Single-action type variable length connecting rod and crank-connecting rod transmission mechanism

A transmission mechanism, single-acting technology, applied in the direction of connecting rod, transmission device, mechanical equipment, etc., can solve the problems of complex electrical control, unfavorable installation and maintenance, long time, etc., to achieve easy electrical control, convenient and fast adjustment, and economical to match the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

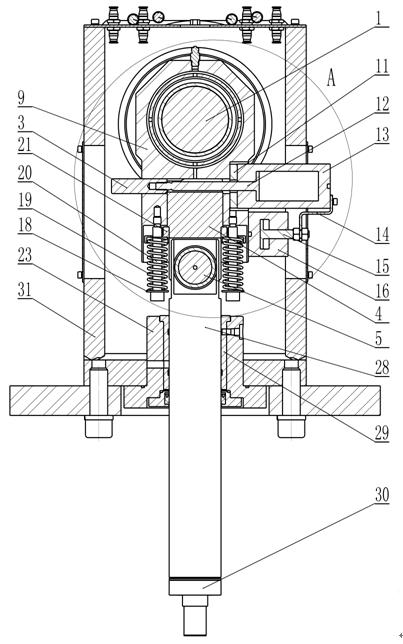

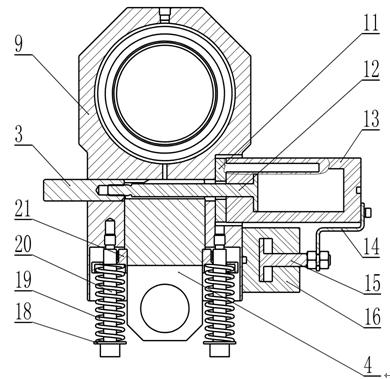

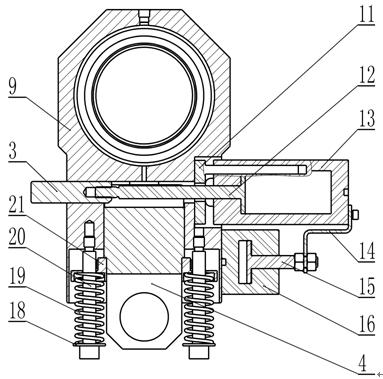

[0020] Embodiment 1: single-acting variable-length link mechanism.

[0021] A single-acting variable-length connecting rod, which includes an inner connecting rod 4 and an outer connecting rod 9 that are nested together to form a sliding fit connection. A guide groove is opened on the outer connecting rod 9, and a sliding rod is set in the guide groove. Matched pad 3; the two sides of the inner connecting rod 4 and the pad 3 are respectively provided with connecting plates 25 that hinge the inner connecting rod 4 and the pad 3 together; the outer connecting rod 9 is equipped with a guide cylinder, and the guide cylinder guides The plate 11 and the outer connecting rod 9 are fixed by screws, the guide hole provided on the guide cylinder wall is slidingly matched with the guide short axis on the guide plate of the guide cylinder, and the guide cylinder piston rod 12 is fixed with the spacer 3; the outer link 9 is located on the guide A short-stroke cylinder is installed below th...

Embodiment 2

[0025] Embodiment 2: single-acting crank-link transmission mechanism with variable length of connecting rod.

[0026] The similarities between this embodiment and Embodiment 1 will not be repeated. The difference is that it is a crank-link transmission mechanism, which includes a crankshaft and a single-acting variable-length connecting rod connected thereto.

[0027] Such as figure 1 , 6 As shown, the crankshaft 1 , the single-acting variable-length connecting rod, the pin shaft 5 , the slider 28 and the striking head 30 are located in the casing 31 . The servo motor 17 drives the crankshaft 1 to rotate through the reducer 22 , and the crankshaft 1 rotation can be transformed into the reciprocating motion of the slider 28 in the guide sleeve 29 through the crank linkage mechanism. Through the single-action variable link mechanism, three different heights of the striking head can be easily realized, namely: initial position, middle position and striking position. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com