Frictional conveying system with grouped bogies

A conveying system and trolley technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of complex structure of the roller table system, difficulty in ensuring synchronous conveying, inability to circulate within the level, etc., and achieve simple electrical control , simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

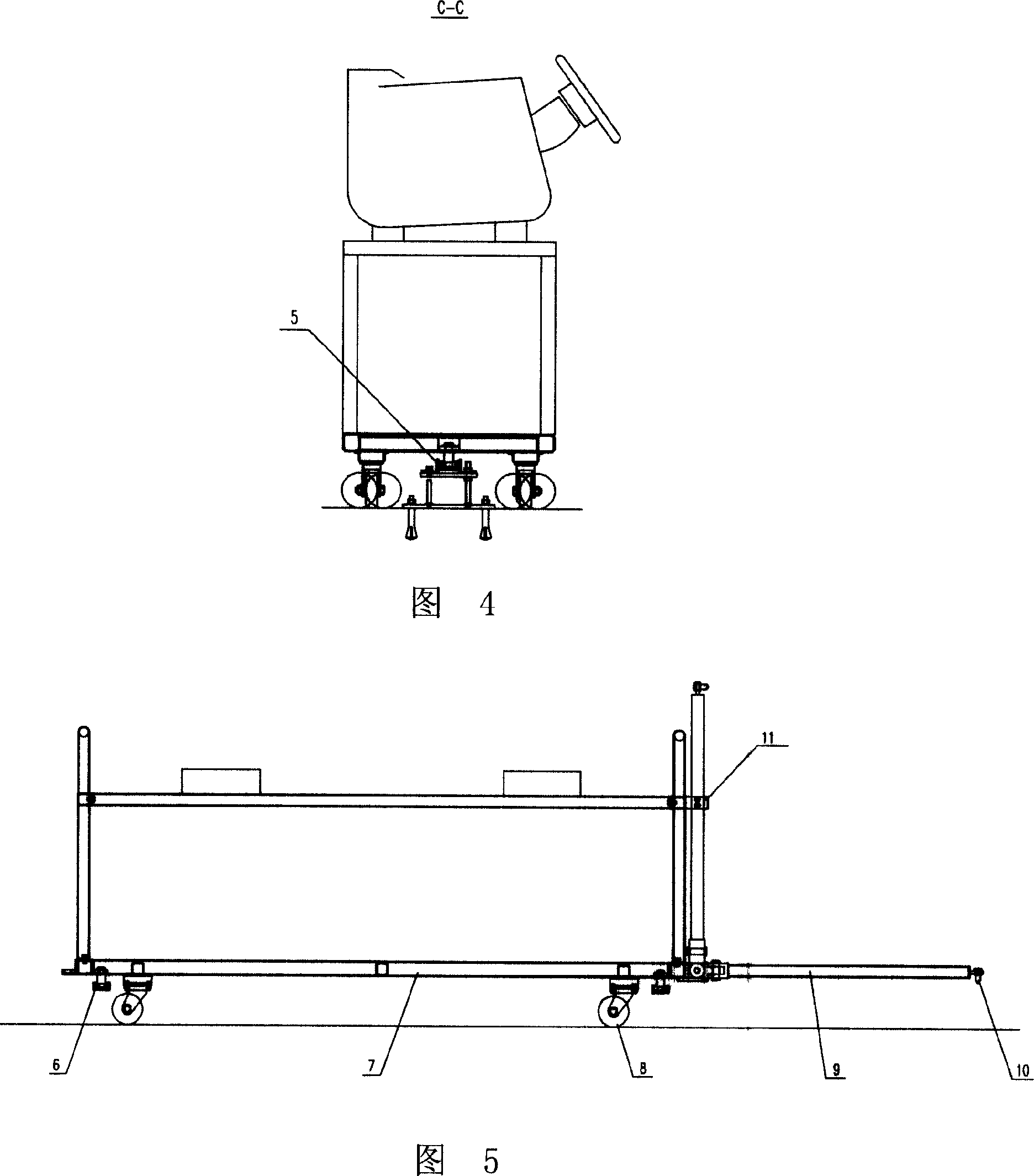

[0020] The present invention mainly consists of friction driving mechanisms 1, 2, carrying trolley 3, guide device 4, rail system 5, guide wheel 6, vehicle body 7, traveling wheel 8, connecting rod 9, hanging pin assembly 10, spring clamp 11, The pressing wheel bracket 12, the pressing wheel 13, the motor bracket 14, the friction wheel 15, the motor 16 and the tie rod assembly 17 are composed.

