Patents

Literature

155results about How to "Less likely to wrinkle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

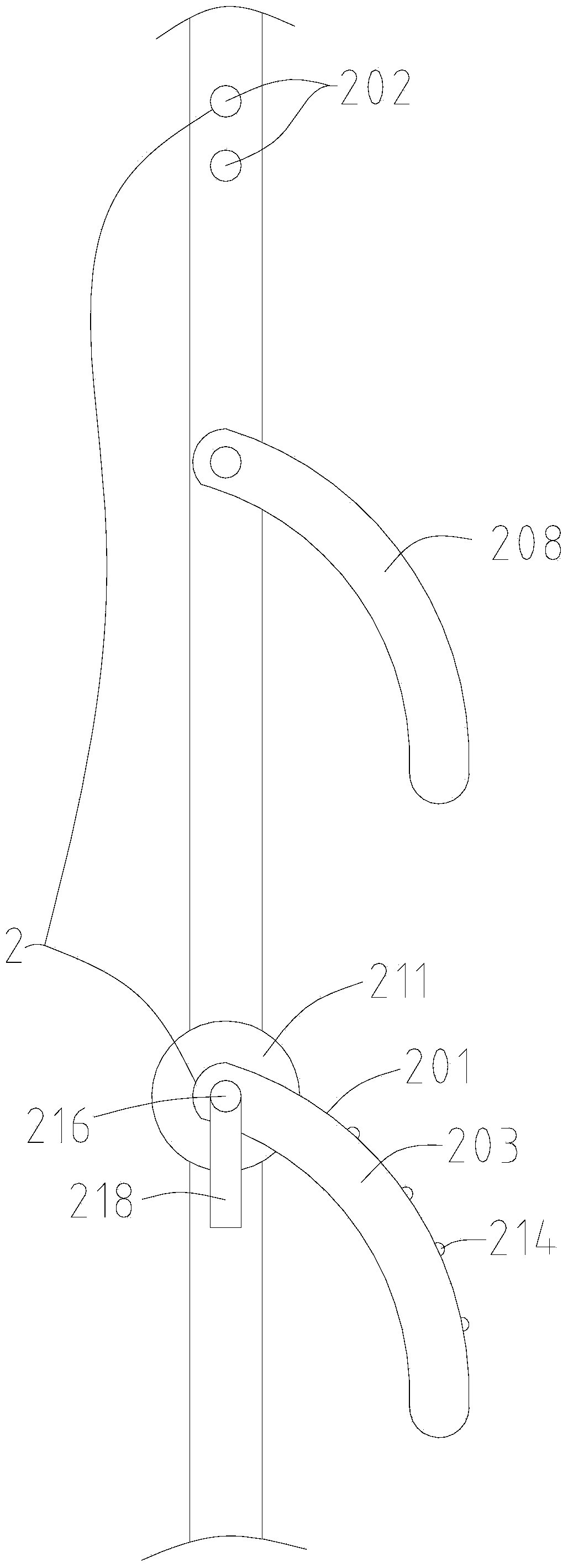

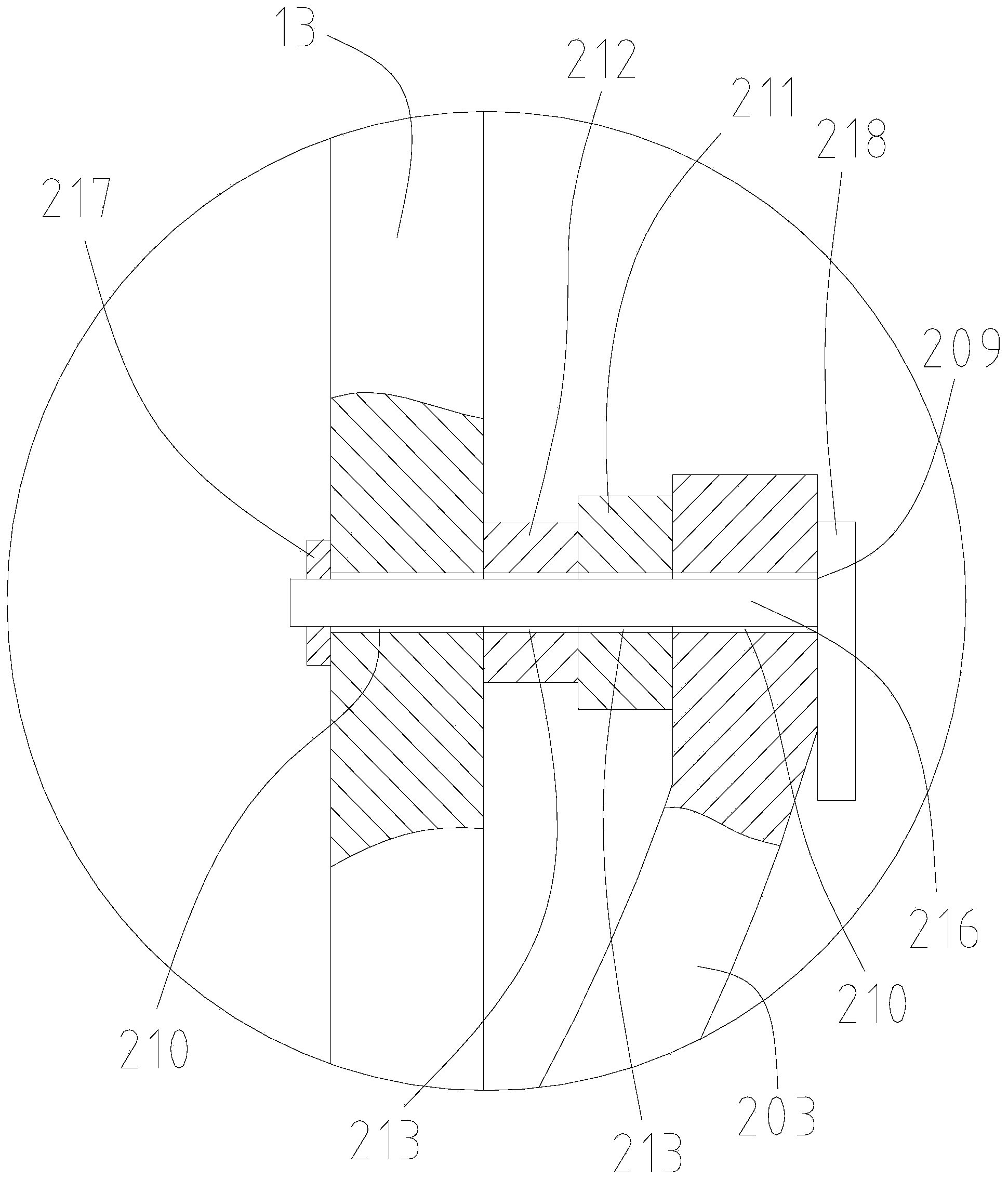

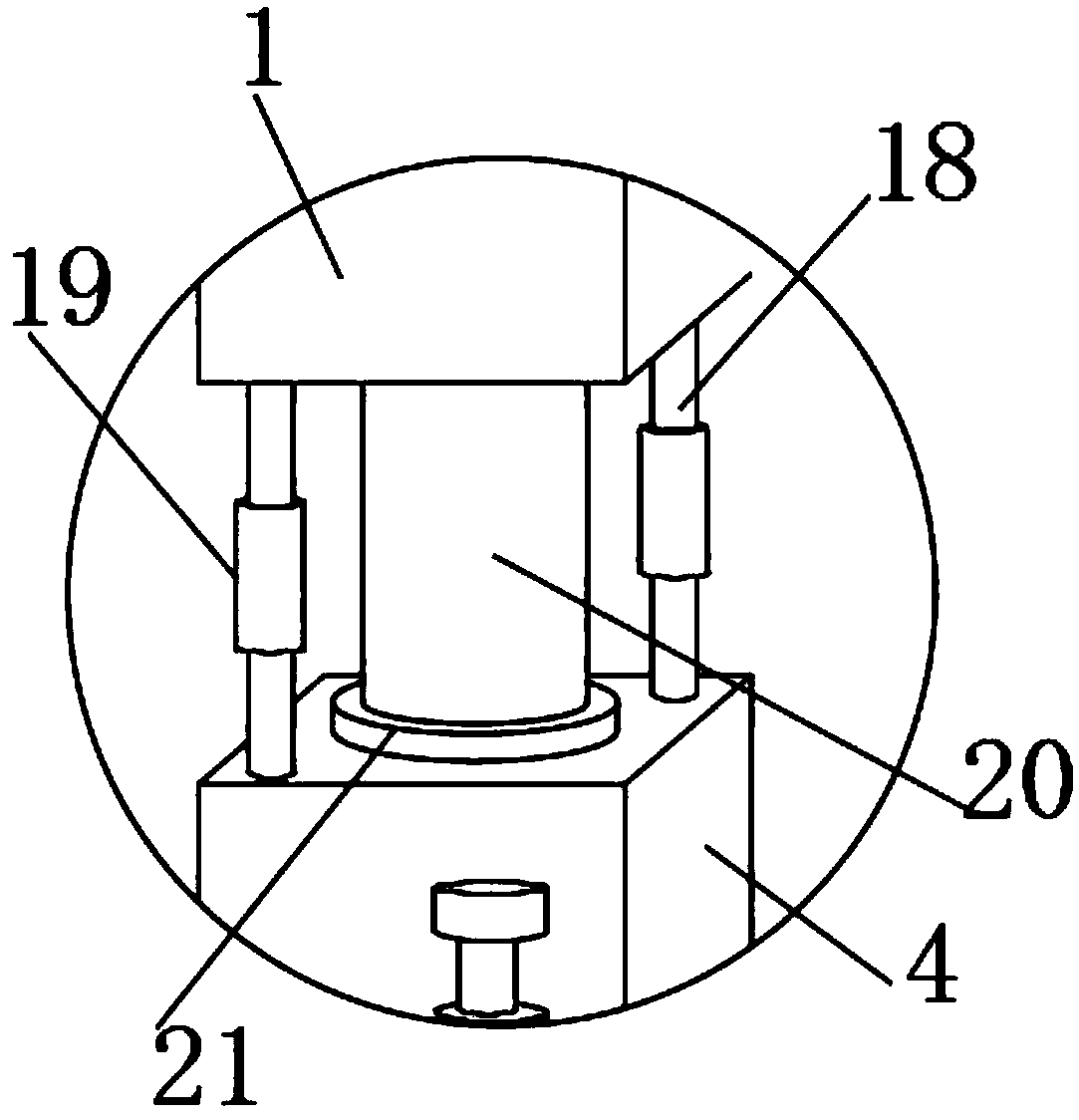

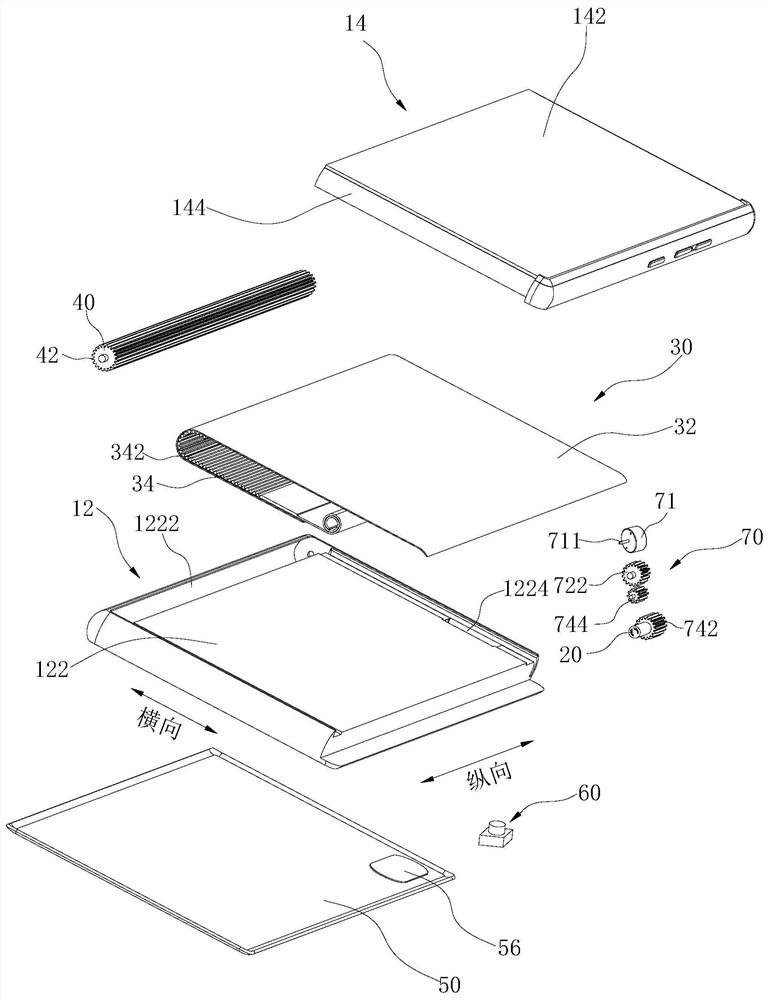

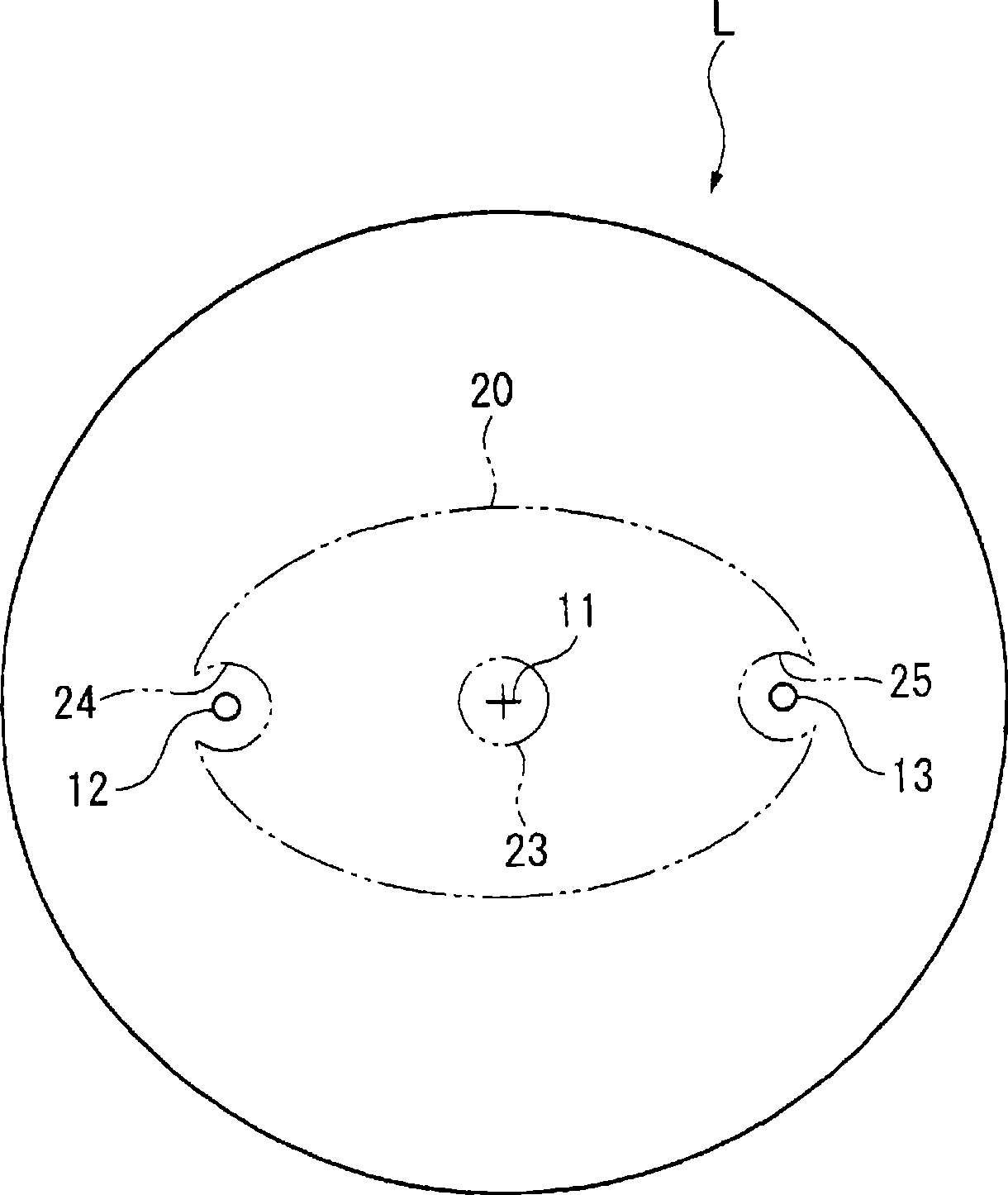

A supporting structure of a foldable display device and the foldable display device

ActiveCN109922181AImprove the display effectExtended service lifeTelephone set constructionsDisplay deviceEngineering

