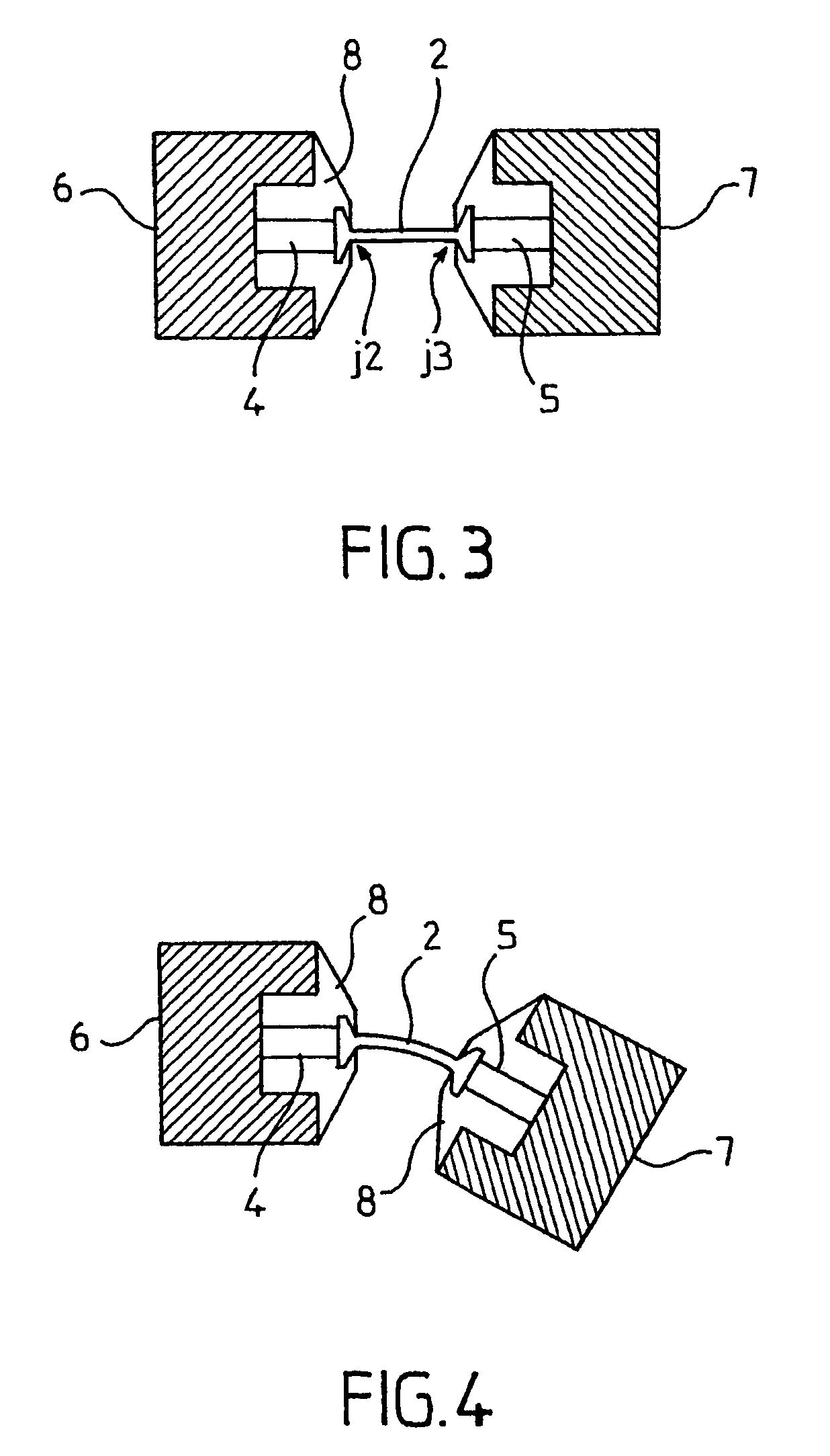

Clamping jaws and clamping device for clamping workpieces

InactiveUS20080157453A1Small sectionSimple electrical controlPositioning apparatusVicesMagnetorheological fluidBiomedical engineering

The invention relates to a clamping device (11) comprising clamping jaws (13) in which a plurality of clamping rods (16) are disposed. The clamping rods (16) are enabled to move by means of an interlinked system of rod chambers (22) and channels (24, 28) in which a magnetorheological fluid (26) is contained. If a magnetic field is applied by means of a magnet (30), the fluid solidifies, the liquid-carrying connection between the rod chambers (22) is interrupted and the rods (16) are fixed in a defined position.

Owner:HAINBUUFU GMBH SHUPANENDE TEHINIKU

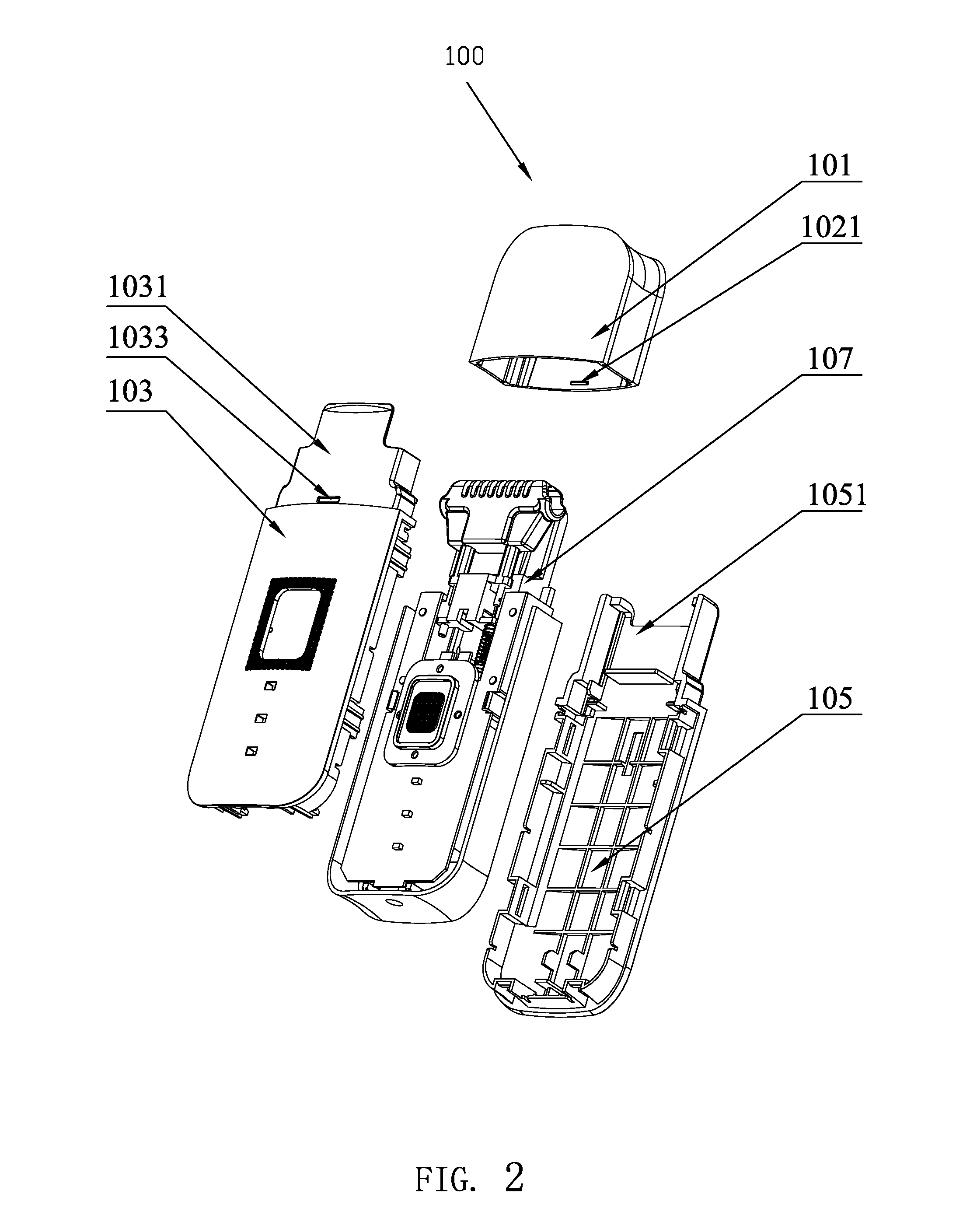

An Electrical Hair Removal Device and Control Method

InactiveUS20160166038A1Easy to disassembleHigh heating temperatureHair-singeingHeater elementsEngineeringRemoving hair

A control method for an electrical hair removal device, the electrical hair removal device including a heat generator having a heating wire formed thereon, including the steps of step S11: starting the electrical hair removal device and letting it go into a standby state; step S12: placing the heat generator on an hair removal needed area; and step S13: electrifying the heating wire to a predetermined temperature, for realizing hair removal with a constant heating temperature. An electrical hair removal device includes a main body and a cover for accommodating the main body. The main body has a heat generator having a heating wire thereon, a supporting element and a printed circuit board (PCB). The heating wire is electrically connected to the PCB, which is electrified and heated to a predetermined temperature, for realizing hair removal with a constant heating temperature.

