Patents

Literature

224 results about "Fixation side" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

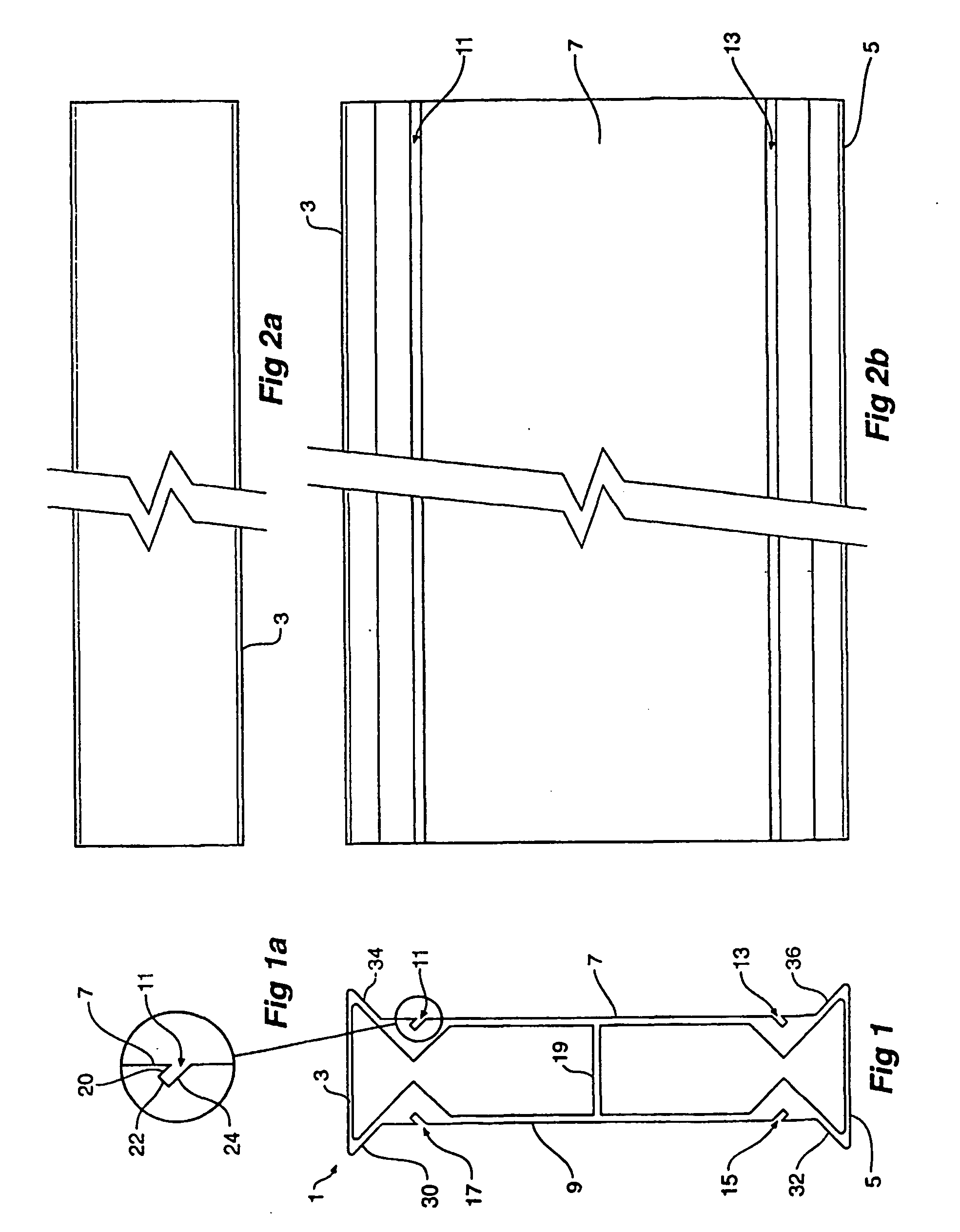

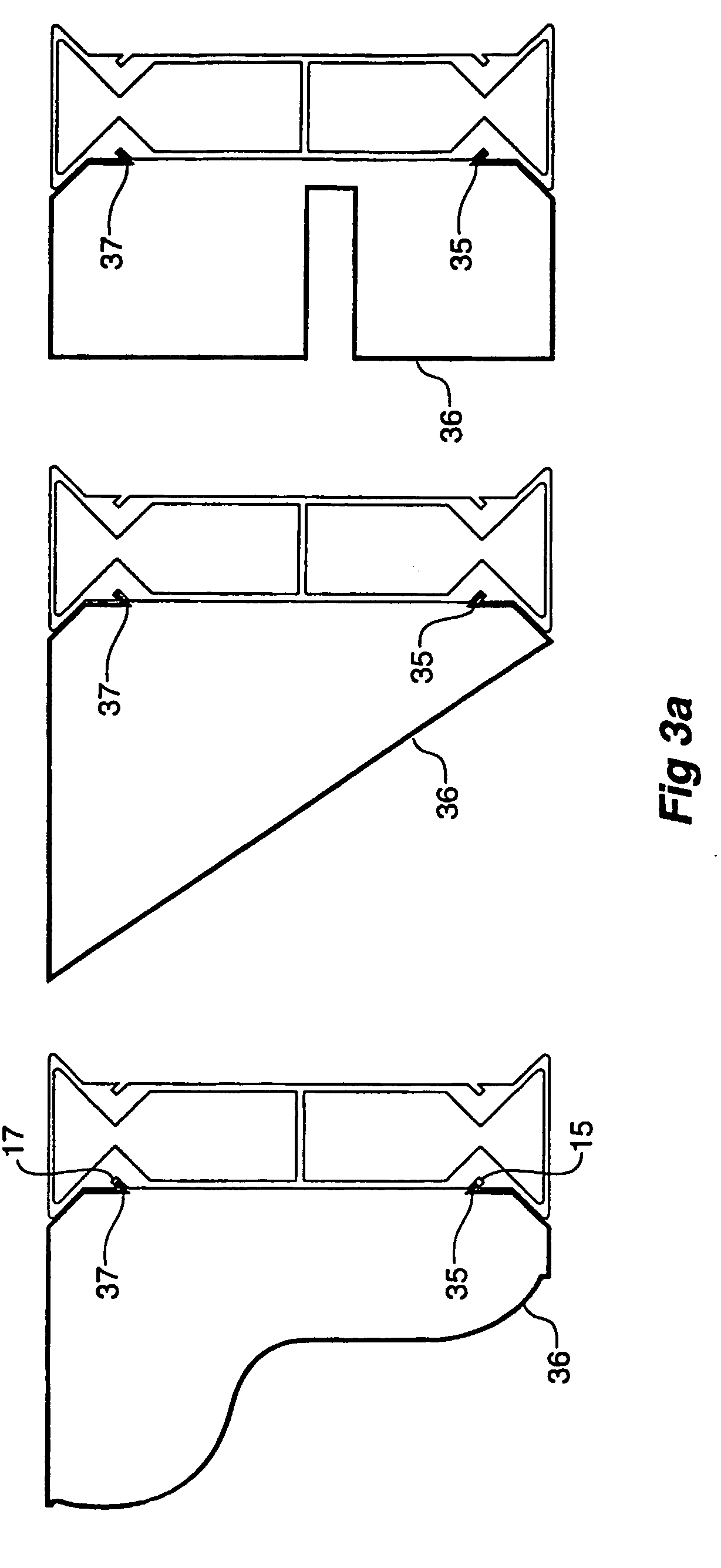

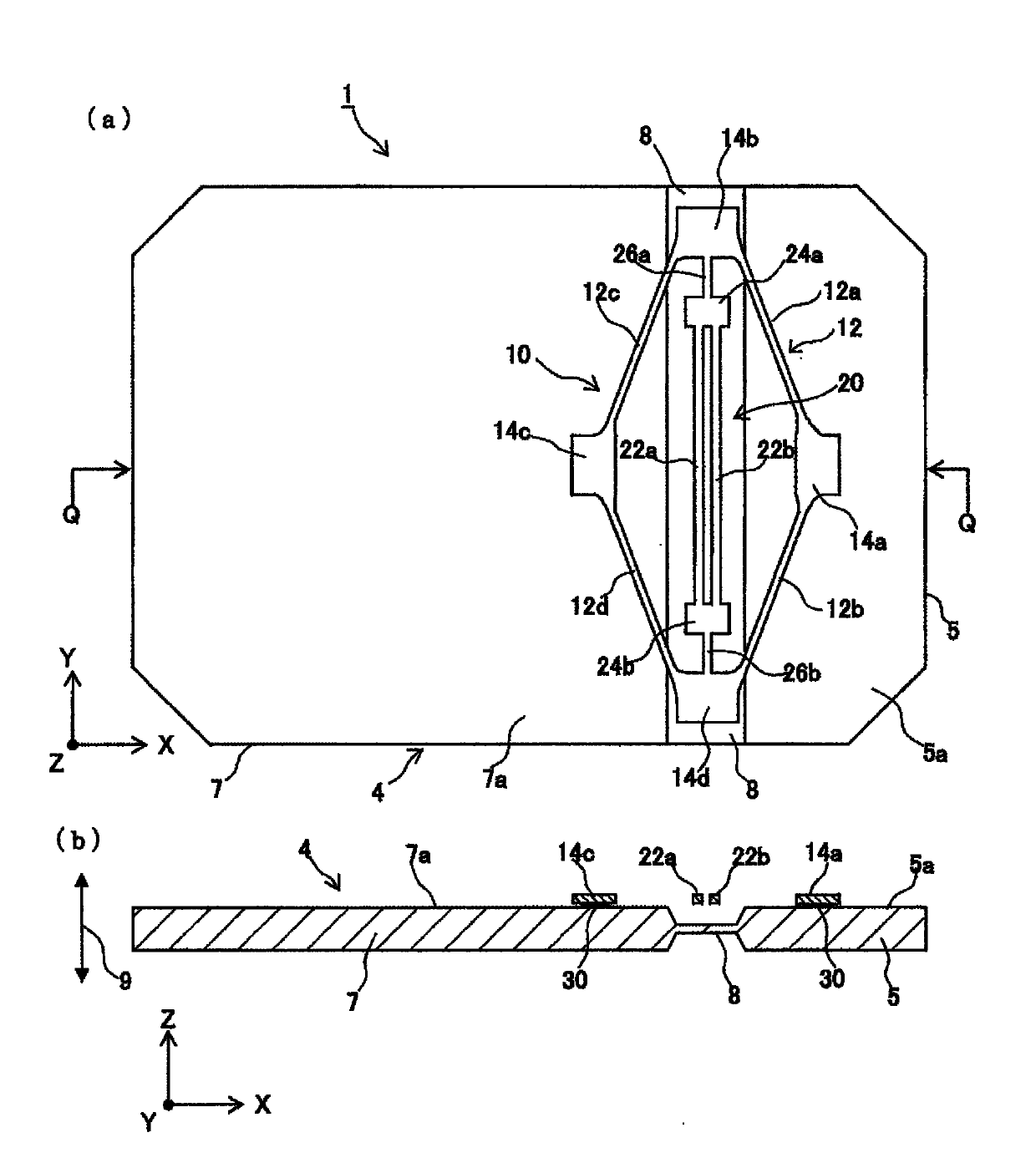

Touch panel

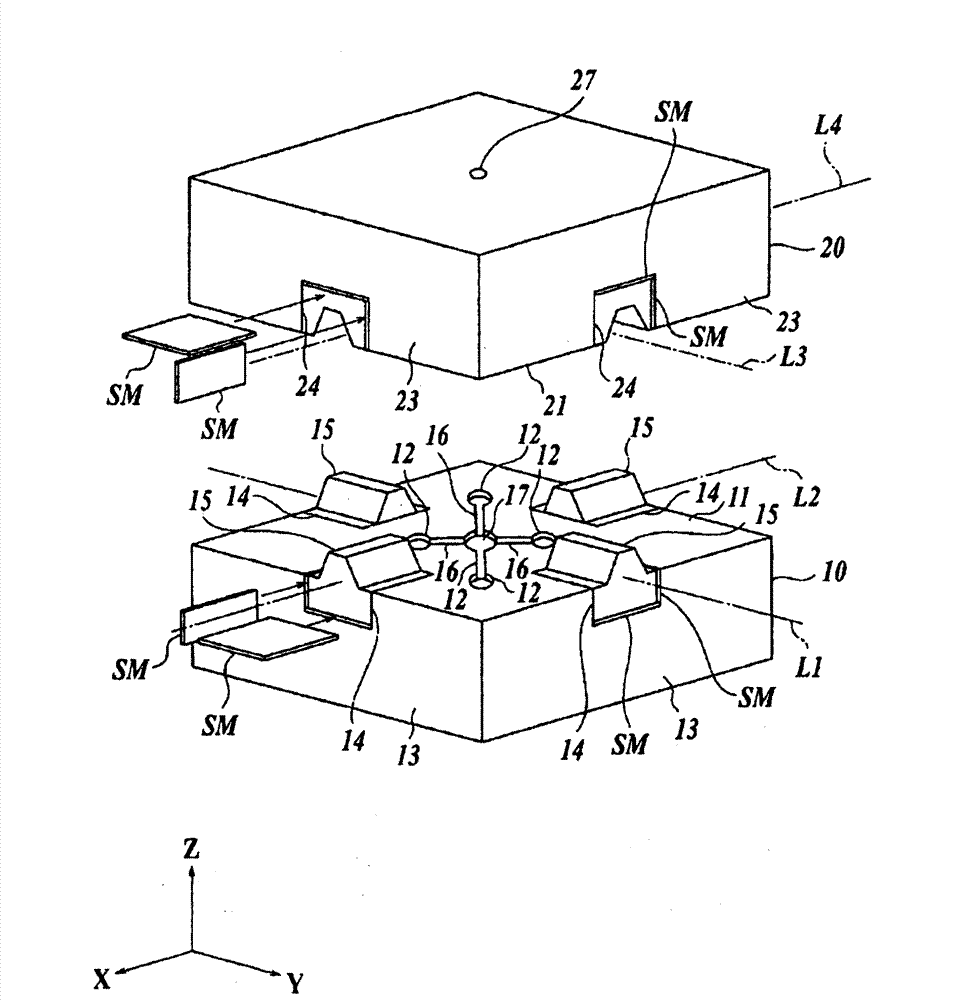

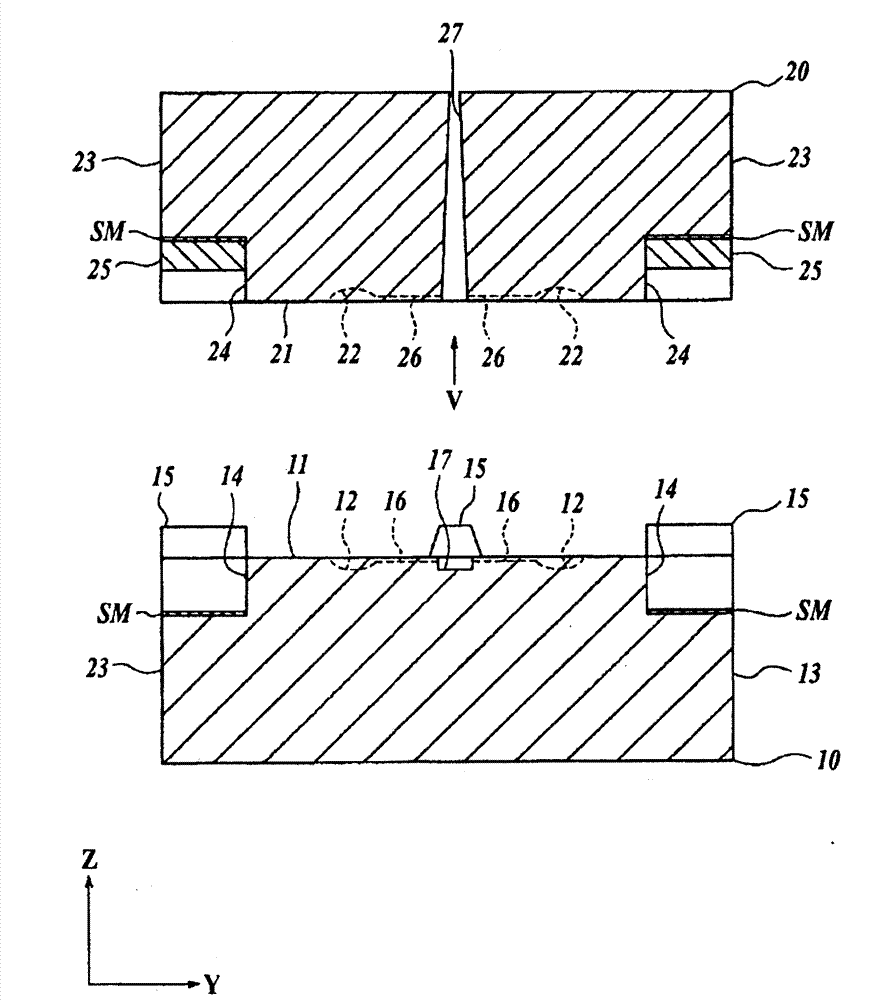

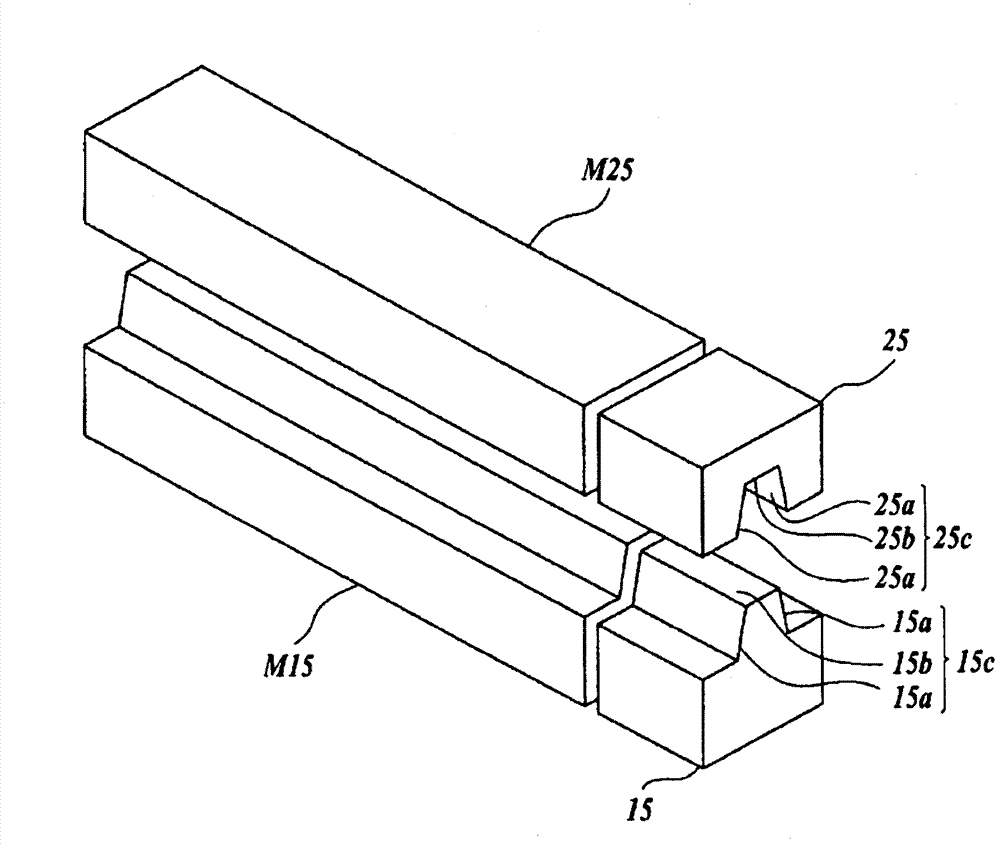

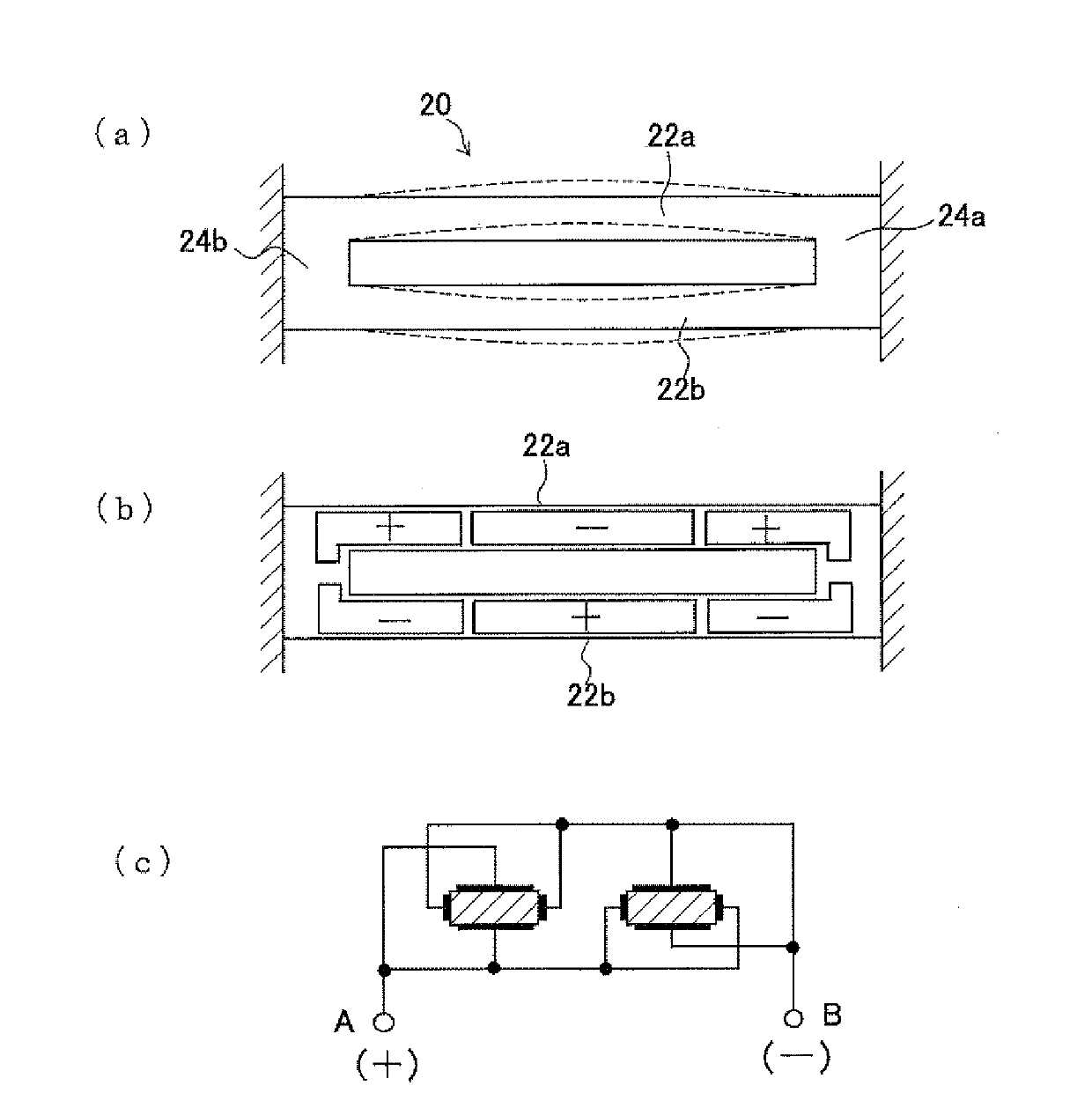

InactiveUS20080236905A1Eliminate riskMaintain consistencyTransmission systemsGraph readingEngineeringTouch panel

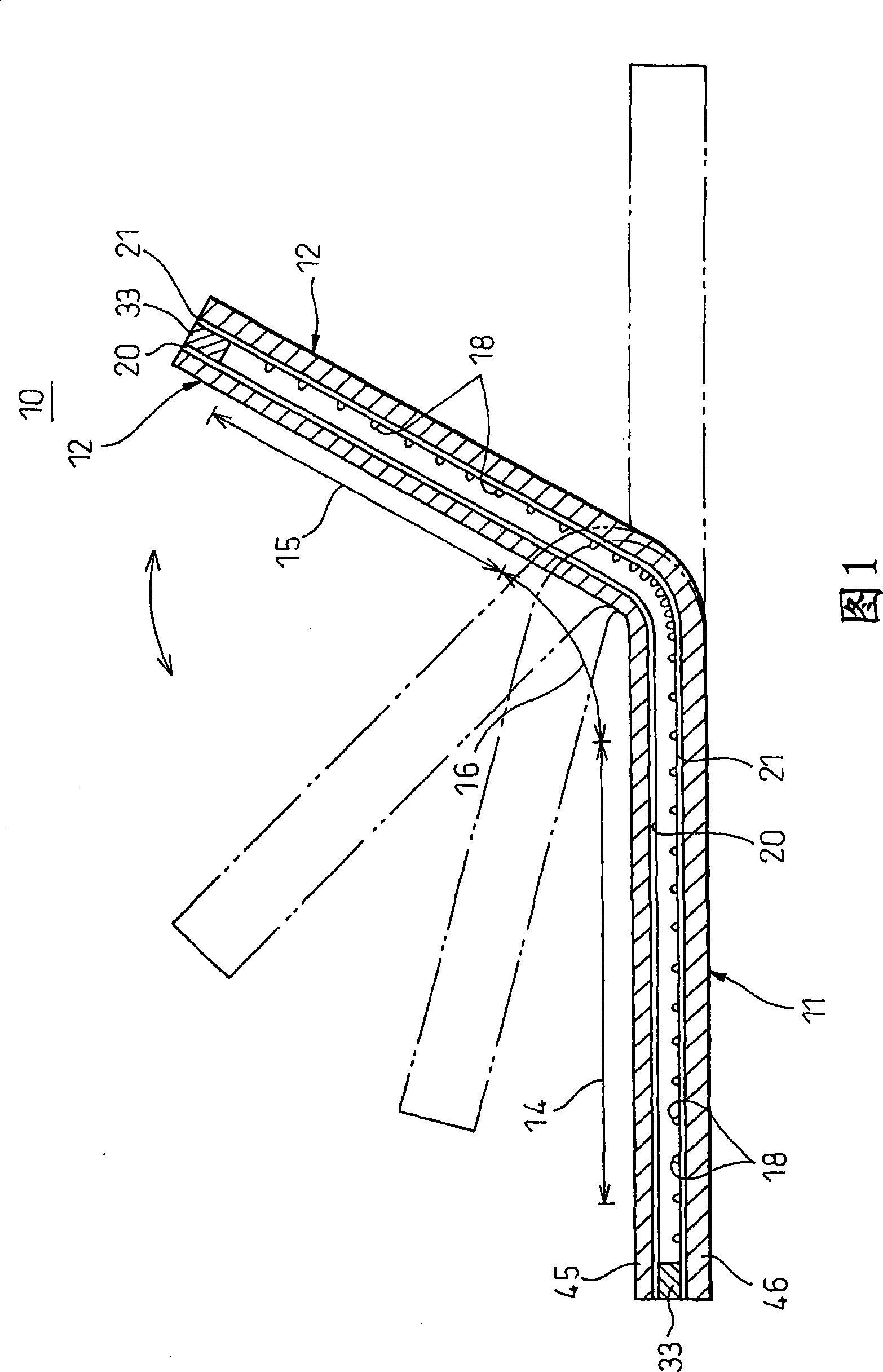

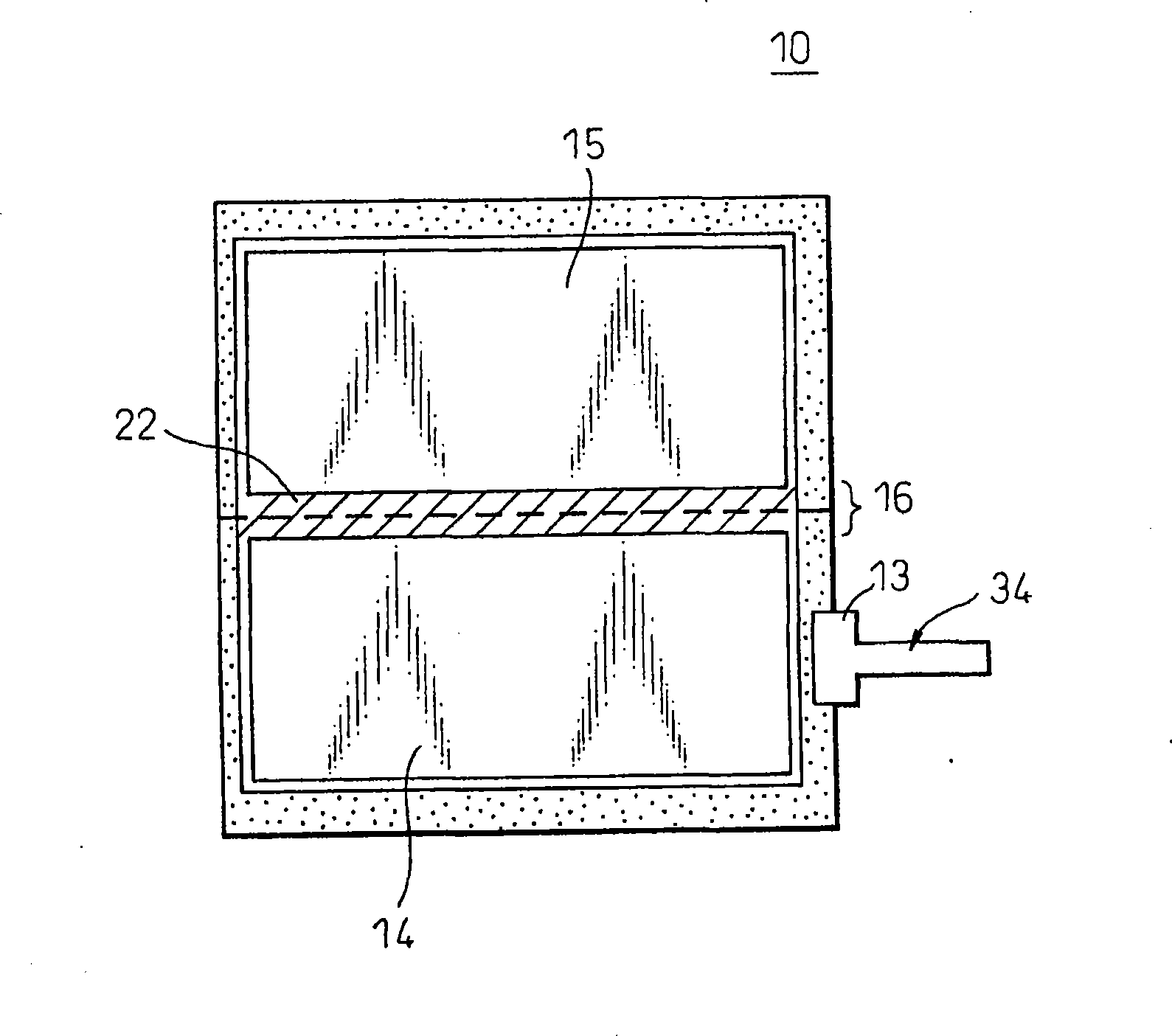

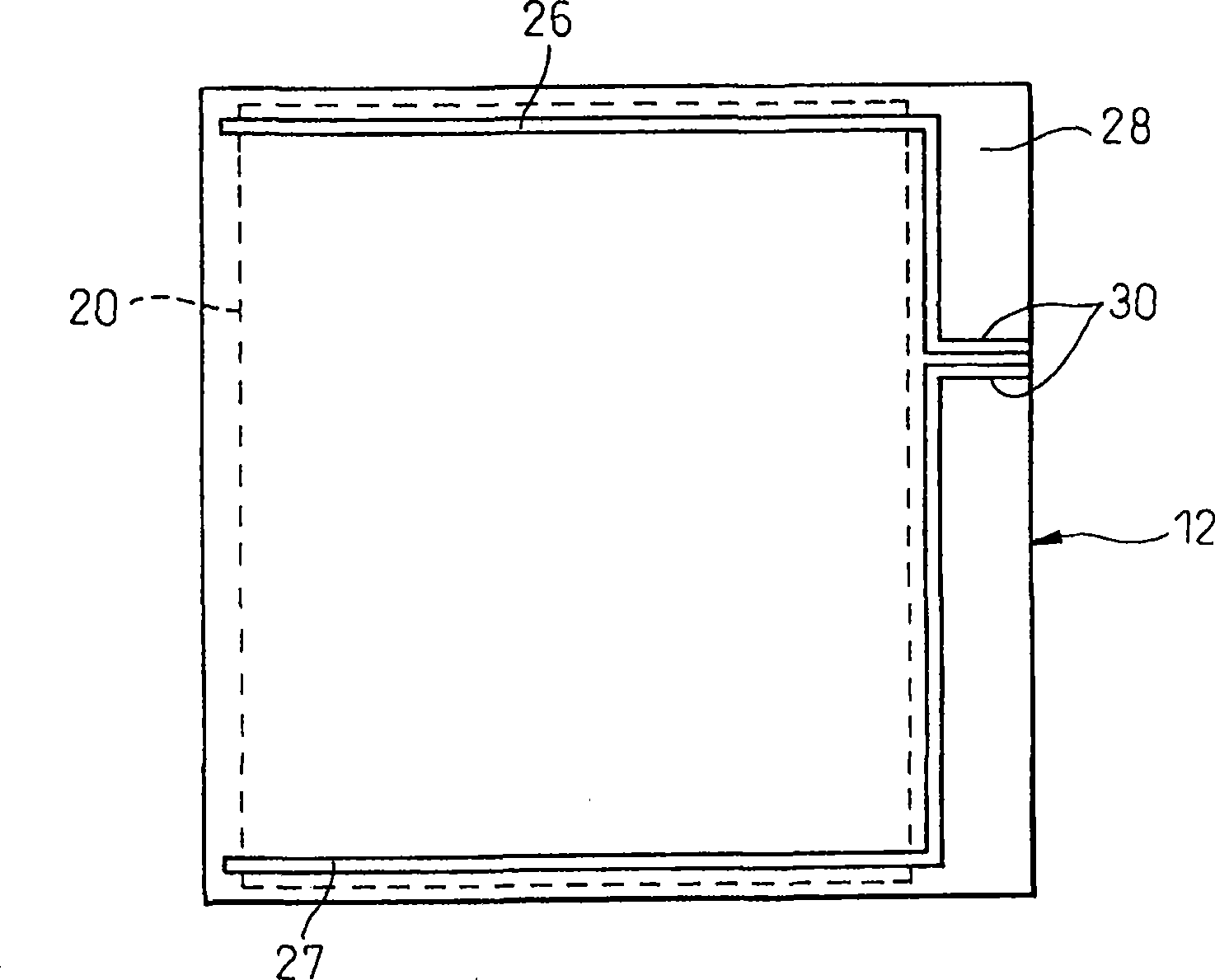

A touch panel including a fixation side substrate and an operation side substrate disposed in opposition and adhered to each other, having a fixation side conductive film and an operation side conductive film respectively formed on opposing faces of the fixation side substrate and the operation side substrate, and being capable of detecting any contact point on the fixation side conductive film and the operation side conductive film as a 2-dimensional coordinate, wherein a bending section is formed between one end and the other end thereof, and wherein two input operation regions are defined and formed on both sides of the bending section.