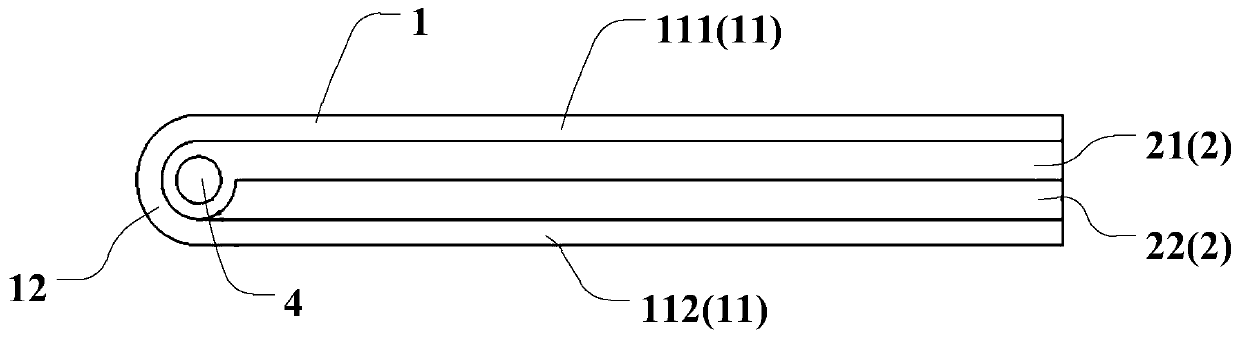

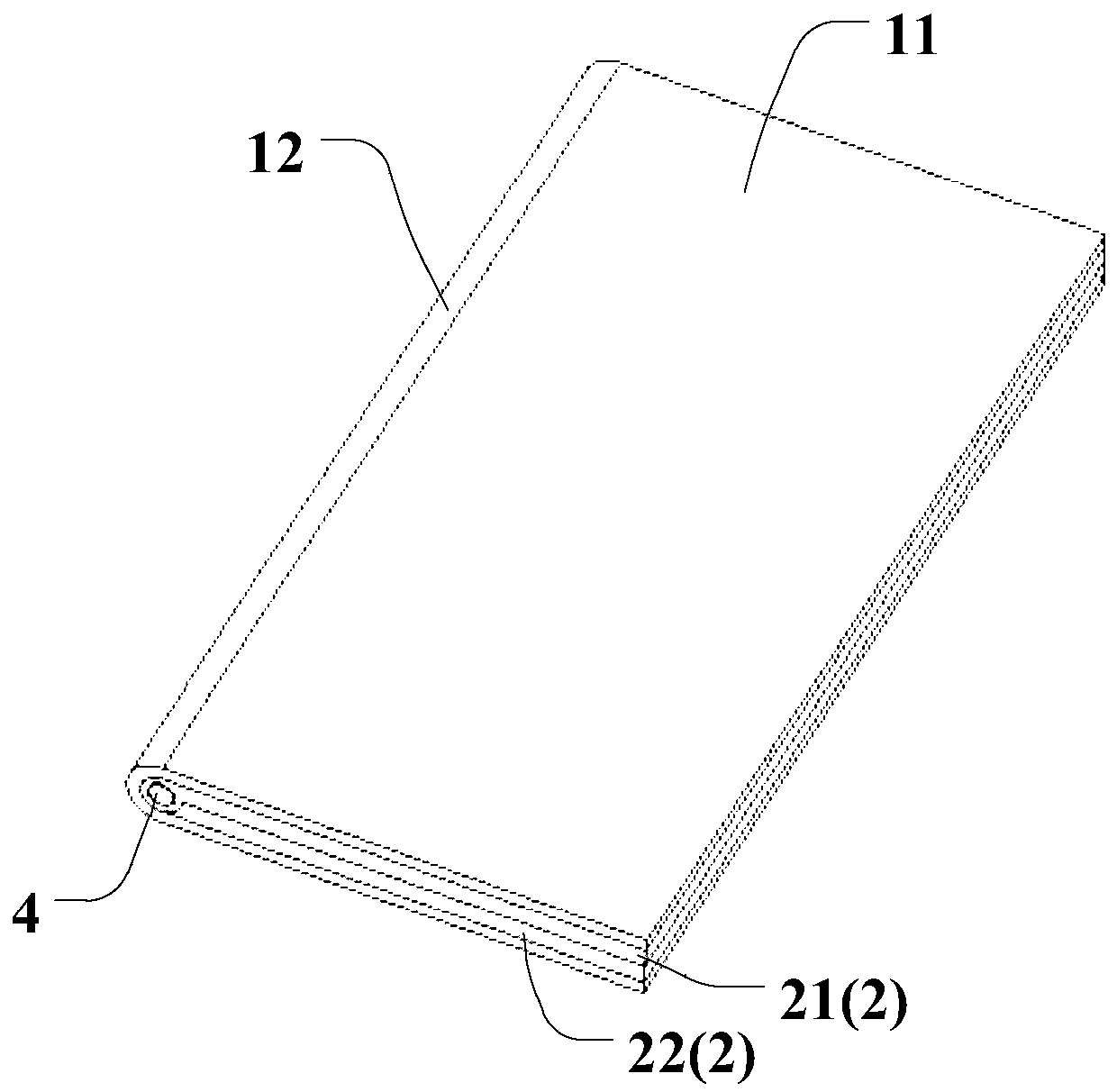

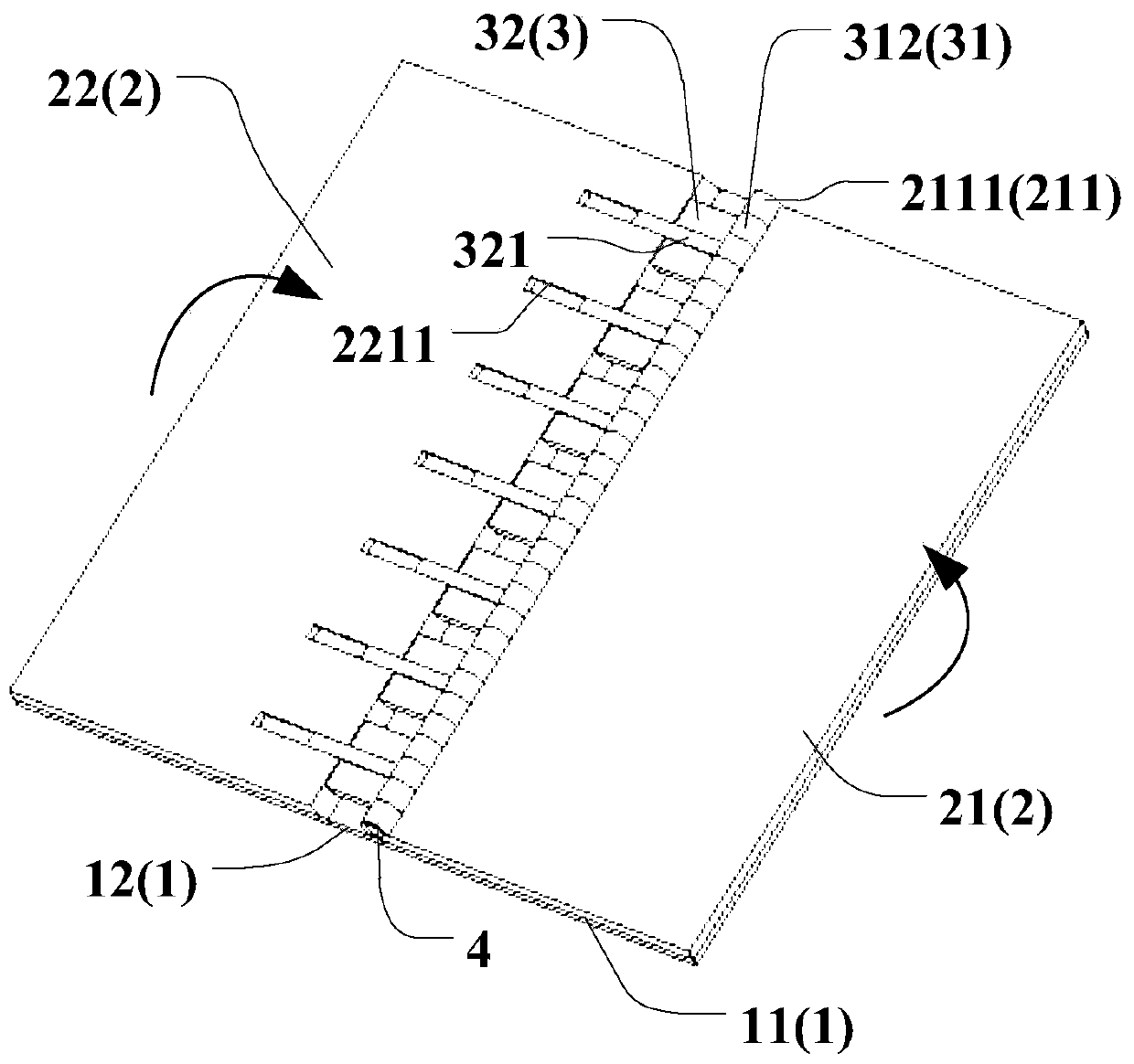

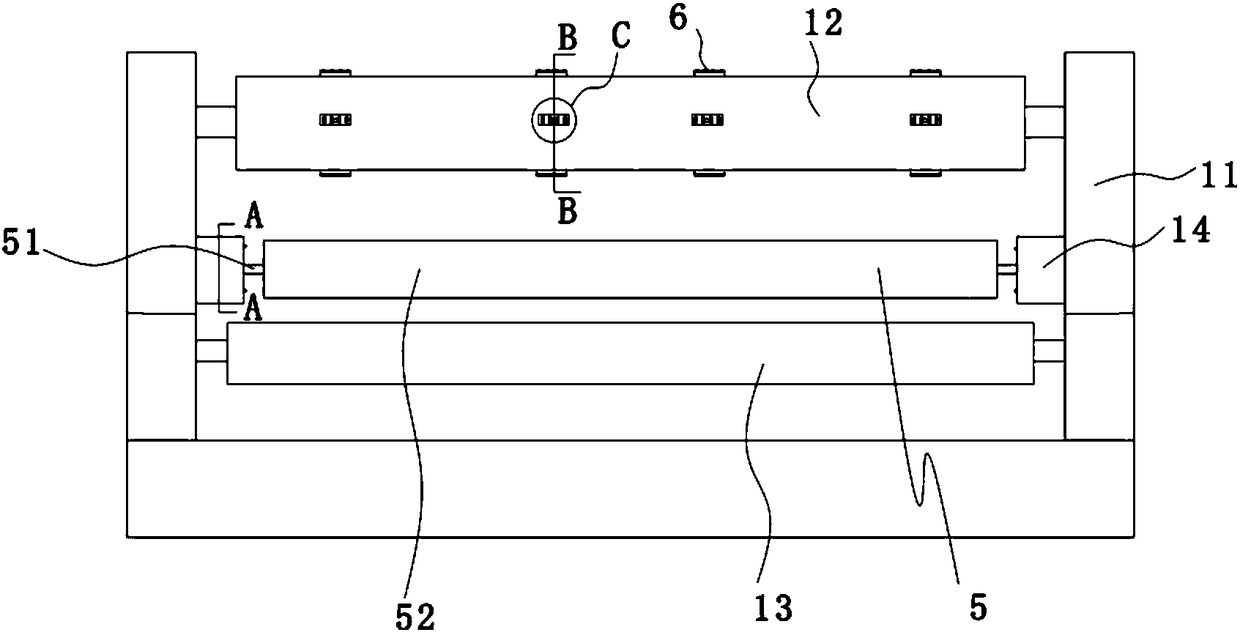

The invention discloses a supporting structure of a foldable display device and the foldable display device, the supporting structure of the foldable display device is used for supporting a flexible screen of the foldable display device, and the flexible screen comprises at least two plane areas and a bending area for connecting the two adjacent plane areas; the supporting structure comprises supporting plates in one-to-one correspondence with the plane areas and a sliding piece arranged between any two adjacent supporting plates, the supporting plates on the two sides of the sliding piece area first supporting plate and a second supporting plate respectively, the first supporting plate is rotationally connected with the sliding piece, and the second supporting plate is slidably connectedwith the sliding piece. The first supporting plate and the second supporting plate can be folded in the direction away from the flexible screen, when the supporting structure is unfolded, the secondsupporting plate moves in the direction away from the first supporting plate, and the sliding piece is opposite to the bending area. According to the supporting structure of the foldable display device, the stress of the bending area of the flexible screen can be reduced, the flatness of the bending area is improved, and the display effect of the foldable display device is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

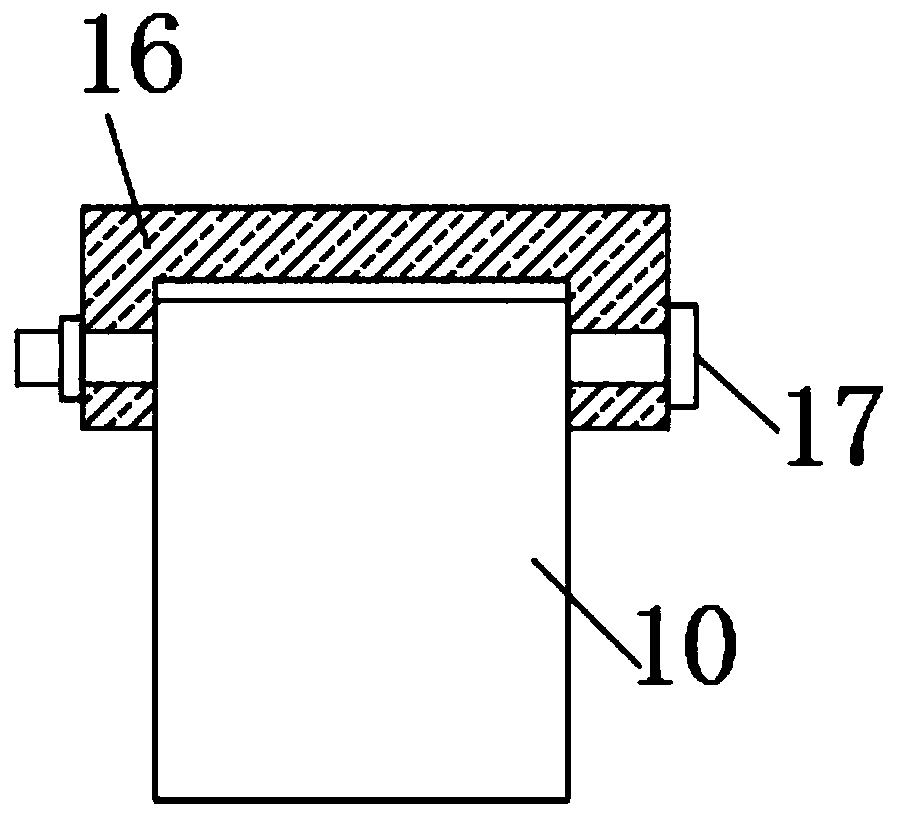

Method for making electric core of lithium ion battery

InactiveCN101267050AGood discharge performanceLower battery internal resistanceFinal product manufactureElectrolyte accumulators manufactureAirplaneWrinkle

The present invention is an improvement of the preparing method of a lithium ion battery electrical core, characterized in that a diaphragm and / or electrode plate binding face has adhesive which is capable of resisting electrolyte, redox reaction and solid content is 2-30%, voltage attaching after mutually stacking, and the diaphragm voidage is above 30%. A gap does not exist between the diaphragm and the electrode pate, the battery has large rate discharge ability, especially for a battery product of a power battery, an electrical tool battery, a model airplane battery which has requirement to large rate discharge; the battery has a small internal resistance, small self-consumption power. The diaphragm is patched with the electrode plate at the same time, not only reducing the alignment degree adjustment of the diaphragm and the electrode plate under the winding or overlapping course, greatly enhancing the battery preparing production efficiency; the diaphragm and the electrode plate not easy wrinkle, benefit to improve the battery life service, the capability is more stable and credible.

Owner:JIANGSU DIO ENERGY SCI TECH

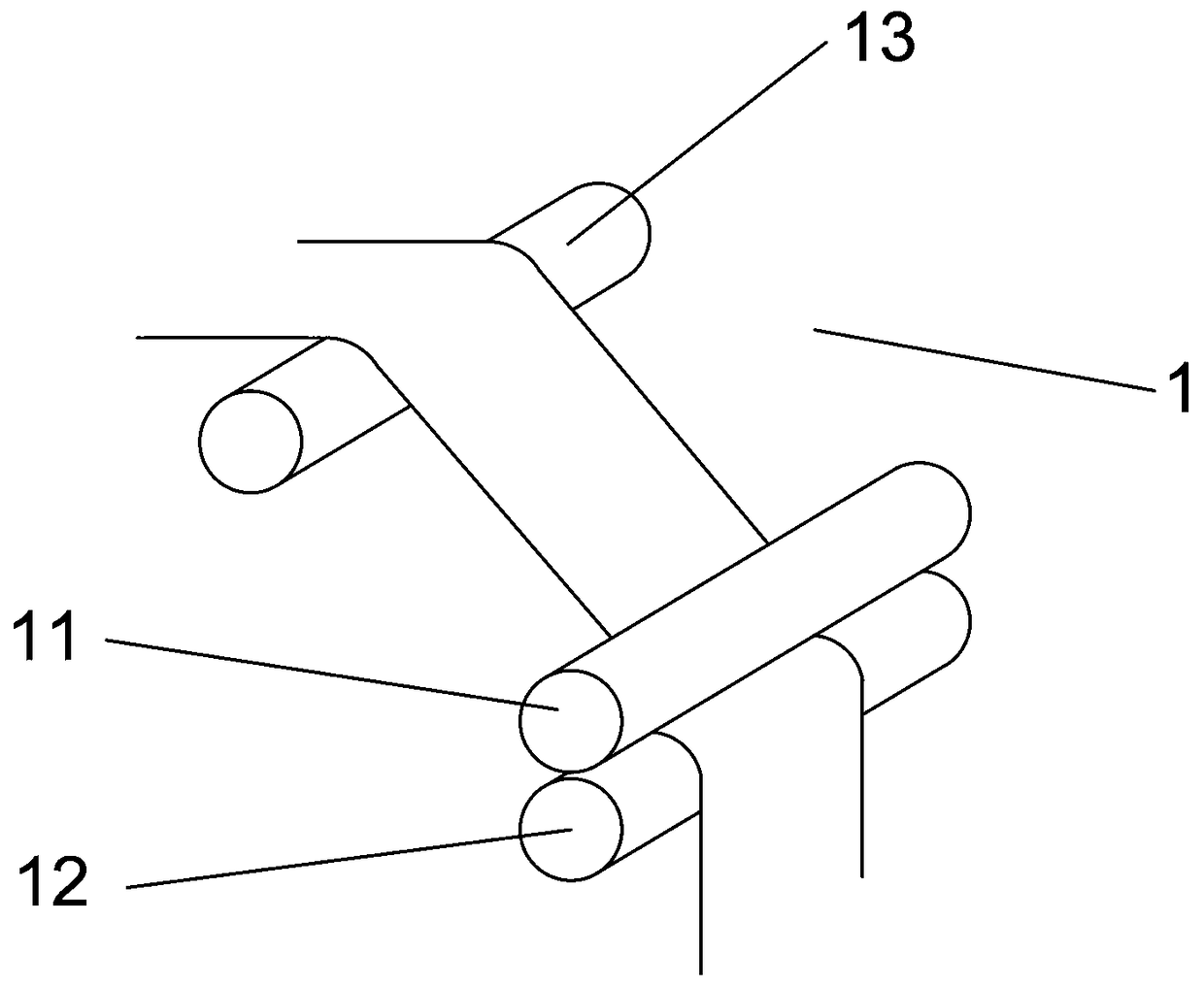

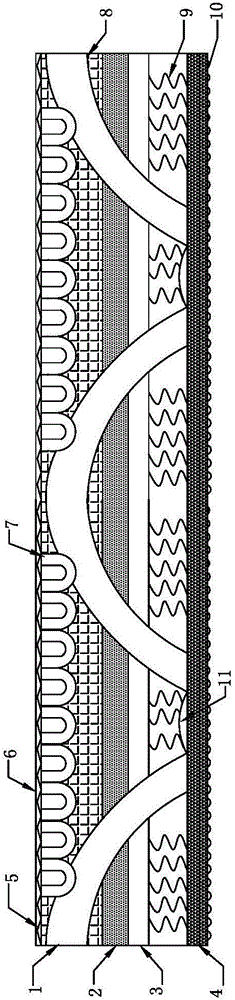

Cloth spreading device for shaping machine

The invention relates to an accessory of a spinning device, in particular to a cloth spreading device for a shaping machine. At least one pair of V-shaped cloth guide rods used for spreading cloth are arranged to be a cloth spreading support, the V-shaped cloth guide rods are in the involute shape and protrude out of the plane where the support body is located, the cloth guide rods have the good guiding effect and can well spread the cloth in the specific using process, and the cloth is not prone to wrinkling in the conveying process; due to the fact that a middle rod is arranged, the cloth spreading device for the shaping machine can remotely convey the cloth, and the cloth is not prone to wrinkling in the cloth conveying process; in addition, due to the fact that a correction rod is arranged, before entering the next working procedure, the cloth will be corrected by the correction rod, and it is ensured that the cloth is completely spread when entering the next working procedure; due to the fact that the correction rod is connected to the support body in a rotating mode, the correction rod rotates flexibly, and the phenomenon that the cloth wrinkles due to the uneven stress is avoided.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

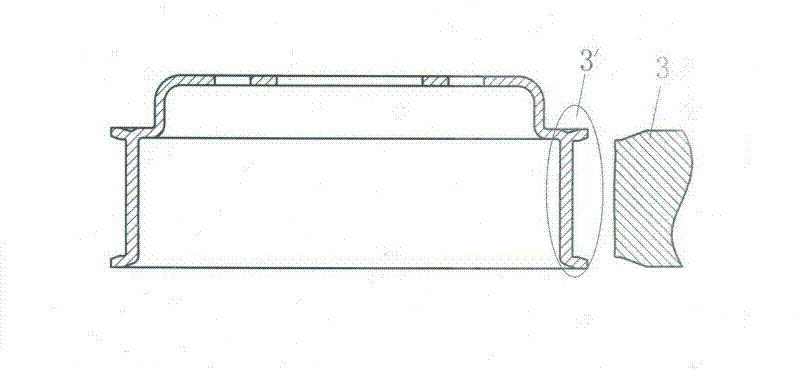

Spinning technique of pulley

The invention relates to a production technique of pulley and specifically to a spinning technique of pulley, comprising the following steps of: 1) blanking; 2) performing spinning; 3) upsetting spinning; 4) spinning forming. The external edge of said blank employs orthodrome transition. The spinning technique of pulley provided by the invention improves the shape of the blank, thus the blank is free of fillet transition area; with the orthodrome transition, crack or wrinkle cannot be occurred in the process of spinning. Meanwhile, with this spinning technique, the tooth flute of finished component is thicker than that formed by other techniques; therefore, the strength of pulley can be enhanced obviously and the qualification rate of the pulley manufacture by this spinning technique is improved obviously. The invention belongs to the field of pulley manufacturing technique.

Owner:湖州湖锻液压机床厂

Near infrared nano-silver ion dressing shielding knitted fabric

The invention relates to near infrared nano-silver ion dressing shielding knitted fabric, which is characterized in that the fabric is formed by spinning raw materials of nano-silver ion dressing short fiber, near infrared auxiliary short fiber and knitting material short fiber. Weight percentage of the raw materials is 10 to 30% of nano-silver ion dressing short fiber, 5 to 10% of near infrared auxiliary short fiber, and 60 to 85% of knitting material short fiber. The near infrared nano-silver ion dressing shielding knitted fabric not only has superstrong absorptive power, can effectively resist radiation, obviously improves antibacterial and antiseptic performance, breathes and is inflaming retarding.

Owner:ANHUI WANXING IND LTD

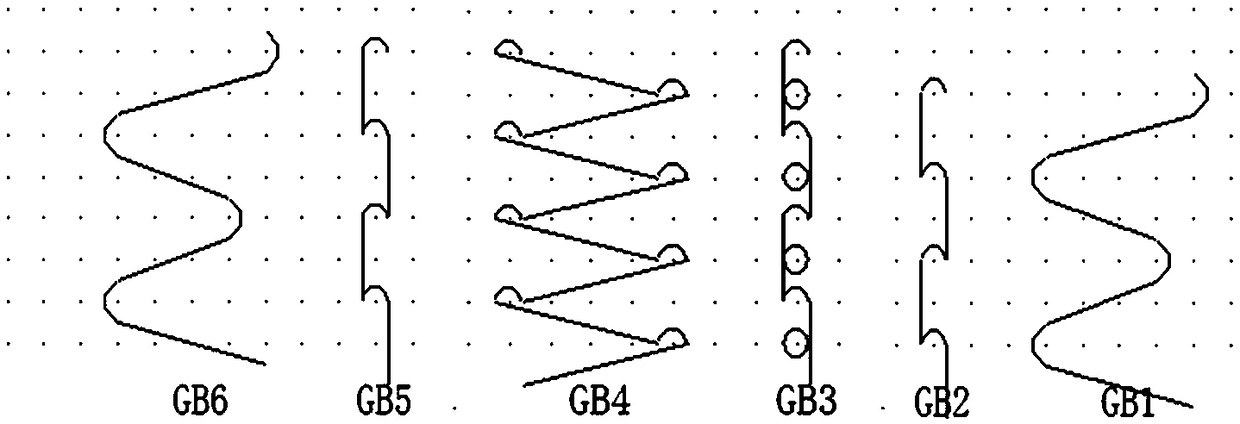

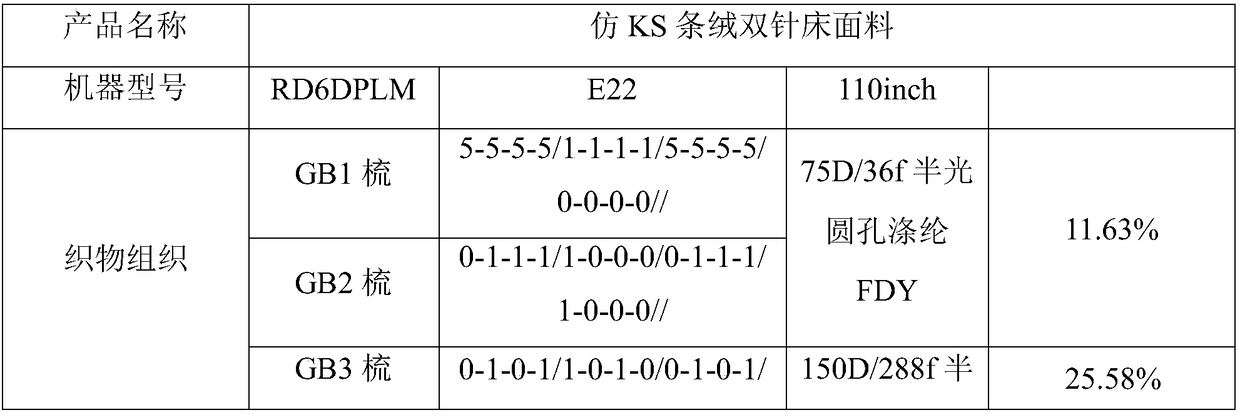

KS-corduroy-simulation double-needle bar fabric and production method thereof

The invention discloses a KS-corduroy-simulation double-needle bar fabric and a production method thereof and belongs to the field of textiles. According to the fabric, a corduroy fabric is combined with fashionable warp-knitting double-needle jacquard weave flannelette, by designing and improving a yarn threading mode, the made KS-corduroy-simulation double-needle bar fabric product is stable instructure and good in size stability, the fabric is not easily loosened, the plush height of the fabric is low, and the fabric is non-lodging, high in pressure resistance, good in straight effect andmoderate in weight per gram; the weight of a finished product can be controlled below 330 g / m<2>, compared with the corduroy fabric on a KS machine, the fabric has more full handfeeling, the softnessof the fabric is improved, the elastic feeling of the suede is improved, the fabric is non-lodging and high in wrinkle resistance, the shrinkage rate after water washing is small and is only about 2%generally, 4 widths of gray fabric can be produced at the same time, the production efficiency is improved, and the fabric is suitable for industrial application.