Owner:405 LIMITED COMPANY SHENZHEN

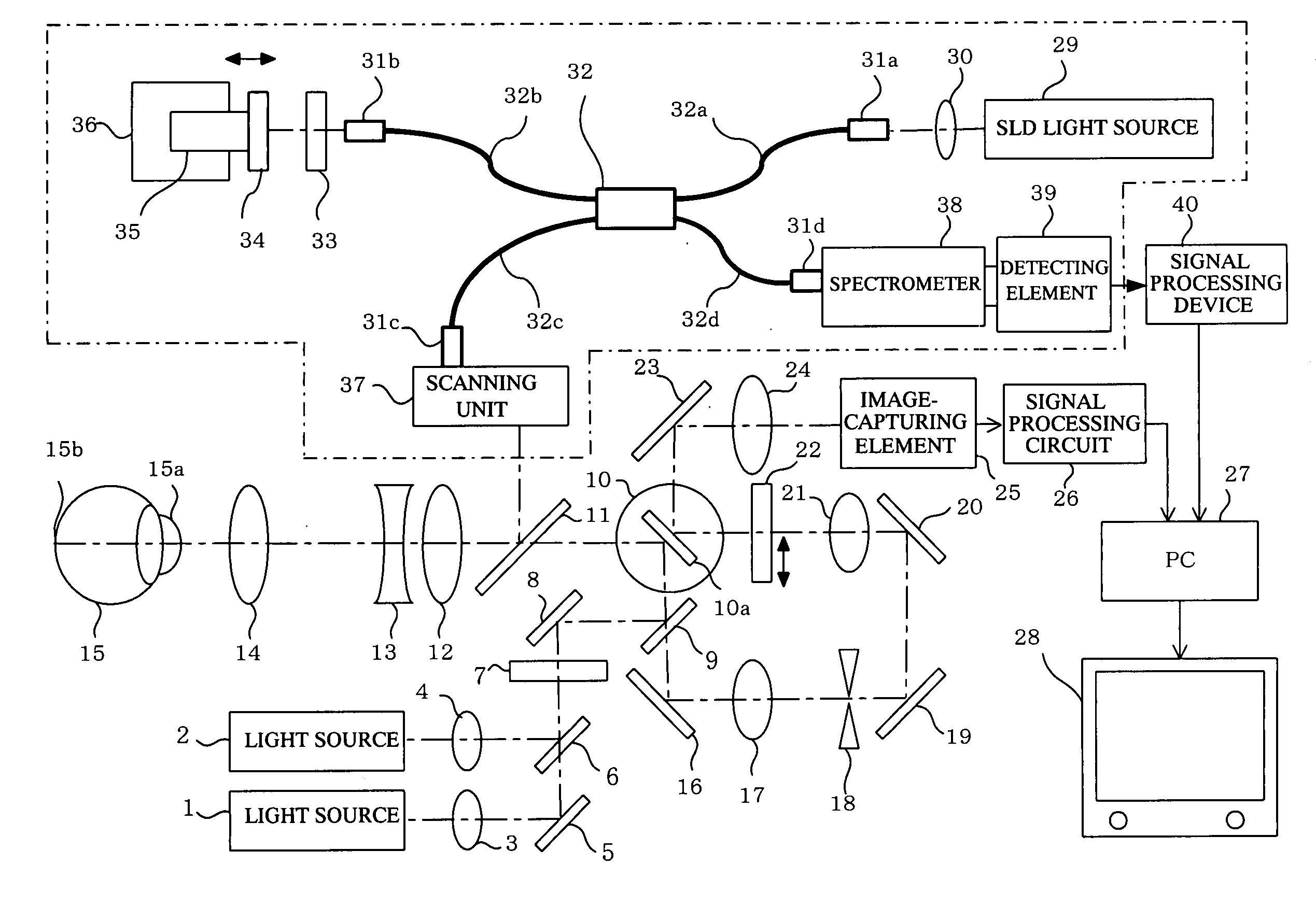

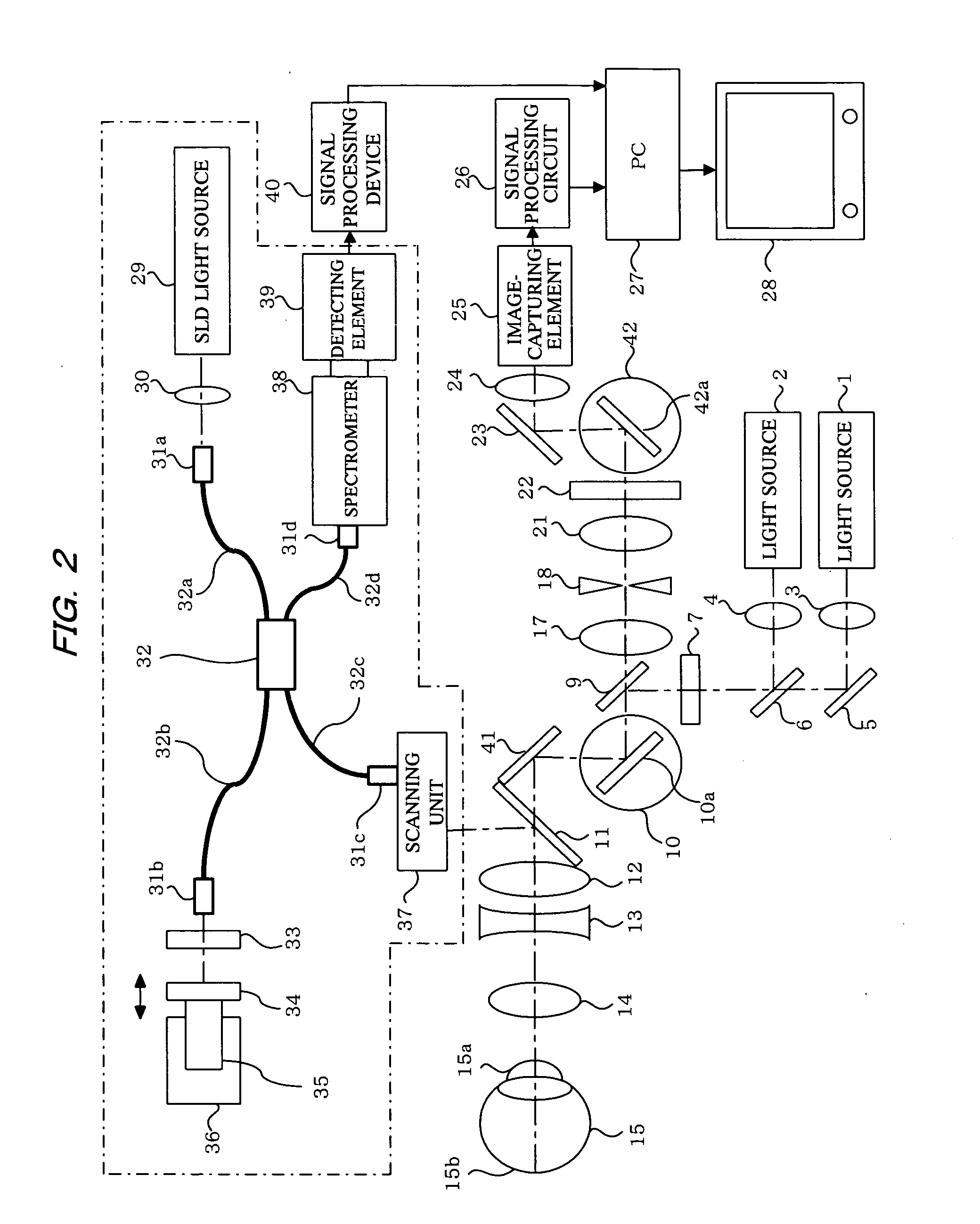

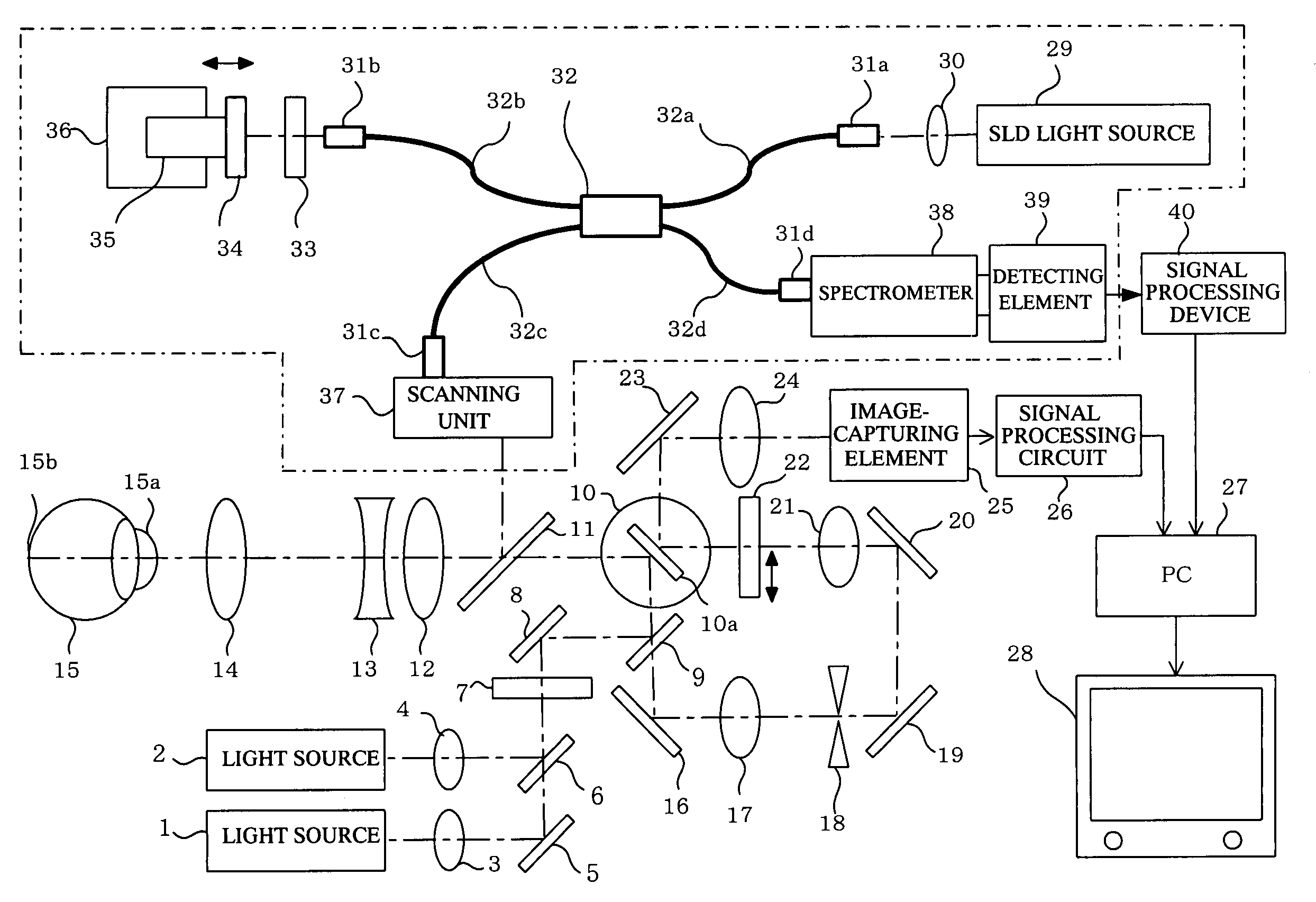

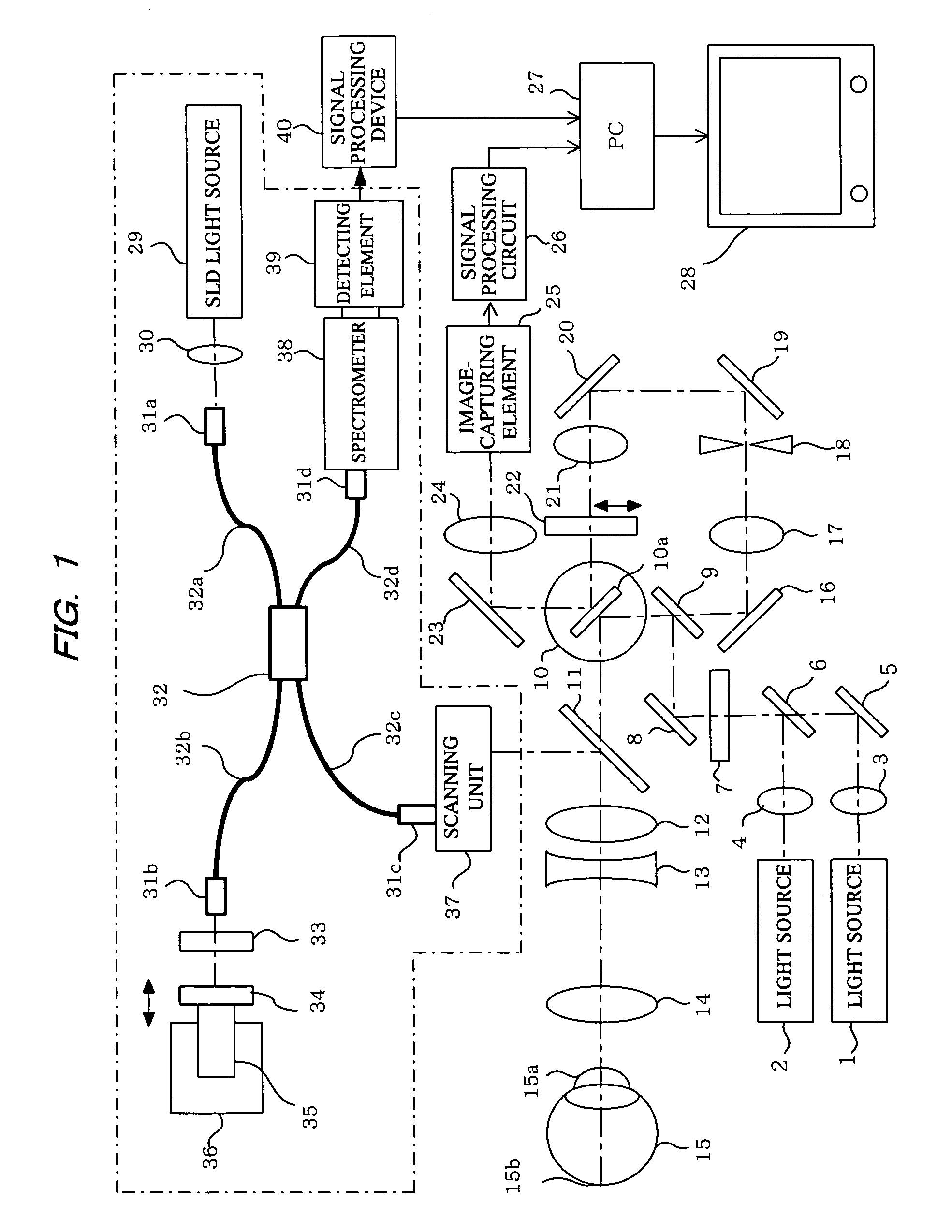

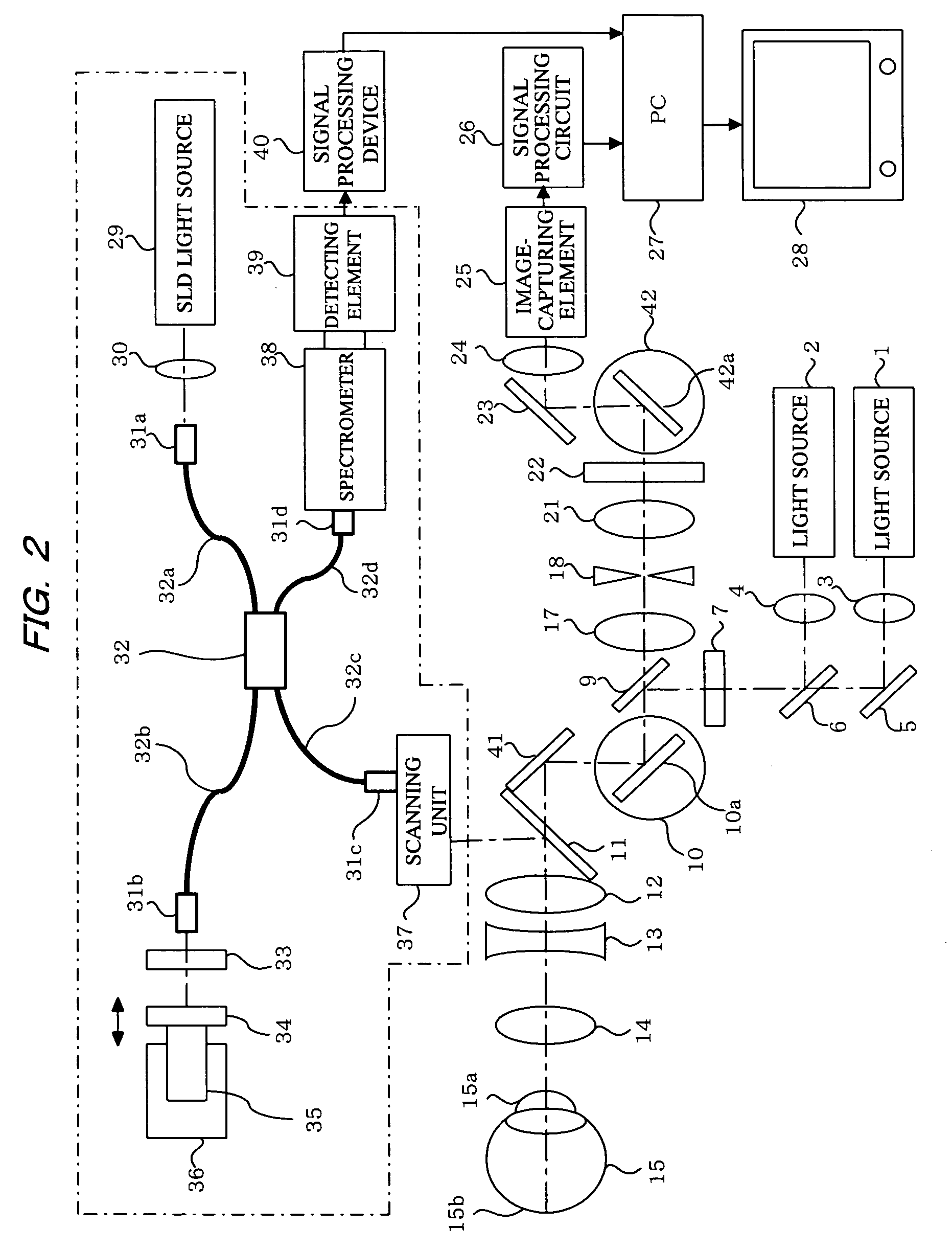

Optical image-capturing apparatus

InactiveUS20110273757A1Simple electrical controlIncrease contrastBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansDisplay deviceLight beam

Light beams from light sources 1, 2 are scanned by a galvano mirror 10a to illuminate a predetermined portion 15b of an object to be observed 15 via an objective lens 14. The reflected light from the object is re-scanned by the galvano mirror 10a to obtain a two-dimensional image via an image-capturing element 25. Measuring means composed of an OCT interferometer 32 is branched or coupled in the optical path between the objective lens 14 and the galvano mirror 10a to obtain a tomographic image of the object. In this configuration, the two-dimensional image and the tomographic image of the object can be displayed simultaneously on a display device 28.

Owner:KOWA CO LTD

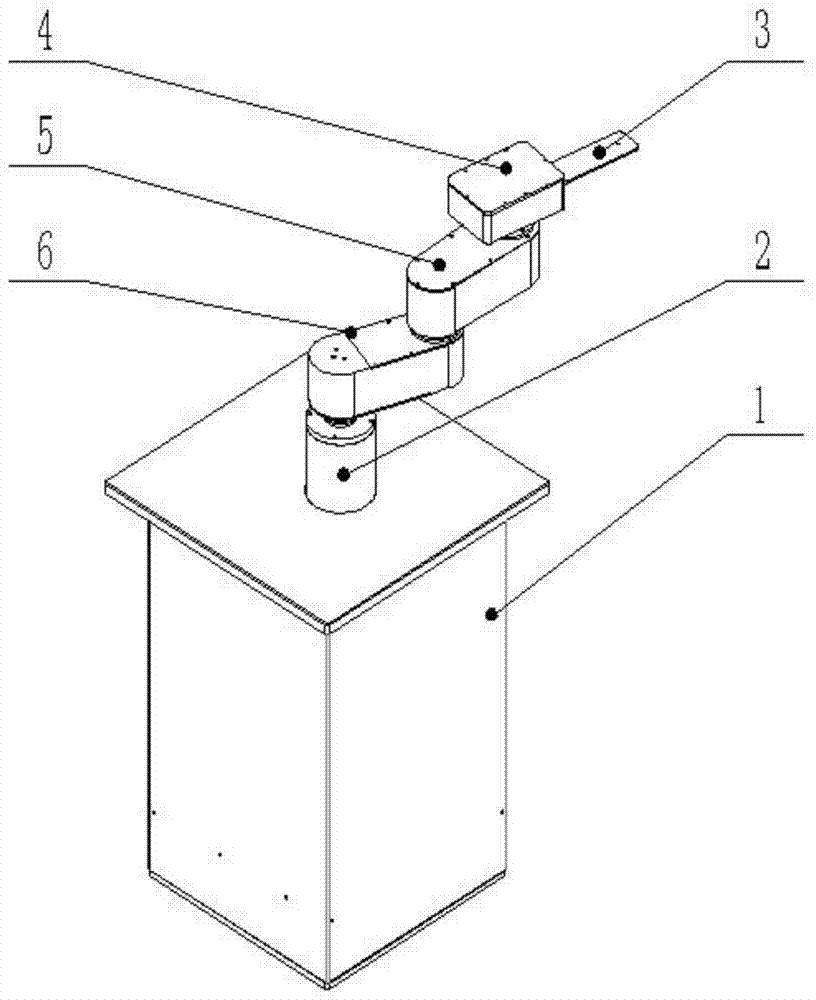

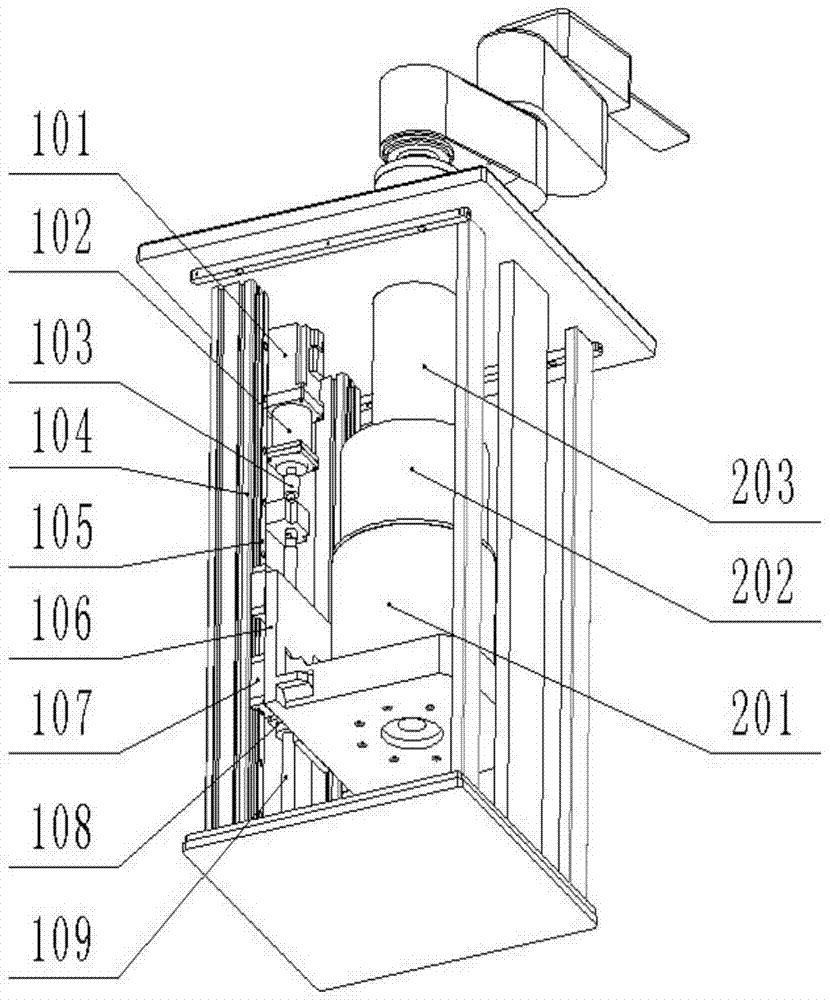

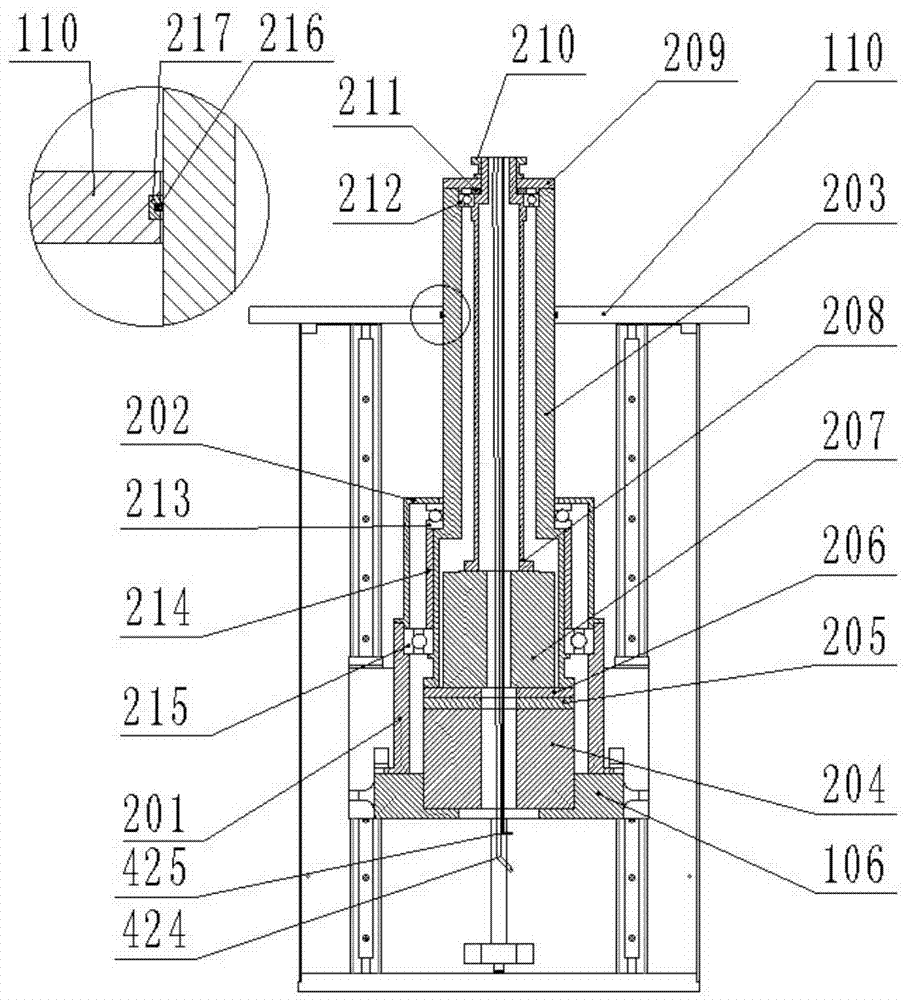

Direct drive type reversible wafer transmission robot

ActiveCN104723332AHigh transmission precisionImprove transmission efficiencyProgramme-controlled manipulatorConveyor partsDegrees of freedomEngineering

The invention discloses a direct drive type reversible wafer transmission robot. A lifting and dropping and swing mechanism is installed on the inner portion of a base seat, the lifting and dropping and swing mechanism is connected with one end of a big arm, the other end of the big arm is connected with one end of a small arm, the other end of the small arm is connected with one end of a reverse wrist, and the other end of the reverse wrist is connected with a vacuum adsorption tail end. When the wafer transmission robot moves, a three-connection rod which composed of the big arm, the small arm and the reverse wrist fixes a specific speed movement, and a straight line expansion movement in the radial direction is achieved; a motor is used for driving the vacuum adsorption tail end, so that a reverse movement of the reverse wrist is achieved; by the adoption of the direct drive motor to drive directly, an interior structure of the robot is simplified, the number of intermediate links is reduced, and the rotating precision and the rotating efficiency of the robot are improved. Due to fewer part mechanisms, the robot is convenient to assemble and produce. A steel belt is used rotatably, so that the rotating precision is provided, the reliability of the robot is enhanced, the production of contaminant particles is lowered, and the level of cleanliness of the robot is improved. The degree of freedom of reversing of the robot is increased by the reverse wrist, and the range of application of the robot is enlarged.

