Adhesive sheet and method of edging operation

A processing method and technology of adhesive film, which are applied in chemical instruments and methods, metal processing equipment, machine tools suitable for grinding the edges of workpieces, etc. The effect of shaft deviation prevention, excellent adhesion, simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

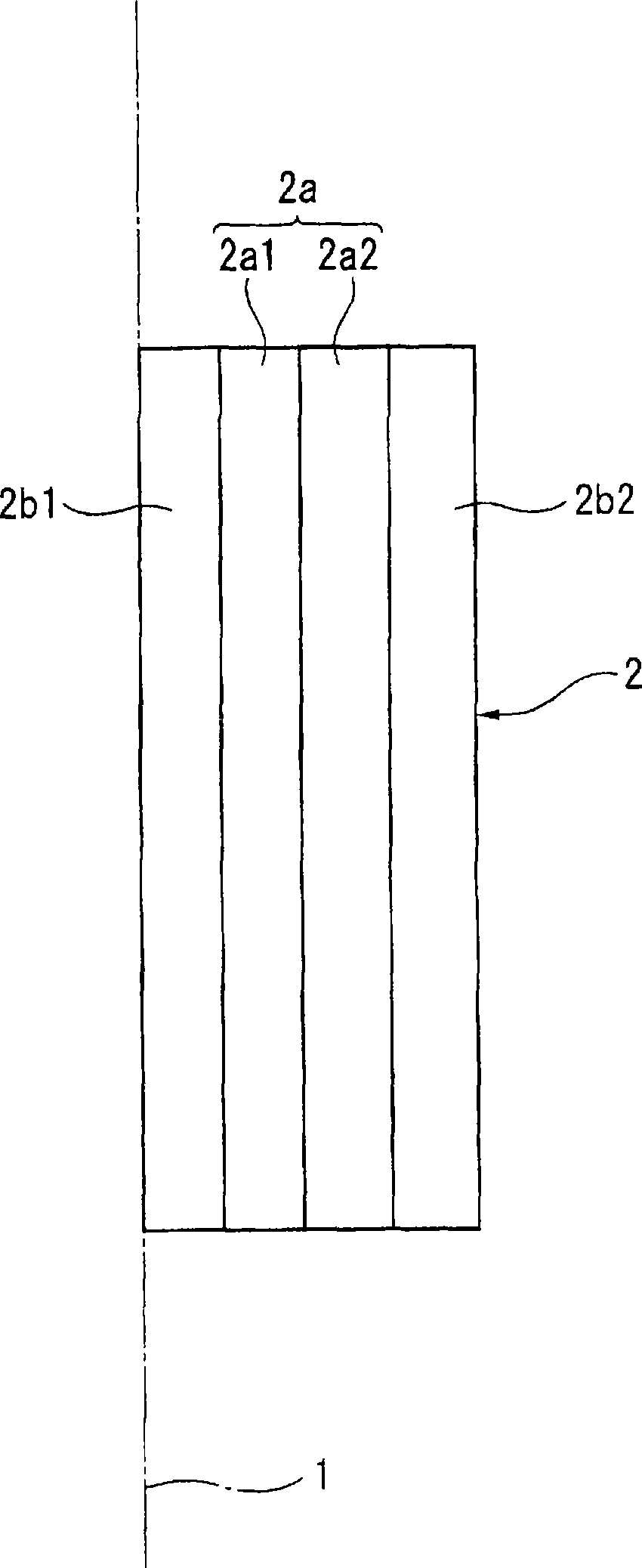

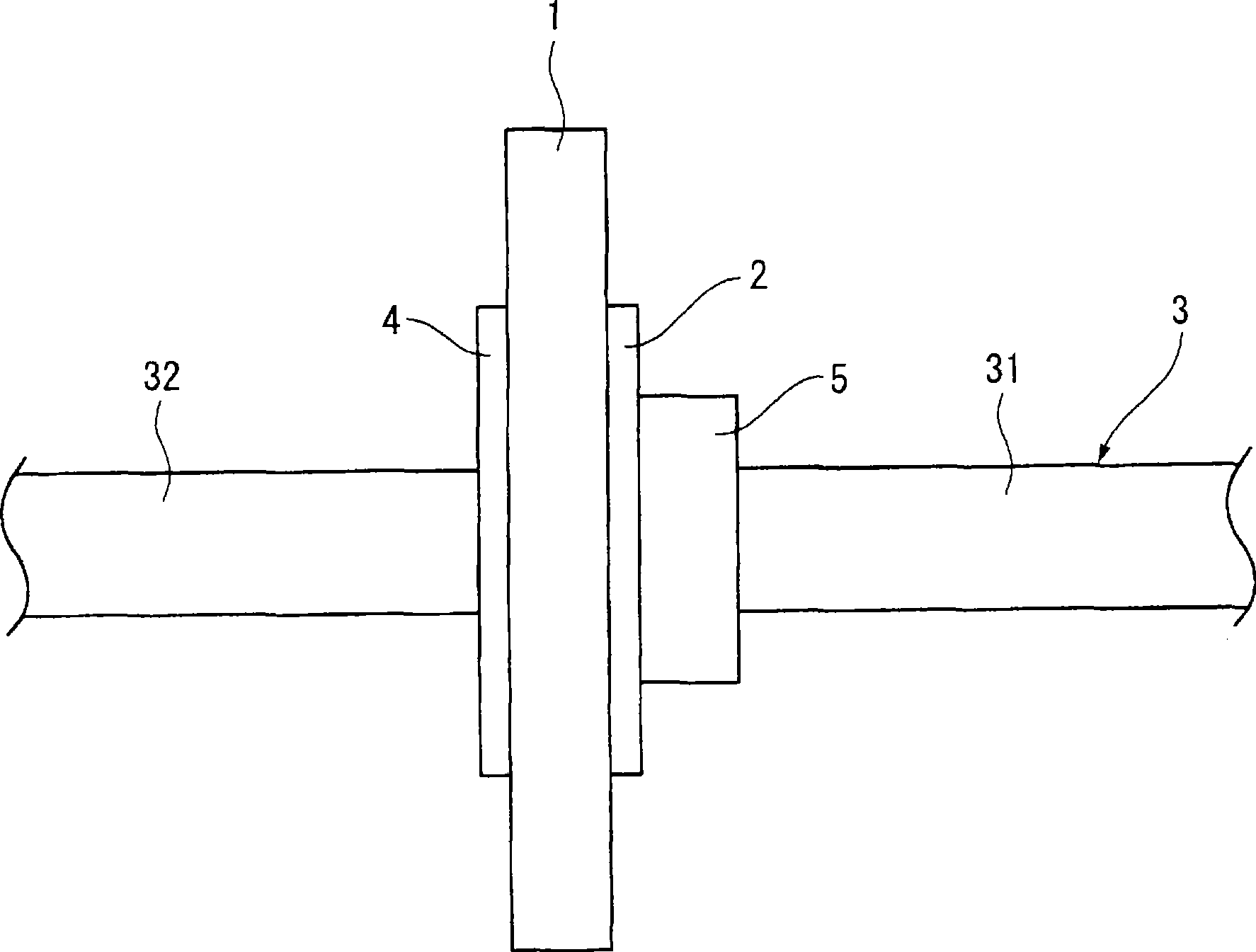

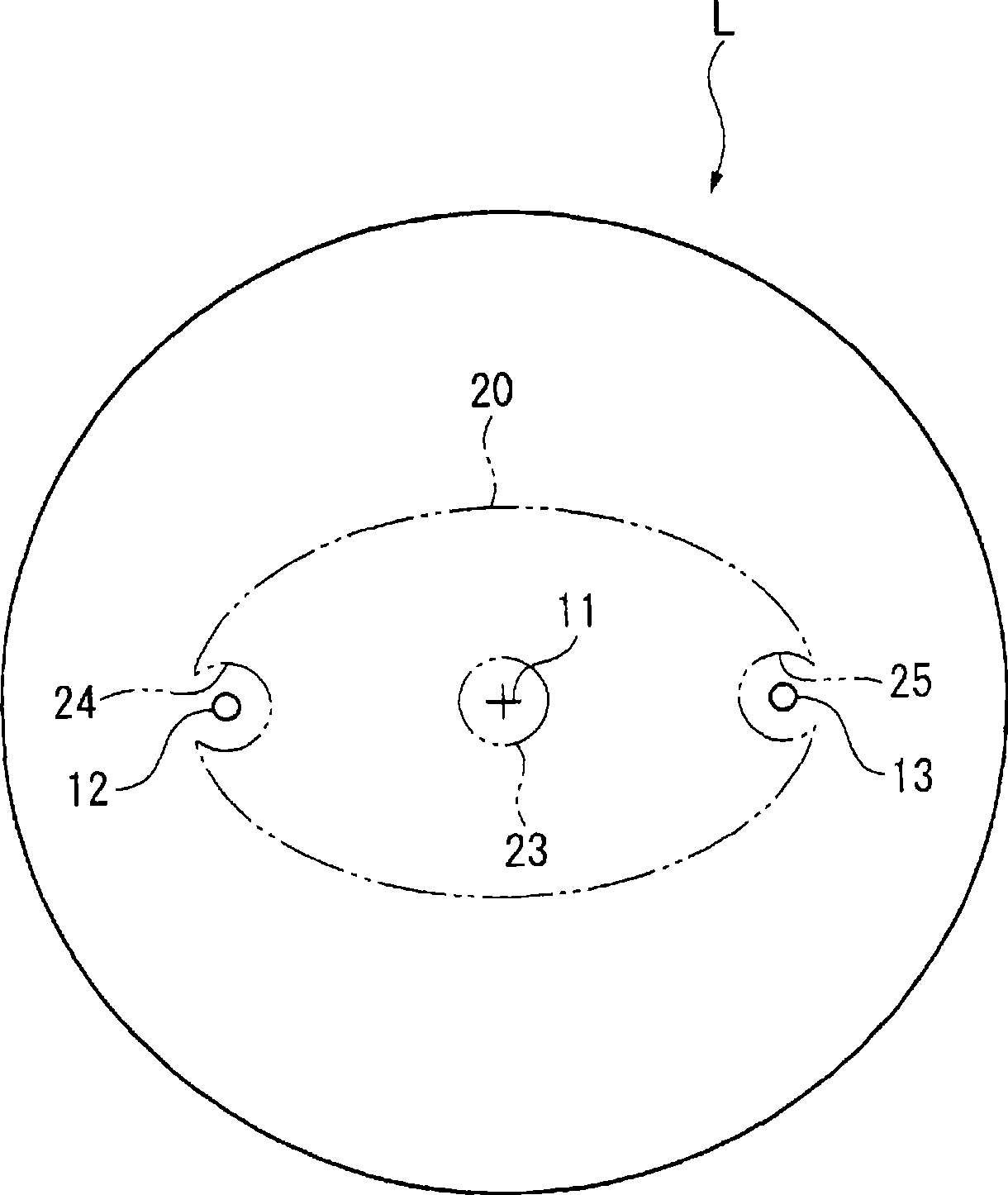

[0088] The following substances were blended at the following ratio: 100 parts by weight of acrylic adhesive SZ-2647 (Nippon Carbide Industry Co., Ltd. (Nippon Carbide Industry Co., Ltd.) Manufactured by Japan Ka-Bide Industry Co., Ltd.); as a small amount of acrylic adhesive SZ-2647 (for example, about 3 parts by weight relative to 100 parts by weight of a polymer mainly composed of (meth)acrylate) Compatible tack-imparting resin, 5 parts by weight of YS Polysta-T145 (trade name) (manufactured by Yasuhara Chemical Co., Ltd.); and 3 parts by weight of Coronet