Owner:苏州吴坤纺织品有限公司 +1

Intelligent wardrobe management system

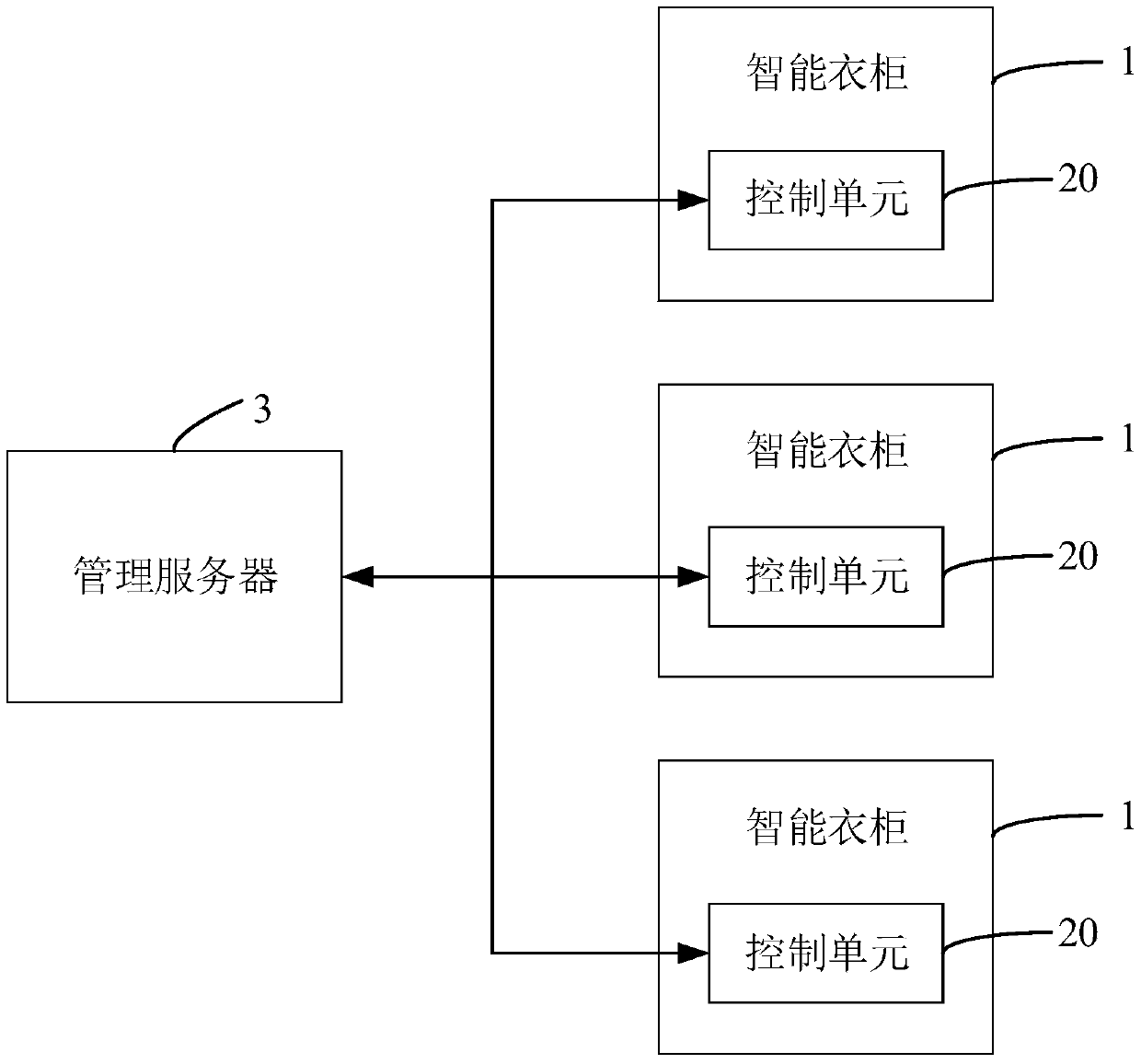

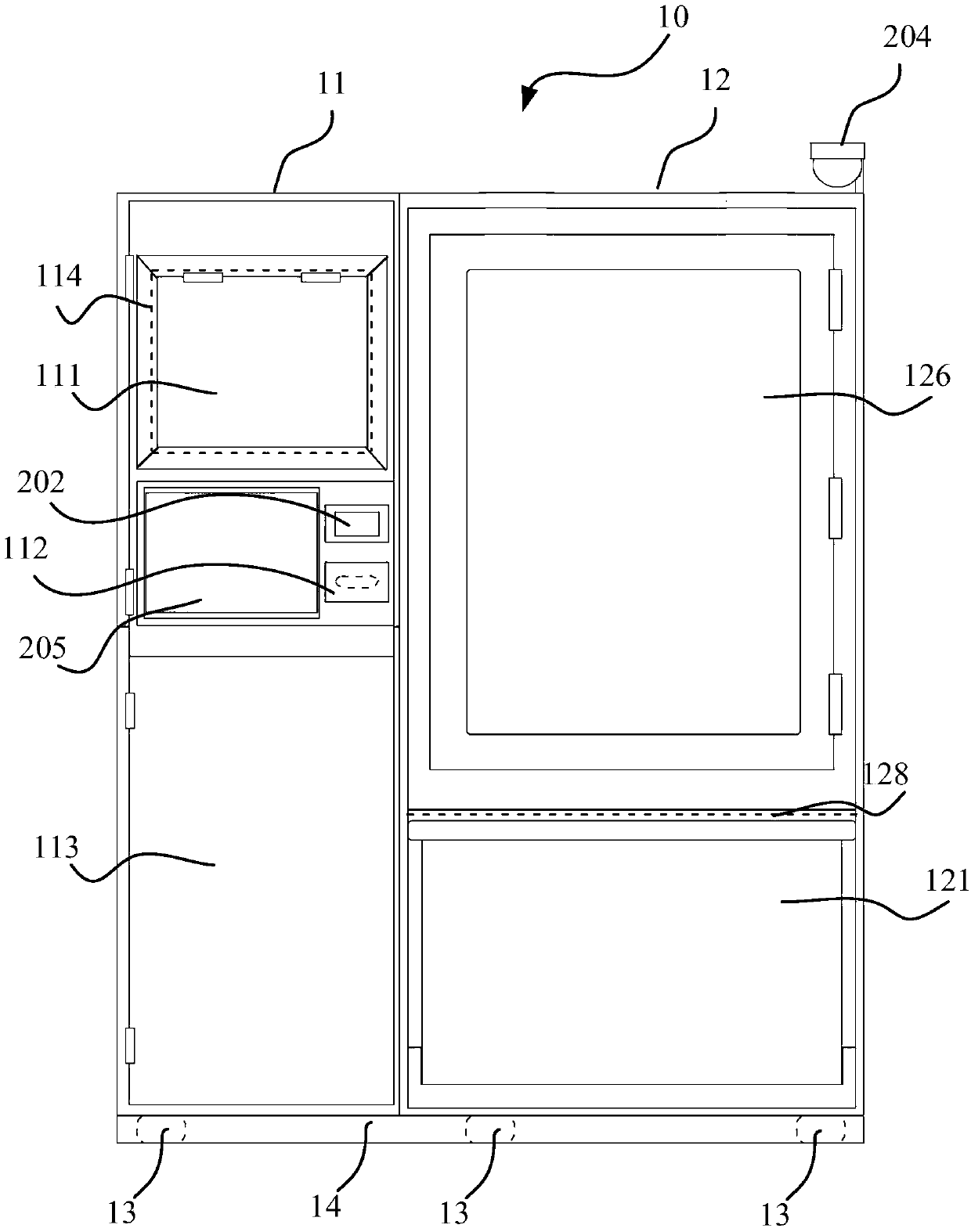

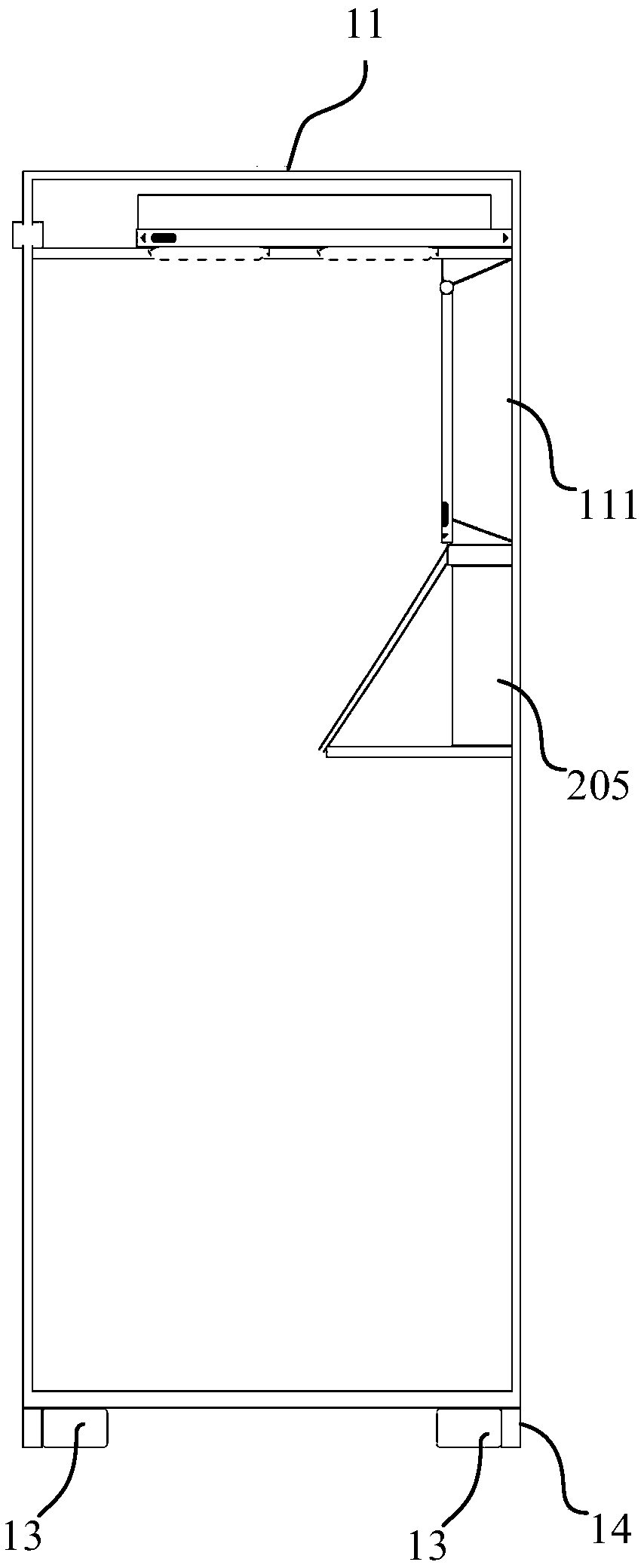

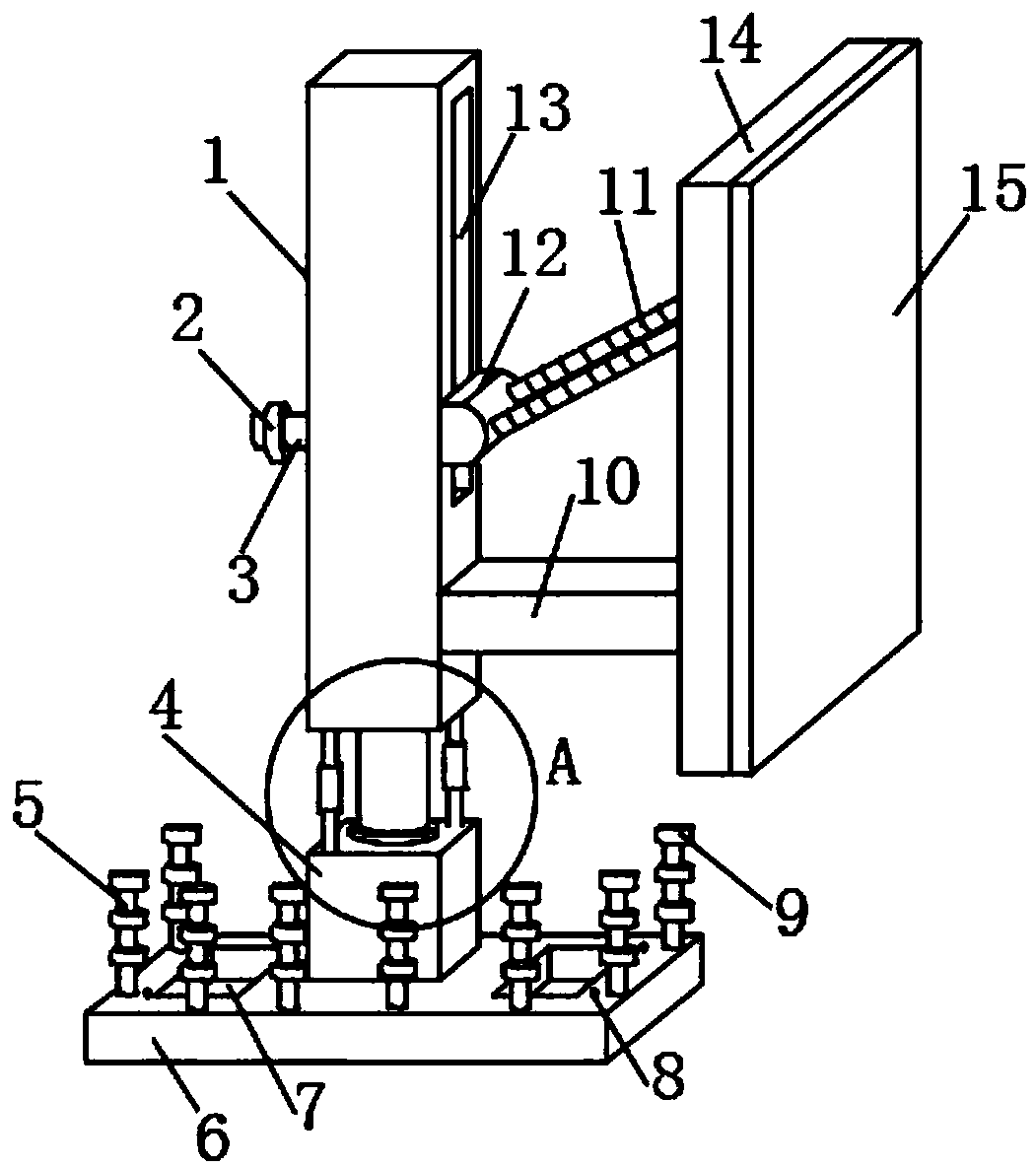

PendingCN111047790AConvenient operation and managementHang neatlyWardrobesFurniture partsRemote controlControl cell

The invention discloses an intelligent wardrobe management system. The intelligent wardrobe management system comprises at least one intelligent wardrobe and a management server. The intelligent wardrobe comprises a wardrobe body and a control unit; the wardrobe body comprises at least one clothes throwing wardrobe and at least one clothes taking wardrobe, the clothes throwing wardrobe is used forstoring clothes thrown by a user, and the clothes taking wardrobe is used for storing clothes to be taken by the user; and the control unit is in communication connection with the management server.Under remote control of the management server, the control unit controls the clothes throwing cabinet to achieve a clothes throwing service process and controls the clothes taking cabinet to achieve aclothes taking service process. The intelligent wardrobe disclosed by the invention can replace a laundry store to enter each community, so that consumers can independently finish terminal services of storing and taking clothes, and the professional washing service coverage crowd is greatly improved at extremely low cost.

Owner:北京蓝壳科技有限公司

Protective structure used for outdoor advertisement

Owner:合肥超必达网络技术服务有限公司

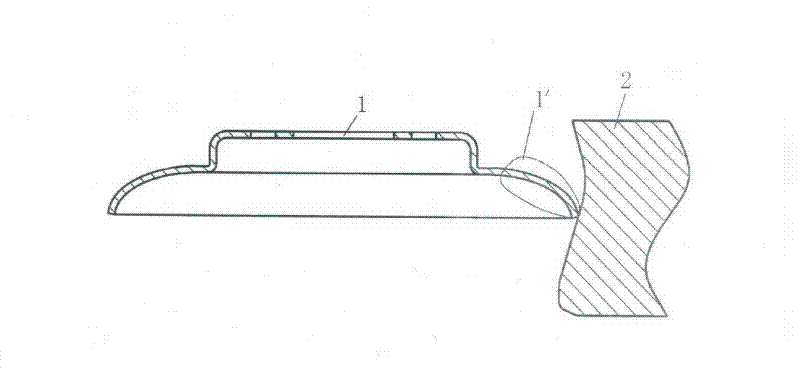

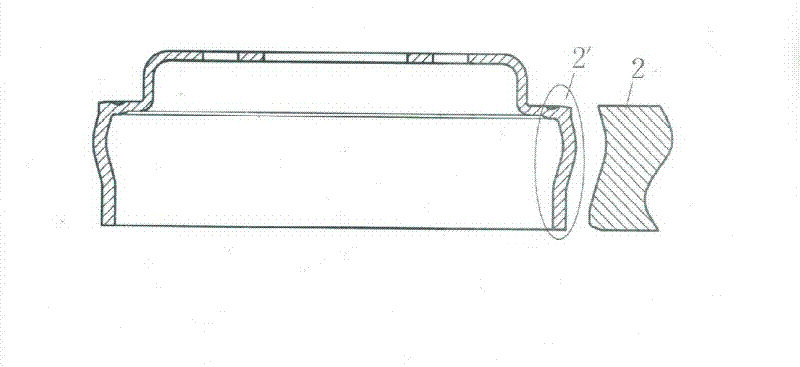

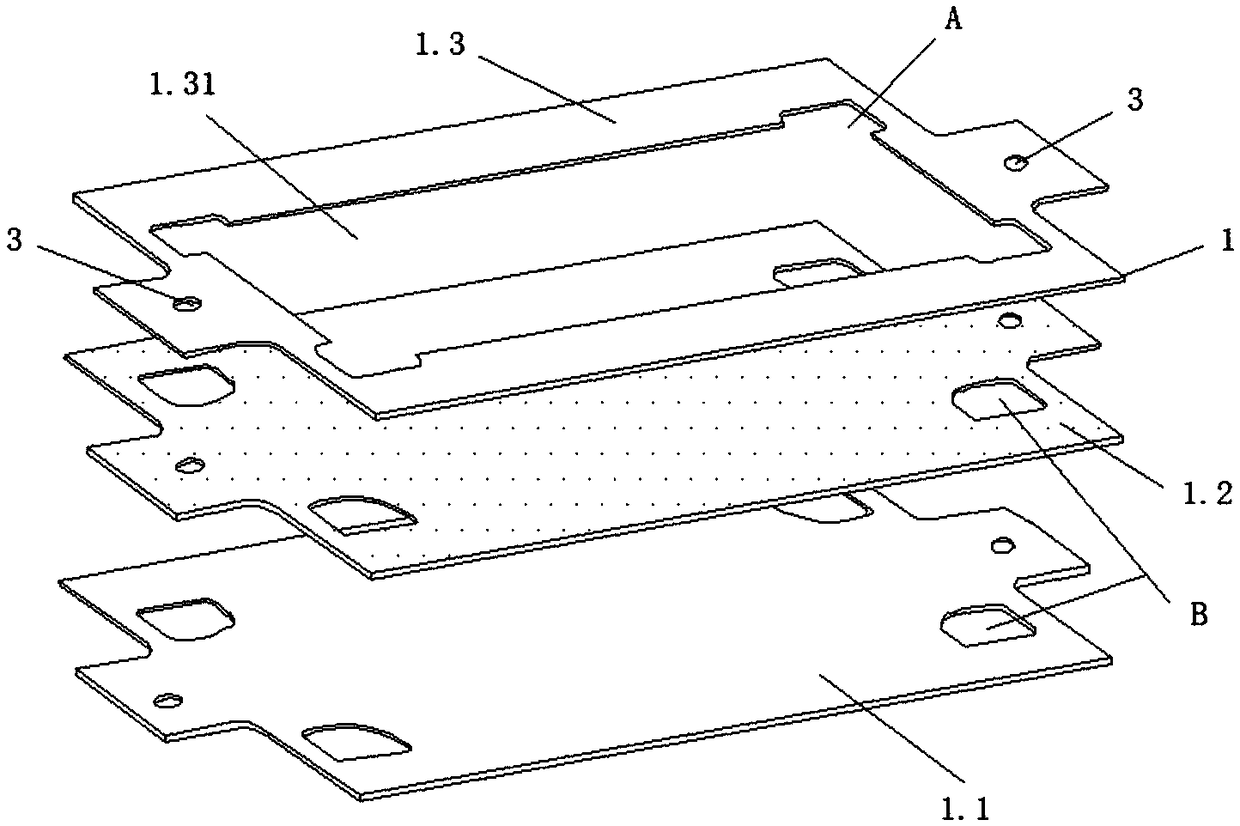

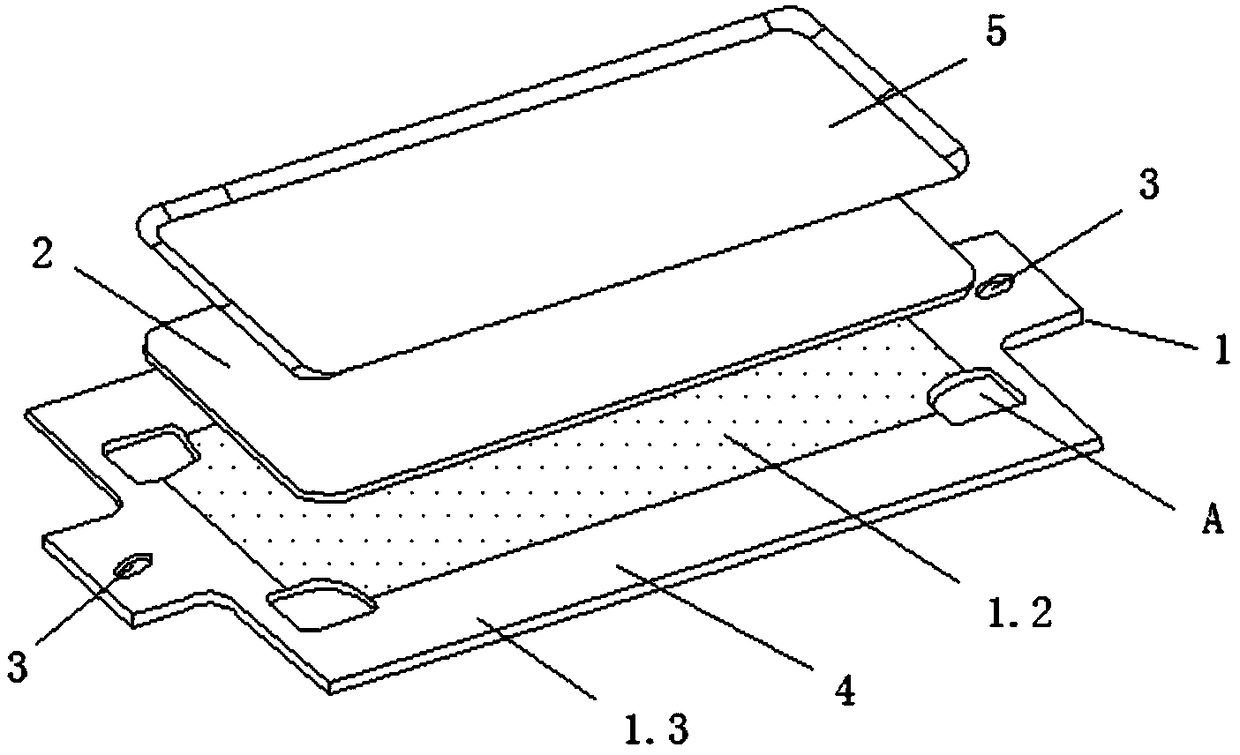

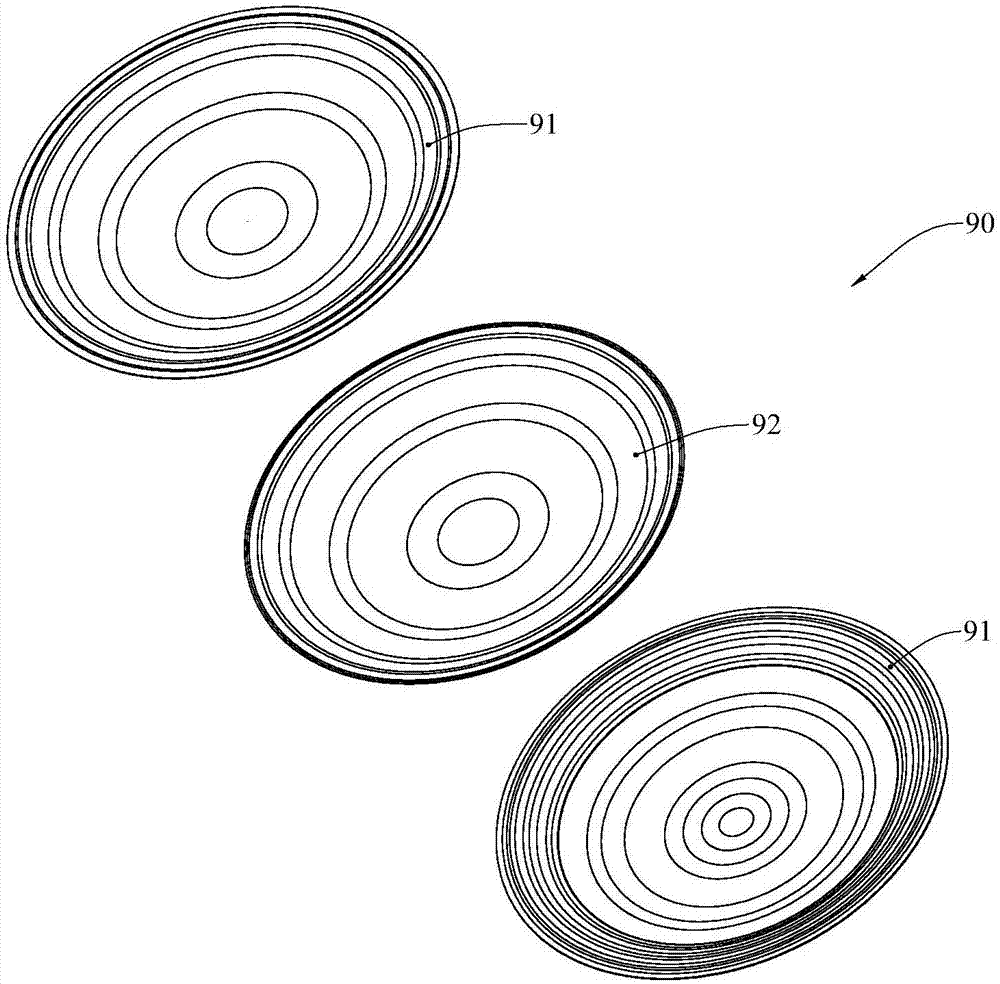

Bearing film for 3D product, composite film comprising bearing film and film laminating method

ActiveCN108724865AGuaranteed yieldImprove yieldSynthetic resin layered productsPackagingComposite filmEngineering

The invention provides a bearing film for a 3D product. The bearing film comprises a bearing film body, wherein the bearing film body comprises a first film layer, a bonding layer and a second film layer which are sequentially superposed; and a hollow part which is matched with the contour of a to-be-laminated 3D product is arranged on the second film layer. The bearing film is simple in integralstructure and is convenient to manufacture. The invention further discloses a composite film for a 3D product, and the composite film comprises the bearing film for the 3D product and an independentlyarranged film sheet; the film sheet is arranged on the hollow part of the second film layer; the back surface of the film sheet is bonded with the bonding layer; a protective layer is arranged on thefront surface of the film sheet, so that the 3D product can be laminated with the film very well; the bonding layer is designed by adopting an unique material, and the bearing film for the 3D productis easily taken off after film laminating, and residues are avoided, so that the yield of the film-laminated 3D product is high. The invention further discloses a method for laminating the compositefilm for the 3D product, and the method is simple in process step, easily controls process parameters, and is high in product yield.