Owner:BEIJING UNIV OF TECH

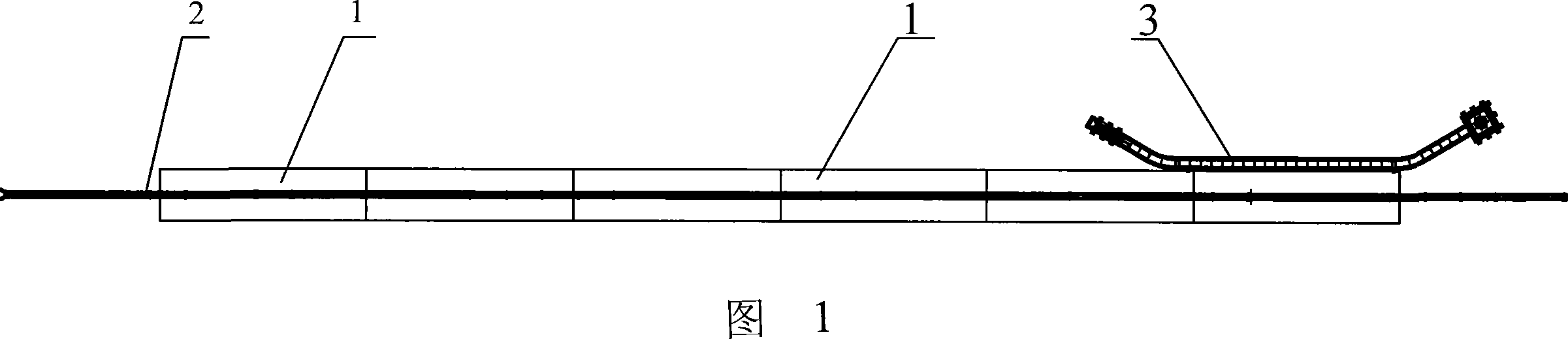

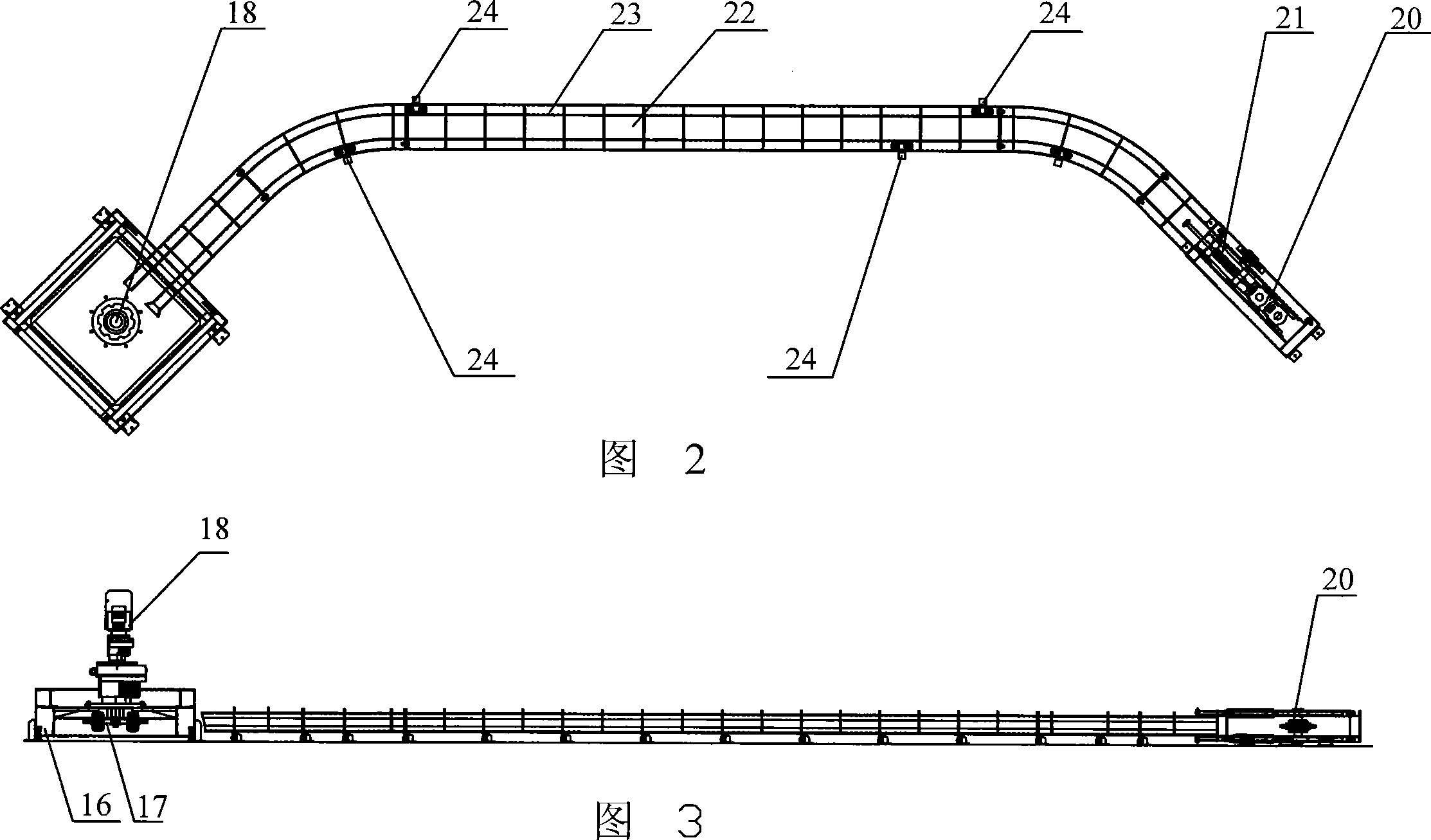

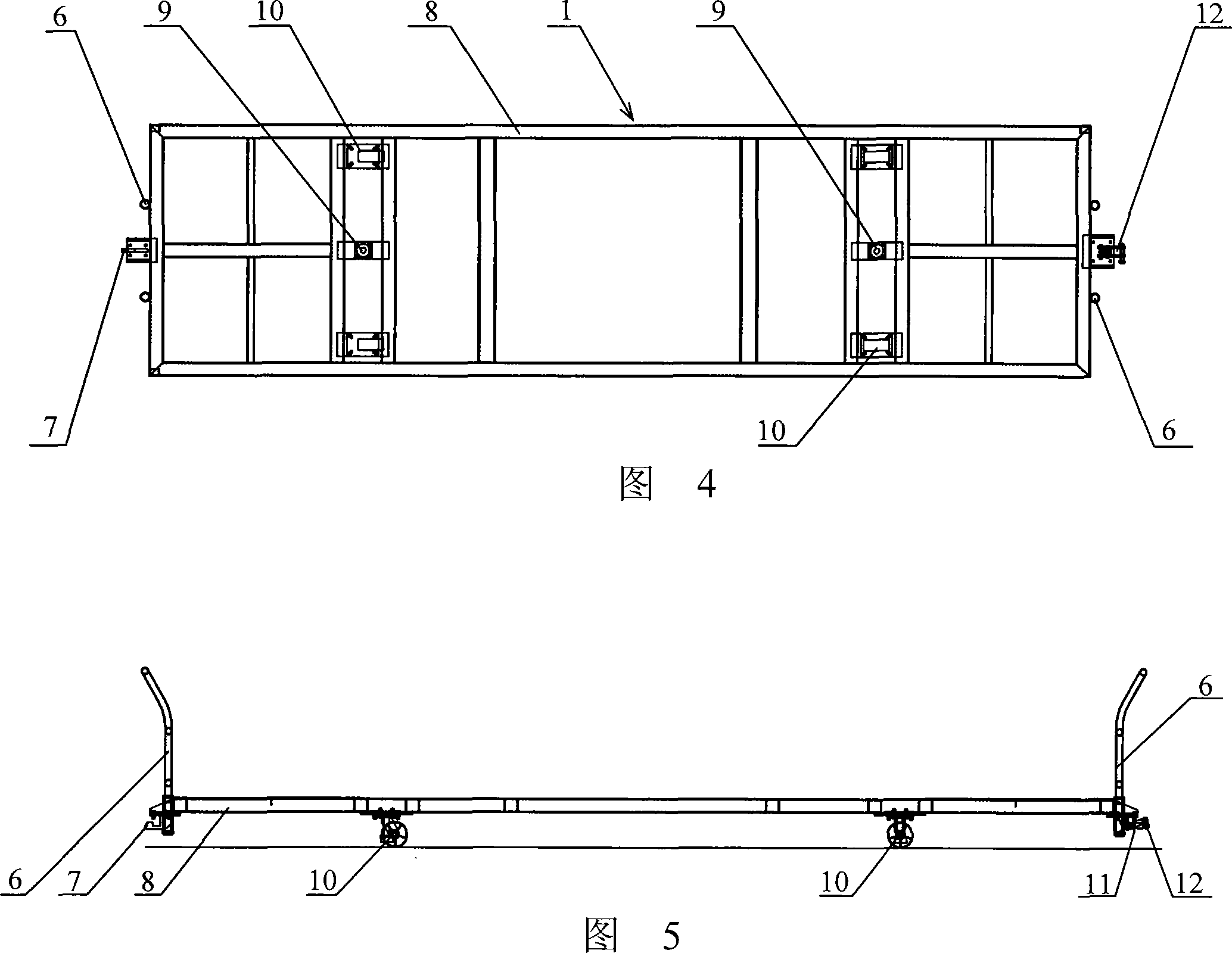

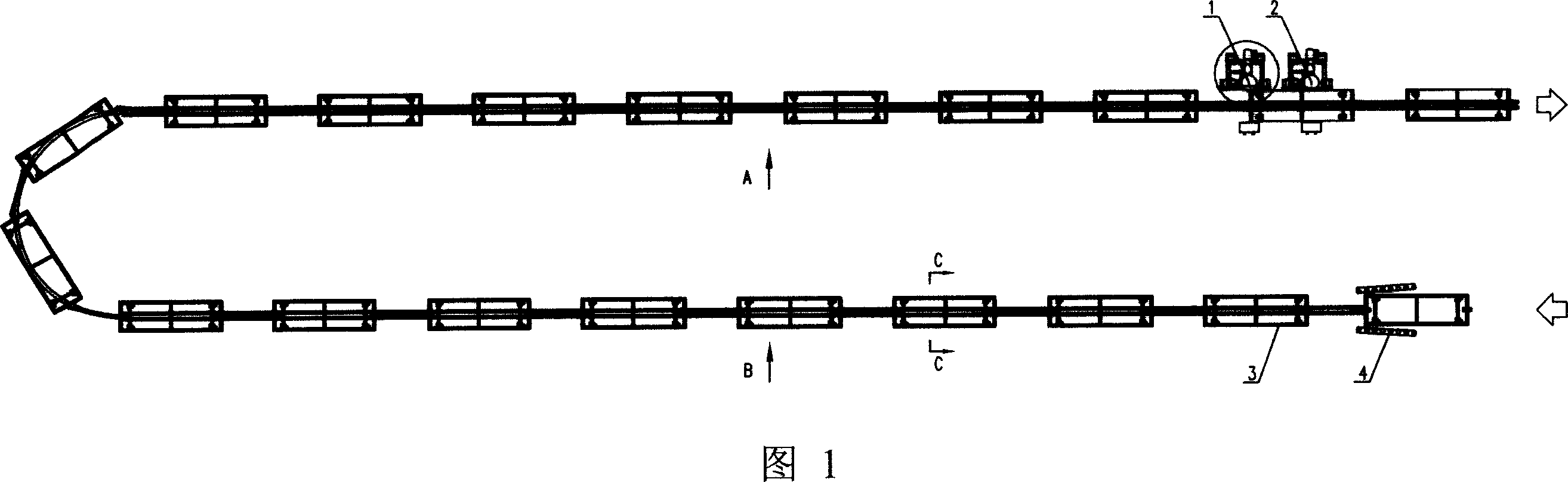

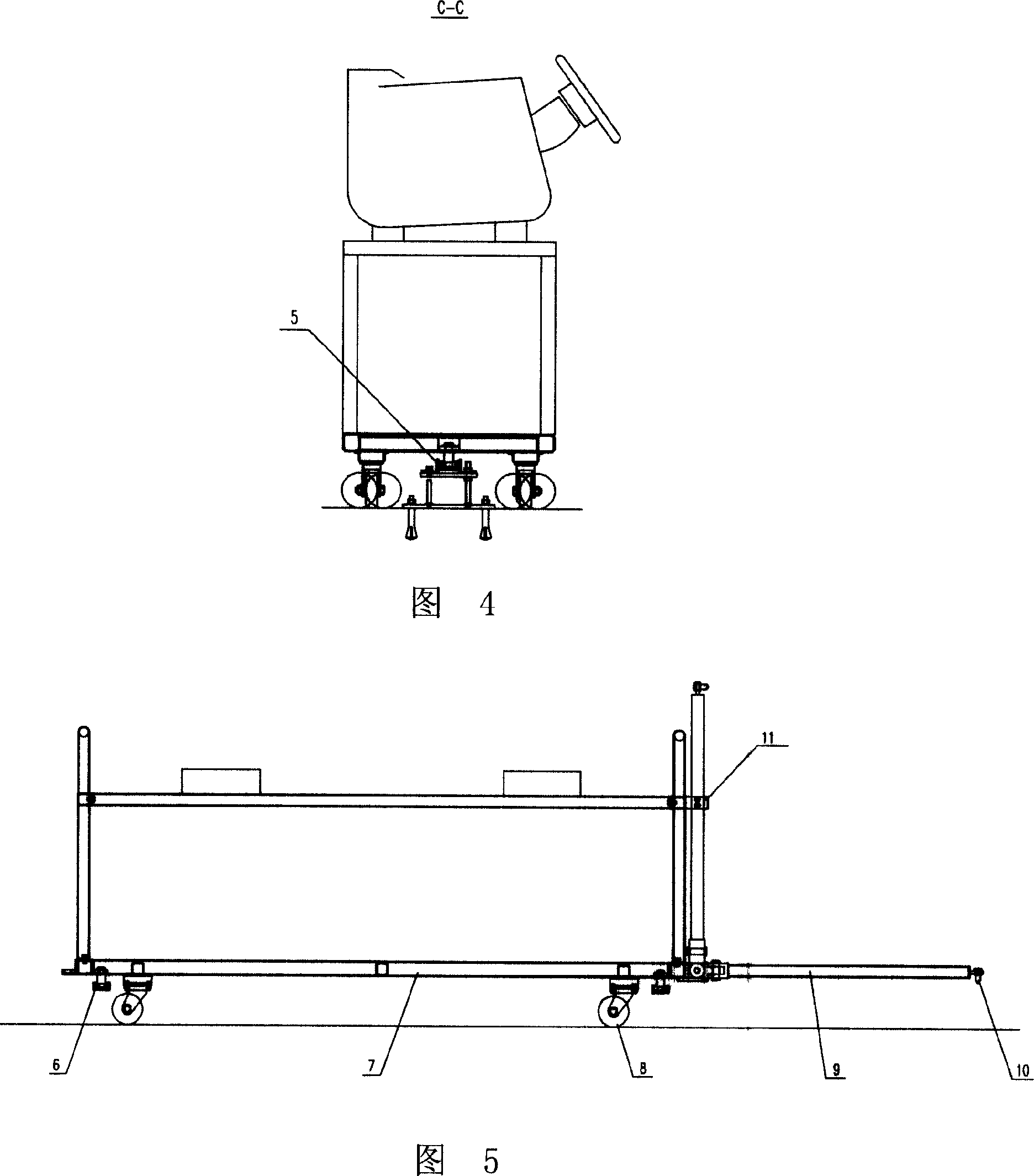

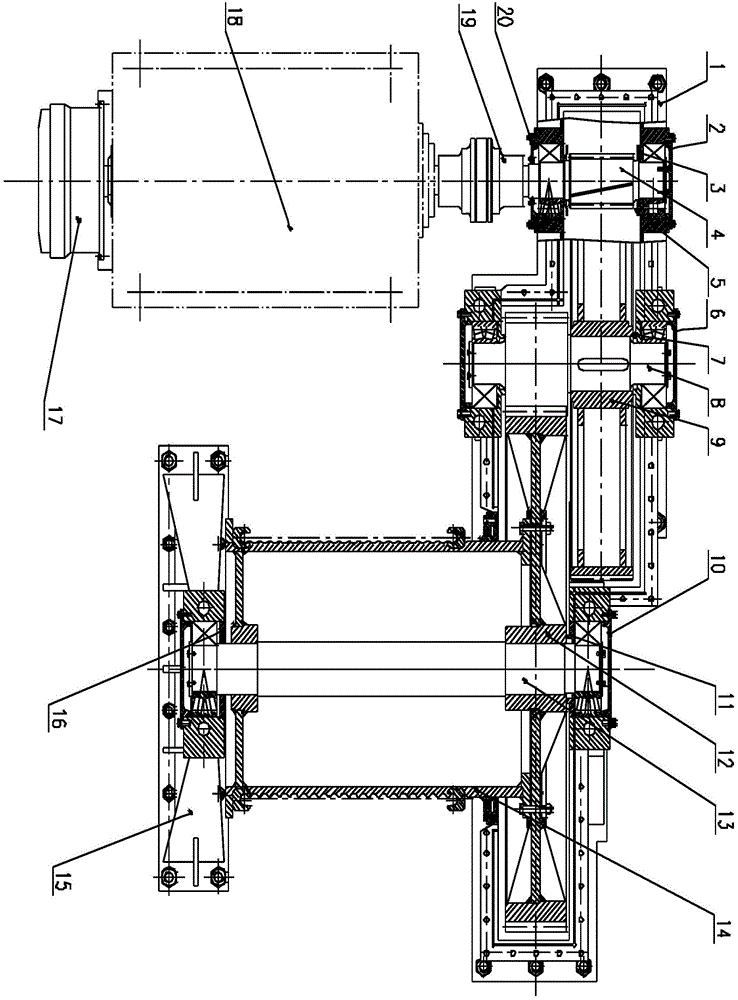

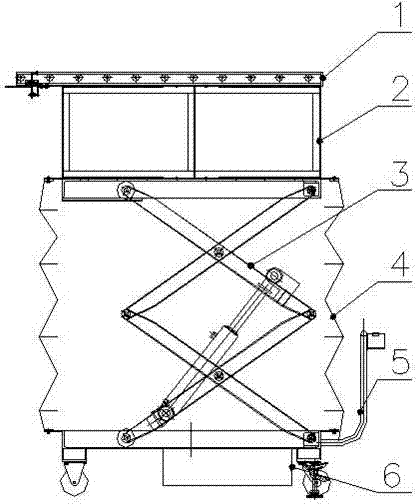

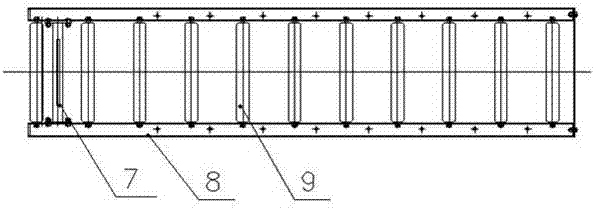

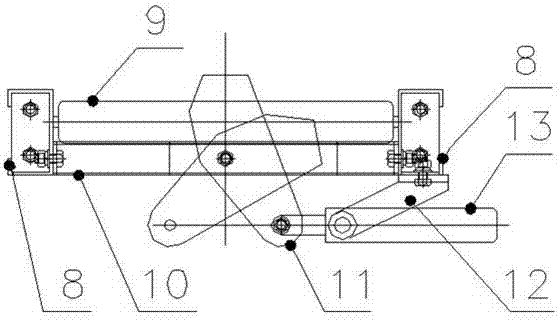

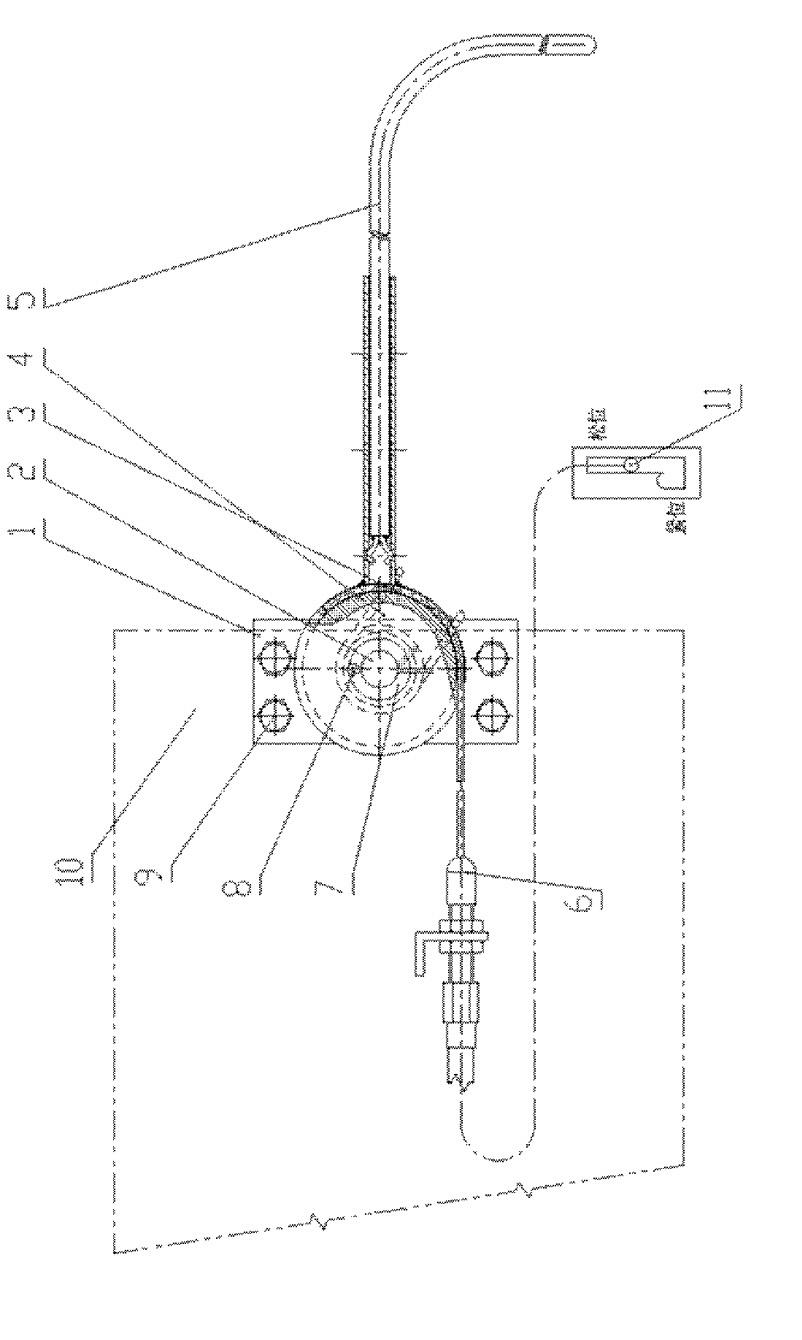

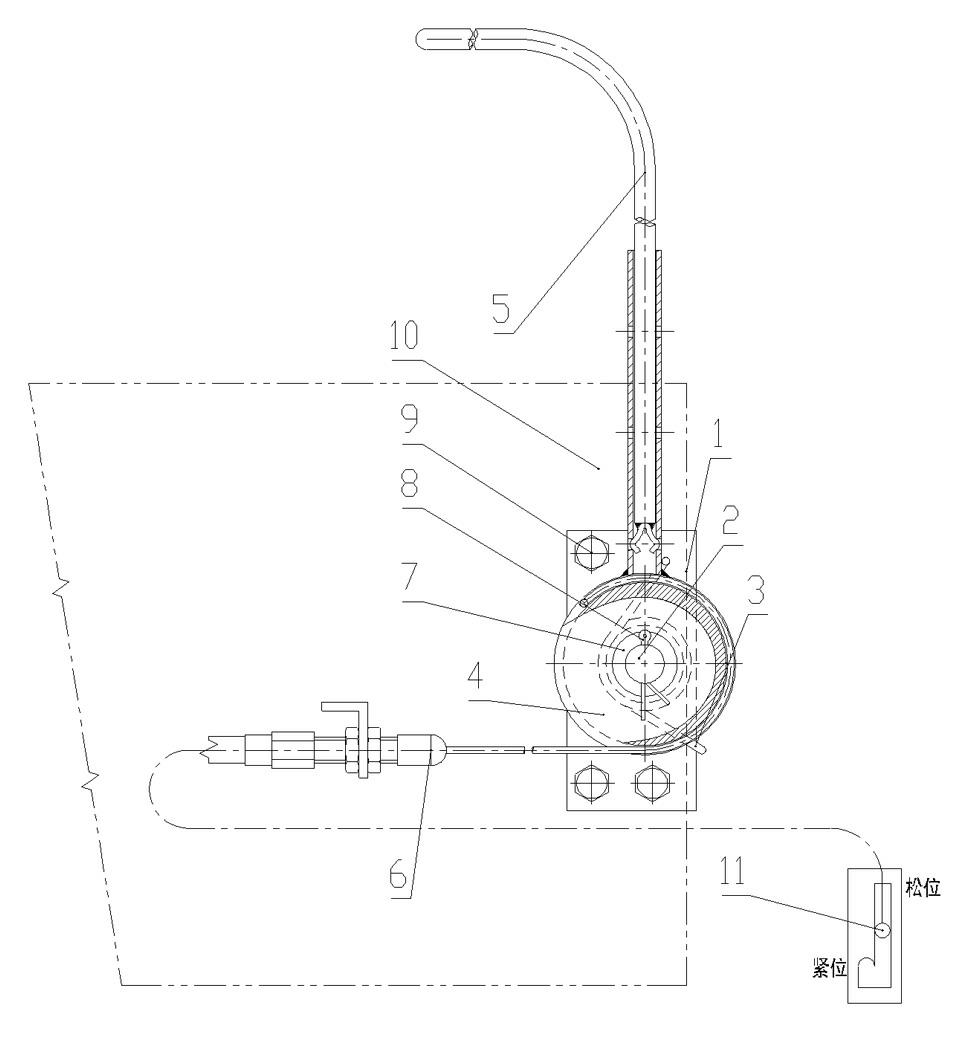

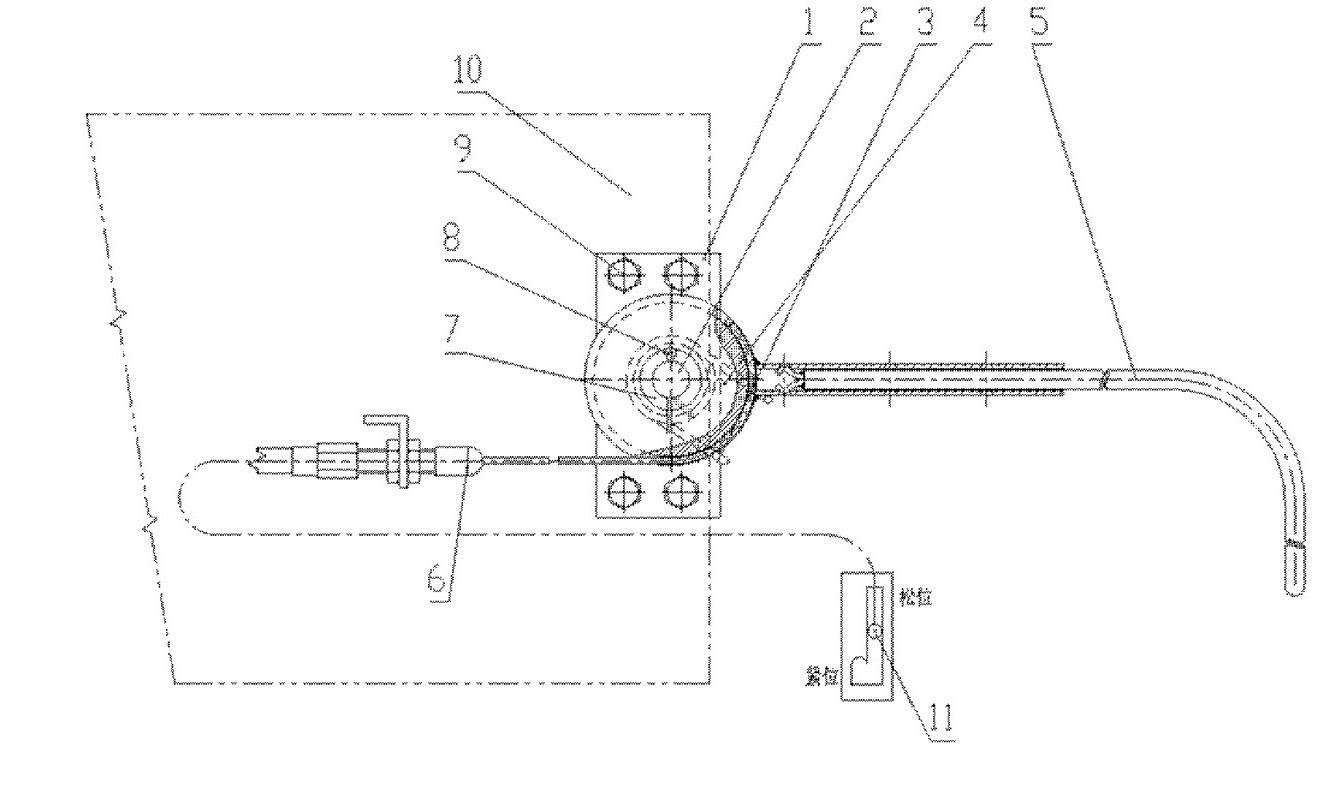

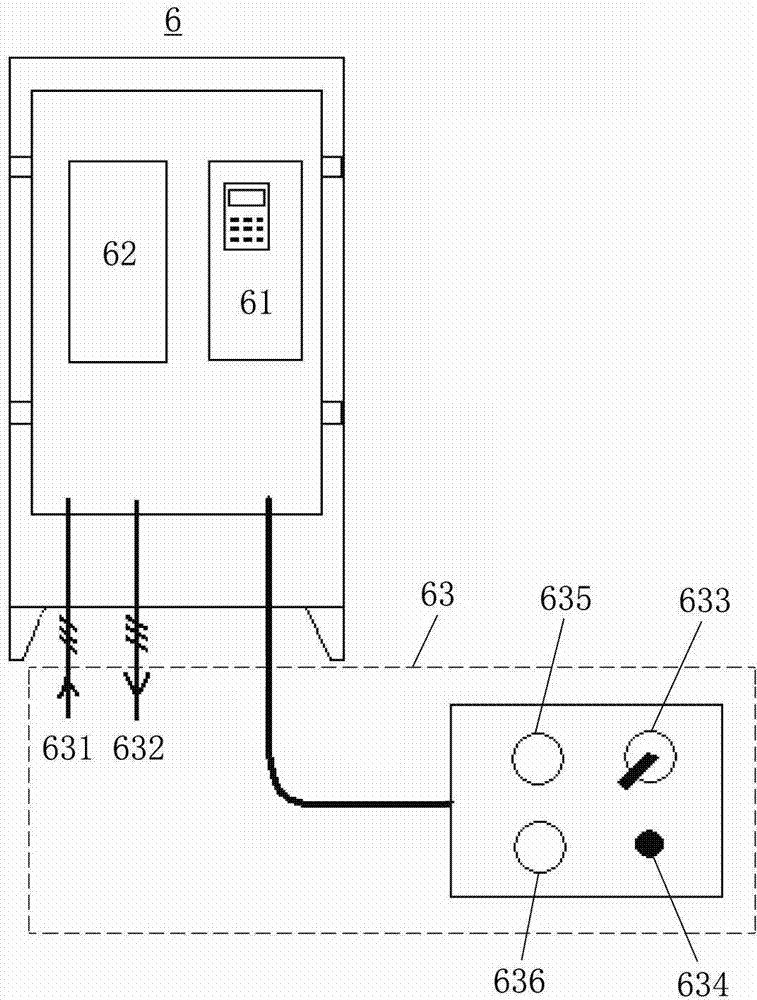

Unitization bogie chain side-pulling delivery system

InactiveCN101100240ASimple structureSimple electrical controlMechanical conveyorsBogieRolling resistance

The present invention is one kind of independent complete ground conveying apparatus with conveying chain to push tracked bogies from lateral side. According to the technological scheme of the present invention, there are conveying bogies with guide device set in the conveying direction, one driving chain and driving unit set inside the driving track in the lateral side of the conveying bogies, and one side push unit in the lateral side of the driving chain and the conveying bogies. The ground conveying apparatus has guide track with no load bearing, small rolling frictional resistance between the guide roller and the track and high conveying efficiency, and possesses compact structure, easy installation and maintenance, low cost, simple electric control and long service life.

Owner:MIRACLE AUTOMATION ENG CO LTD

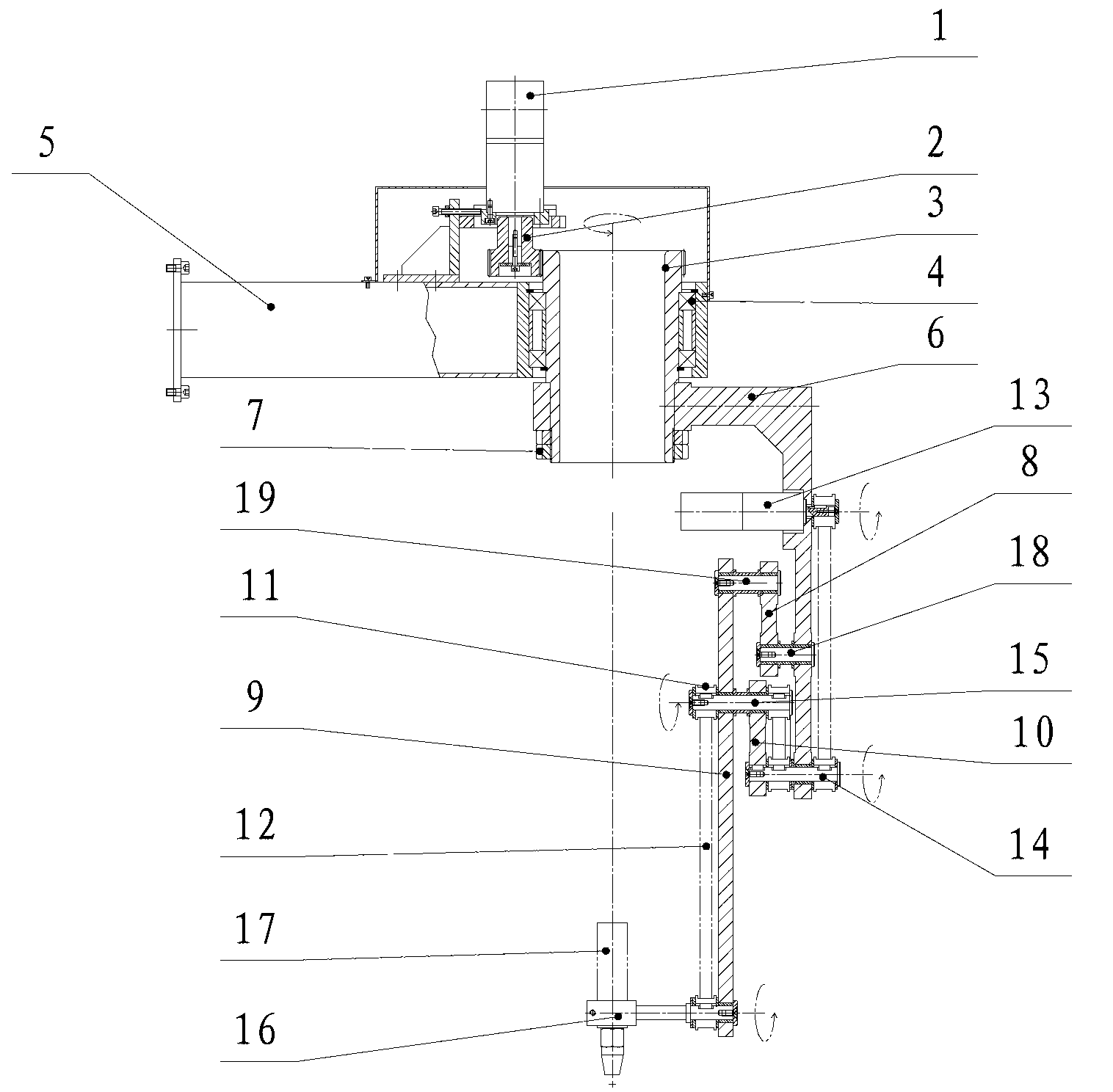

