Grey cloth cleaning equipment

A technology for cleaning equipment and gray cloth, which is applied in the direction of removing liquid/gas/steam by suction, processing textile material drums, and processing textile material carriers, etc., which can solve the problem of not being able to effectively clean up and ensure smooth surface and affect the automatic cloth inspection machine Problems such as detection efficiency, false detection and missed detection of cloth inspection, etc., achieve the effect of simple structure, not easy to wrinkle, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

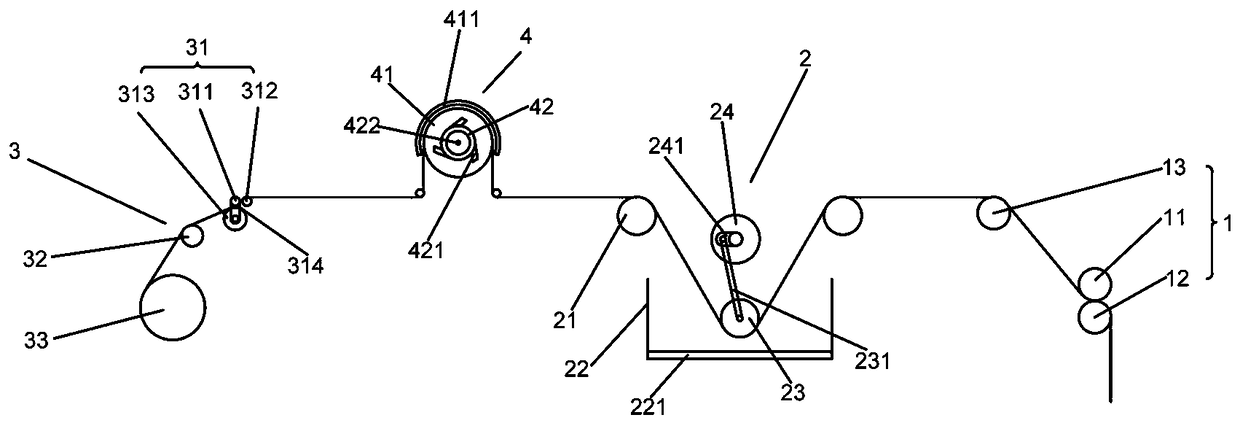

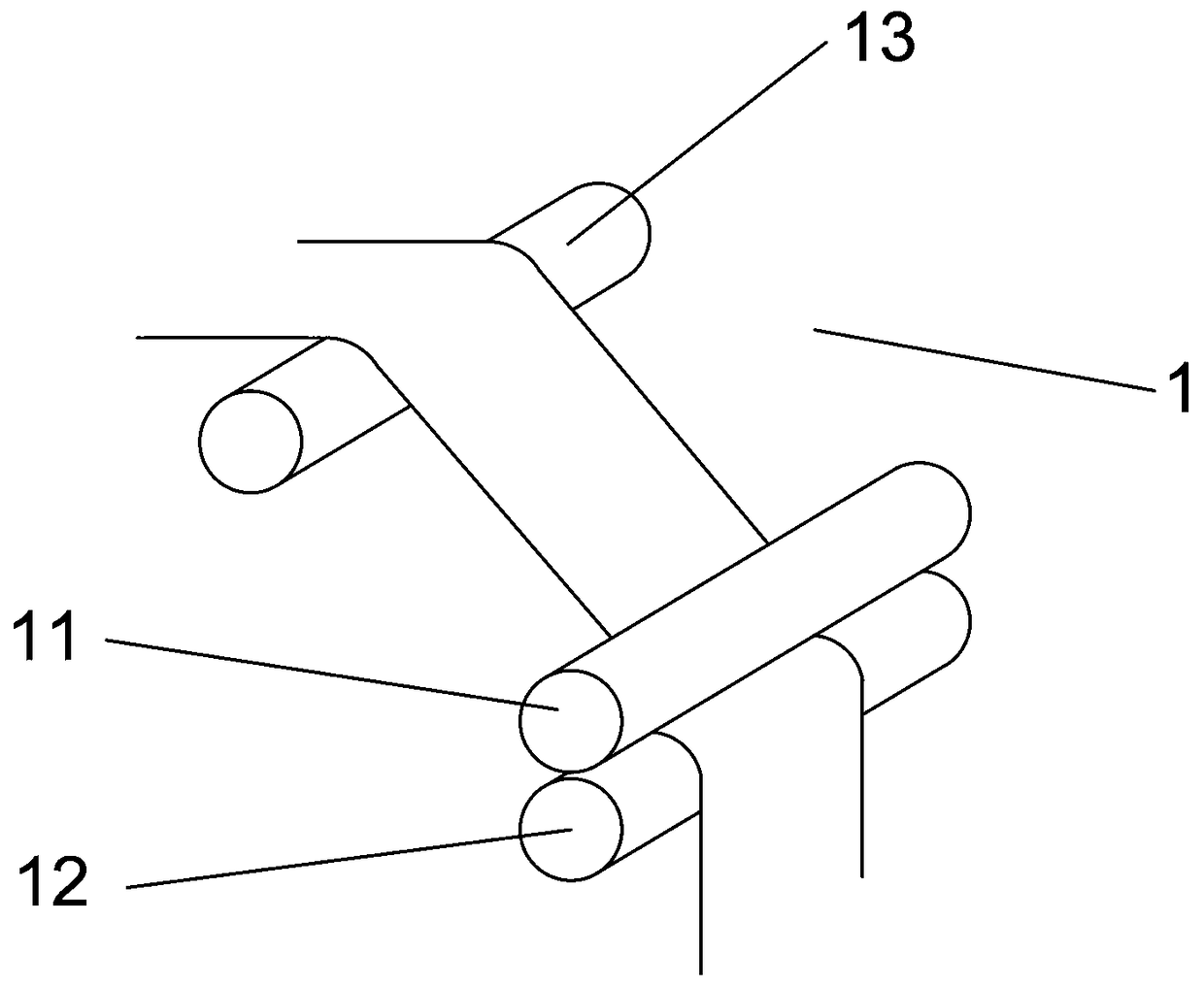

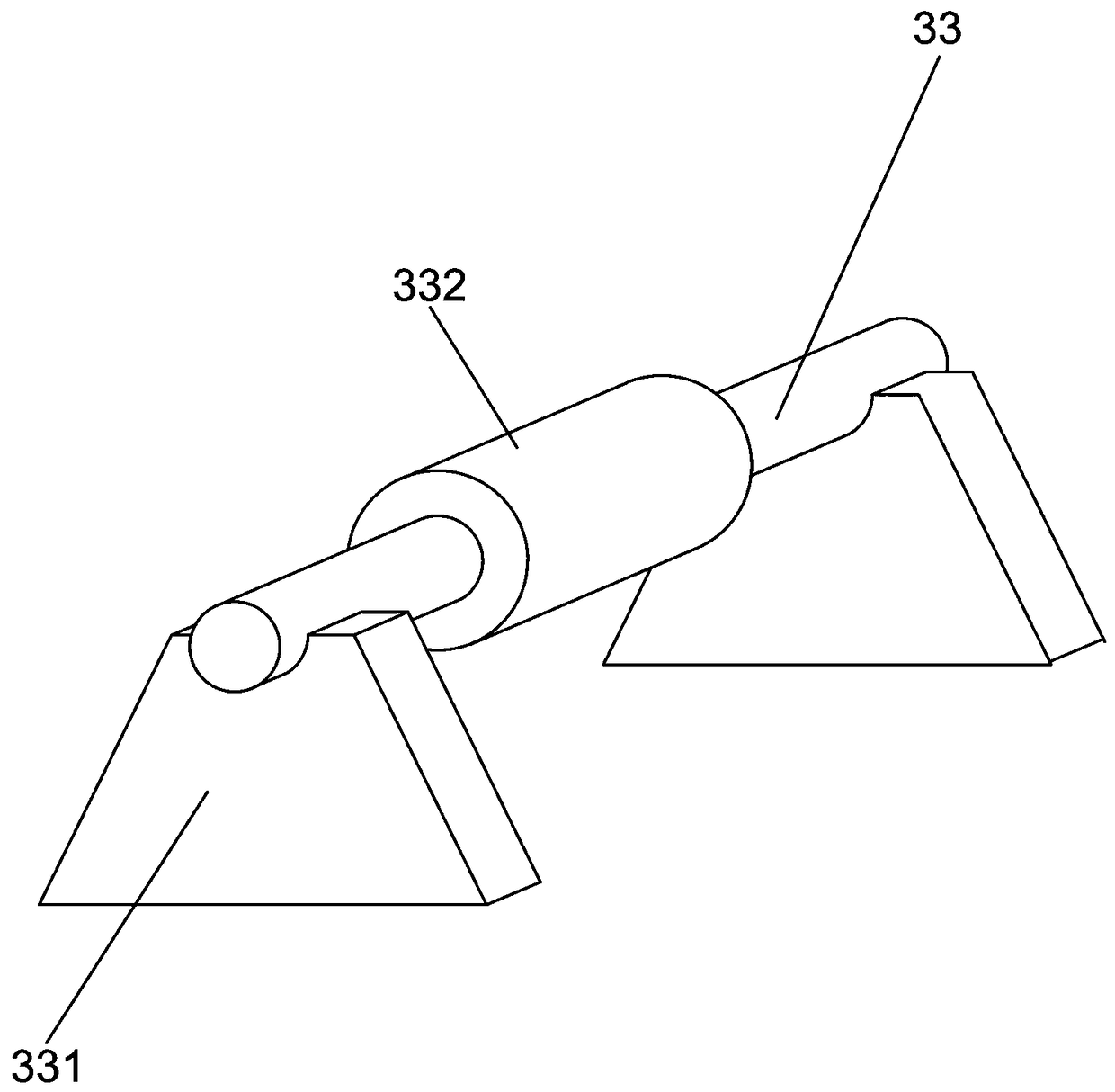

[0025] Embodiment one: if Figures 1 to 3 As shown, it is only one of the embodiments of the present invention, a kind of gray cloth cleaning equipment, including a cloth loading device 1, a cleaning device 2 and a winding device 3, and the cloth loading device 1 includes a first cloth upper roller 11, a second The upper cloth roller 12 and the upper cloth guide roller 13, the first upper cloth roller 11 and the second upper cloth roller 12 constitute an upper cloth roller group for guiding the cloth into the cleaning device 