Owner:LENS TECH CHANGSHA

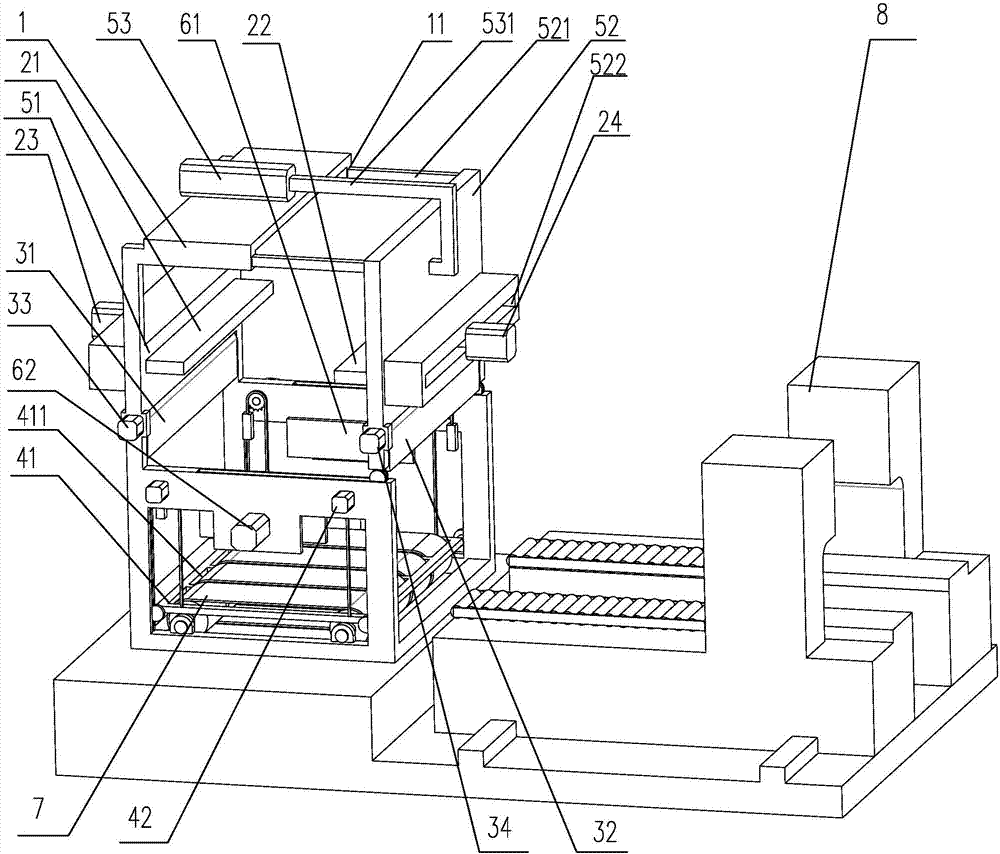

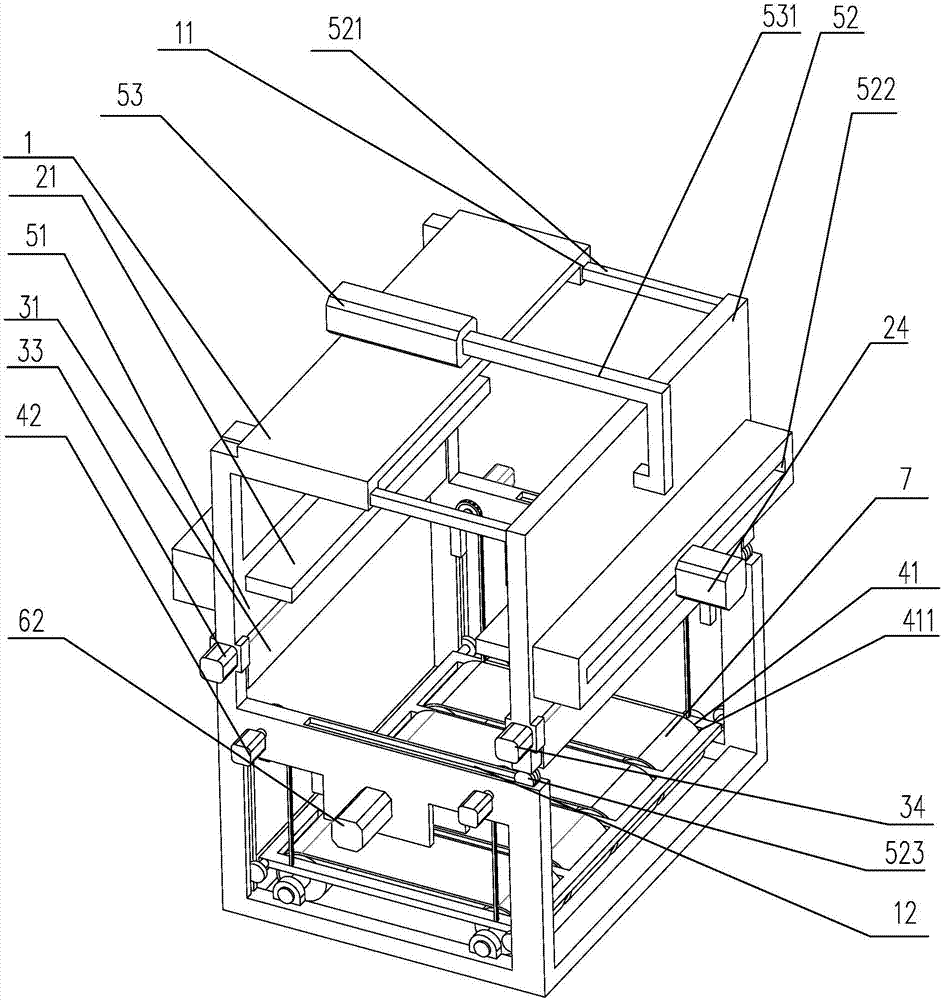

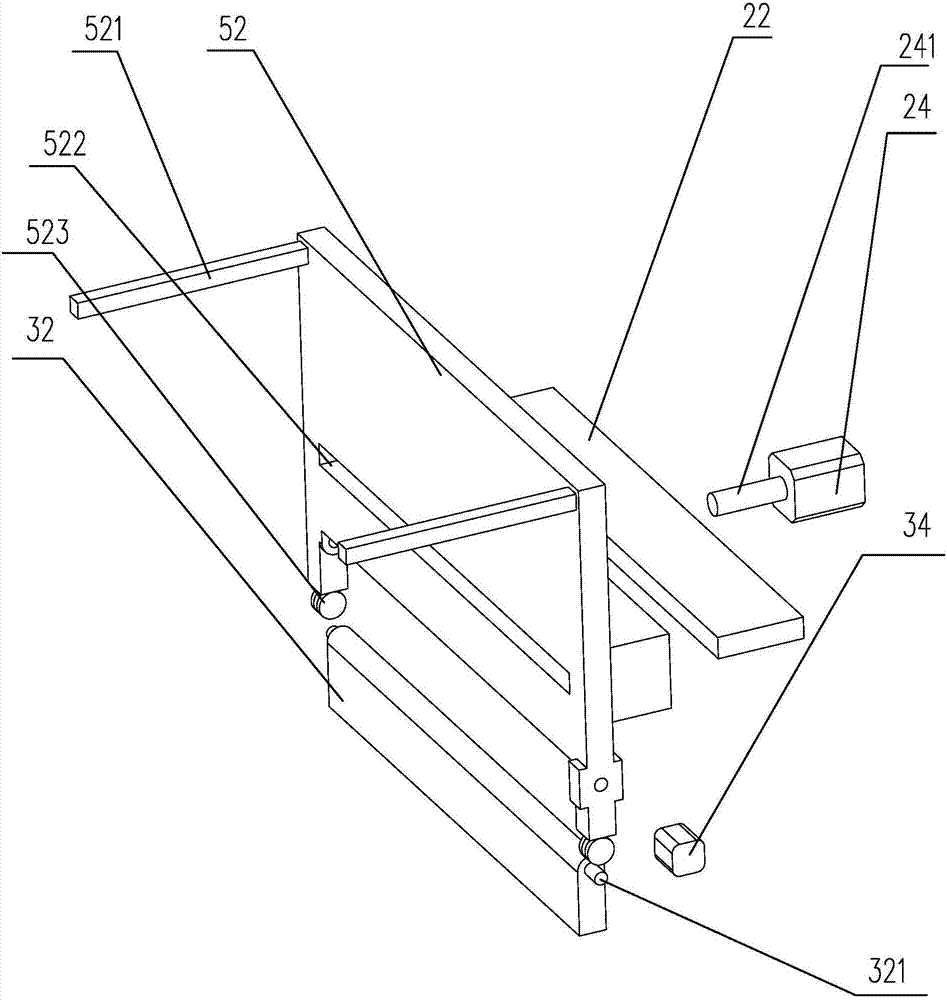

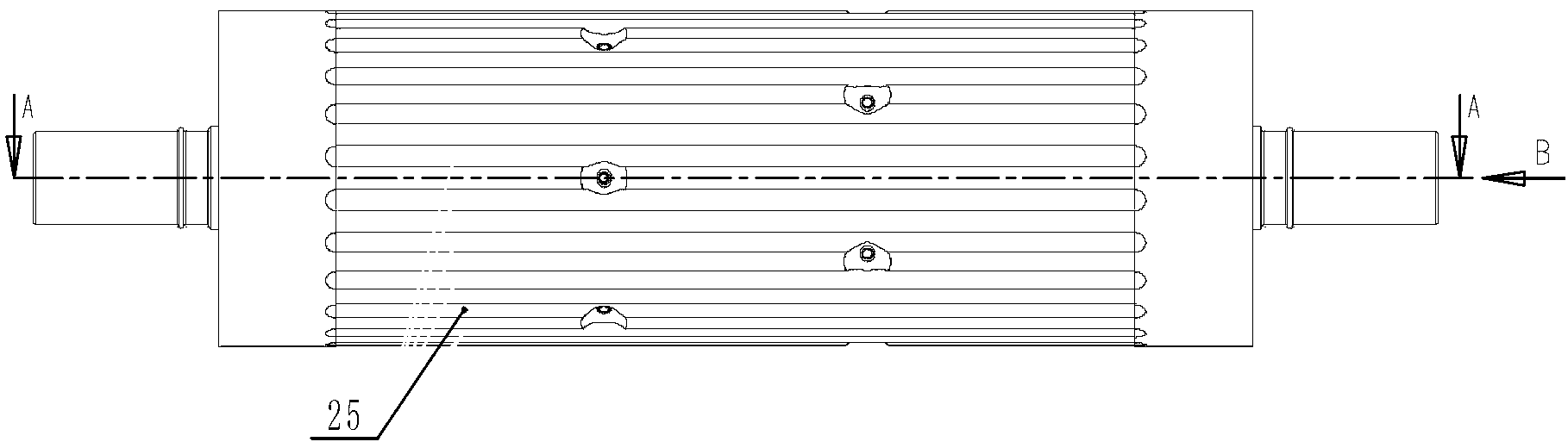

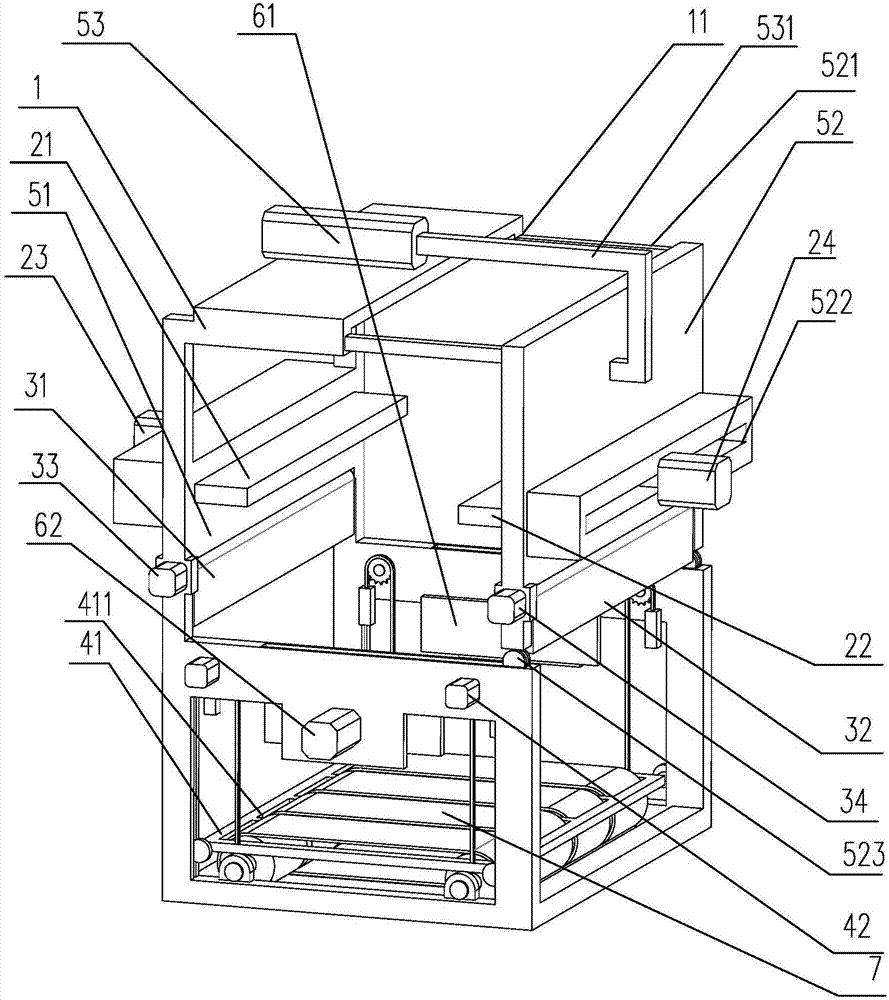

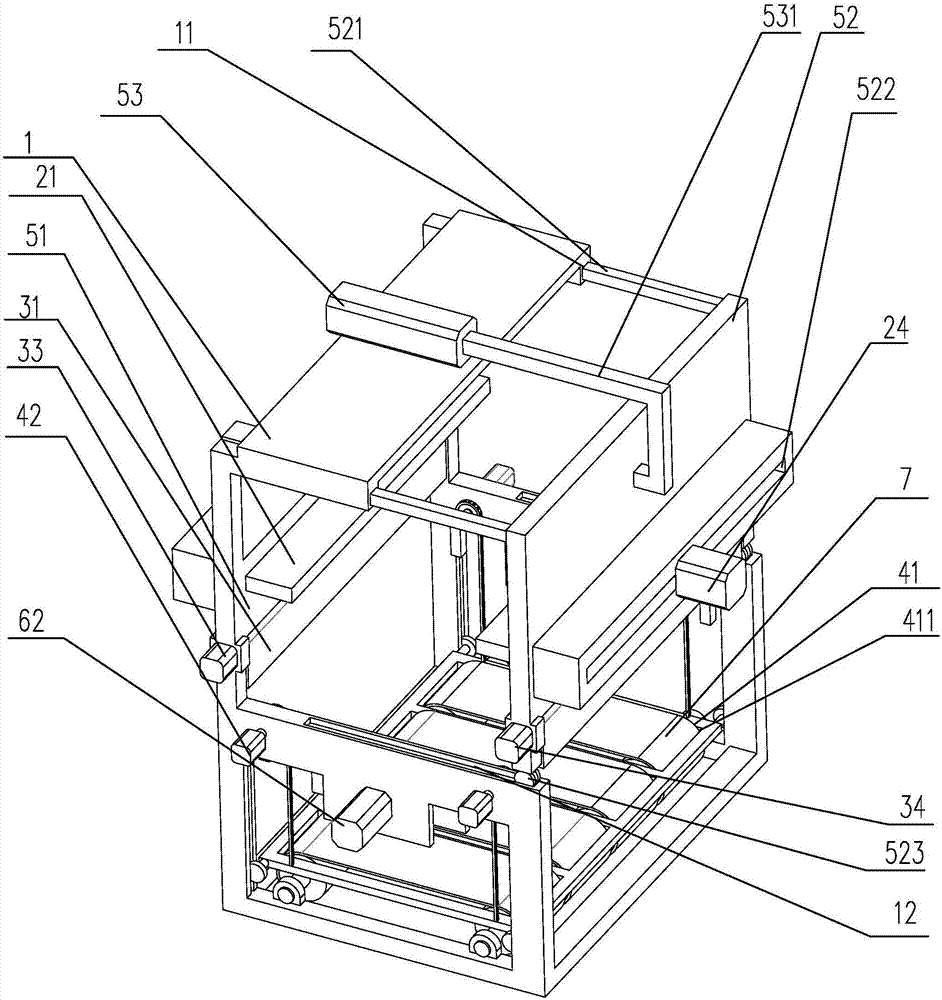

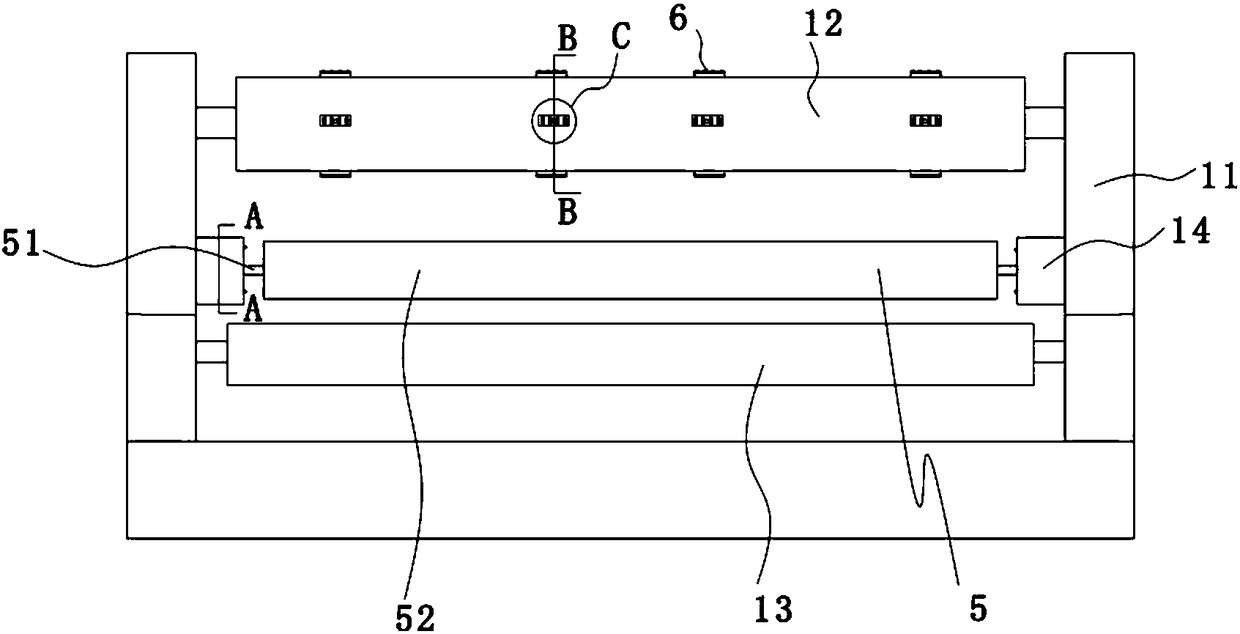

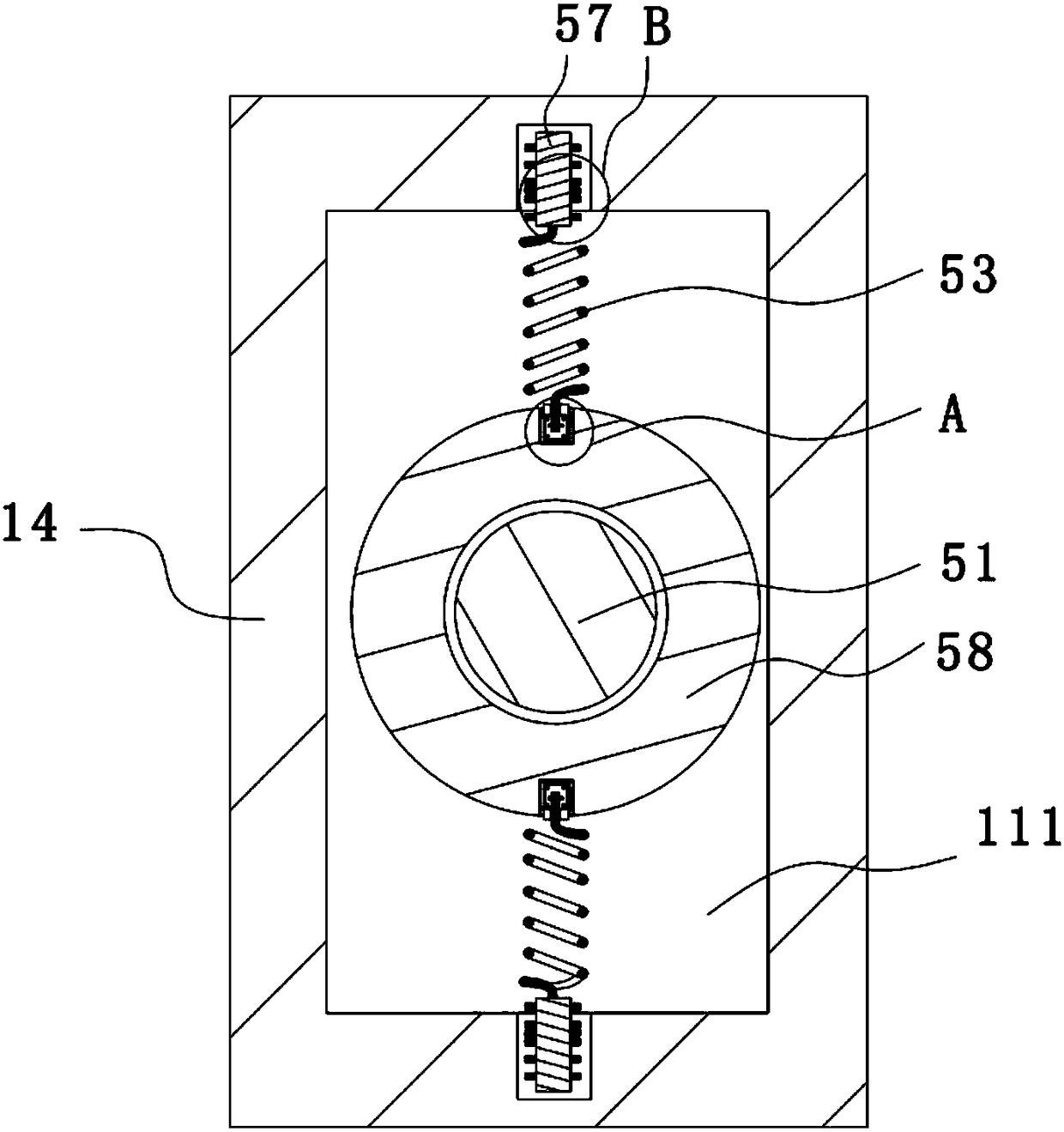

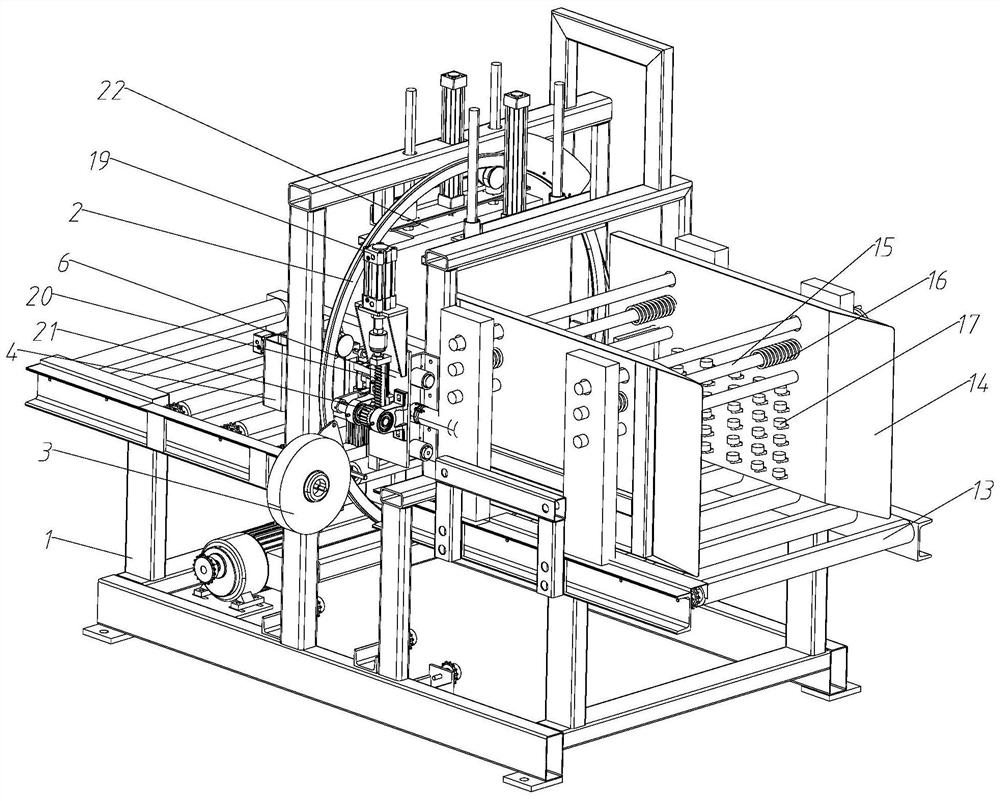

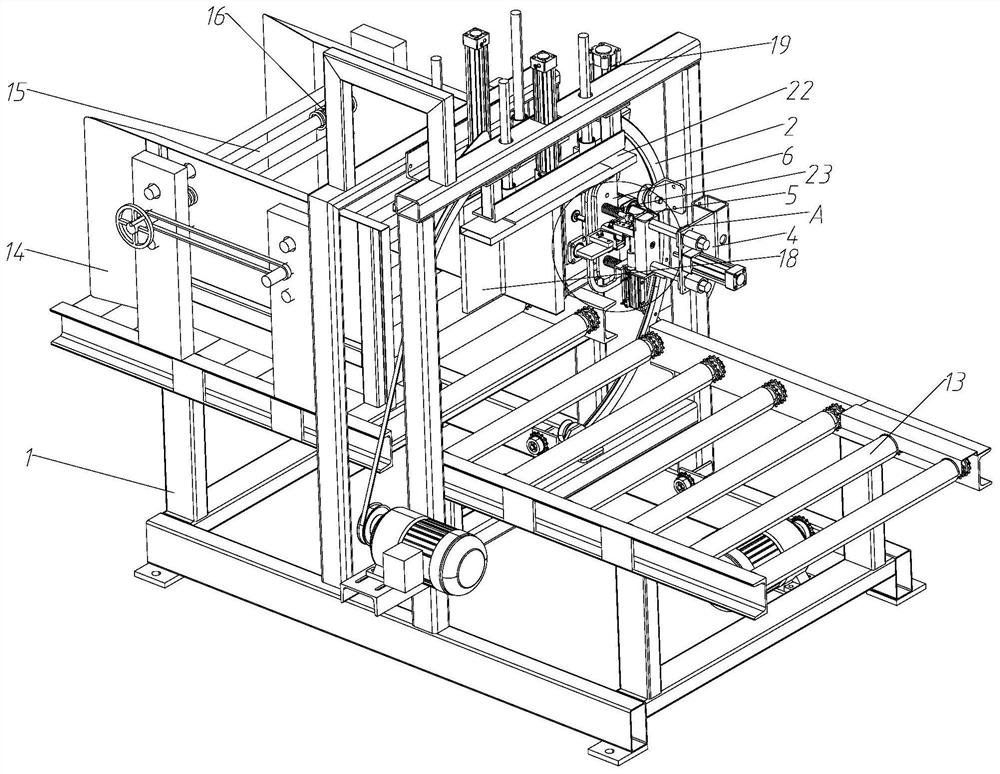

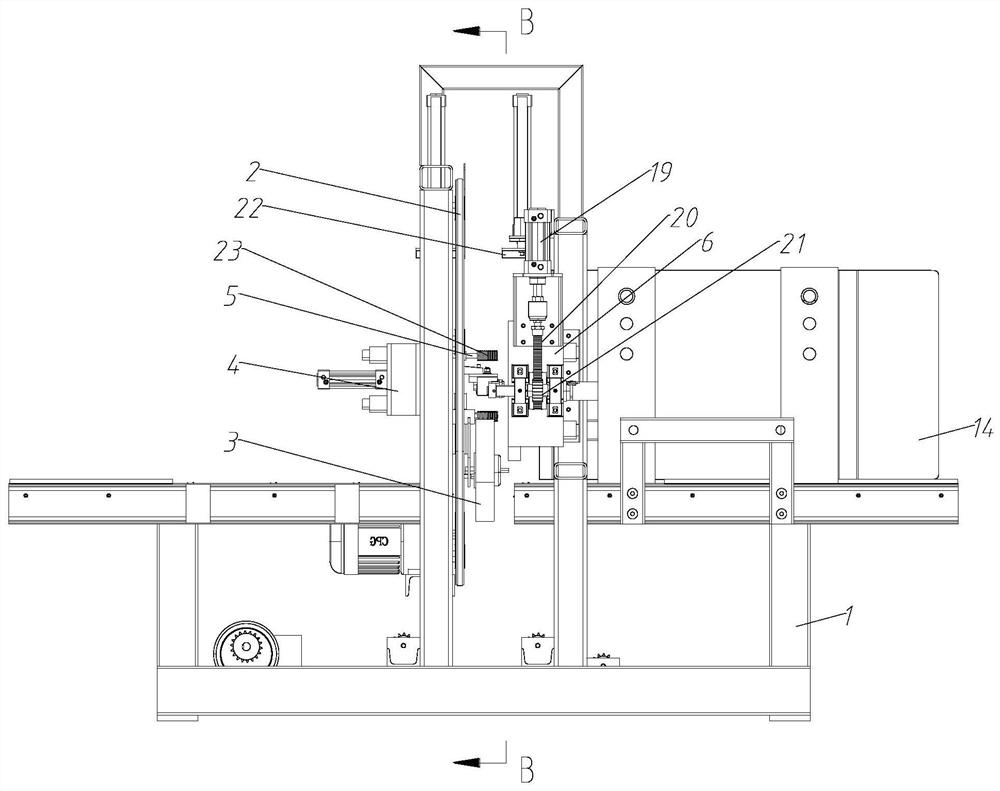

Paperboard stacking and packaging device

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

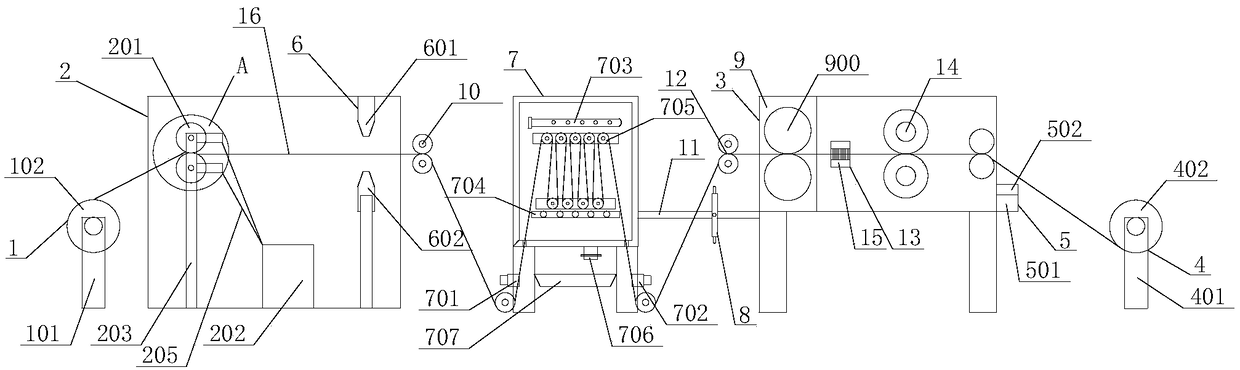

Novel fabric singeing machine

InactiveCN108642782AConvenient production workAvoid scratchesSingeingProgrammable logic controllerElectric machinery

The invention relates to a novel fabric singeing machine. The novel fabric singeing machine comprises a cloth charge mechanism, a singeing mechanism, a cooling mechanism, a cloth discharge mechanism and a control mechanism, wherein the cloth charge mechanism comprises a cloth charge frame and a cloth charge roll, and the cloth charge roll is arranged on the cloth charge frame; the cloth dischargemechanism comprises a cloth discharge frame and a cloth discharge roll, and the cloth discharge roll is arranged on the cloth discharge frame; the singeing mechanism comprises an electrostatic roll and a singeing device; a fire extinguishing box is arranged between the singeing mechanism and the cooling mechanism; the cooling mechanism comprises a cooling device, a dedusting device and a third cloth guide roll; the control mechanism comprises a control panel and an alarming device; the control panel is respectively electrically connected with motors of the cloth charge roll and the cloth discharge roll. The novel fabric singeing machine has the beneficial effect that an acceleration signal of the third cloth guide roll monitored by an acceleration sensor in real time is sensed by a PLC (programmable logic controller), namely monitoring a signal about whether the singed fabric has naps or not, so as to automatically judge whether the fabric is smooth or not, and facilitate the subsequent production.

Owner:广东南豆科技有限公司

Shaping process for cotton percale shirt stitches

InactiveCN107183816AImproved elasticityAvoid wrinklesShirtsClothes making applicancesWrinkleCellulose

The invention discloses a shaping process for cotton percale shirt stitches, which comprises the following steps: a, tailoring: according to a garment sample, the garment parts are tailored, wherein the garment parts comprise a collar, sleeves, cuffs, sleeve slits, body front parts and body back parts; b, sewing: the garment parts are sewn, wherein cellulose reactive strip adhesive substrates are imported synchronously into every stitch during the sewing process; c, shaping: the shaping process through hot pressing and solidification is carried out on the sewn garment parts under presetting conditions. On the basis of the original wrinkle-resistant fabric, through the process that the stitches of every garment part are sewn with the cellulose reactive strip adhesive substrates, the substrate is in a state of hot pressing and melting under certain conditions, and elastic protection is formed in the stitches, thereby making the stitches of the garments provided with stronger elastic restoring force, making the cloth folds capable of being not easily produced and improving the non-ironing property of the garments. Furthermore, the cooling and patting process needs to be carried out on the garment, which can improve comfort of the garment and reduce burrs on the garment.

Owner:上海杰西衬衫有限公司

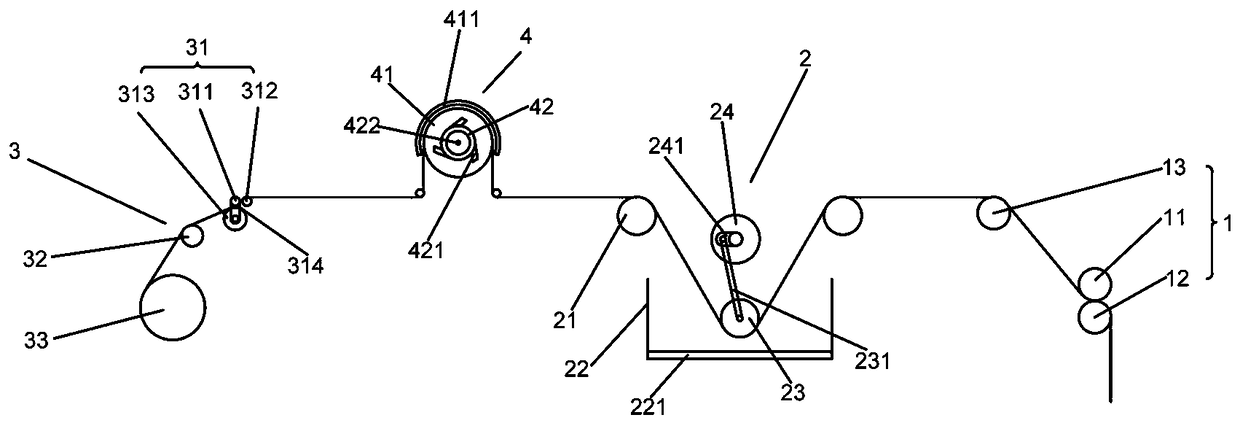

Polymer plastic film preparing processing system

PendingCN113071947ASolve the disadvantages of slittingNot prone to tearingArticle deliveryWebs handlingPolymer scienceThin membrane