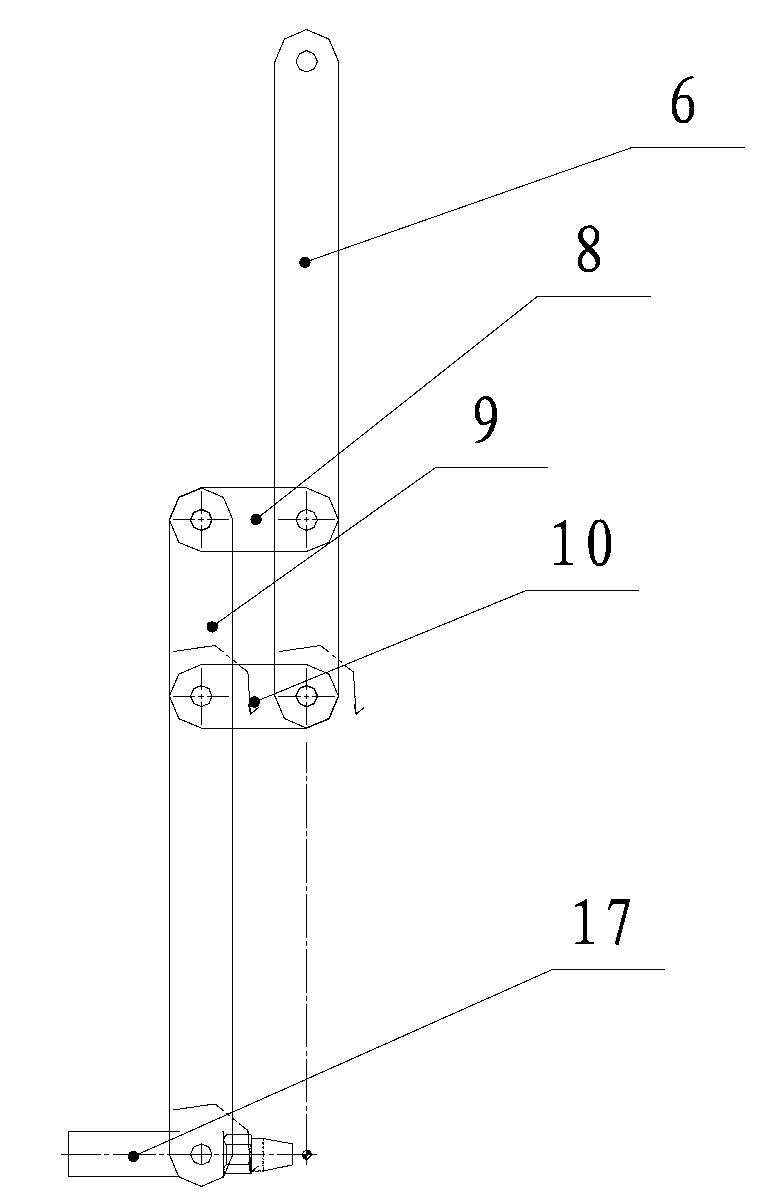

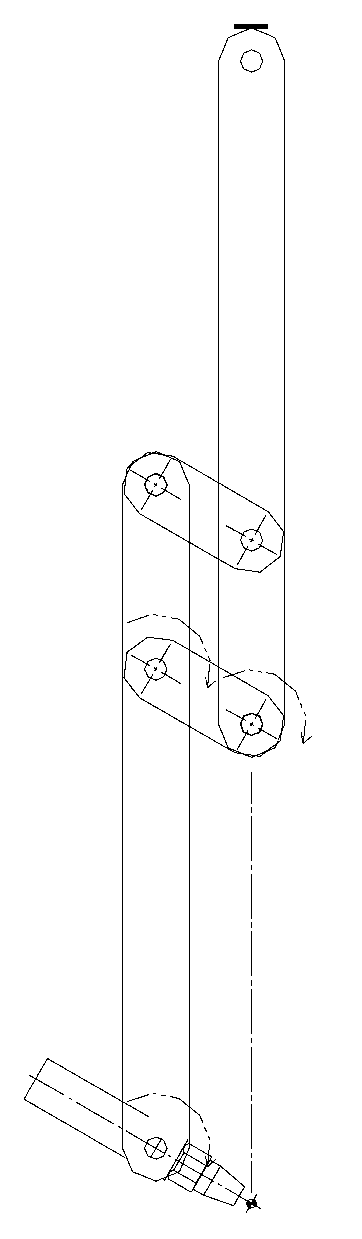

Vertical-type and connecting-rod-type intersecting line cutting head

ActiveCN103157933ASimple electrical controlLess programming effortWelding/cutting auxillary devicesAuxillary welding devicesElectrical controlEngineering

The invention discloses a vertical-type and connecting-rod-type intersecting line cutting head which comprises a main arm, a driven gear shaft and a pivot angle assembly installed on the driven gear shaft. The driven gear shaft is installed on the main arm through a bearing; a rotating speed reduction motor is installed on the main arm. A driving gear installed on the rotating speed reduction motor is meshed with a driven gear installed on the driven gear shaft to drive the driven gear shaft to rotate. A frame is fixed installed on the lower portion of the driven gear shaft through a round nut. The pivot angle assembly is installed on the frame. + / -90 degrees of an accurate pivot angle of a cutting torch is achieved through a four-connecting-rod mechanism of the pivot angle assembly. Mechanism motion needed by pipe cutting can be achieved through the combination of a rotating mechanism and the pivot angle assembly. The vertical-type and connecting-rod-type intersecting line cutting head guarantees a constant height position of a cutting point in the lifting process of the pipe; and because only a rotating shaft and a pivot angle shaft are linked, electrical control is relatively simple and programming workloads are substantially reduced.