2, the cleaning Device 2 comprises at least one cleaning unit, and described cleaning unit comprises transmission roller 21, cleaning tank 22 and the cleaning roller 23 that is arranged in described cleaning tank 22, and described cleaning roller 23 is connected with driving machine 24, and described driving machine 24 A guide beam 241 is arranged on the rotating shaft of the guide beam 241, and the cleaning roller 23 is connected with the guide beam 241 t...

Embodiment 2

[0039] Embodiment two, still as Figures 1 to 3 As shown, it is still one of the embodiments of the present invention. In order to make a kind of gray cloth cleaning equipment of the present invention more practical and stable, and to take materials conveniently, the present invention also has the following designs:

[0040] A processing device 4 is arranged between the cleaning device 2 and the winding device 3. The processing device 4 includes a hollow roller 41 and a rotating block 42 arranged in the hollow roller 41. The hollow roller 41 is provided with a hole.

[0041] After the gray cloth is cleaned at the cleaning device 2, there may be some cleaning liquid on the gray cloth. These gray cloths with liquid are not suitable for winding, and they are easy to be polluted during winding, which is inconvenient for post-processing. Therefore, asynchronous processing is required before the gray cloth can be collected. roll.

[0042]When the gray cloth passes through the holl...

Embodiment 3

[0044] Embodiment three, still as Figures 1 to 3 As shown, it is still one of the embodiments of the present invention. In order to make a kind of gray cloth cleaning equipment of the present invention more practical and stable, and to take materials conveniently, the present invention also has the following designs:

[0045] First of all, the cleaning tank 22 is provided with a heating block 221, so the temperature of the cleaning solution in the cleaning tank 22 is higher, which is more convenient for cleaning the gray cloth, and the cleaning effect is better.

[0046] Then, the number of the conveying rollers 21 is at least one. At first each cleaning unit is provided with at least two conveying rollers 21 to prevent the gray cloth from being scratched when passing through the cleaning tank 22. Secondly, when there are multiple cleaning units, there should be as many The group of transmission rollers 21 work together, and the gray cloth transmission is more stable.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com