The invention provides a polymer plastic film preparing processing system. The polymer plastic film preparing processing system comprises a base, a wall base, an unwinding mechanism, a slitting mechanism and a winding mechanism. The invention provides the polymer plastic film preparing processing system which can overcome the defects existing in current polymer plastic film slitting: a, in the polymer plastic film slitting process, a film vibrates due to some objective factors such as artificial real objects and air flow, in the film slitting process, the film does not make contact with slitting tools, and film slitting failure is caused; b, when the film is subjected to multi-section slitting, due to the fact that the tools are distributed too densely, the film is torn due to the fact that prestress generated by the film is too large, and the ideal slitting effect cannot be achieved; and c, the film is of an elastic structure, the film is prone to shrinkage after being cut excessively, and the phenomena of wrinkling and edge deviation are prone to occurring in the film rolling operation.

Owner:刘雁燕

After-treatment assistant for cellulosic fiber fabric

InactiveCN106012523ALess likely to wrinkleReduce formaldehyde contentWrinkle resistant fibresAbrasion resistant fibresAfter treatmentPulp and paper industry

The invention relates to a post-finishing auxiliary agent for cellulose fiber fabrics, which is used for post-finishing cellulose fiber fabrics. The additives include the following components by weight: 32±2% modified N-methylol dihydroxyethylene urea, 35±2% silicone, 12±0.5% color fixing agent, 11±0.5% textile waterproof agent. After finishing the cellulose fiber fabric with the post-finishing auxiliary agent of the present invention, the cellulose fiber fabric is not easy to wrinkle and shrink during use, and the formaldehyde content of the fabric after finishing is far lower than 75ppm. Make the surface of cellulose fiber fabrics more rich and colorful, make the fabric feel fuller and more elastic, and at the same time give the fabric a silky touch, which helps to improve the effect of non-ironing finishing.

Owner:JIANGSU GIRMES SPECIAL TEXTILES

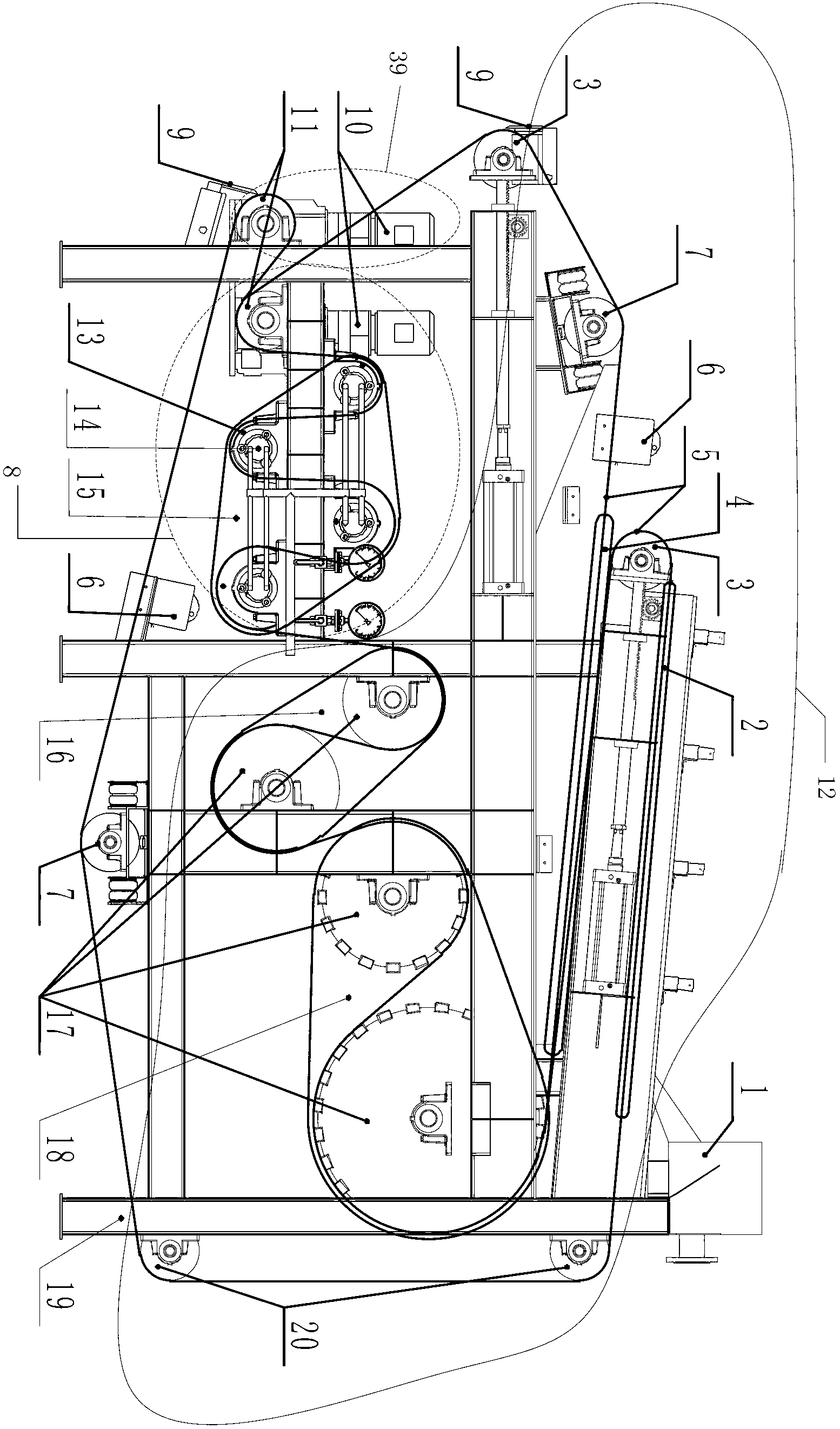

Vacuum presser

ActiveCN103285647AEasy to handleWide range of applicationsMoving filtering element filtersClosed loopDistributor

The invention relates to a vacuum presser which comprises a distributor, a pressing system, an unloading device, a vacuum system, a driving system, two pieces of filter cloth and a frame, wherein the pressing system is arranged on the top and the middle lower part on the right side of the frame; the distributor is arranged at one end of the top of the pressing system; the unloading device is arranged on one side, which is opposite to the distributor, of the pressing system; the vacuum system is arranged on the left lower part of the frame; the driving system is arranged on the frame below the unloading device; the two pieces of filter cloth are respectively wound into two closed loops; the two pieces of filter cloth are meshed in the right middle part of the pressing system. The traditional pressing dehydration and vacuum negative pressure dehydration are perfectly combined together, and materials can be well treated, so that the equipment is wide in application range, and the dehydration efficiency in unit time is greatly improved.

Owner:YANTAI SUNNY HEXING ENVIRONMENT PROTECTION EQUIP

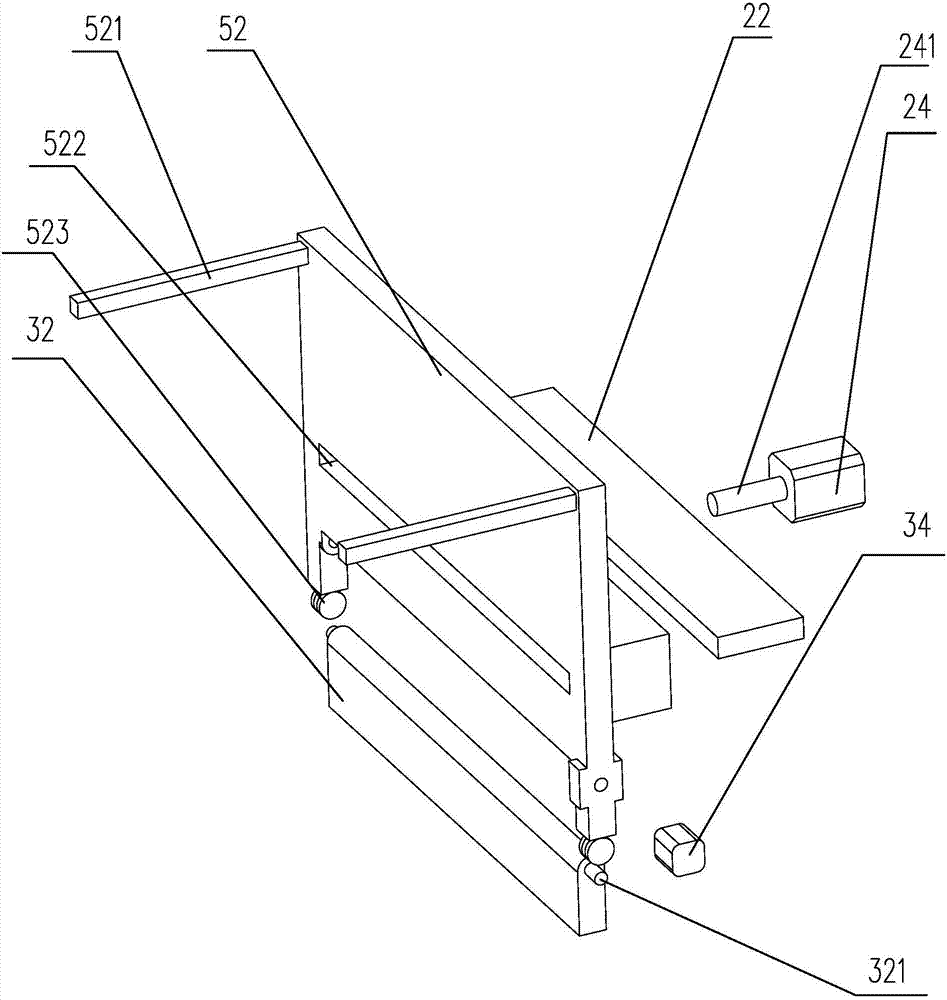

Paperboard stacking device

The invention discloses a paperboard stacking device. The paperboard stacking device comprises a bracket, a partition board, a collecting carrier, a pushing plate and a lifting plate, wherein baffles capable of sliding forwards and backwards are arranged at the front and rear sides of the bracket; both the collecting carrier and the partition board are arranged on the baffles; the partition board is arranged above the collecting carrier; the lifting plate is arranged below the collecting carrier and is in sliding fit with the bracket; and the pushing plate is arranged on the bracket, a conveyor belt is arranged below the lifting plate, and a plurality of through grooves for helping the conveyor belt be in contact with a paperboard stack are arranged in the lifting plate at intervals. The paperboard stacking device is simple in structure and can collect paperboards with different sizes and at the same time tidily stack the paperboards, thereby facilitating the following operation.

