Patents

Literature

55results about How to "Won't loosen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

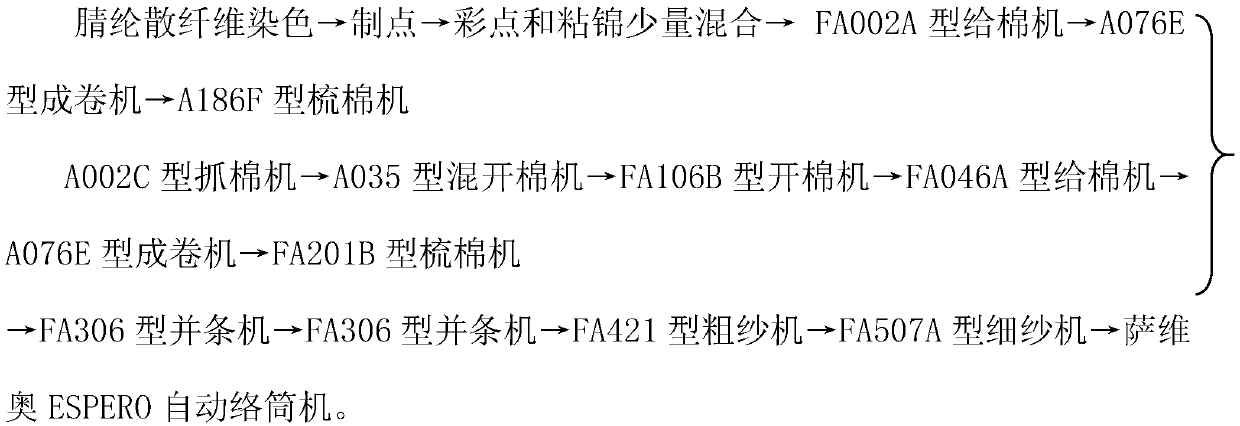

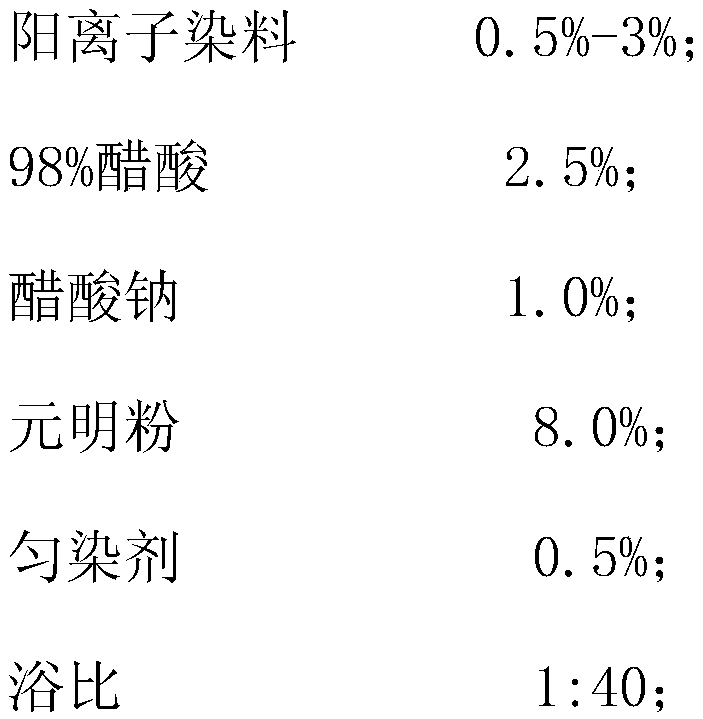

Method for producing PBT (Polythylene Terephthalate) color point core spun yarns

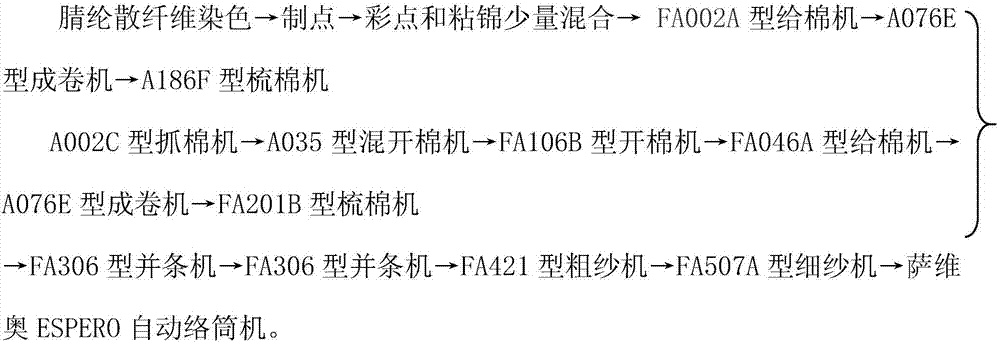

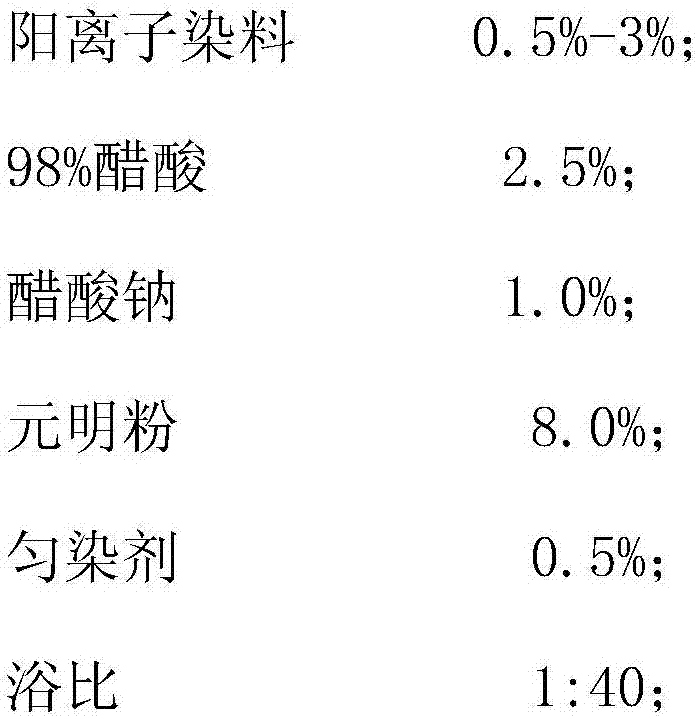

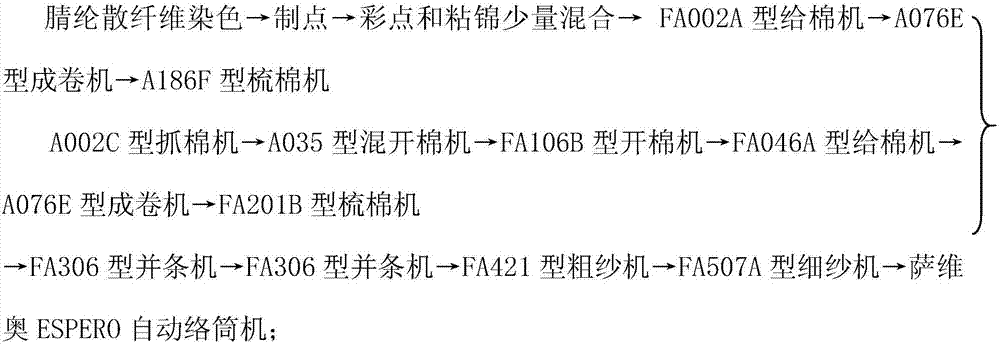

The invention discloses a method for producing PBT (Polythylene Terephthalate) color point core spun yarns. The method comprises the following steps: selecting yarn materials; performing process procedures of the PBT color point core spun yarns; implementing the specific production process. According to the method disclosed by the invention, acrylic fibers serve as raw materials of the points, the color point has rich colors, the color is bright, the stereoscopic impression is excellent, and the price can be saved by 20000 Yuan per tonnage compared with that of common chinlon points. A waterproof agent is diluted according to a ratio and uniformly sprayed onto the points, and the points are dried and roasted at a high temperature, so that the colored point achieves a water-repellent effect, the colored points are prevented from being loosened in the subsequent processing procedure, staining of dyes on the color points is reduced in the dyeing process, the shape and brightness of the color points can be guaranteed, and the quality of the yarns is improved. The PBT serves as the core yarn, viscose cotton serves as an outer packaging material, and the problems that the spandex core-spun yarns are poor in acid resistance and chlorine resistance and have non-ideal dyeing effect are solved. The color point core spun yarns produced by the method disclosed by the invention are excellent in fluffiness and crimpiness and high in elasticity and shape stability and have hand feel of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

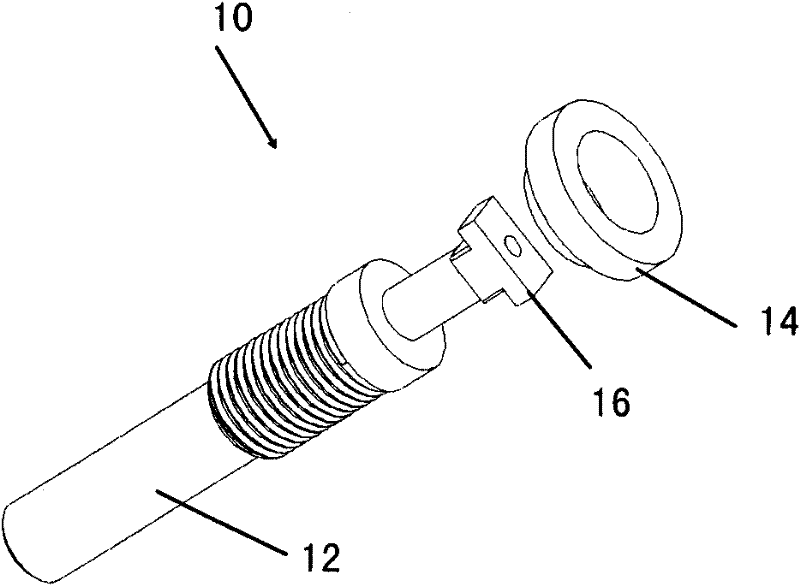

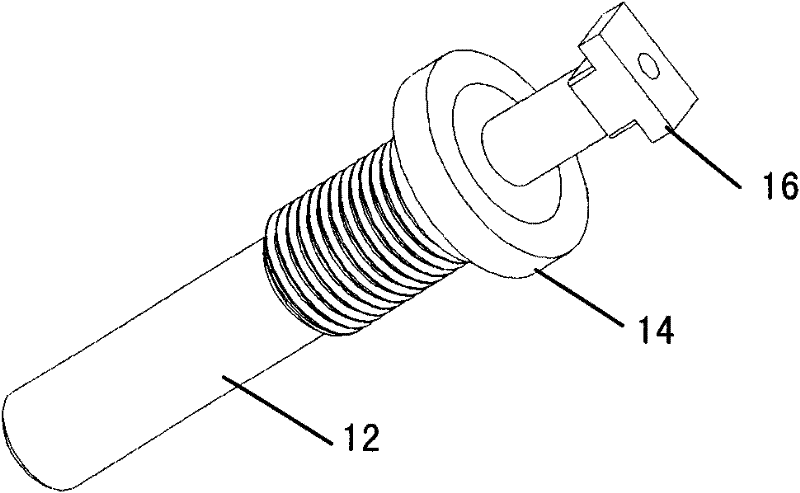

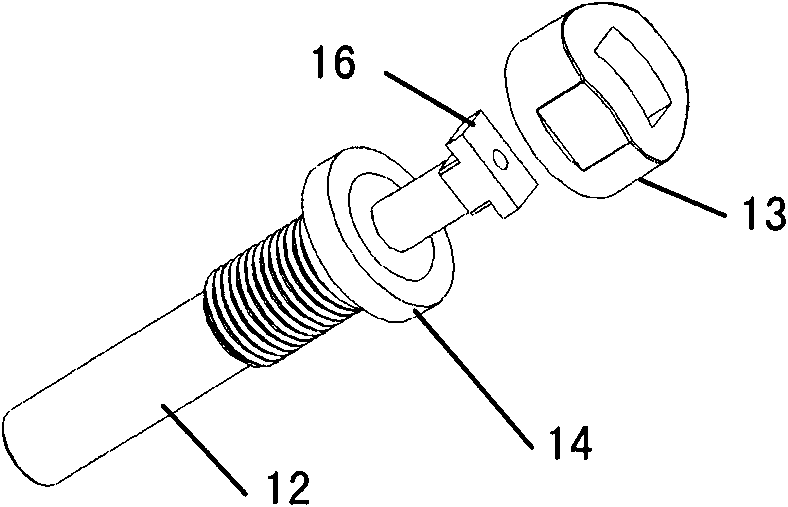

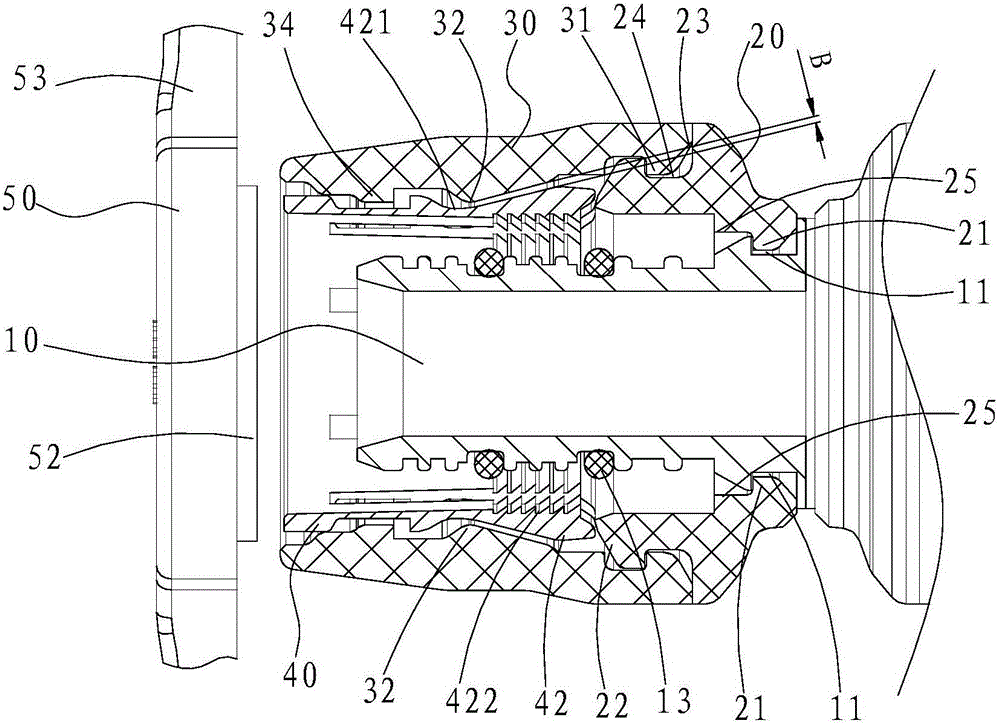

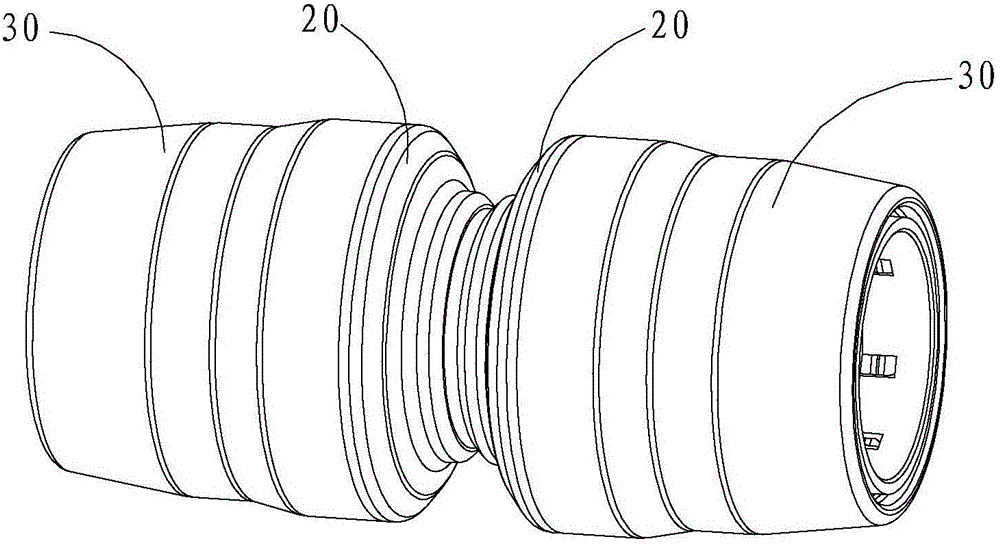

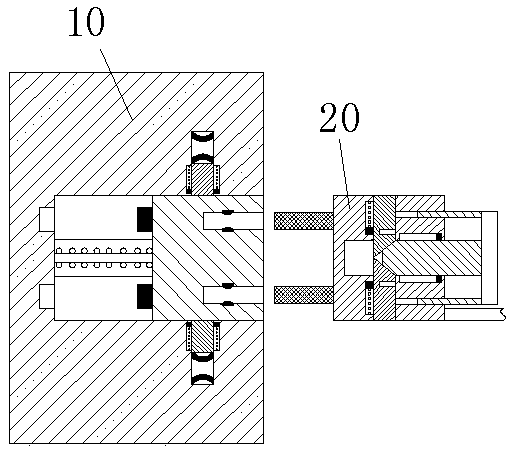

Angle adjustable valve

ActiveCN102259566AGuaranteed stabilityWon't loosenTyre measurementsTyre-inflating valvesEngineeringAtmospheric pressure

The invention discloses an angle adjustable valve which is arranged on a wheel rim of the automobiles, the wheel rim possesses a wheel rim surface and an inclined surface. The valve comprises a nozzle rod, a nozzle rod cover, nuts and a sensor. The nozzle rod is provided with a screw thread segment, and the end part of the nozzle rod is provided with a stop part. The nozzle rod cover is sleeved on the nozzle rod. The sensor is provided on the wheel rim surface of the wheel rim and used for detecting and emitting the air pressure of the tires. The sensor is provided with a shell, a connecting slot is provided on the shell, the connecting slot is provided with a first side and a second side which is opposite to the first side, wherein the first side forms a first curved surface. One end of the nozzle rod is connected with the shell and extended out of the tire from a rim hole of the wheel rim. The stop part of the nozzle rod passes through the connecting slot and pressed on the first curved surface by rotating at an angle for stopping the separation of the nozzle rod and the shell. When the nuts is being screwed in the screw thread segment of the nozzle rod, the end face of the stop part slides towards the direction of the compacted shell on the first curved surface until the angle of the nozzle rod matches with the angle of the inclined surface of the wheel rim.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP

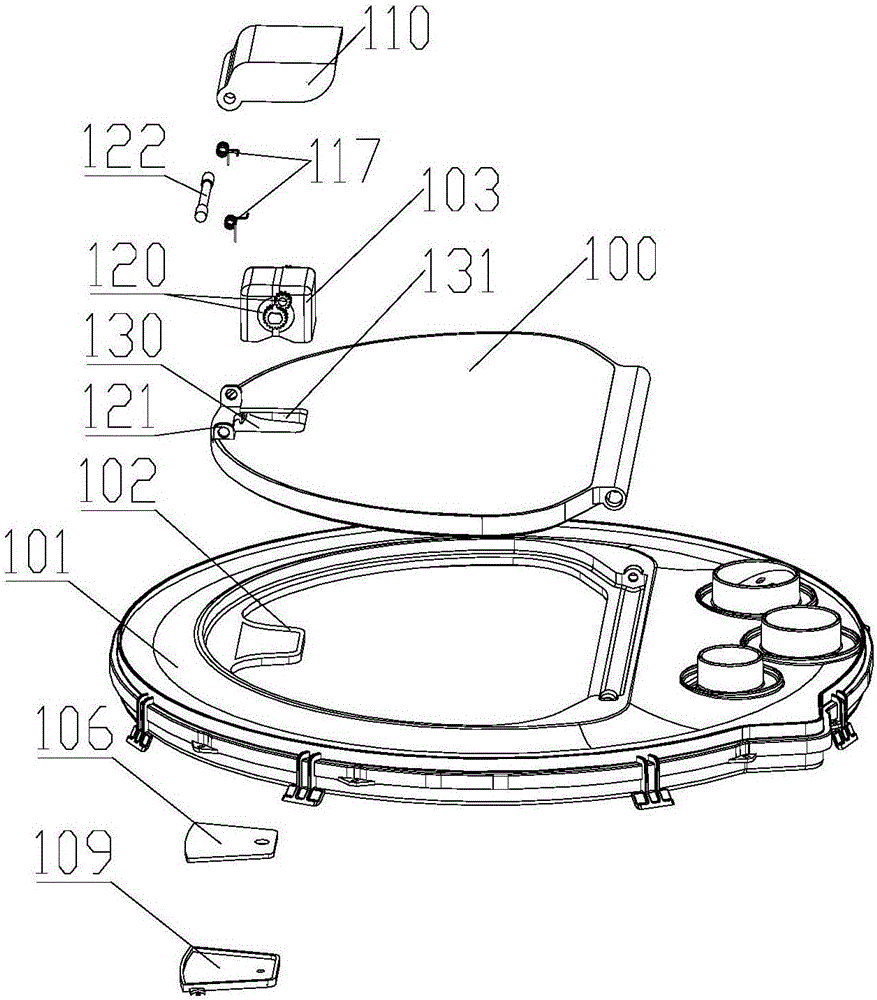

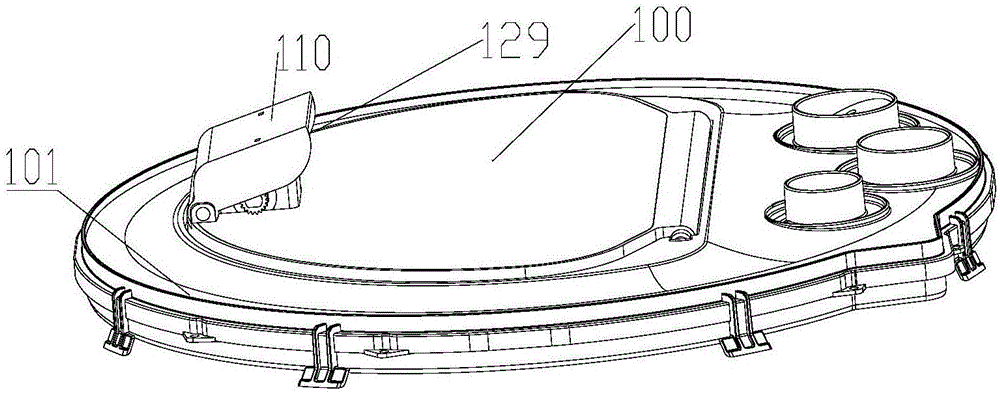

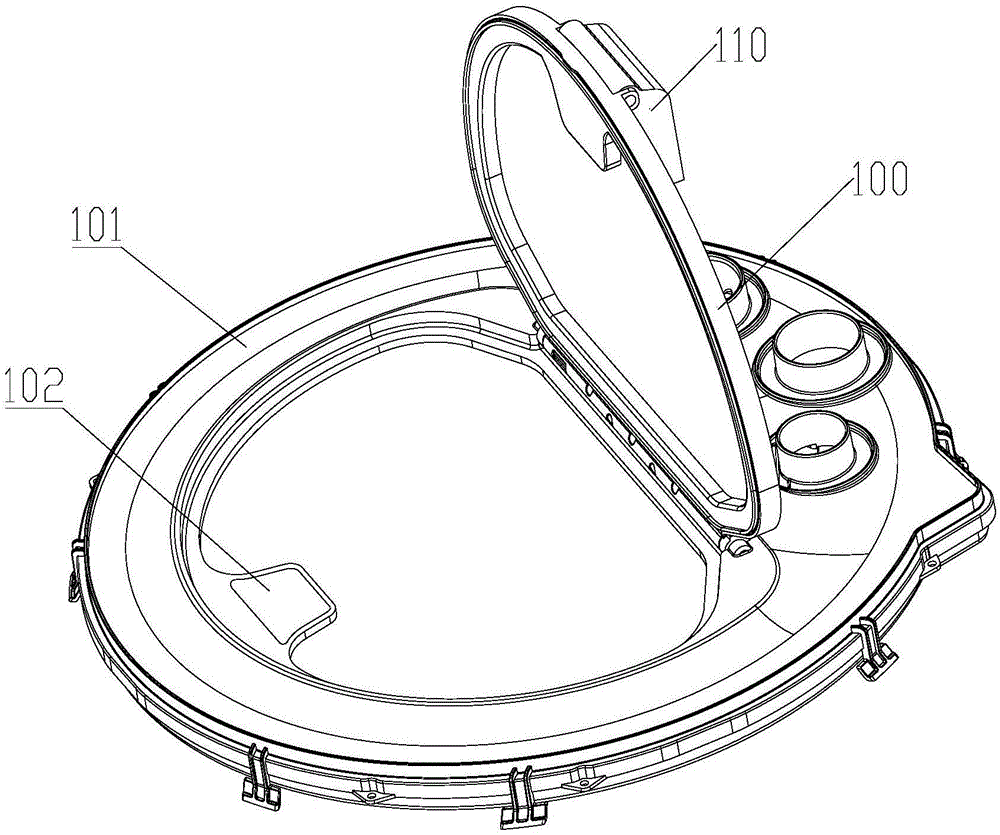

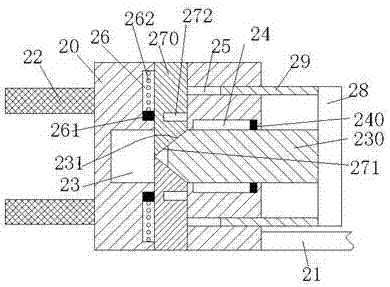

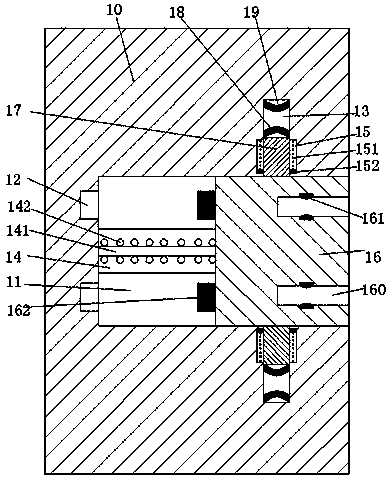

Washing machine cover body opening-closing structure and washing machine

ActiveCN107523970AEffortless adjustmentEffort-saving adjustment deviceOther washing machinesTextiles and paperEngineeringMagnet

The invention belongs to the field of washing machines and particularly relates to a washing machine cover body opening-closing structure and a washing machine. The washing machine cover body opening-closing structure comprises a base and a cover body covering the base and also comprises a housing arranged on the cover body, a permanent magnet and an adjusting device for adjusting the direction of the permanent magnet, wherein the housing comprises a magnetism isolating body and a magnetism conducting body, the magnetism conducting body and the magnetism isolating body jointly define a closed ring, the permanent magnet is arranged in the closed ring and rotates with the axis of the closed ring as a rotary axis, poles N and S of the permanent magnet face the closed ring, a magnetic body is arranged on the base, the adjusting device adjusts the direction of the permanent magnet to achieve attraction / separation of the housing and the magnetic body, and the cover body and the base are driven to close / open. The washing machine cover body opening-closing structure has the advantages that the opposite positions of the permanent magnet and the magnetism isolating body and the magnetism conducting body are adjusted by arranging the adjusting device and are more convenient to adjust, the problem is solved that the attraction position is difficult to open due to the structure, more effort is saved during cover body opening, the cover body is not likely to loosen after being closed, and noise is decreased.

Owner:FOSHAN SHUNDE HAIER ELECTRIC APPLIANCES CO LTD +1

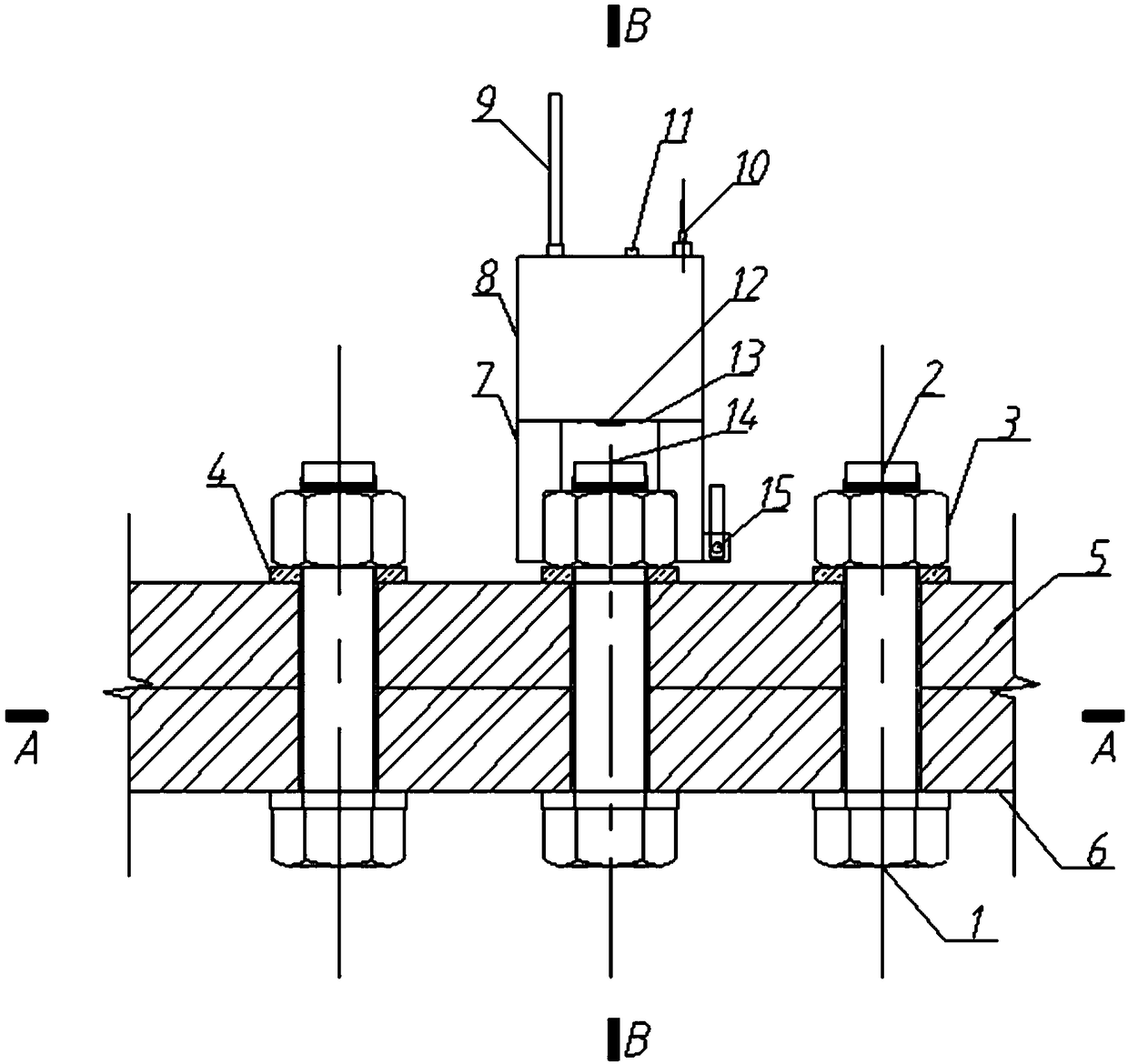

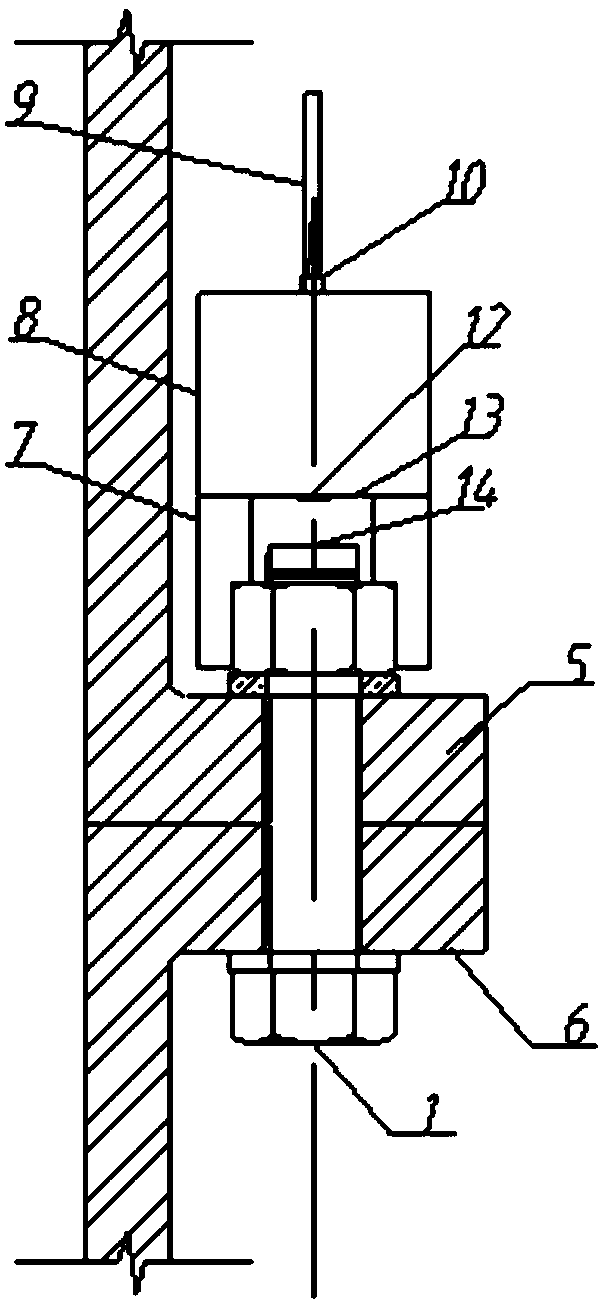

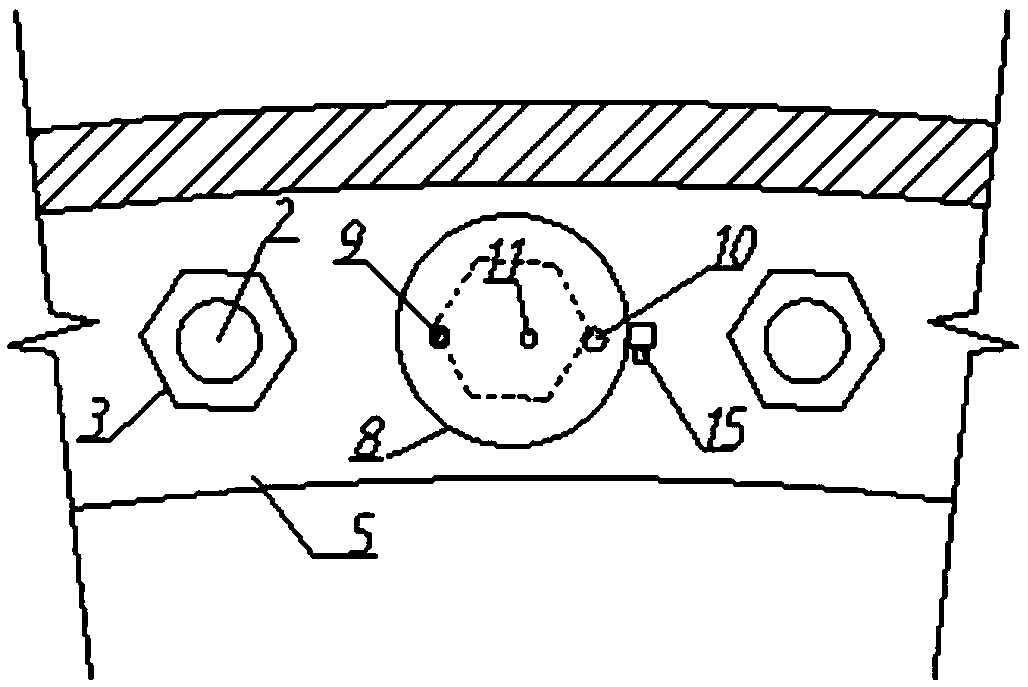

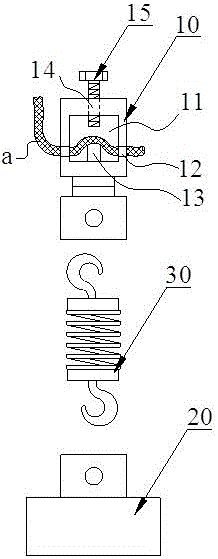

Bolt looseness-prevention early-warning monitoring device

The invention relates to a bolt looseness-prevention early-warning monitoring device. The device comprises a sticker and a photographic communication module; the sticker is stuck on the threaded end face of a bolt to be detected, and has a photographic measurement mark; the photographic communication module is used for detecting sticker information, displacement and rotation angle; the photographic communication module comprises an upper enclosure and a lower enclosure, which are connected with each other; the lower enclosure is arranged on the bolt to be detected in a buckling manner; a micro-lens and a light supplementary lamp just aligned to the sticker are arranged on the lower enclosure; a processing chip, a signal antenna and a wireless communication module are arranged on the upperenclosure; and the processing chip is separately connected with the signal antenna, the wireless communication module, the micro-lens and the light supplementary lamp. Compared with the prior art, thebolt looseness-prevention early-warning monitoring device in the invention has the advantages of being simple and convenient to install, firm, reliable, high in stability, accuracy, timeliness and economy, etc.

