Processing method of manual chip mounter

A processing method and technology of placement machine, applied in electrical components, electrical components and other directions, can solve the problems of inaccurate placement of manual placement machines, achieve stable movement, avoid offset errors, and improve placement quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

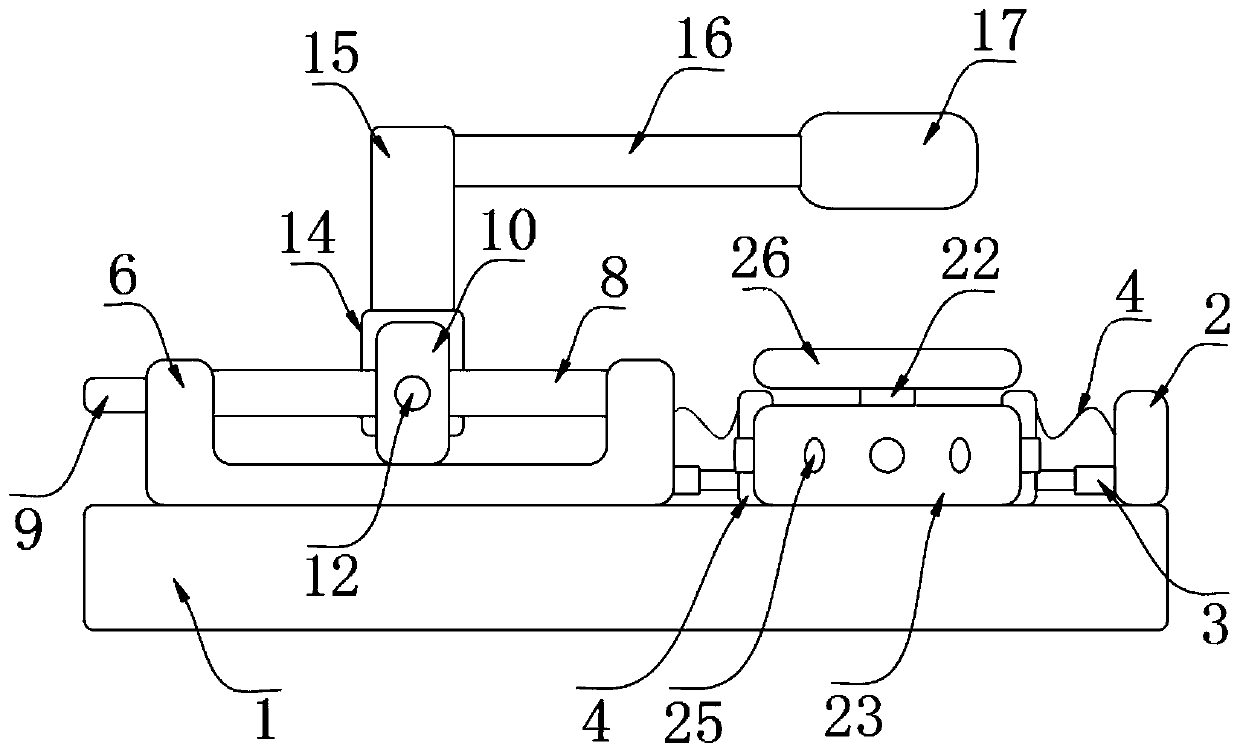

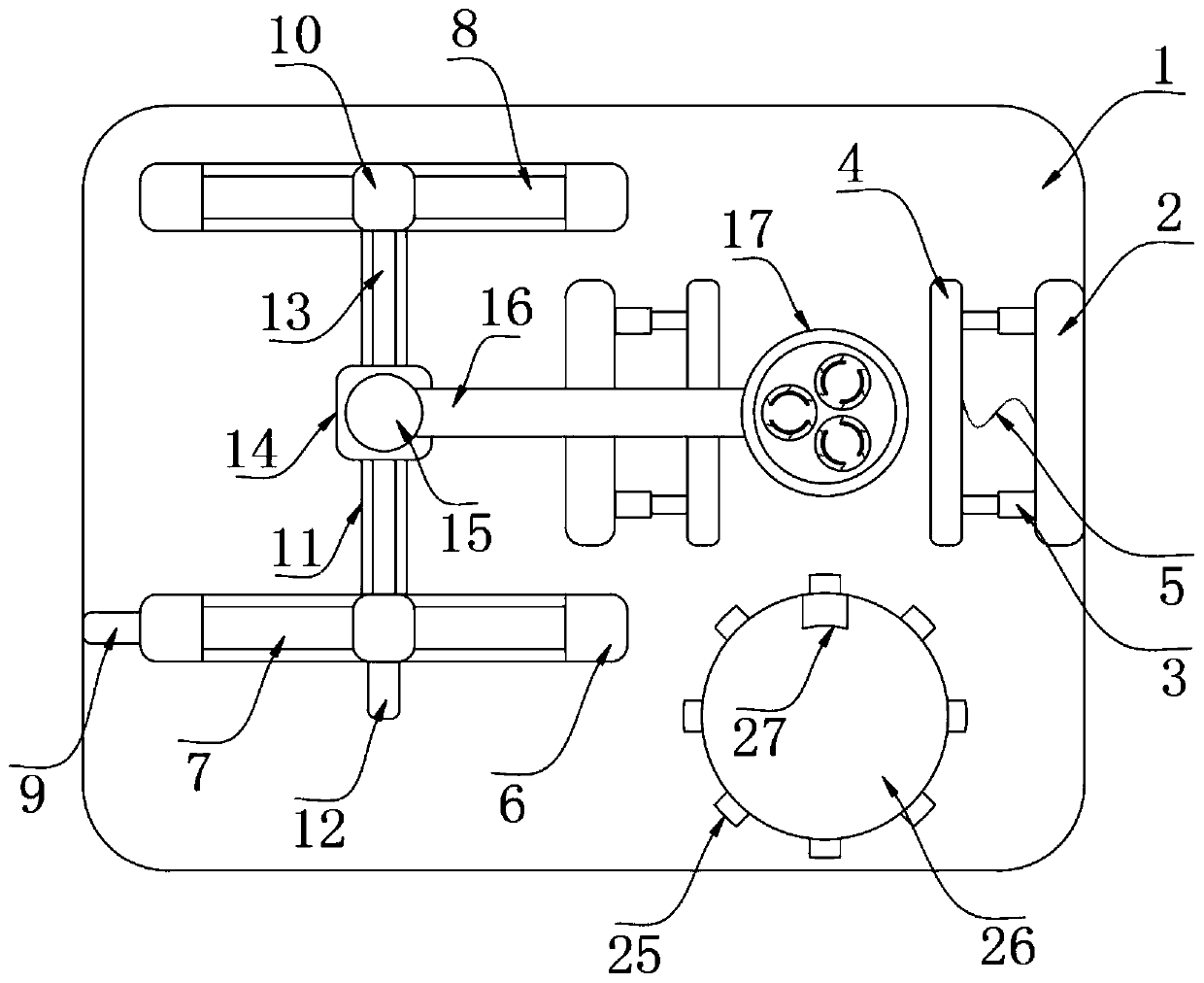

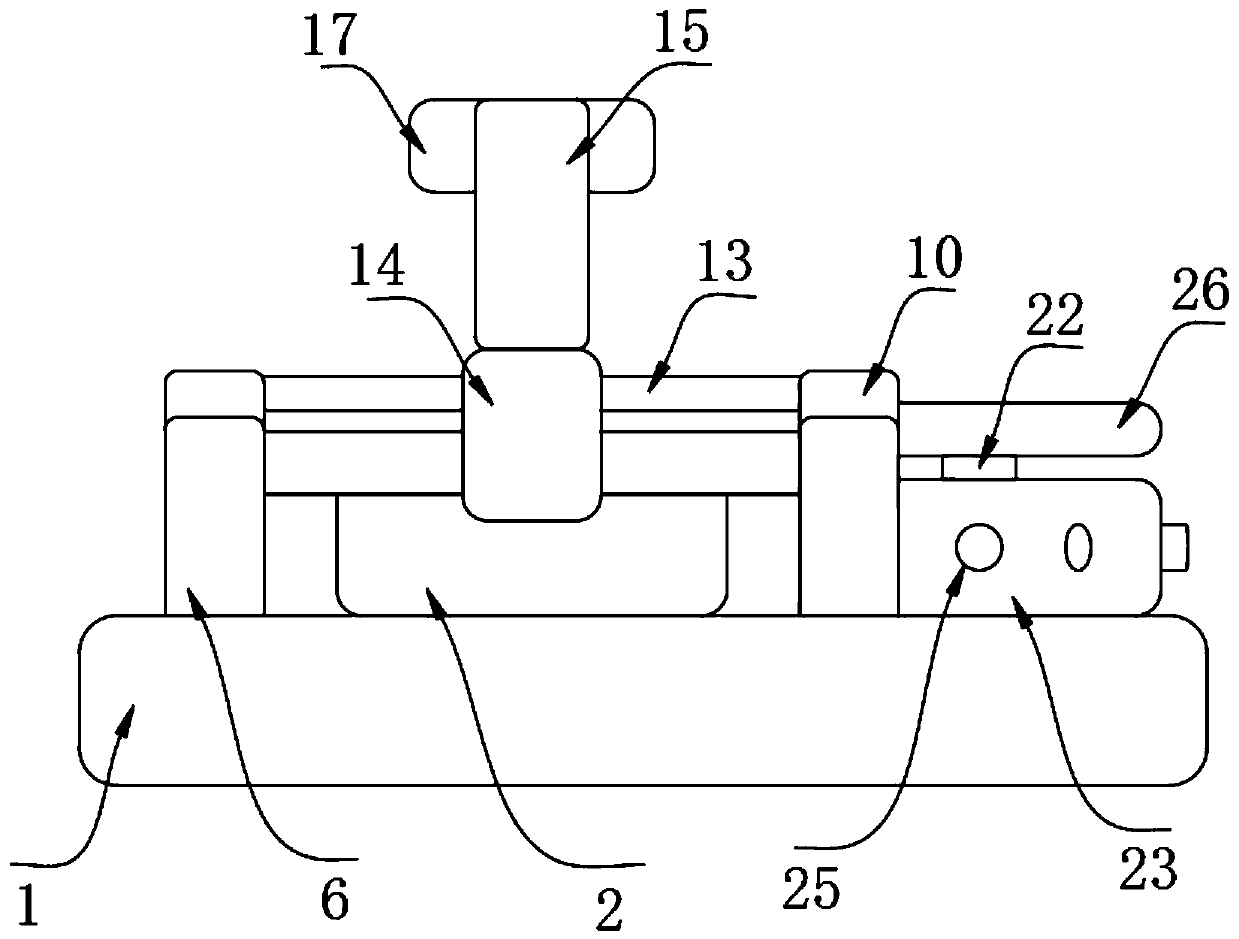

[0028] refer to Figure 1-6 , a manual placement machine processing method, mainly including the following processing steps:

[0029] S1. Preparation and fixation of materials: Fix the PCB board through the positioning and clamping mechanism, place various mounting components required in each storage slot 24 through the access slot 27, and synchronize them on the surface of the corresponding indicator rod 25 Paste the corresponding name label, prepare multiple pneumatic suction pens and install them in multiple card slots 19, and connect the pneumatic suction pens to the air pump at the same time;

[0030] S2. Take the material and adjust the position: hold the handle 15 to move the rotary plate 18 to the position of the access slot 27, then turn the rotary plate 18 to select a suitable pneumatic suction pen to absorb the mounted components inside the storage slot 24, and then pass the displacement device Adjust the position of the corresponding pneumatic suction pen to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com