Owner:ZHEJIANG DONGJIN TECH CO LTD

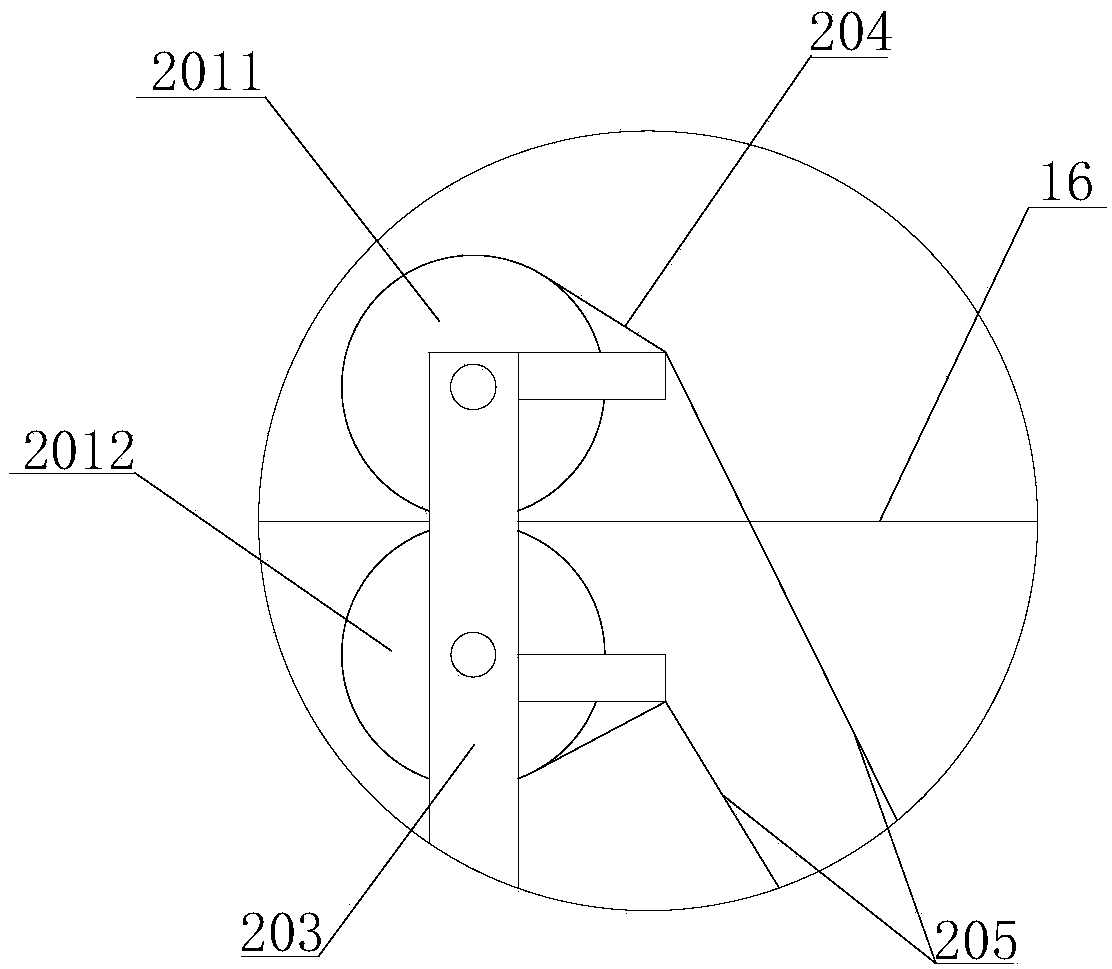

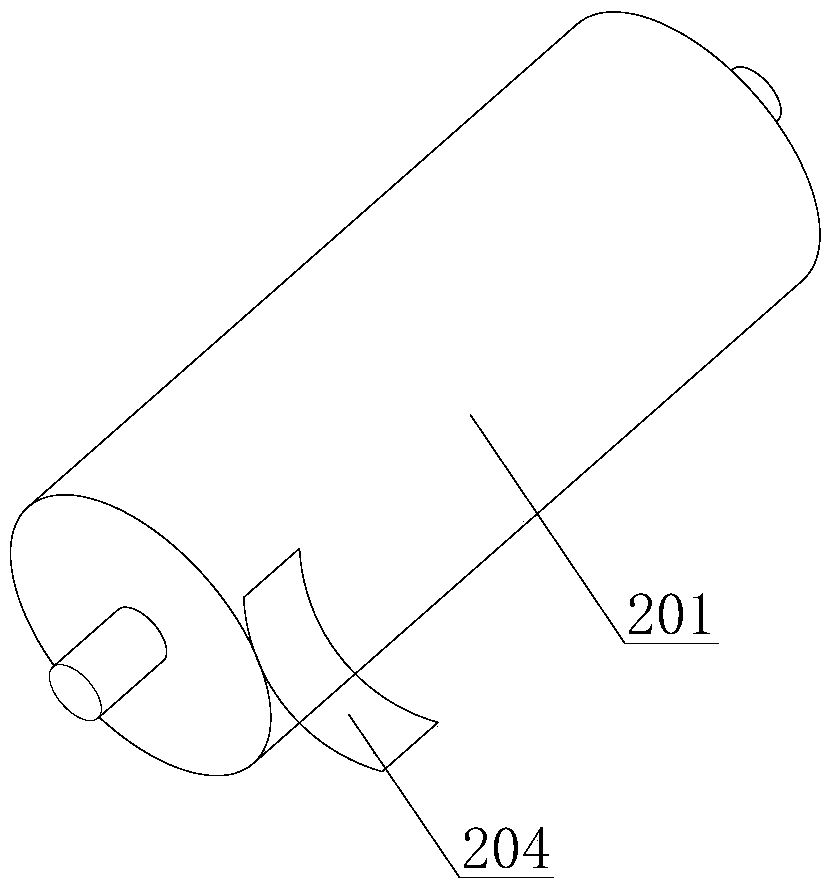

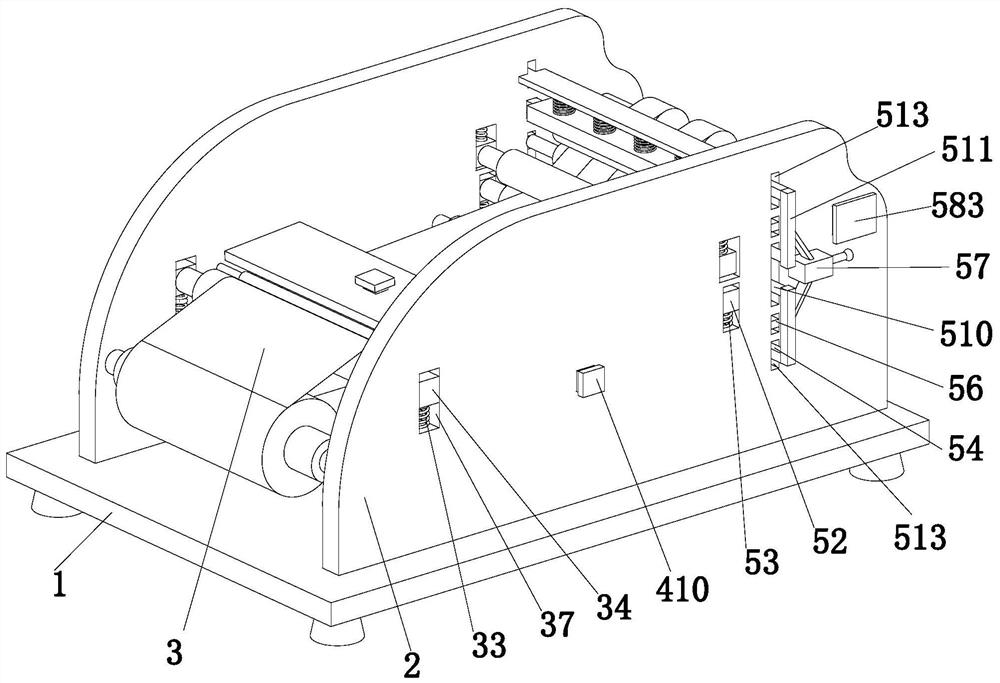

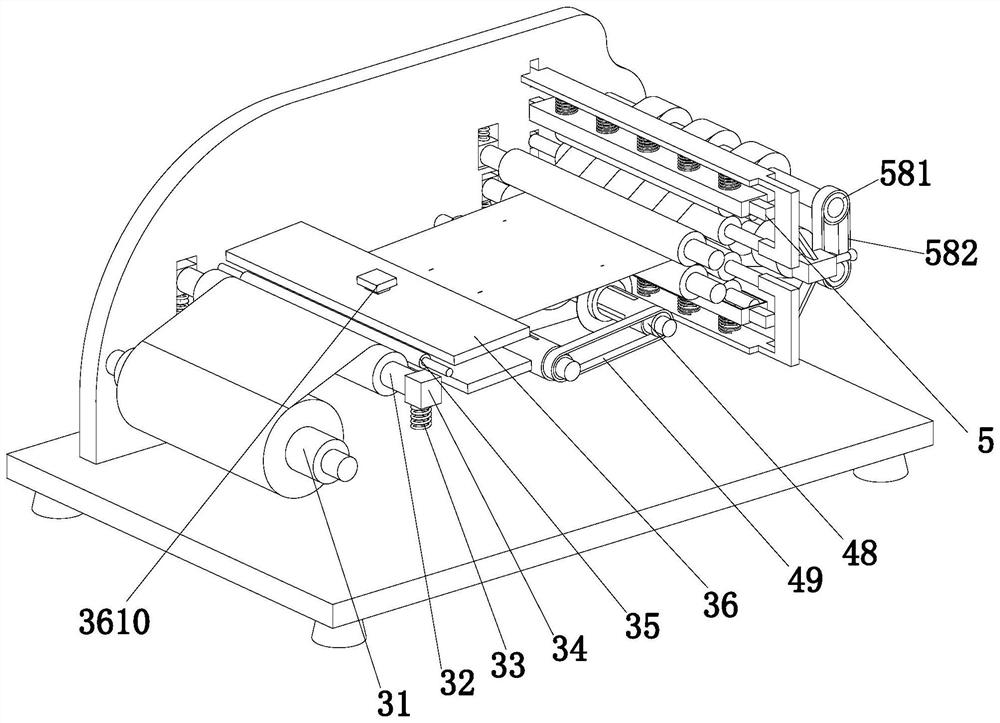

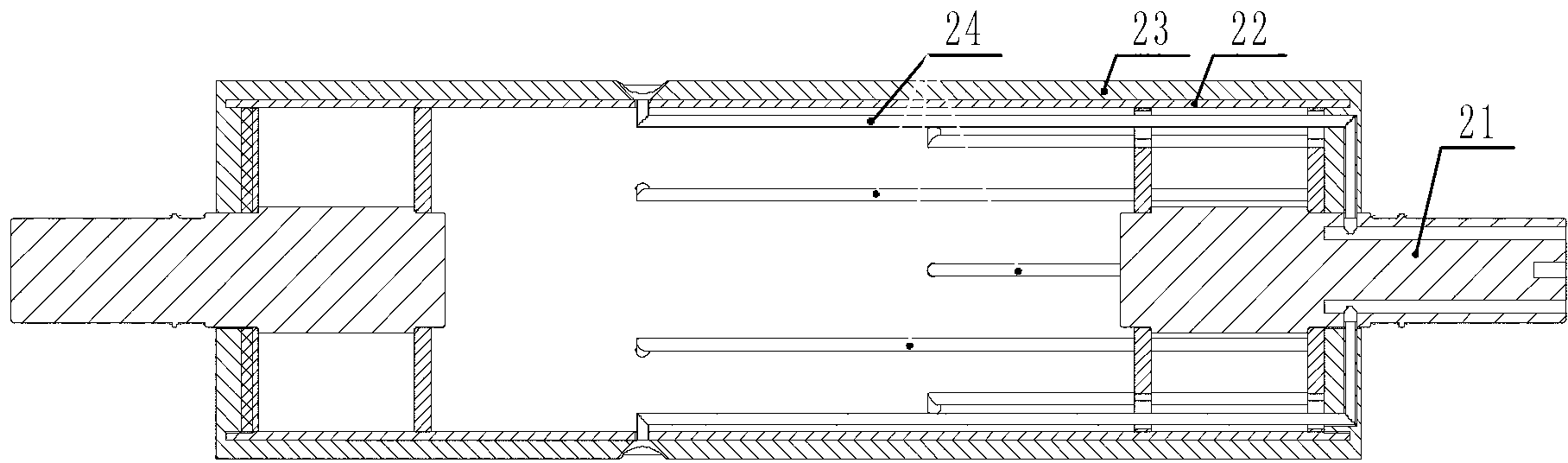

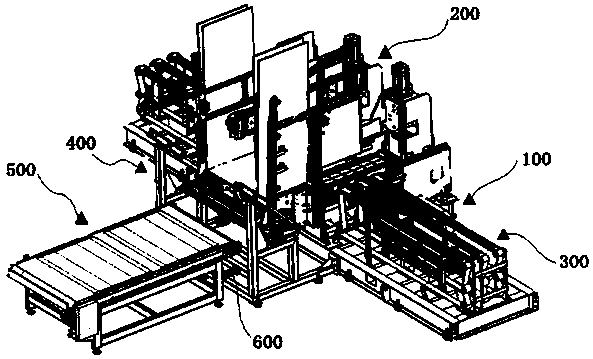

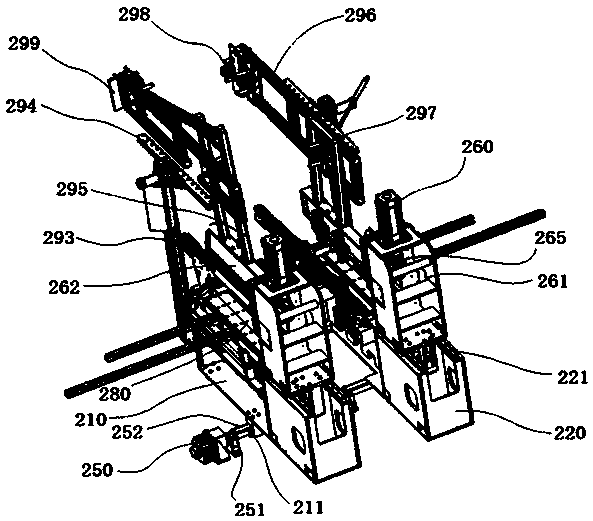

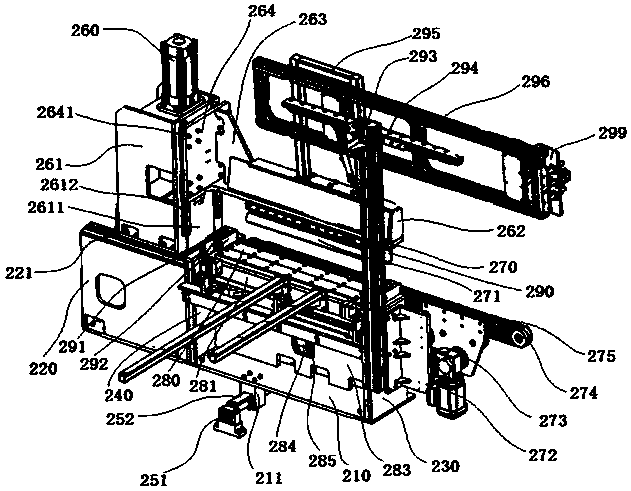

U-shaped bending turnover blanking machine

ActiveCN108994117ARealize one-time processing and transportationAdjustable bending angleStripping-off devicesPulp and paper industryManipulator

The invention discloses a U-shaped bending turnover blanking machine. The U-shaped bending turnover blanking machine comprises a base assembly, a U-shaped bending assembly, a conveying belt assembly,a suction turnover manipulator assembly, a blanking assembly, the U-shaped bending assembly and the conveying belt assembly are arranged at the upper end of the base assembly, the suction turnover manipulator assembly is arranged at the front end of the U-shaped bending assembly, and the blanking assembly is connected with the suction turnover manipulator assembly through a connecting rod; the U-shaped bending assembly comprises a bending assembly base, a bending mechanism, a side positioning mechanism and a U-shaped plate conveying mechanism; the sucking turnover manipulator assembly comprises a manipulator base and a suction turnover manipulator, and the manipulator base is arranged at the bottom of the suction turnover manipulator. According to the U-shaped bending turnover blanking machine, the U-shaped bending, sucking and turnover and blanking and the like of the plate material can be completed, the continuous blanking of the U-shaped plate material is realized, deviation and wrinkling are not easy to happen in the blanking process, the sucking and overturning process is stable, the acting is small, the cost is low, and the efficiency is high.

Owner:江苏天辰智能装备有限公司

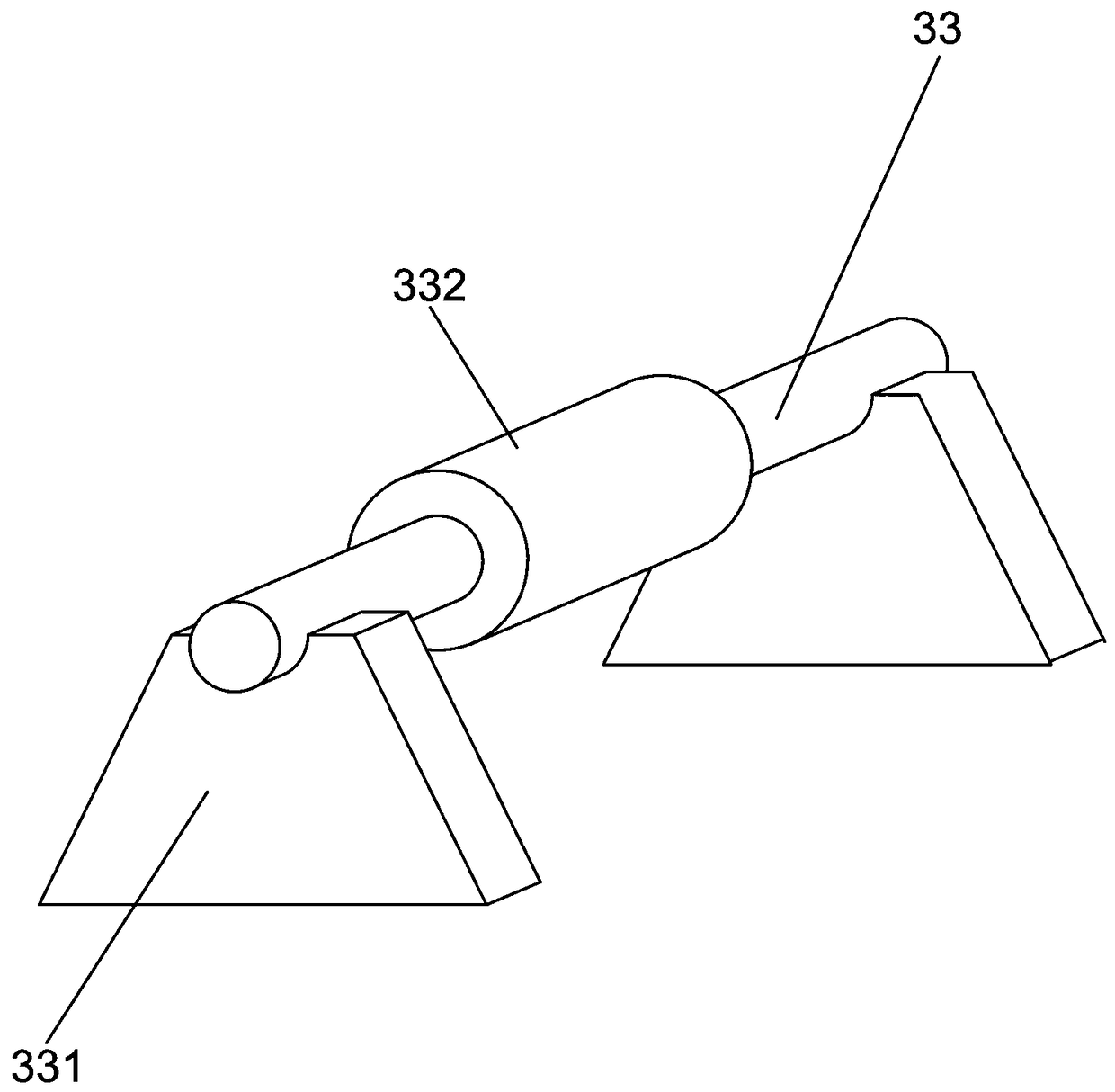

Material rolling device used for PVC machining

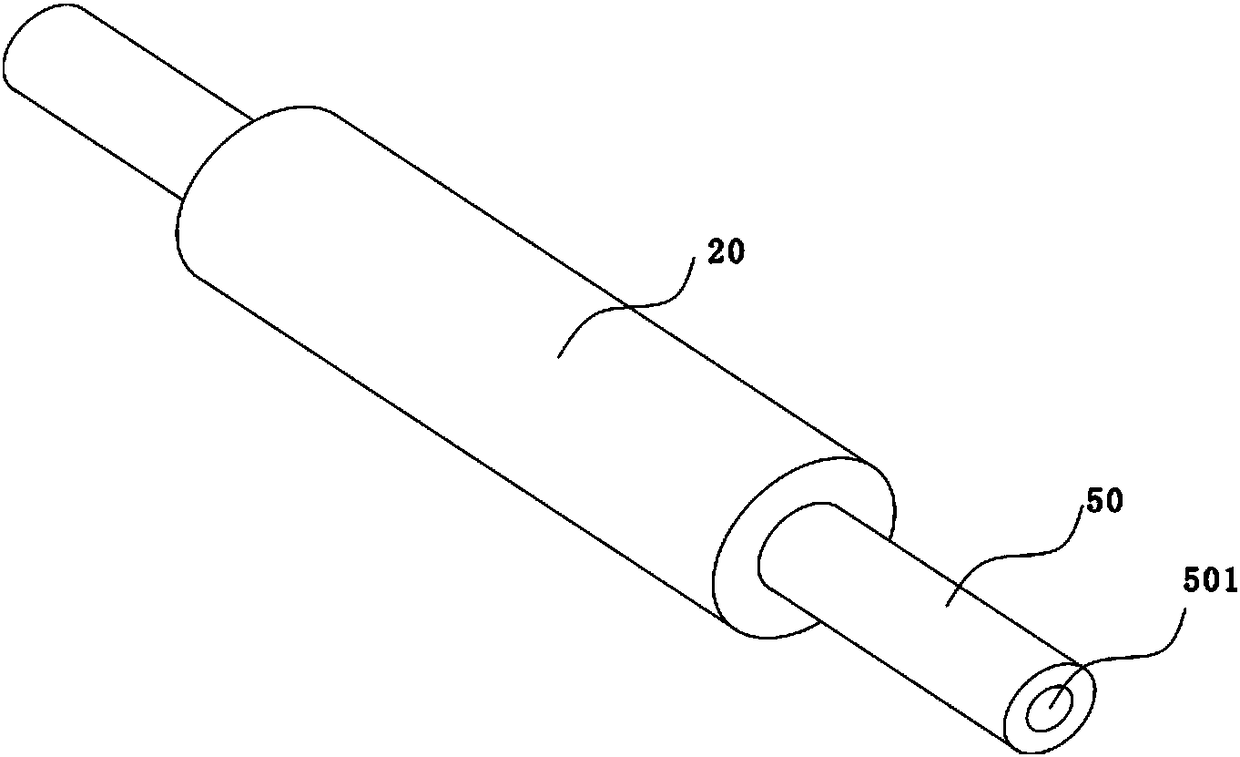

ActiveCN108249190AExtended service lifeReduce the number of replacementsWebs handlingEngineeringMaterial transfer

The invention discloses a material rolling device used for PVC machining. The material rolling device comprises a rack, a material receiving roller and a material transferring roller, and further comprises a balance roller; and the balance roller comprises a supporting shaft and a drum movably arranged on the supporting shaft in a sleeving manner, and the supporting shaft can be connected to the rack in an up-and-down floating manner. The material rolling device is provided with the balance roller, it is guaranteed that a PVC film can be tightly rolled together round and round, and the rolledPVC film is not prone to wrinkling, and the product quality is guaranteed.

Owner:JIANGSU HIMEI NEW MATERIAL CO LTD

Method for separating polyvinyl dichloride (PVDC) thin film and method for preparing PVDC composite film

InactiveCN103042784AImprove separation efficiencyIncreasing the thicknessLamination ancillary operationsSynthetic resin layered productsComposite filmAdhesive

The invention discloses a method for separating a polyvinyl dichloride (PVDC) thin film and a method for preparing a PVDC composite film. The separation method comprises the following steps of: respectively adhering thickened layers on two sides of a double-layer PVDC thin film serving as a middle layer, and separating the double-layer PVDC thin film from the middle to obtain the PVDC thin film. The preparation method comprises the following steps of: respectively compositing first films to be composited on two sides of the double-layer PVDC thin film serving as the middle layer through an adhesive, and separating the double-layer PVDC thin film from the middle to obtain the PVDC composite film. By the method for separating the PVDC thin film, the efficiency of separating the double-layer PVDC thin film is improved, the problem of high rejection rate caused by drapes of a single-layer PVDC thin film easily produced during separation of the single-layer PVDC thin film is effectively solved, and the separation quality is improved. By the method for preparing the PVDC composite film, the production efficiency, the production quality and the yield of the PVDC composite film are improved.