Owner:FUJITSU COMPONENENT LTD

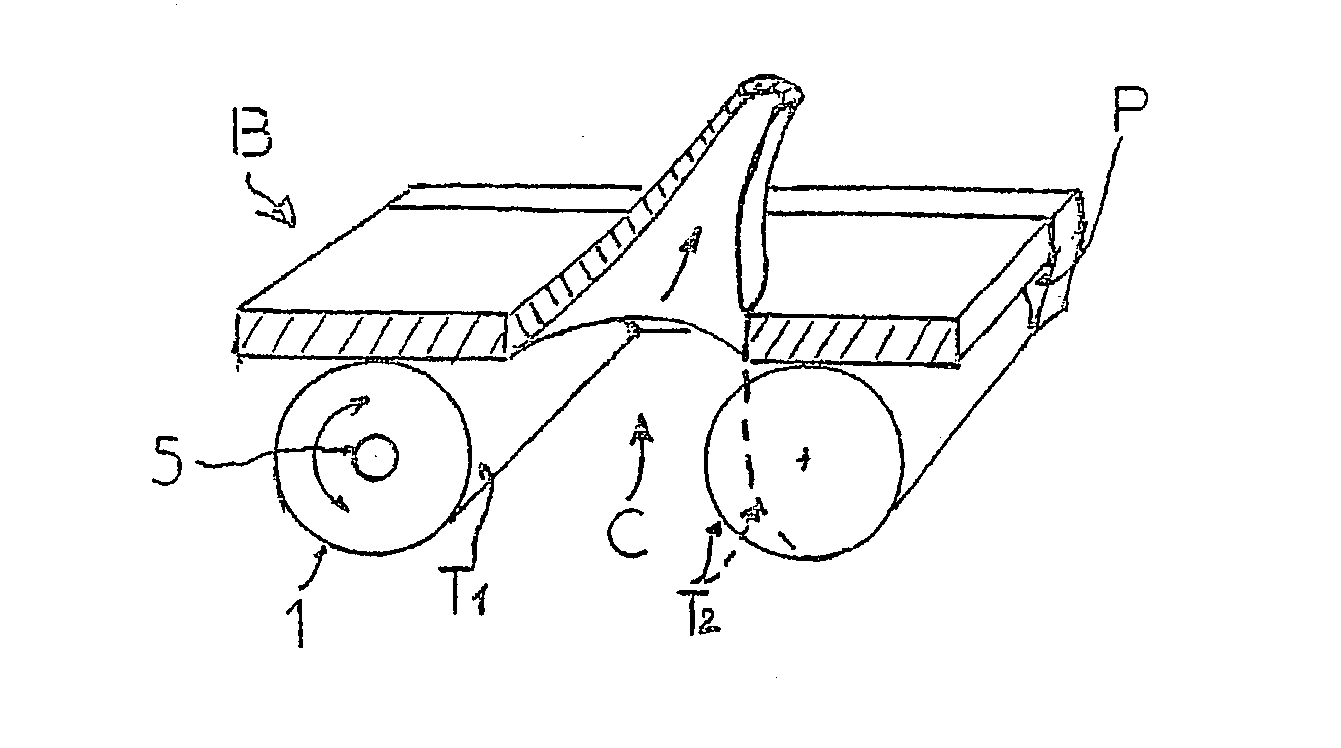

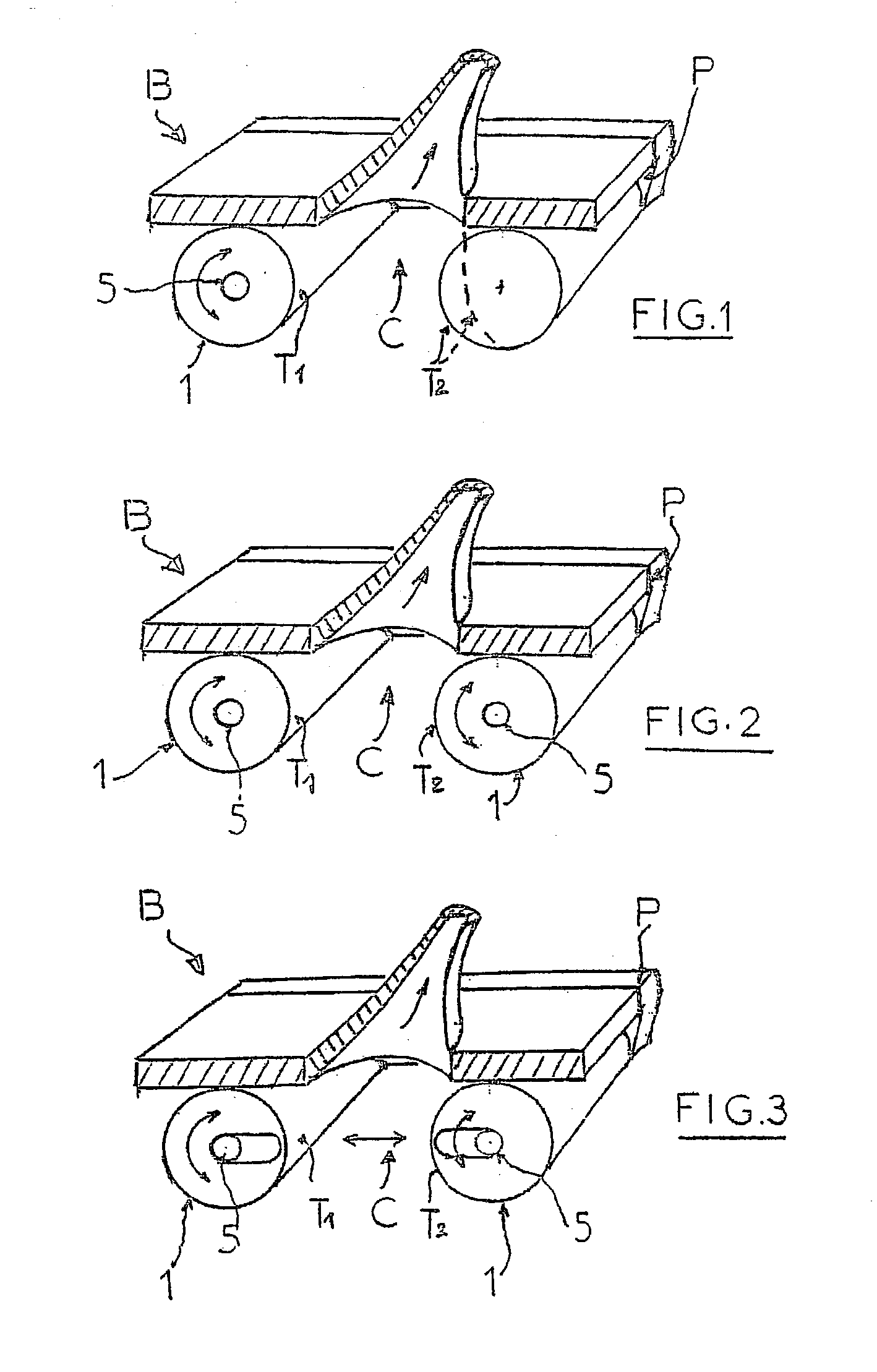

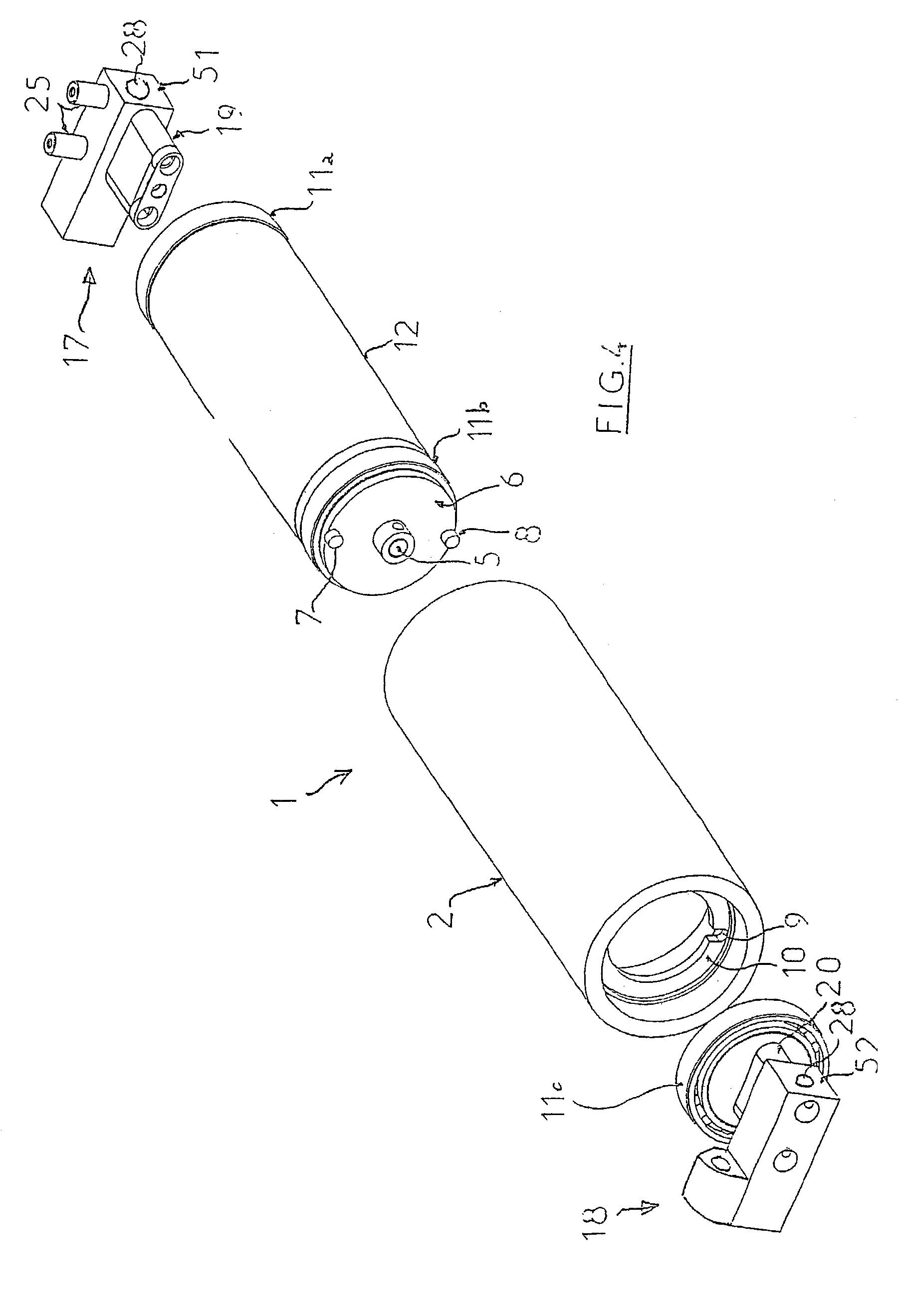

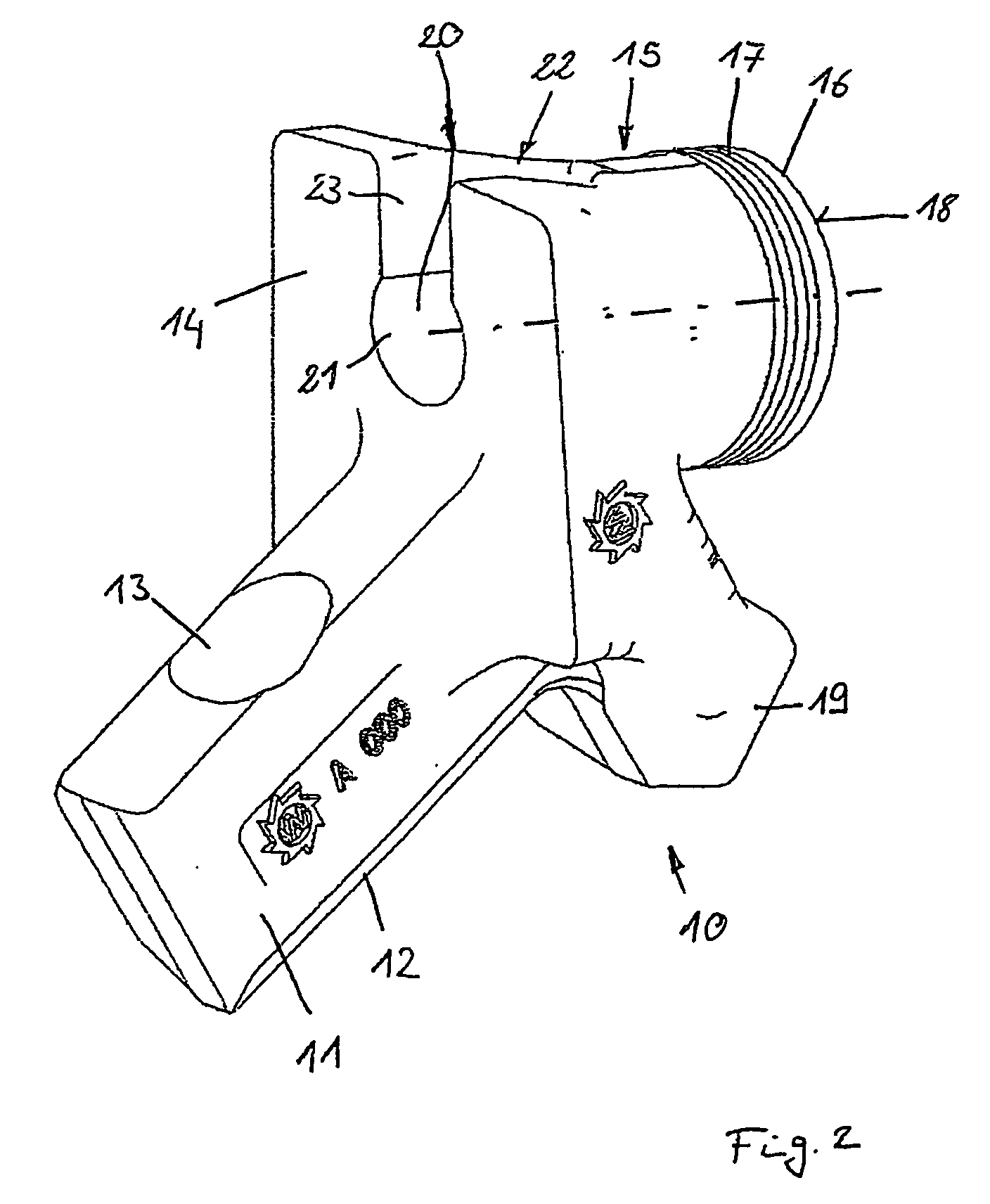

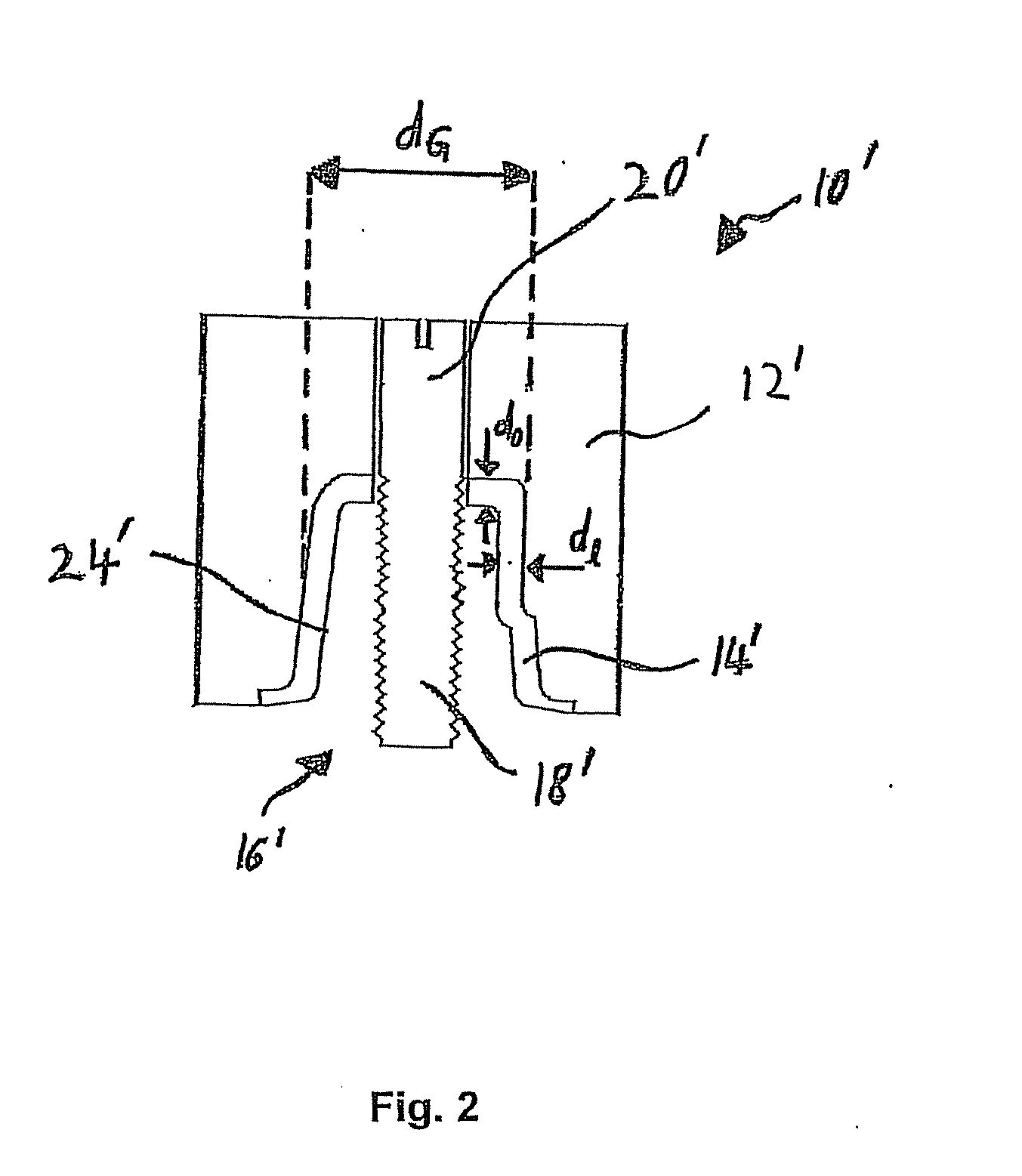

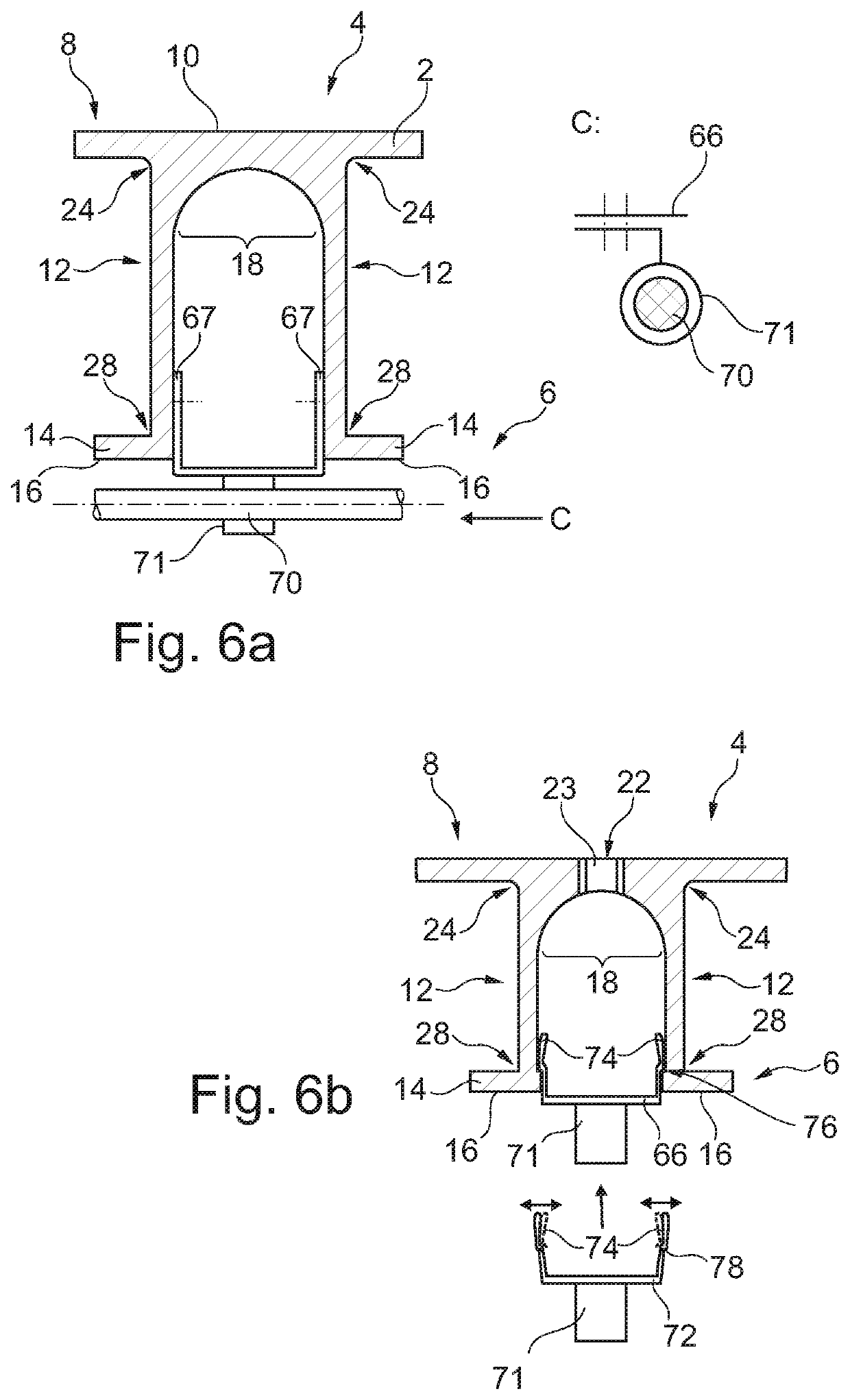

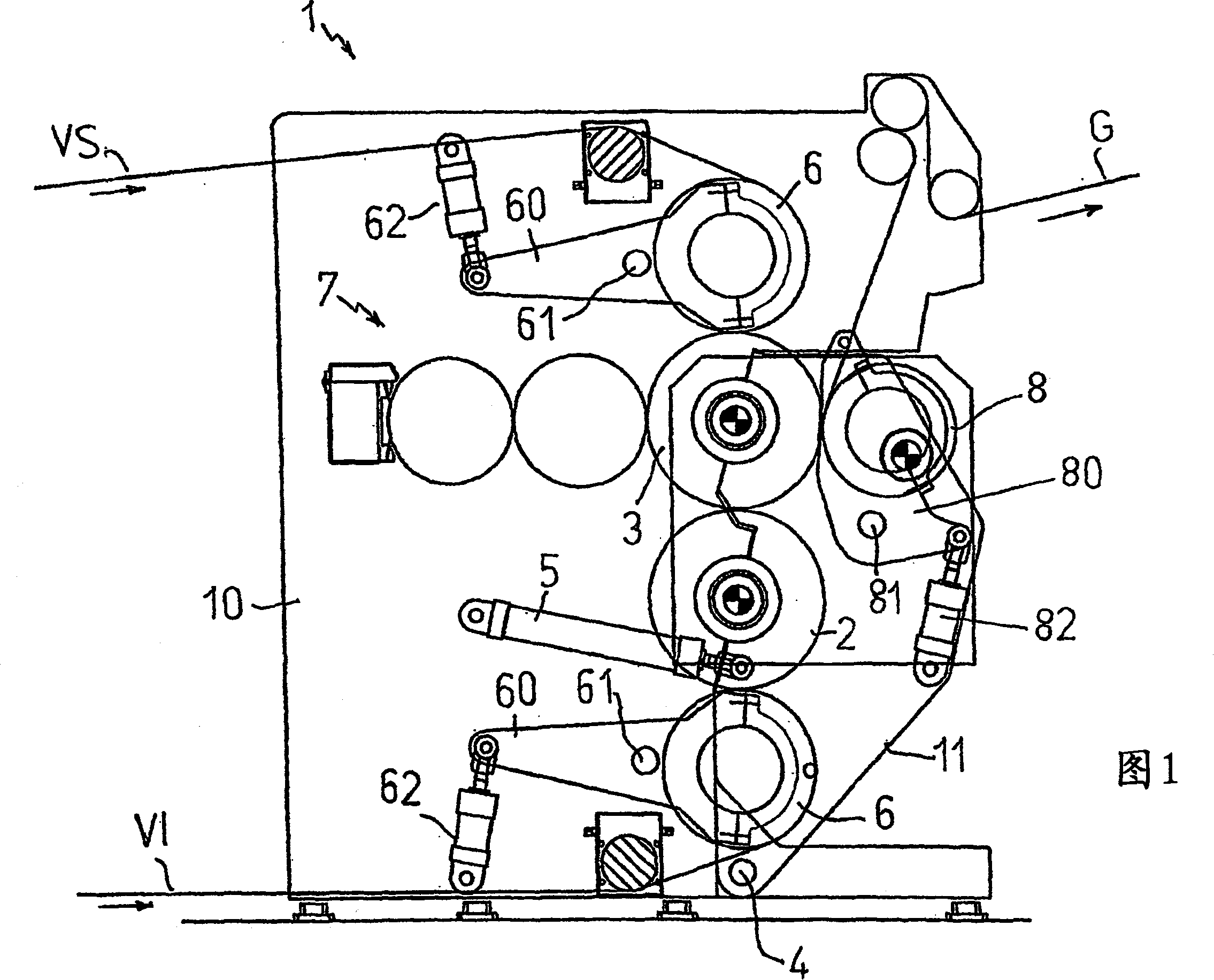

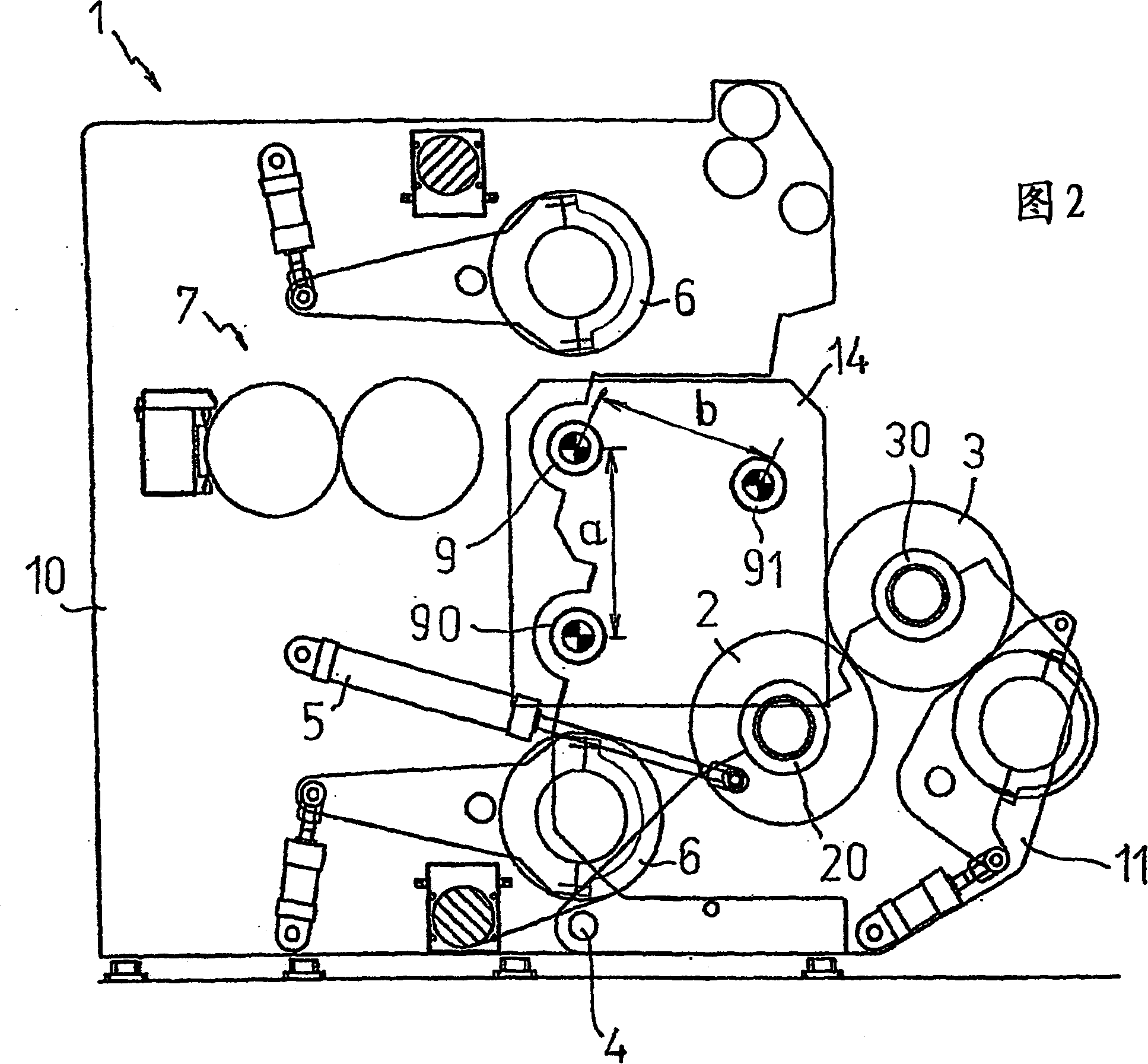

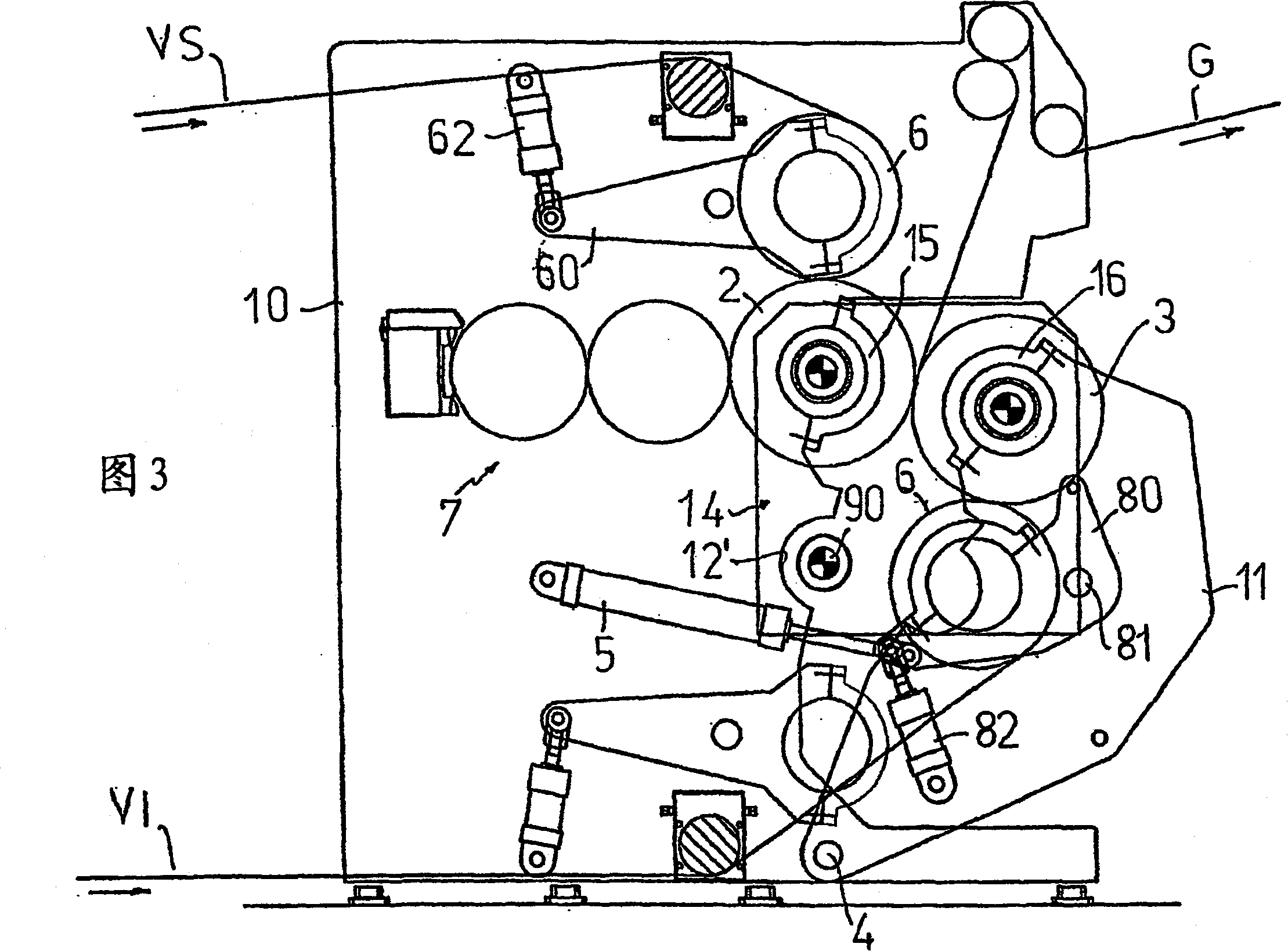

Massage apparatus comprising at least one roller driven positively in rotation

Massage apparatus consisting of a treatment head connected to a suction circuit, the said treatment head comprising a box (B) that can be operated manually, comprising an internal chamber (C) open at its base, which chamber is defined by two fixed side walls (P1, P2) and two transverse surfaces (T1, T2) arranged facing one another between the two side walls (P1, P2), at least one of these surfaces (T1) consisting of the periphery of a roller (1) driven positively in rotation, the suction circuit opening into the said chamber (C) and making it possible to create suction when the apparatus is applied against the body of the patient, which suction tends to form a fold of skin pressing against the transverse surfaces (T1, T2), characterized in that the positive drive of the roller (1) is obtained via a geared motor unit mounted fixed and coaxially inside it, and in which the output shaft (5) of the reduction gear comprises means of coupling to the said roller (1), the said apparatus being associated with means for adjusting the speed and / or direction of rotation of the motorized roller(s) and the amount of suction, possibly varying this, and doing so during operation.

Owner:CNLP SA

Tool Holder

ActiveUS20080223744A1Simple processSupporting function is reducedSlitting machinesOther accessoriesFree rotationCentrifugal force

A tool holder including a tool box with a tool seat in a holding projection for receiving a tool in such a manner that it can be replaced. The tool seat is configured as a bore and has a tool insertion opening. The tool holder has a fastening side with a fastening projection and, facing away from said fastening side, an exterior, and during use of the tool centrifugal forces are effective in the direction from the fastening side to the exterior. This invention ensures the free rotability of a tool inserted in the tool holder even if overburden material enters the tool seat. For this purpose, the holding projection has an opening penetrating the inner wall of the tool seat and creating a spatial connection to the exterior, and the opening opens the tool seat towards the exterior.