Owner:南京奥特自动化有限公司

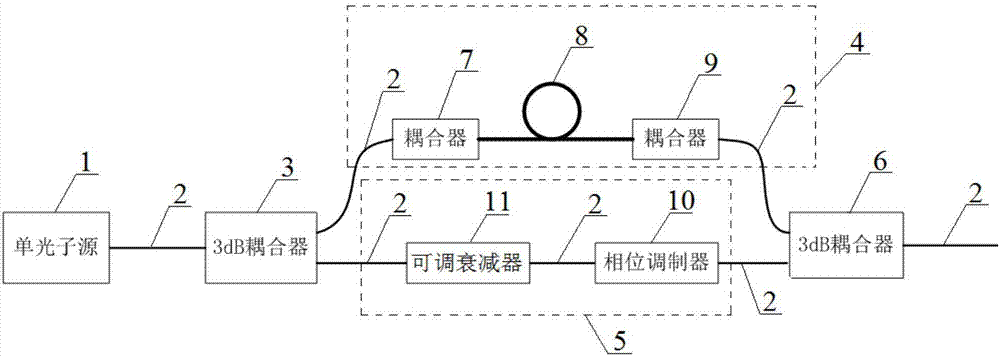

Phase encoding device based on silicon substrate integrated waveguide

PendingCN107204813AImproving Qubit Generation EfficiencyLow loss characteristicCoupling light guidesElectromagnetic transmission optical aspectsEngineeringWaveguide

The invention discloses a phase encoding device based on a silicon substrate integrated waveguide. A single photon emission source is connected with the input end of a front-end coupler through a silicon waveguide; both a long-arm waveguide unit and a short-arm waveguide unit are connected to the output end of the front-end coupler; one rear-end coupler is connected to each of the output end of the long-arm waveguide unit and the output end of the short-arm waveguide unit; the long-arm waveguide unit comprises a first coupler, a delay waveguide and a second coupler; the first coupler is connected with the output end of the front-end coupler through the silicon waveguide and connected with the second coupler through the delay waveguide; the second coupler is connected with the input end of the rear-end coupler through the silicon waveguide; the silicon waveguide and the delay waveguide are produced on a silicon substrate. Compared with the prior art, the phase encoding device disclosed by the invention has the advantages that a long-arm delay part of an interferometer is realized by adopting a delay waveguide; the delay waveguide has the characteristic of low loss; the problem that an ordinary silicon waveguide has great loss in delay is solved, and the quantum bit generating efficiency of the encoding device is improved to a certain degree.

Owner:ZHEJIANG QUANTUM TECH CO LTD

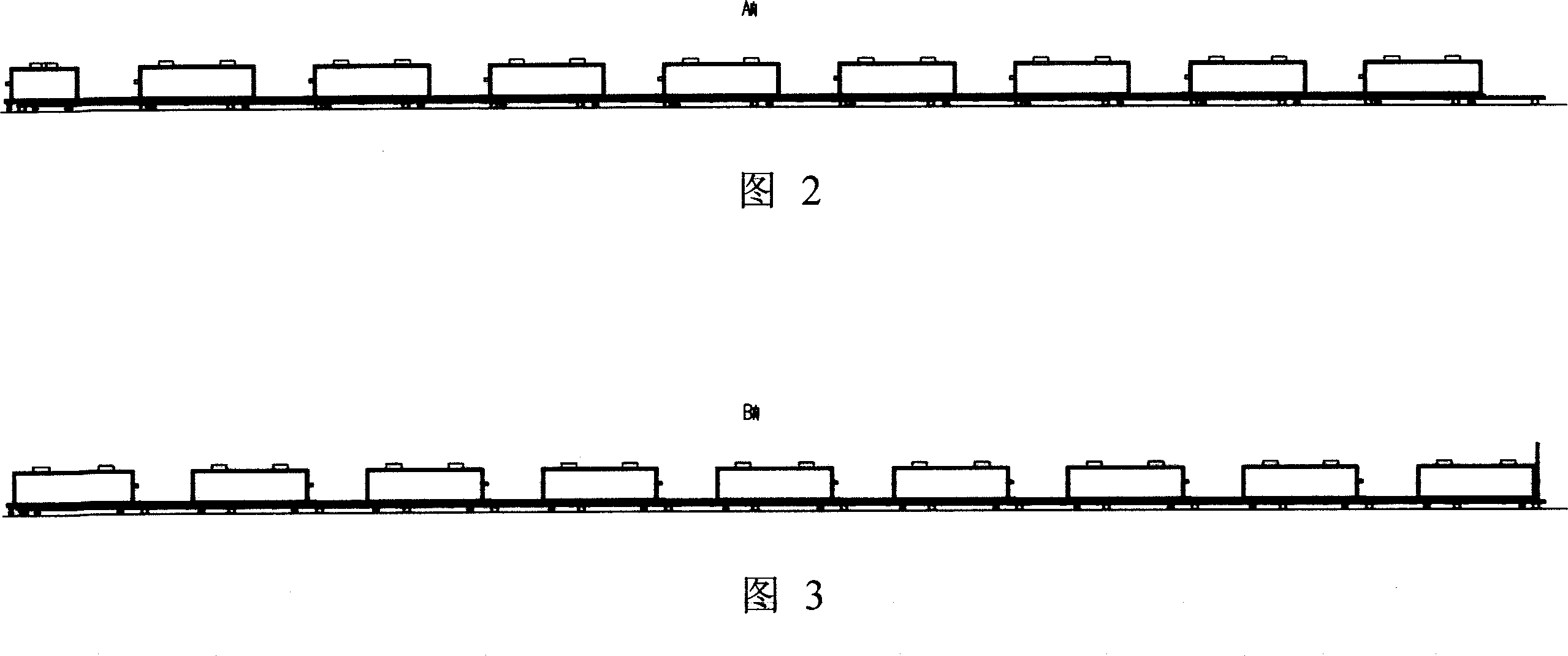

Frictional conveying system with grouped bogies

The present invention relates to frictional conveying system with grouped bogies, belongs to the field of conveying apparatus technology, and is especially one independent complete simple annular ground conveying system. The conveying system includes mainly two friction driving mechanisms set beside tracks, conveying bogies, one guide device to guide the running of the conveying bogies in the tracks, and connecting rods to connect the conveying bogies integrally. The present invention has compact structure, precise synchronous conveying, high conveying efficiency, long service life and other advantages.

Owner:MIRACLE AUTOMATION ENG CO LTD

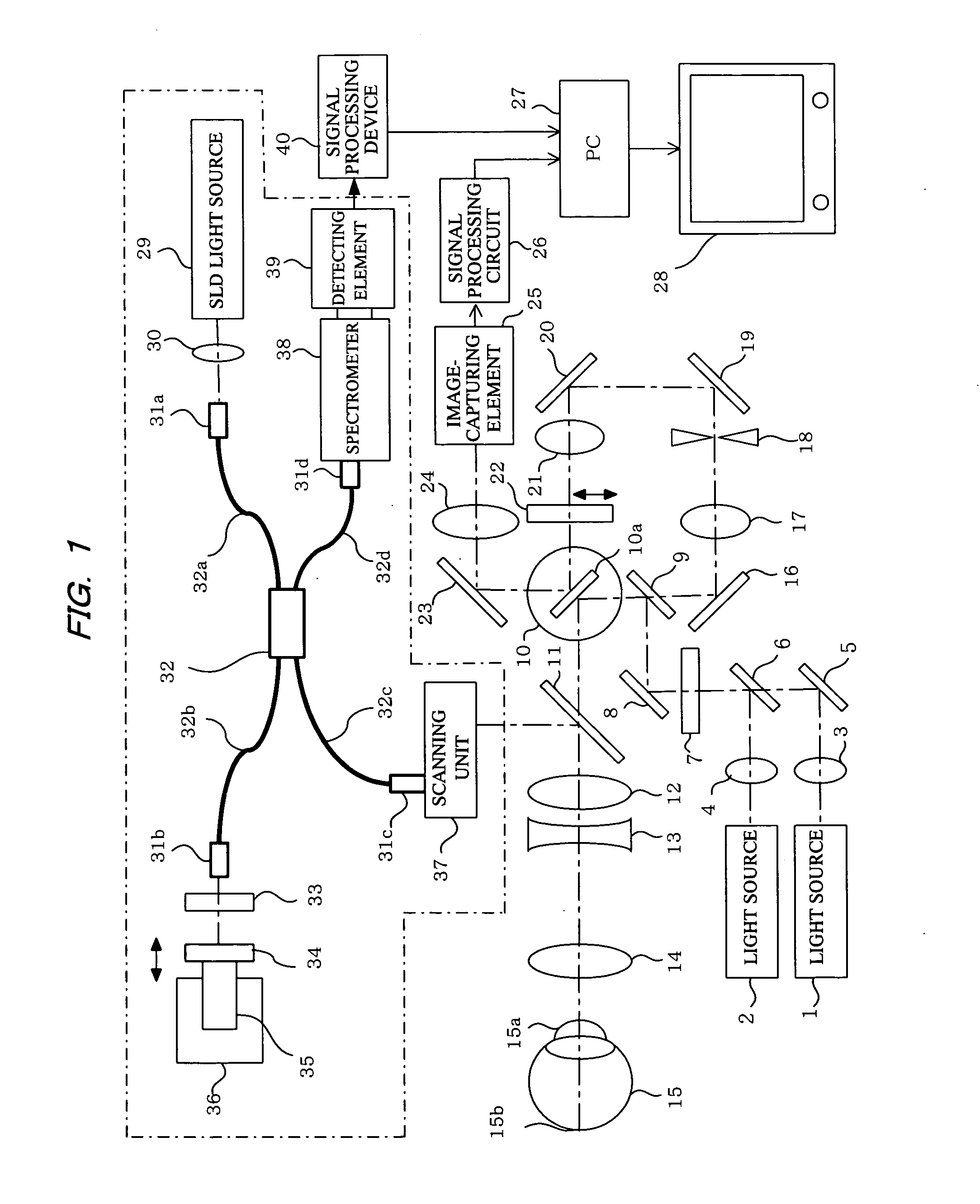

Optical image-capturing apparatus

InactiveUS8238012B2Scanning confocal optical system can be simplifiedSimple electrical controlBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansLight beamDisplay device

Light beams from light sources 1, 2 are scanned by a galvano mirror 10a to illuminate a predetermined portion 15b of an object to be observed 15 via an objective lens 14. The reflected light from the object is re-scanned by the galvano mirror 10a to obtain a two-dimensional image via an image-capturing element 25. Measuring means composed of an OCT interferometer 32 is branched or coupled in the optical path between the objective lens 14 and the galvano mirror 10a to obtain a tomographic image of the object. In this configuration, the two-dimensional image and the tomographic image of the object can be displayed simultaneously on a display device 28.

Owner:KOWA CO LTD

Mining excavator lifting mechanism

The invention relates to a lifting mechanism and belongs to the field of engineering equipment, in particular to a mining excavator lifting mechanism. The mining excavator lifting mechanism comprises a primary speed reduction drive mechanism, a secondary speed reduction drive mechanism and a motor, the non-load end of the motor is provided with a brake, and the load end is connected with the primary speed reduction drive mechanism through a coupling. Because the mining excavator lifting mechanism uses a single-motor single-winding drum structure and two hoisting ropes, the diameter of each hoisting rope is small, the diameter of the lifting winding drum is small, the drive ratio is reduced, the whole mechanism is simple in structure, light in weight, small in volume, less in drive piece number and small in processing and assembly workload, and the manufacturing cost is greatly lowered.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

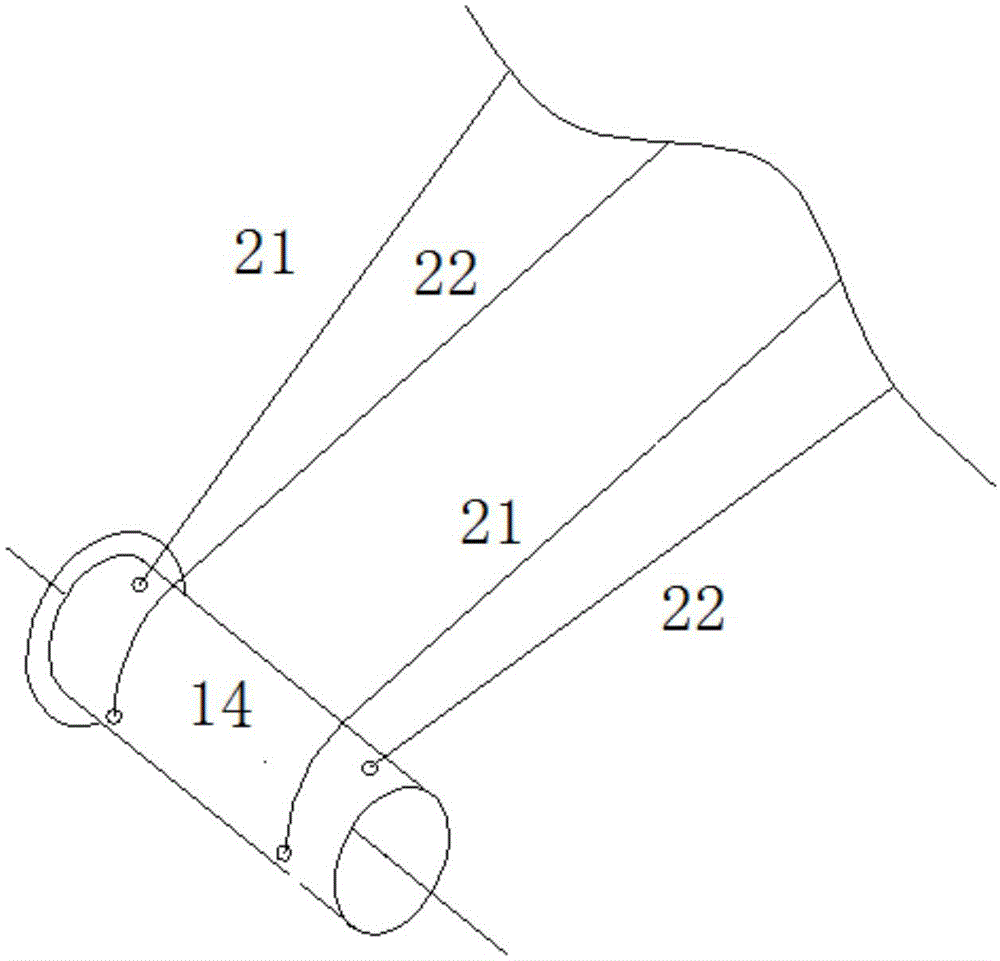

Control method, equipment, system and crane of dynamic arm pulling pin of single-cylinder bolt-type telescopic arm

The invention discloses a control method, equipment, a system, and a crane of a dynamic arm pulling pin of a single-cylinder bolt-type telescopic arm. The equipment comprises a receiving device for receiving a forwarding signal of the cylinder pine of a telescopic oil cylinder and / or length of a telescopic oil cylinder, and a control device. The control device starts to pull the arm pin and continues to pull out a telescopic oil cylinder so as to pull out the arm pin after receiving a forwarding signal and / or the length of the telescopic oil cylinder is equal to the corresponding length of a front position. The provided equipment can dynamically pull out an arm pin during the process when an oil cylinder is pulled out, the oil cylinder does not need to be stayed on a predetermined position for the arm pin pulling operation, the electric control is simplified, the continuity of oil cylinder pulling-out improved, thus the work efficiency is improved, and the service life of arm pin is prolonged.

Owner:ZOOMLION HEAVY IND CO LTD

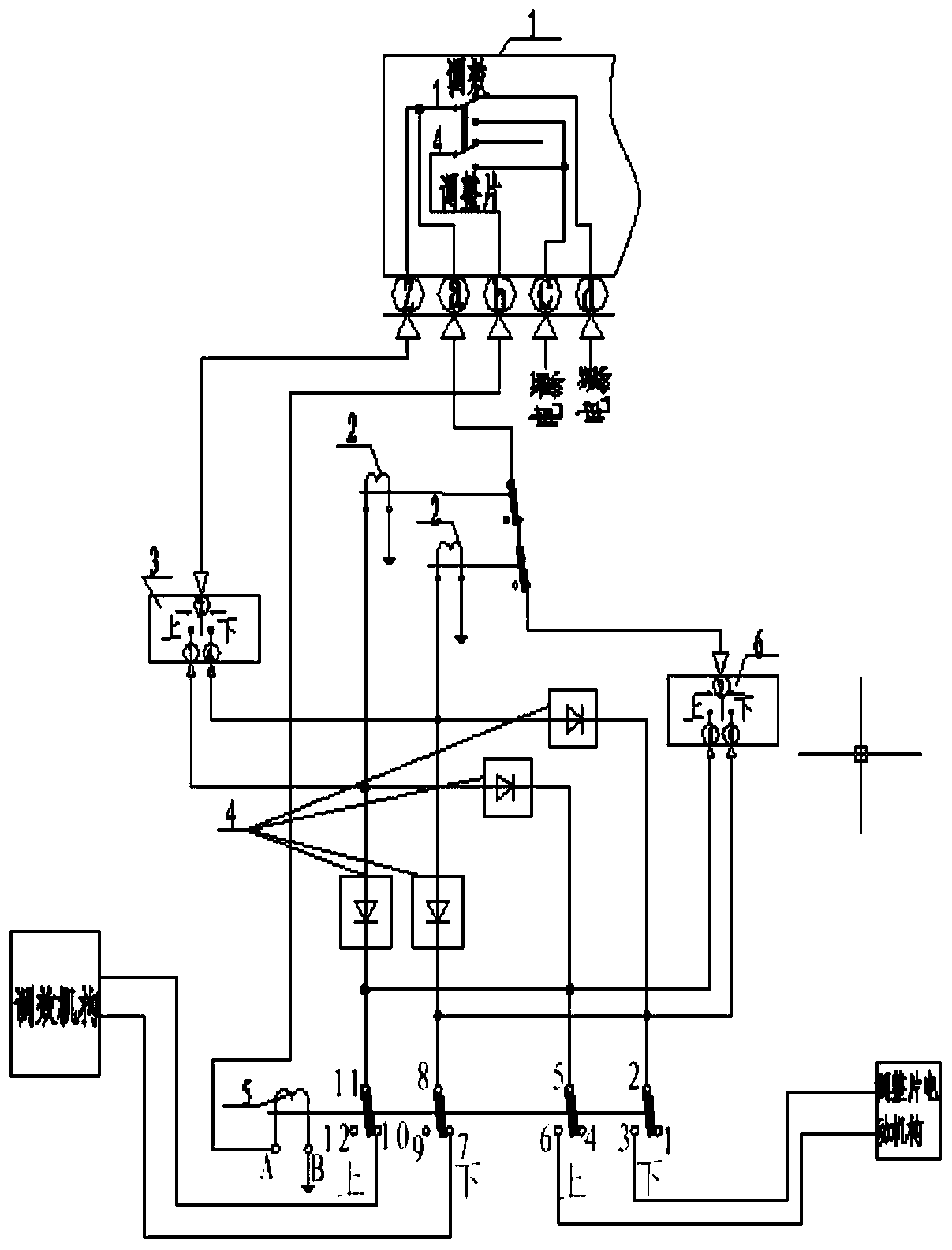

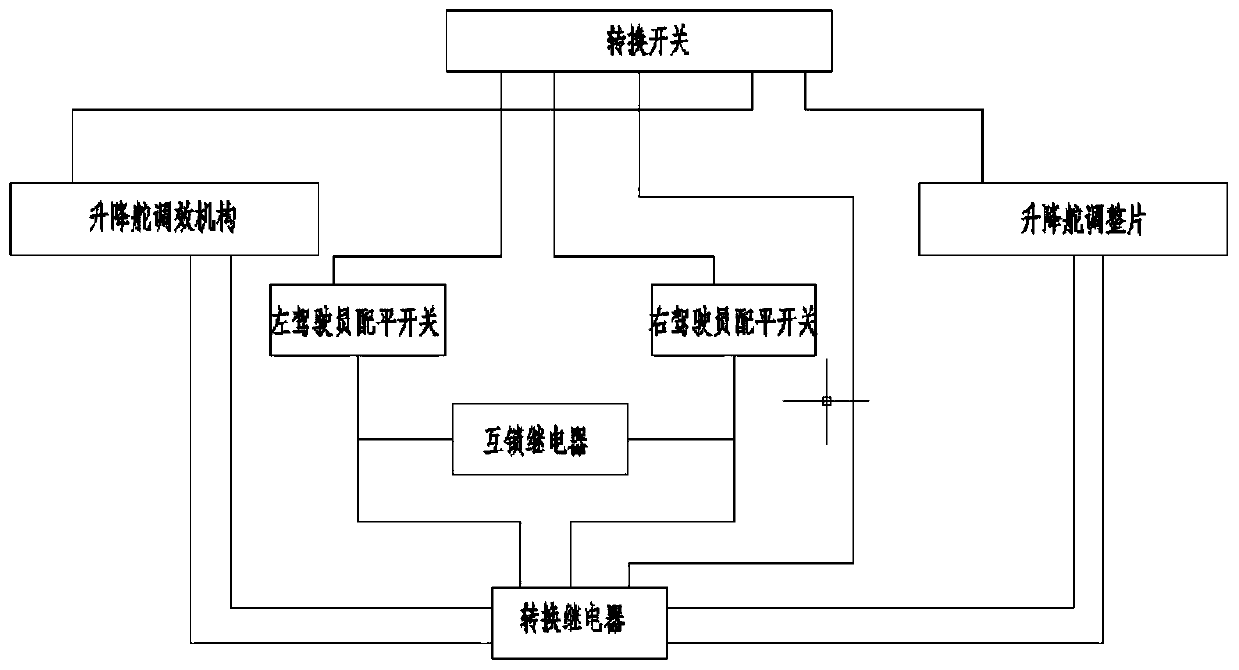

Elevator balancing control circuit of aircraft

The invention belongs to the technical field of aviation, and particularly relates to an elevator balancing control circuit of an aircraft. The elevator balancing control circuit comprises a conversion switch, a left driver balancing switch, a right driver balancing switch, a relay B, two sets of relays A, an effect regulating mechanism and an adjusting sheet electric mechanism. An integrated design is adopted for the electrical control design of the effect adjusting mechanism and the adjusting sheet control system, the conversion control between the systems is realized through the conversionswitch, the electrical control is simple, the number of lines is small, and the weight is light. Through the control of the relay, the left driving balancing authority can be higher than the right driving balancing authority, and the system is convenient to operate.