Owner:郑州宝蓝包装技术有限公司

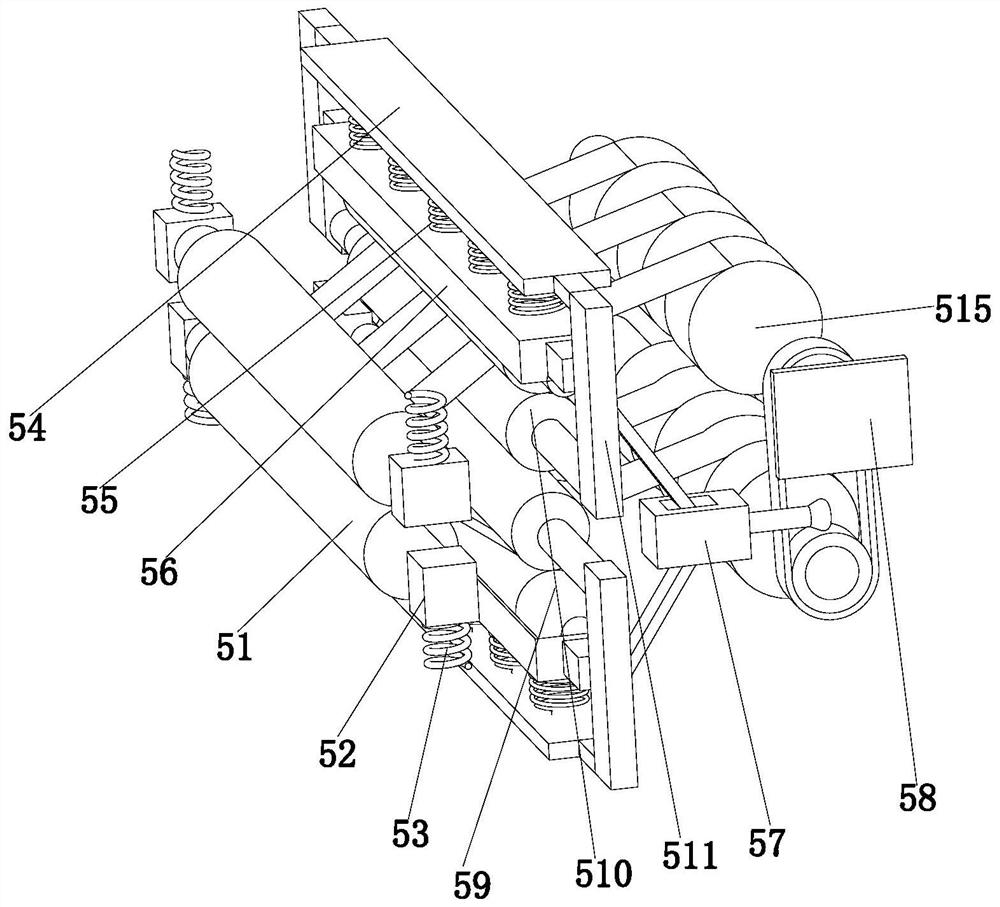

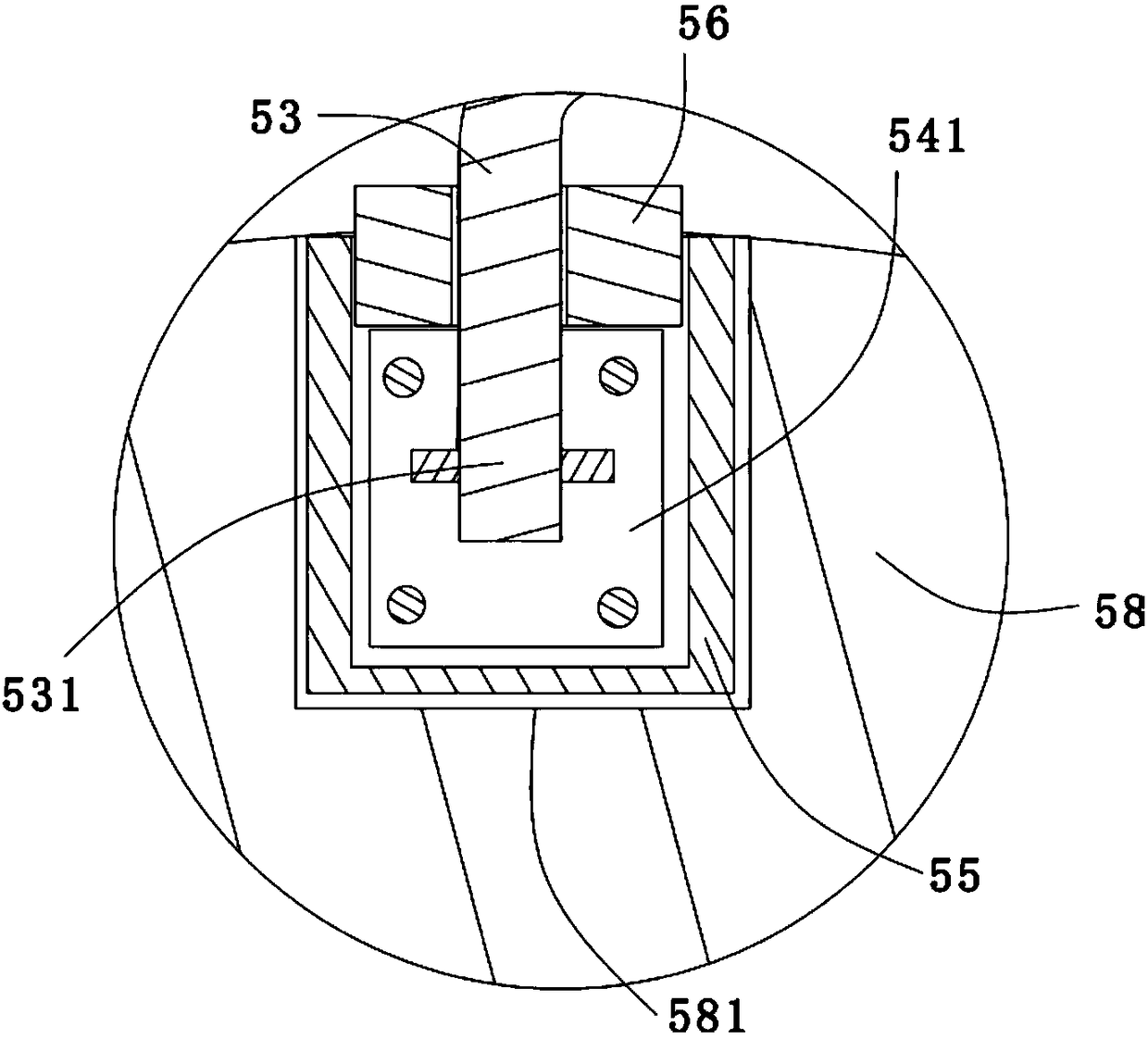

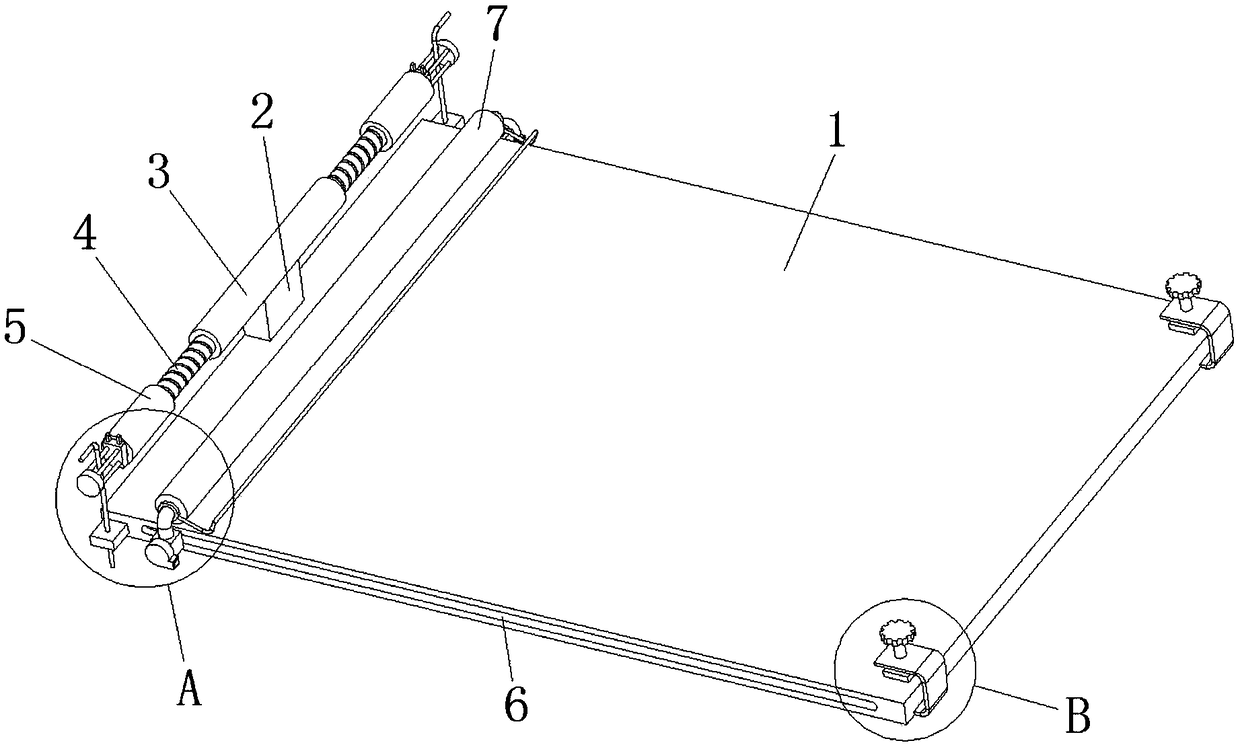

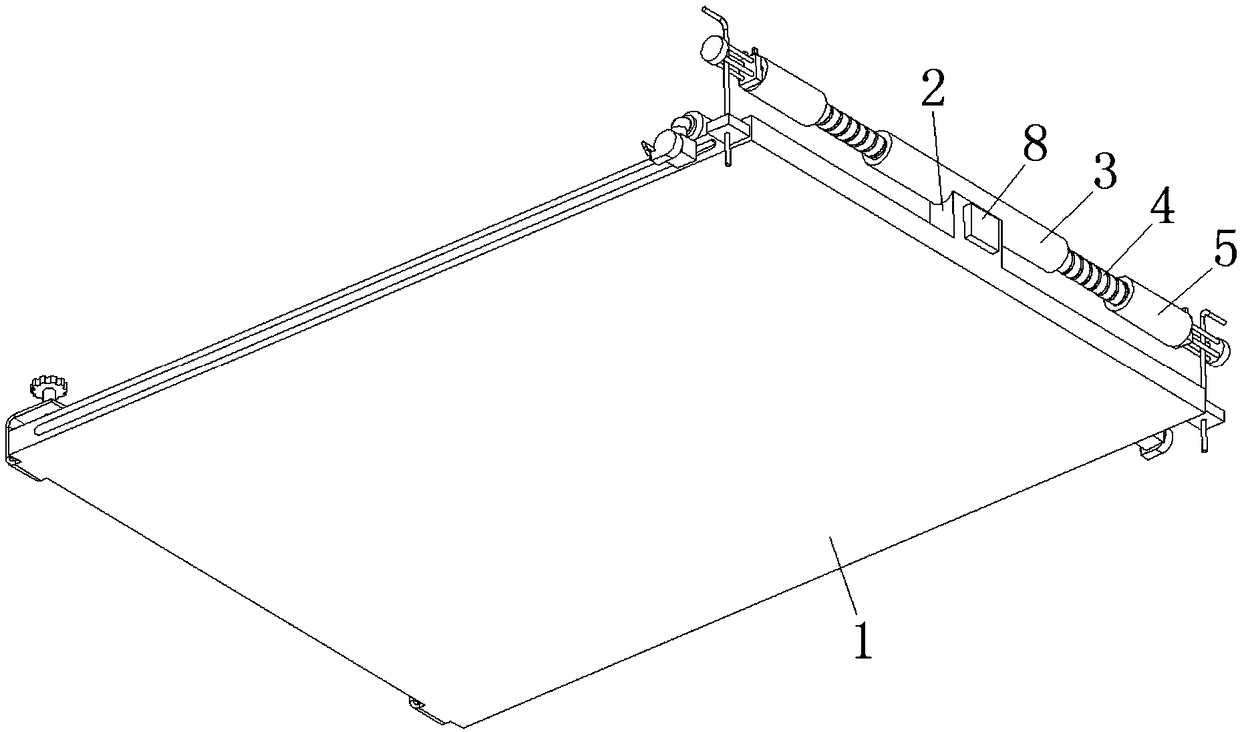

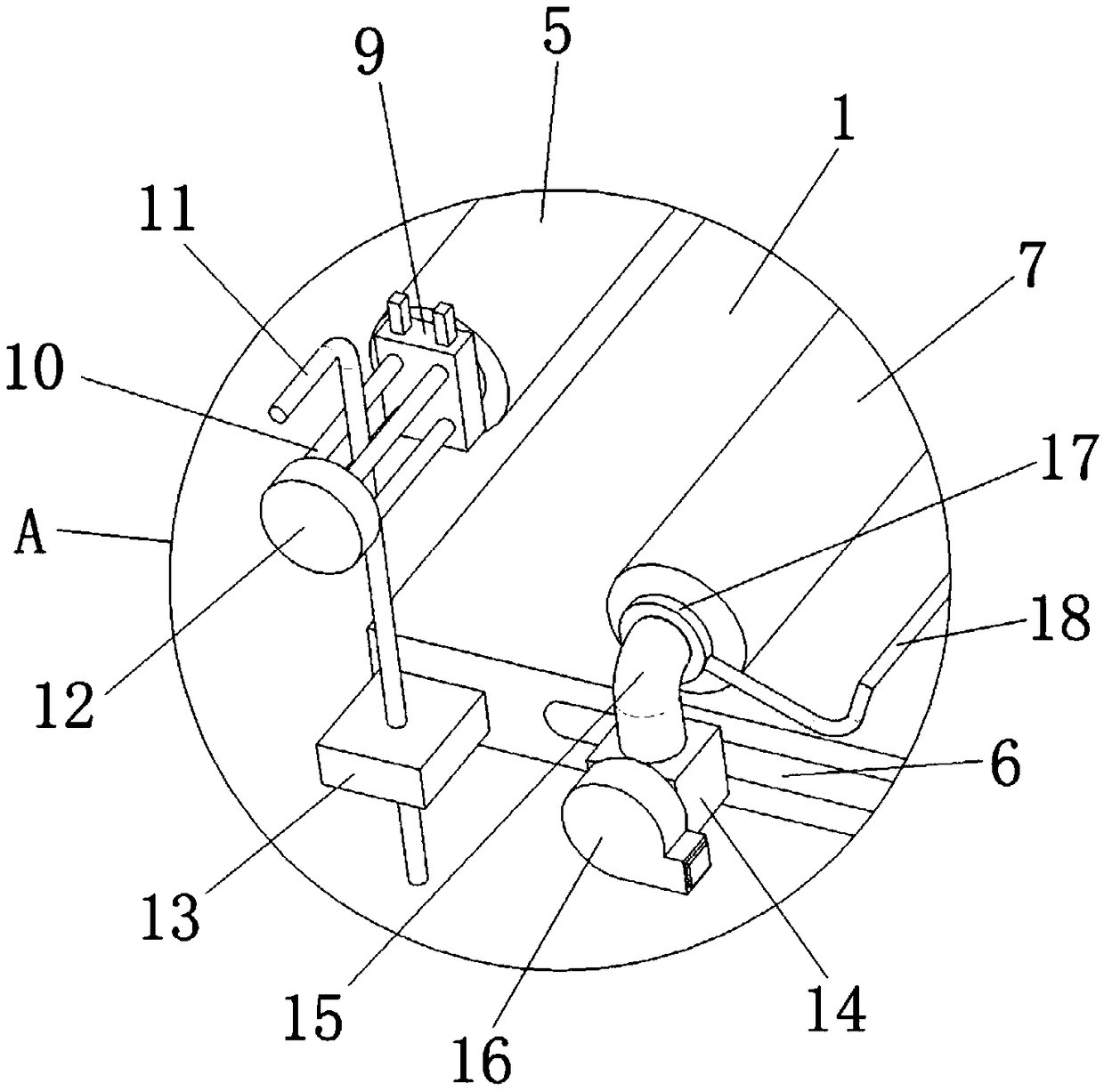

Rapid positioning device for garment tailoring

InactiveCN109295683ALess likely to wrinkleAvoid crop offsetSevering textilesClothes making applicancesEngineering

The invention discloses a rapid positioning device for garment tailoring, and relates to the technical field of garment production. The rapid positioning device comprises a working table. A fixed baseis fixedly connected with one surface of the working table. A fixed rod is fixedly connected with one surface of the fixed base. The two ends of the fixed rod are each fixedly connected with a screw.The peripheral face of each screw is in threaded connection with a rotating pipe sleeve. One end of each rotating pipe sleeve is fixedly connected with a pneumatic finger. One surface of each pneumatic finger is fixedly connected with a plurality of rotating rods. One end of each rotating rod is fixedly connected with a connecting cover. The two sides of the working table are each fixedly connected with a fixed block. The inner surface of each fixed block is slidingly connected with an L-shaped slider. The peripheral face of each L-shaped slide rod is movably connected with the correspondingrotating rods. By the rotary unfolding structure of the rotating pipe sleeves, one side of cloth is unfolded and tightened when unwound, no creases easily appear, the cloth is supported on one side ofa supporting frame to be tailored, tailoring deviation can be effectively avoided, and the tailoring precision is improved.

Owner:开平市逸宏制衣有限公司

Craftwork in plastic-sealed three-dimensional shape, and manufacturing method of craftwork

InactiveCN106965609ALose weightLess likely to wrinkleDecorative surface effectsOrnamental structuresMetallic foilHot melt

The invention relates to a craftwork in a plastic-sealed three-dimensional shape, and a manufacturing method of the craftwork. The craftwork is a dish, a bowl, a spoon or a cup, and comprises two films and one precious metallic foil sheet which are adhesive to each other and jointly molded by hot pressing and bending, wherein the two films are consistent in shape and size; the shape of each film is consistent with that of the craftwork; the foil sheet is arranged between the two films; the shape of the foil sheet is consistent with that of the craftwork; an adhesive layer used for enabling the foil sheet and each film to be fixedly connected is clamped between the foil sheet and the corresponding film, and each adhesive layer and the foil sheet are consistent in shape and area; each adhesive layer is a film with glue or a hot melt adhesive layer; and the surface of the craftwork is smooth or is provided with embosses. The craftwork disclosed by the invention has the advantages that precious metal gram weight can be greatly reduced, and besides, the quality problem of a formed three-dimensional shape, which influences the rate of finished products, can be avoided; and manufacturing cost is reduced, and purchasing threshold is reduced, so that market promotion is facilitated.

Owner:SHENZHEN JINBAOYING CULTURE

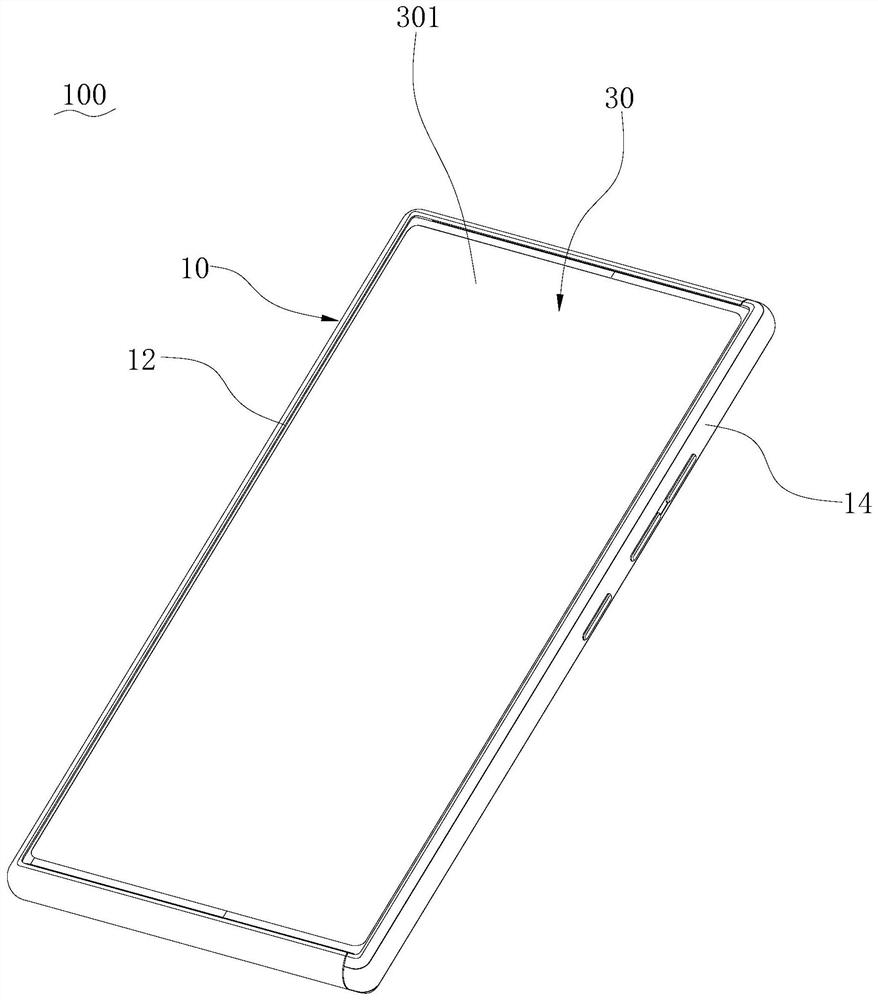

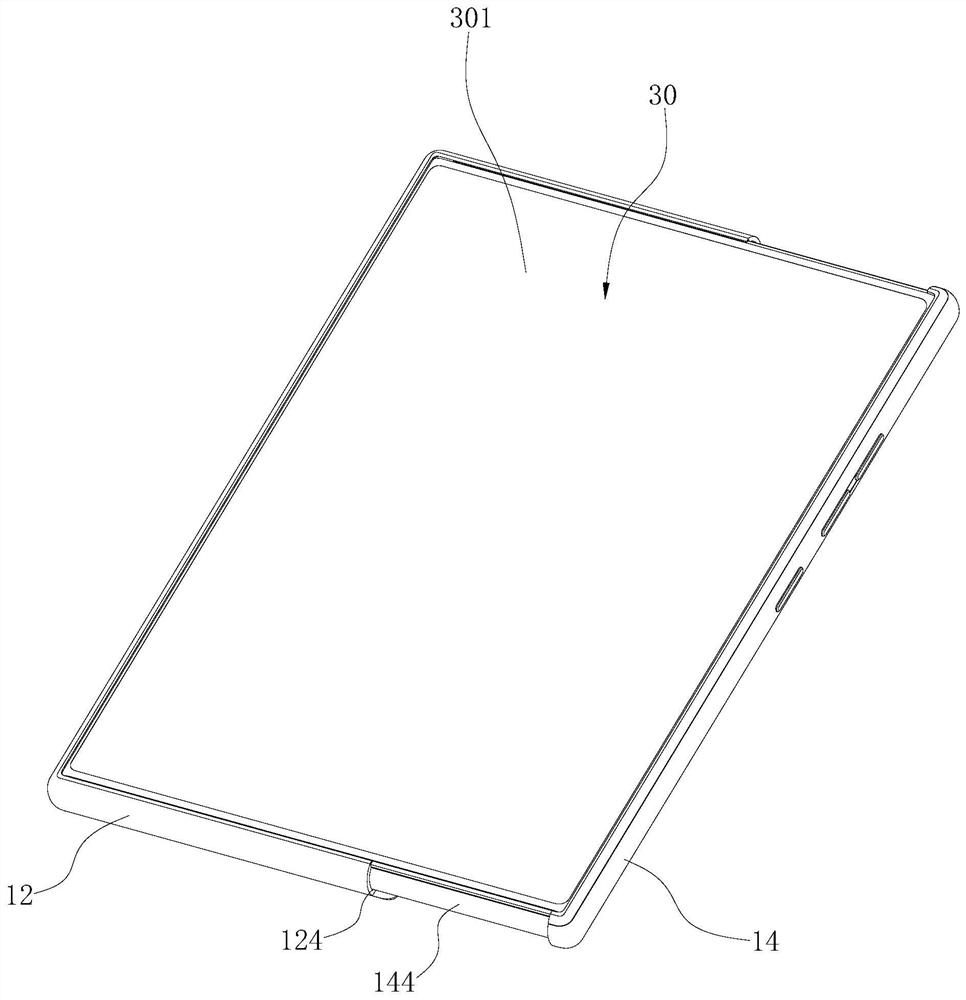

Electronic device

ActiveCN112991930AIncrease display areaLess likely to wrinkleDigital data processing detailsIdentification meansEngineeringFlexible display