Owner:WIRTGEN GMBH

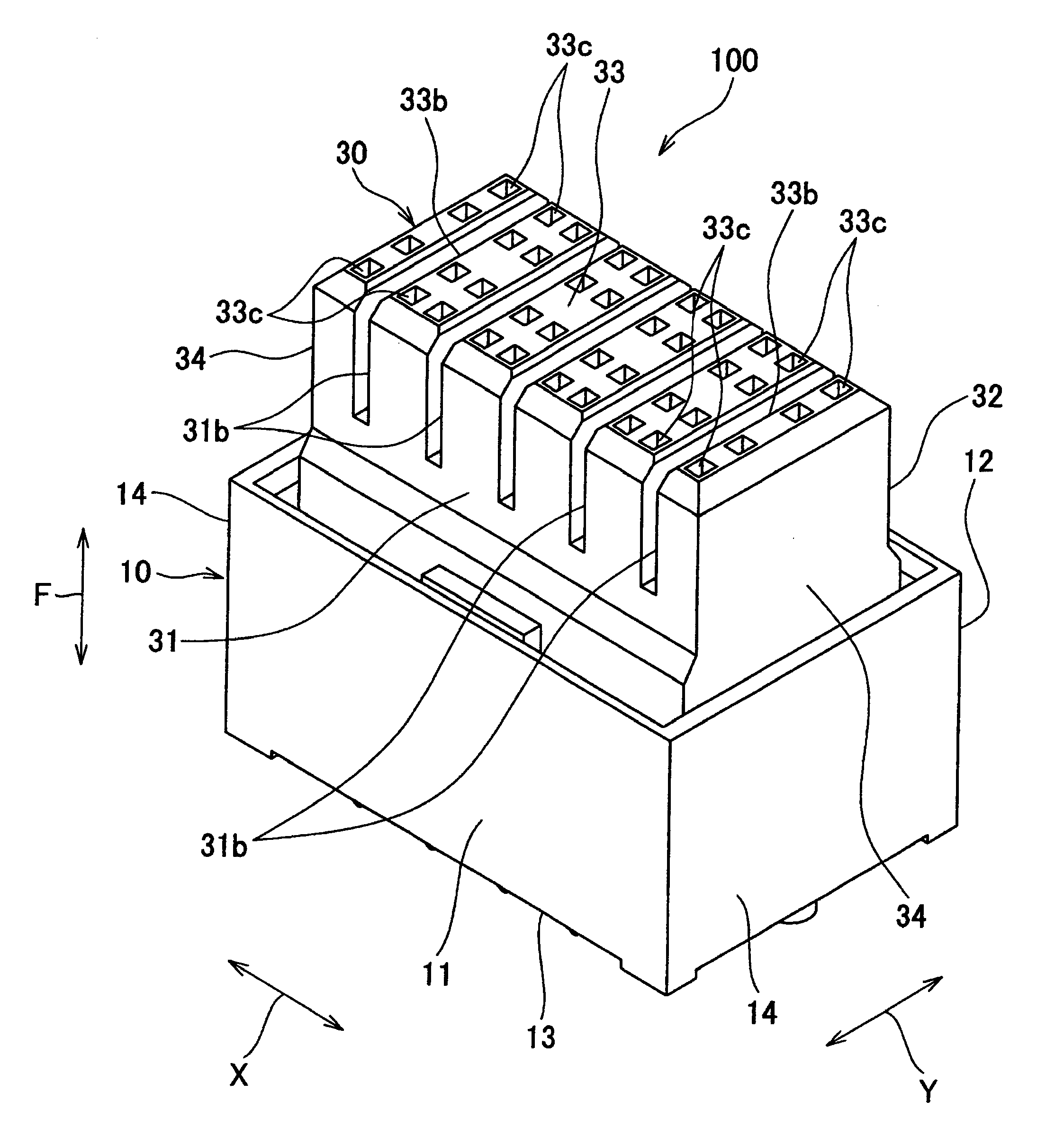

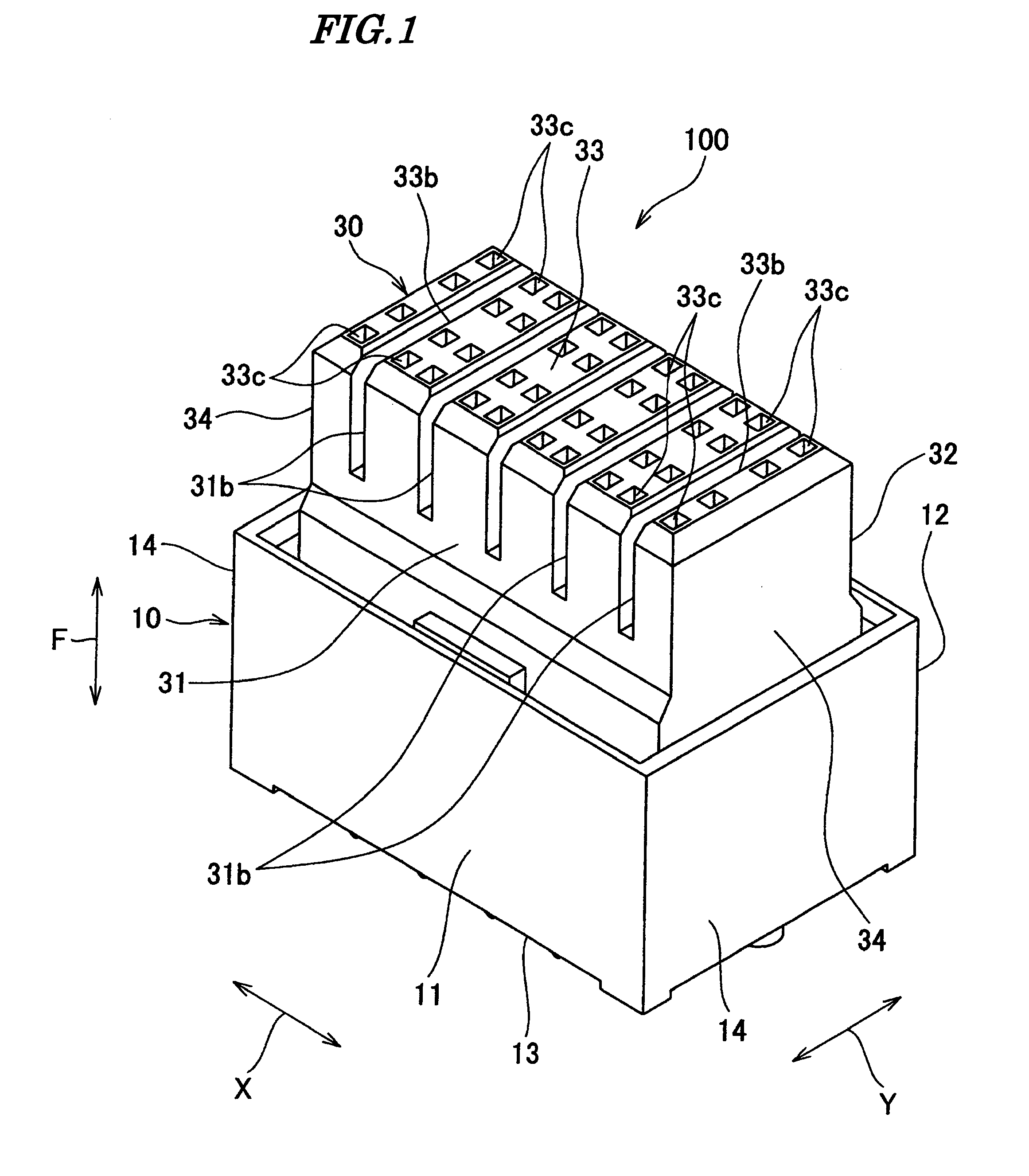

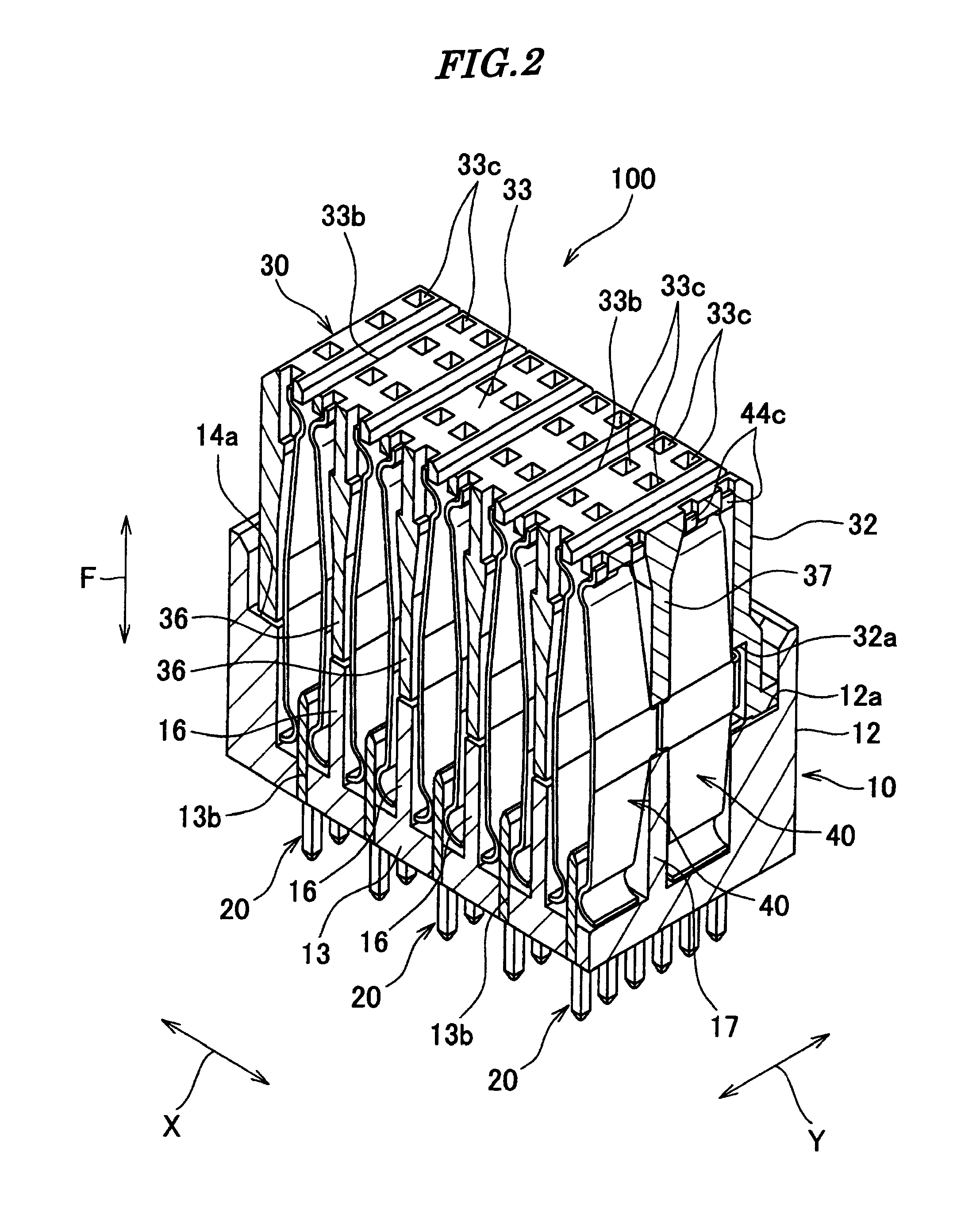

Connector

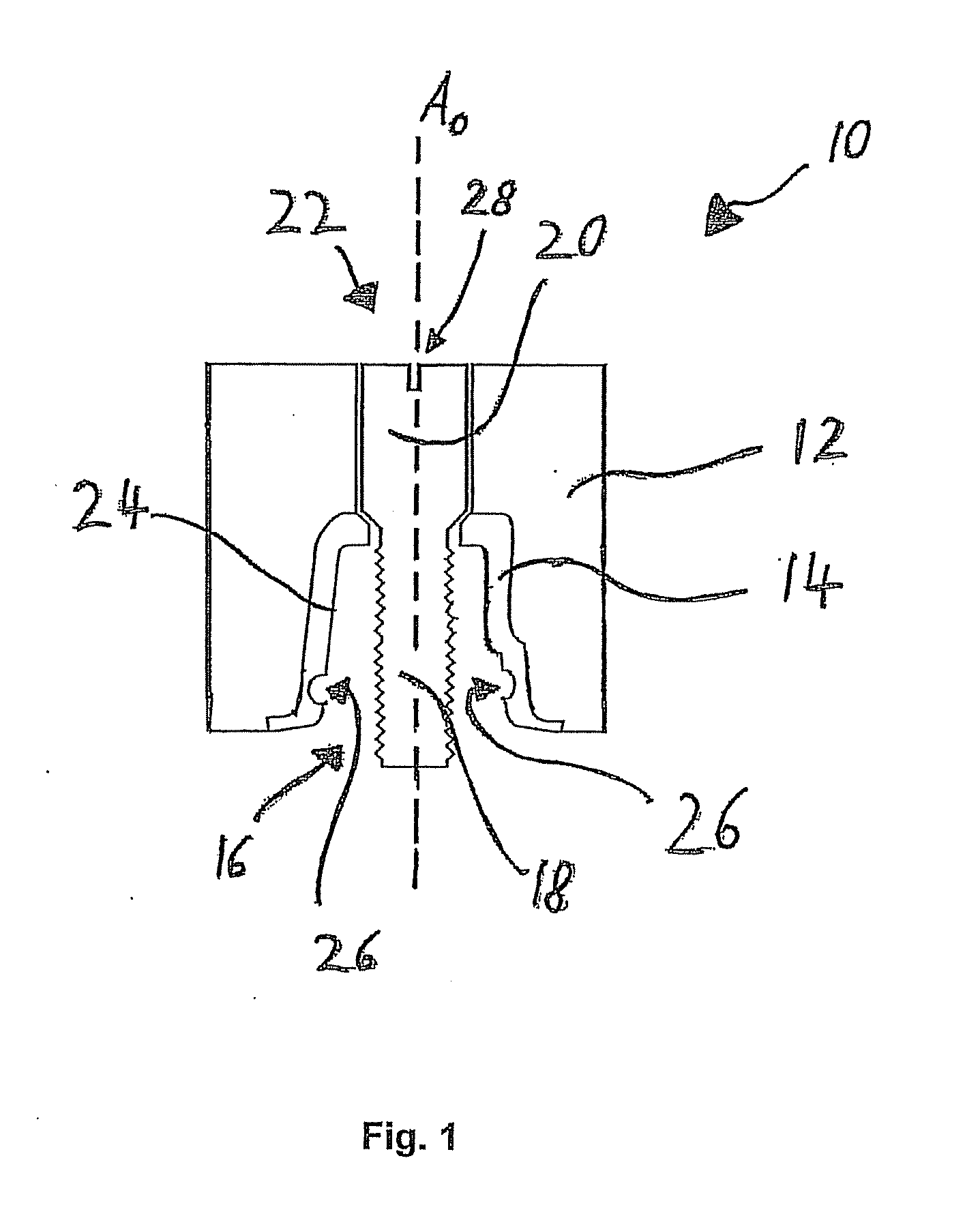

InactiveUS20110065331A1Inhibition amountAvoid forceIncorrect coupling preventionSecuring/insulating coupling contact membersMating connectionContact force

A connector which makes it possible to accommodate positional displacement from a mating connector, and prevent the contact force and the amount of deformation of contacts from becoming too large. Fixed-side contacts are fixed to a fixed-side housings. A movable-side housing is assembled to the fixed-side housing slidably in a direction orthogonal to a fitting / removing direction in which the movable-side housing is fitted to and removed from the mating connector. Movable-side contacts each include first contact portions brought into contact with an associated one of the fixed-side contacts, and second contact portions brought into contact with an associated one of mating contacts of the mating connector. Contact-accommodating chambers for accommodating the movable-side contacts are formed in the movable-side housing such that each movable-side contact can be pivoted about a pivotal axis extending orthogonal to the fitting / removing direction.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

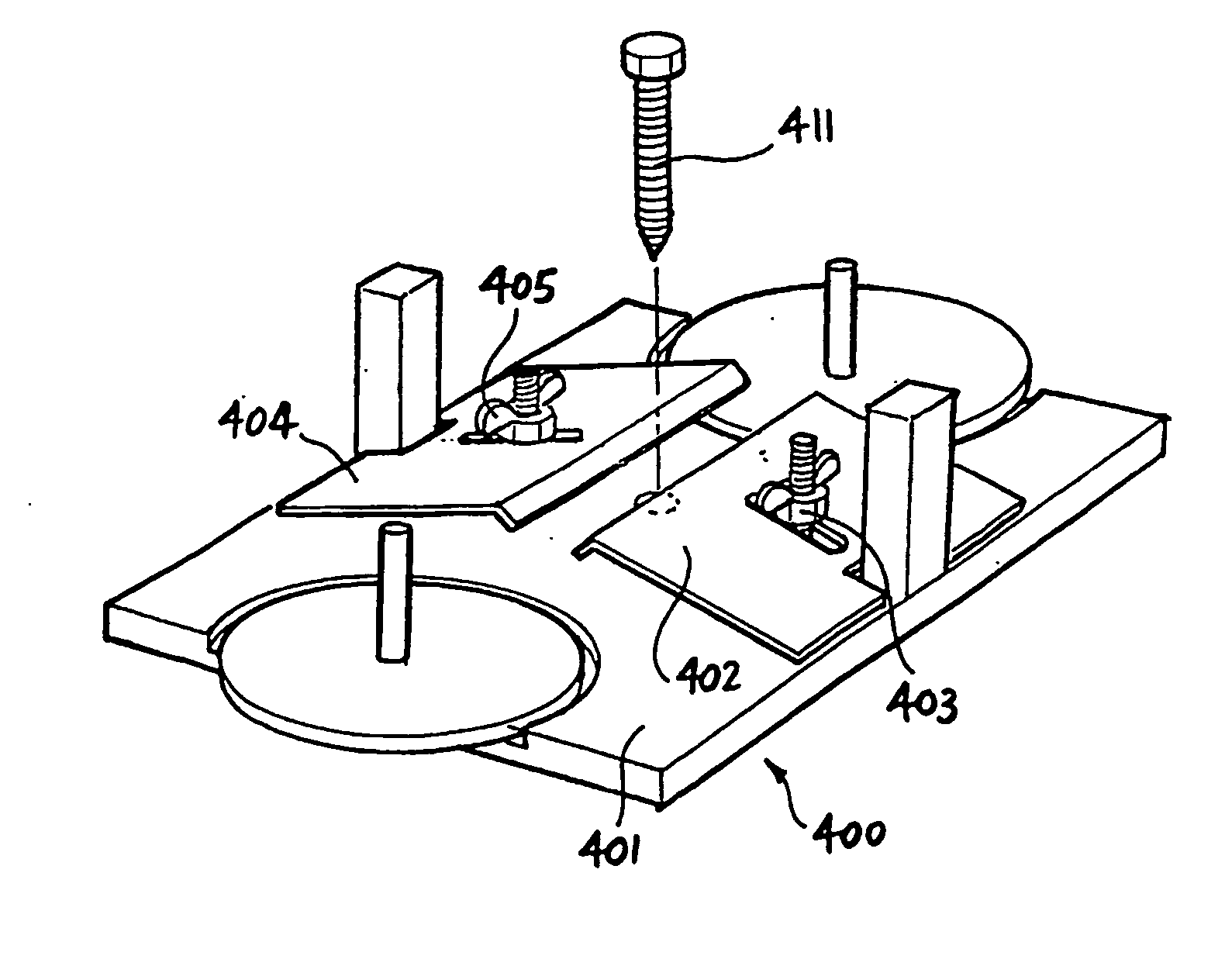

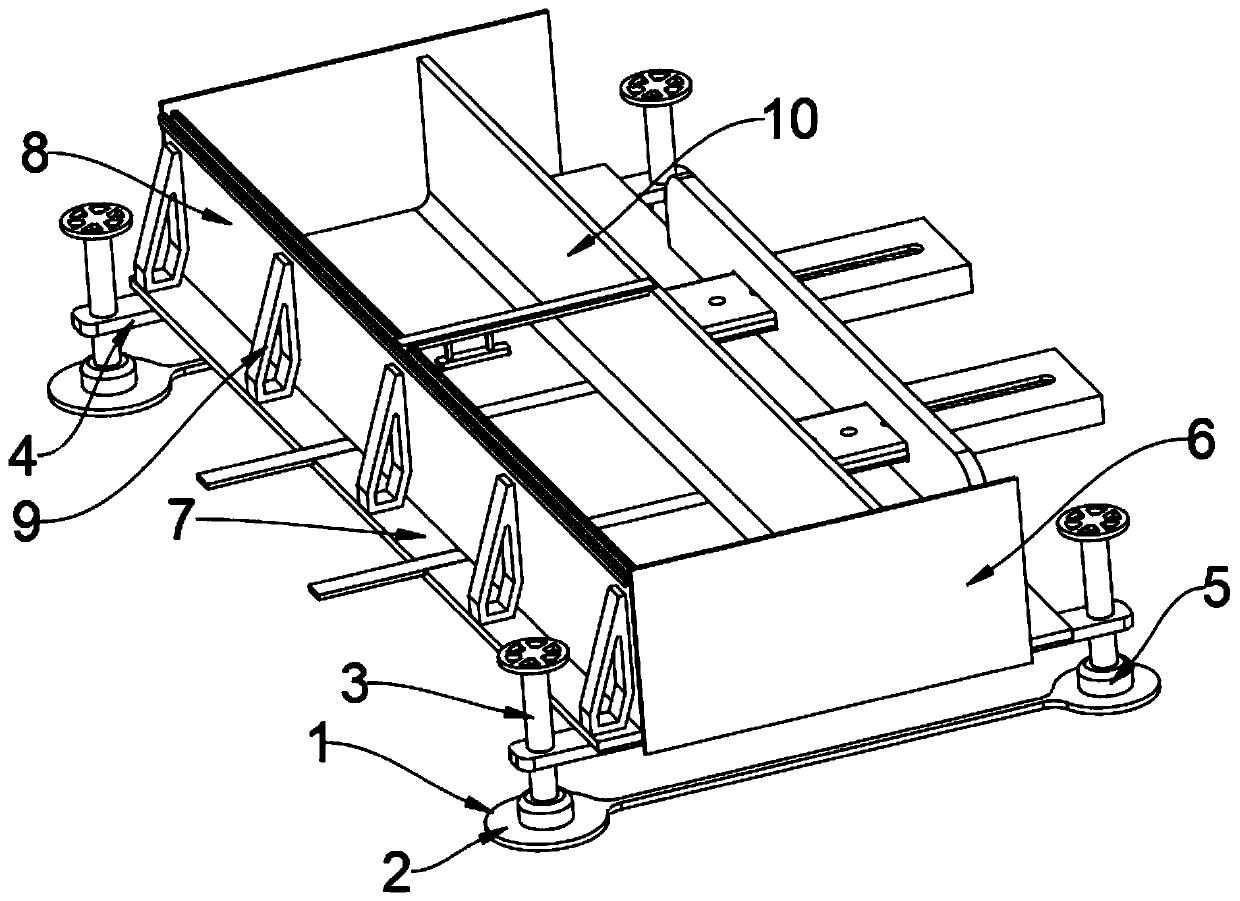

Method and apparatus for forming construction panels and structures

InactiveUS20050061948A1Low costEasy to useMouldsForms/shuttering/falseworksEngineeringFixed position

The present invention includes a formwork structure located on supporting surface, the structure having a side form perimeter including side form members, the perimeter defining a curable non-solid material retaining area; the formwork including side form support members that support the side form members, at least one of the side form support members being held in a fixed position relative to the supporting surface by a surface-to-member releasable securing device fixed to the supporting surface and which engages the side form support member, characterised in that the secured side form support member is adapted to permit another side form support member to be secured thereto by one or more releasable inter-member securing devices, which are separate to the surface-to-member securing device.

Owner:NICOLO ASSUNTA

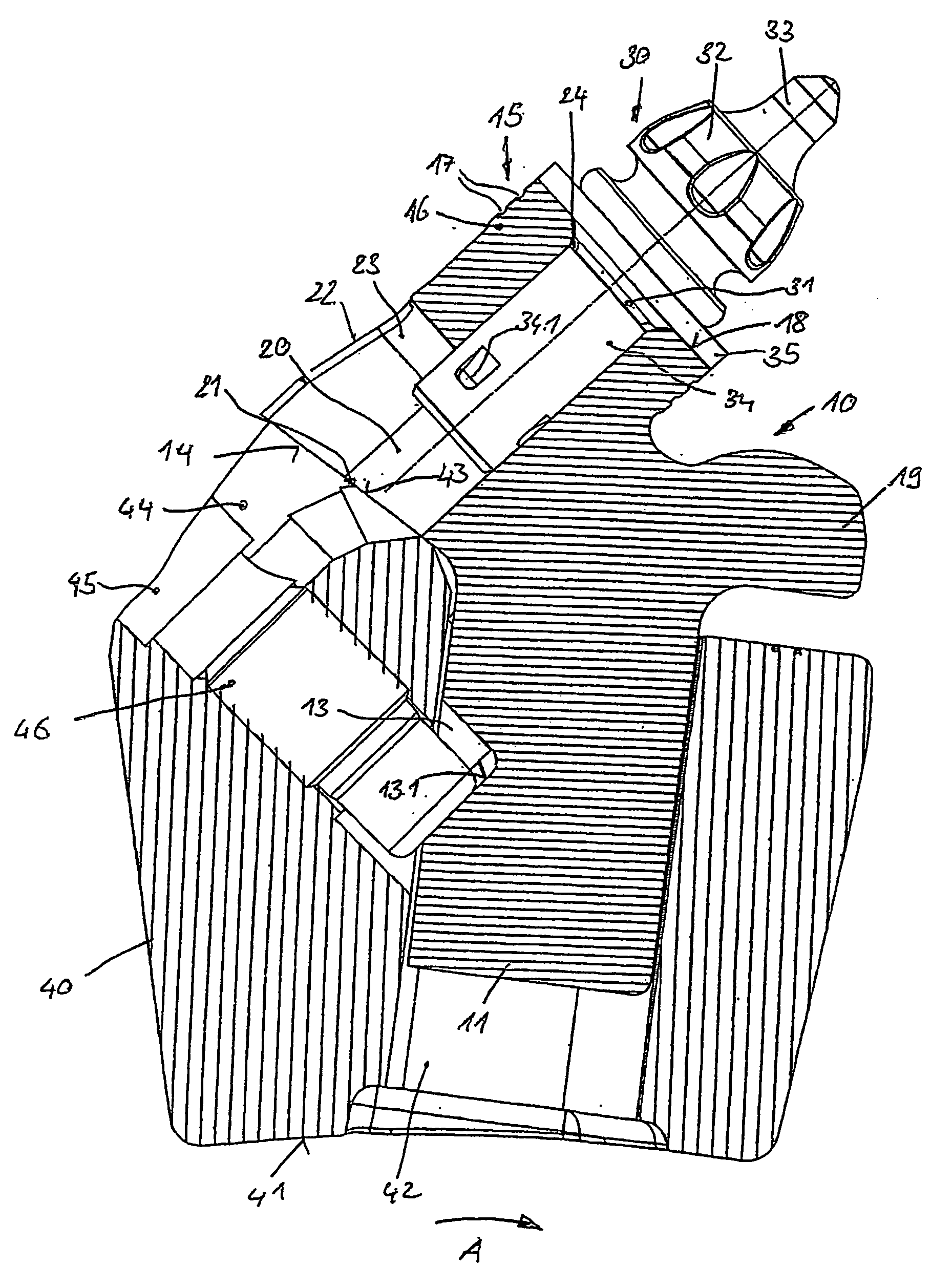

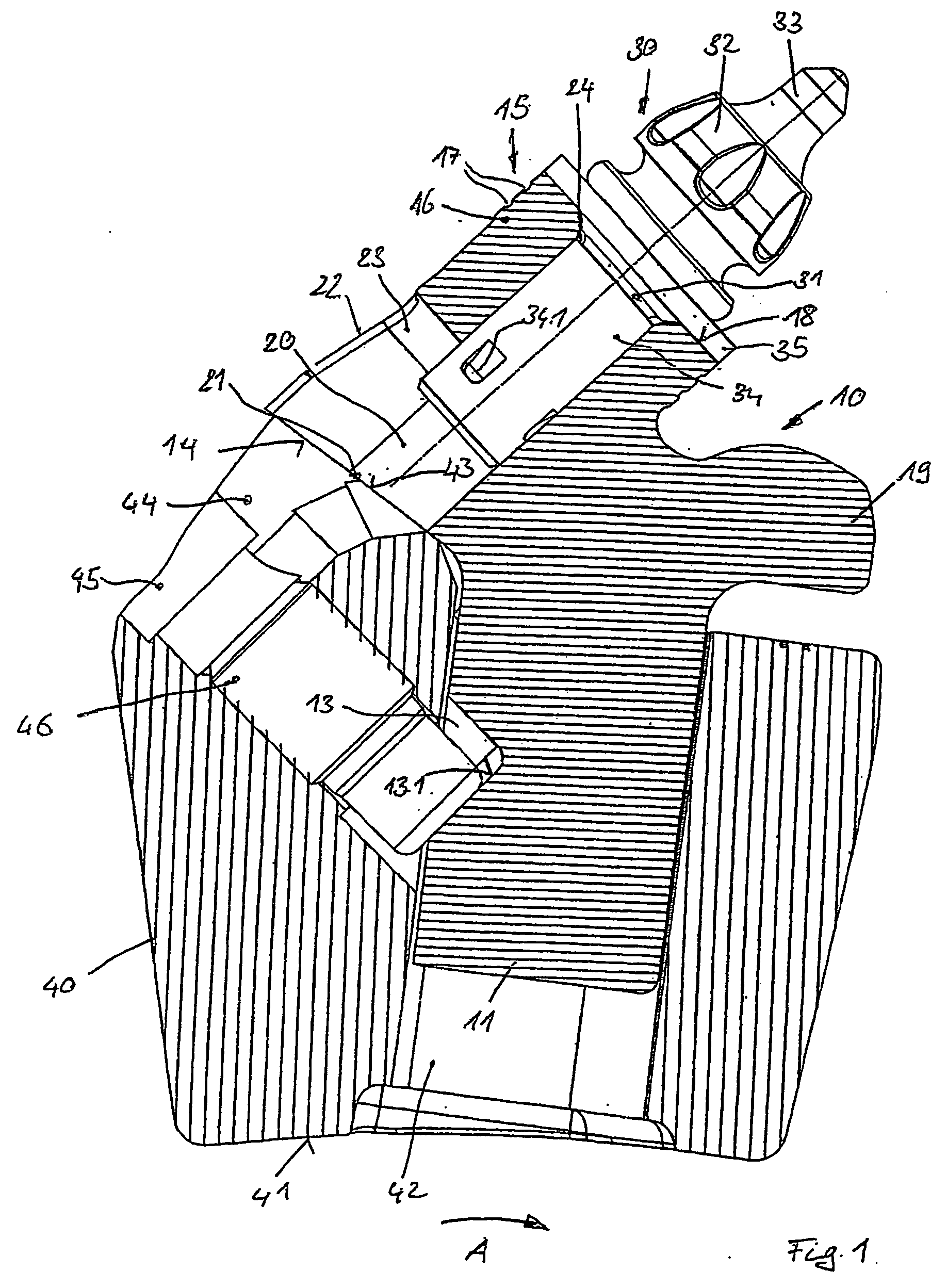

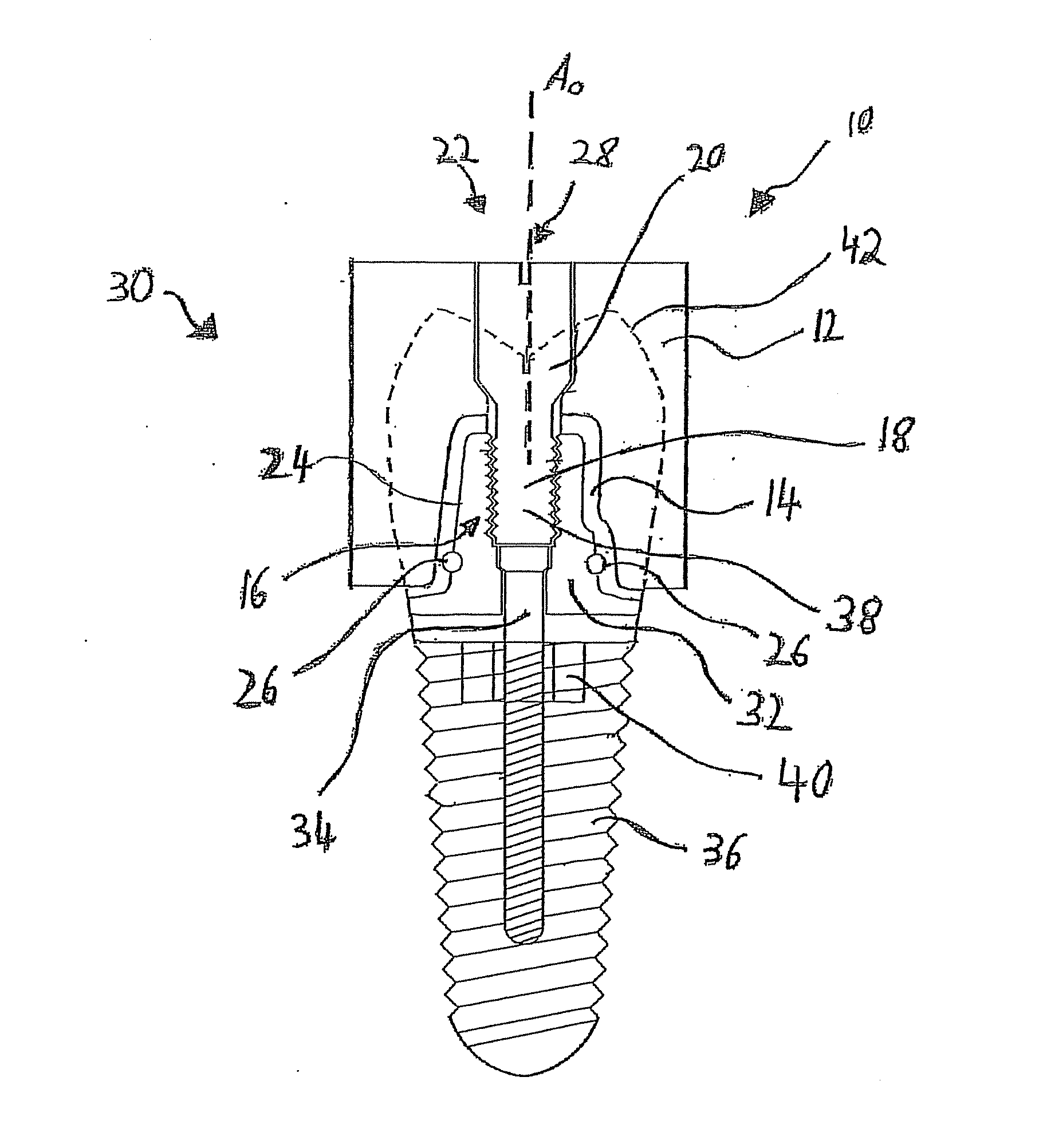

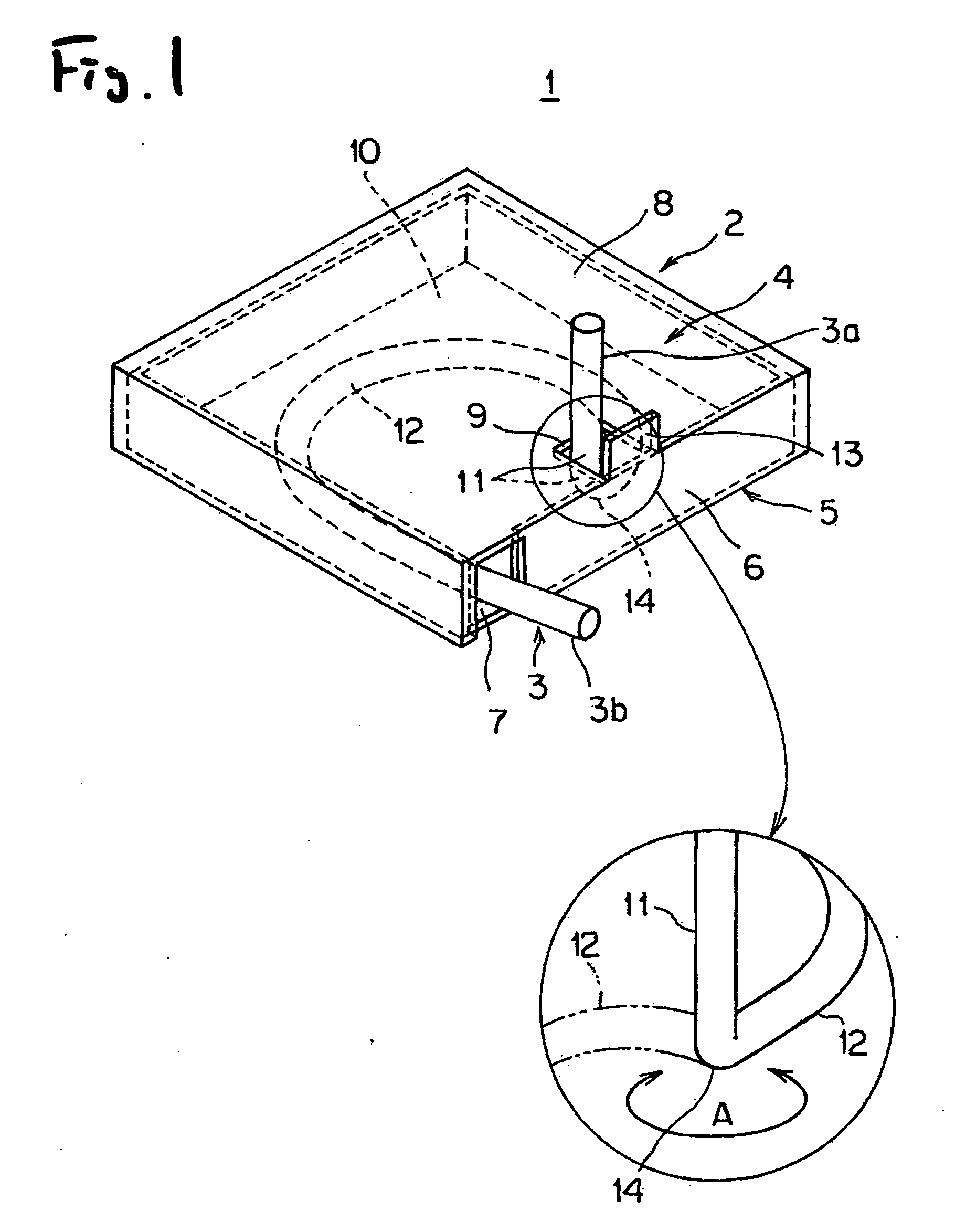

Blank and process for producing a dental restoration by subtractive machining

InactiveUS20150216635A1High natural appearanceHigh strengthDental implantsWashersAngular orientationImplant retainer

A blank is provided for producing a dental prosthesis (tooth crown) comprising a mechanically processable material block and a holder connected thereto for clamping in an automatic processing tool. Said block is provided with a subgingival anatomic implant connecting part which is protrusively arranged thereon and in which an implant fixture for fixing it to the implant head is formed. The holder is arranged on the surface of the block arrangement side and the implant fixture to a surface on the implant side, thereby making it possible to work the blank by means of a computer-controlled conventional tool. A threaded channel which is embodied in the centre of the block in a parallel direction with respect to the surface on the fixation side, the angular orientation of the mastication surface of the tooth crown with respect to the occlusion vertical and the subgingival anatomic implant connecting part make it possible to fix the prosthetic element (tooth crown) directly to the implant without an abutment and with correct orientation in the row of teeth.

