Flexible heat conduction paint for automobile heat insulation

A heat-conducting coating, flexible technology, applied in the direction of radiation-absorbing coatings, coatings, etc., can solve the problems of imperfect heat-insulating sunshade pads, the effect of heat insulation needs to be improved, and ignore the heat absorption of the body, so as to achieve excellent comprehensive performance and consolidate continuous Sexuality, enhance the effect of anti-destructive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

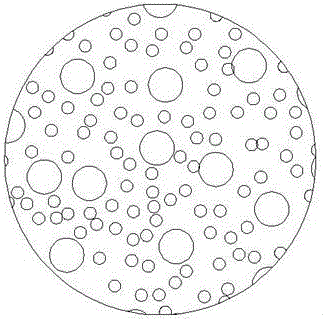

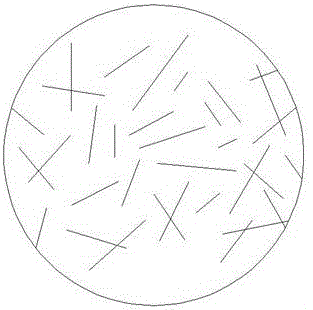

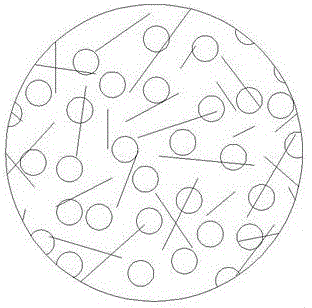

[0030] A flexible thermal conductive paint, which is composed of the following raw materials in parts by weight: 34 parts of silicone modified acrylic resin, 7 parts of expanded graphite, 12 parts of thermally conductive fiber filaments, 6 parts of mica powder, 9 parts of butyl acetate, gas phase 0.5 parts of silicon dioxide, 12 parts of diacetone alcohol, 1 part of dispersant and 0.5 part of leveling agent, 5 parts of transition metal composite oxide powder.

[0031] In the above formula, the silicone-modified acrylic resin is copolymerized with vinyl organosiloxane monomers and acrylate monomers. It has excellent high temperature resistance, weather resistance, good flexibility, and strong adhesion. Using this as the base material of the flexible thermal conductive paint can make the base material have good thermal conductivity, flexibility and stability. In this embodiment, a silicone acrylic resin containing hydroxyl groups is selected, with a solid content of 50% and a silico...

Embodiment 2

[0046] The second embodiment is the same as the first embodiment, but the difference is that the flexible thermal conductive coating is composed of the following raw materials in parts by weight: 38 parts of silicone modified acrylic resin, 8 parts of expanded graphite, 14 parts of thermally conductive fiber filaments, and 6 parts of mica powder. Parts, 6 parts of transition metal composite oxide powder, 10 parts of butyl acetate, 0.7 parts of fumed silica, 15 parts of diacetone alcohol, 1.3 parts of dispersant and 0.7 parts of leveling agent.

Embodiment 3

[0048] The third embodiment is the same as the first and second embodiments. The difference is that the flexible thermally conductive coating is composed of the following raw materials in parts by weight: 36 parts of silicone modified acrylic resin, 7 parts of expanded graphite, and 13 parts of thermally conductive fiber filaments. , 7 parts of mica powder, 6 parts of transition metal composite oxide powder, 10 parts of butyl acetate, 0.5 parts of fumed silica, 12 parts of diacetone alcohol, 1.2 parts of dispersant and 0.6 parts of leveling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com