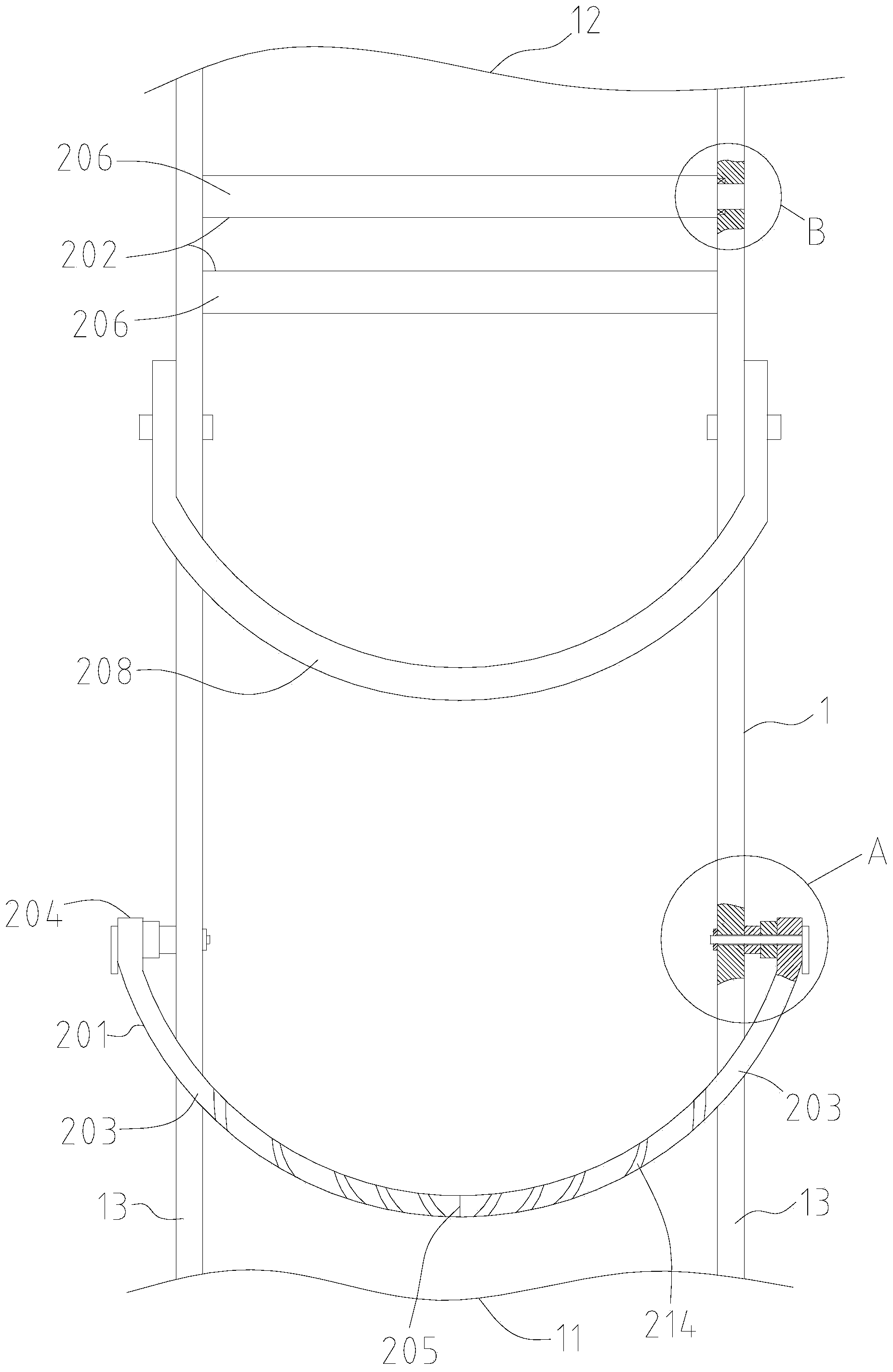

The invention discloses an electronic device. The electronic device comprises a shell, a reel, a flexible display screen assembly and a driving mechanism, wherein the shell comprises a first part and a second part which can move relatively; the reel is rotationally arranged on the first part; one end of the flexible display screen assembly is connected to the second part, and the other end of the flexible display screen assembly is wound on the reel; the driving mechanism is arranged on the first part, the driving mechanism is connected with the second part and the reel, and the driving mechanism is used for driving the second part to do separation motion relative to the first part so as to enable the flexible display screen assembly to stretch and driving the reel to rotate so as to release the flexible display screen assembly so that the display part of the flexible display screen assembly is expanded. The electronic device is advantaged in that the driving mechanism can drive the reel to rotate to gradually release the other end of the flexible display screen assembly while driving the flexible display screen assembly to extend through the second part, so movement is relatively stable due to the extension of the flexible display screen assembly and the synchronous release of the reel, and the flexible display screen assembly is not easy to wrinkle.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Flexible heat conduction paint for automobile heat insulation

ActiveCN106398433AImprove performanceImprove thermal conductivityRadiation-absorbing paintsFiberDiacetone alcohol

The invention discloses flexible heat conduction paint for automobile heat insulation. The flexible heat conduction paint is prepared from, by weight, 34-39 parts of organic silicone modified acrylic resin, 7-9 parts of expanded graphite, 12-15 parts of heat conduction fiber, 6-8 parts of mica powder, 5-7 parts of transition metal composite oxide powder, 9-11 parts of butyl acetate, 0.5-1 part of fumed silica, 12-17 parts of diacetone alcohol, 1-1.5 parts of a dispersing agent and 0.5-1 part of a flatting agent. The flexible heat conduction paint has excellent heat conduction and heat absorption properties, good stability and high adhesive force and can be sprayed to a flexible base material and bent and folded along with the base material, when the paint is used for a heat insulation sunshading pad, rapid cooling and heat dissipation can be conducted on a target by means of the excellent heat absorption property, and therefore the cooling and heat preservation effects are achieved, and the heat insulation capacity of the heat insulation sunshading pad is obviously improved.

Owner:广东安捷伦新材料科技有限公司

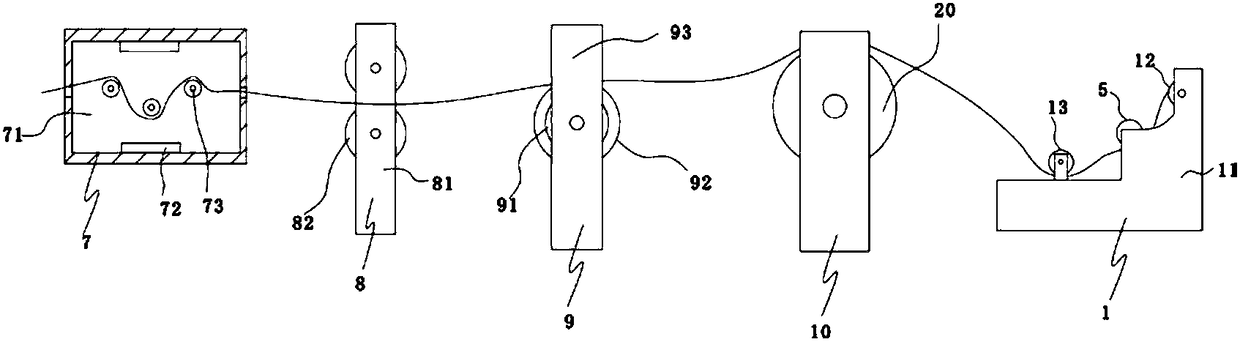

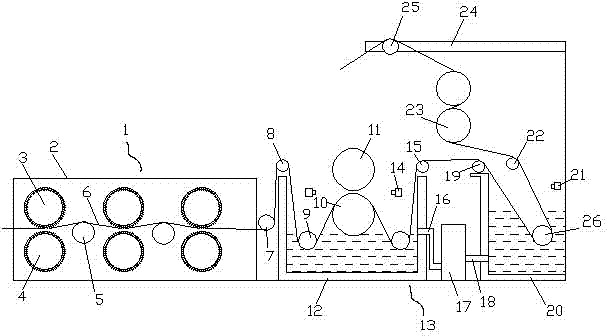

Grey cloth cleaning equipment

PendingCN109440341ASimple structureEasy to operateLiquid/gas/vapor removal by suctionTextile treatment carriersWrinkle skinConductor Coil

The invention provides grey cloth cleaning equipment, and relates to the technical field of textile equipment. The grey cloth cleaning equipment comprises a cloth loading device, a cleaning device anda winding device. The cloth loading device comprises a first cloth loading roll, a second cloth loading roll and a cloth loading guide roll, the first cloth loading roll is connected with the secondcloth loading roll, the cleaning device comprises at least one cleaning unit, the cleaning units comprise transport rolls, cleaning grooves and cleaning rolls, the cleaning rolls are arranged in the cleaning grooves and are connected with drivers, guide beams are arranged on rotary shafts of the drivers, the cleaning rolls are connected with the guide beams by connecting beams, the winding devicecomprises a limit portion, a stabilizing roll and a winding roll, the limit portion comprises a first limit roll, a second limit roll and an adjusting roll, and the first limit roll is connected withthe adjusting roll by a telescopic rod. The grey cloth cleaning equipment has the advantages that the grey cloth cleaning equipment is simple in structure and convenient to operate, wrinkles can be prevented when grey cloth is transported, and good cleaning effects can be realized by the grey cloth cleaning equipment; cleaning solution can be thoroughly eliminated, and influence in winding can beprevented.

Owner:福建省新宏港纺织科技有限公司

PVC film processing system

InactiveCN108262905AExtended service lifeReduce the number of replacementsWebs handlingMechanical engineeringMachining system

The invention discloses a PVC film processing system. The PVC film processing system comprises a heating mechanism, a pressing roll mechanism, a humidifying mechanism, a cooling mechanism and a rolling mechanism used for rolling a cooled PVC film; and the rolling mechanism comprises a rack, a collecting roll, a conveying roll and a balancing roll, the balancing roll comprises a supporting shaft and a roller movably arranged on the supporting shaft in a sleeving mode, and the supporting shaft is connected to the rack in a vertical floating mode. According to the PVC film processing system, thebalancing roll is arranged in the rolling mechanism, it is guaranteed that the cooled PVC film can be quickly and closely rolled up and the rolled PVC film is not prone to being folded, and the product quality is high.

Owner:娄军

Washing dolly

InactiveCN103572573ALess likely to wrinkleSave waterMechanical cleaningPressure cleaningProcess engineeringTextile

The invention discloses a washing dolly, and belongs to washing equipment of textile fabrics. The washing dolly is characterized in that a dry brushing area and a washing area are included, the dry brushing area is provided with an upper squeeze roller and a lower squeeze roller, the washing area is arranged on the rear portion of the dry brushing area, the washing area is provided with a prewasher and a second washer, a filter is arranged between the prewasher and the second washer, and the filter can filter liquid in the second washer and then supply the liquid to the prewasher for use. The washing dolly is reasonable in structure, convenient to use and capable of saving water resources.

Owner:谭国华

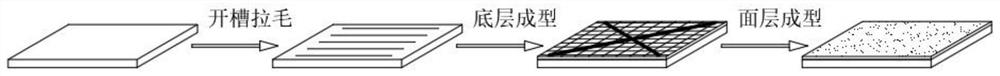

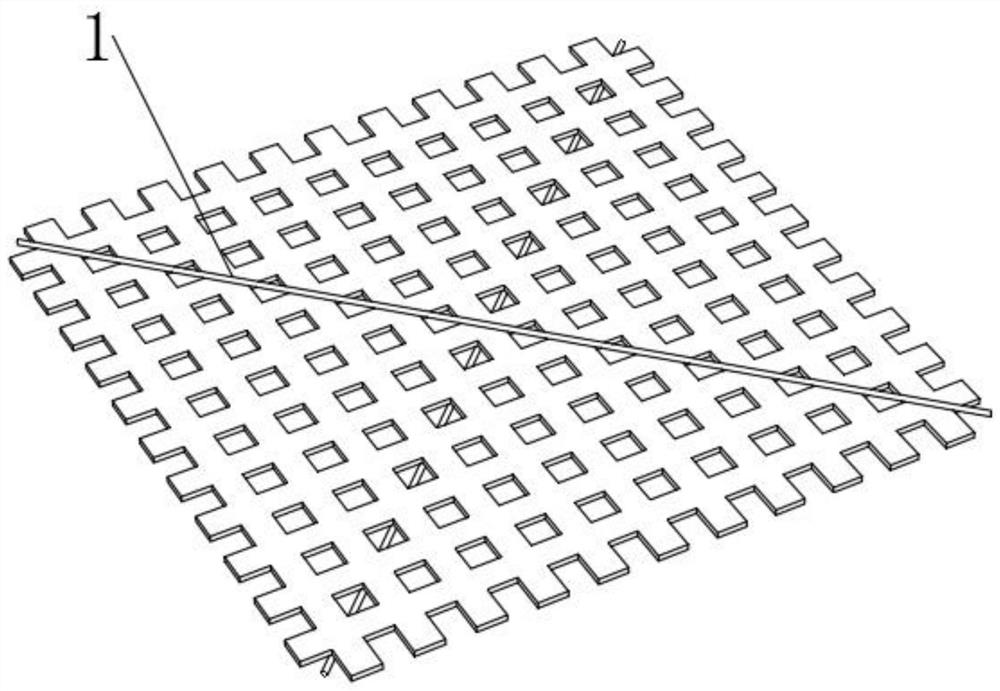

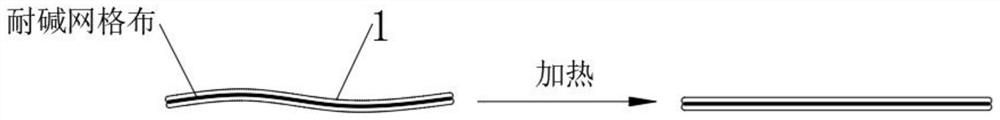

High-strength lightweight composite mortar board

InactiveCN113547610AReduce the effectAchieving continuity of resistanceCeramic shaping apparatusHeat proofingStress concentrationArchitectural engineering

The invention discloses a high-strength lightweight composite mortar board, and belongs to the technical field of building materials. The high-strength lightweight composite mortar board can be heated in the construction process in a manner of diagonally bonding stretching strips on alkali-resistant gridding cloth, so that the interior of the alkali-resistant gridding cloth can be inflated and swelled, and the original compression state is converted into the stretching state, the alkali-resisting gridding cloth is pulled to be autonomously leveled while being fully stretched, it is guaranteed that the alkali-resisting gridding cloth is flatly laid in mortar without wrinkles, resistance continuity in the mortar is effectively achieved, excessive stress concentration is avoided, and compared with existing alkali-resisting gridding cloth which needs to be manually adjusted during laying, the phenomenon of local unevenness or wrinkling still occurs in the mortar pouring process, the effect of the alkali-resisting gridding cloth is greatly reduced, the overall strength of the composite mortar board is low, and the service life of the composite mortar board is shortened.

Owner:王赛

Moisture-resistant and flame-retardant fabric

ActiveCN106364107AImprove toughnessLess likely to wrinkleFireproof paintsSynthetic resin layered productsEpoxyPolyurethane coating

The invention provides a moisture-resistant and flame-retardant fabric, and belongs to the technical field of texture products. The problems of poor water and fire resistance, easiness in heat absorption and body sticking, poor toughness and easiness in wrinkling of fabrics in the prior art are solved. The moisture-resistant and flame-retardant fabric comprises a water absorption gauze, an epoxy resin layer, a mica layer and a polyurethane coating layer which are sequentially arranged from bottom to top, and 86-90 parts of dimethyl formamide, 1-3 parts of a pigment, 3-6 parts of wood powder, 0.5-1 part of a surfactant, 3-6 parts of an anti-wear assistant and 3-6 parts of a flame retardation assistant are added to the polyurethane coating layer. Two or three spring fuses are adopted to make earpieces have large elasticity and be firmly worn on the head of a user. The fabric has the advantages of strong fireproof and waterproof property, heat release, body non-sticking, difficulty in wrinkling and high toughness.

Owner:YANGZHOU HETAI PLUSH & CARPET INDAL

Adhesive tape winding type packaging machine and winding packaging process

ActiveCN113895683ALess likely to wrinkleAvoid deformationWrapping material feeding apparatusFinal product manufactureAdhesive beltStructural engineering

The invention relates to the technical field of adhesive tape packaging equipment, and provides an adhesive tape winding type packaging machine and a winding packaging process. The adhesive tape winding type packaging machine comprises a base and an annular rotary table, the annular rotary table is provided with an adhesive tape mounting seat, the base is provided with an adhesive tape cutting mechanism, and the base is additionally provided with an adhesive tape smoothing mechanism; the adhesive tape cutting mechanism comprises a first mounting seat, an adhesive tape stop lever and a cutter assembly, the first mounting seat is arranged on the base in a sliding mode, the adhesive tape stop lever and the cutter assembly are both arranged on the first mounting seat, the adhesive tape stop lever extends to the inner side of the annular rotary table through the first mounting seat, and the cutter assembly abuts against the adhesive tape stop lever; and the adhesive tape smoothing mechanism comprises a second mounting seat and a swing arm, the second mounting seat is slidably arranged on the base, the swing arm is arranged on the second mounting seat in a swinging mode, the swing arm extends to the inner side of the annular rotary disc through the second mounting seat, and the swing arm is used for tightly attaching an adhesive tape to the surface of a to-be-packaged piece. According to the technical scheme, the problem that in the prior art, the adhesive tape winding and packaging efficiency of the to-be-packaged piece is low is solved.

Owner:邯郸市瑞冠智能化装备有限公司

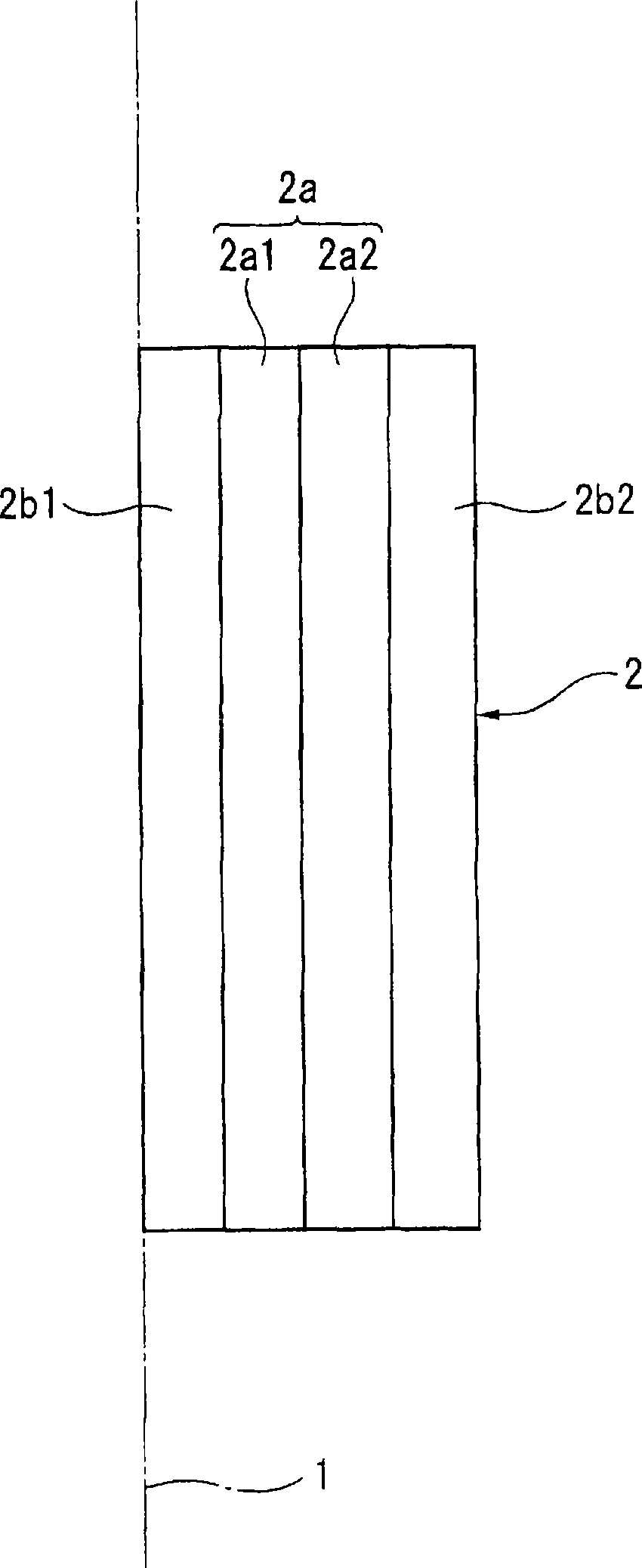

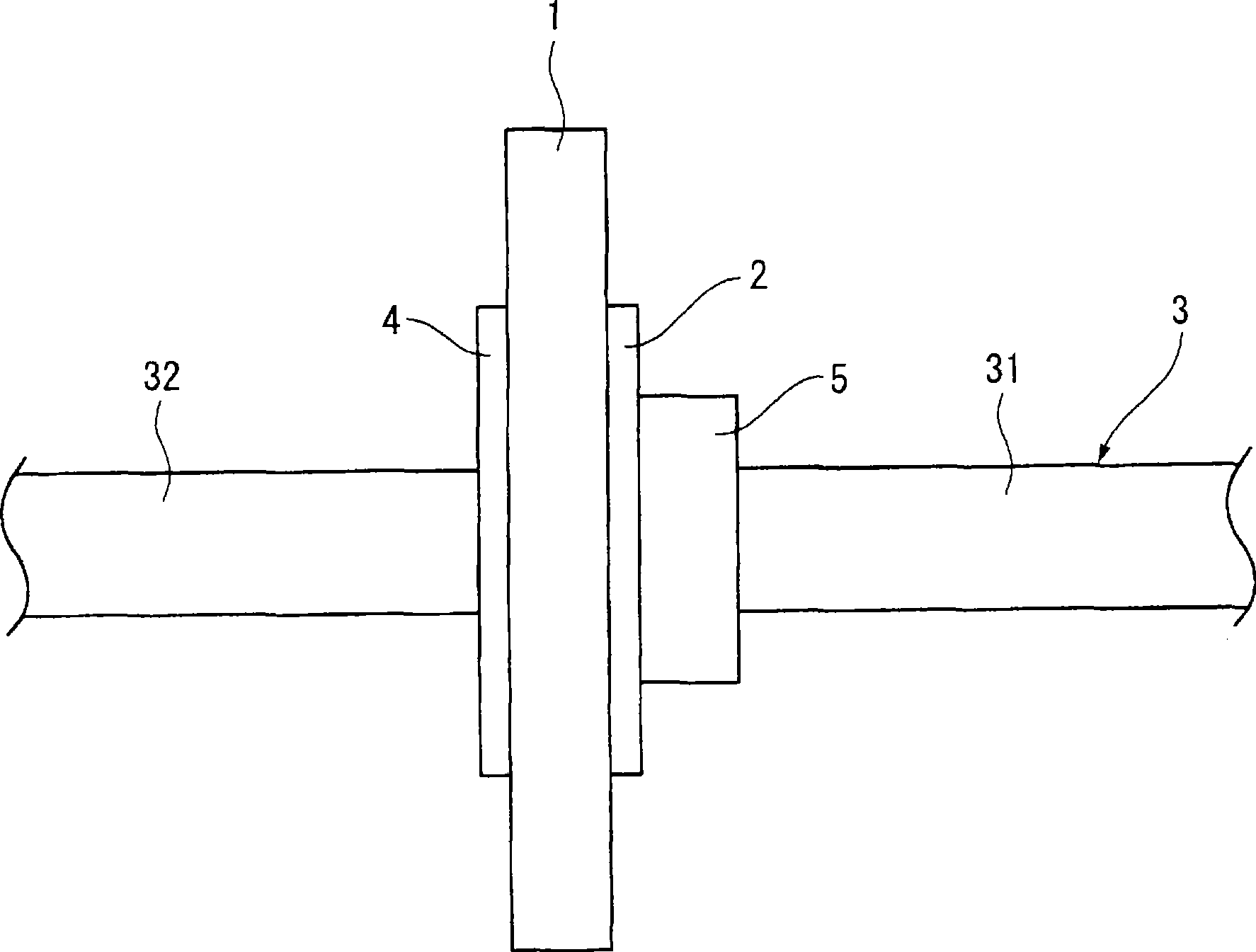

Adhesive sheet and method of edging operation

ActiveCN101443156ALess likely to wrinkleStrong adhesionEdge grinding machinesOptical surface grinding machinesMeth-Sheet film

In pressure sensitive adhesive sheet (2), first coating layer (2b1) as a pressure sensitive adhesive layer is formed at a portion opposed to a lens surface. The pressure sensitive adhesive layer consists of a pressure sensitive adhesive composition containing a polymer composed mainly of a (meth)acrylic ester, a pressure sensitive adhesiveness imparting resin and a crosslinking agent.Thus, by virtue of excellent pressure sensitive adhesiveness thereof, a high axial deviation preventing effect can be exerted even on a lens of low friction coefficient having been surface-treated with a fluorosilane compound, etc.

Owner:HOYA LENS MFG PHILIPPINES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com