Owner:JOSEF SCHWEIGER

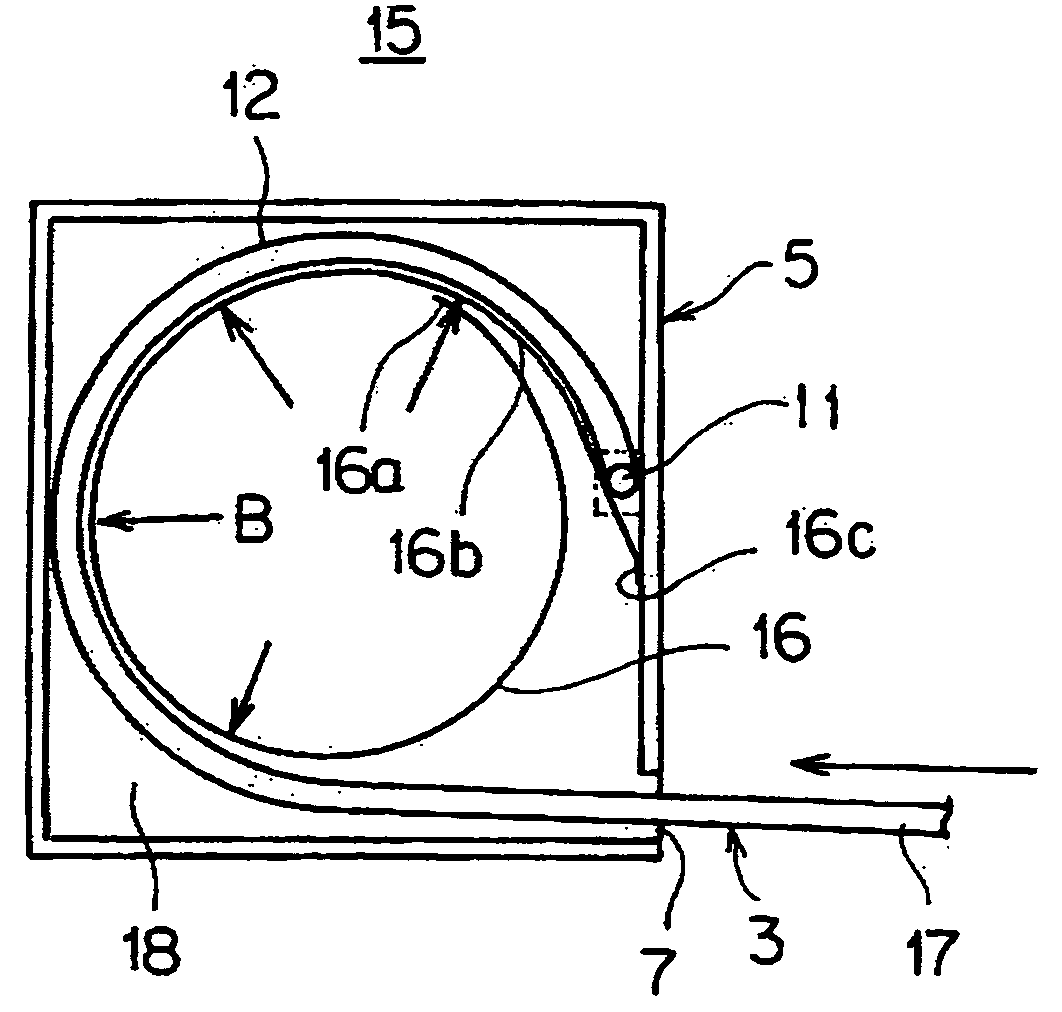

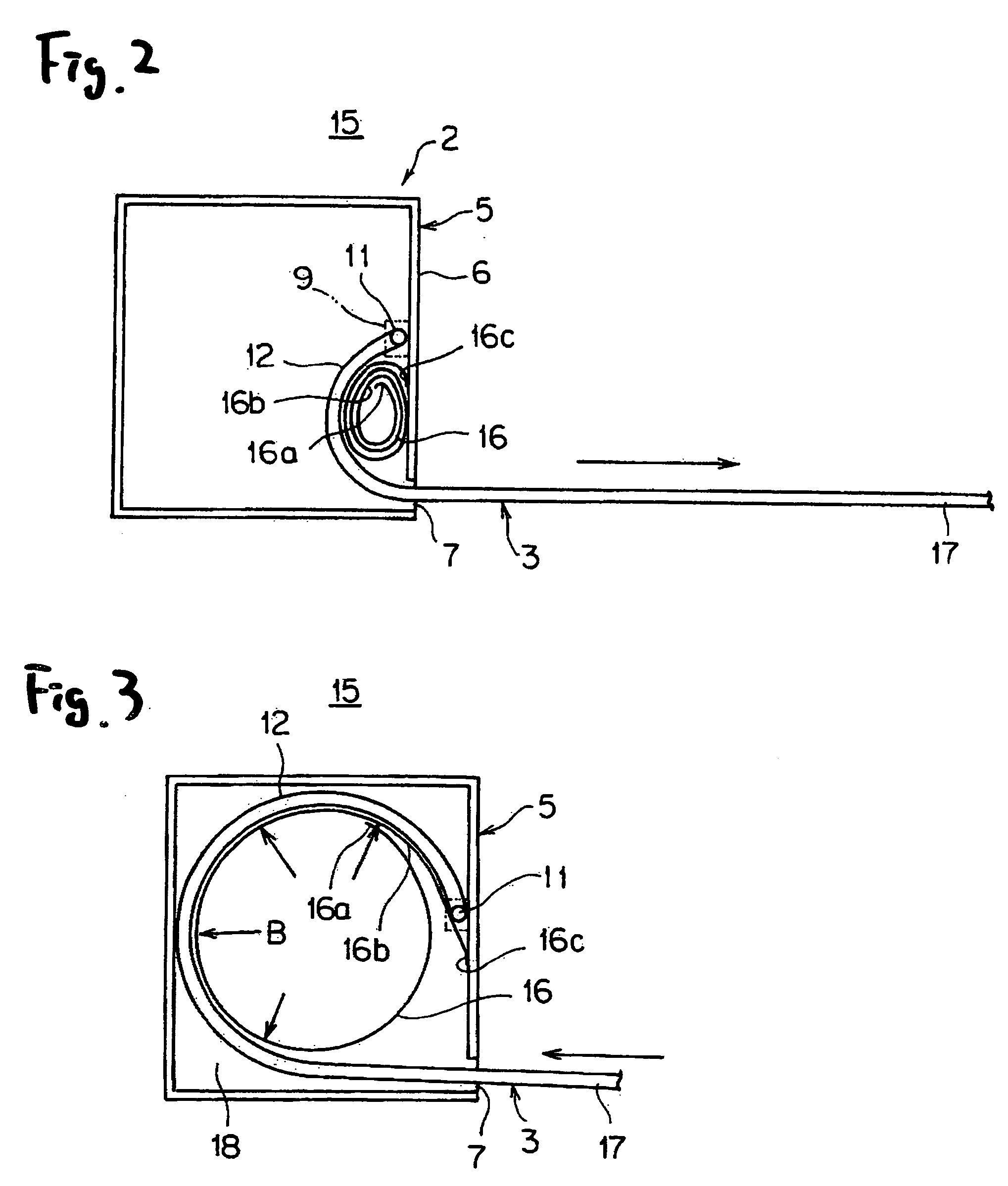

Wiring harness excess length absorbing device

ActiveUS20060292923A1Lower component costsLow number of componentsExtensible conductorsElectric/fluid circuitEngineeringCable harness

A wiring harness excess length absorbing device includes a supporting portion that rotatably supports a straight part of a wire harness, and a pullout portion through which a pass-through portion of the wire harness is passed. The supporting portion and the pull out portion define a form of the wire harness in which an incompletely annular curved portion of the wire harness is formed, one end of the curved portion continues to the straight portion, the straight portion continues to a stationary side wiring harness portion, the other end of the curved portion continues to the pass-through portion which is continued to a movable side wiring harness portion, and a plane defined by the curved portion is perpendicular to an extending direction of the straight portion. When the movable side wiring harness portion is moved, the straight portion twists in a circumferential direction thereof while a diameter of the curved portion is expanded or contracted.

Owner:YAZAKI CORP

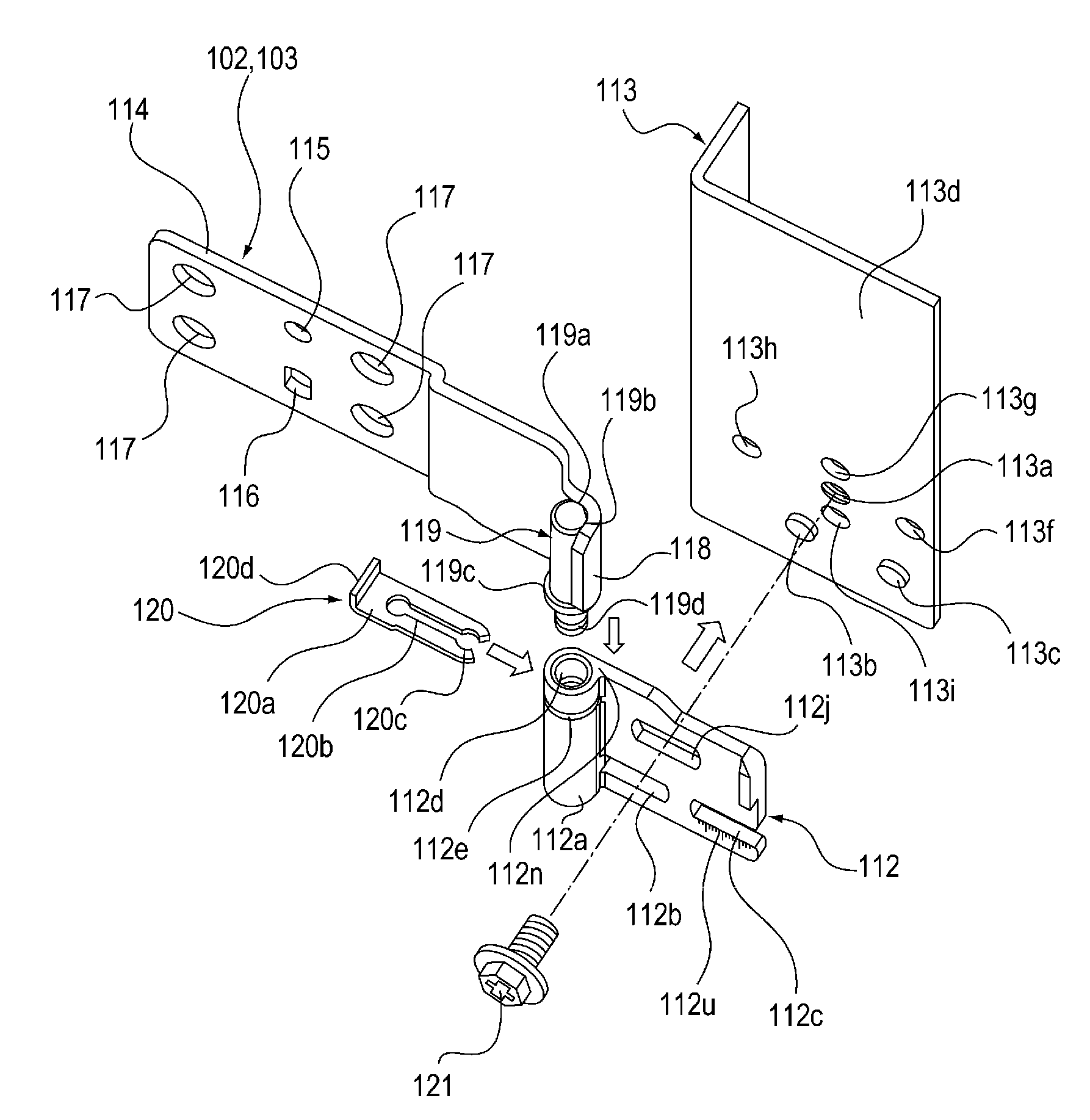

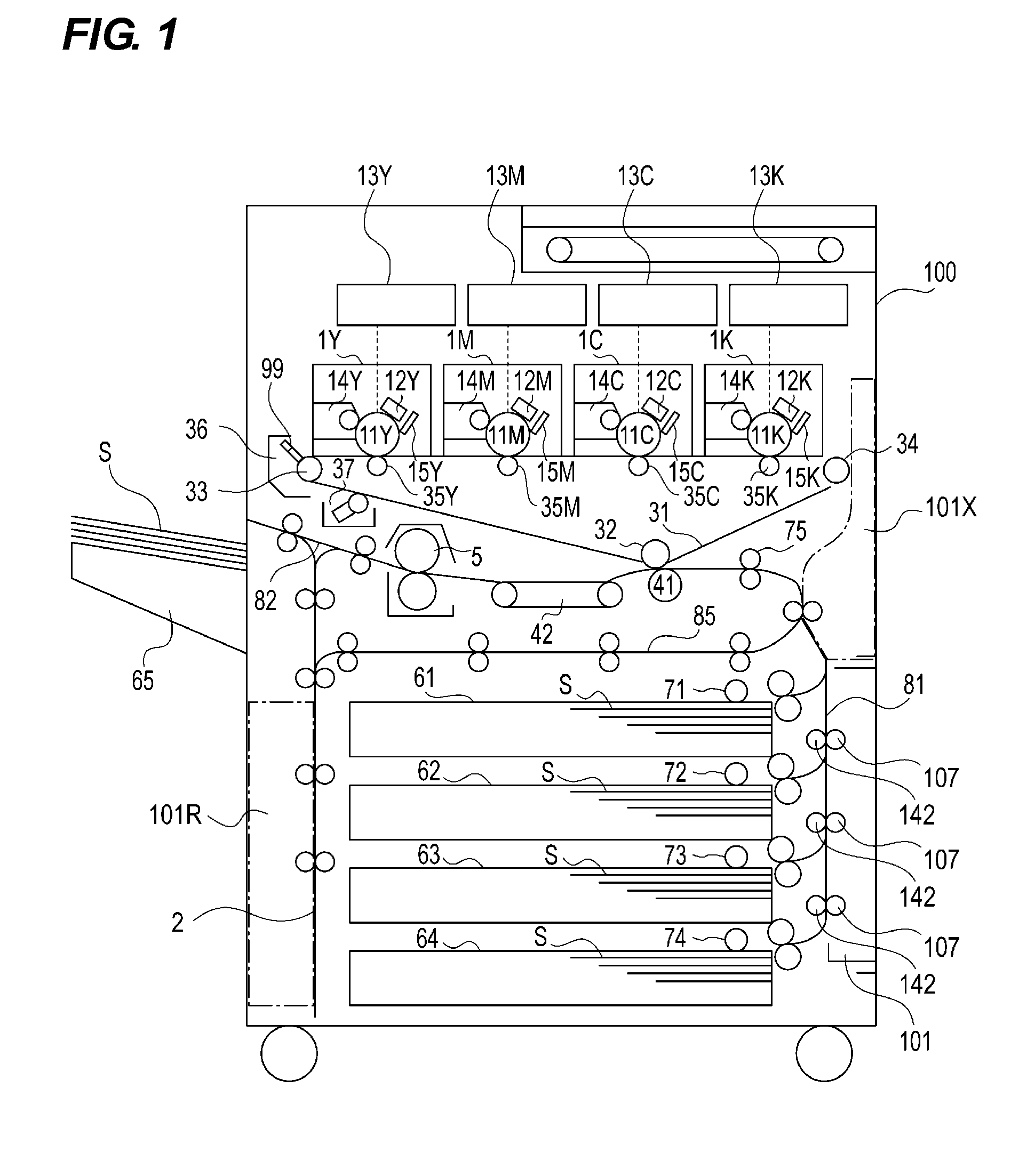

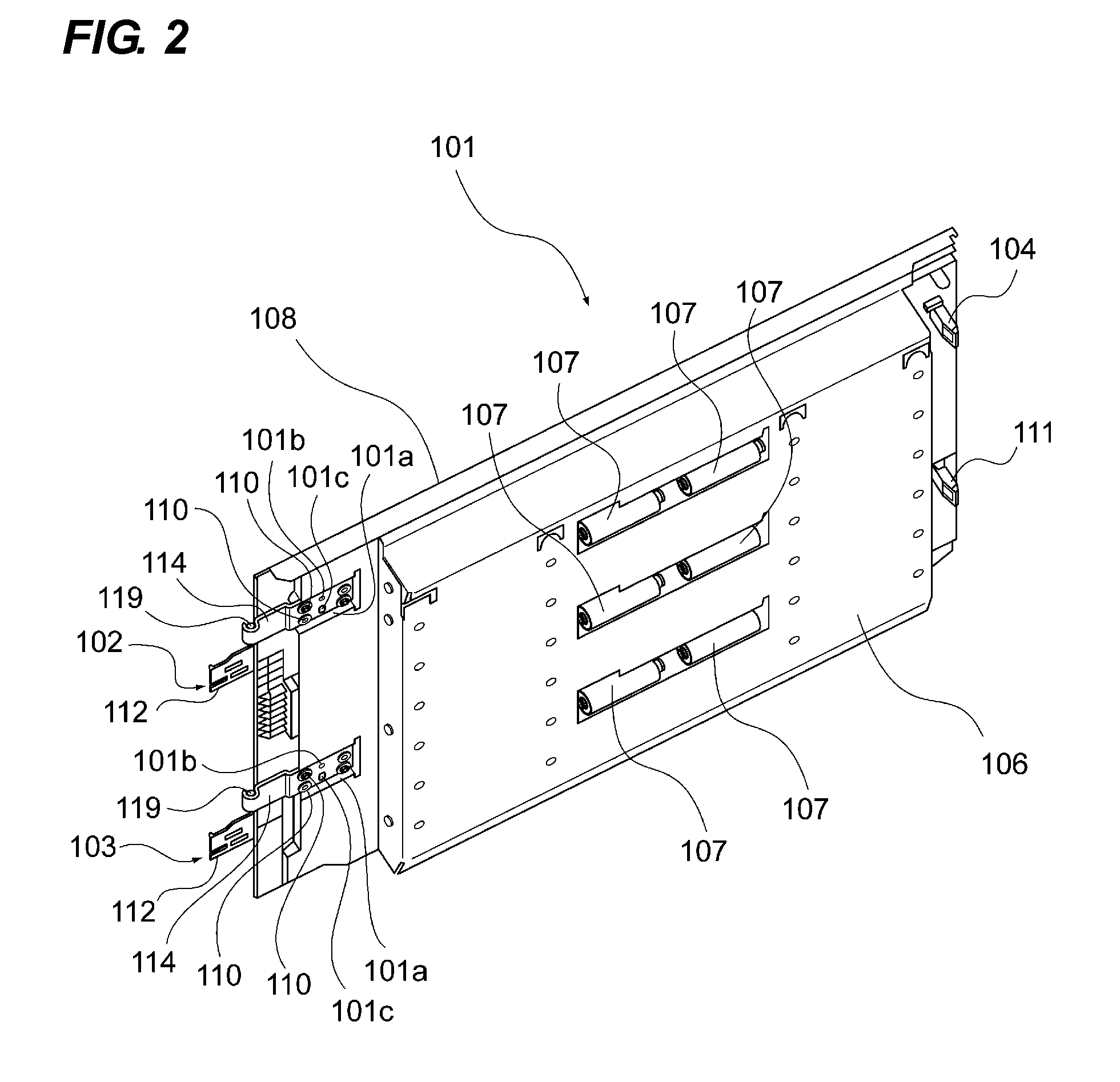

Image forming apparatus

A hinge mechanism arranged between a main body and a door, and openably and closably supporting the door, comprising: a fixed-side hinge plate disposed at the main body; and a movable side hinge plate disposed at the door, wherein the fixed-side hinge plate includes a bearing surface and a plurality of projection portions projected from the bearing surface, and the fixed-side hinge plate is mountable to (1) a first mounting portion of the main body, having holes through which the projection portions can be inserted, and being capable of abutting to the bearing surface, and (2) a second mounting portion of the main body, being capable of abutting to end surfaces of the plurality of projection portions.

Owner:CANON KK

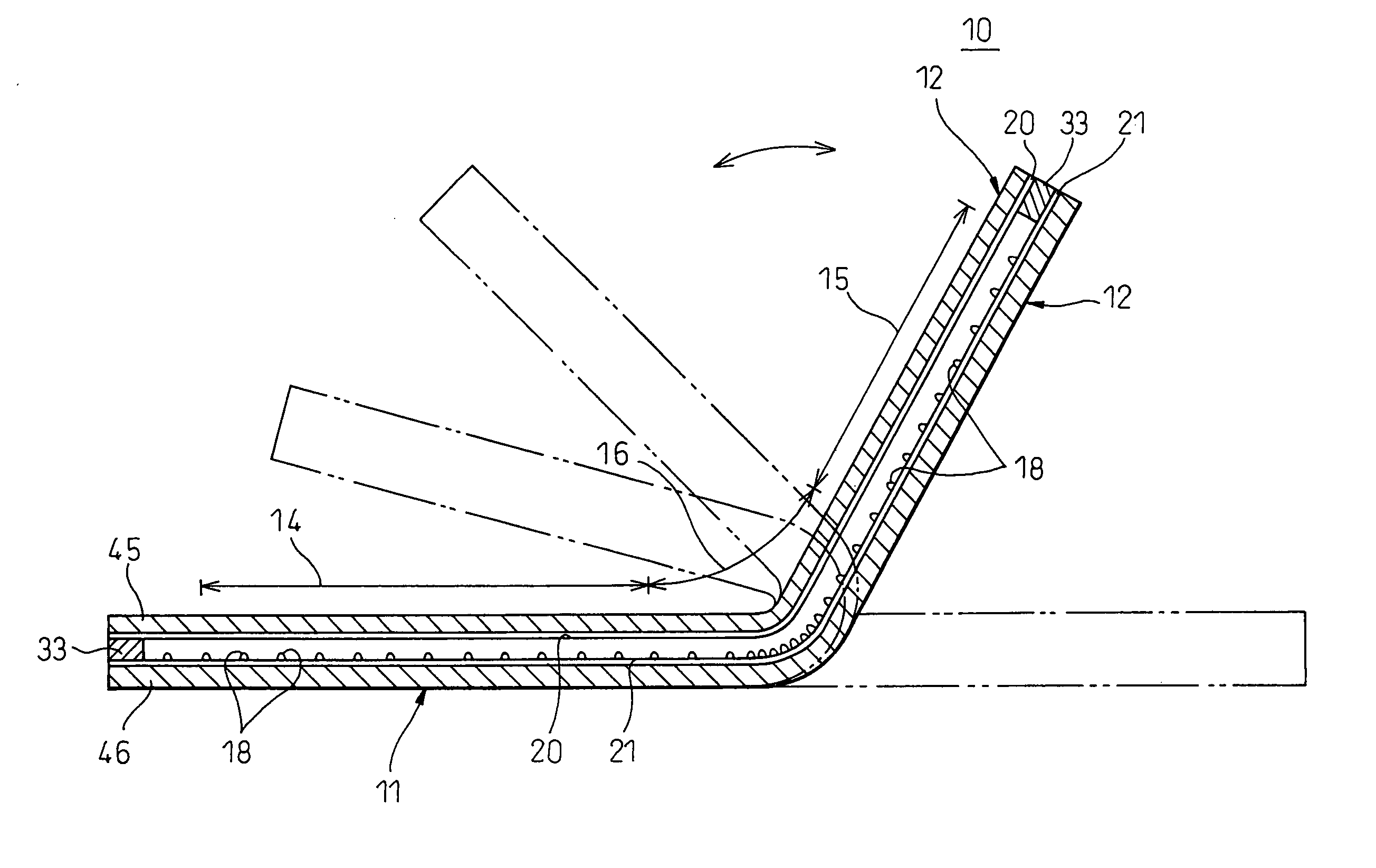

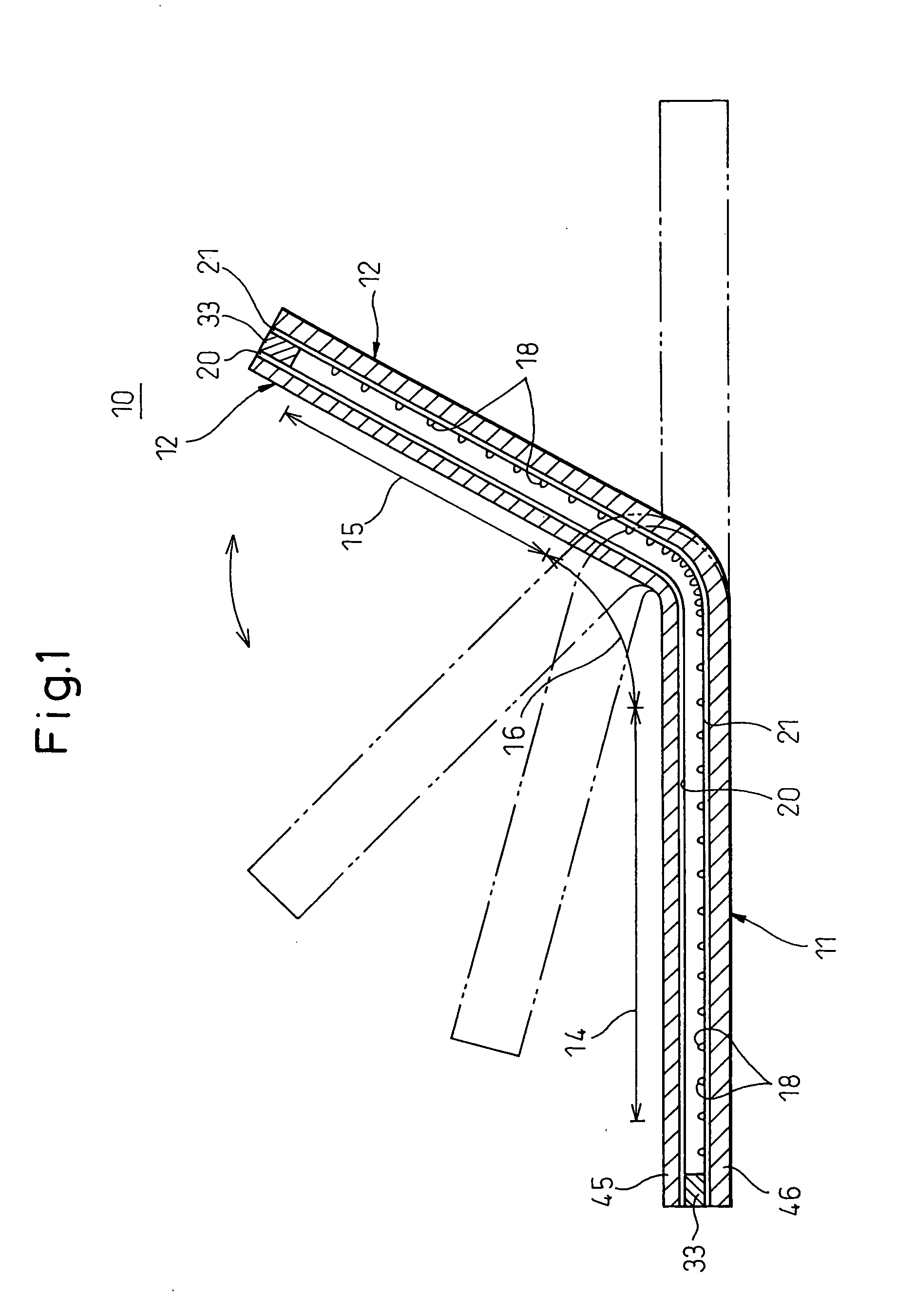

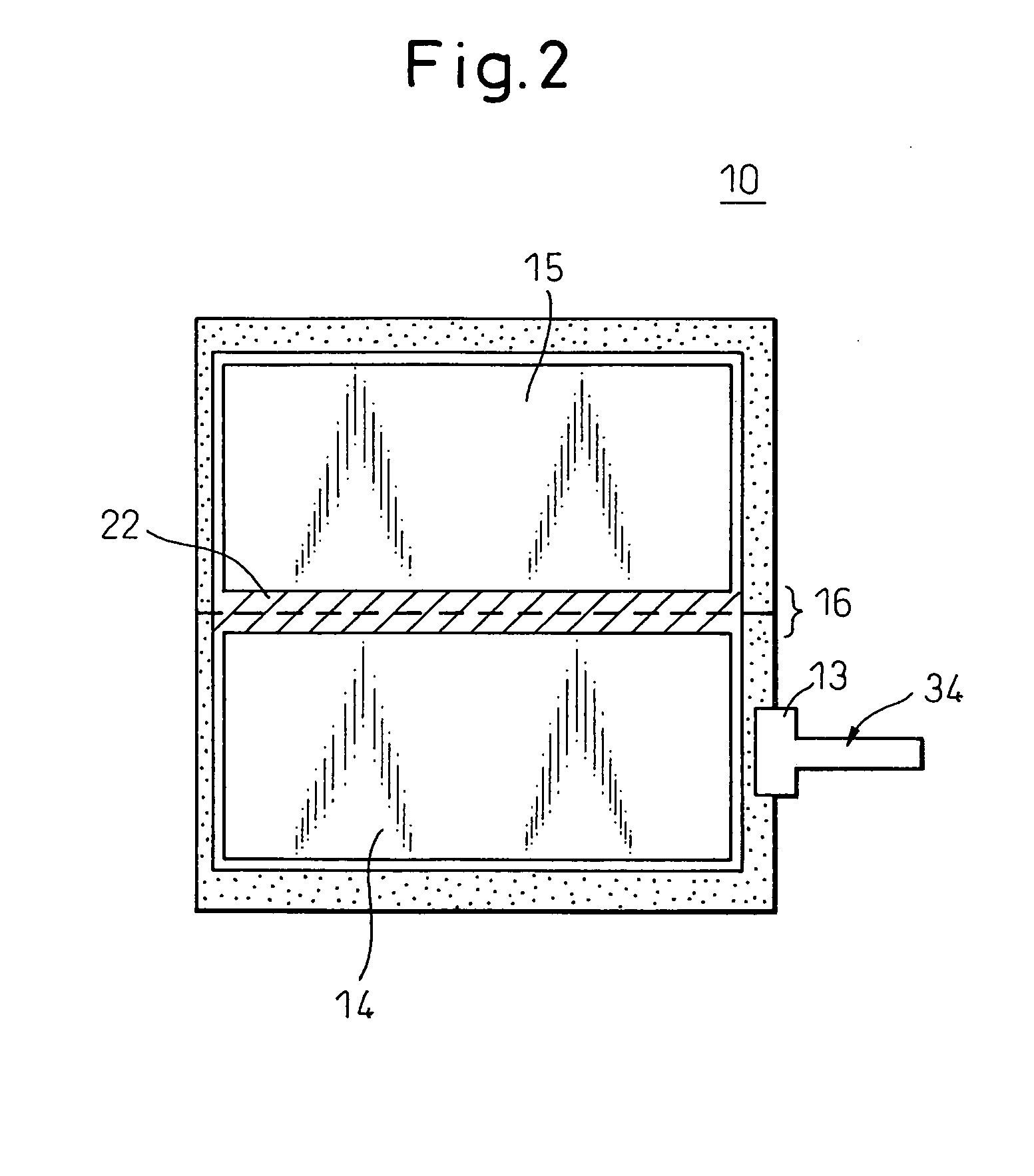

Touch panel

A touch panel includes a fixation side substrate and an operation side substrate disposed in opposition and adhered to each other, having a fixation side conductive film and an operation side conductive film respectively formed on opposing faces of the fixation side substrate and the operation side substrate, and being capable of detecting any contact point on the fixation side conductive film and the operation side conductive film as a 2-dimensional coordinate, wherein a bending section is formed between one end and the other end thereof, and wherein two input operation regions are defined and formed on both sides of the bending section.

