Electronic type phase conversion switch

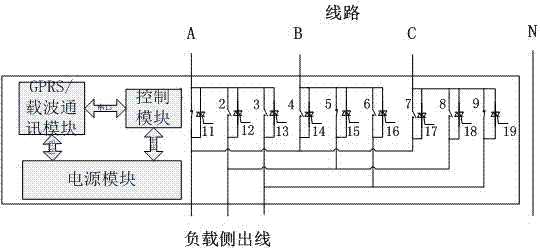

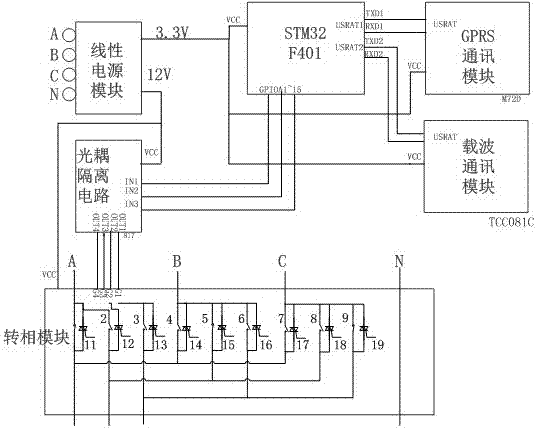

An electronic, phase-inverting technology, which is applied in the direction of reducing the asymmetry of electrical components, circuit devices, and multi-phase networks, can solve the problems of long commutation switching time, unbalanced three-phase load, and asymmetrical three-phase load. Achieve the effects of simplifying electrical control, improving reliability and reducing switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

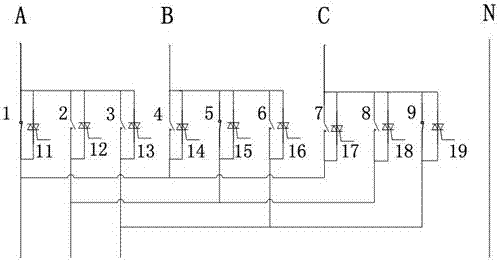

[0044] Grid voltage 220V, frequency 50HZ, clockwise phase rotation:

[0045] 1) In the initial state, A magnetic latching relay 1, E magnetic latching relay 5, and I magnetic latching relay 9 are closed, and the remaining magnetic latching relays and all thyristors are all disconnected. At this time, the circuit is controlled by A magnetic latching relay 1, E magnetic latching relay Holding relay 5 and I magnetic holding relay 9 supply power, and the phase sequence of the outgoing line on the load side is A, B, C;

[0046] 2) After receiving the clockwise phase rotation command:

[0047] 2.1 Turn on A anti-parallel thyristor 11, E anti-parallel thyristor 15, I anti-parallel thyristor 19, and wait for 20ms;

[0048] 2.2 A magnetic latching relay 1, E magnetic latching relay 5, and I magnetic latching relay 9 are disconnected. Wait for 100ms to ensure that the magnetic latching relay is completely disconnected. At this time, the line is composed of A anti-parallel thyristor 11,...

Embodiment 2

[0055] Grid voltage 220V, frequency 50HZ, counterclockwise phase rotation:

[0056] 1) In the initial state, A magnetic latching relay 1, E magnetic latching relay 5, and I magnetic latching relay 9 are closed, and the remaining magnetic latching relays and all thyristors are all disconnected. At this time, the circuit is controlled by A magnetic latching relay 1, E magnetic latching relay Holding relay 5 and I magnetic holding relay 9 supply power, and the phase sequence of the outgoing line on the load side is A, B, C;

[0057] 2) After receiving the counterclockwise phase rotation command:

[0058] 2.1 Turn on A anti-parallel thyristor 11, E anti-parallel thyristor 15, I anti-parallel thyristor 19, and wait for 20ms;

[0059] 2.2 A magnetic latching relay 1, E magnetic latching relay 5, and I magnetic latching relay 9 are disconnected. Wait for 100ms to ensure that the magnetic latching relay is completely disconnected. At this time, the line is composed of A anti-parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com