Owner:SHAANXI AIRCRAFT CORPORATION

Longitudinally-steerable structure and endoscope comprising said structure

InactiveUS7918789B2Reduce the overall diameterHigh resolutionSurgeryEndoscopesElectricityShape-memory alloy

The invention relates to a longitudinally-steerable structure, comprising essentially longitudinal actuators made from shape memory alloy, Peltier effect elements with N and P doping and electrical control device. The above is characterized in that the actuators are arranged in pairs in an antagonistic manner, each actuator being connected at the ends thereof with a Peltier effect element with N doping and a Peltier effect element with P doping respectively. The invention further relates to an endoscope comprising at least one such structure.

Owner:CENT NAT DE LA RECHERCHE SCI +1

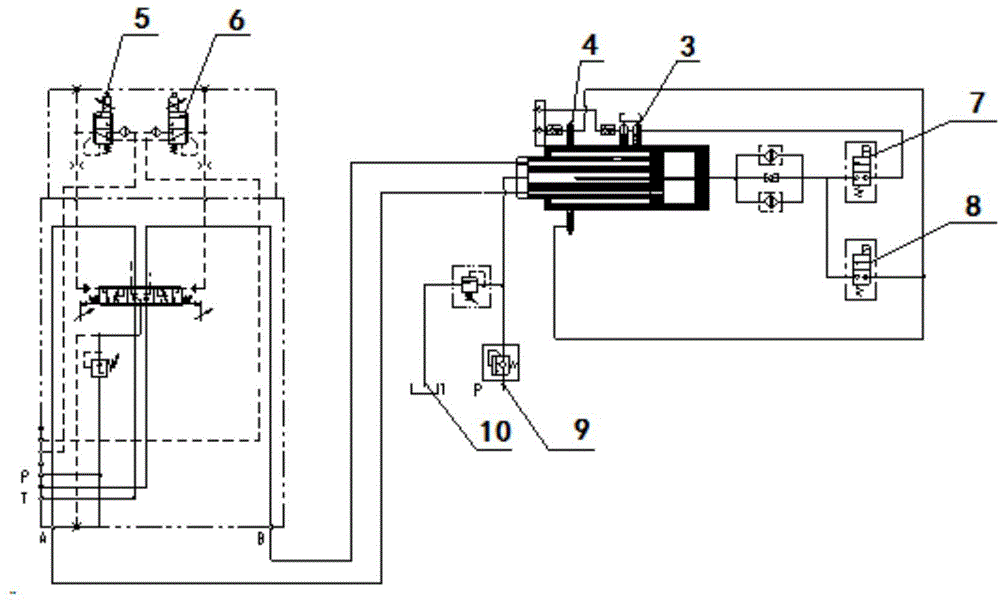

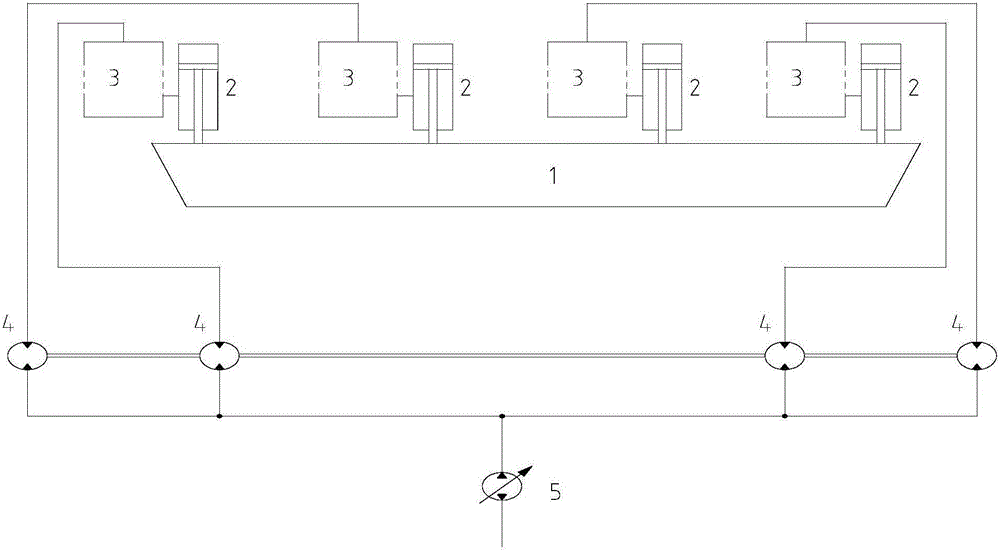

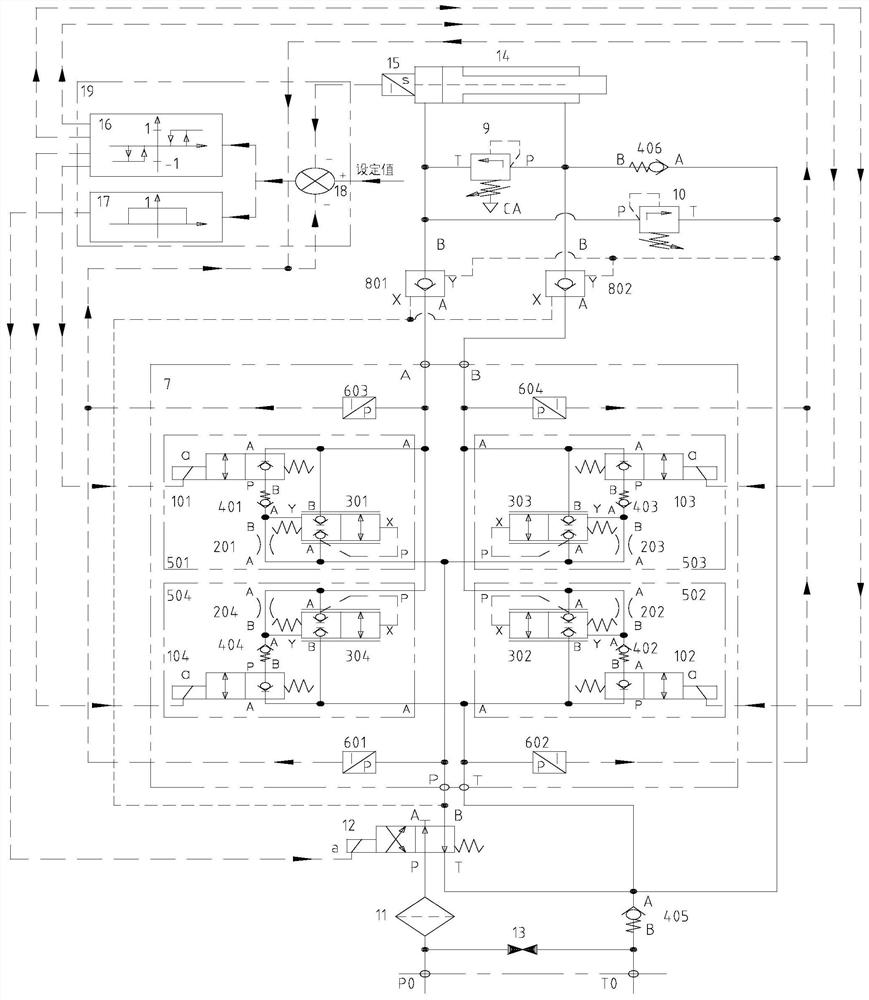

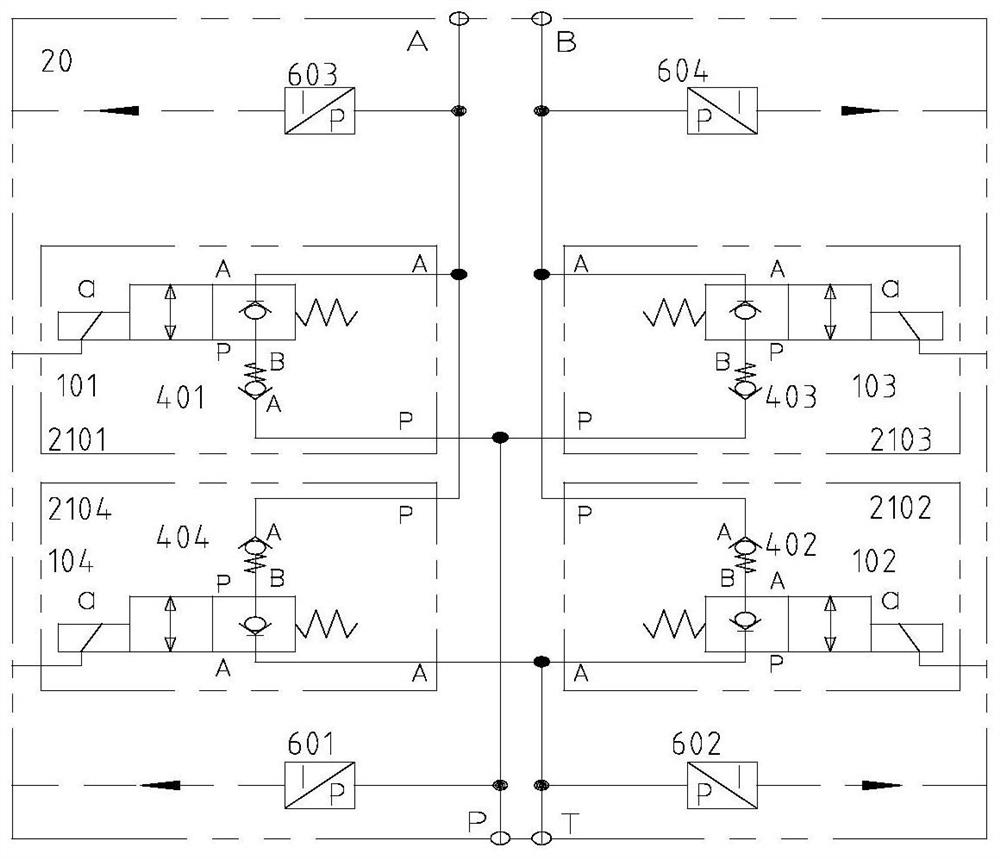

Novel steel ladle lifting synchronous control system

InactiveCN105020192AMeet various control requirements for synchronous operationEasy maintenanceServomotor componentsServomotorsHydraulic cylinderAutomatic control

The invention discloses a novel steel ladle lifting synchronous control system. The novel steel ladle lifting synchronous control system comprises four steel ladle lifting hydraulic cylinders, position locking devices, proportional valves, a hydraulic main pump, position detection devices and synchronous electric control devices, wherein the four steel ladle lifting hydraulic cylinders are arranged on a steel ladle, the position locking devices and the proportional valves are connected with the steel ladle lifting hydraulic cylinders respectively, the hydraulic main pump is connected with the four proportional valves, the position detection devices are mounted on the steel ladle lifting hydraulic cylinders respectively, and the synchronous electric control devices are connected with the position detection devices and the proportional valves. The steel ladle is synchronously lifted through the four steel ladle lifting hydraulic cylinders. The lifting position of the steel ladle is controlled through the proportional valves. The position of the steel ladle is detected in real time through the position detection devices. The synchronous electric control devices can independently control the opening degrees of the corresponding proportional valves in real time according to actual values fed back by the position detection devices and automatically control the flow flowing to the steel ladle lifting hydraulic cylinders from the hydraulic main pump through the proportional valves, and thus it is guaranteed that the steel ladle is lifted synchronously. According to the novel steel ladle lifting synchronous control system, the synchronous lifting control function that four lifting hydraulic cylinders are controlled through existing large-flow synchronous motors connected in parallel is replaced with the function that the lifting hydraulic cylinders are independently controlled through the proportional valves, and accordingly the defects in the prior art are overcome.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

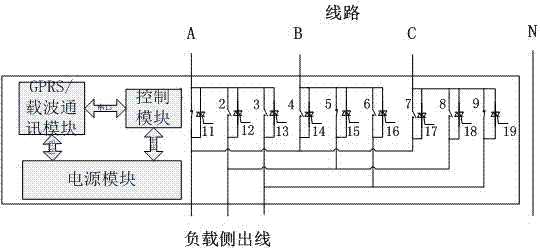

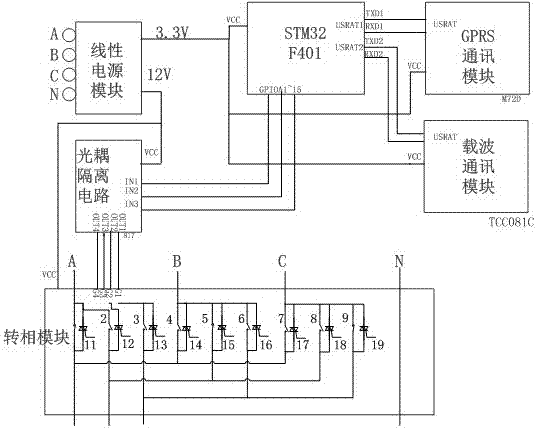

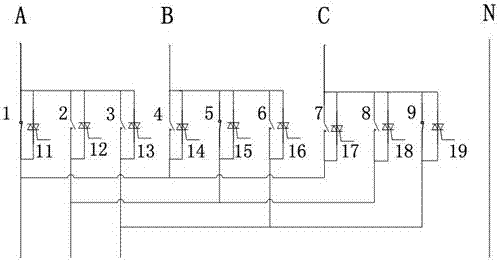

Electronic type phase conversion switch

PendingCN107104449AShort switching timeImprove reliabilityPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionPhase conversionElectricity

The present invention provides an electronic type phase conversion switch. The structure of the switch comprises a phase conversion module; and the phase conversion module comprises an A magnetic latching relay, a B magnetic latching relay, a C magnetic latching relay, a D magnetic latching relay, an E magnetic latching relay, an F magnetic latching relay, a G magnetic latching relay, an H magnetic latching relay, an I magnetic latching relay, an A anti-parallel thyristor, a B anti-parallel thyristor, a C anti-parallel thyristor, a D anti-parallel thyristor, an E anti-parallel thyristor, an F anti-parallel thyristor, a G anti-parallel thyristor, an H anti-parallel thyristor and an I anti-parallel thyristor. The electronic type phase conversion switch is employed to reduce the switching time of a mechanical type phase inversion switch and control the phase inversion time in 11ms so as to realize phase conversion with continuous electricity at a user side, improve the reliability and simplify the electrical control.