Owner:FUJITSU COMPONENENT LTD

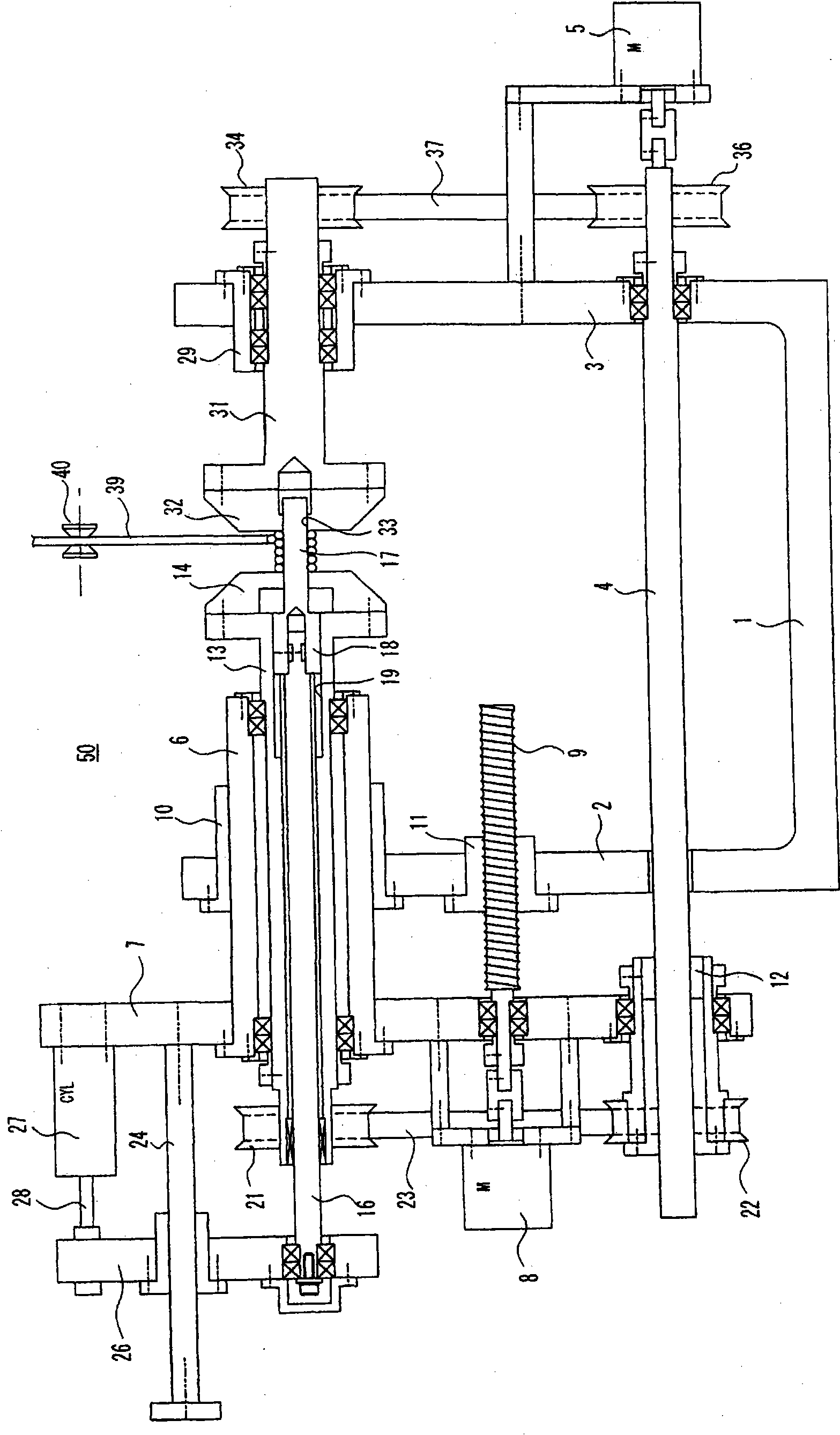

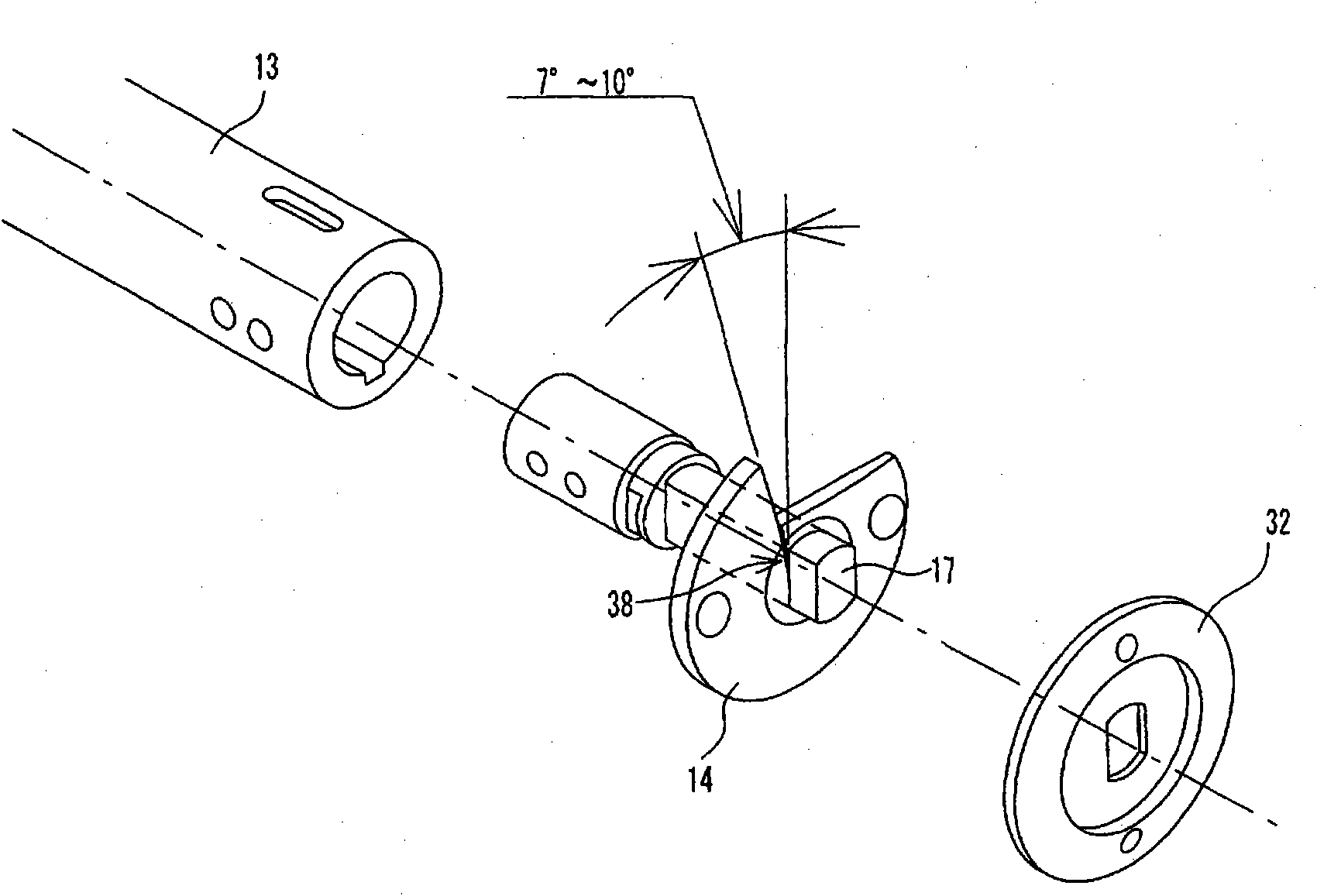

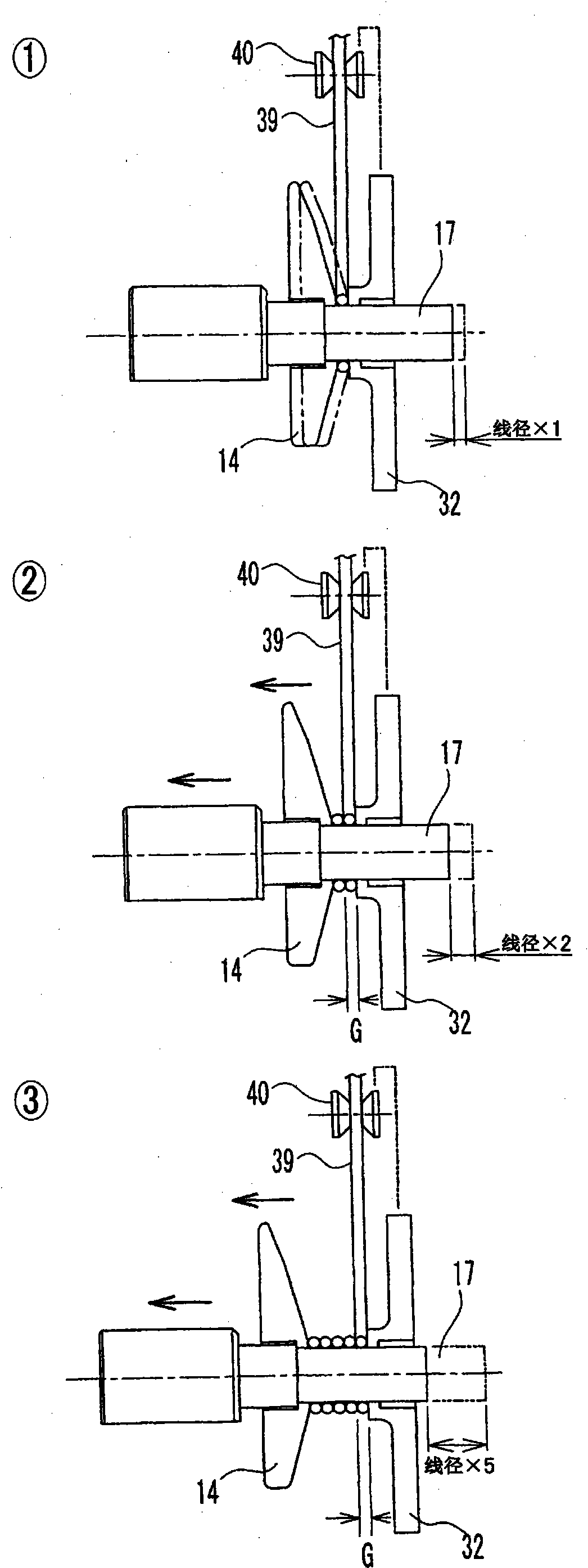

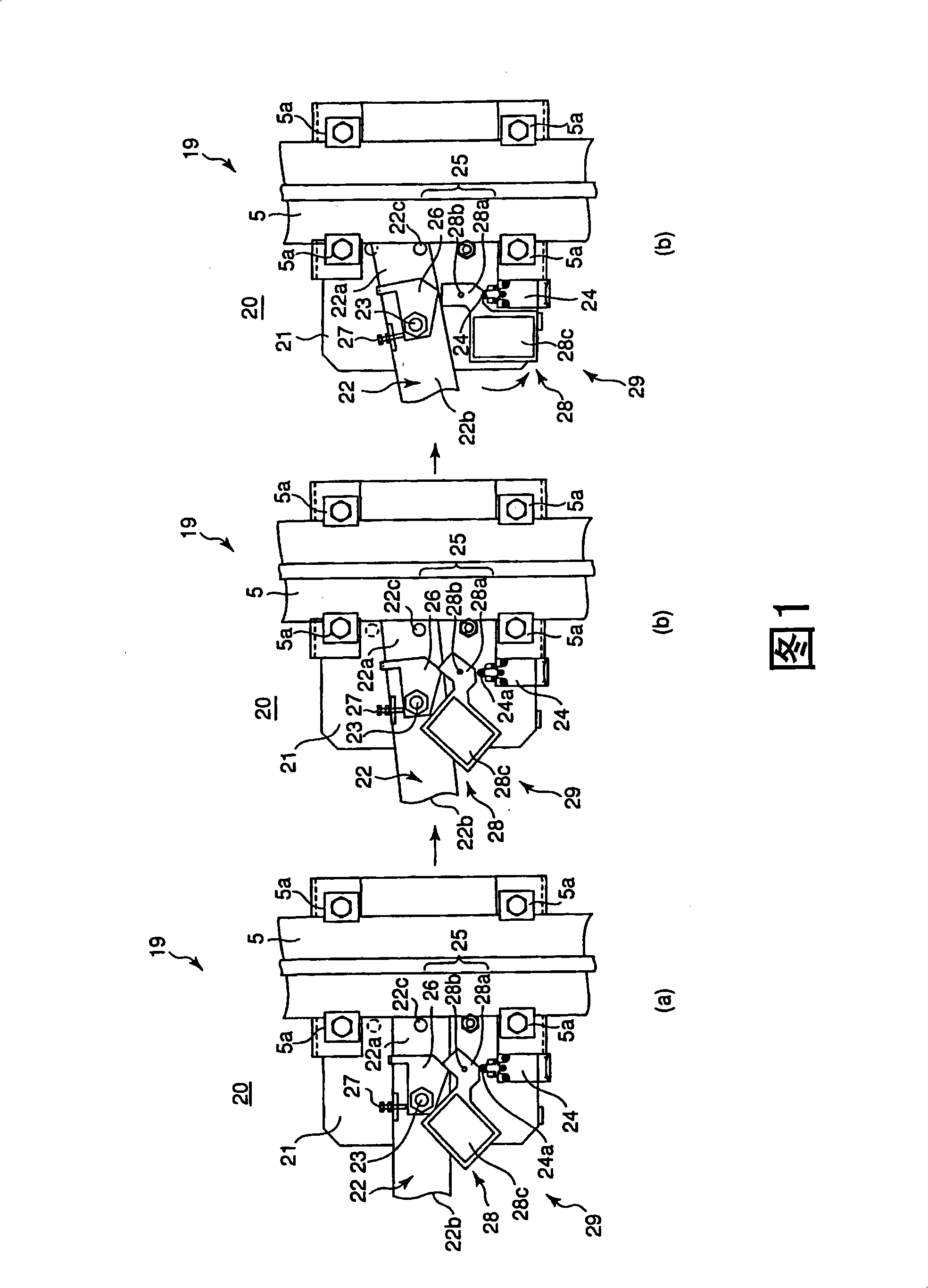

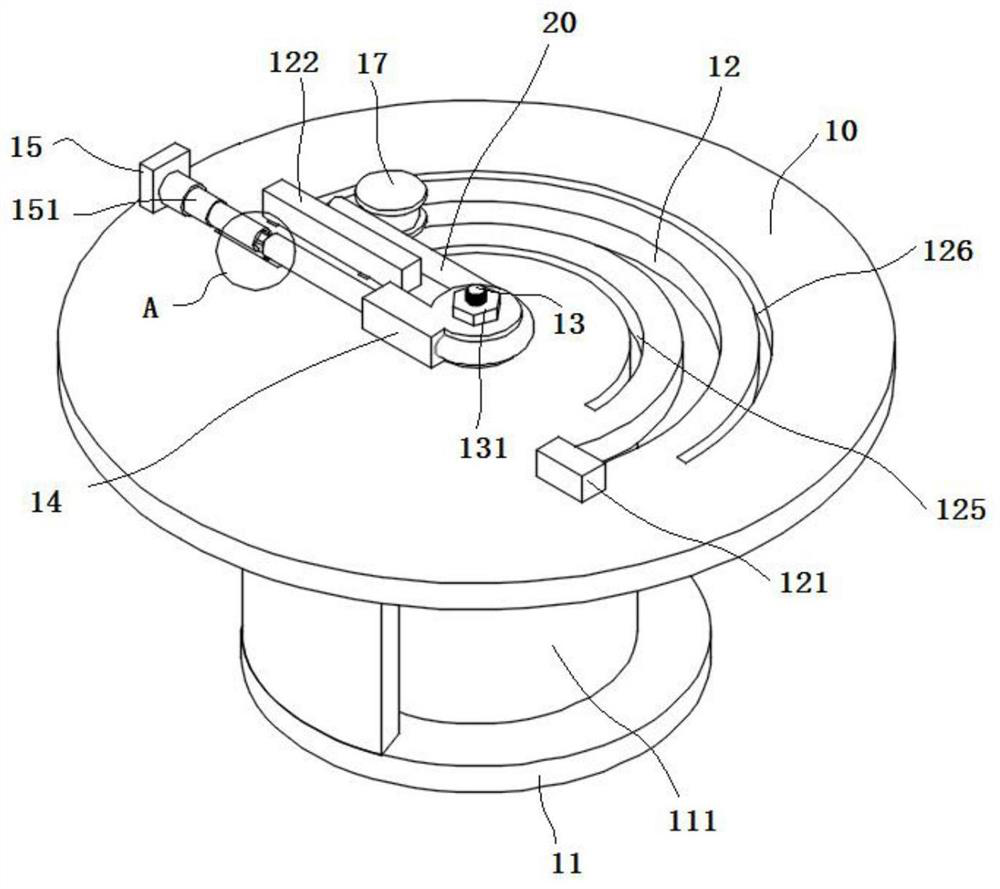

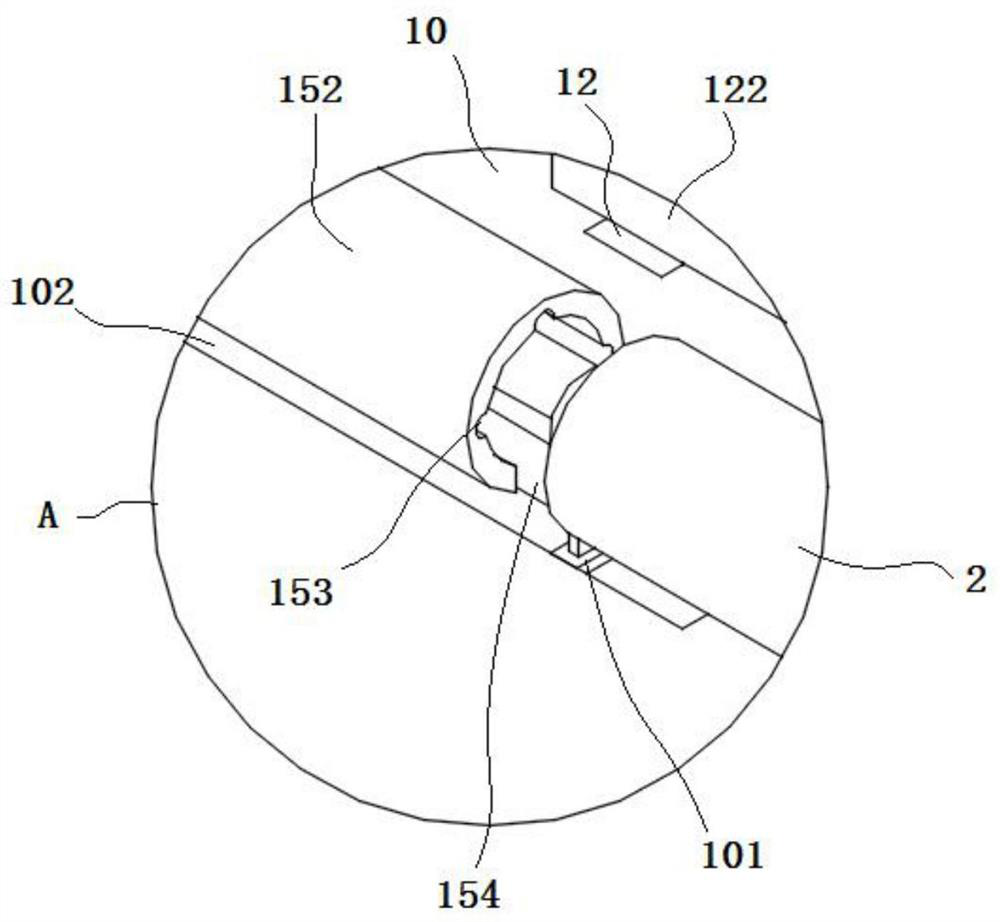

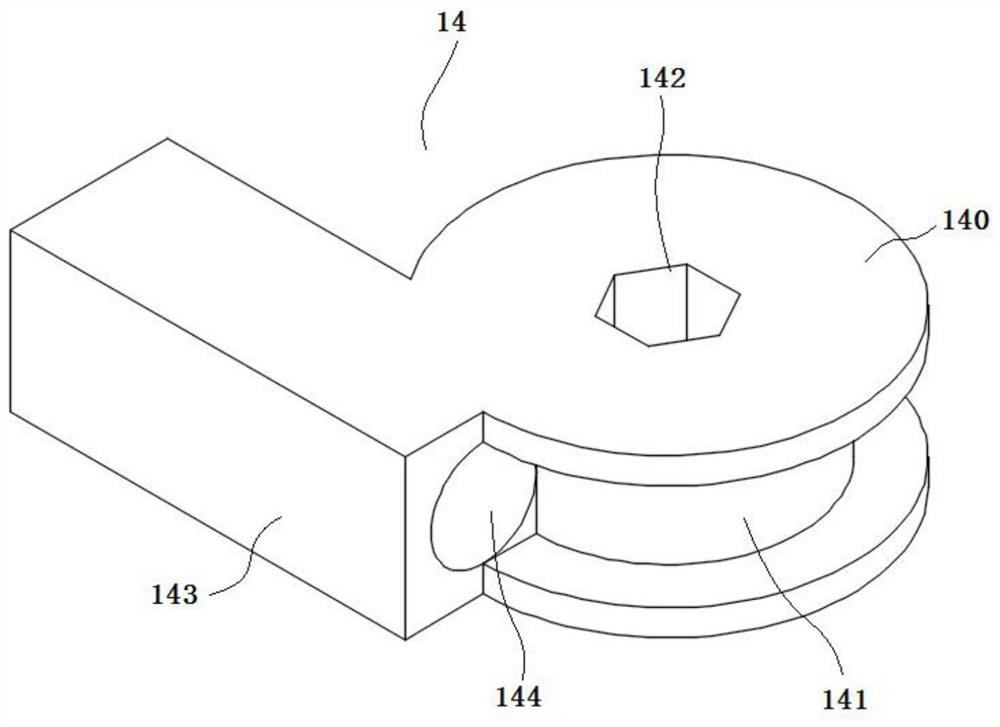

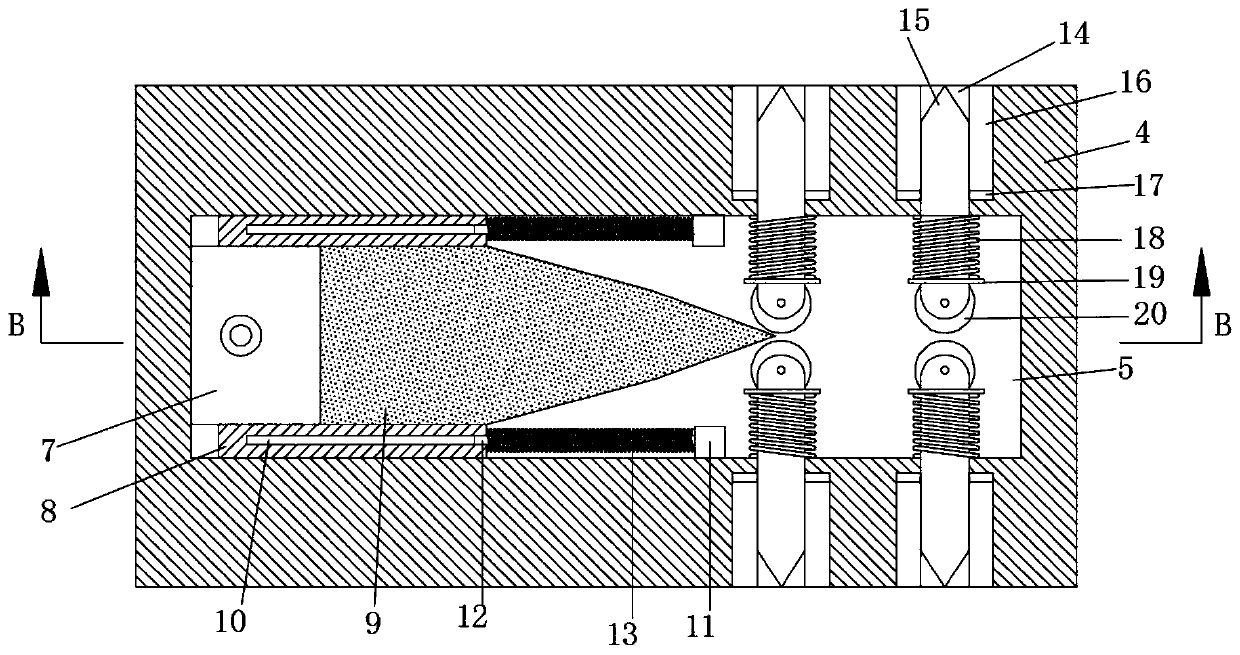

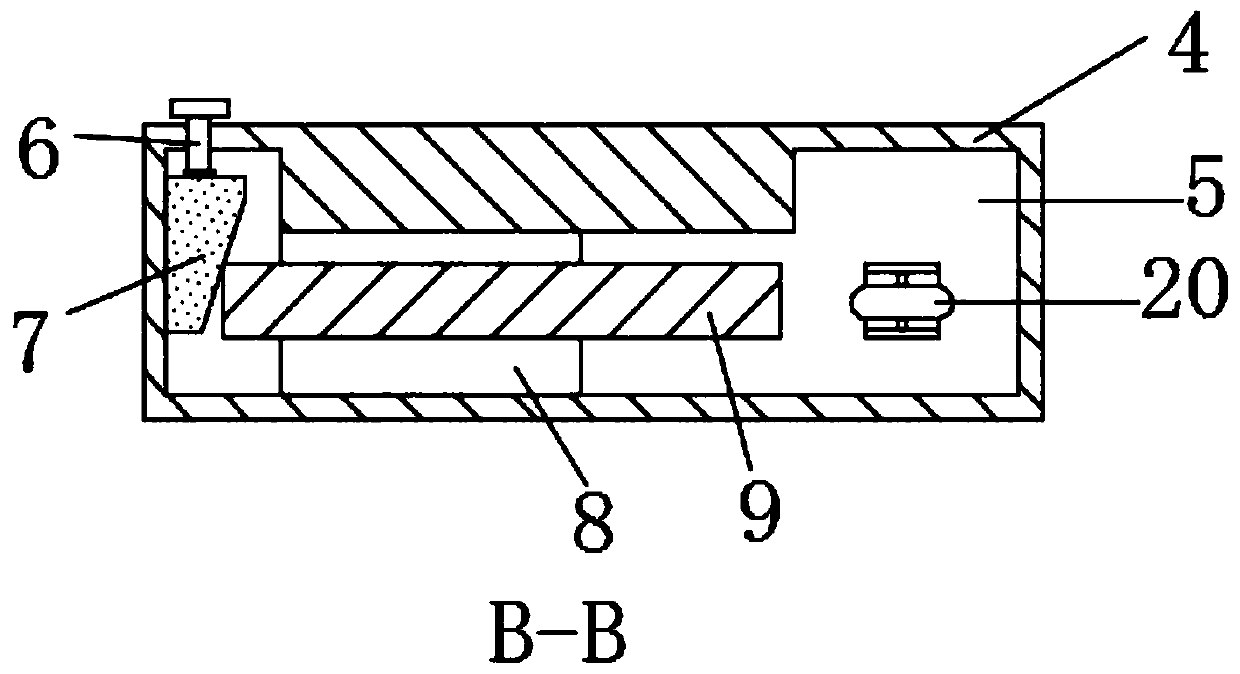

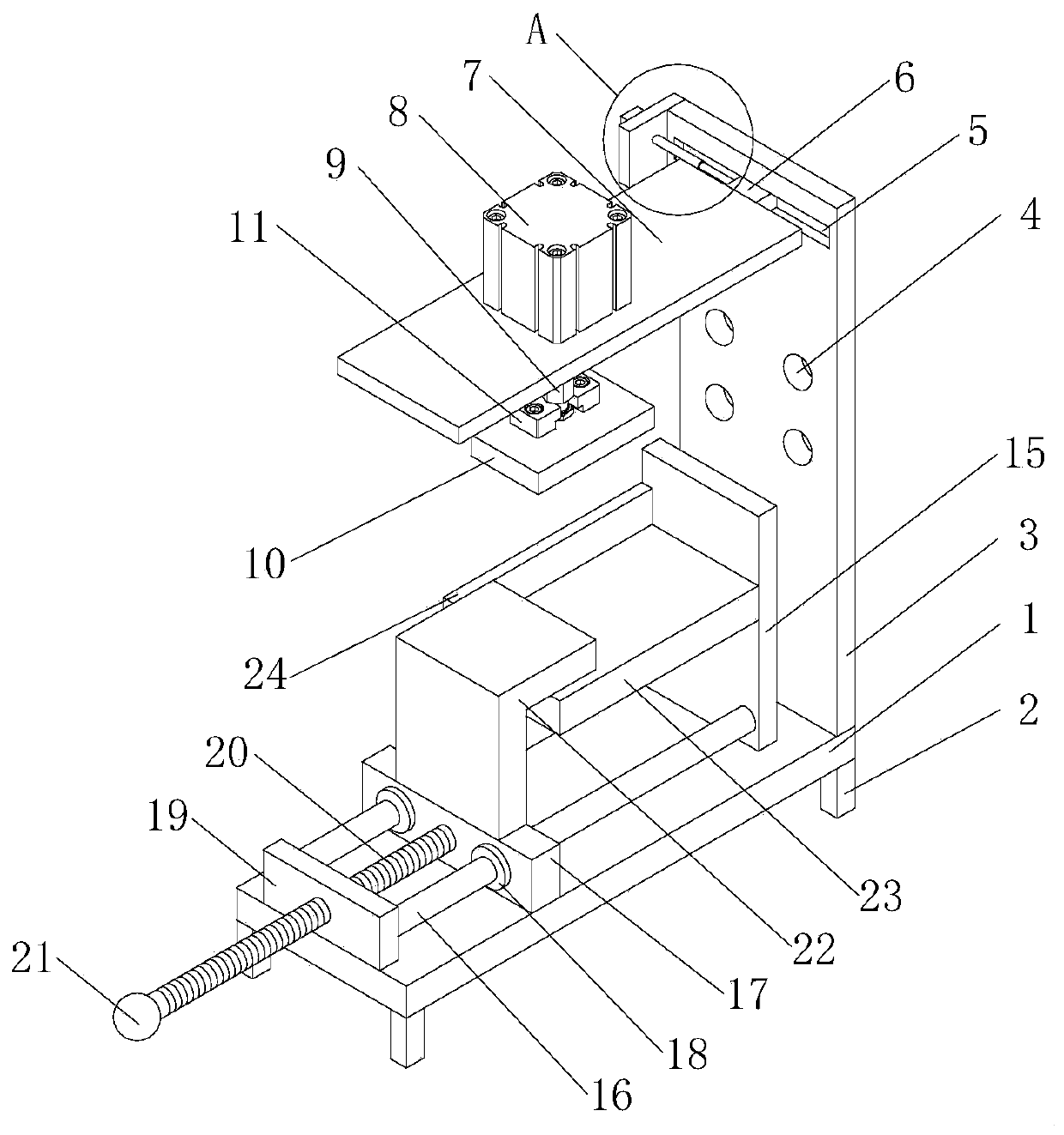

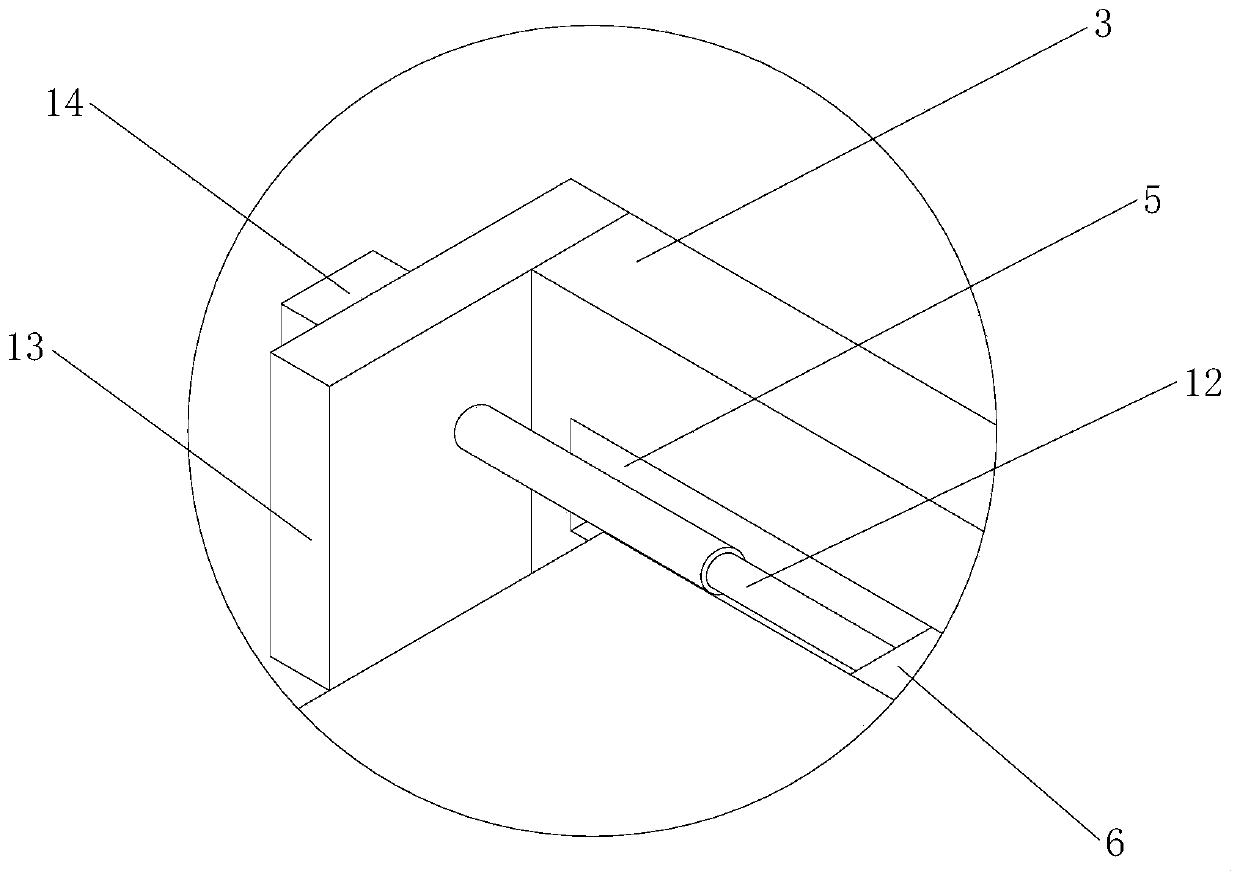

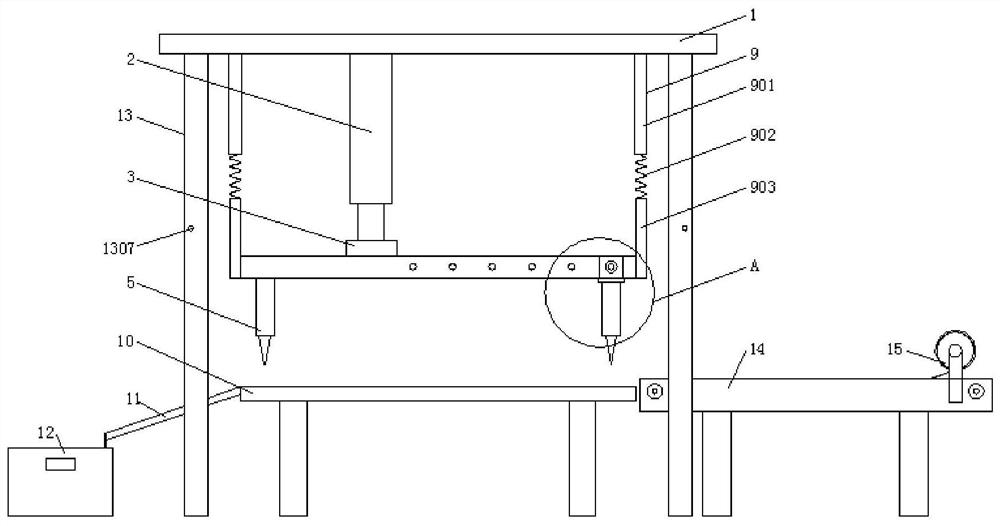

Wire winding method and wire winding machine

Provided are a wire winding method and a wire winding machine, in which aligning performance of particularly the first layer, a positional stability of a cross-point, and so on can be maintained in the progress of thinning of a wire, decreasing of the diameter of a winding core, diversifying of the sectional surface of a winding core and so on, whereby the wire can be wound at a higher speed and a preparation time is not required to take so much for alteration of a product. During a period from the start of winding of the first layer up to the completion of the winding, a fixation side winding frame (32), a wire guide (40) and a tension device (not shown in the figures) are set to remain unchanged in position relationship. During the same period up to the completion of the first layer winding, a winding core (17) and a movable side frame (14) are intermittently separated by every predetermined amount with respect to the fixation side winding frame (32). By such a separation, a predetermined gap (G) compatible with an outer diameter of a wire (39) is maintained between the wire (39) already wound and the fixation side winding frame (32) at a position where a new wire (39) is then wound. Under these conditions, the wire supplied from the tension device enters into the maintained gap and is successively wound around the winding core (17), whereby the first layer winding is carried out.

Owner:NIPPON SERBIG

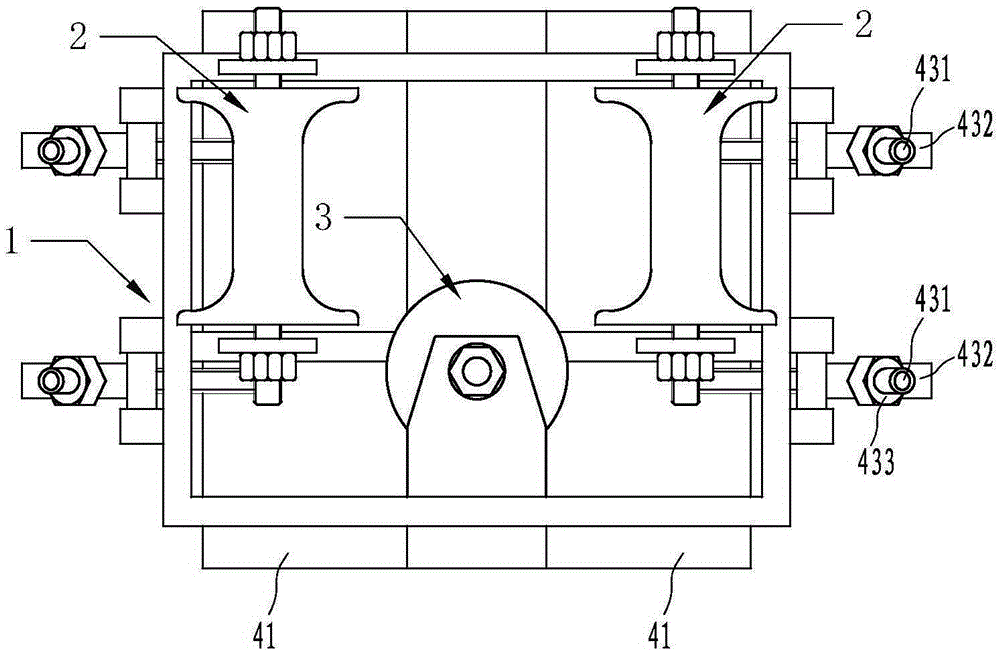

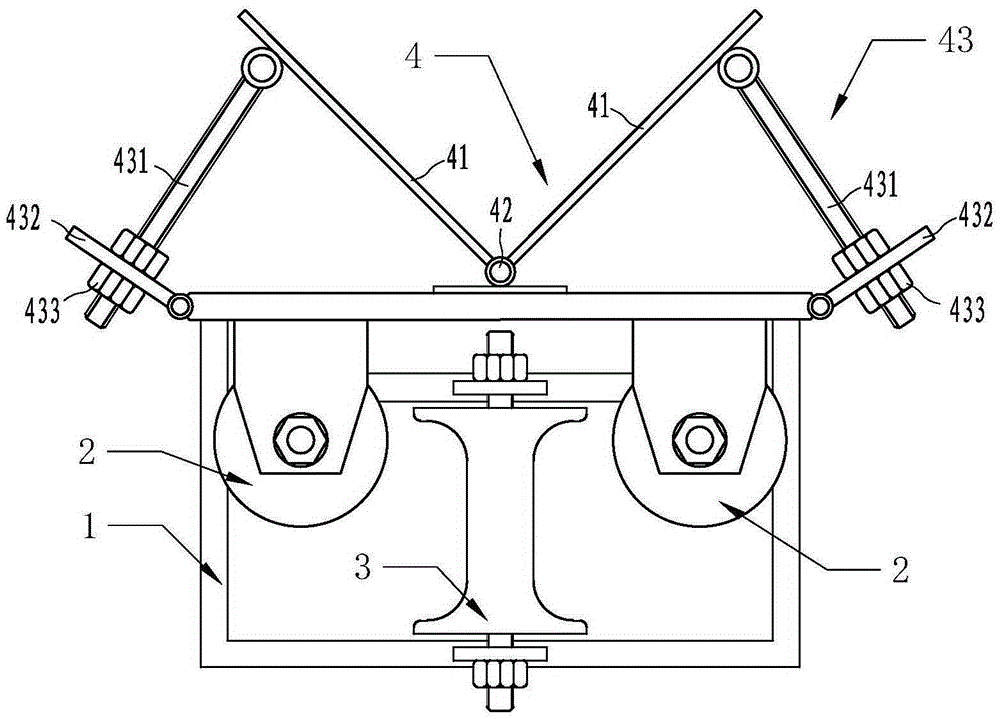

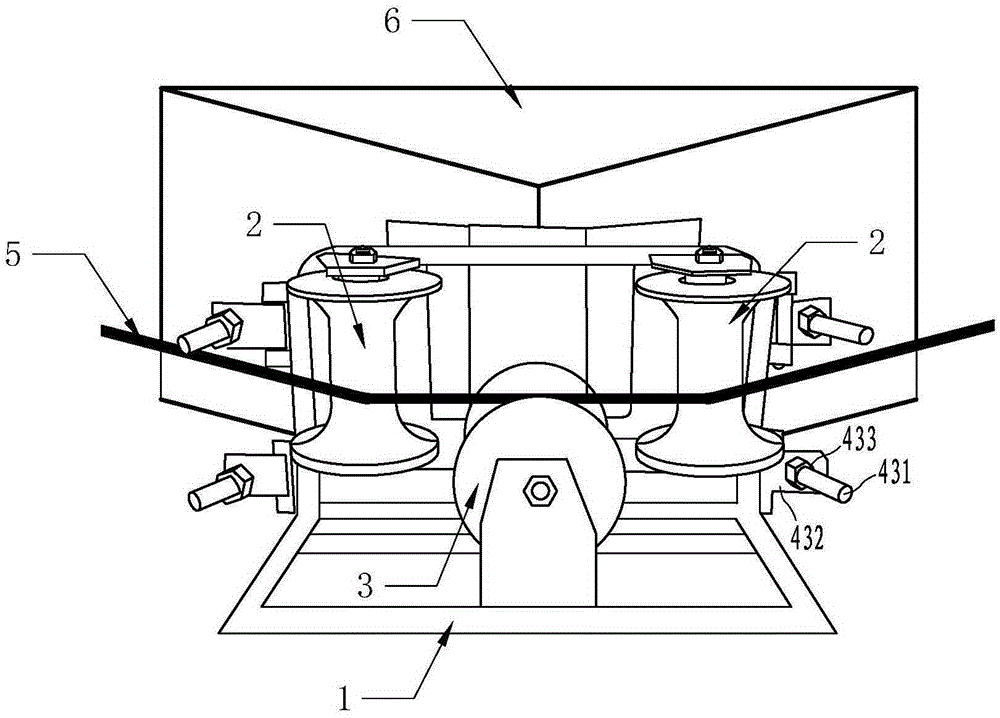

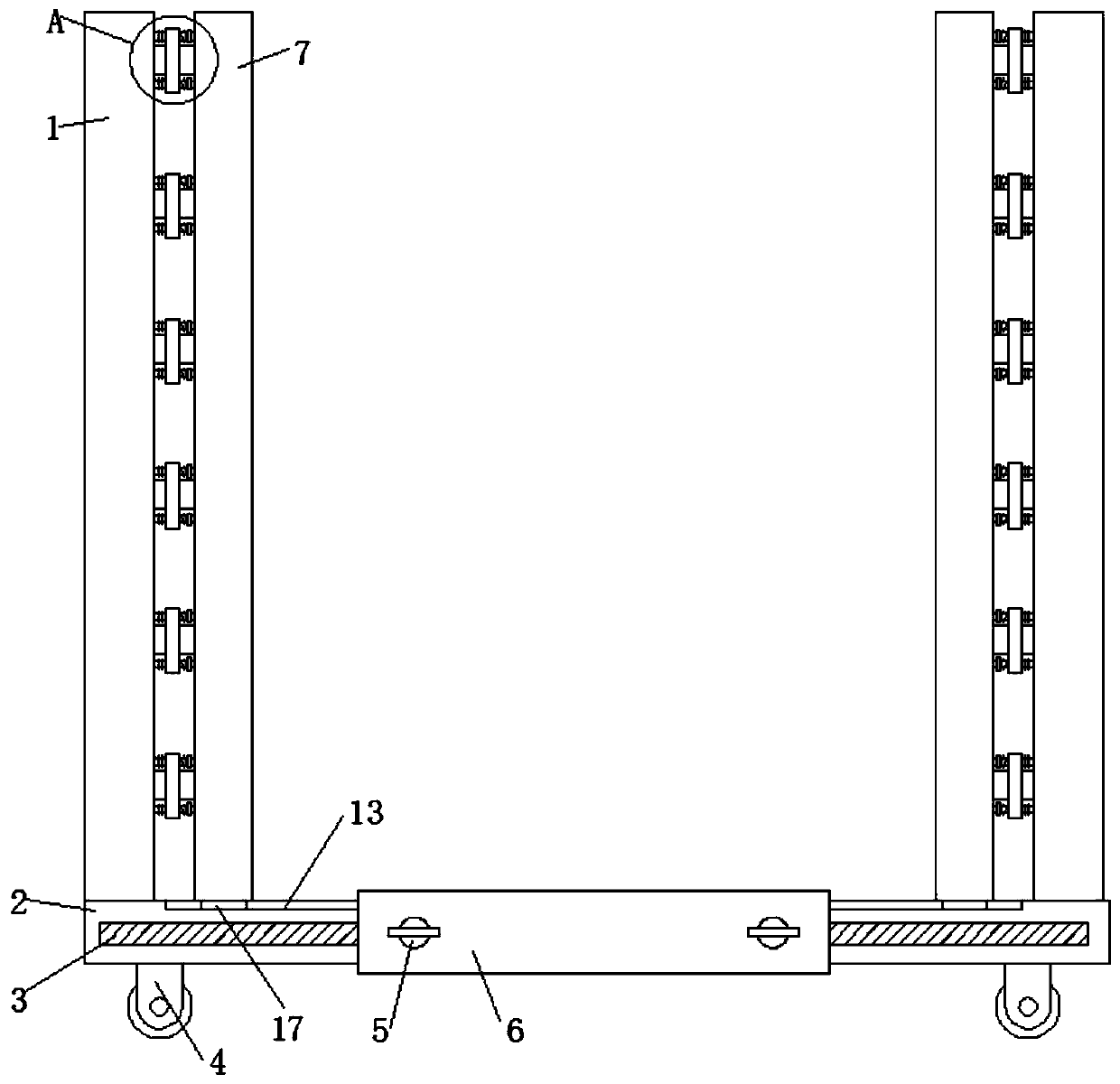

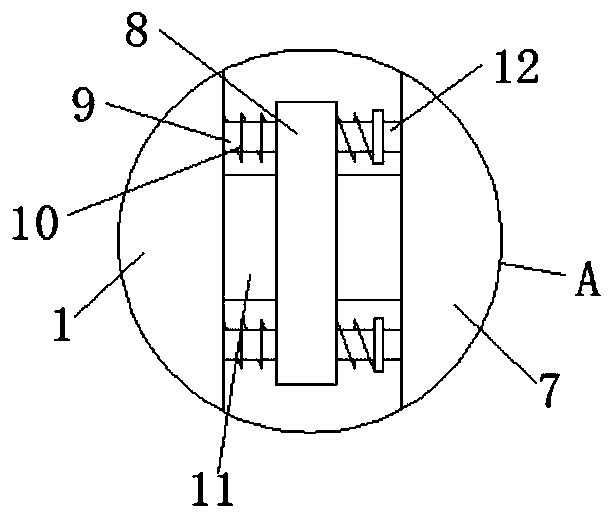

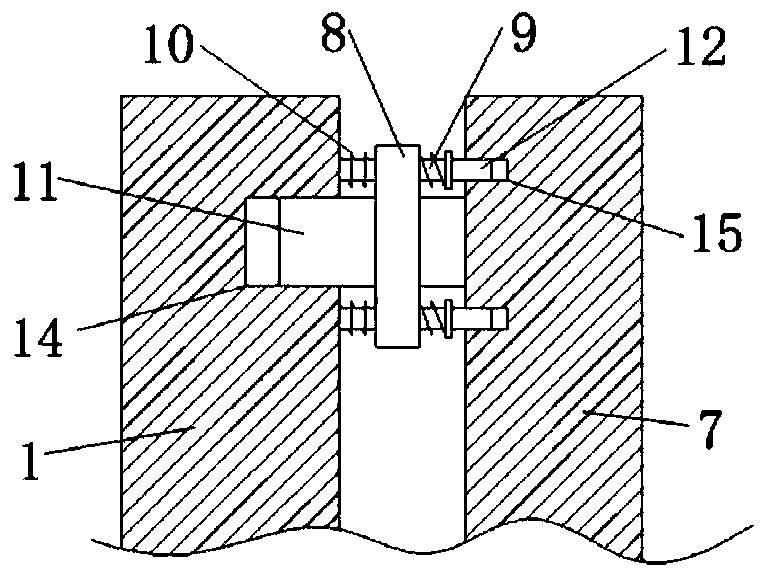

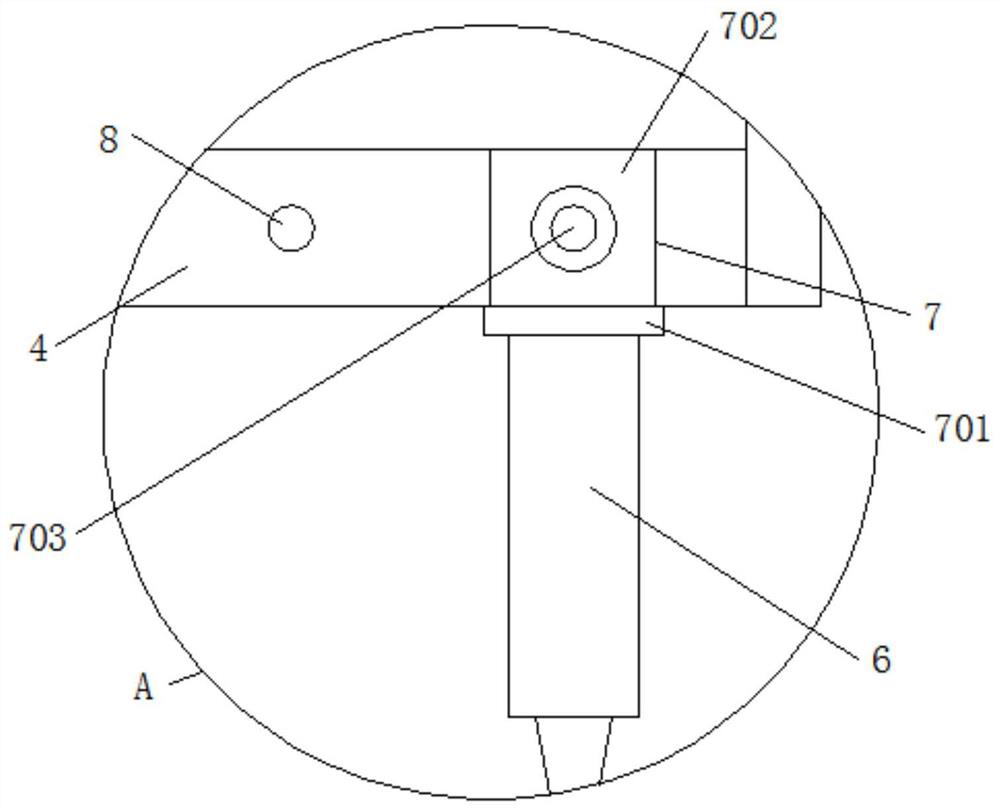

Corner line laying pulley

InactiveCN105305320AChange distanceSimple structureApparatus for laying cablesTraveling blockElectric power