L45 as a solid content as a crosslinking agent (trade name) (manufactured by Nippon Polyurethane Industry Co., Ltd.), after mixing, it was diluted with toluene until the solid content became 20%, to prepare a first coating liquid. Apply the first coating liquid on the release surface of a 50 μm thick biaxially stretched polyester film that has been subjected to a silicone-based release treatment on one side, and dry it at...

Embodiment 2

[0093] The following substances are blended in the following proportions: 100 parts by weight of acrylic adhesive SZ-2647 as a solid content of a polymer mainly composed of (meth)acrylate; 7 parts by weight of KE311 (manufactured by Arakawa Chemical Industry Co., Ltd.) of an incompatible adhesion-imparting resin of SZ-2647; The first coating solution was prepared by diluting until the solid content became 20%. In addition, except for the first coating liquid, the double-sided adhesive sheet 2 for fixing spectacle lenses described in Example 1 has the same structure, and is obtained in the same manufacturing method as the first covering layer 2b1 and the second covering layer 2b1. Adhesive sheets 2 for fixing spectacle lenses having a structure of a release film are laminated on the layer 2b2, respectively.

Embodiment 3

[0095] The following substances were blended in the following proportions: as a polymer mainly composed of (meth)acrylate, 100 parts by weight of acrylic adhesive SZ-2647 as a solid content; Parts by weight of YS Polyster-T145; and 3 parts by weight of Coronet-L45 as a cross-linking agent, which is a solid content, after blending, diluted with toluene until the solid content becomes 20%, thereby making the first coating liquid. In addition, except for the first coating liquid, the double-sided adhesive sheet for fixing spectacle lenses described in Example 1 has the same structure, and the first coating layer 2b1 and the second coating layer 2b2 are obtained by the same manufacturing method. Adhesive sheets 2 for fixing spectacle lenses with a release film laminated on them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com