Owner:上海矩尺土木科技有限公司 +1

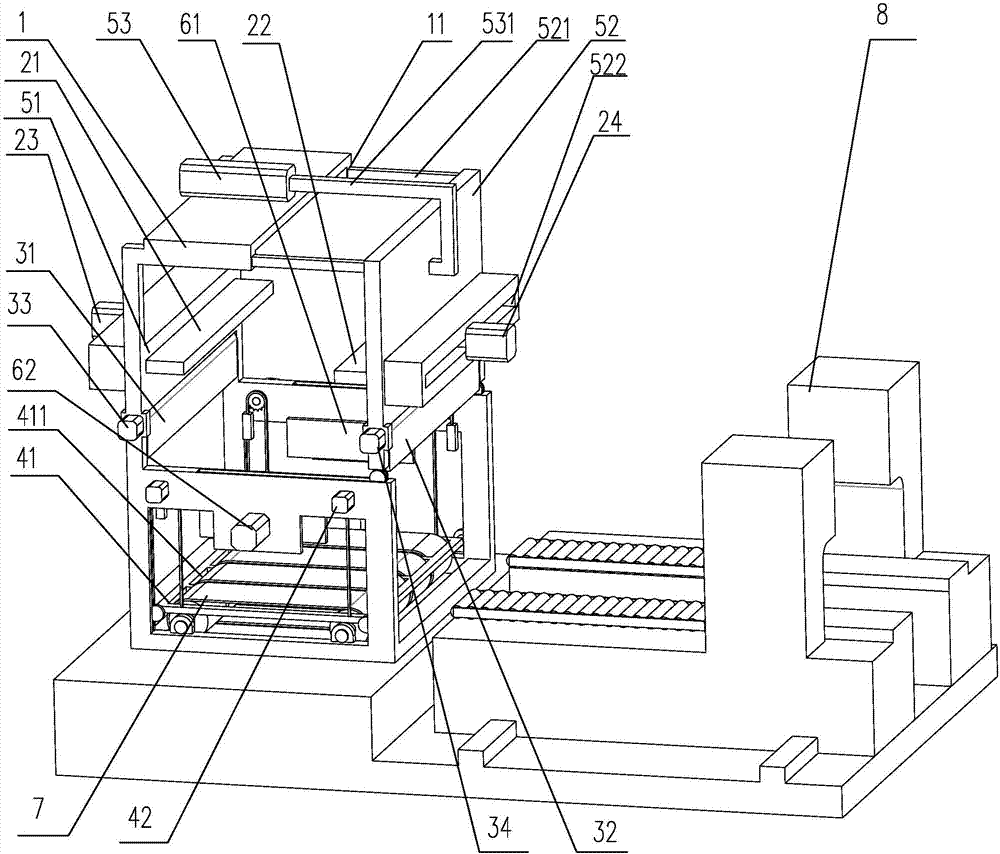

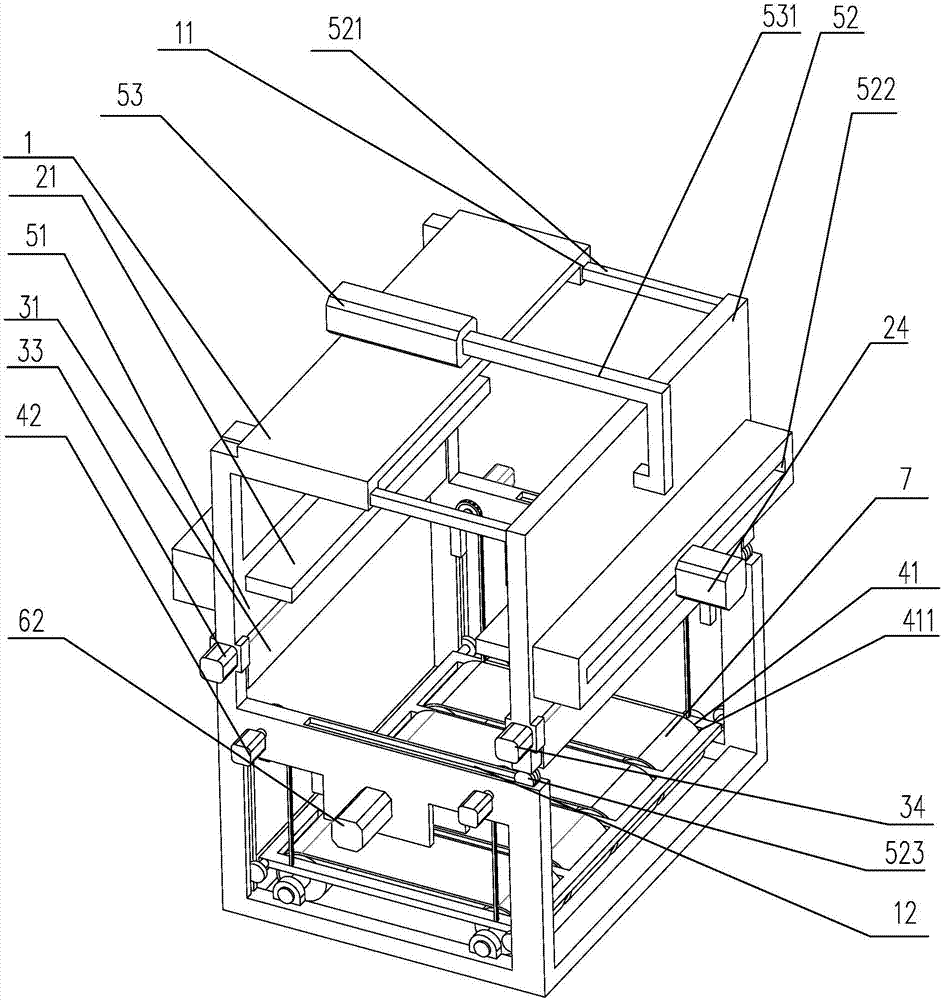

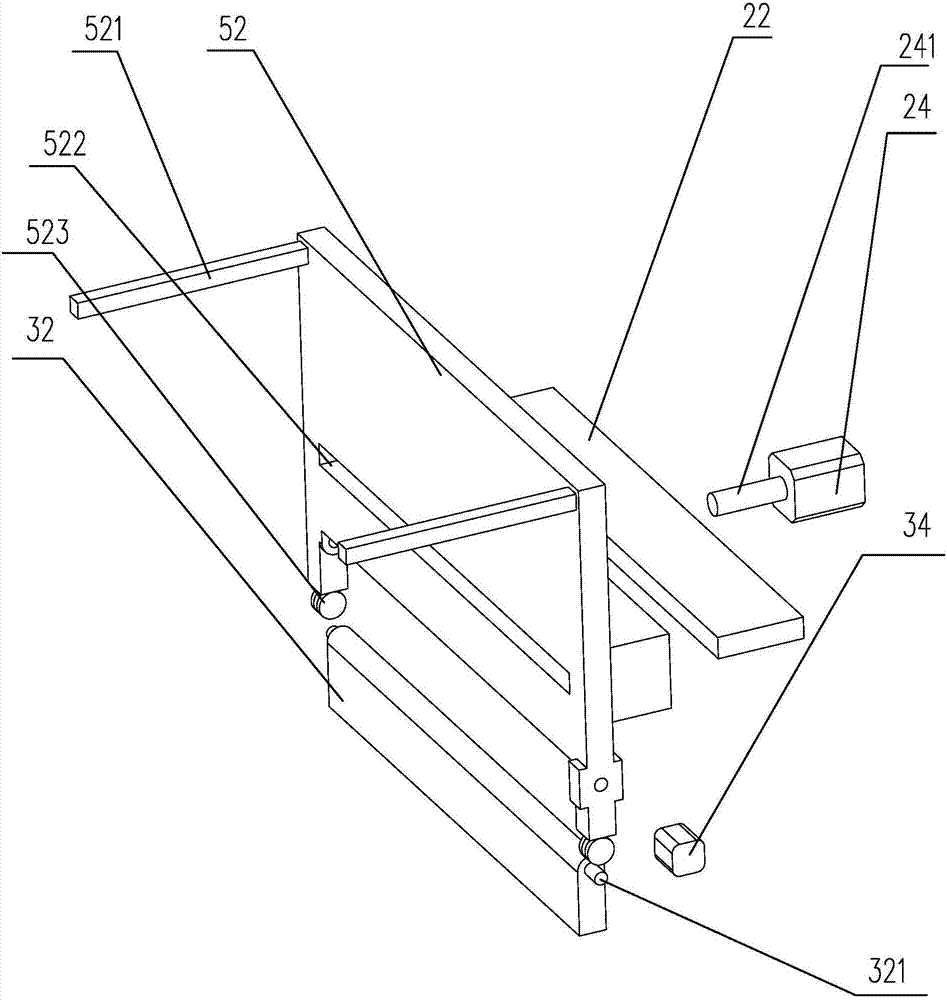

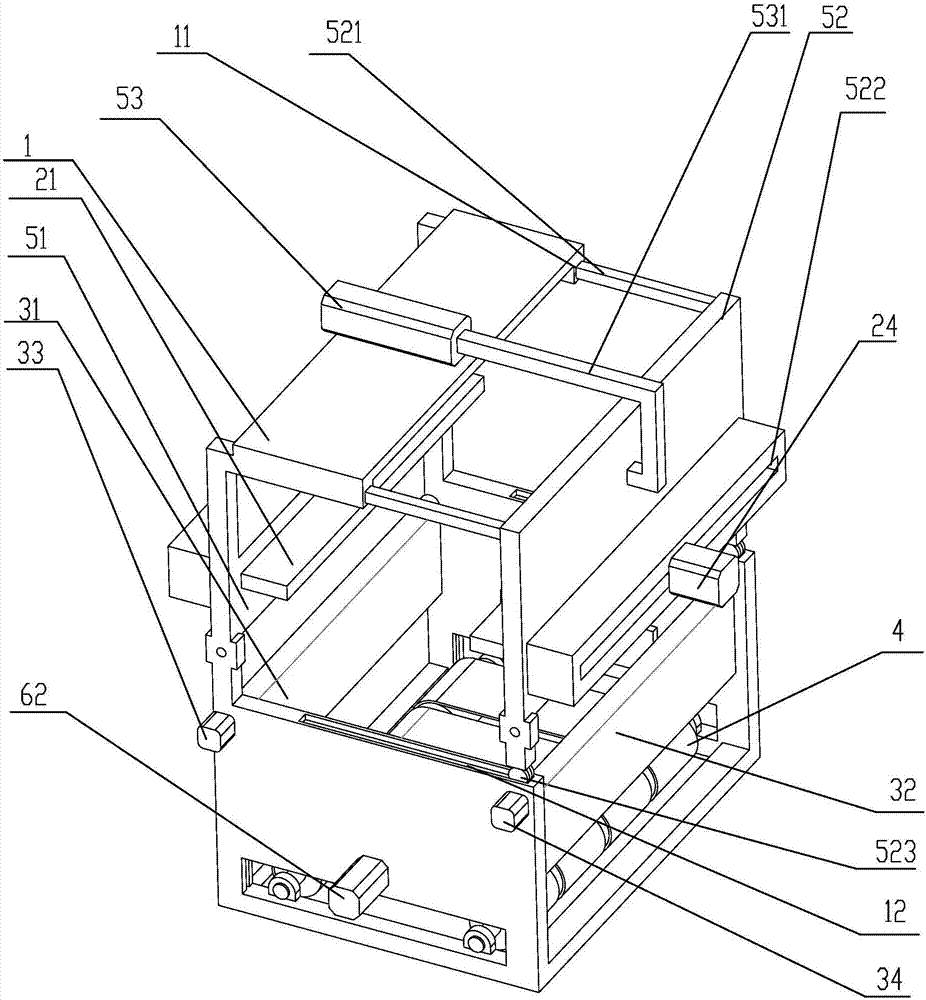

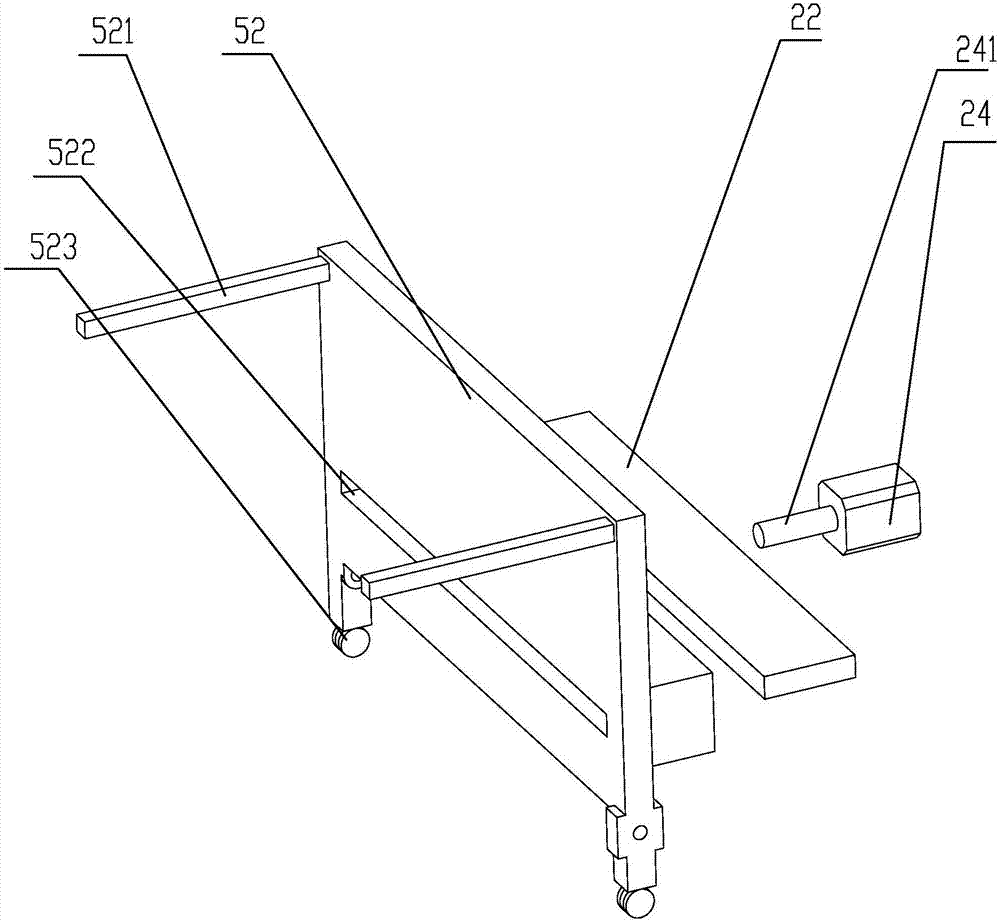

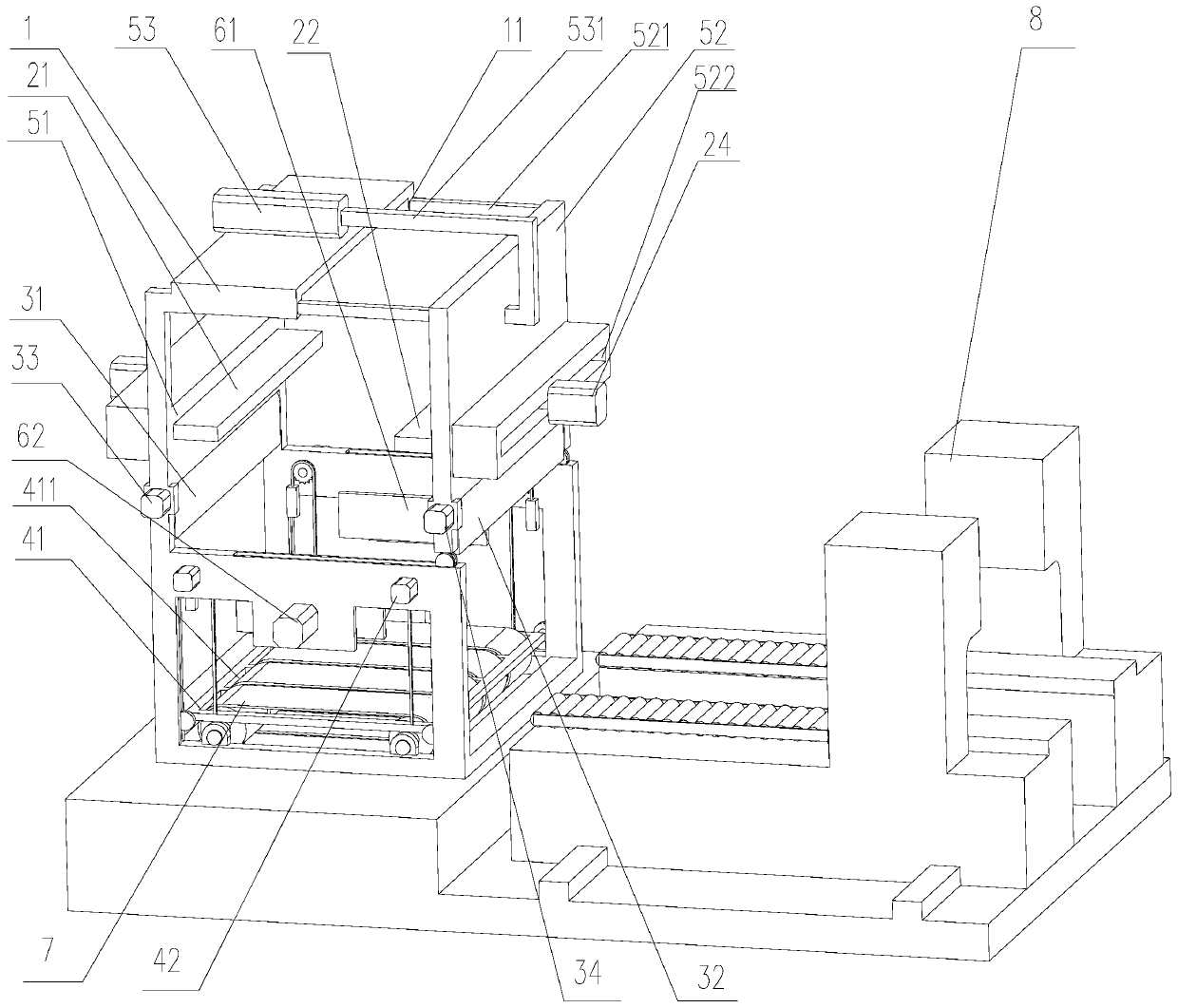

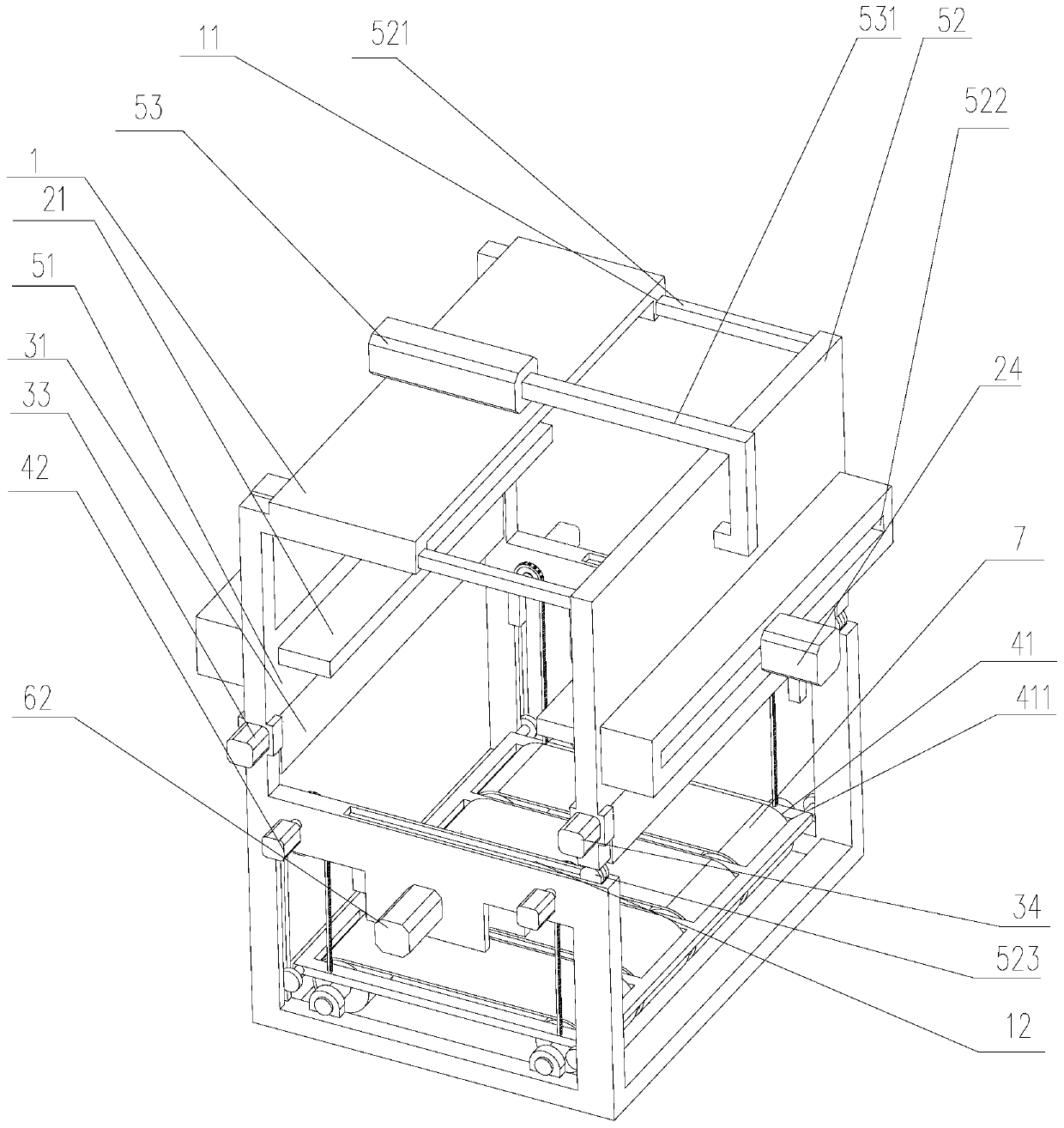

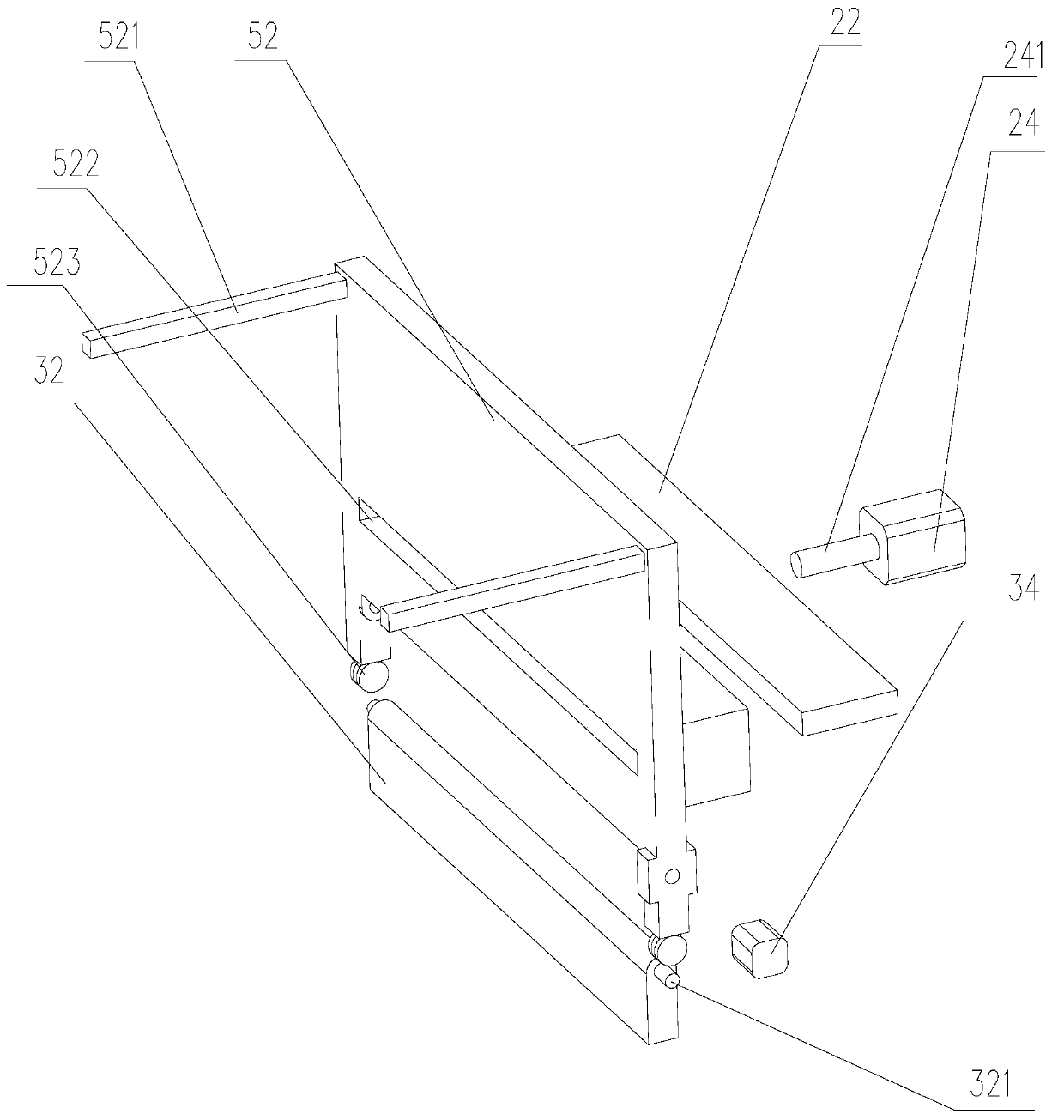

Paperboard stacking and packaging device

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

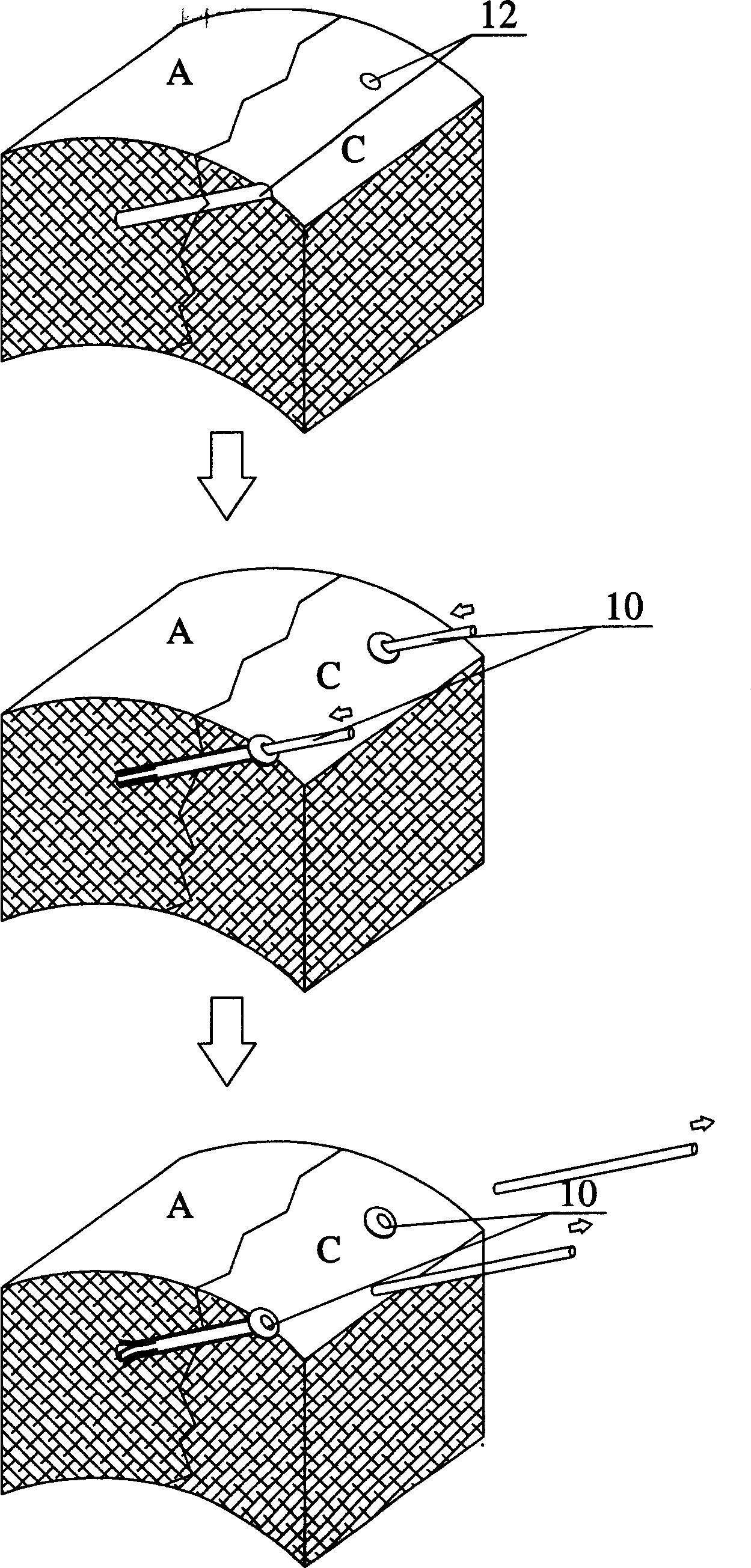

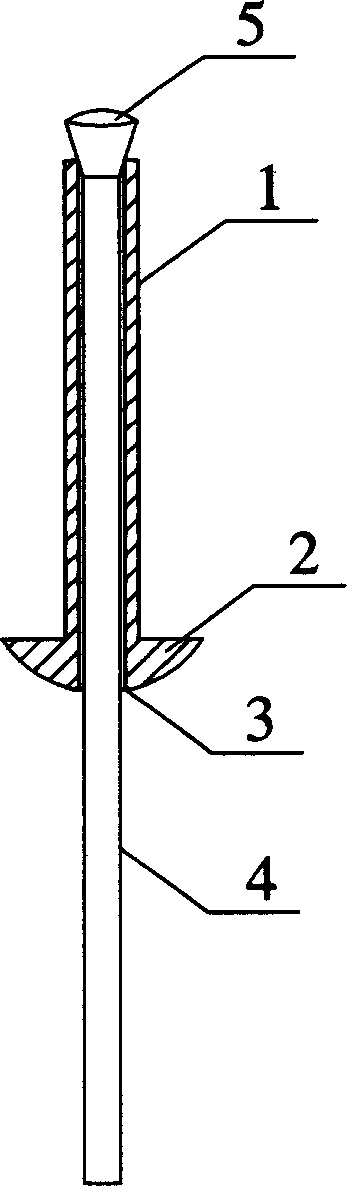

Skeleton fixation method for medical use, and its fixation nails

ActiveCN1785131ASmall lateral pressureAvoid damageInternal osteosythesisFastenersFixation methodUltimate tensile strength

A method for fixing bone in orthopaedic repair operation includes such steps as primary location of fractured bone at the fixing position, installing the fixing nails, deforming the end of said nails for fixing it at the internal side of bone, and using the nail cap to connect the bone to the fixing plate. Said nail features that the deformation at its end is controllable.