The invention relates to the technical field of power installation equipment, and provides a corner line laying pulley. The corner line laying pulley comprises a support, a pulley fixed at one side of the support, and a fixation apparatus arranged at the other side of the support; the pulley comprises guiding pulleys and a supporting pulley which are arranged to be vertical to each other, and the two guiding pulleys are respectively arranged at the two sides of the supporting pulley; and the fixation apparatus comprises two fixation side plates hinged to each other. The corner line laying pulley is simple in structure and convenient to use, can fix the pulley at a corner of a building, enhances the contact area between the pulley and the building, protects the building from being damaged, effectively prevents a cable from unlocking and is higher in adaptability due to an adjustable included angle between the two fixation side plates.

Owner:国网山东潍坊市寒亭区供电公司 +1

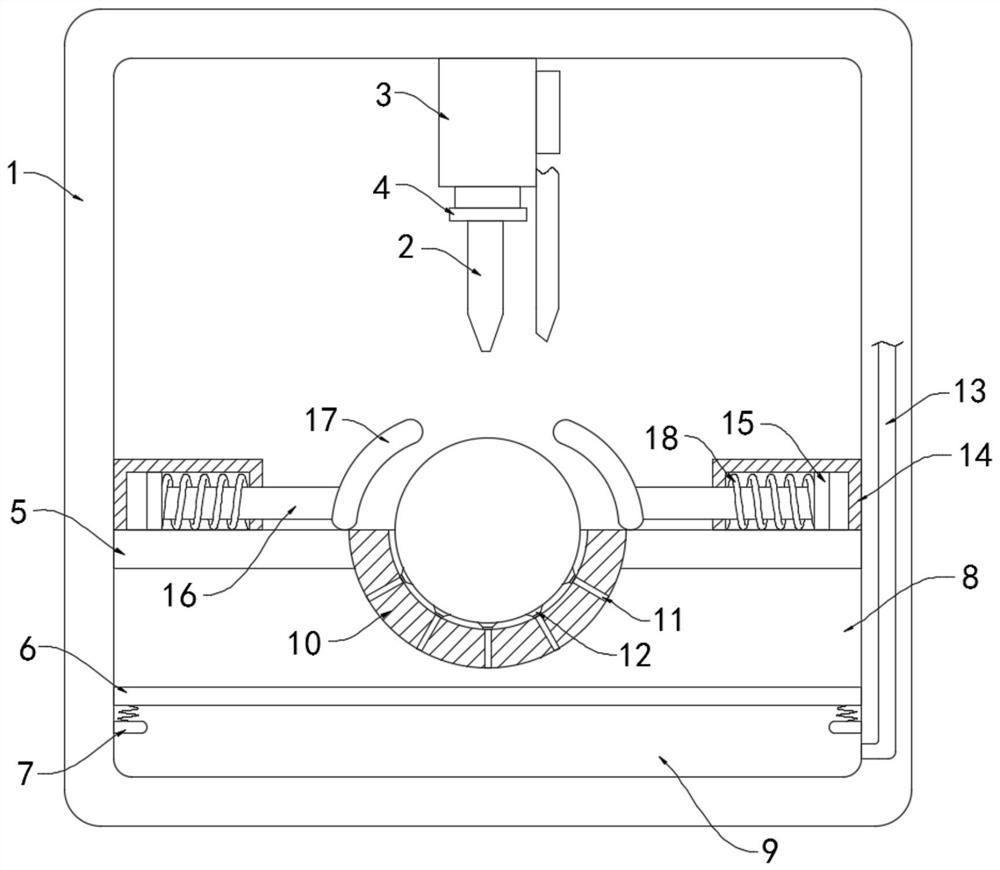

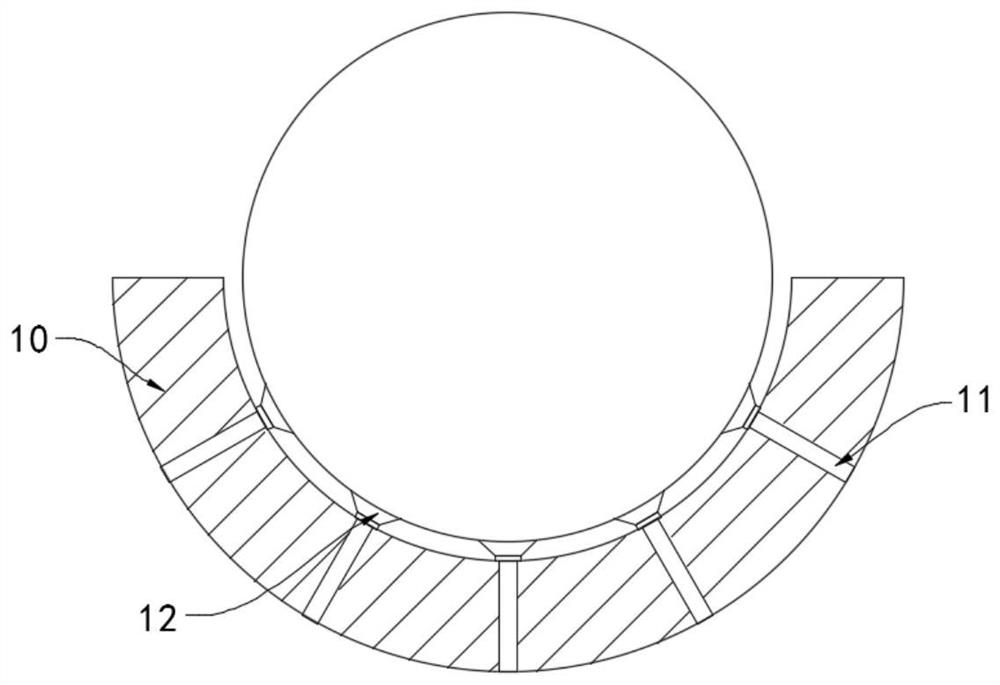

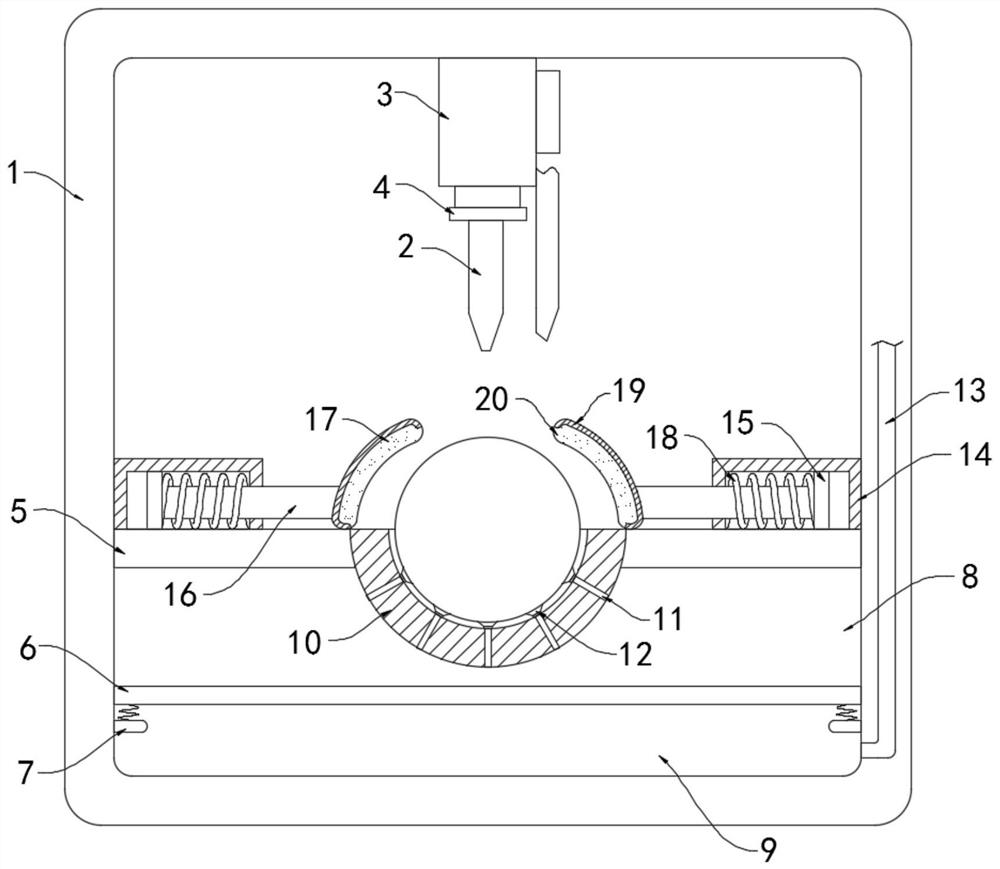

Spherical workpiece fixing method for riveting press

InactiveCN111906234AAvoid the effect of rivetingPrevent rotationCleaning using gasesInterior spaceEngineering

The invention belongs to the field of riveting machines, and particularly relates to a spherical workpiece fixing method for a riveting press. The specific fixing method comprises the following stepsof placing, bottom surface fixing, side surface fixing, and cleaning. A fixing device is further included in the fixing process, and the fixing device comprises a fixing frame and a riveting head conducted with micro-current. A fixing base is fixedly connected to the inner top face of the fixing frame, the riveting head is fixedly installed at the lower end of the fixing base, the riveting head isfixedly sleeved with a magnetic ring, a fixing table is fixedly connected to the lower end of the fixing frame, and a horizontally-arranged sliding plate is slidably connected into the fixing table.A plurality of magnetic blocks in polar repulsion to the magnetic ring are fixedly embedded in the sliding plate. By arranging an upper cavity, when the riveting head moves downwards, repulsive forcebetween the riveting head and the magnetic blocks in the sliding plate can push the sliding plate to slide downwards, the internal space of the upper cavity is increased, the air pressure in the uppercavity is reduced, a suction cup can be tightly attracted to the lower surface of a spherical workpiece, and the spherical workpiece is fixed at the bottom.

Owner:湖州浪佩智能科技有限公司

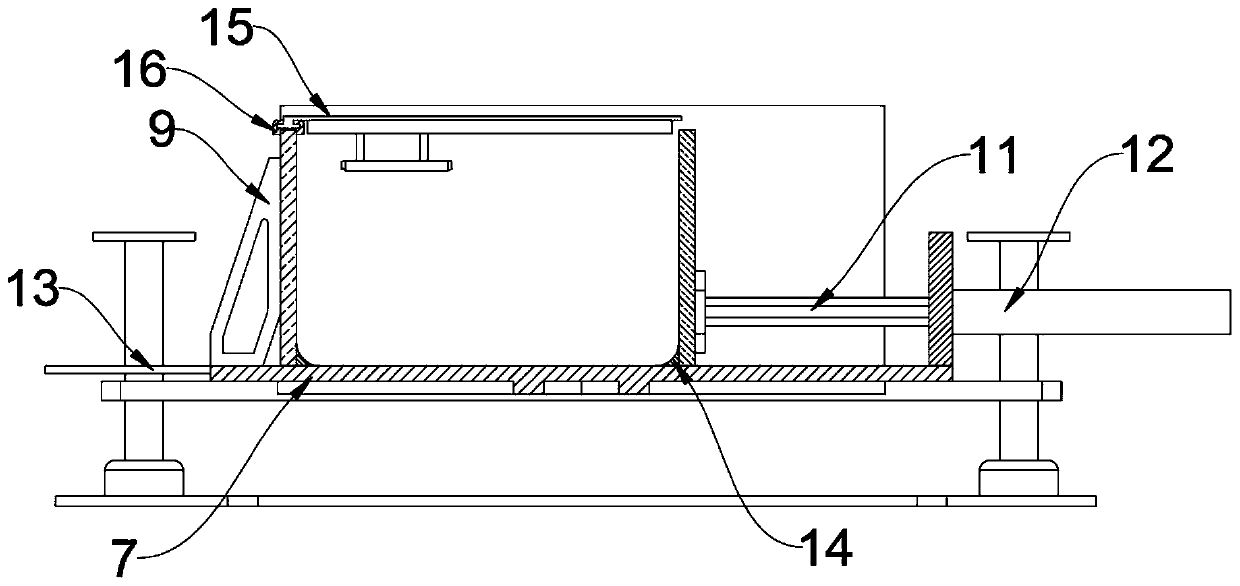

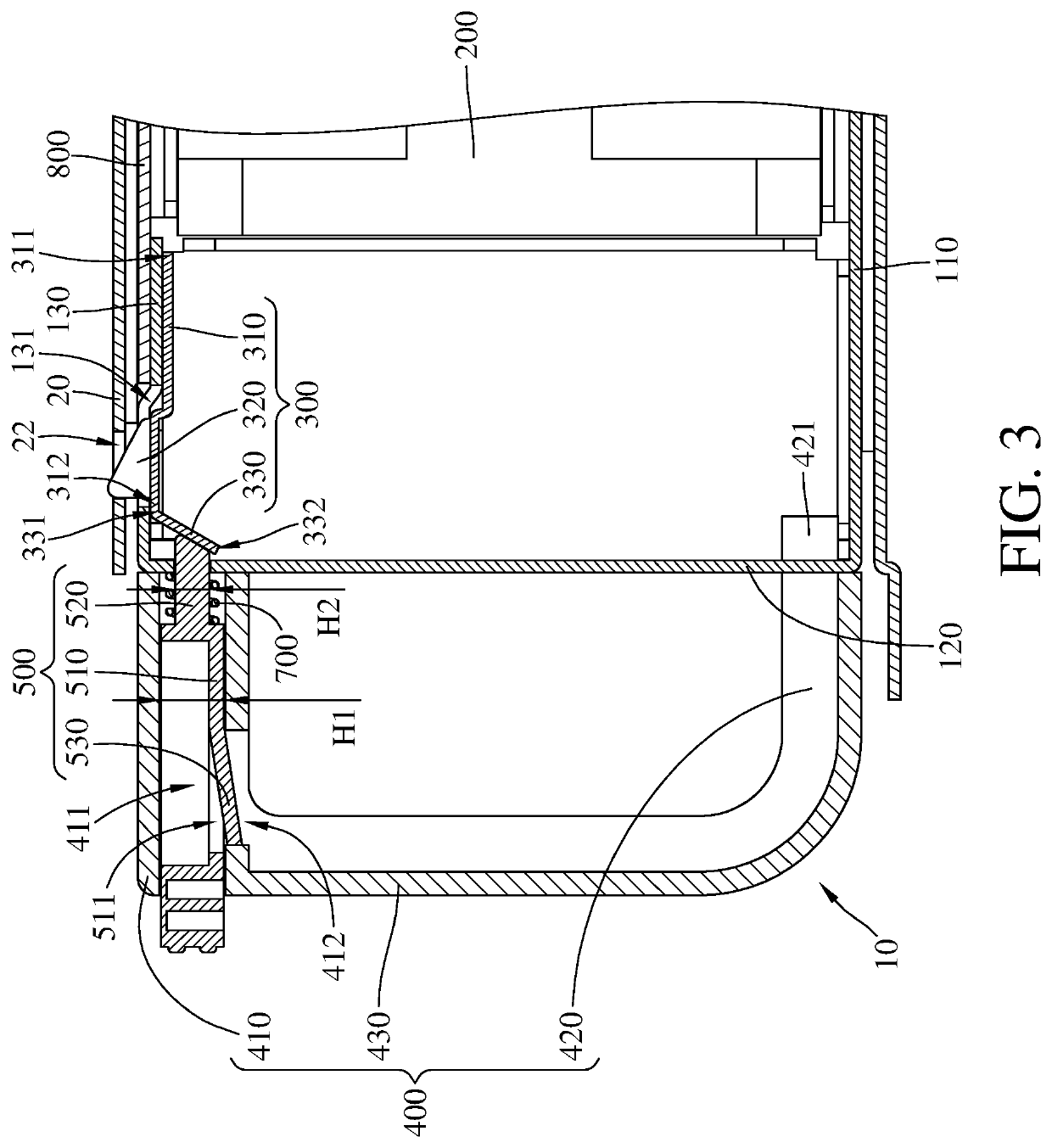

Molding device and molding method

InactiveCN103025496AHigh precisionSuppression of working hoursOptical articlesThermal dilatationEngineering

A molding device aligns a fixed-side mold (10) and a movable-side mold (20) by mating protruding blocks (15) and recessed blocks (25), and thus has excellent alignment repetition accuracy, and is capable of effectively minimizing the eccentricity between lens forming surfaces of both molds (10, 20). In addition, since the mating position can be shifted in the direction in which the protruding blocks (15) and the recessed blocks (25) cross at right angles in the direction of closing, by aligning the direction in which the molds (10, 20) thermally expand and the direction in which shifting is permitted, misalignments due to the occurrence of temperature differences in the molds (10, 20), in other words, misalignments due to thermal expansion differences can be minimized without placing a load on the molds.

Owner:KONICA MINOLTA OPTO

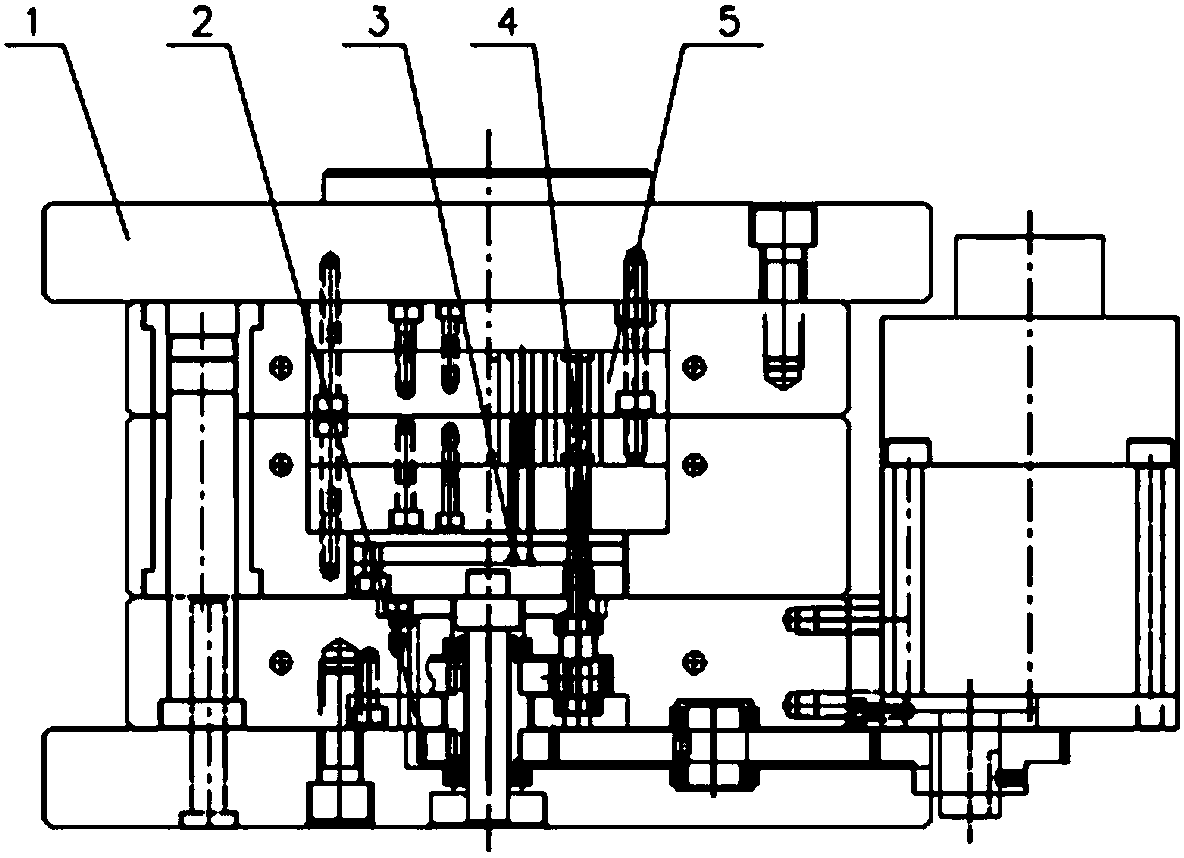

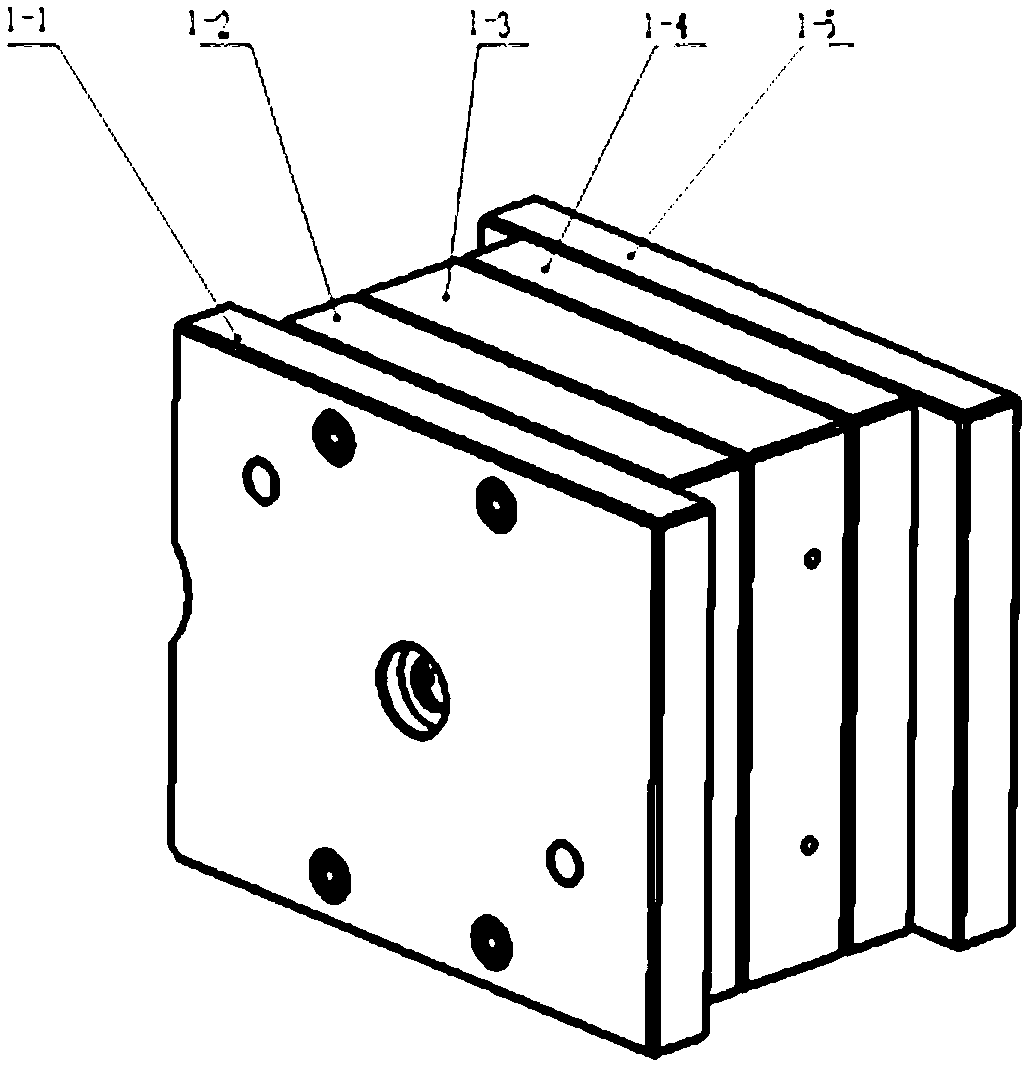

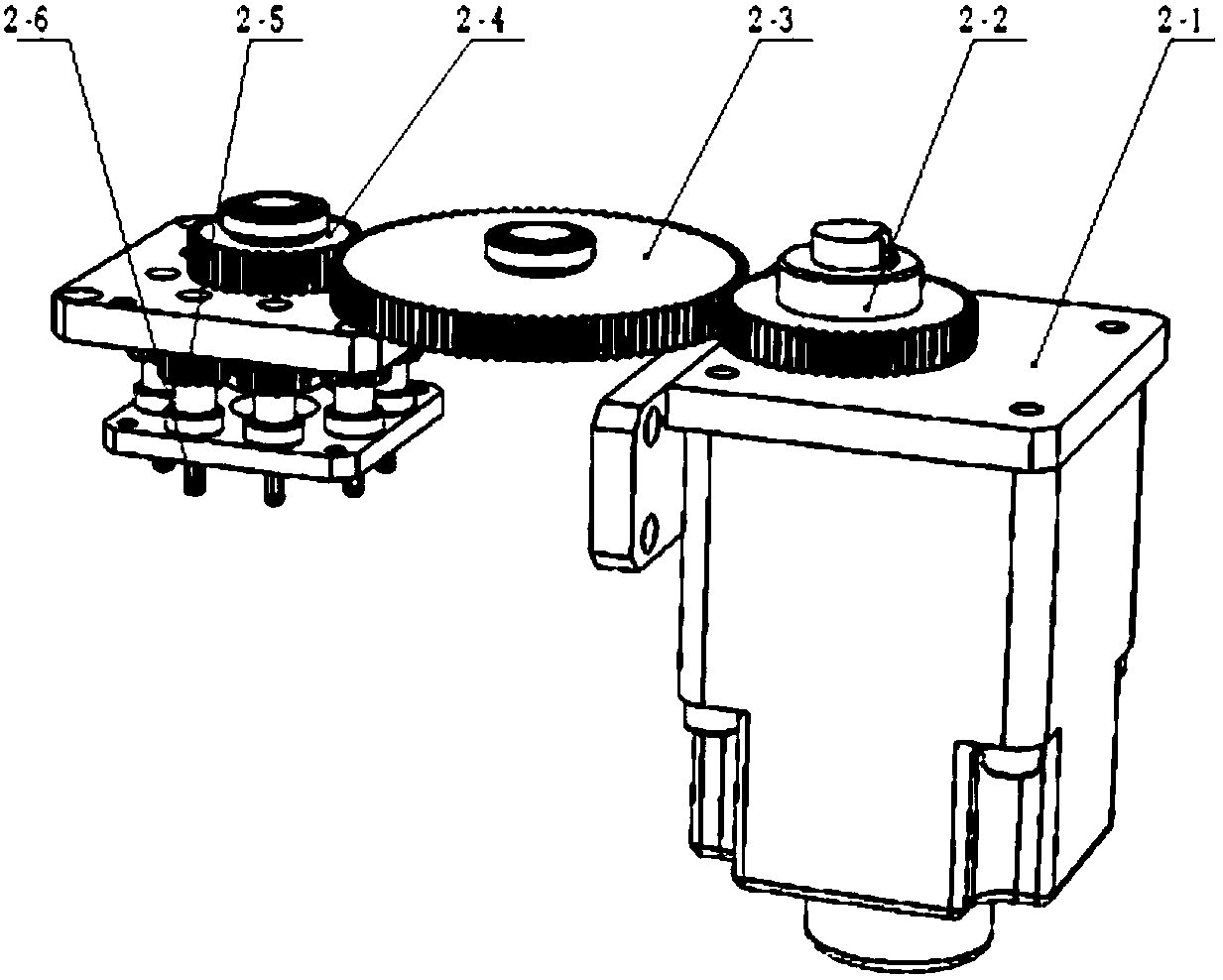

Mini-type thread mold with front mold hinged thread mechanism

The invention discloses a mini-type thread mold with a front mold hinged thread mechanism. The mini-type thread mold with the front mold hinged thread mechanism comprises a mold frame, a gear transmission mechanism, an ejection mechanism, a thread connection rod and a molding pouring system; the mold frame is composed of a fixed side mounting plate, a female mold plate, a male mold plate, a bearing plate and a movable mounting plate; the gear transmission mechanism is composed of a small servo motor speed reducer and a series gear mechanism; the ejection mechanism is composed of an ejector rob, an upper ejector plate, a lower ejector plate and centres; and the molding and pouring system is composed of a male mold insert, a female mold insert, a base plate, a male mold bush, a female mold bush and a machine nozzle. The overall mechanism is matched with an injection molding machine to finish molding of a base product, specifically, through high-pressure casting of the injection molding machine and mold opening, the servo motor speed reducer drives the gear mechanism, the connection rod transmits torque to a threaded rod to achieve hinged thread demolding action, the ejection mechanism ejects the product out, and the structure has the characteristics that the gear mechanism is concentrated on a front mold and embedded with the ejection mechanism in a concentrated mode, the size ofthe whole mold frame is reduced, and the machining precision of the mold and the product production efficiency are improved fundamentally.

Owner:辽宁中蓝光电科技有限公司

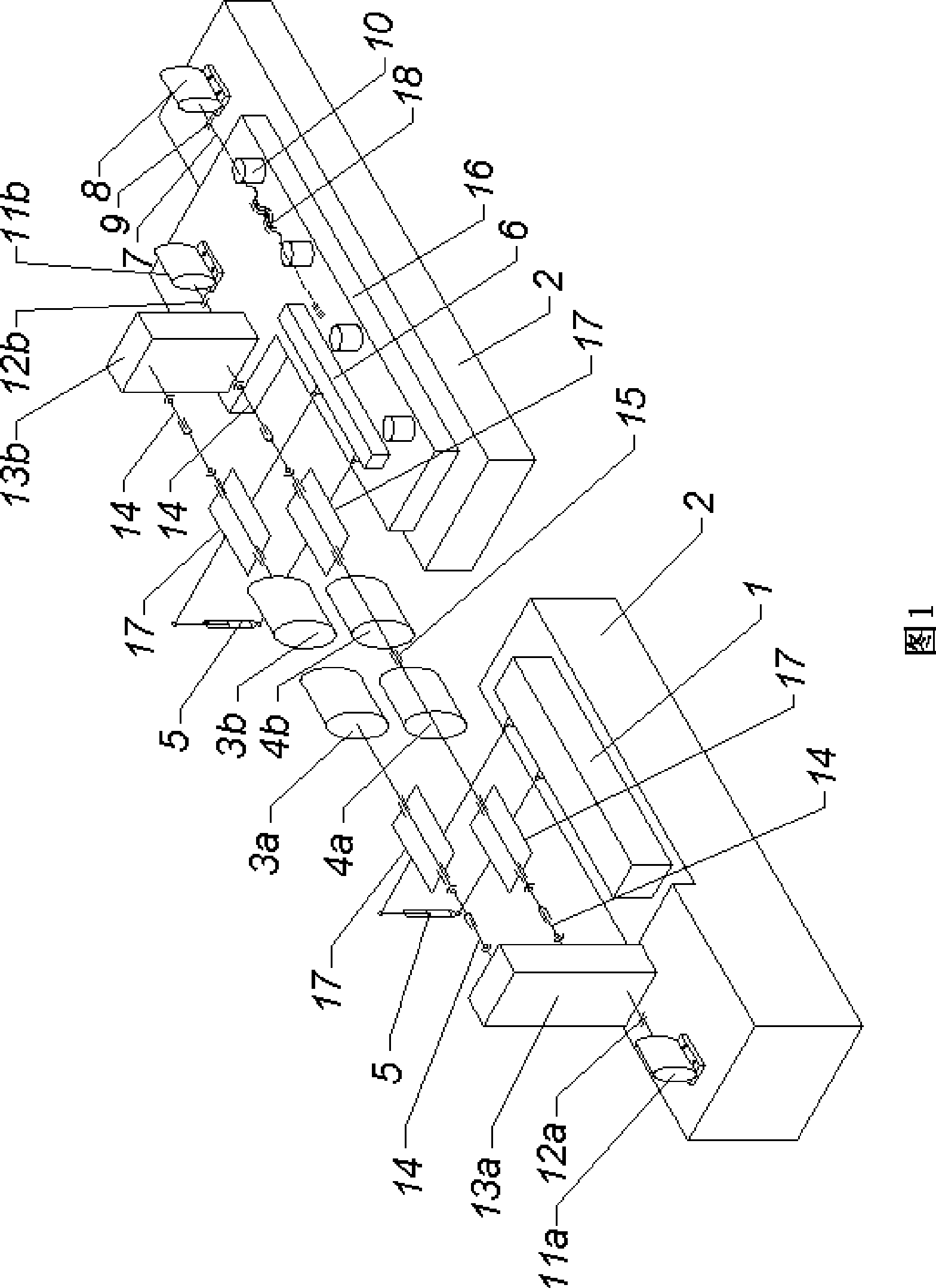

Withdrawal roll device of end trimming shear

InactiveCN101433937AConsistent speedPrevent deviationMetal-working feeding devicesPositioning devicesProduction lineSheet steel

The invention discloses an end trimming shears pinch roll device on a steel rolling production line of medium plates. The device can prevent the phenomenon that steel plates 'are pulled to one side' during conveying. The end trimming shears pinch roll device comprises a fixed side upper pinch roll, a fixed side lower pinch roll, a movable side upper pinch roll and a movable side lower pinch roll, wherein the fixed side lower pinch roll is axially connected with the movable side lower pinch roll through a synchronous shaft; the fixed side upper pinch roll and the fixed side lower pinch roll are synchronously driven by a driving mechanism; and the movable side upper pinch roll and the movable side lower pinch roll are synchronously driven by a driving mechanism, so that the end trimming shears pinch roll device can guarantee consistent linear velocity of roll surfaces between two opposite upper and lower pinch rolls, avoid the phenomenon that the steel plates are 'pulled to one side' during the conveying, and improve the quality of the steel plates sheared by a pair of end trimming shears.

