Vacuum presser

A press and vacuum technology, applied in filtration separation, separation methods, moving filter element filters, etc., can solve the problems of unsatisfactory dehydration effect and dehydration effect, and achieve the effect of improving dehydration efficiency and wide practical range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

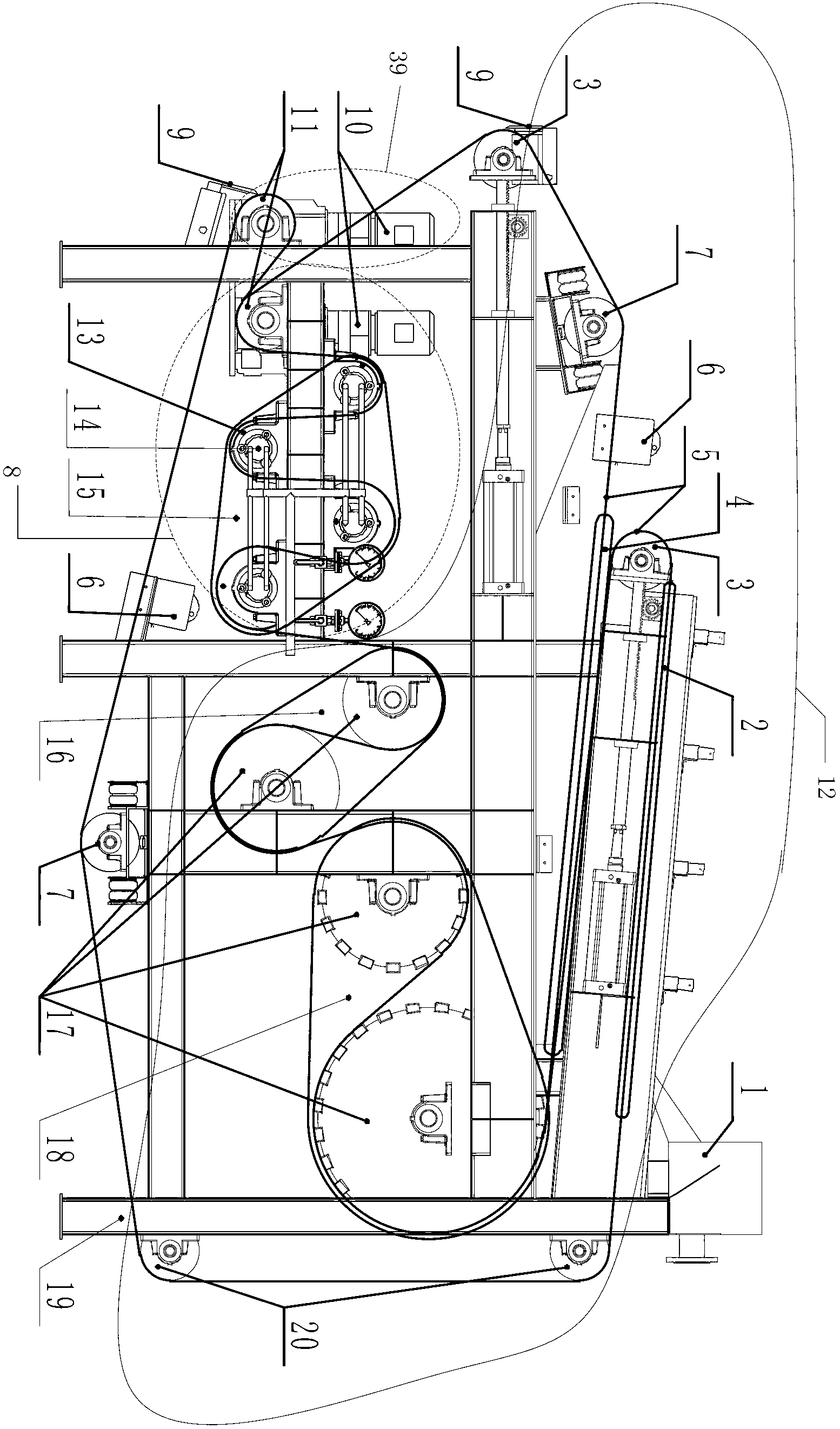

[0043] A vacuum press such as figure 1 As shown, it includes a distributor 1, a pressing system 12, a discharge device 9, a vacuum system 8, a drive system 39, two filter cloths 5 and a frame 19;

[0044] The pressing system 12 is arranged on the top and the middle and lower part of the right side of the frame 19, the distributor 1 is arranged on the top right side of the pressing system 12, and the unloading device 9 is arranged on the top left side of the pressing system 12 , the vacuum system 8 is arranged on the middle and lower part of the left side of the frame 19, the drive system 39 is arranged on the frame 19 below the unloading device 9, and the two filter cloths 5 are respectively wound into two closed Loop, one is from the top of the right side of the pressing system 12, the middle of the right side of the pressing system 12, the vacuum system 8, the bottom of the pressing system 12, and the top of the right side of the pressing system 12 is a closed loop, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com