Owner:梁巍

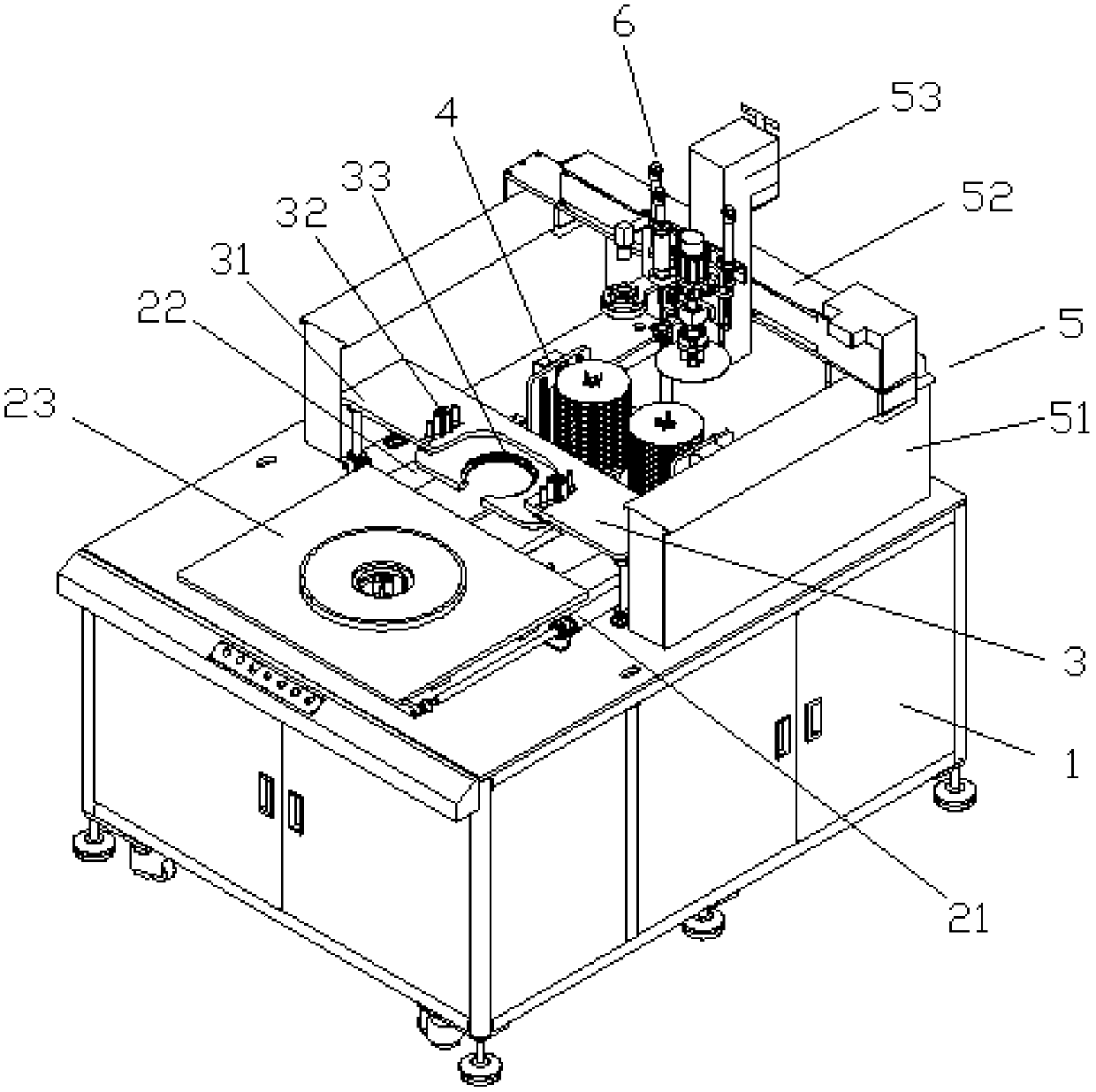

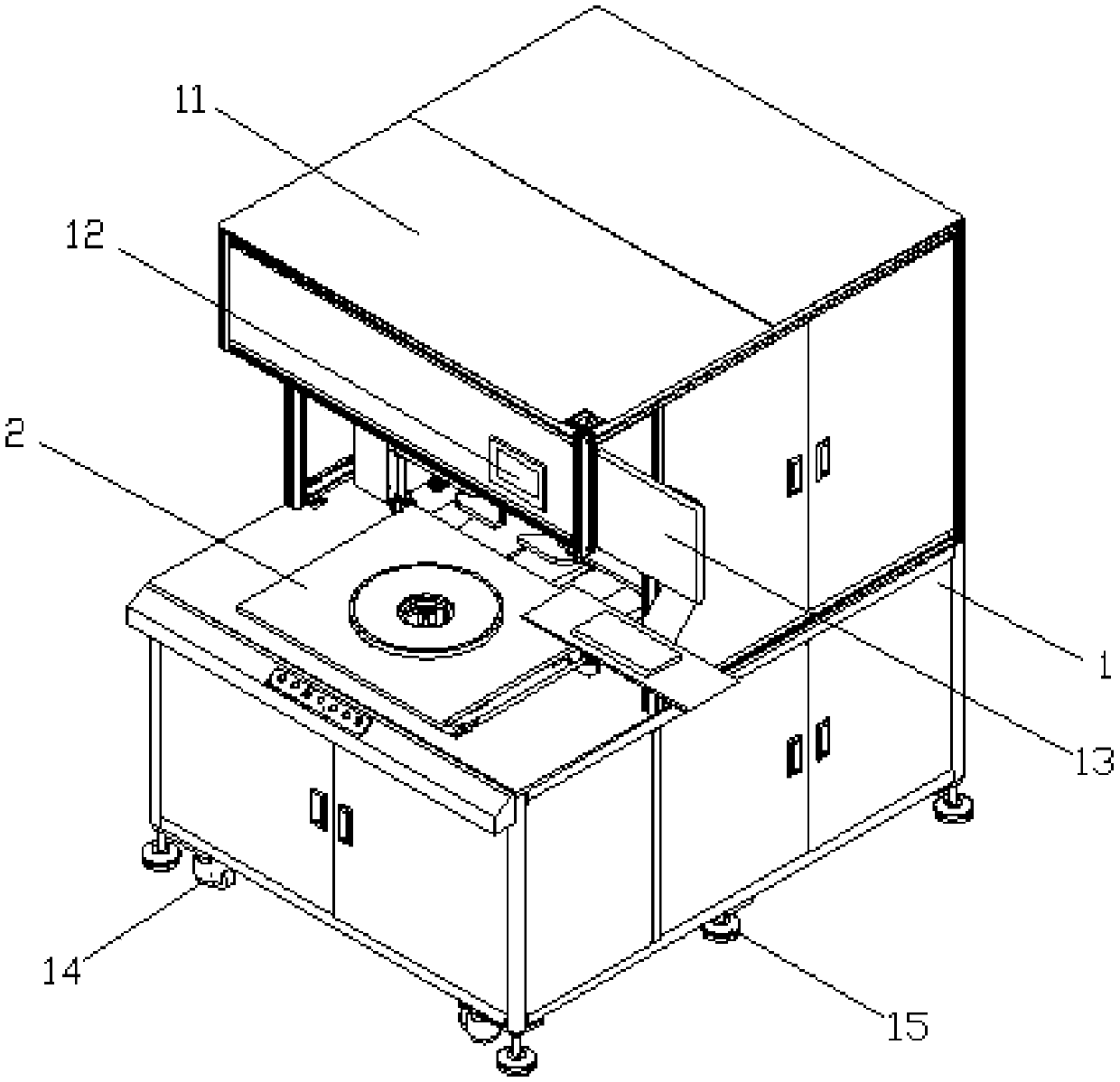

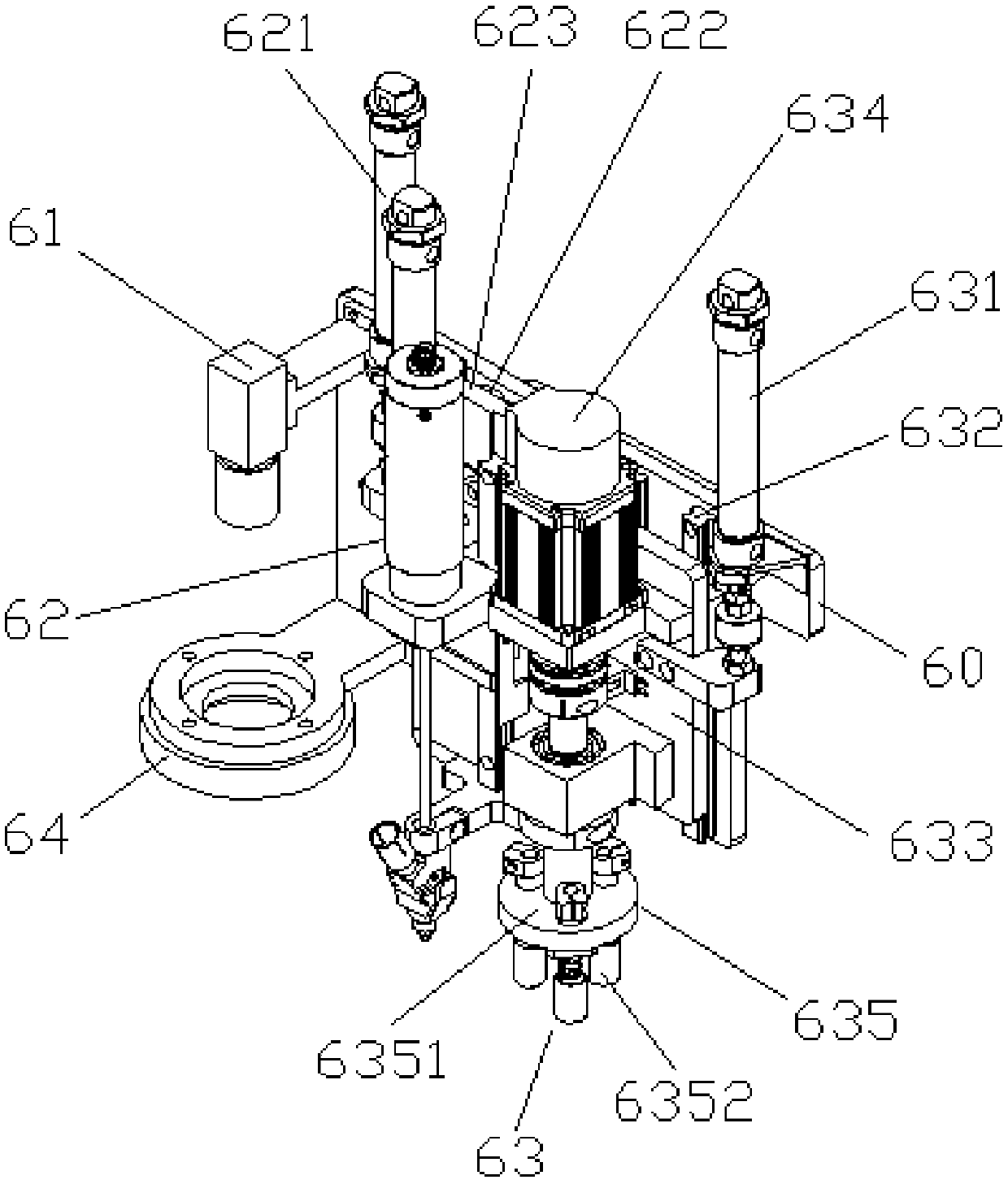

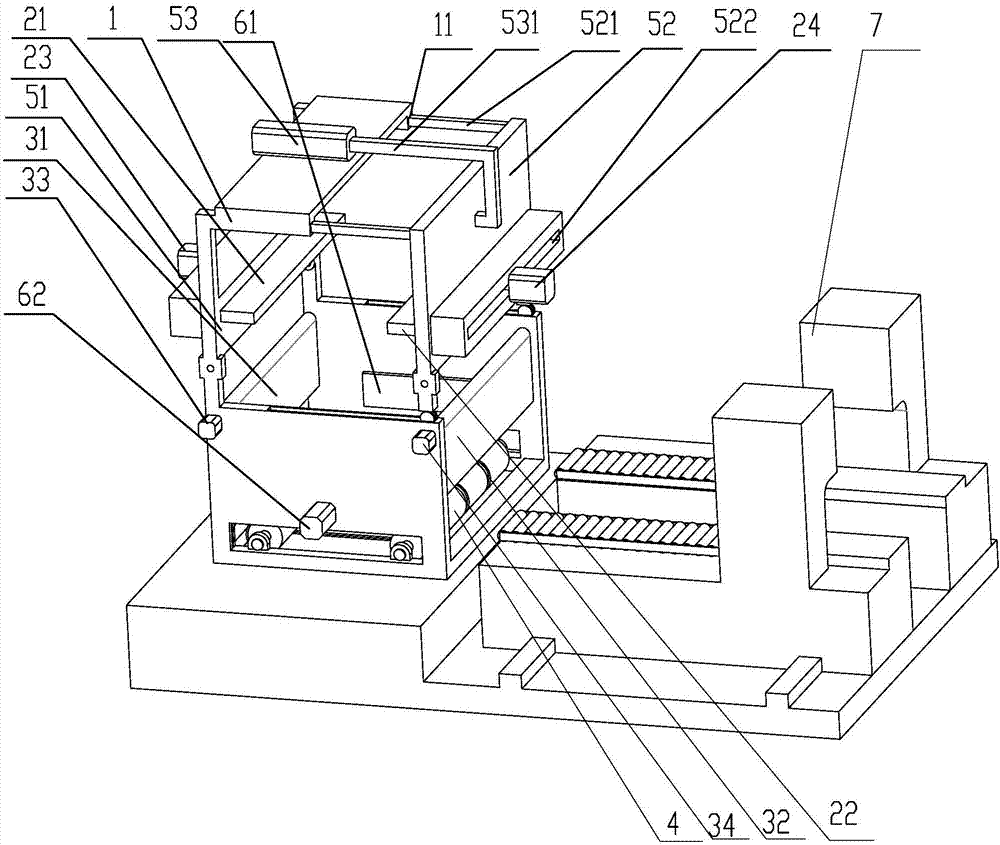

Automatic assembling equipment for bicycle hub brake pads

The invention discloses automatic assembling equipment for bicycle hub brake pads. A hub feeding mechanism, a brake pad positioning mechanism, an interval feeding mechanism, a three-axis movement mechanism and a locking device are arranged on a machine frame, wherein the locking device comprises a sliding seat, a CCD camera, a locking module and a brake pad feeding mechanism, the CCD camera is arranged on the sliding seat, the locking module comprises a first switching cylinder, a first sliding rail, a first sliding block and a locking mechanism, the first sliding block is slidably arranged onthe first sliding rail, the locking mechanism is arranged on the first sliding block, the brake pad feeding mechanism comprises a second switching cylinder, a second sliding rail, a second sliding block, a rotating motor and a suction cup, the second sliding block is arranged on the second sliding rail in a sliding mode, and is connected with the stretchable end of the second switching cylinder,the rotating motor is arranged on the second sliding block, and the output end of the rotating motor is connected with the suction cup. According to the equipment, the precision of the brake pad on ahub is guaranteed, a screw is prevented from being scratched and damaged, and the production efficiency and quality are improved.

Owner:苏州华维乐自动化科技有限公司

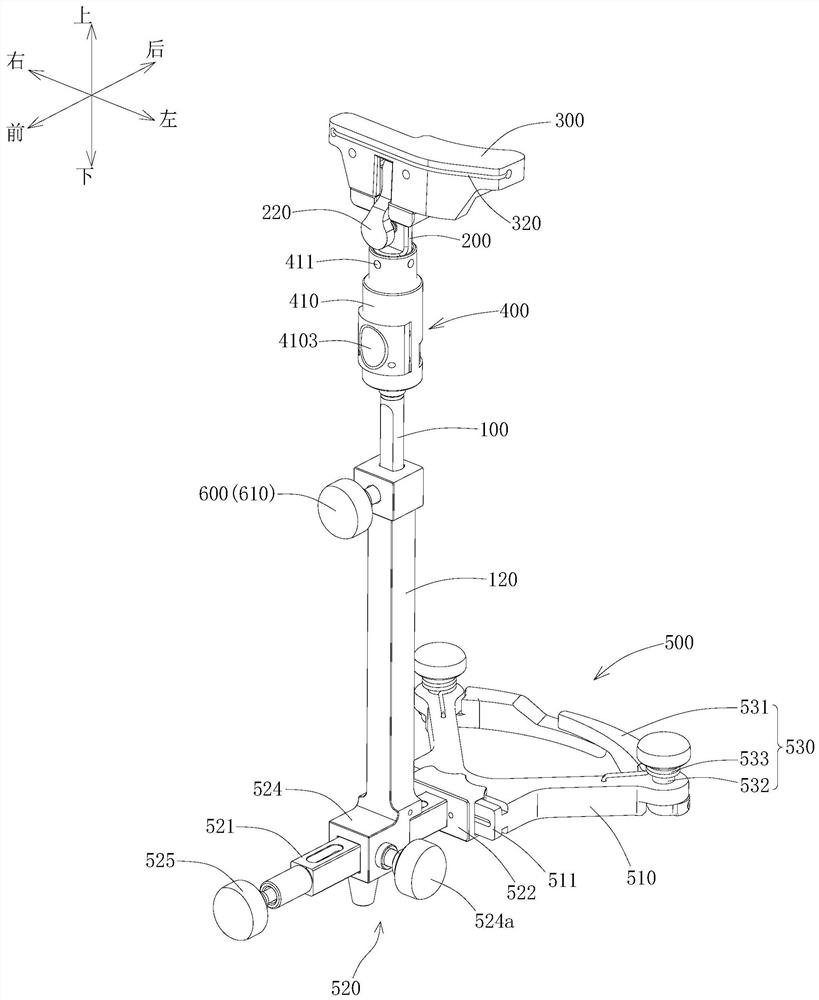

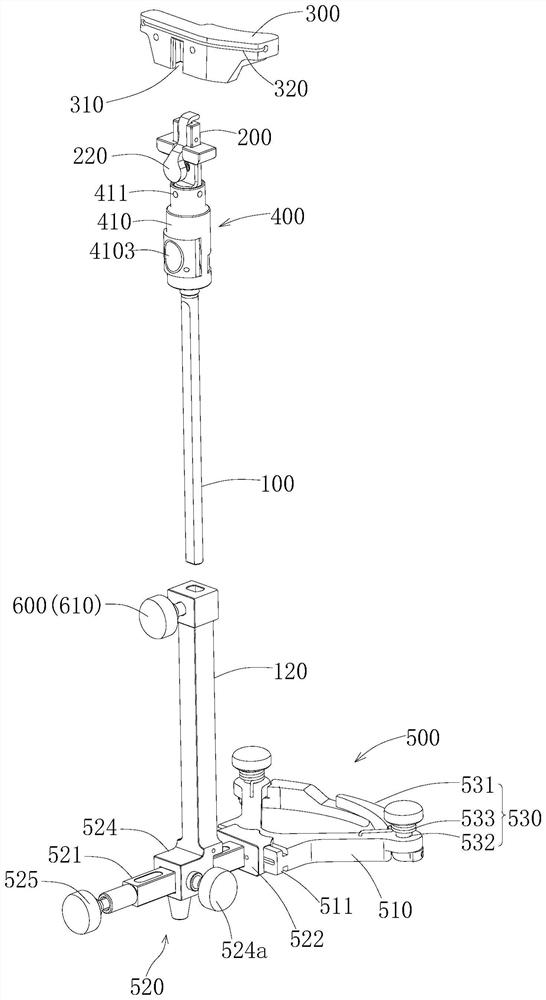

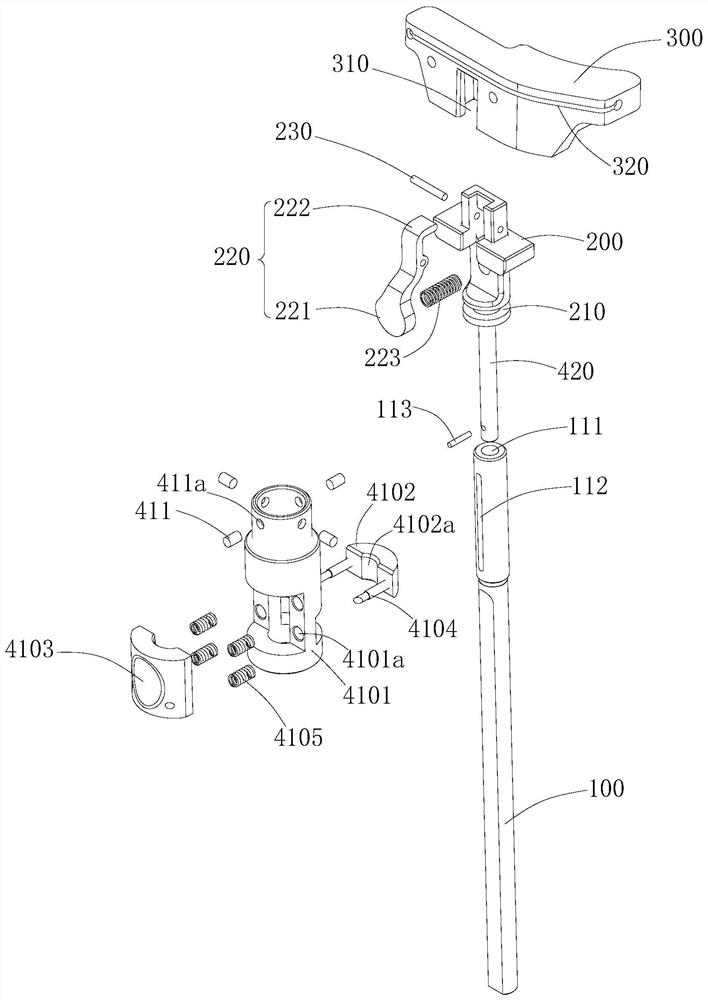

Osteotomy positioning device

PendingCN112336412ALow costSimple designSurgical sawsBone drill guidesSurgical operationSurgical Manipulation

The invention relates to an osteotomy positioning device,. The device comprises an extramedullary positioning rod, an osteotomy plate, a first adjusting mechanism, a ankle holding device and a secondadjusting mechanism, wherein the upper end of the extramedullary positioning rod is provided with an osteotomy fixing seat, the osteotomy plate is arranged on the osteotomy fixing seat and used for positioning the osteotomy position of a tibial plateau, the first adjusting mechanism is arranged between the extramedullary positioning rod and the osteotomy fixing seat and used for adjusting the distance between the osteotomy fixing seat and the upper end of the extramedullary positioning rod, the ankle holding device is arranged at the lower part of the extramedullary positioning rod and is usedfor wrapping and fixing an ankle joint, and the second adjusting mechanism is arranged on the extramedullary positioning rod and used for adjusting the length of the extramedullary positioning rod. According to the device, fixing nails do not need to be punched on the tibial plateau for fixing, and the damage to sclerotin of a patient is reduced; the position of the osteotomy plate can be rapidlyand accurately adjusted to adjust osteotomy errors, and the implementation efficiency of surgical operation is improved; and the osteotomy plate can be assisted to be fixed in real time through the fixing effect of the extramedullary positioning rod and the ankle holding device, it is guaranteed that the position of the osteotomy plate is stable enough in the osteotomy operation process, and theaccuracy of osteotomy operation is improved.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

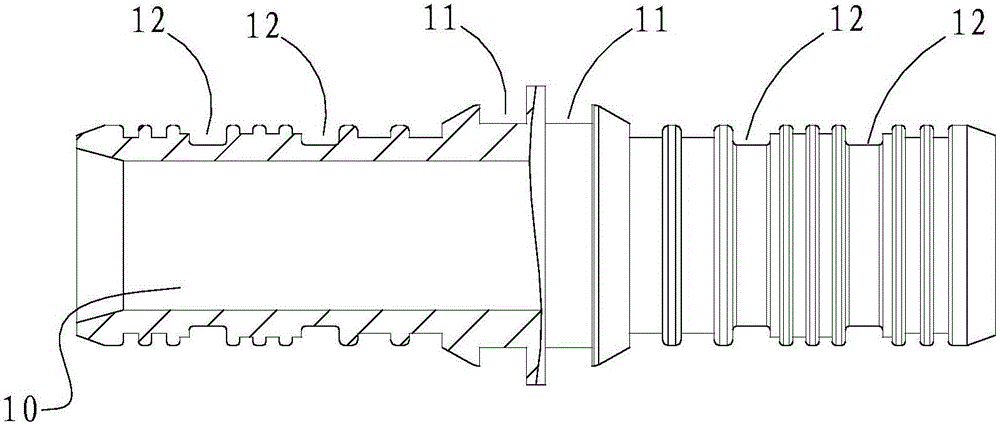

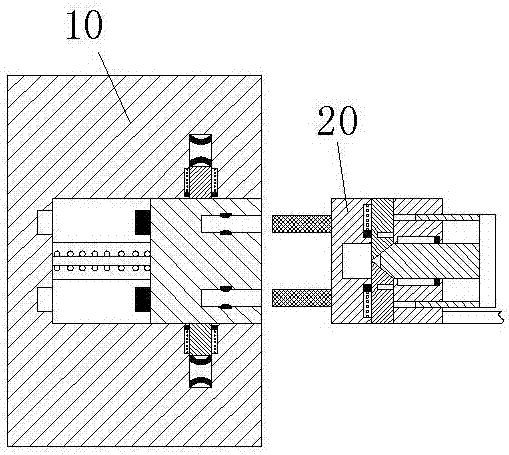

Fast connection pipe fitting

The invention provides a fast connection pipe fitting. The fast connection pipe fitting comprises a pipe core, a shell base, a shell sleeve and a jacket pipe sleeve. A first installing groove is formed in the outer side wall of the pipe core. The shell base is provided with a channel for containing the pipe core. The side wall used for forming the channel is provided with a first flange. The first flange is installed in the first installing groove. The shell sleeve is arranged outside the pipe core in a sleeving manner. The end of the shell sleeve is connected with the shell base. The jacket pipe sleeve is arranged outside the pipe core in a sleeving manner. A containing space used for a pipe material to be inserted is arranged between the jacket pipe sleeve and the pipe core. The jacket pipe sleeve is clearance fit with the shell sleeve. The jacket pipe sleeve comprises an annular pipe arranged outside the pipe core in a sleeving manner and a plurality of clamping pieces connected with the annular pipe. The end of the shell base is provided with a gradual expansion face which is gradually expanded in the axial direction of the pipe core. The end of each clamping piece makes contact with the gradual expansion face at the end of the shell base. Compared with a connecting pipe in the prior art, the fast connection pipe fitting makes the pipe material convenient to disassemble and assemble, and the effect of preventing the pipe material from getting loose is good.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

Safe power supply device for power consuming apparatus

InactiveCN107394518AWill not cause electric shock accidentsNot easy to kickIncorrect coupling preventionCoupling contact membersEngineeringElectric wire

The invention discloses a safe power supply device for a power consuming apparatus. The safe power supply device comprises a plug socket fixedly mounted in a wall and a plug head connected with the power consuming apparatus via an electric wire, the plug socket is provided with a sliding chamber which opens to the right, a sliding block is mounted in the sliding chamber in a sliding way, plugging grooves which open to the right are symmetrically arranged in an upper part and a lower part of the sliding block, first elastic electric conduction sheets are mounted in the plugging grooves, a power supply block is fixedly arranged on a left end face of the sliding block, a power supply groove matched with the power supply block is arranged in a left end wall of the sliding chamber, telescoping grooves that extend up and down are symmetrically arranged in upper and lower end walls of the sliding chamber, and sliding arms are mounted in the telescoping grooves in a sliding manner; second elastic electric conduction sheets are fixedly mounted on end faces, positioned away from the sliding chamber, of the sliding arms; third elastic electric conduction sheets opposite to the second elastic electric conduction sheets are mounted in the telescoping grooves, electric conduction arms matched with the plugging grooves are symmetrically arranged on an upper part and a lower part of a left end of the plug head, a lengthwise groove of which an upper end and a lower end are communicated with each other is arranged in the plug head, and a horizontal groove which opens to the left and runs through the lengthwise groove is arranged in the plug head.