Owner:ERZHONG GROUP DEYANG HEAVY EQUIP

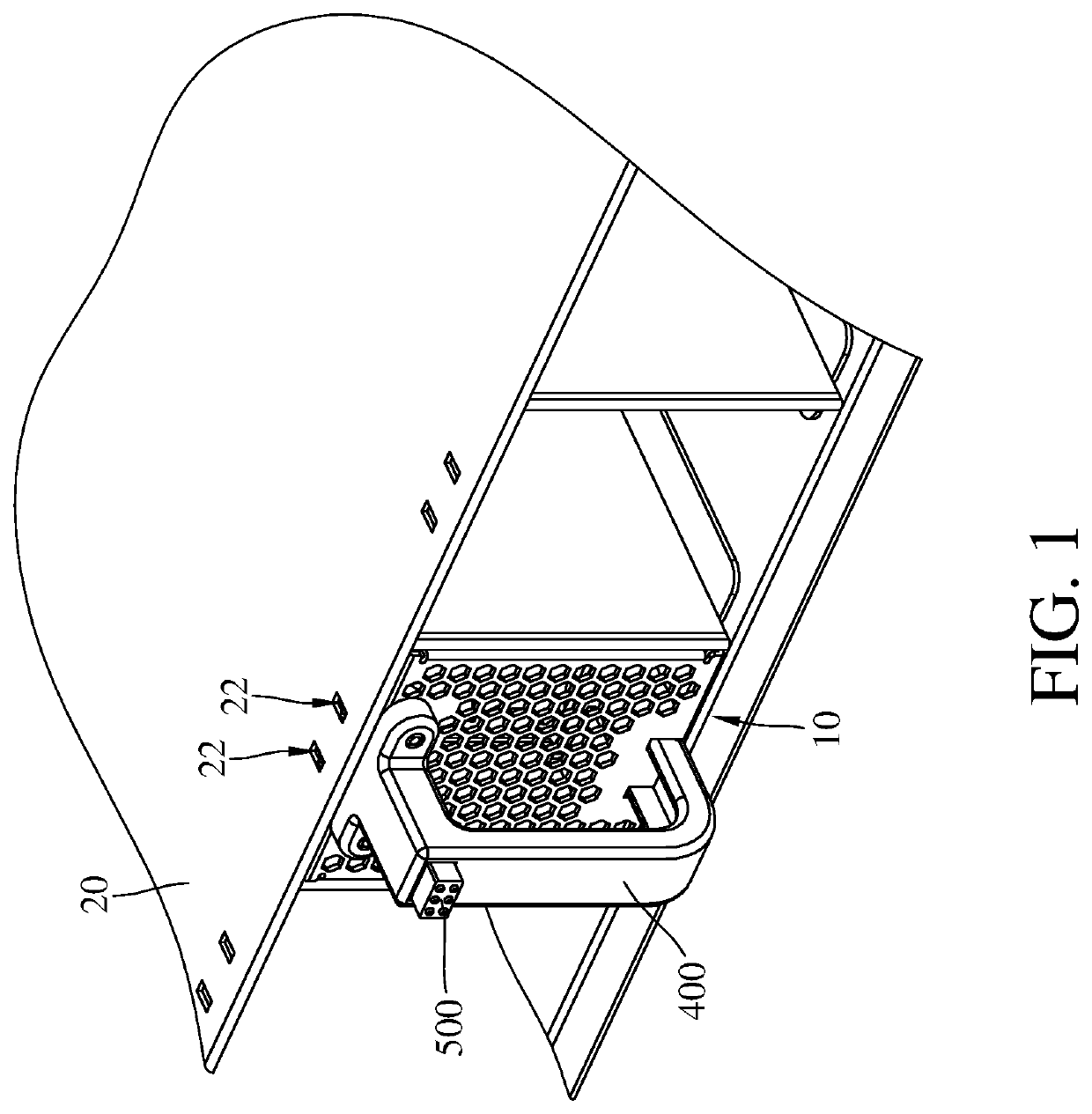

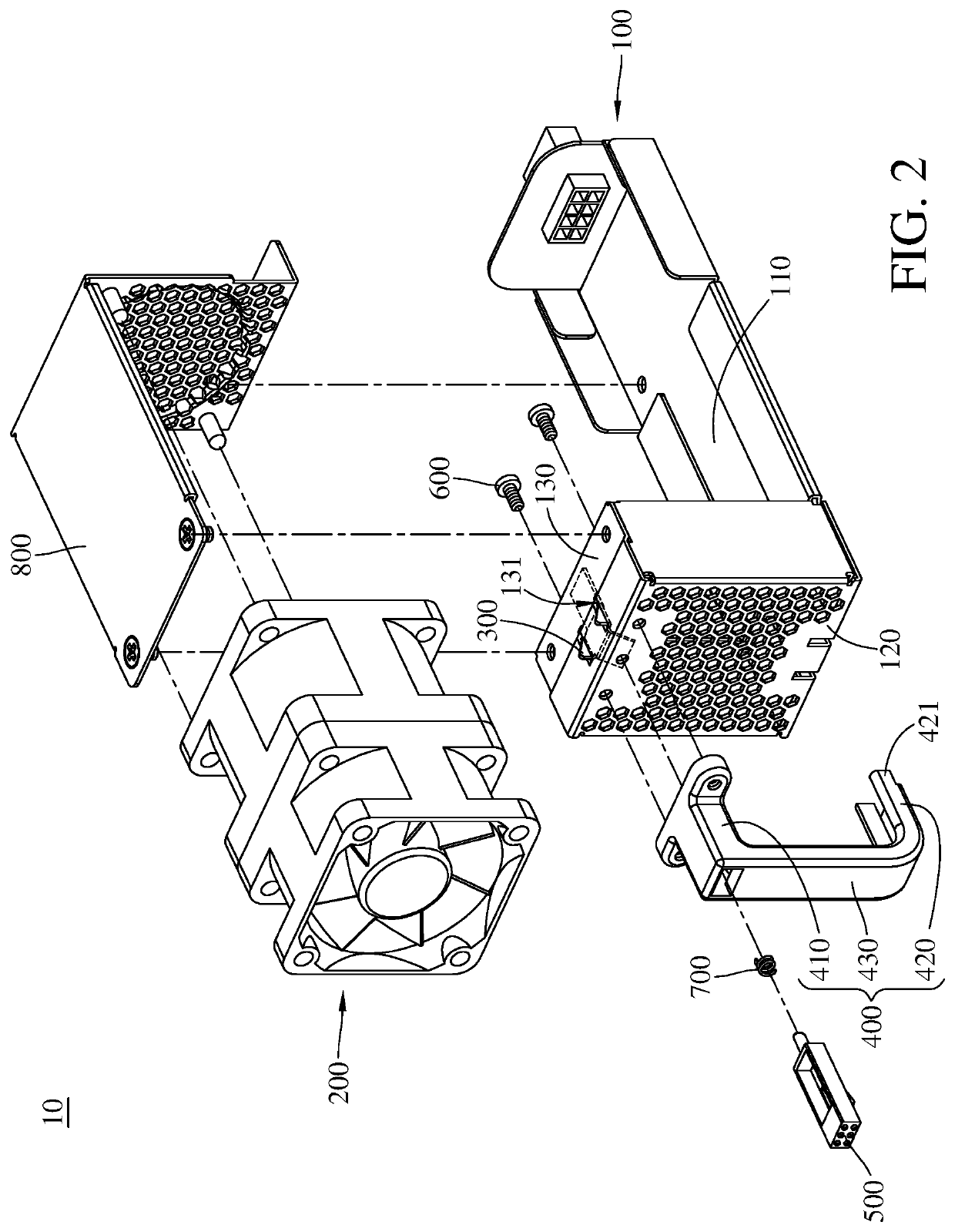

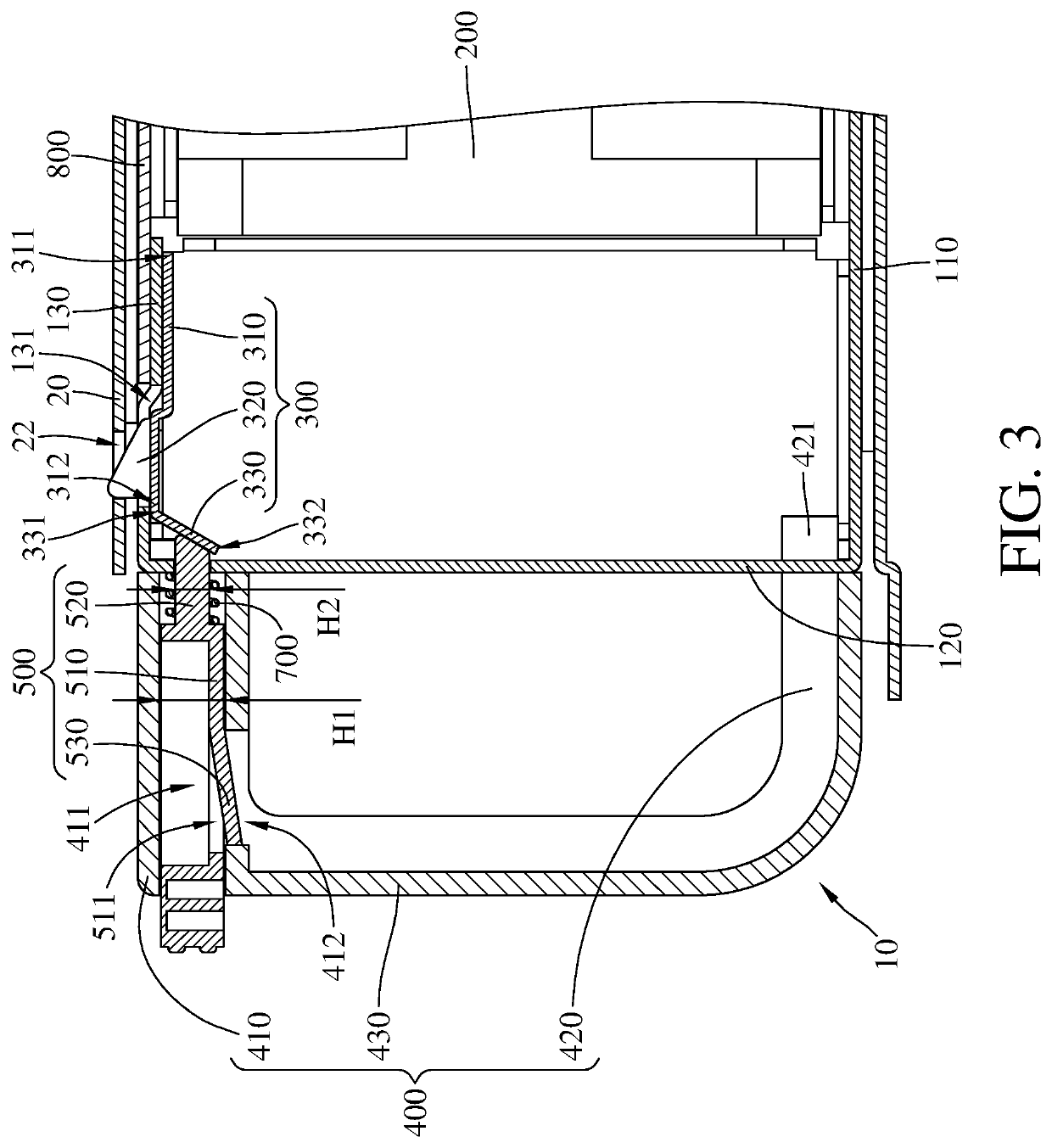

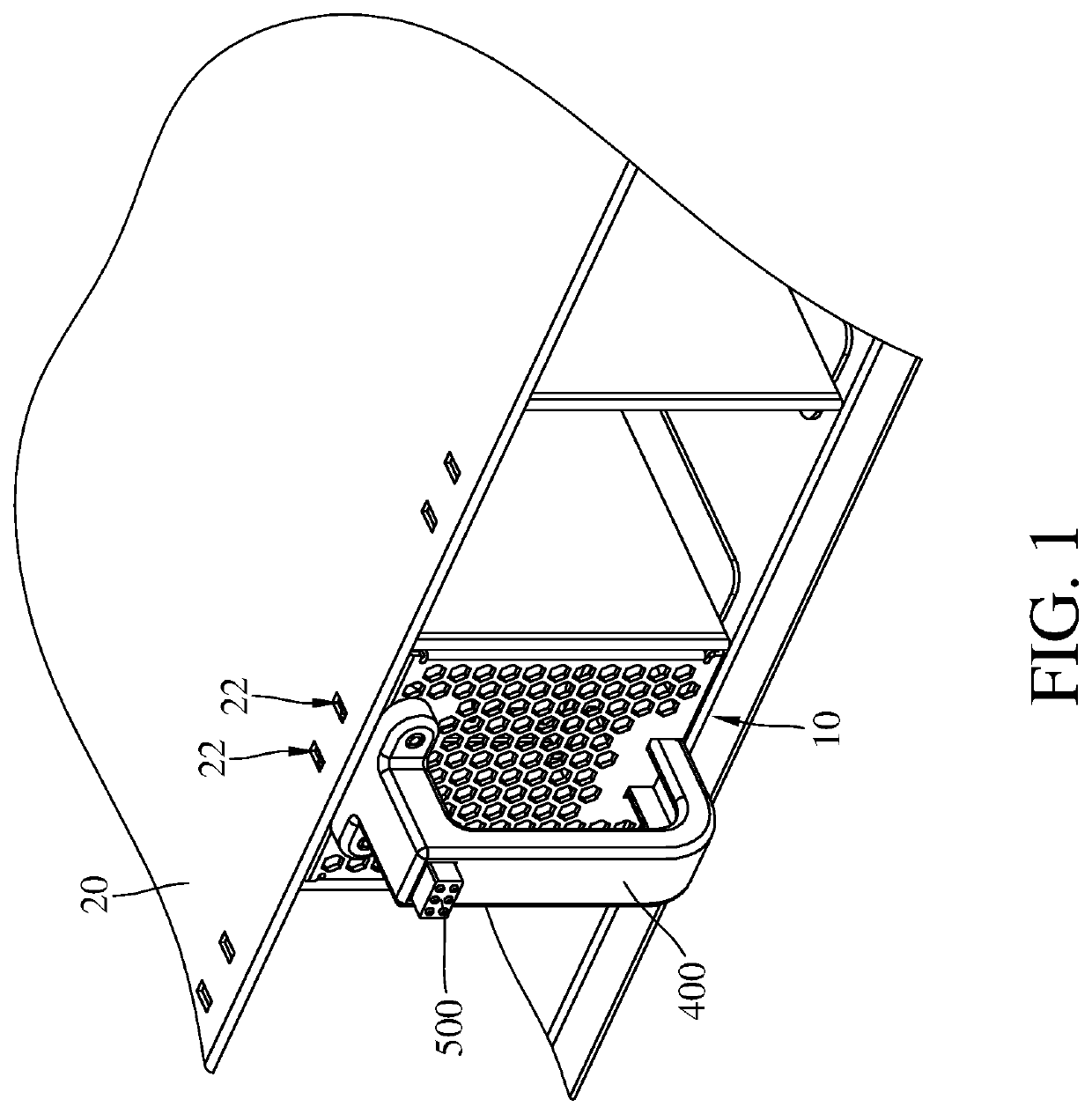

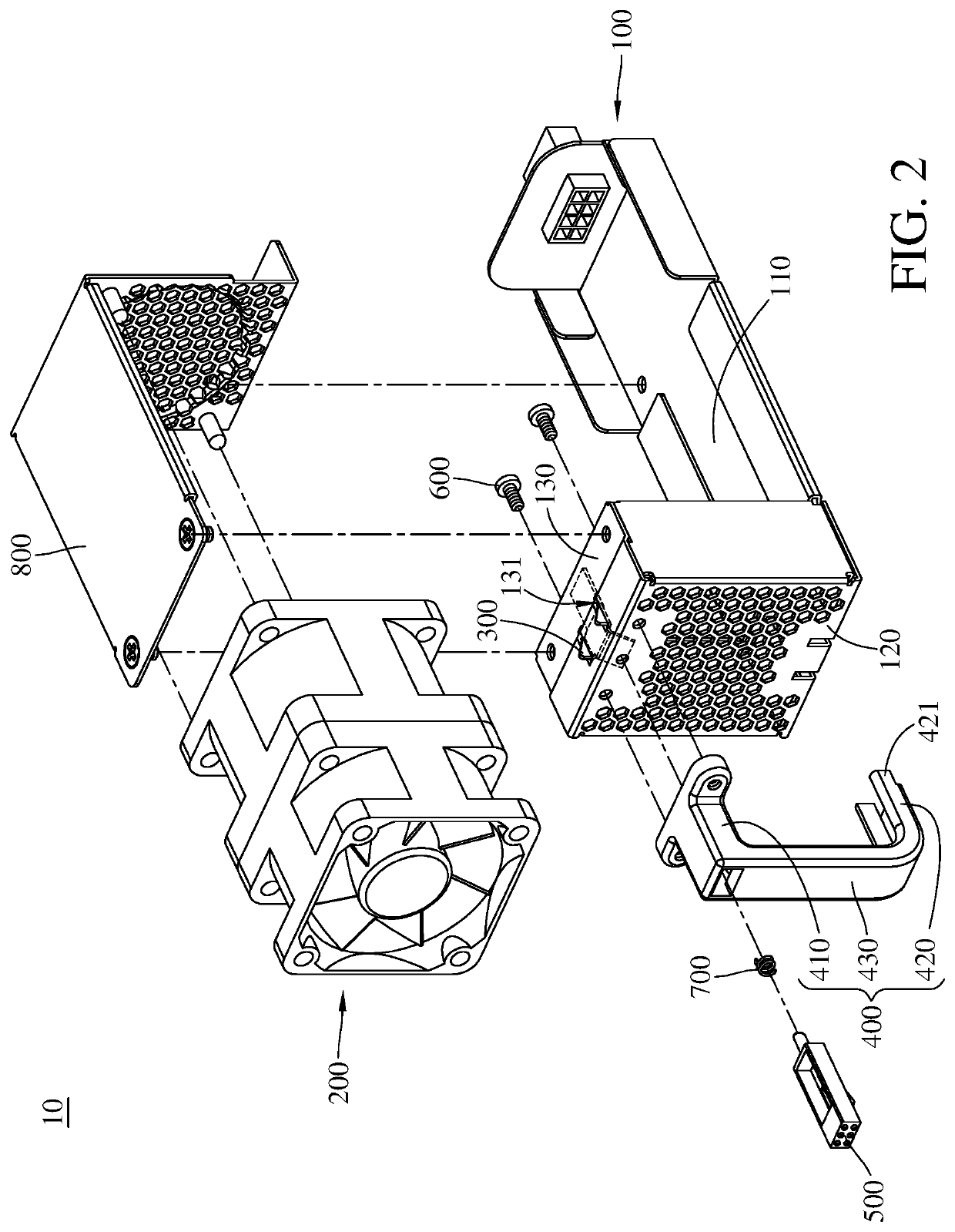

Fan device

A fan device configured to be assembled to chassis having engagement slot and including casing, fan, clip, handle, and trigger. Casing includes bottom plate, front plate and top plate. Top plate at least partially covers bottom plate and has through hole. Opposite sides of front plate are respectively connected to bottom plate and front plate. Fan is disposed on casing. Clip includes elastic part, engagement part and pressed part. Elastic part has fixed side and movable side that are opposite. Fixed side is disposed on top plate. Movable side is located closer to top plate than fixed side. Engagement part is connected to movable side. Engagement part is disposed through the through hole to be engaged with engagement slot. Pressed part is connected to movable side. Handle is disposed on front plate. Trigger is movably disposed on handle.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Mould capable of automatically adjusting space size

Owner:KUNSHAN SANJING SCI & TECH

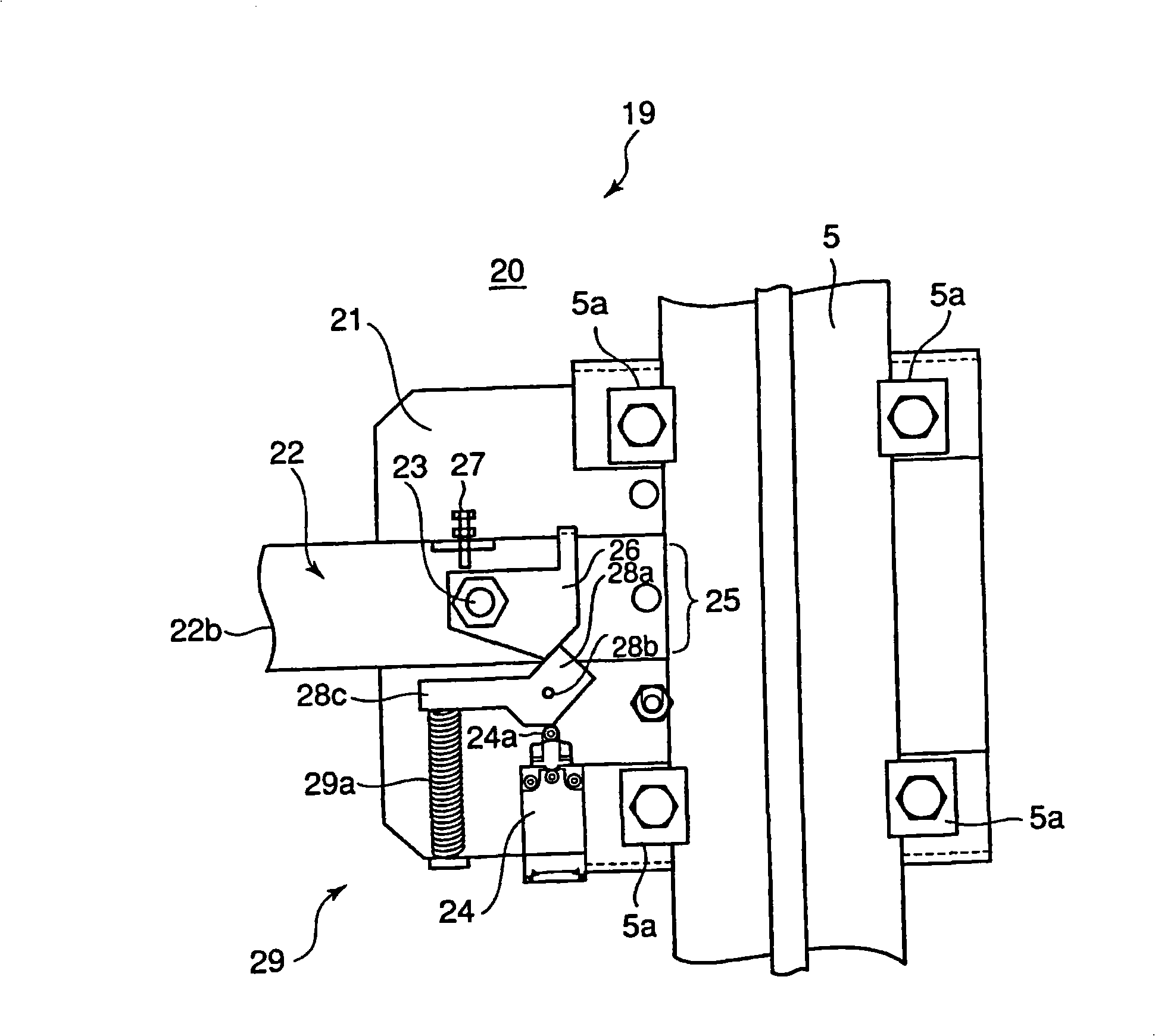

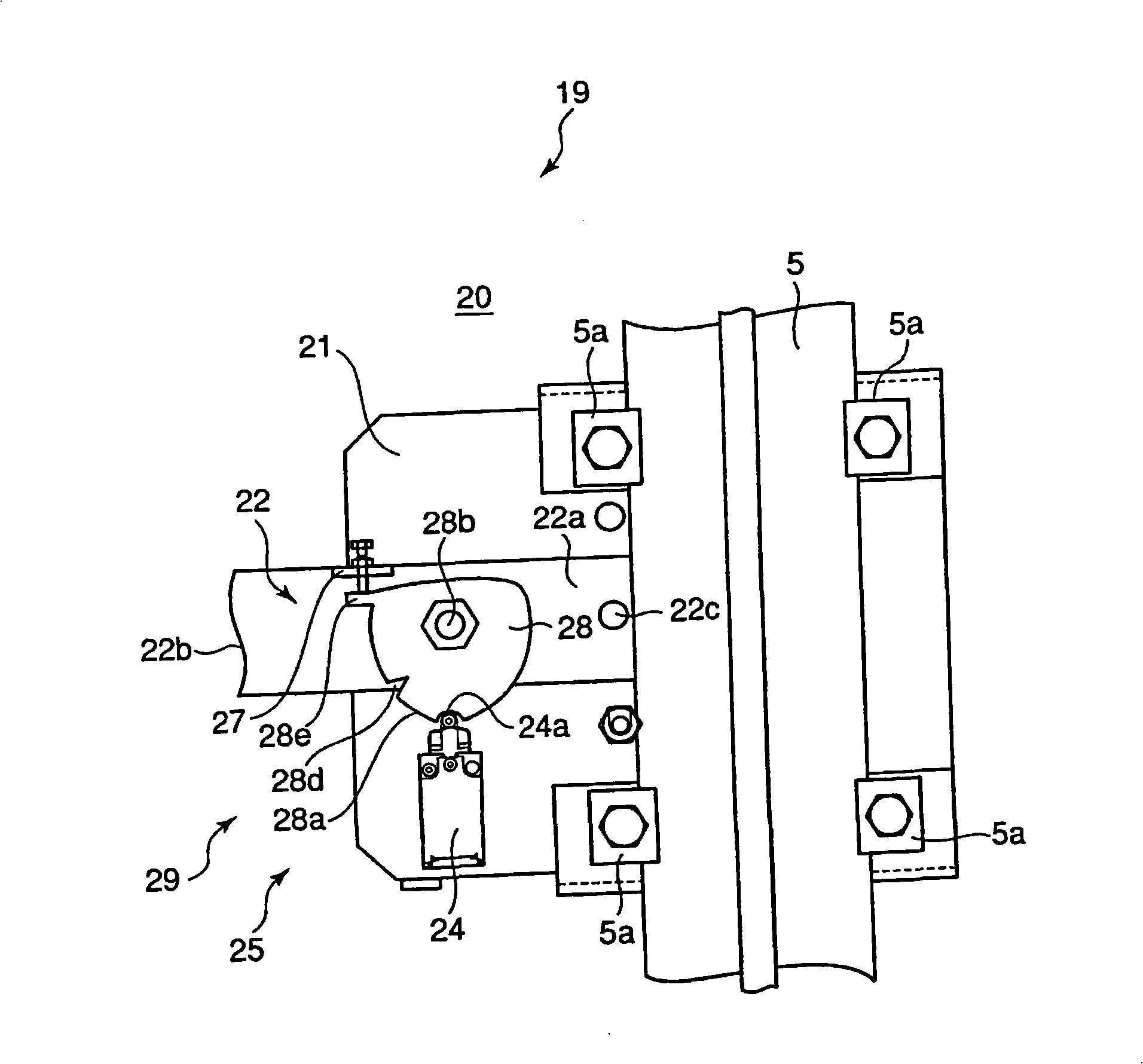

Speed governor tensioner apparatus for elevator

A speed regulator tensioner (20) for elevator, wherein a speed regulator cable (9) winds among a speed regulator sheave (7) of a speed regulator (6) mounted at the superior side of an elevator lifting path (19) and a tensioner sheave (8) at the inferior side and the tensioner sheave extends by a hung balance weight (10). The rotation axle of the tensioner sheave is axially beard on the front end (22b) of a swing arm (22) and a proximal end (22a) is freely axially beard on a fixation component (21) of the lifting path in a swing manner and the switch at the fixation side of the lifting path detects the speed regulator cable extension of more than a certain length due to the balance weight. A push-pressing action section (25) is arranged around the proximal end of the swing arm and presses a movable contact (24a) of the switch (24), when the front end of the swing arm swings downwards by a preset degree through the balance weight. A state keeping section (29) keeps the state of movable contact of the switch pressed by the push-pressing action section.

Owner:TOSHIBA ELEVATOR KK

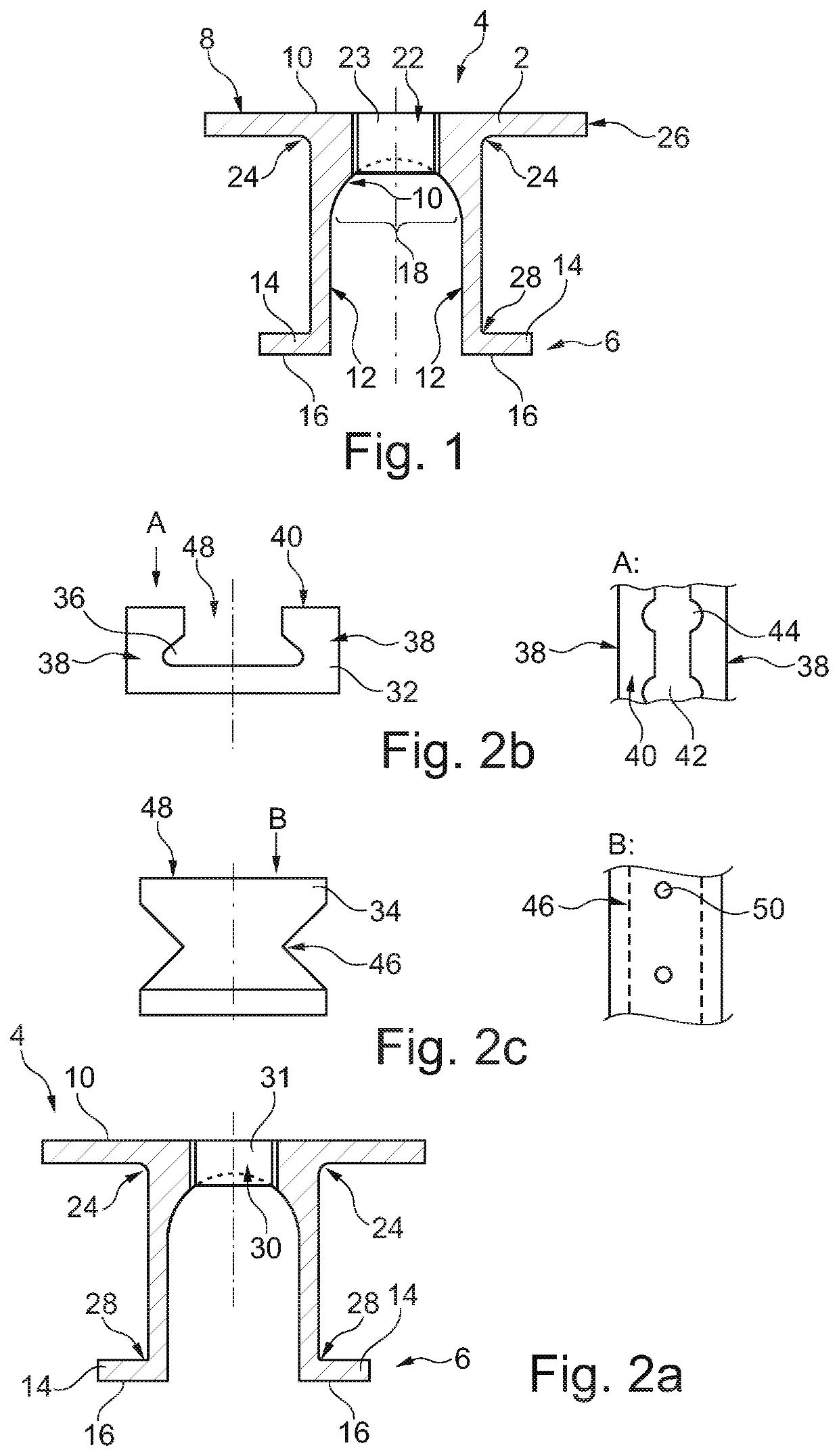

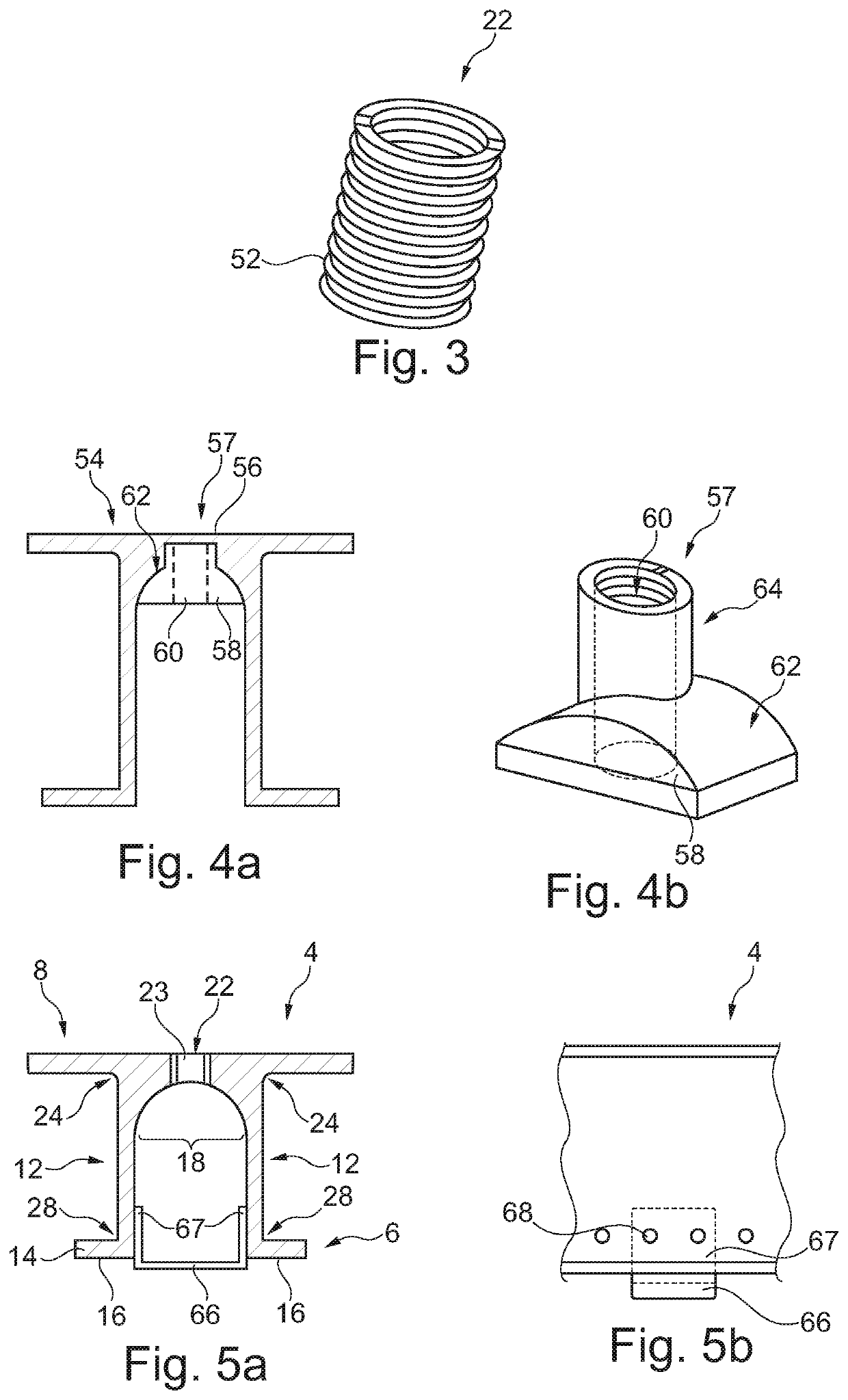

Rail Systems for Fixing Fittings in a Cabin of a Vehicle

A rail system for fixing fittings in a cabin of a vehicle includes a first elongate rail body with a fixing side for fixing to a vehicle structure, an opposite support side with a support surface for receiving fittings, and a rail cross-section extending between the fixing side and the support side, and several fixing inserts which can be fixed along the support surface. The rail cross-section has two mutually opposing legs which are spaced apart from each other and run perpendicularly to the support surface, and the fixing inserts are configured so as not to protrude beyond the support surface.