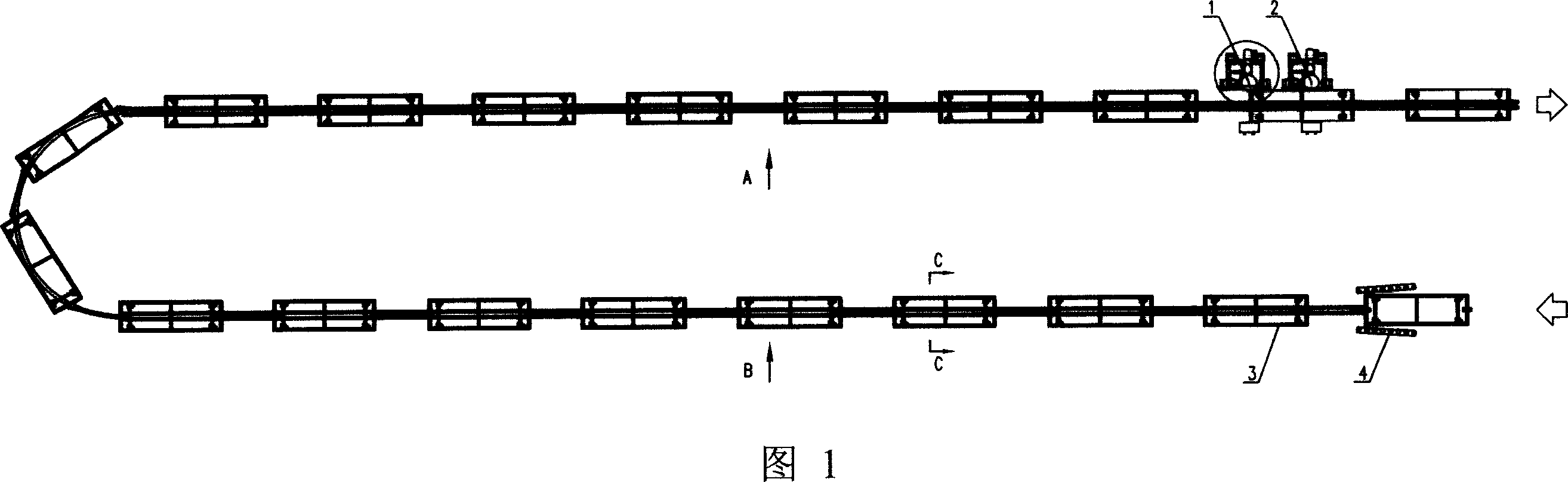

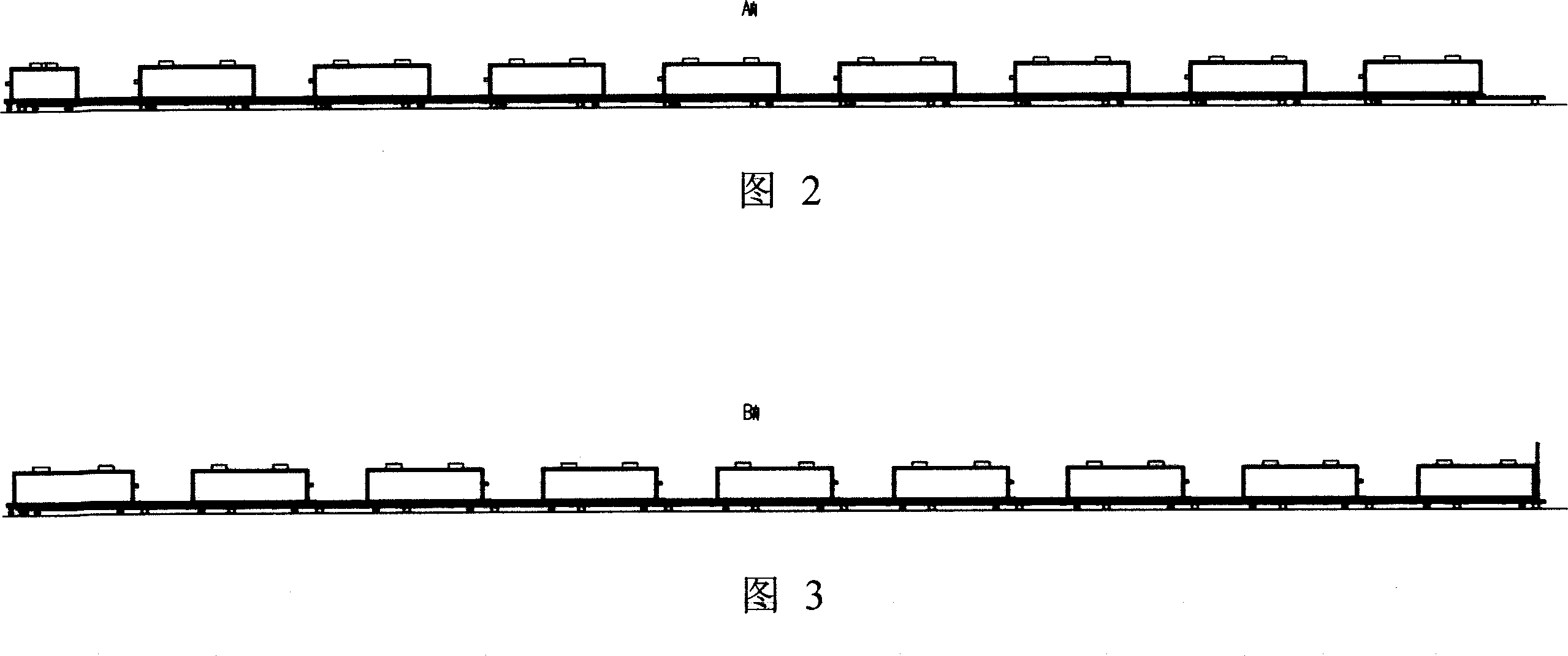

[0021] As shown in Figures 1 to 4: the present invention mainly uses two friction drive mechanisms 1 and 2 adjacent to each other as the power mechanism of the system, so that the carrying trolley can always be driven before it is separated from the drive, thereby ensuring accurate Synchronous conveying ensures correct and stable conveying speed.

[0022] The friction drive mechanism 1 and the friction drive mechanism 2 are arranged beside the track accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com