Owner:虞海杰

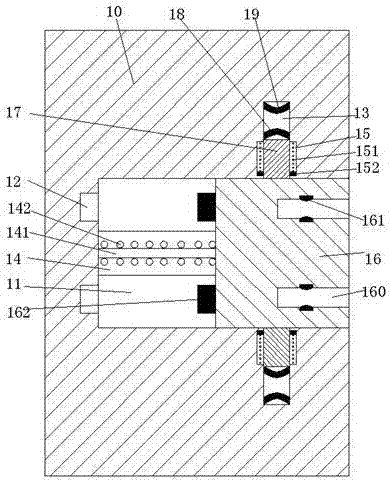

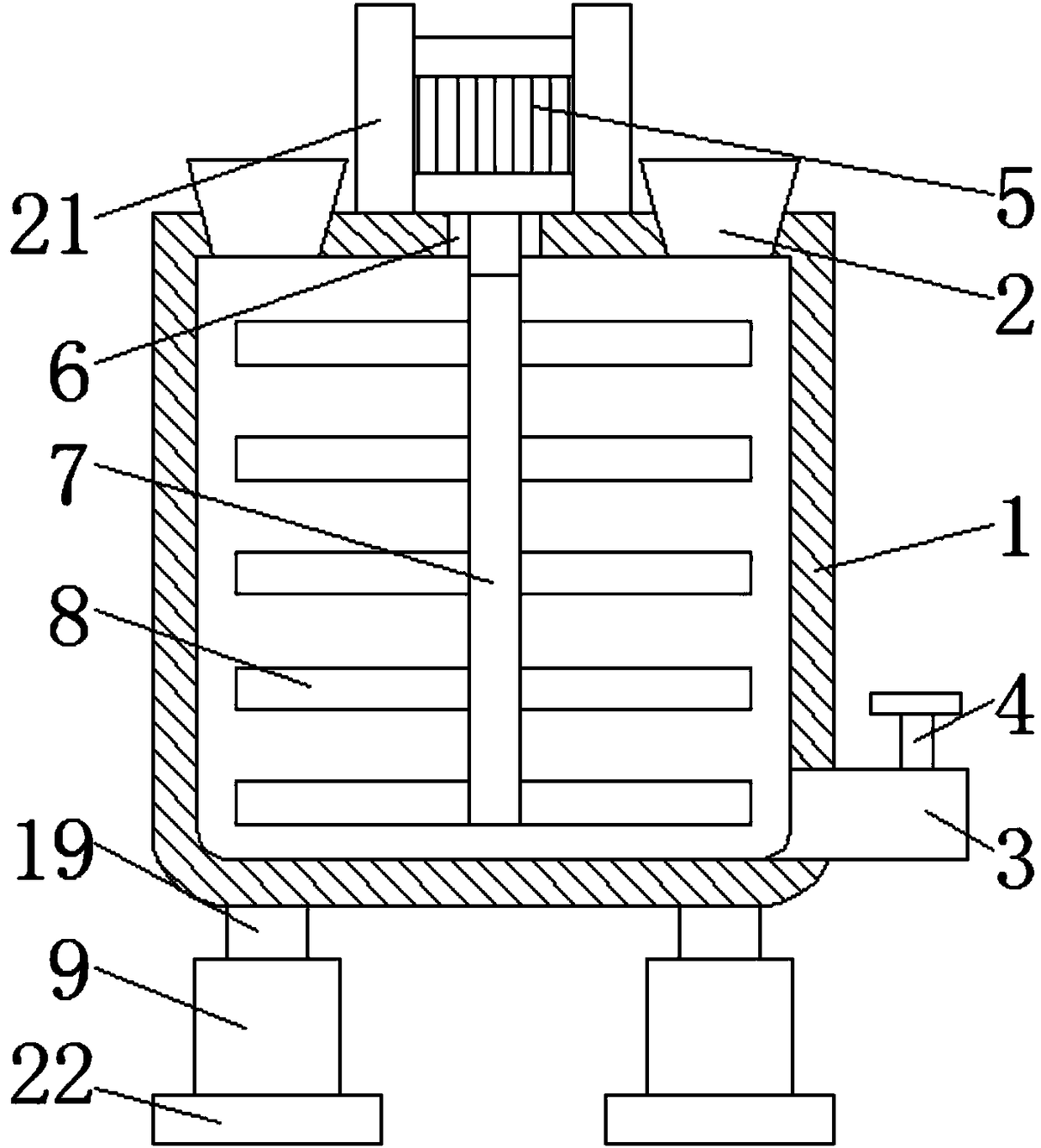

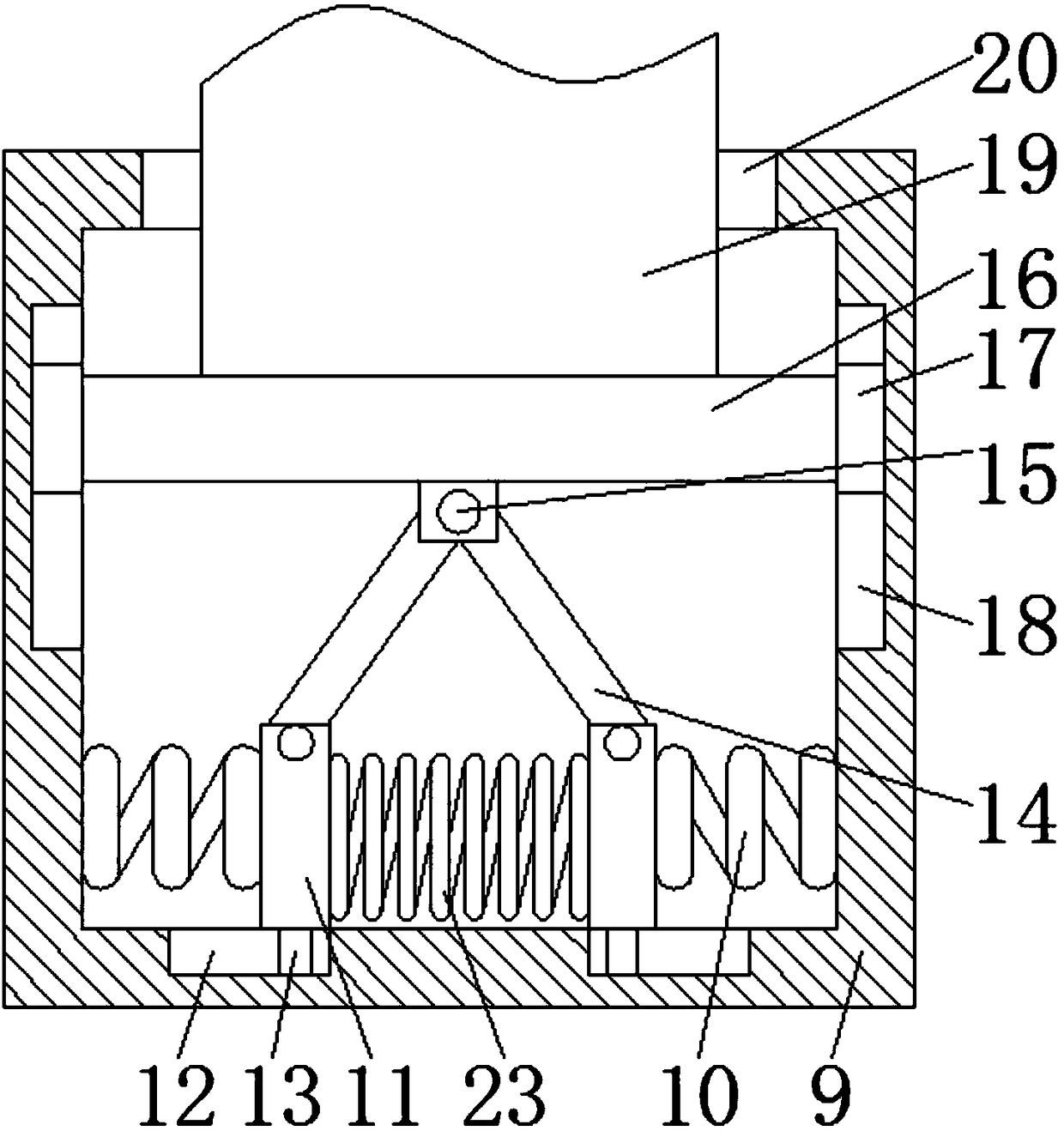

Damping type chemical raw material stirring device

InactiveCN108607429AGuaranteed uptimeWon't loosenShaking/oscillating/vibrating mixersTransportation and packagingCompound (substance)Engineering

The invention discloses a damping type chemical raw material stirring device which comprises a cylinder, wherein support legs are symmetrically fixedly arranged around the bottom of the cylinder; first damping springs and second damping springs are arranged on the support legs. In a stirring process, the whole cylinder can be vibrated intensively, due to adoption of the first damping springs and the second damping springs on the support legs, the impact to the cylinder can be buffered twice, a good buffer effect can be achieved, furthermore stirring components inside the cylinder are subjectedto small vibration, and looseness and damage are not easily caused; the cylinder is intensively shaken in the stirring process, so that due to adoption of the first springs and the second springs, the impact of the cylinder can be buffered twice, furthermore, a good damping effect can be achieved, the whole cylinder can be operated stably, the stirring components inside the cylinder can be prevented from large impact which can cause looseness or damage.

Owner:章慧

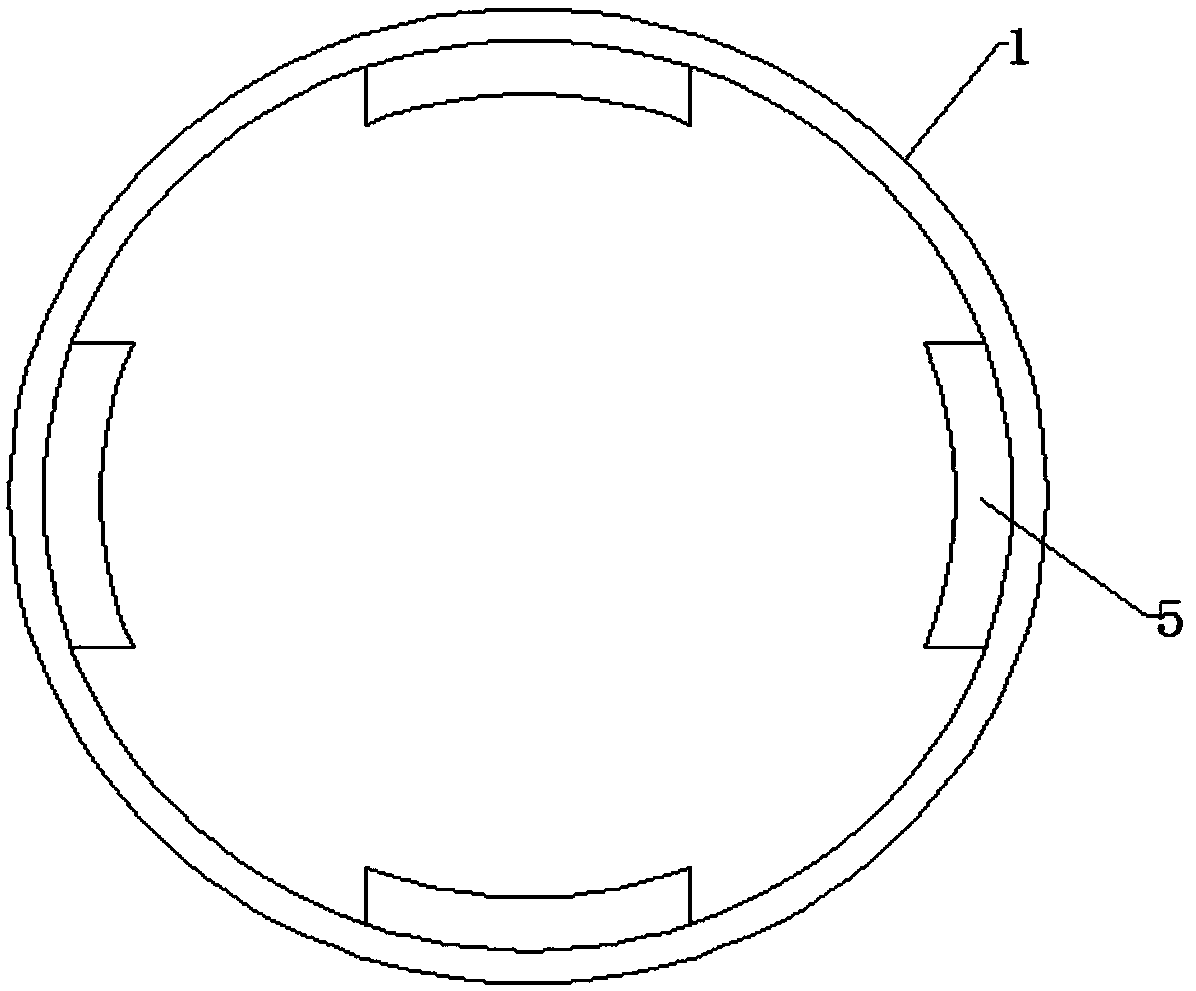

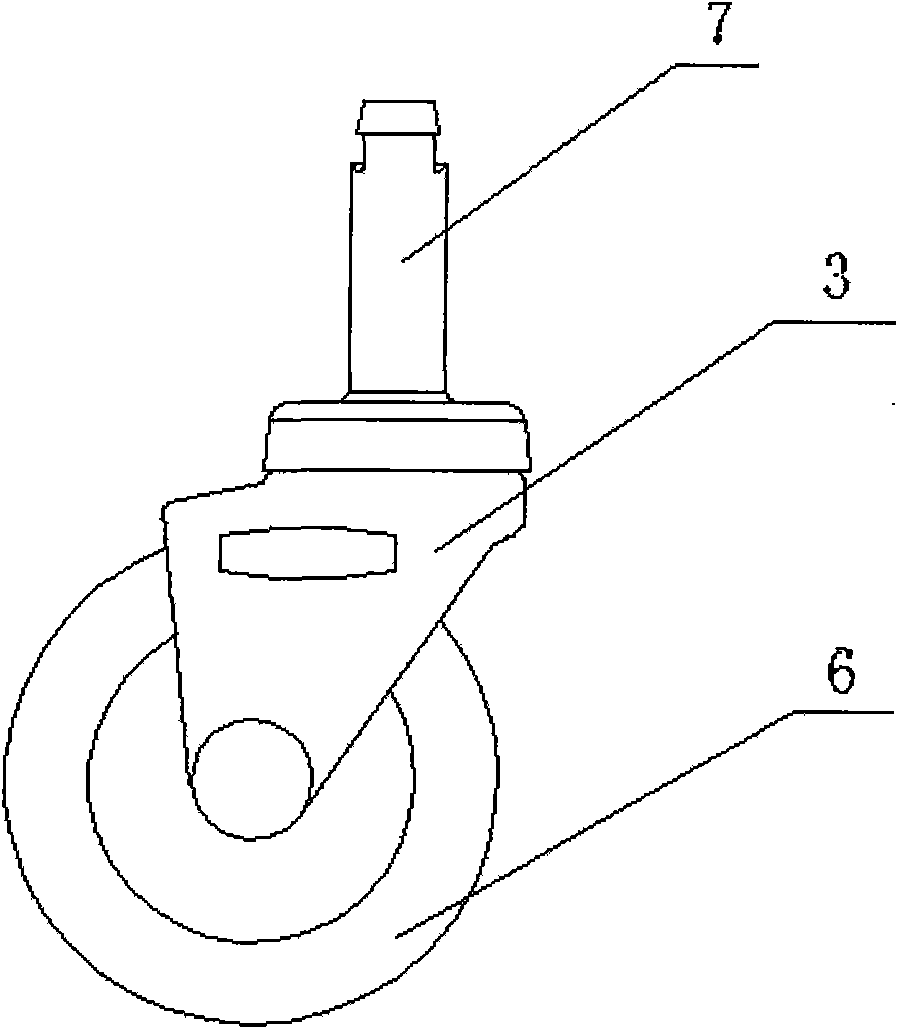

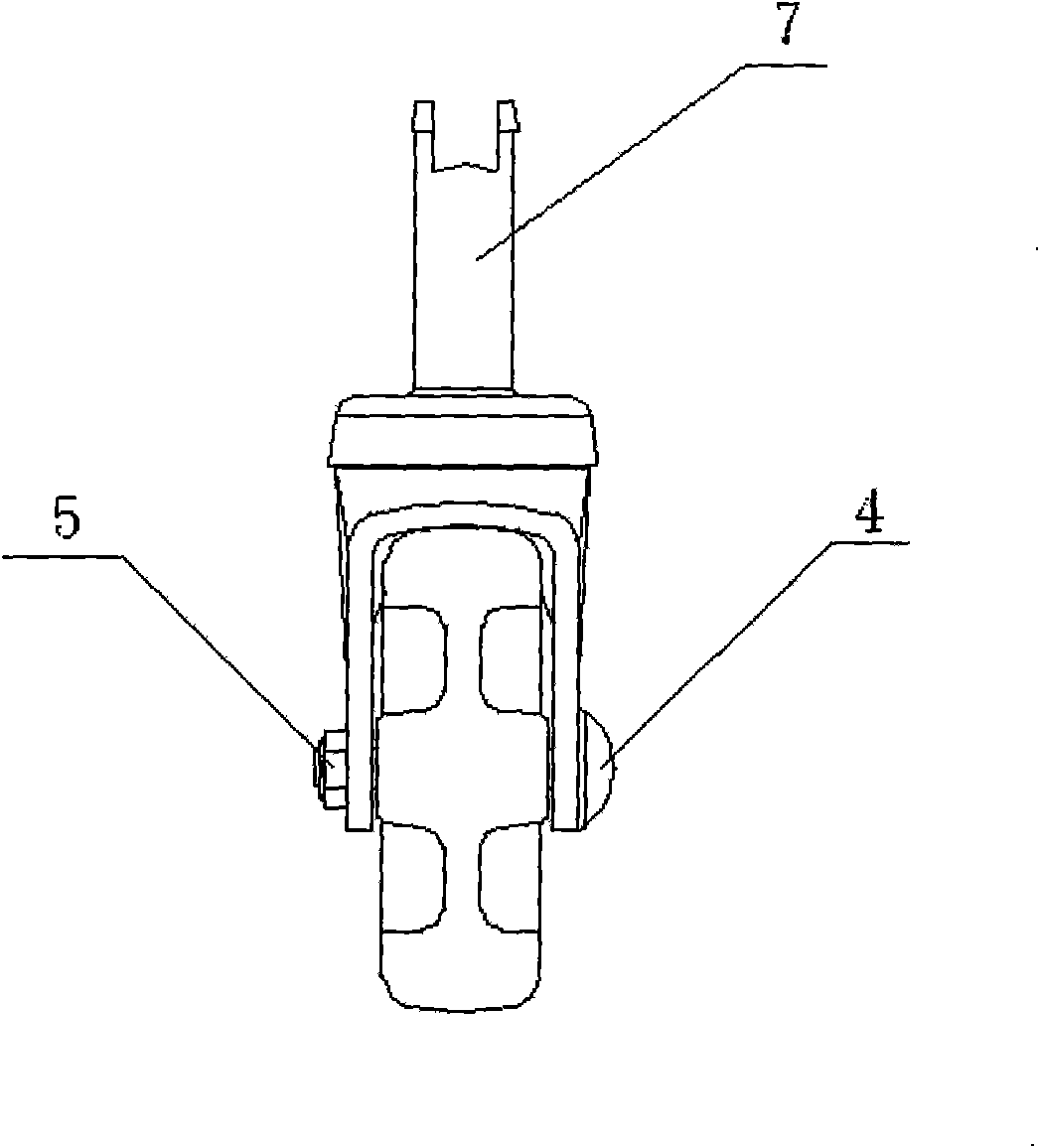

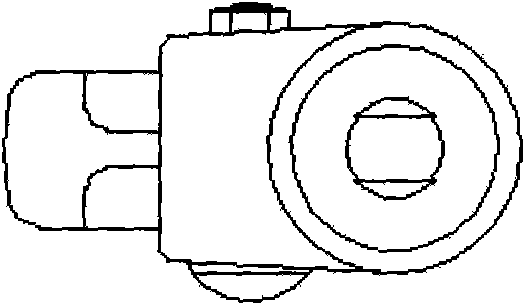

Pluggable universal caster wheel

The invention relates to a pluggable universal caster wheel belonging to the technical field of common caster wheels and comprising a main shaft, a steel ball, a support, a bolt, a nut, a wheel, a beam barrel and a shaft housing, wherein the beam barrel comprises a bottom housing, a beam barrel body and an upper cover comprising a top insert buckle and a lower end slotted hole, and the shaft housing is fixedly connected with a case; the upper end of the top insert buckle is of a clamping structure, and the top insert buckle and the shaft housing are in buckling connection; the clamping structure is a left elastic structure and a right elastic structure symmetrically arranged mutually; the lower end slotted hole of the upper cover of the beam barrel is an inward bulge slotted hole; the upper end of the main shaft is buckled in the inward bulge slotted hole of the upper cover; the number of the steel ball is only one; the steel ball is arranged between the lower end inward bulge slot of the upper cover and the upper end of the main shaft and is in rolling connection. The invention has the advantages of simple structure, convenient manufacture and easy installation and disassembly; when the wheel is damaged, only the clamping structure needs to be pulled to change the caster wheel, and therefore, the case can continuously work. The invention can be widely applied to objects of cases, carts, baby carriers, seats, medical carriages and the like.

