Unitization bogie chain side-pulling delivery system

A conveying system and trolley technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of chain drive wear, difficult maintenance, uneven load, etc., achieve low rolling friction resistance, simple electrical control, The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

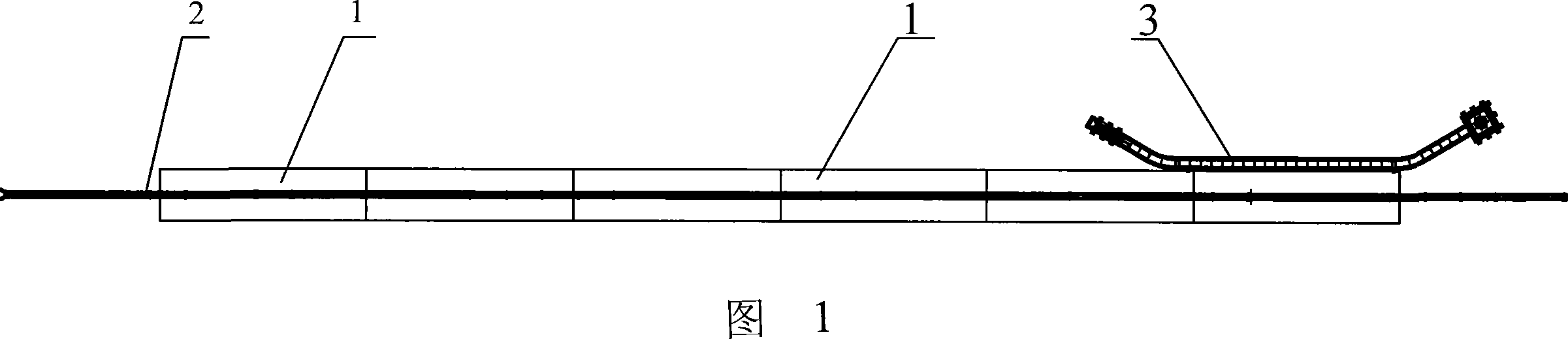

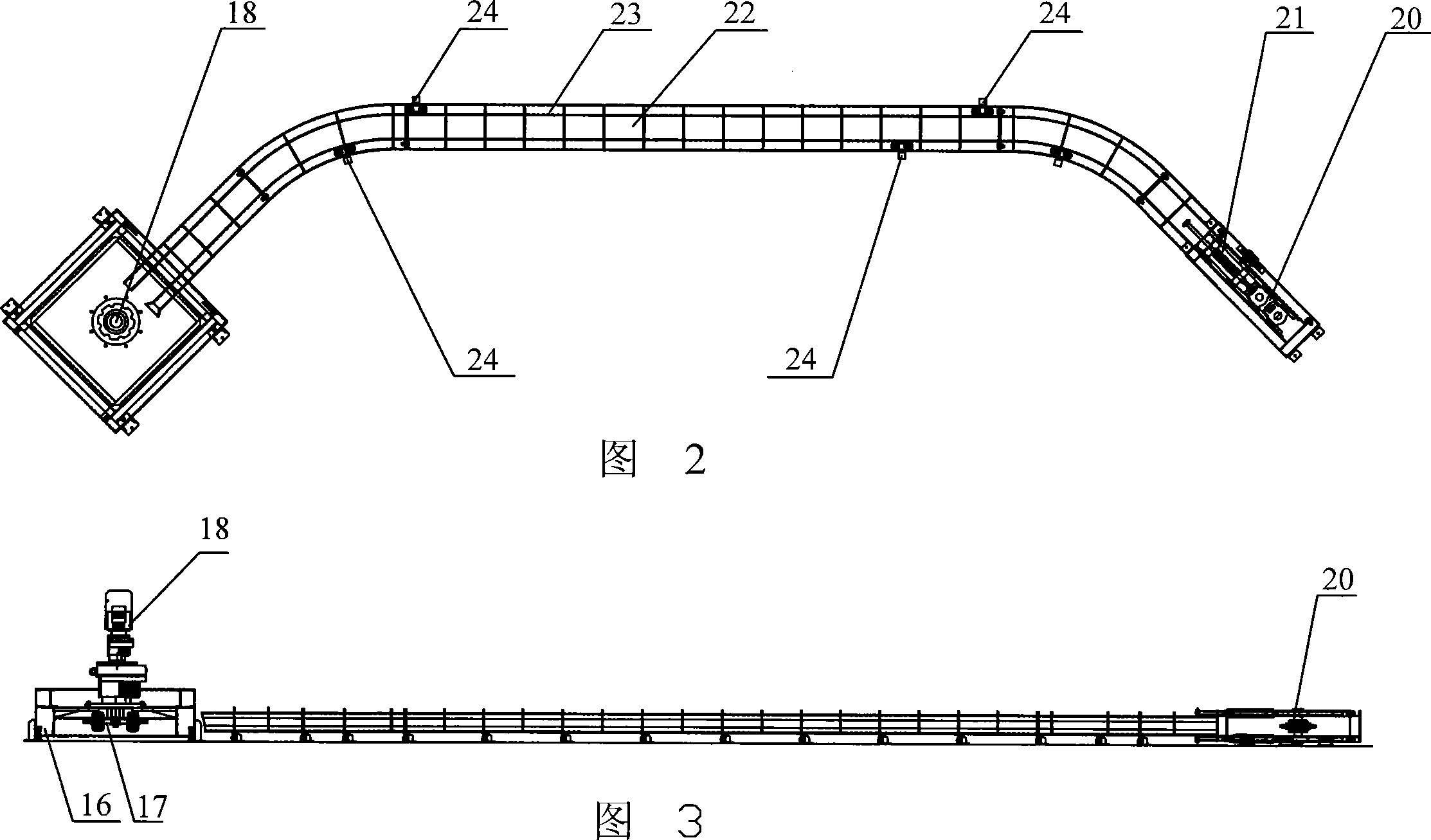

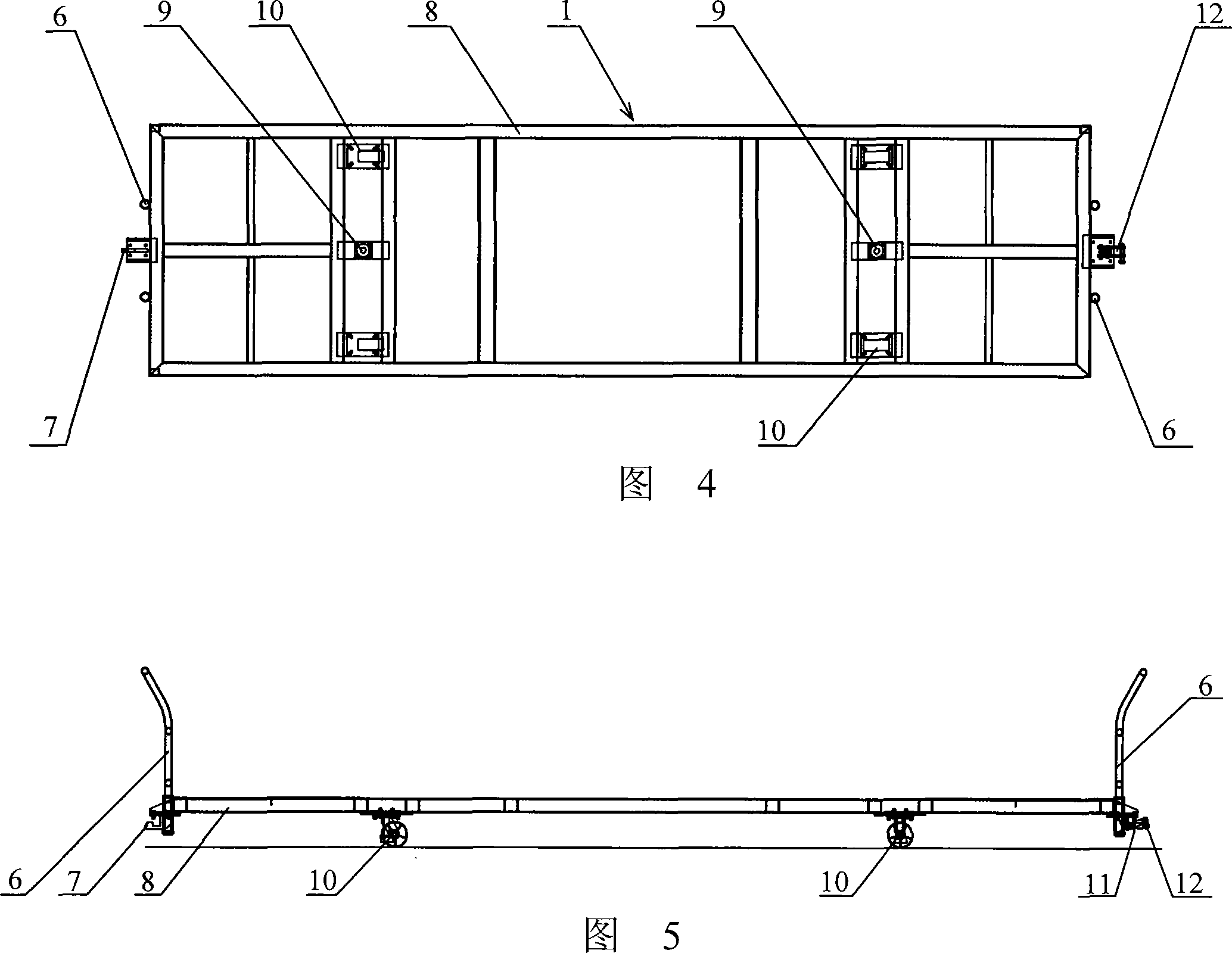

[0025] As shown in the figure: the carrying trolley 1 and its guiding device are arranged in the conveying direction. The side of the carrying trolley 1 is provided with a drive chain 23 that is close to it and arranged in the drive rail 22 and a drive device 2 composed of a power device. The driving device is arranged on the driving bracket 16. The driving device includes a motor 18 and a drive sprocket 17 driven by the motor 18. The drive sprocket 17 meshes with the drive chain 23, and the drive chain 23 and the side of the carrying trolley 1 are mutually provided Matching side push device.

[0026] The side pushing device includes a drive lever 24 that is arranged on the drive chain 23 and protrudes outward, and a blocking lever 13 that extends downward on the bottom side of the carrier trolley 1 and cooperates with the drive lever 24. The table 38 is provided with a drive rail 22 with an opening outwardly in the shape of a "U". The drive rail 22 is composed of a vertical plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com