Owner:NANJING XINLIAN ENERGY TECH

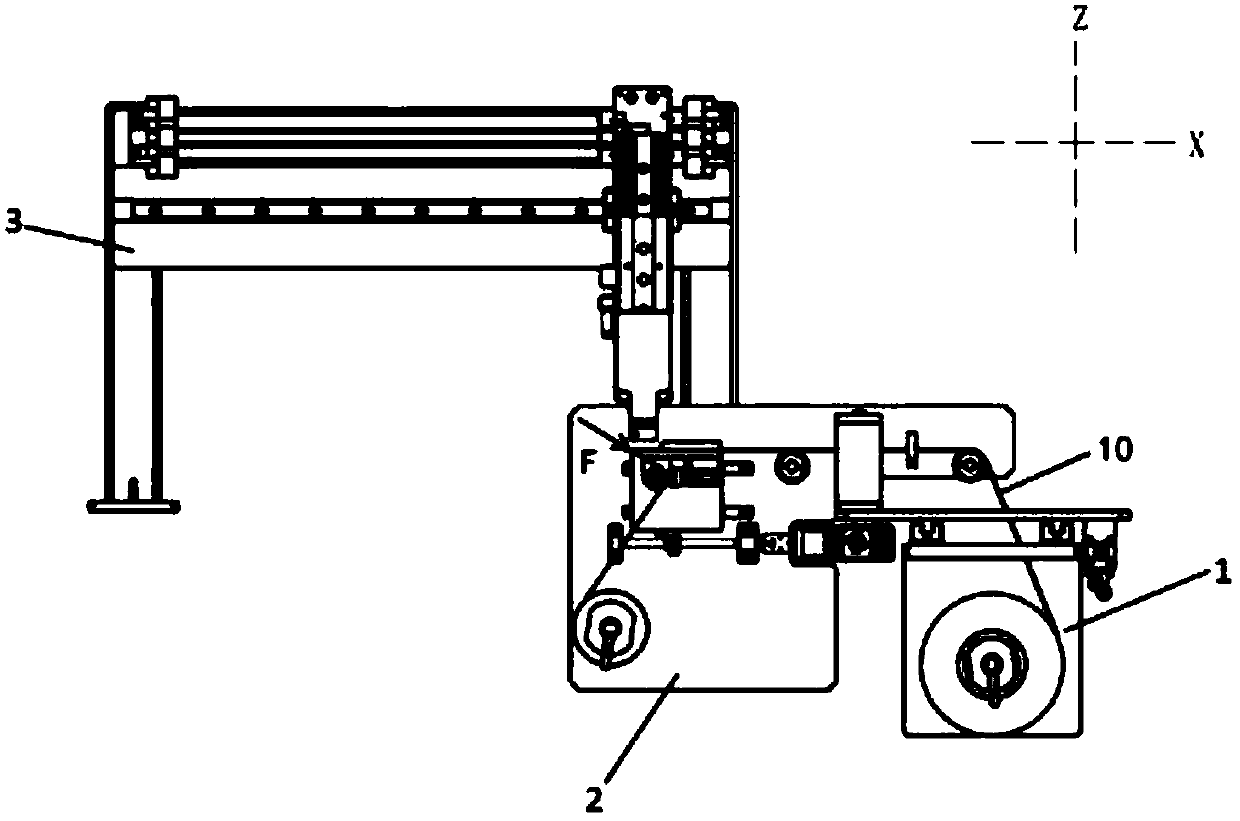

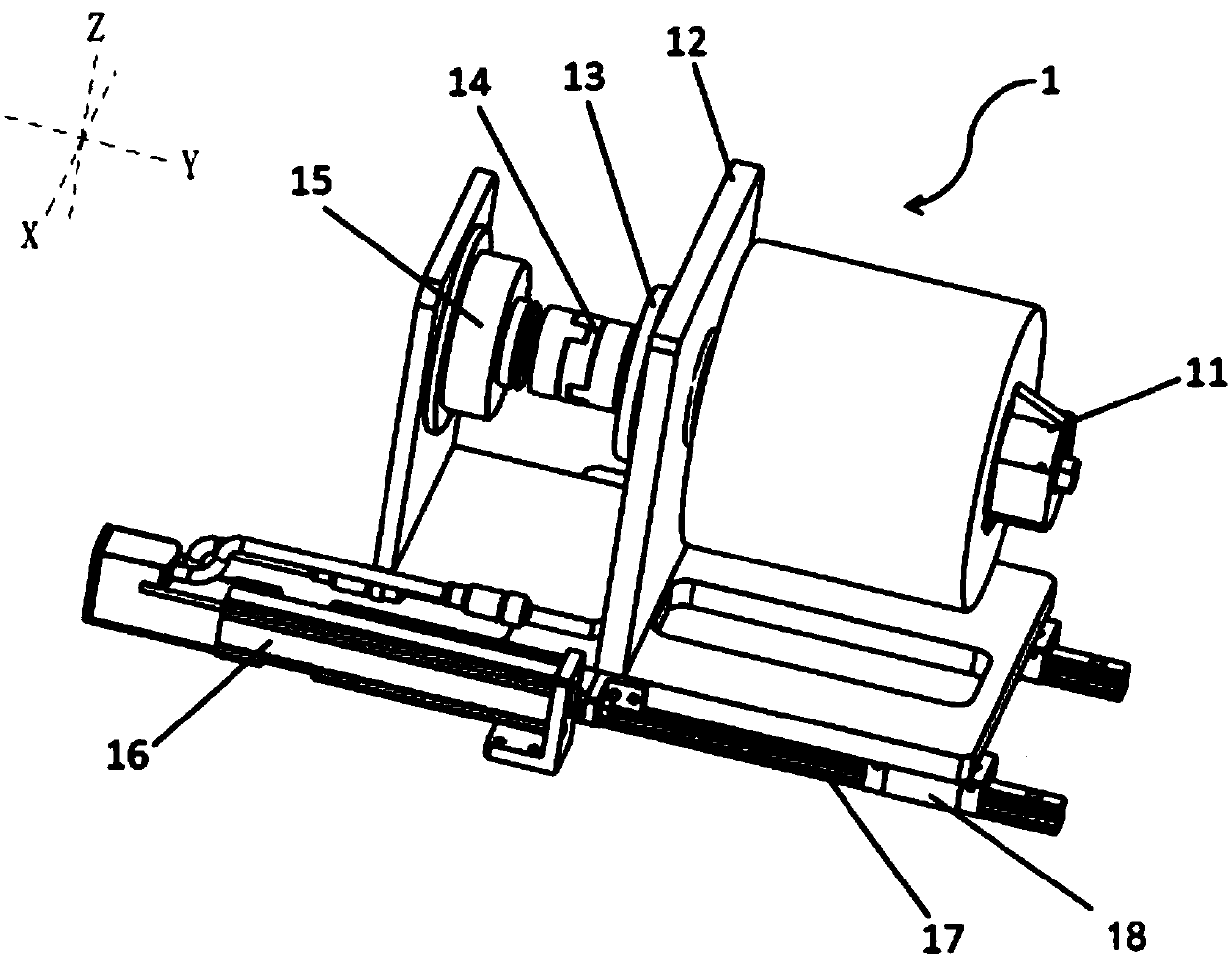

Unpowered unreeling machine, cell top surface protecting film tearing device, film adhering device and film adhering method

PendingCN108054421AUnwinding structure is simpleSimple electrical controlAssembling battery machinesFinal product manufactureElectrical controlMagnetic powder

The invention discloses an unpowered unreeling machine, a cell top surface protecting film tearing device, a film adhering device and a film adhering method. The unpowered unreeling machine comprisesan unreeling shaft for placing a reeled material; the unreeling shaft is rotatably arranged on a support frame through a bearing; the unreeling shaft is connected with a limiter which limits rotationof the unreeling shaft; when the tensile force applied to the reeled material is smaller than the torque limited value of the limiter, the unreeling shaft does not rotate; and when the tensile force applied to the reeled material is greater than torque limitation of the limiter, the unreeling shaft rotates. According to the unpowered unreeling machine, the degree of freedom of rotation of the unreeling shaft is limited by the limiter, therefore, the problem that follow-up processing is affected by unreeling of the reeled material due to the rotation inertia of the unreeling shaft or the tensile force when the unreeling shaft does not work can be avoided, and thus, a foundation is laid for development and utilization of the cell top surface film adhering equipment; and moreover, an unreeling mode is optimized into magnetic powder brake unreeling from traditional motor unreeling, the unreeling structure is simple, and electrical control of unreeling is greatly simplified.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

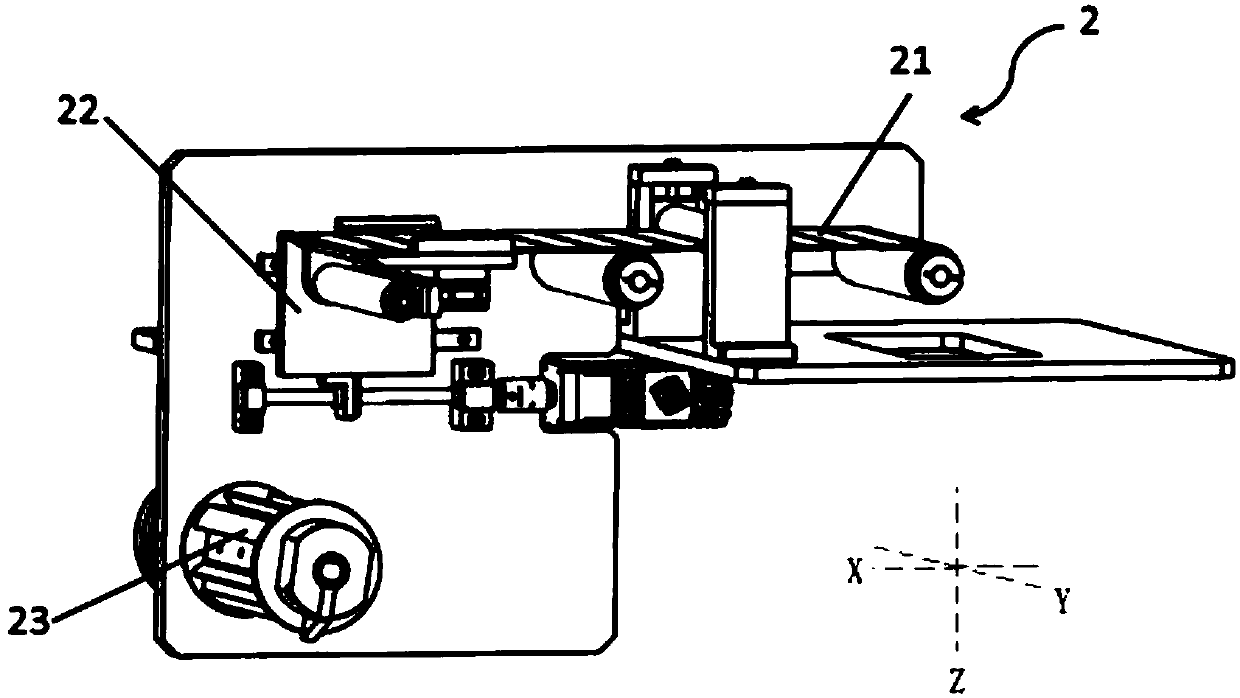

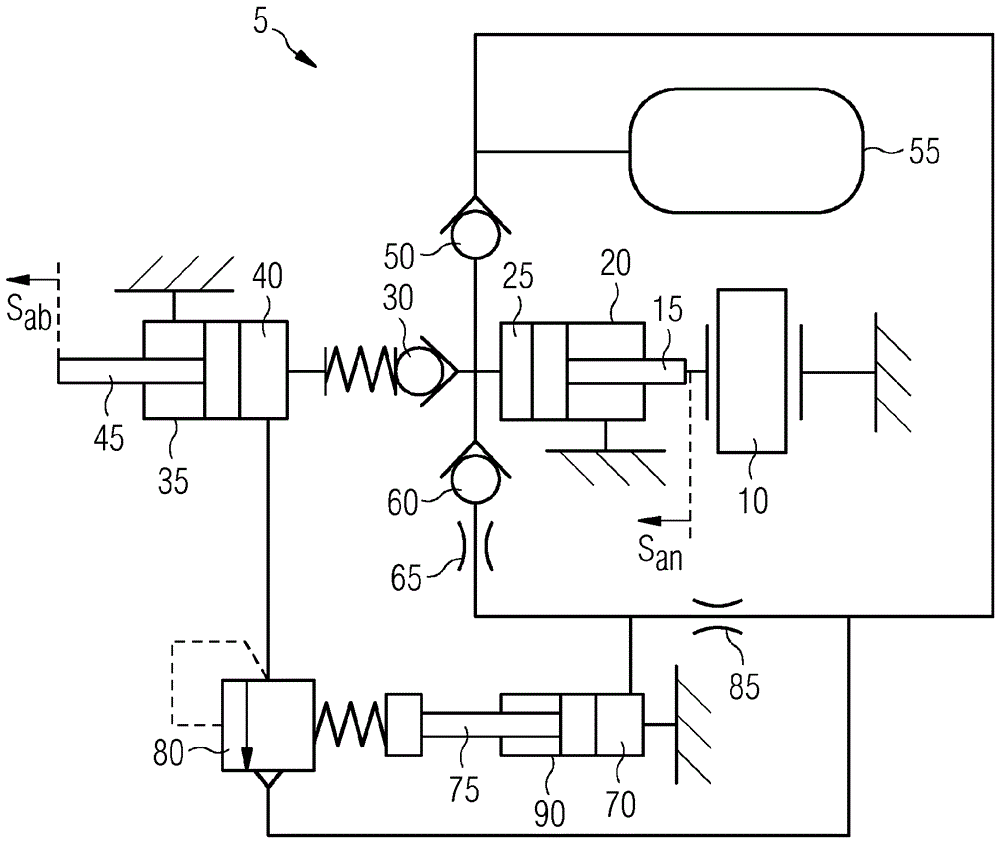

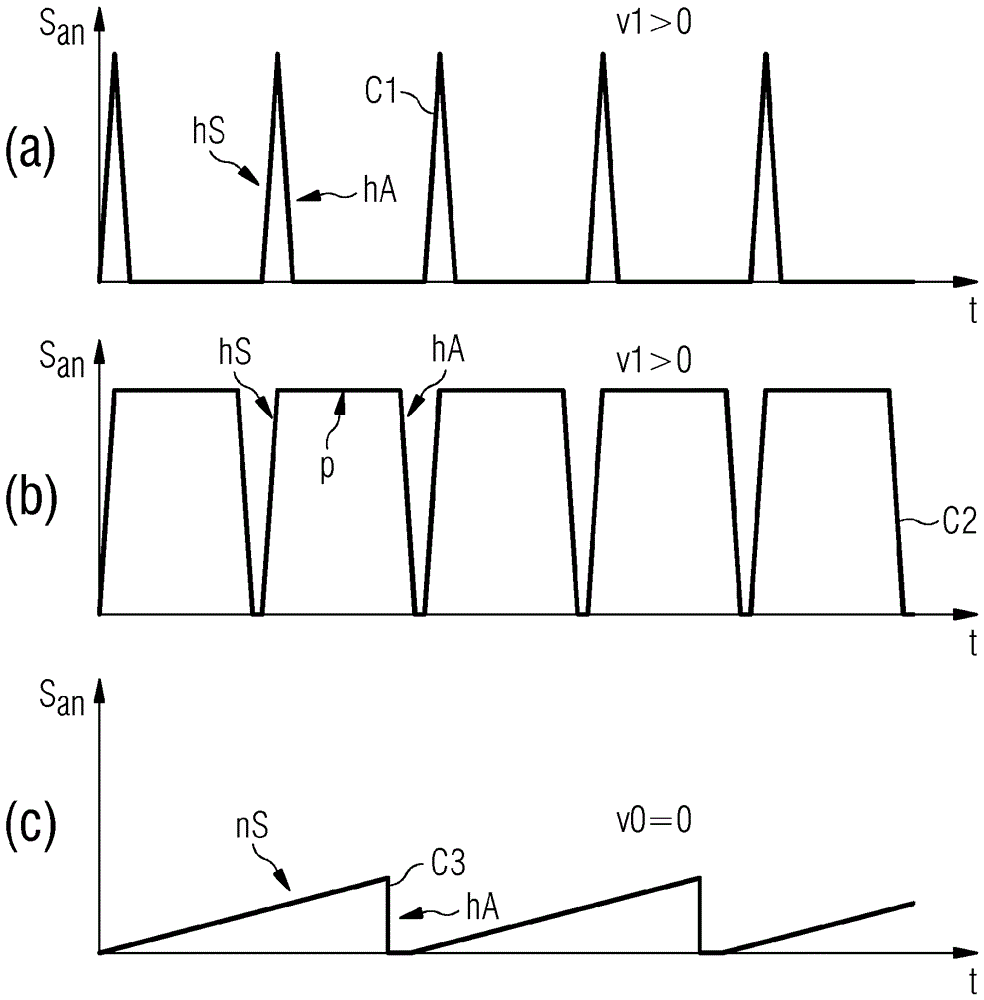

Hydraulic actuator and method for operating a hydraulic actuator

ActiveCN106536943ASimple electrical controlIncrease stiffnessPiezoelectric/electrostriction/magnetostriction machinesServomotor componentsHydraulic cylinderActuator

The hydraulic actuator comprises: a hydraulic input cylinder having an input piston; a hydraulic output cylinder, which is hydraulically coupled to the input cylinder; and a pressure-limiting valve, which limits the output cylinder with respect to pressure in dependence on the usability of a force on the input piston. The method is a method for operating such a hydraulic actuator, wherein the drive actuator is deflected with deflections having a deflection duration at a deflection frequency for the duration of an acting or a non-acting phase of the hydraulic actuator, wherein the deflection duration defines a movement stiffness of the hydraulic actuator and the deflection frequency defines the resulting deflection speed of the hydraulic actuator.

Owner:METISMOTION GMBH

Lifting roller way machine

InactiveCN103662789ARun smoothlySimple electrical controlConveyor partsRoller-waysPower unitEngineering

The invention discloses a lifting roller way machine which comprises a roller way, a rack, a four-rod connecting mechanism, a protective cover, a trolley and a power unit. The roller way is connected with the four-rod connecting mechanism through the rack, the four-rod connecting mechanism is installed on the trolley, and the power unit is installed on the lower portion of the trolley. The lifting roller way machine is stable in operation, adjustable in lifting height and multifunctional, and achieves the purpose that the whole lifting roller way machine is movable, and electric appliances can be easily controlled.

Owner:DALIAN JIALIN EQUIP MFG

Ultrasonic assembly with adjustable fluid lens

InactiveUS20100185126A1Simple and economic useSimple and economical to useUltrasound therapyChiropractic devicesUltrasonic sensorTransducer

An ultrasonic assembly suited for attachment to a catheter, e.g. for medical treatment. The ultrasonic assembly includes an adjustable ultrasonic focus mechanism arranged in connection with the ultrasonic transducer to adjust focus of ultrasonic waves generated by the transducer. The ultrasonic focus mechanism includes a fluid focus lens with at least two fluids separated by an interface such that ultrasonic waves are substantially reflected at the interface. At least two electrodes are arranged in connection with the fluid focus lens so as to allow adjustment of the interface shape, e.g. a curvature of the interface, when a voltage is applied to the electrodes. In preferred embodiments the electrodes are arranged so as to allow adjustment of the fluid focus lens in an elevation direction as well as in a radial direction. In simple embodiments with rotational symmetric geometry with the transducer positioned in the centre of the fluid focus lens, ultrasonic waves can be focused in an annular ring. This is e.g. suitable for ablative or coagulative necrotic treatment of human tissue, e.g. for atrial fibrillation treatment. In some embodiments, the assembly has a number of separate individually adjustable fluid focus lens compartments allowing a more detailed control of the ultrasonic focus pattern.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