Owner:宁波科盛光电有限公司

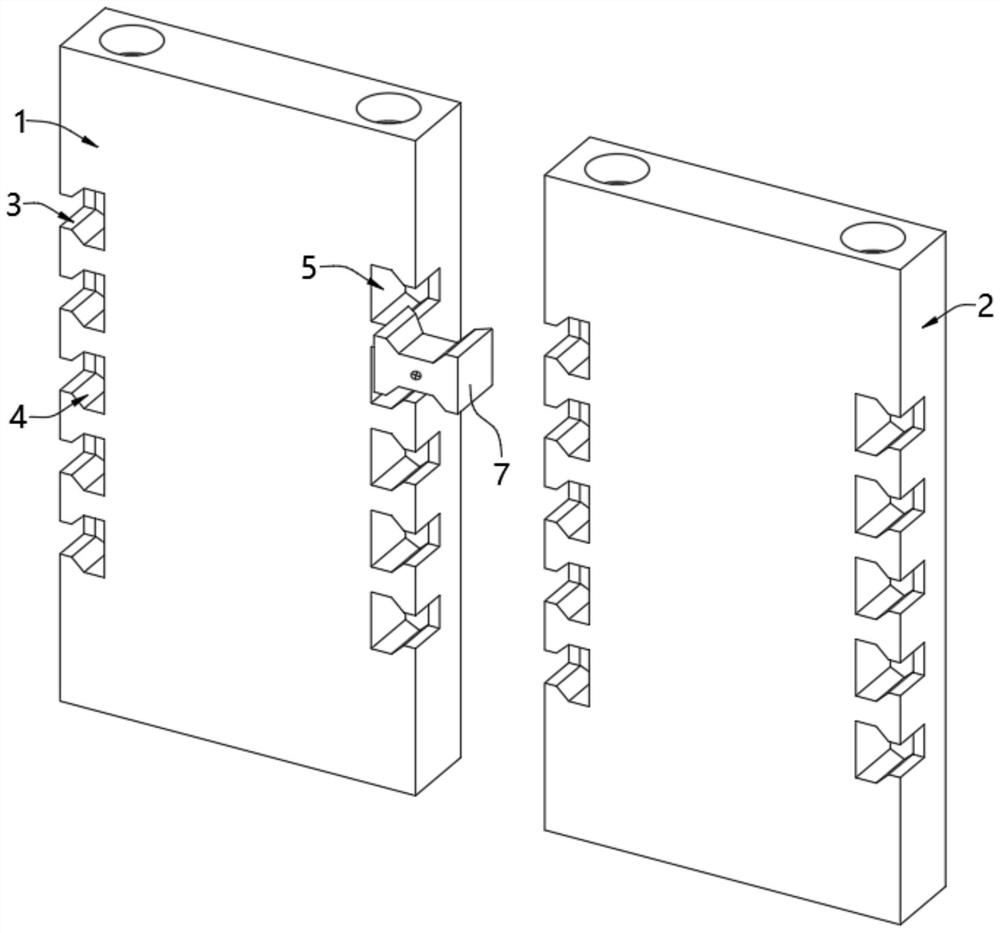

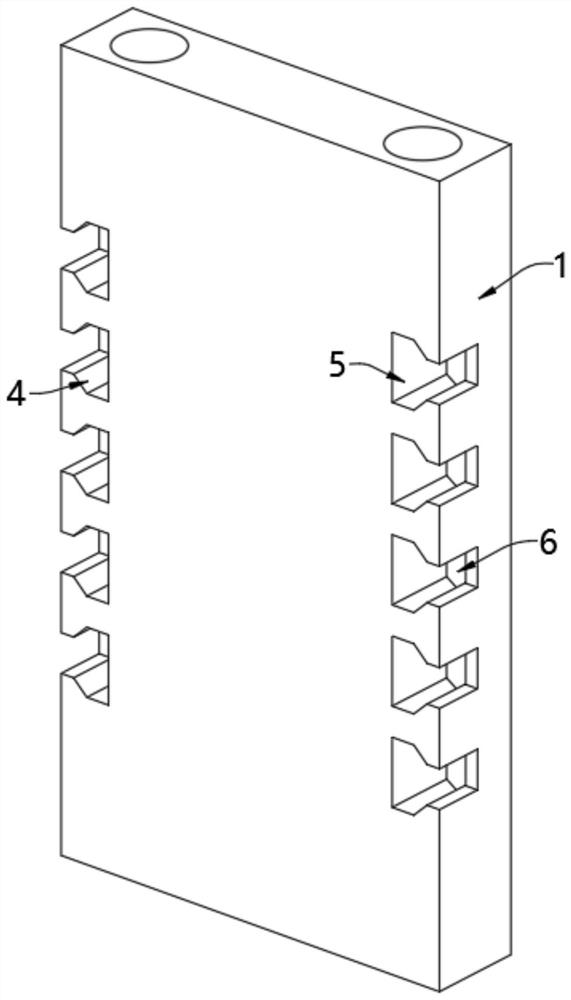

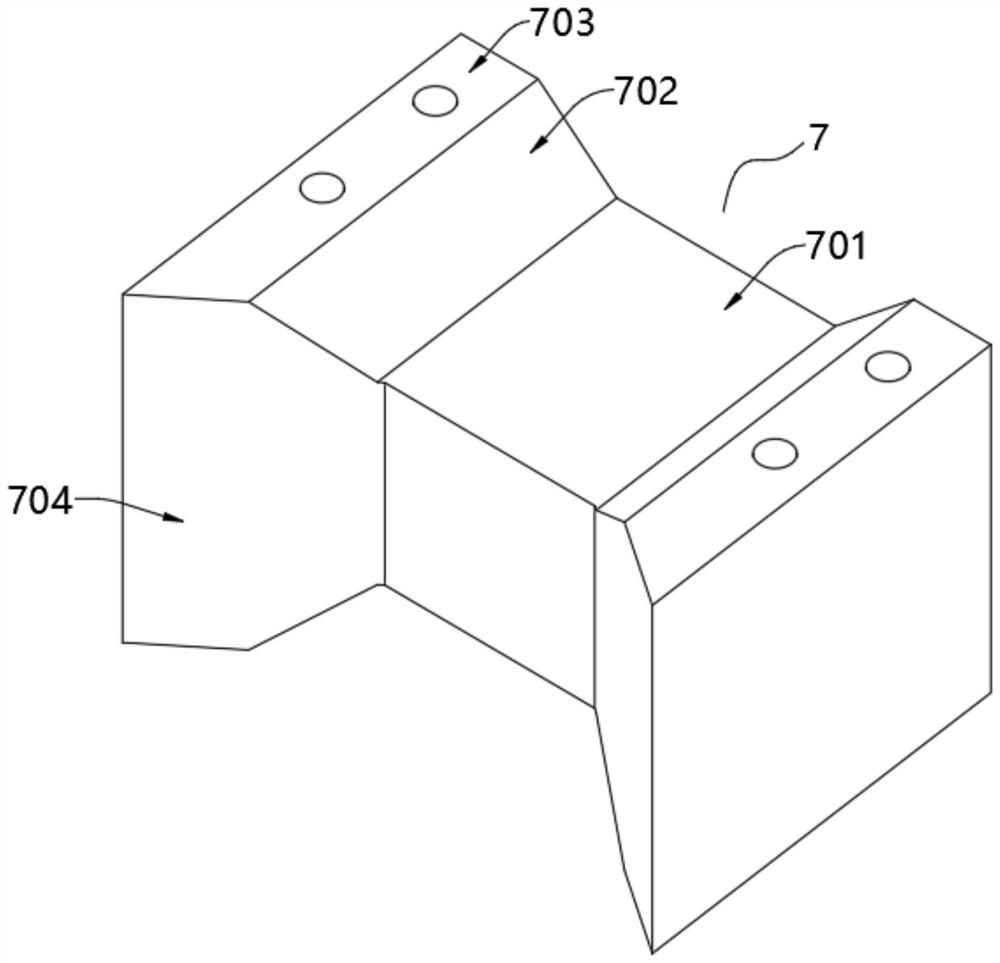

Light partition wall batten mounting structure and preparation method thereof

ActiveCN113530021AFirmly connectedImprove installation efficiencyWallsCeramic shaping apparatusIsosceles trapezoidBatten

The invention relates to the technical field of partition wall battens, and discloses a light partition wall batten mounting structure and a preparation method thereof. The light partition wall batten mounting structure comprises a first batten and a second batten, side grooves are formed in the two sides of the first batten and the two sides of the second batten correspondingly, slope grooves with the cross sections being isosceles trapezoids are formed in the inward sides of the side grooves, clamping grooves are formed in the inward sides of the slope grooves, and fixing pins are movably arranged on the inner walls of the side grooves, the slope grooves and the clamping grooves. When the first batten and the second batten are connected, the fixing pins are embedded in the side grooves, the slope grooves and the clamping grooves in the opposite sides of the first batten and the second batten, slope plates and clamping plates on the two sides of the fixing pins are embedded in the slope grooves and the clamping grooves of the first batten and the second batten correspondingly and connected through connecting columns, and under blocking of the side grooves, the slope plates and the clamping plates cannot be transversely separated from the first batten and the second batten, connection is very convenient, and the installation efficiency is greatly improved.