Owner:AIRBUS OPERATIONS GMBH

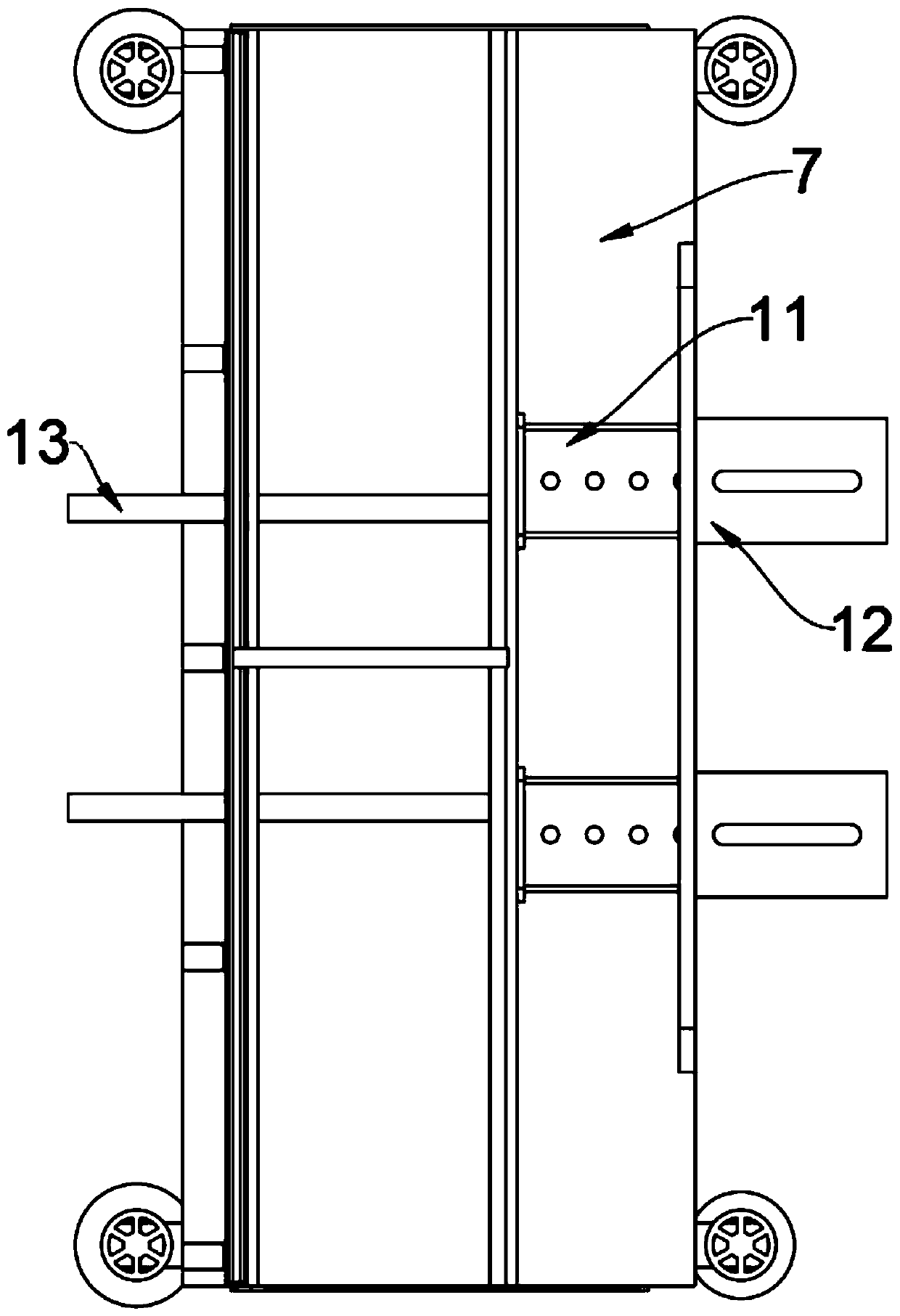

Movable mold capable of adjusting size of prefabricated member

InactiveCN110978231AImprove stabilityAvoid outside interferenceMouldsMould fastening meansSlide plateSupport plane

Owner:无锡住信建筑构件有限公司

Automation-based metal pipe bending device

InactiveCN111687253AAvoid dent damageTelescopic adjustmentMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention discloses an automation-based metal pipe bending device and relates to the technical field of metal pipe machining equipment. The device comprises a bending system, the bending system comprises a working platform, a bending fixing end is arranged at the center of the upper surface of the working platform in a matched mode, and the bottom side surface of the working platform is connected with a supporting plate through a fixing side plate; a bending motor is fixed on the supporting plate, a bending driver is fixed on an output shaft of the bending motor, the bending driver comprises a fixing part which is in matched connection with the output shaft of the bending motor, a swing arm is connected to one side of the fixing part, a bending shaft rod is fixed to the other end of the swing arm, and the top end of the bending shaft rod is connected with a bending head or a bending end head. Two arc-shaped fixing grooves are arranged, and stop blocks are arranged on the two arc-shaped fixing grooves in a matched mode, so that any bending angle can be formed by bending according to requirements; and meanwhile, due to the arrangement of the bending head or the bending end head,the concave damage of the stressed part of a metal pipe in the bending process can be effectively avoided.

Owner:界首市神机合自动化科技有限公司

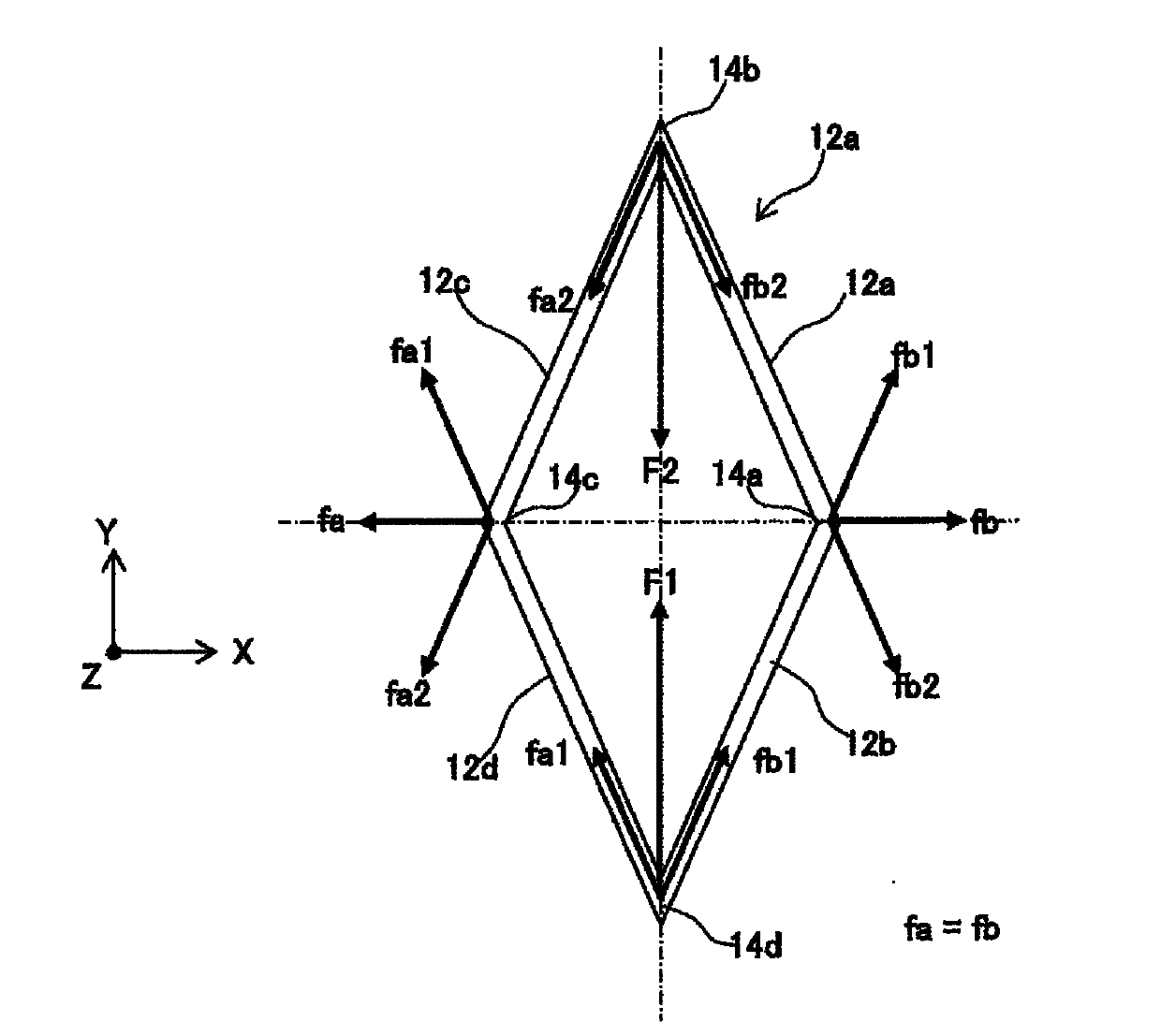

Acceleration sensor and acceleration detecting apparatus

InactiveCN102169128AAchieving Detection AccuracyImprove acceleration detection sensitivityPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesManufacturing cost reductionHigh acceleration

The invention provides an acceleration sensor and an acceleration detecting apparatus, which has a simple structure and high acceleration detecting performance and can reduce the manufacturing cost thereof. The acceleration sensor includes a piezoelectric sensor and a support plate. The piezoelectric senso comprises: a piezoelectric sensor element; a first fixed portion (14a) and a second fixed portion (14c) to support the piezoelectric sensor element on the support plate; and first to fourth beams (12a-12d) connecting the piezoelectric sensor element to the first fixed portion and the second fixed portion. The support plate includes a fixation-side first plate piece (5) for fixing the first fixed portion, a movement-side second plate piece for supporting the second fixed portion, and a hinge portion, wherein the piezoelectric sensor element has a longitudinal shape extending in a direction perpendicular to the sensing axis direction and the center of the sensor element in the lateral direction is located within the width of the hinge portion in the lateral direction.

Owner:SEIKO EPSON CORP

Fan device

A fan device configured to be assembled to chassis having engagement slot and including casing, fan, clip, handle, and trigger. Casing includes bottom plate, front plate and top plate. Top plate at least partially covers bottom plate and has through hole. Opposite sides of front plate are respectively connected to bottom plate and front plate. Fan is disposed on casing. Clip includes elastic part, engagement part and pressed part. Elastic part has fixed side and movable side that are opposite. Fixed side is disposed on top plate. Movable side is located closer to top plate than fixed side. Engagement part is connected to movable side. Engagement part is disposed through the through hole to be engaged with engagement slot. Pressed part is connected to movable side. Handle is disposed on front plate. Trigger is movably disposed on handle.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

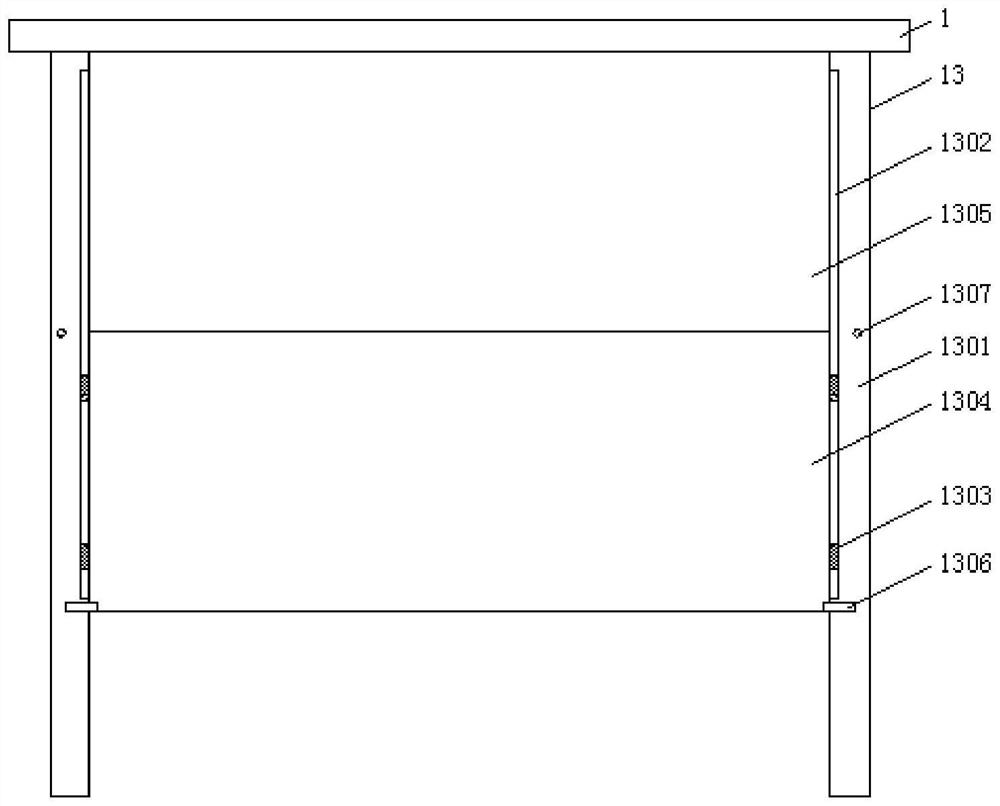

Plate wall fixing device and fixing method for building

Owner:CHINA MCC17 GRP

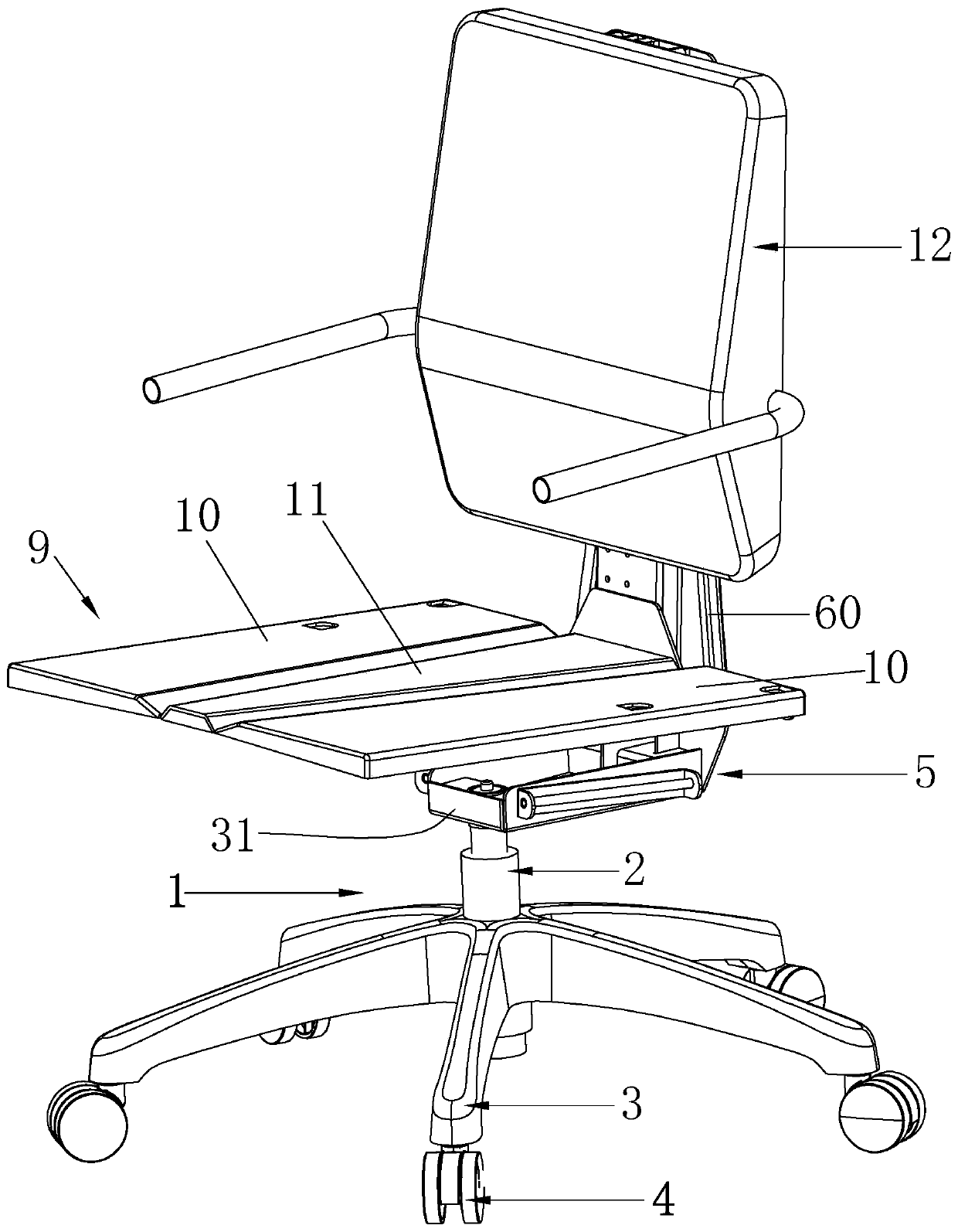

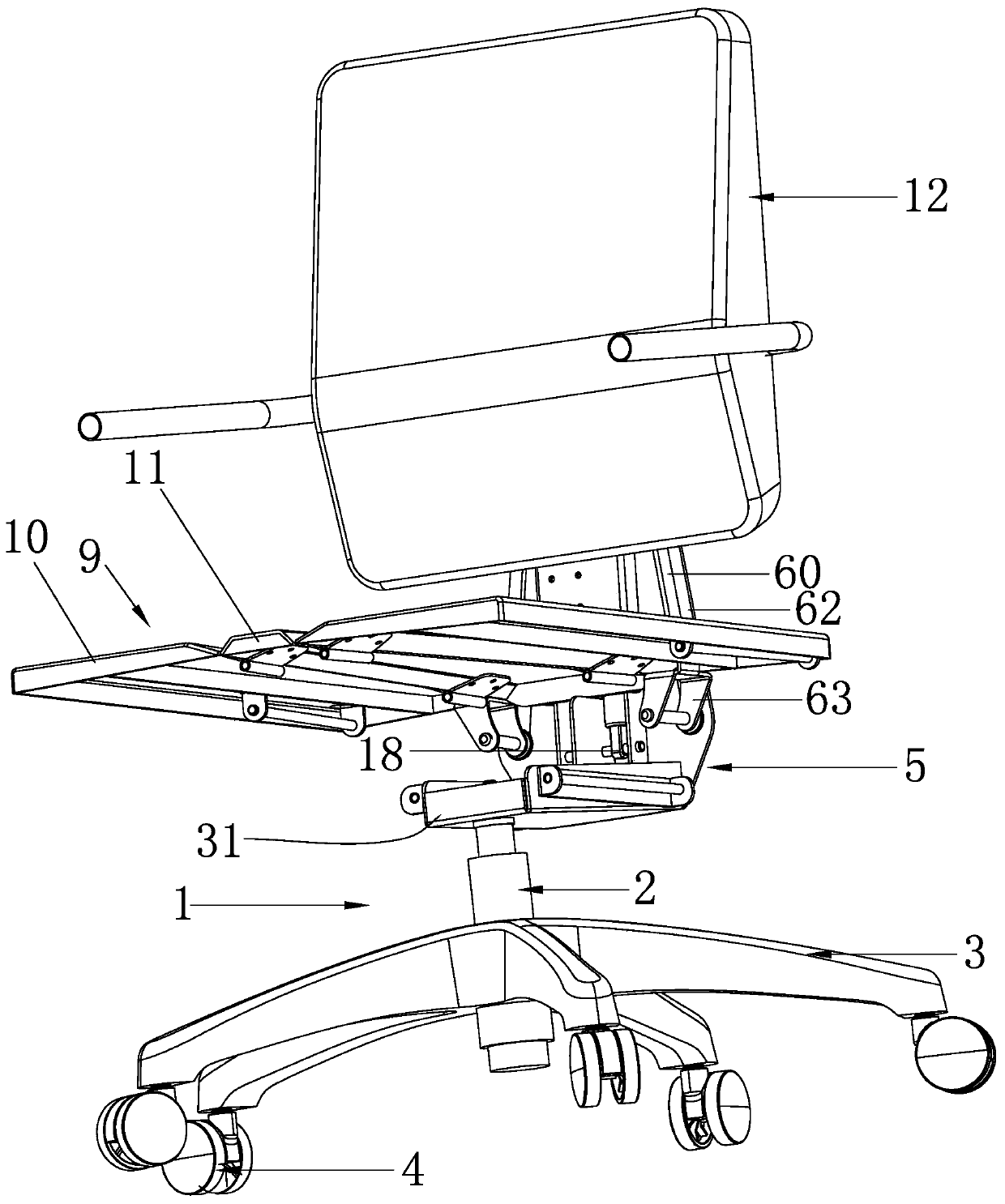

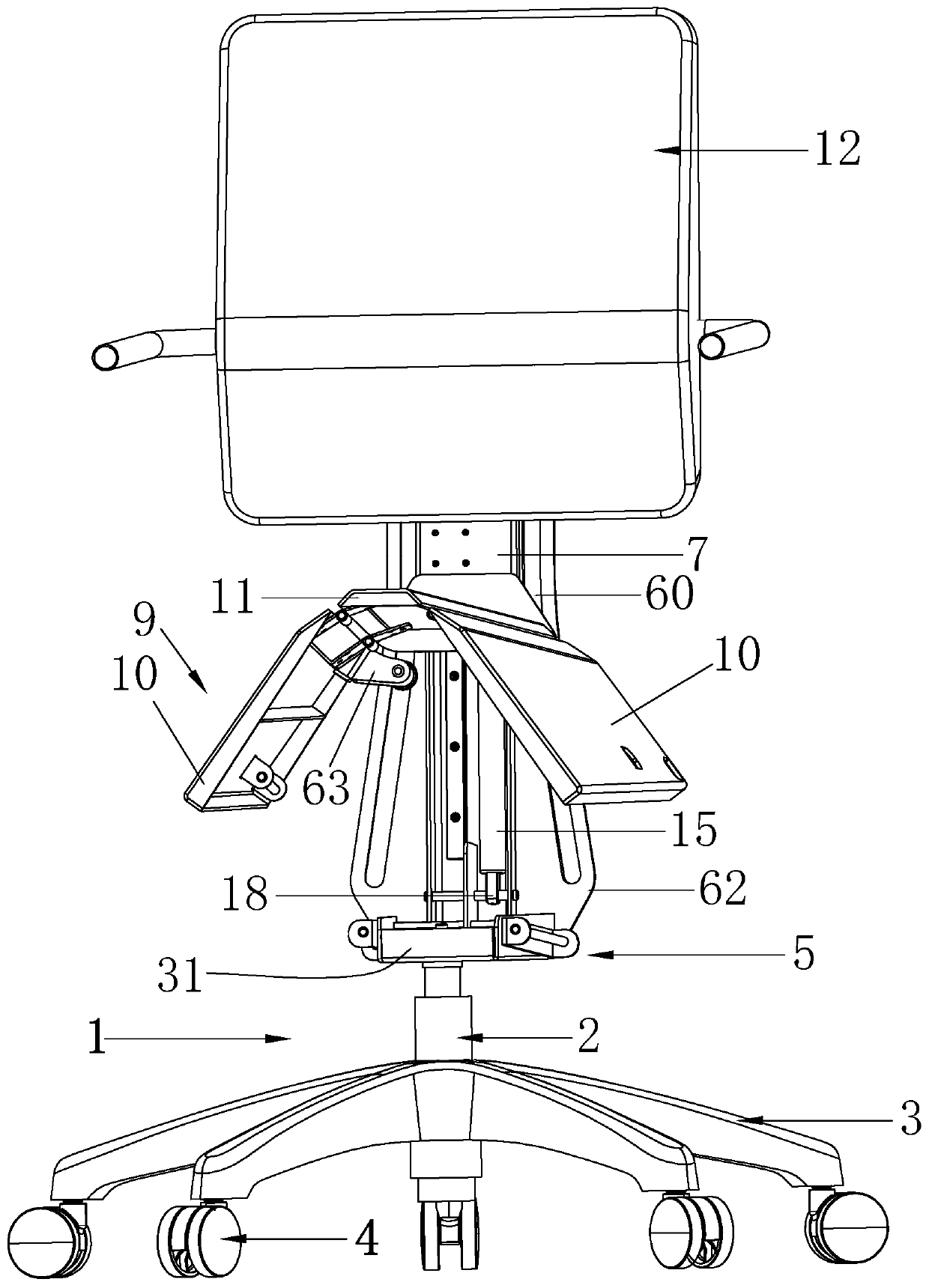

Chair unit and chair

InactiveCN110693219AIn line with physical healthImprove experienceBenchesConvertible chairsAcute angleBack support

The invention discloses a chair unit and a chair. The chair unit comprises a base and a sliding rail assembly with a movable rail and a static rail, and the static rail is fixedly connected with the base; a seat supporting piece comprises a middle seat and a side seat, wherein the middle seat is configured to be always kept in an approximately horizontal state or form an acute angle with the horizontal plane, and the middle seat and the movable rail are relatively fixed; the side seat is hinged with the middle seat; a back supporting piece is connected with the movable rail and moves up and down along with the movable rail, and a linkage mechanism responds to lifting movement of the middle seat and acts on the side seat to enable the side seat to turn over relative to the middle seat. Thechair unit provided by the invention has two states, namely a flat sitting state and a standing posture state, and a chair conversion mechanism can freely convert between the two states and can convert only by sliding fit of the sliding rail assembly; compared with the prior art, the structure is simple, operation is easy and convenient, and the experience feeling of a user is good. The chair unit disclosed by the invention is convenient and rapid to switch between sitting and standing and can be widely applied to occasions such as offices and families.

Owner:UE FURNITURE CO LTD

Automobile body stamping device with cleaning device

InactiveCN111112441ARealize telescopic adjustmentRealize stamping operationsMetal-working feeding devicesPositioning devicesBolt connectionFixation side

The invention discloses an automobile body stamping device with a cleaning device. The automobile body stamping device with the cleaning device comprises a fixed bottom plate, wherein a first fixed side plate is fixedly connected to one side of the top of the fixed bottom plate; a slide groove is formed in the top of the inner wall of the first fixed side plate; a slide block is connected to one side of the slide groove; and an installation plate is fixedly connected to one side of the slide block. According to the automobile body stamping device with the cleaning device, position adjustment for a movable seat is realized through bolt connection between an adjustment screw rod and a third fixed side plate, so that movement for a clamping plate is realized; a stamped part is clamped at a workbench, and in an adjustment process for the movable seat, a slide sleeve slides in the direction of the slide rod, so that the movement of the movable seat is more stable; a second cylinder is adopted for realizing telescoping adjustment for a second telescopic rod, so that the slide of the slide block at the slide groove is realized, position adjustment for a stamping plate and a stamping headis finally realized, and realization for multi-hole stamping working in the same horizontal line is facilitated; and then telescoping adjustment for a first telescopic rod is realized through a firstcylinder, so that the stamping working of the stamping head at the bottom of the stamping plate is realized.

Owner:江苏万成机械制造有限公司

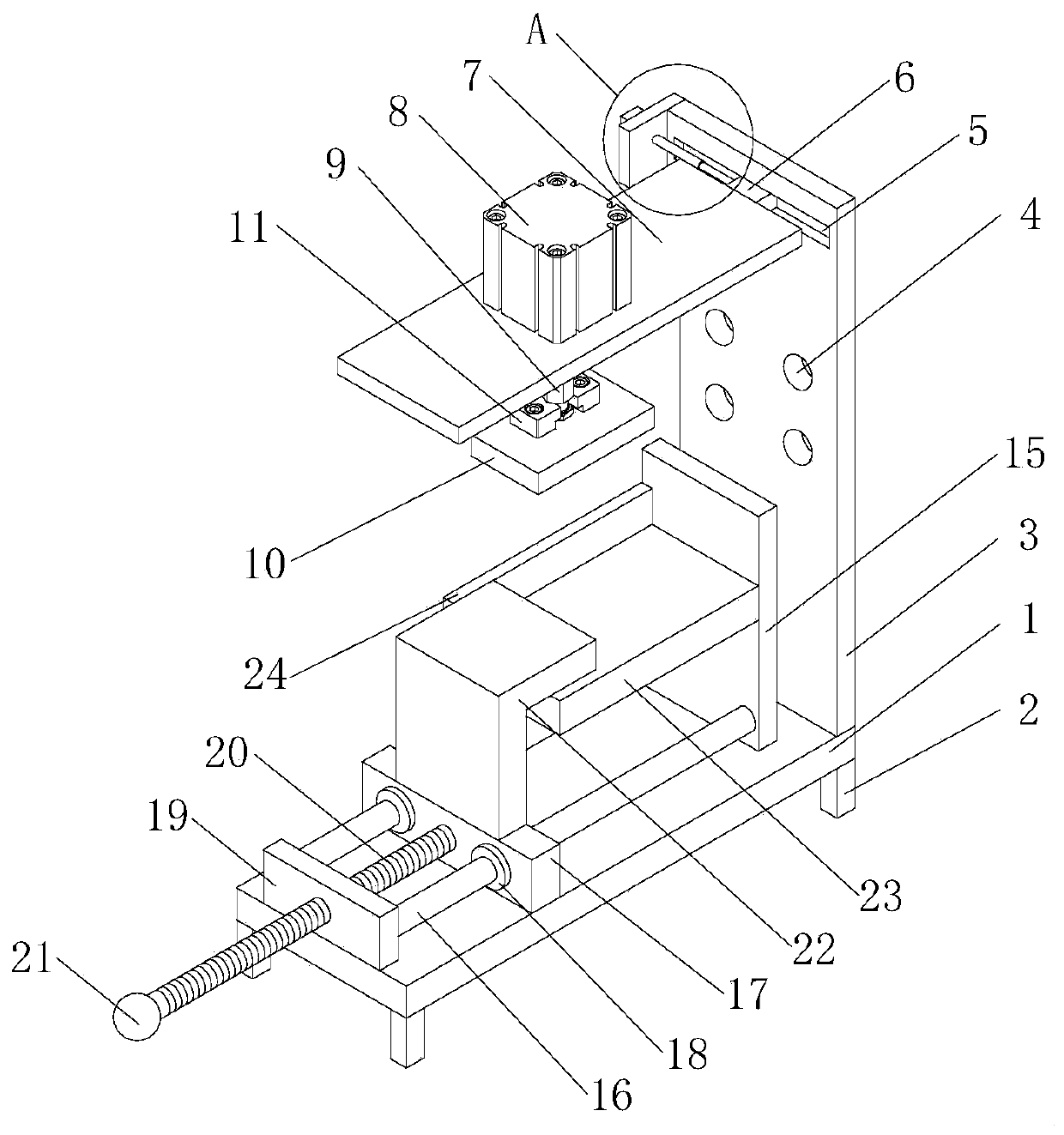

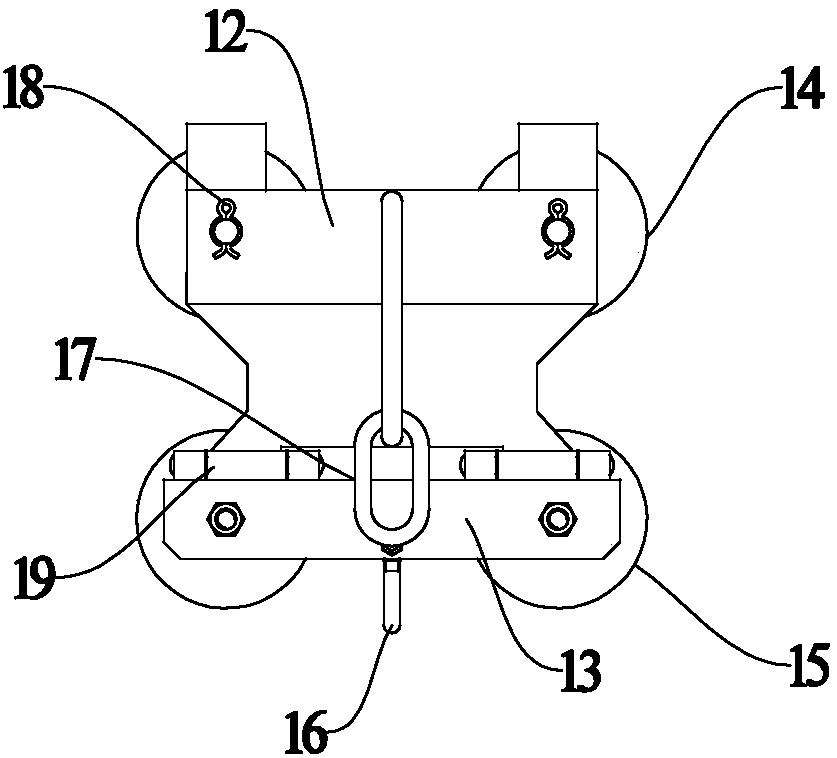

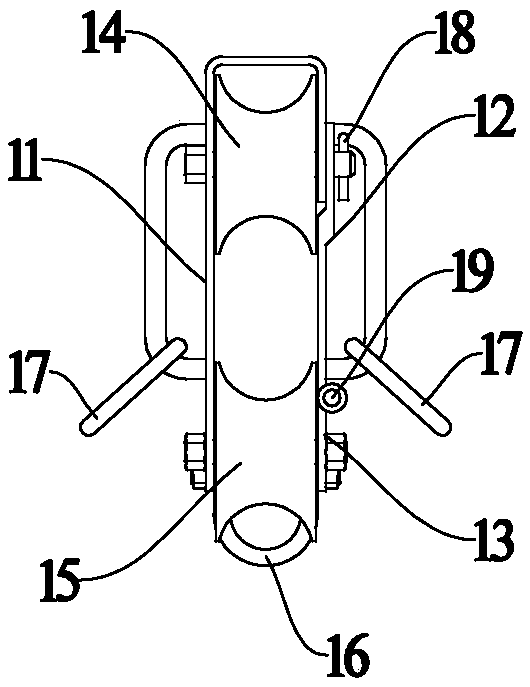

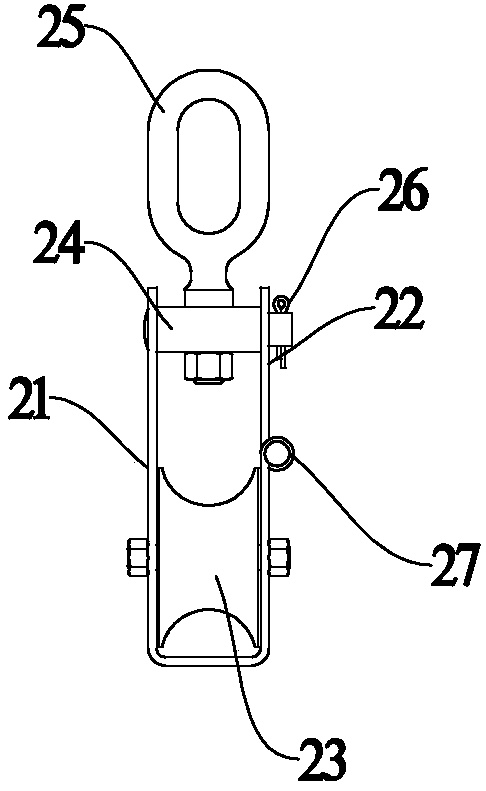

Span-crossing line changing tackle for distributing line and line changing method thereof

PendingCN107947029AFast constructionLow costApparatus for overhead lines/cablesTraveling blockIndustrial engineering

The invention discloses a span-crossing line changing tackle. The span-crossing line changing tackle comprises middle phase tackles and side phase tackles, wherein the middle phase tackles comprises fixed side frames, movable upper side frames and movable lower side frames; double support pulleys are arranged between the fixed side frames and the movable upper side frames; double paying-off pulleys are arranged between the fixed side frames and the movable lower side frames; the movable upper side frames are hinged with the movable lower side frames; spacing rope hanging rings are further arranged on the middle phase tackles; the spacing rope hanging rings are used for connecting spacing ropes; the side phase tackles comprise U-shaped frames and movable doors; single pulleys are arranged between the U-shaped frames; the movable doors are hinged with the U-shaped frames; connecting pieces are arranged between the middle phase tackles and the side phase tackles. A line changing method using the line changing tackle comprises steps A to F. The span-crossing line changing tackle has the advantages of high construction speed, low cost, high safety and no need of erecting any crossing frame.

Owner:宁波华翔东方电力机具有限公司

Convertible embossing device

InactiveCN101124080AEasy to manufactureCost-effectiveMechanical working/deformationAdhesivesEngineeringFlange

Convertible embossing device comprising a structure (1) with two fixed sides (10) and two mobile sides (11) with respective external faces (EF, EM) and internal faces (IF, IM) and provided with, in correspondence of the respective internal faces (IF, IM), two upper recesses (12, 13) and two lower recesses (12', 13') with a circle-arc profile intended to support the end flanges (20, 30) of the two embossing rolls (2, 3) orthogonal to the sides (10, 11) of the same structure (1), wherein the mobile sides (11) are joined to the fixed sides (10) and the respective upper and lower recesses (12, 13, 12', 13') define, by cooperating with one another, two pairs of circular seats for the flanges (20, 30) of the rolls (2, 3), and in that, in a second operating position, the mobile sides (11) are distanced from the fixed sides (10) and the upper recesses (12, 13) of the sides (10) and (11) define, each one by cooperating with corresponding semi-circular closure flanges (15, 16), two pairs of circular seats for the flanges (20, 30) of the rolls (2, 3).

Owner:FUTURA SPA

Cutting-off equipment for cutting off length-adjustable polyester staple fiber

InactiveCN112501719AAvoid accidental injuryEnsure safetySevering to form staple fibresPolyesterFiber

The invention relates to cutting-off equipment for cutting off length-adjustable polyester staple fiber. The equipment comprises a supporting top plate, an air cylinder, a connecting block, a connecting plate, an adjusting mechanism, a stabilizing mechanism and a protection mechanism, wherein the stabilizing mechanism is mounted between the supporting top plate and the connecting plate; a threadedhole is formed in one end of the connecting plate; a first cutting knife is mounted at one end of the bottom of the connecting plate; and a second cutting knife is fixedly mounted at the bottom of the adjusting mechanism. By arranging the adjusting mechanism and the second cutting knife, when the cutting length needs to be changed, the adjusting mechanism on the second cutting knife is held by the hand, fixed side plates are clamped to the two sides of the connecting plate and placed on the two sides of the corresponding threaded hole according to the corresponding cutting length, then the fixed side plates are stably mounted on the connecting plate through fastening bolts, and then through the action of the first cutting knife and the second cutting knife, the fiber with the corresponding length can be cut.

Owner:天长市大发化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com