Direct drive module for OCT

A direct-drive motor, DC technology, applied in the direction of electric components, control mechanical energy, electrical components, etc., can solve the problems of high manufacturing cost, precision bottleneck, cost increase and performance improvement are not proportional, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

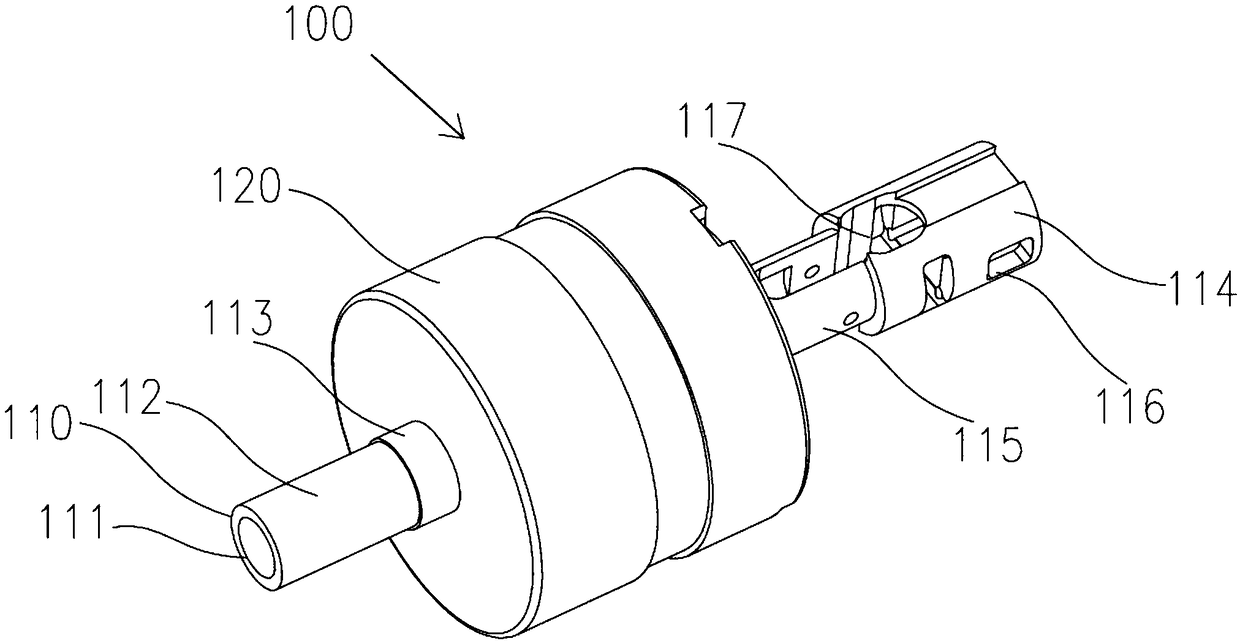

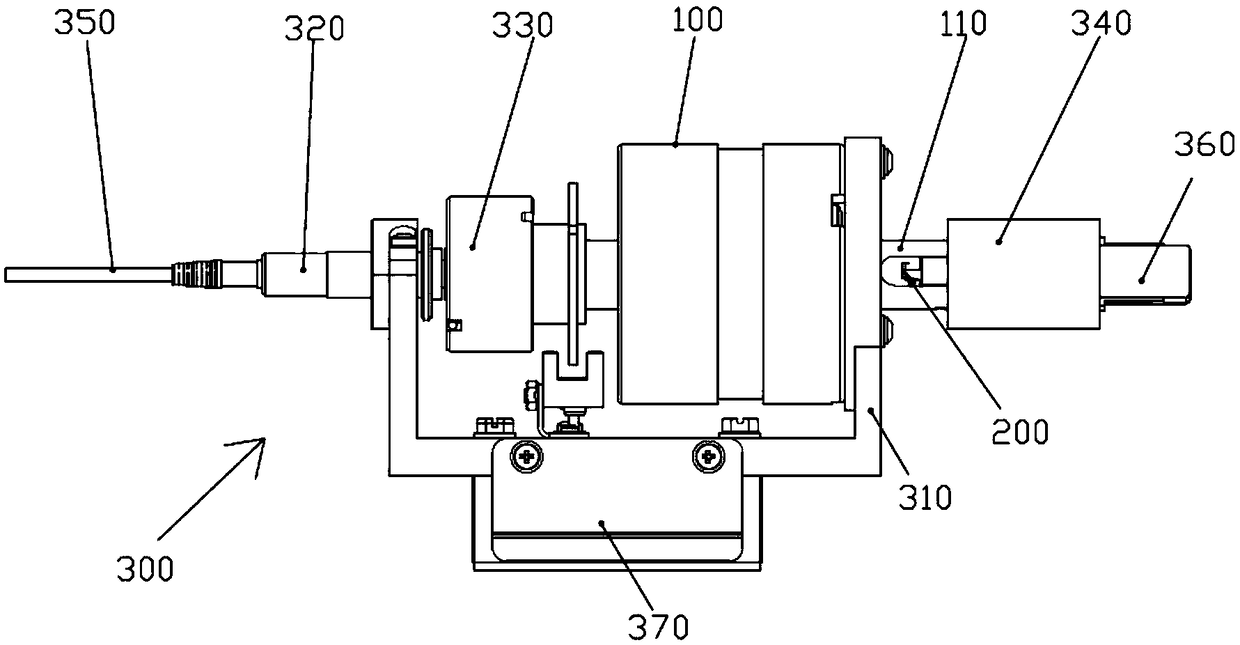

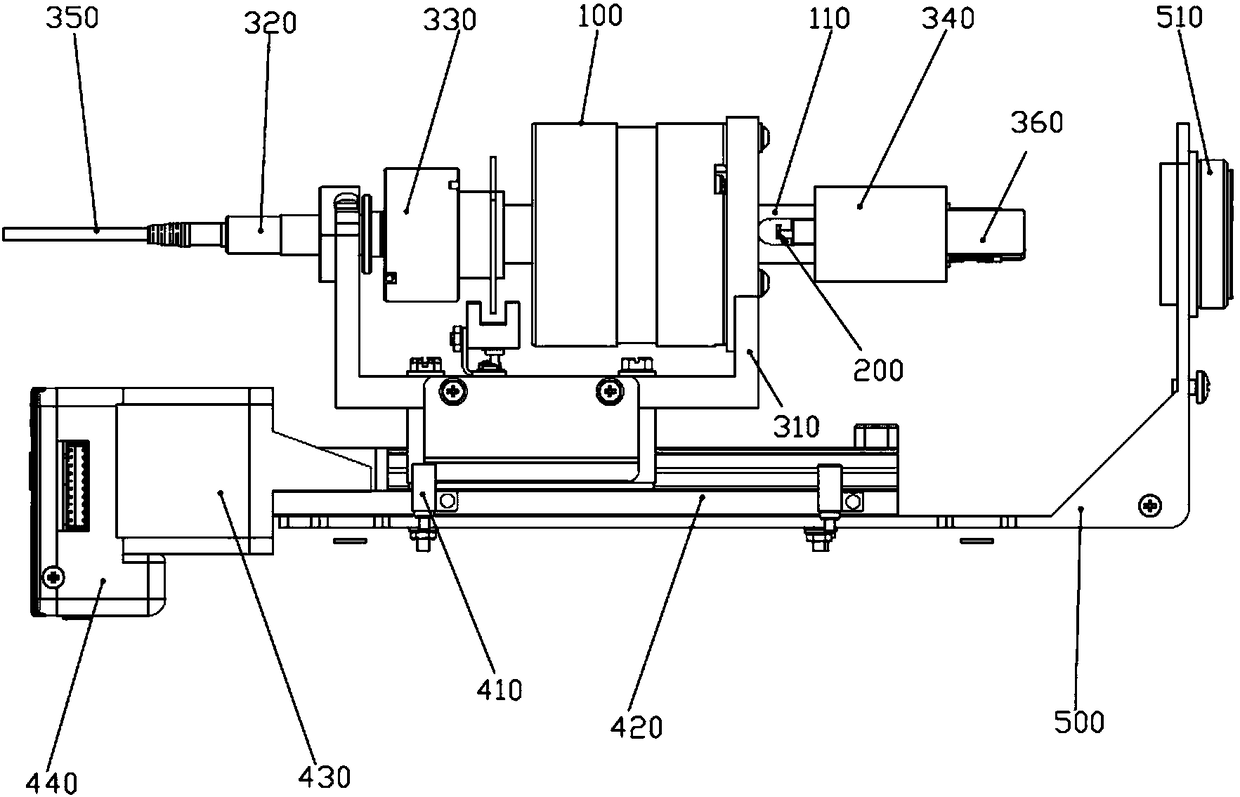

[0039] Such as figure 1 As shown, the brushless DC direct drive motor 100 for OCT detection equipment provided by the embodiment of the present invention includes a permanent magnet (not shown), a multi-pole winding stator (not shown), and a Hall sensor (not shown) , a motor shaft (not shown), a direct drive motor driver (not shown) and a rotating shaft 110. Among them, permanent magnets, multi-pole winding stators, Hall sensors and direct drive motor drivers have mature application solutions in DC direct drive motors, and the technical solutions provided by the present invention have no restrictions on their structures.

[0040] The permanent magnet is fixedly arranged on the rotating shaft 110, and the rotating shaft 110 is provided with a through hole 111 passing through the axis of the rotating shaft 110. The rotating shaft 110 includes a first rotating shaft end provided with a slip ring adapter interface and a second rotating shaft end provided with a catheter adapter in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com