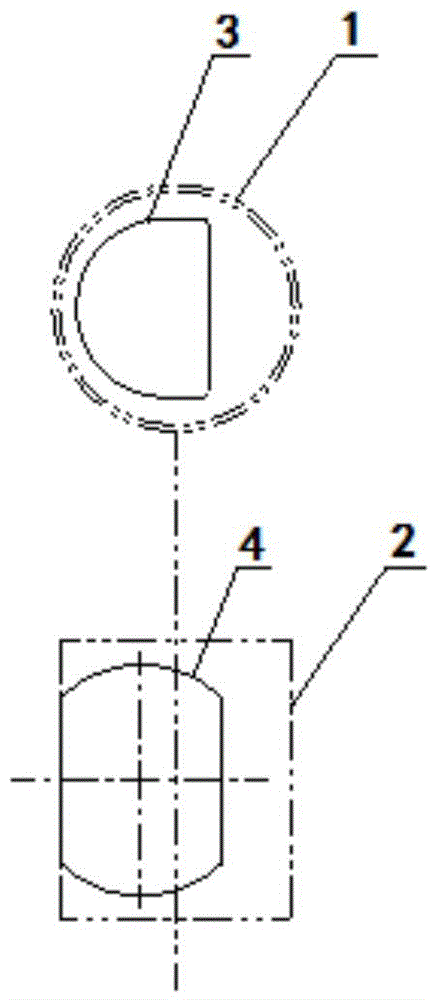

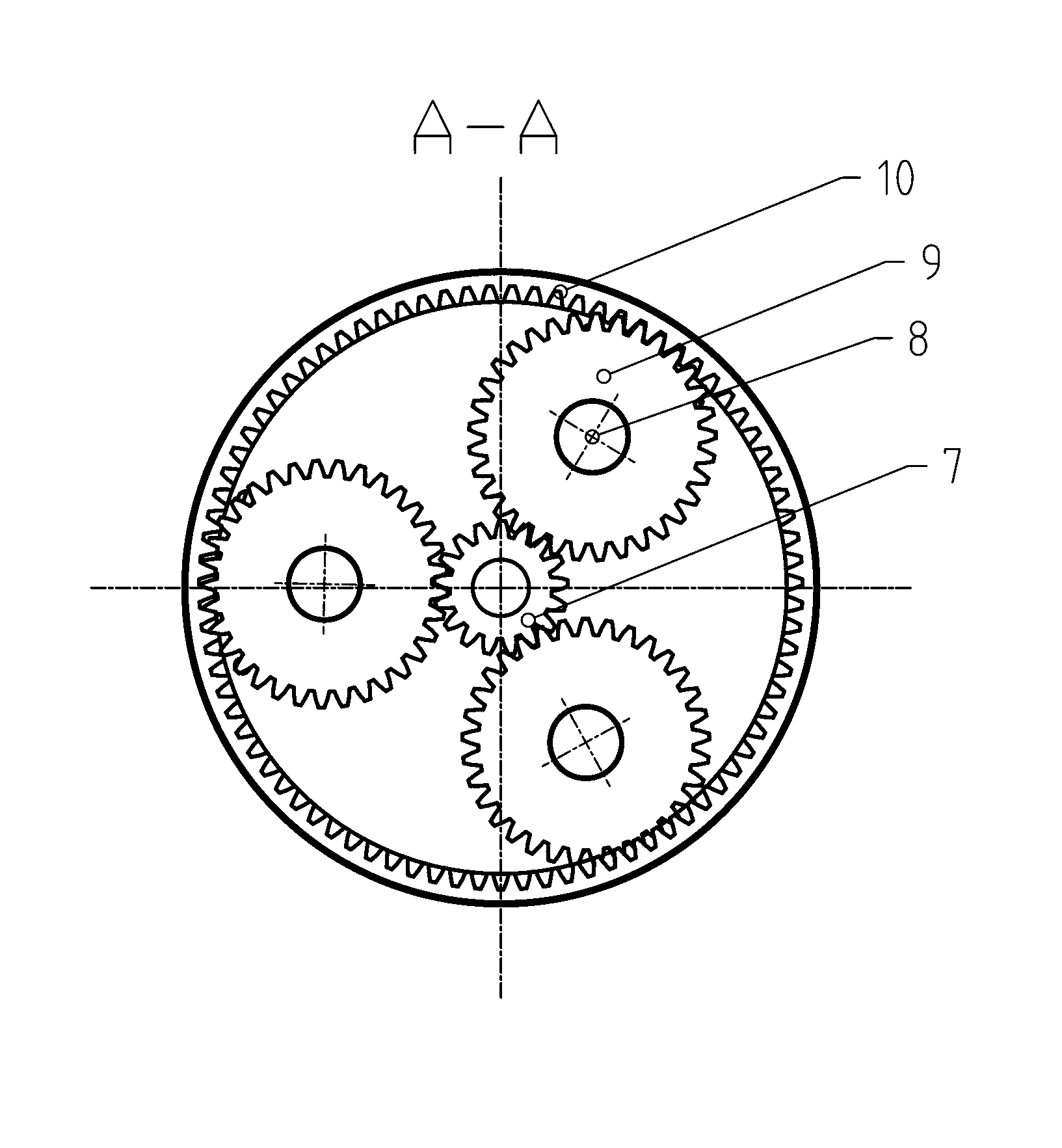

Lifting mechanism of electric shovel

The invention discloses a lifting mechanism of an electric shovel, which comprises a drum inner sleeve, a transmission side spindle, a first grade sun wheel, a first grade planet wheel pin shaft, a first grade planet wheel, a first grade inner gear ring, a first grade planet carrier, a second grade planet carrier, a second grade planet wheel pin shaft, a second grade inner gear ring, a second grade planet wheel, a second grade sun wheel support, a second grade sun wheel and a fixation side spindle, wherein a first grade speed-reduction transmission mechanism comprises the first sun wheel, the first grade planet wheel, the first grade inner gear ring and the first grade planet carrier; and a second grade speed-reduction transmission mechanism comprises the second grade sun wheel, the second grade planet wheel, the second grade inner gear ring, the second grade planet carrier and the second grade sun wheel support. According to the invention, as the single-motor input is adopted, and the two grades of the speed-reduction transmission mechanisms are installed in the drum inner cavity, the space in the drum is completely utilized; the speed-reduction mechanisms adopt two grades of planet gear wheels to realize transmission, so that the transmission of the planet gear wheel has great transmission ratio; and the lifting mechanism is compact in structure and can greatly reduce the weight of the equipment.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Marking method and device for keeping row distance in process of carrying out rice planting or direct-seeding traveling

The invention relates to a marking method and device for keeping a row distance in the process of carrying out rice planting or direct-seeding traveling. A base is provided with a marking seat with an elastic automatic reset function. A marking rod is connected to the marking seat. The marking rod can rotate around the marking seat. The marking seat is provided with a disk with a torsional spring. The excircle of the disk is provided with a disk trough. A cable assembly is embedded in the disk trough. The cable assembly is directly connected to an operating rod of a cab. The marking device is regulated through the operating rod of the cab. When an operator tensions the operating rod, a cable pulls the disk of the marking seat to rotate around a shaft, and the torsional spring is compressed to drive the marking rod inserted in the marking seat to rotate downwards; and when the operating rod is tensioned in place, the marking rod is just in a horizontal state and the inclination degree of the marking rod is regulated so as to carry out marking in a formed paddy field. Conversely, the operating rod is released, the disk of the marking seat rotates around the shaft under the action of an elastic force of the torsional spring so as to drive the marking rod to rotate upwards; and when the operating rod is released in place, the marking rod is in a vertical state, namely a folding state.

Owner:株洲联合收割机有限公司

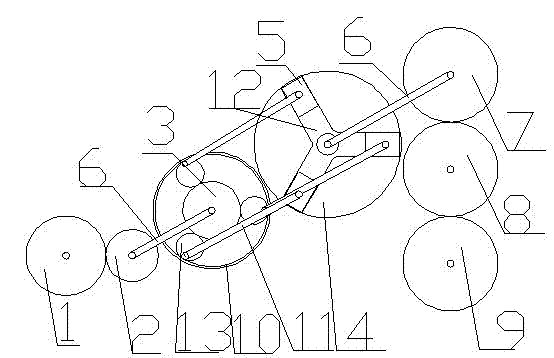

Planet intermittent synchronizing mechanism

The invention discloses a planet intermittent synchronizing mechanism which comprises a driving wheel, a driven wheel, a planet wheel set, a rotary disk, a sliding block, a working gear and driving rods. The driving wheel is connected with the driven wheel, the driven wheel is connected with the planet wheel set through the driving rod, a planet wheel set crank shaft is connected to the sliding block, the sliding block is arranged on the rotary disk, and the rotary disk is connected with the working gear through the driving rod. The planet intermittent synchronizing mechanism has the advantages of being high in reliability, compact in structure, high in transmission accuracy, accurate in motion and long in service life and having simplicity in electrical control and simultaneously has wide market prospect in the field of mechanical equipment.

Owner:苏州建莱机械工程技术有限公司

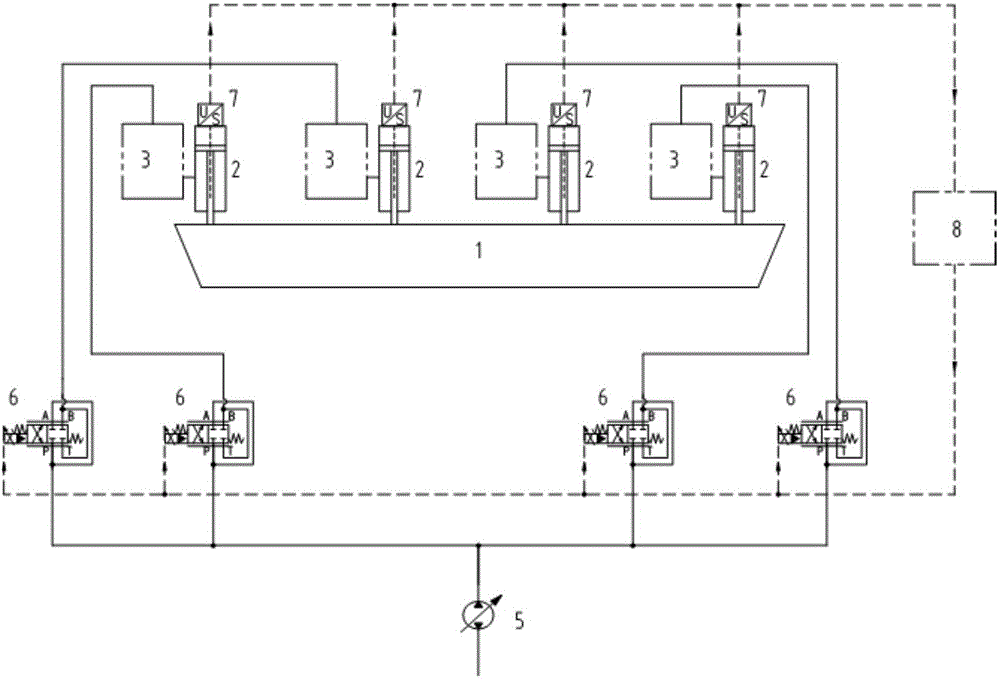

Load port flow pulse independent control digital hydraulic servo system and control method

ActiveCN113124009AAvoid accidentsRealize intelligent control functionFluid-pressure actuator testingServomotor componentsFailure rateDigital control

The invention discloses a load port flow pulse independent control digital hydraulic servo system and a control method, which are used for accurately controlling the position of a hydraulic cylinder. The high-precision control function of the hydraulic cylinder is achieved by adopting a logic array of a flow pulse control intelligent digital valve, load oil way liquid resistance decoupling control of the hydraulic cylinder is achieved through load parameter identification control of an electrical controller, all working points can achieve the optimal control performance and the energy-saving effect, and the problems that a traditional servo valve is high in failure rate and serious in oil liquid heating under the severe service working condition are solved. In addition, the digital control technology of the flow pulse control intelligent digital valve is directly connected with a computer, electrical control is simple, and the technical problems that a traditional servo electrical control system is poor in anti-interference capacity and difficult to maintain are solved; and moreover, based on the fusion technology of the flow pulse control intelligent digital valve and multiple sensors, the intelligent control function of online state monitoring and automatic fault diagnosis of the whole life cycle of the hydraulic system is achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Online turning electric transverse feeding device for four-roll crusher

InactiveCN103042421AStable horizontal feedAdjust speedFeeding apparatusSafety controlElectrical control

The invention provides an online turning electric transverse feeding device for a four-roll crusher. The online turning electric transverse feeding device for the four-roll crusher comprises a turning tool rest, a turning tool rest fixing base, a transverse feeding screw rod, an alternating-current variable-frequency transmission mechanism and a control device. A turning tool is mounted on the turning tool rest, the turning tool rest fixing base is used for fixing the turning tool rest, and the transverse feeding screw rod is used for realizing transverse feeding of the turning tool. The alternating-current variable-frequency transmission mechanism is connected with the transverse feeding screw rod, and the control device is used for controlling operations of the online turning electric transverse feeding device for the four-roll crusher. Transverse feeding control of the turning tool is realized by means of the alternating-current variable-frequency speed regulation technique to enable transverse feeding of the turning tool to be constant in speed and stable. Further, electrical control is simple, the transmission mechanism is compact, operating efficiency is improved, safety control risks are lowered for operators, and roll skin turning quality is improved.

Owner:PANGANG GRP ENG TECH

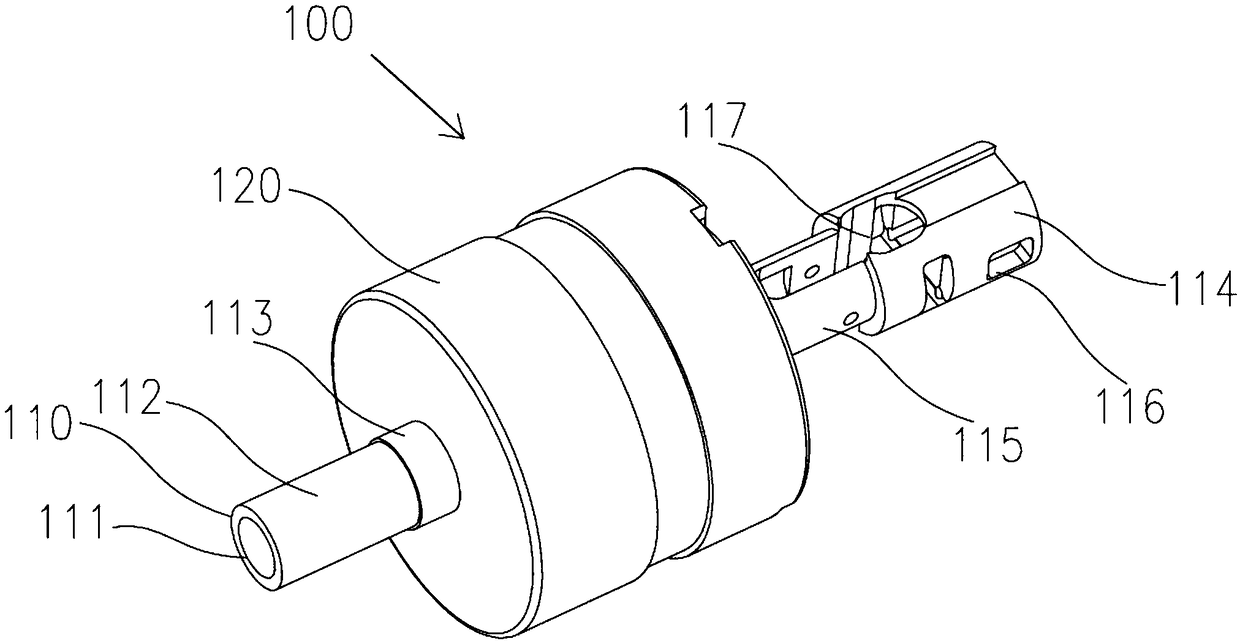

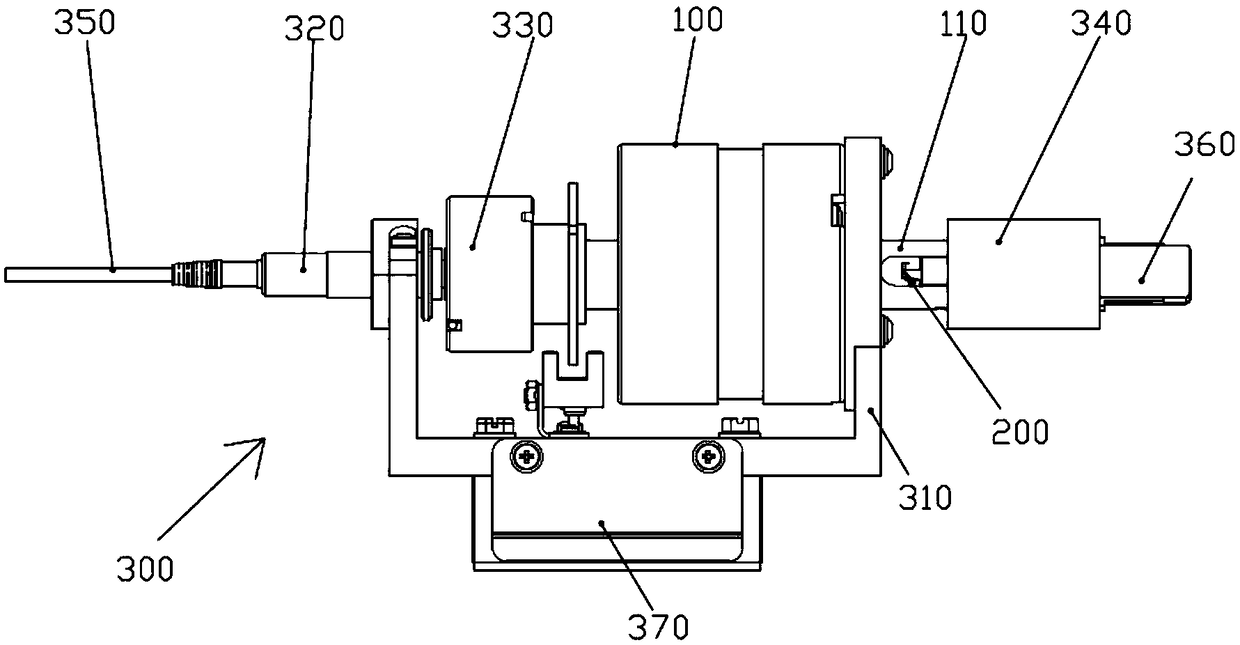

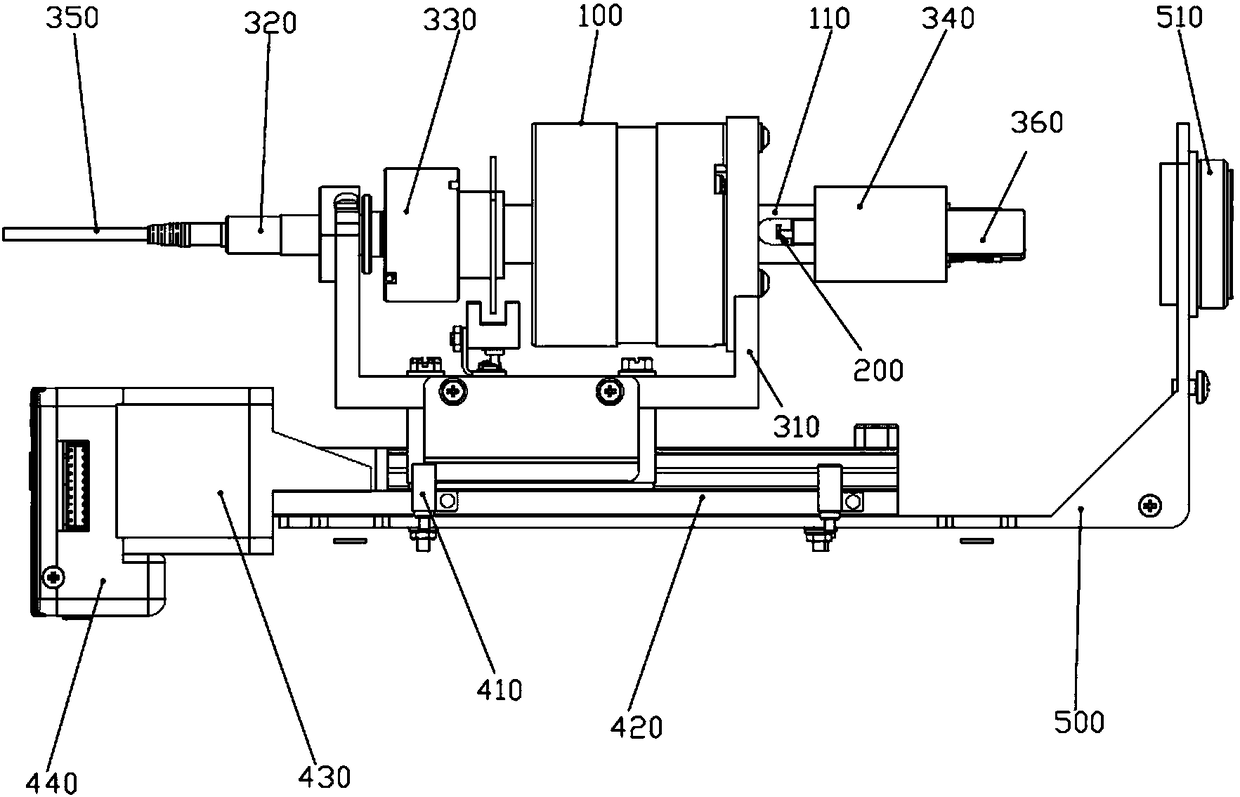

Direct drive module for OCT

PendingCN108768122ASolve technical problemsSimple mechanical structureShaftsMechanical energy handlingDrive motorStator

The invention discloses a brushless DC direct drive motor for an OCT detection device. The motor comprises a permanent magnet, a multi-pole winding stator, a Hall sensor, a motor shell, a direct drivemotor driver, and a rotary shaft, wherein the permanent magnet is fixed on the rotary shaft, the rotary shaft is provided with a through hole penetrating the axis of the rotary shaft, the rotary shaft comprises a first rotary shaft end with a slip ring adapter interface and a second rotary shaft end with a guide tube adapter interface, the multi-pole winding stator, a position sensor and the direct drive motor driver are fixed on a motor bearing, and the Hall sensor is used for detecting a position of a magnetic pole of the permanent magnet on the rotary shaft relative to the multi-pole winding stator and controls a direction of a current input into each electrode of the multi-pole winding stator through the direct drive motor driver. The invention further discloses an OCT detection device direct drive module using the brushless DC direct drive motor, an OCT detection device drive equipment, and an OCT detection device assembly. Through adoption of the brushless DC direct drive motorfor the OCT detection device, the mechanical structure and electrical control are easy, so that assembling and debugging are convenient.

Owner:GUANGZHOU WINSTAR MEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com