Owner:HAINAN UNIVERSITY

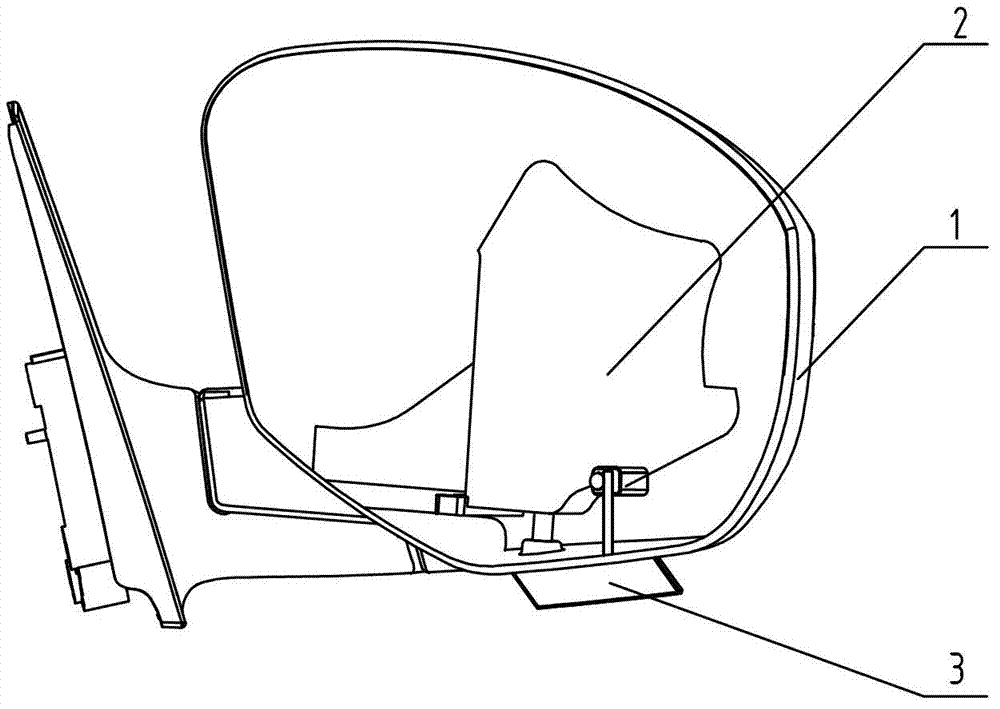

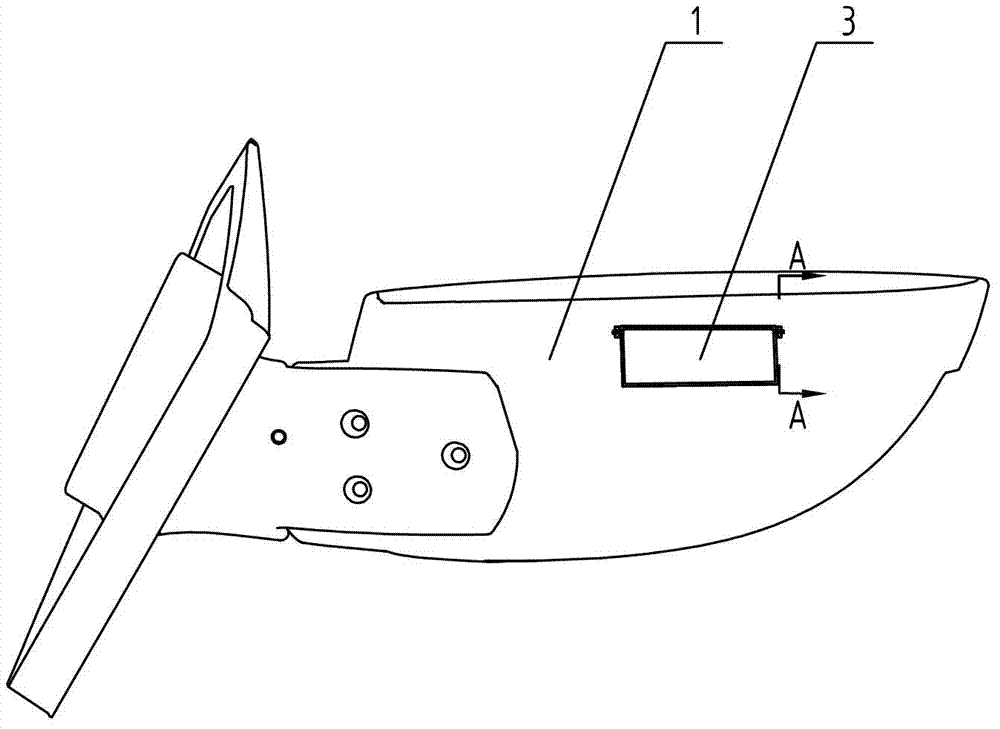

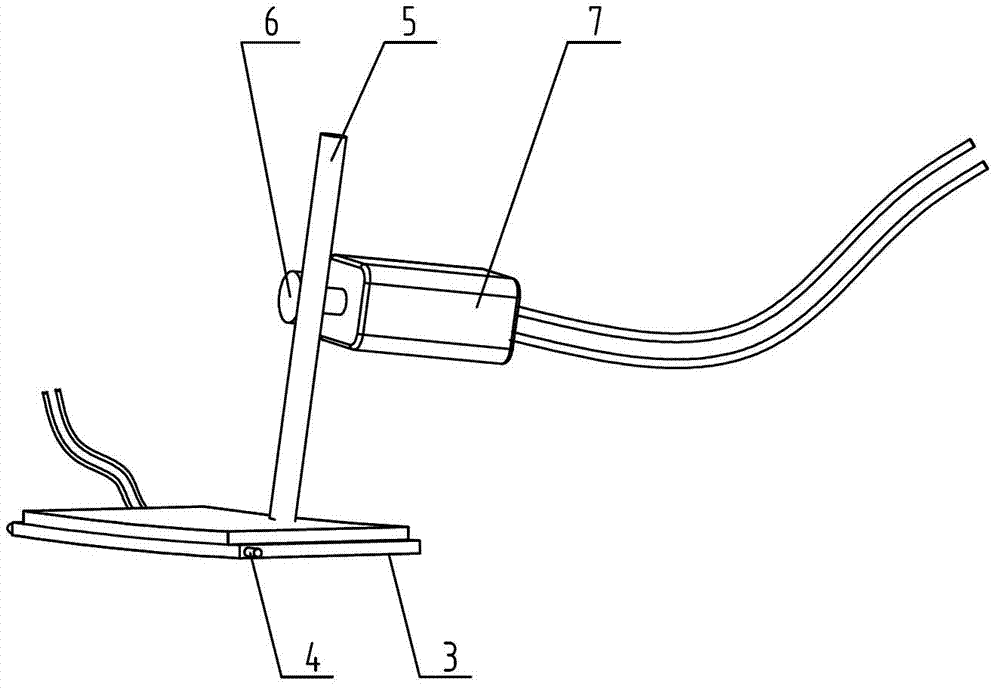

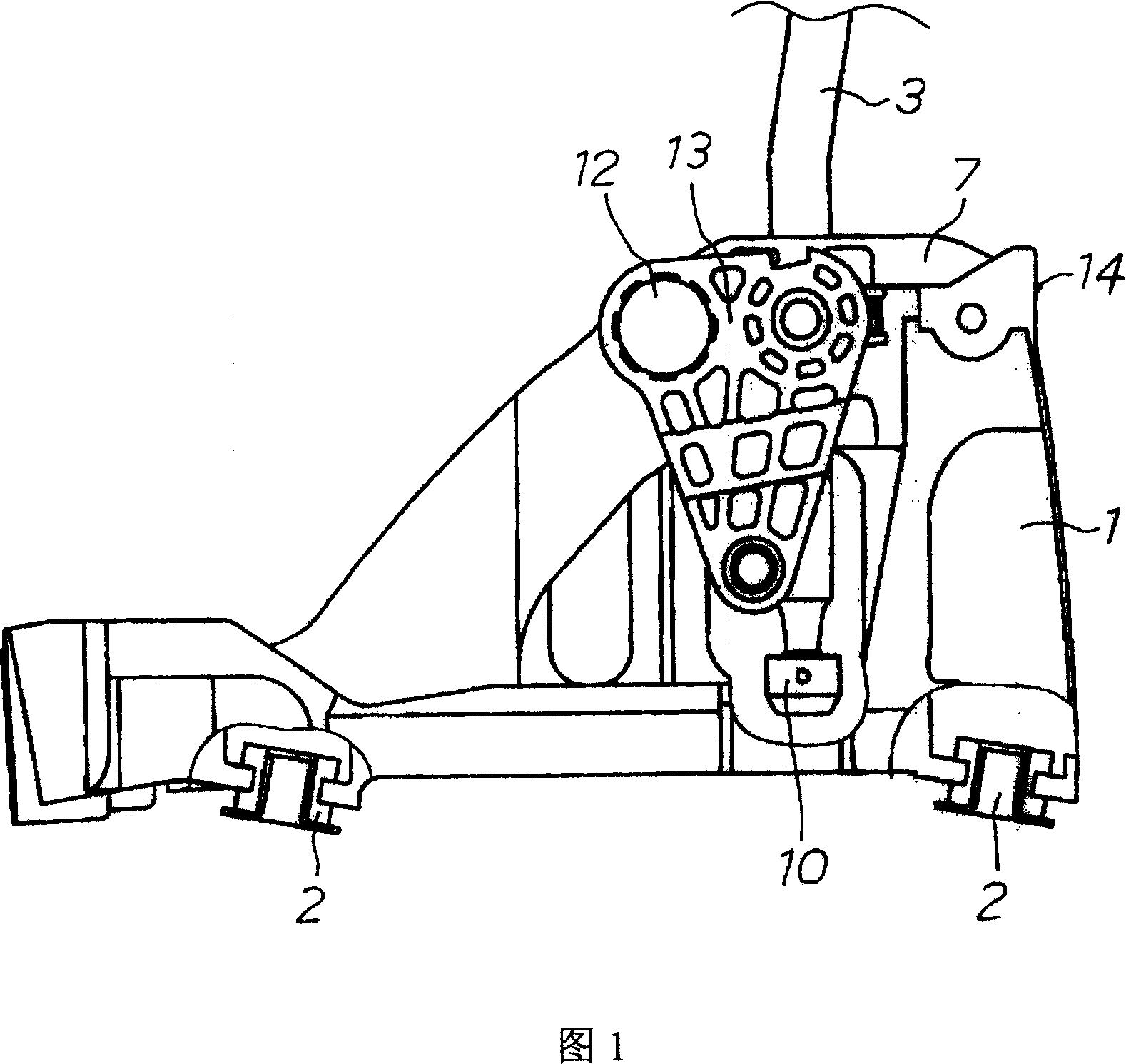

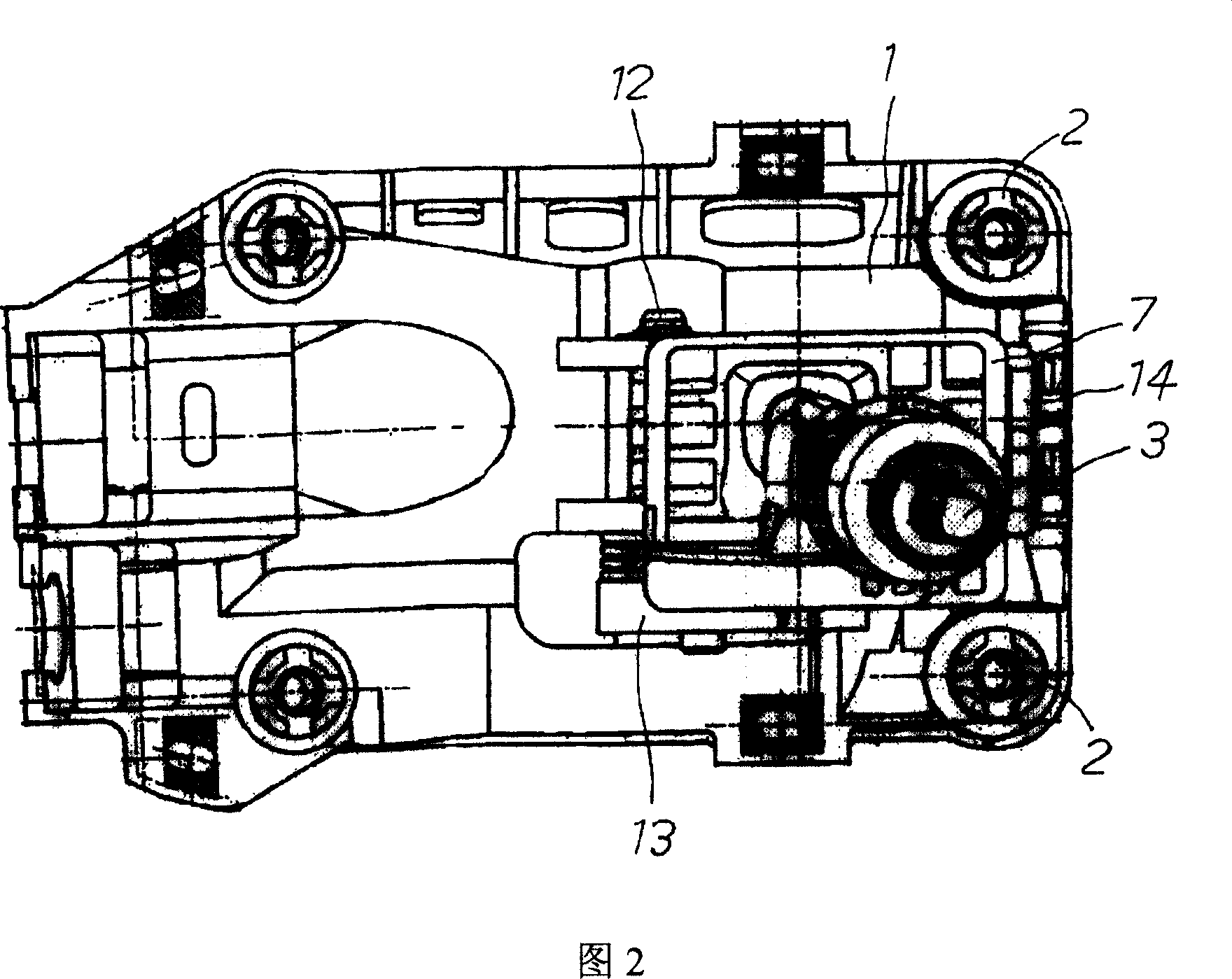

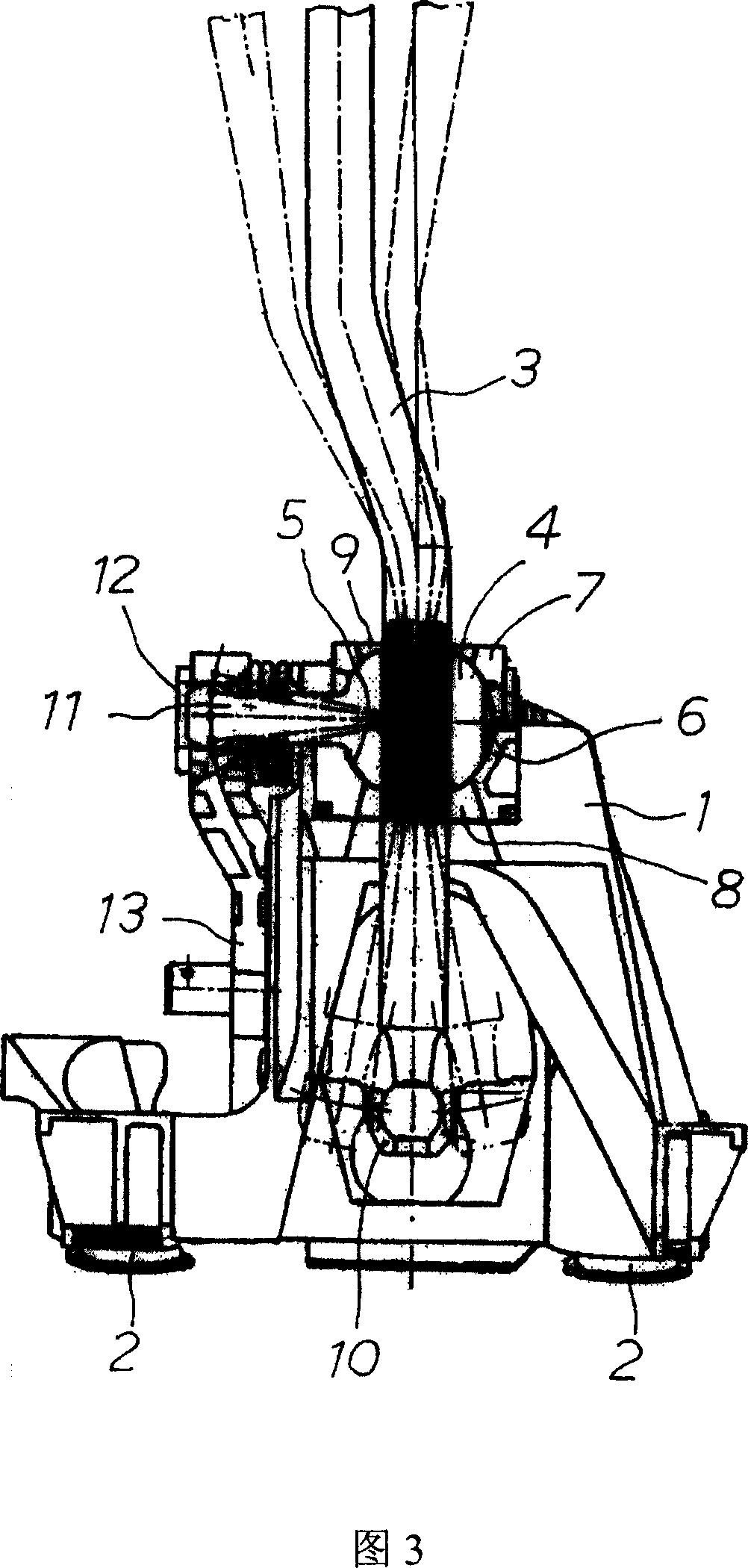

Adjustment mechanism for ground irradiation lamp on rear view mirror outside automobile

InactiveCN103204106ADoes not affect appearanceAchieve regulationOptical signallingOptical viewingEngineeringIrradiation

The invention discloses an adjustment mechanism for a ground irradiation lamp on a rear view mirror outside an automobile. The adjustment mechanism comprises a rear view mirror shell, a rear view mirror rack and the ground irradiation lamp, wherein the rear view mirror rack is arranged in the rear view mirror shell; a window of which the shape and the size are matched with those of the ground irradiation lamp is formed in the bottom of the rear view mirror shell; the ground irradiation lamp is positioned in the window; the left side and the right side of the ground irradiation lamp are hinged with the rear view mirror shell through rotating shafts; a worm is arranged above the ground irradiation lamp and is positioned behind the rotating shafts; the bottom of the worm is fixed on the upper surface of the ground irradiation lamp; the worm is meshed with a worm wheel; the worm wheel is sleeved on an output shaft of a motor; and the motor is arranged on the rear view mirror rack. The adjustment mechanism can adjust an irradiation region of the ground irradiation lamp, so that the ground irradiation lamp can irradiate the lateral rear side of the automobile; and the safety of backing off at night is guaranteed, and the ground irradiation lamp is difficult to damage.

Owner:力帆科技(集团)股份有限公司

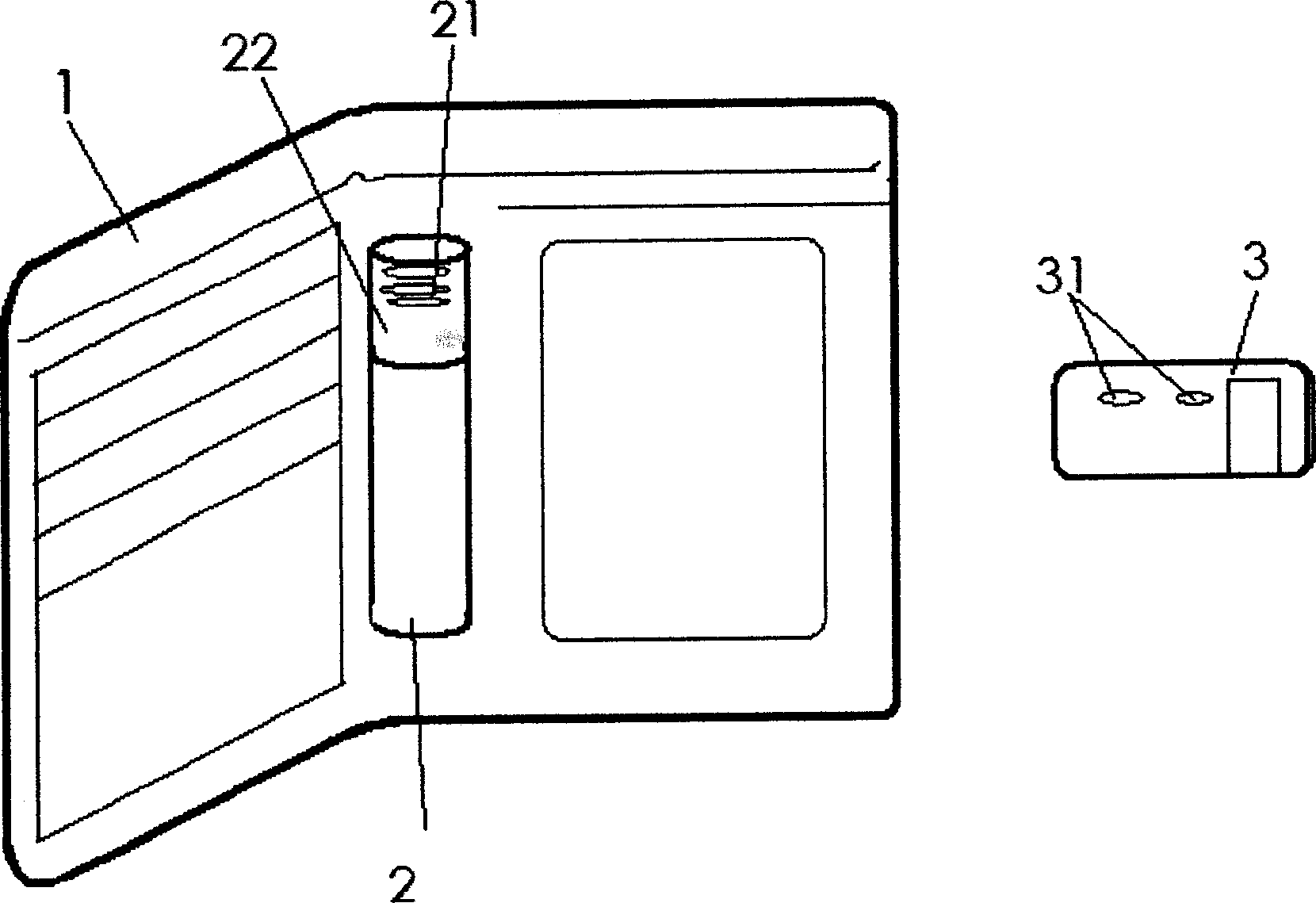

Foreign flavor wallet

The invention discloses a wallet with peculiar smell device and a remote controller, which can be made of leather, textile, metal and plastic, the peculiar smell device is fixed to wallet and comprises tan containing compressed peculiar smell or nontoxic chemical gas and electrical valve, when receiving signal from remote controller, the electrical valve will open tank to emit peculiar smell, as a result which the thief trace is exposed. The remote controller should be equipped with safe switch and the power of remote controller and peculiar smell device is supplied by button battery. The remote controller should not be placed together with wallet. Compared with current technology, the invention is characterized by simple structure, diverse formula and wide usage, and the thief can be caught in time.

Owner:上海广丽工贸有限公司

Paperboard stacking and packing device

The invention discloses a paperboard stacking and packing device. The paperboard stacking and packing device comprises a stacking device and a packing device used for bundling paperboard piles, and the packing device is arranged on the rear side of the stacking device; and the stacking device comprises a support, partition plates, receiving brackets and push plates, wherein baffles capable of sliding forwards and backwards are arranged on the front side and the rear side of the support, the receiving brackets are arranged on the support, each partition plate is arranged on the corresponding baffle and arranged above the corresponding receiving bracket, the push plates are arranged on the support, and conveyor belts are arranged below the push plates. The paperboard stacking and packing device is simple in structure and can be used for receiving paperboards with different sizes; meanwhile, the paperboards can be stacked regularly, and the stacked paperboards can be packed.

Owner:ZHEJIANG DONGJIN TECH CO LTD

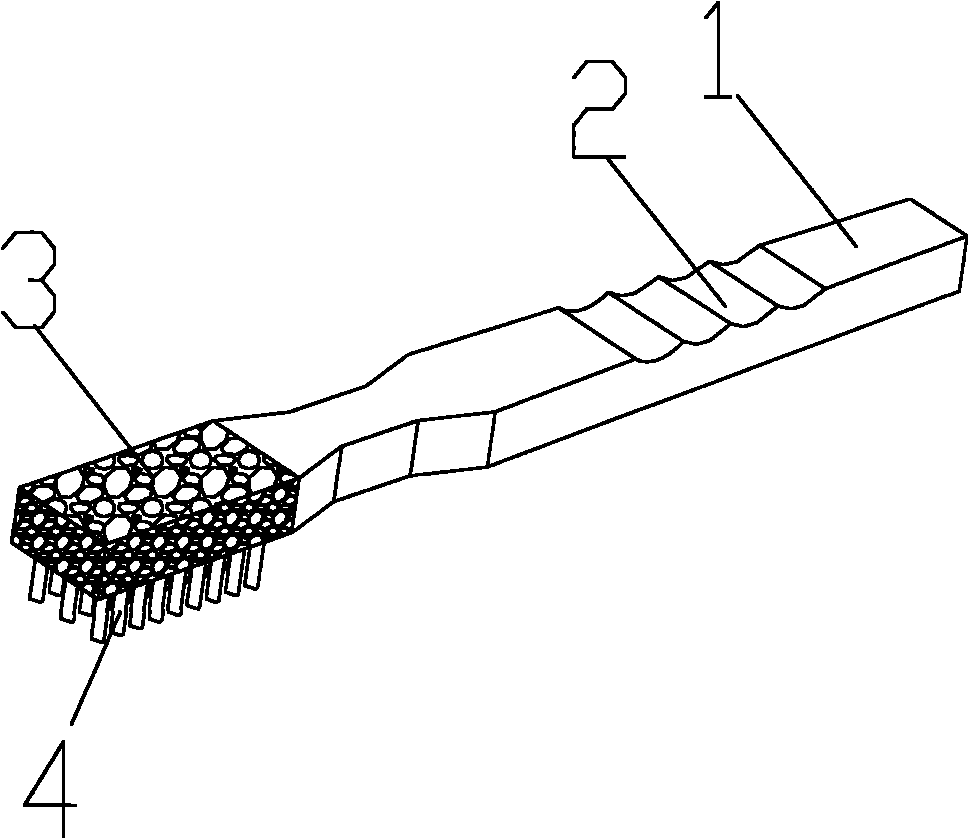

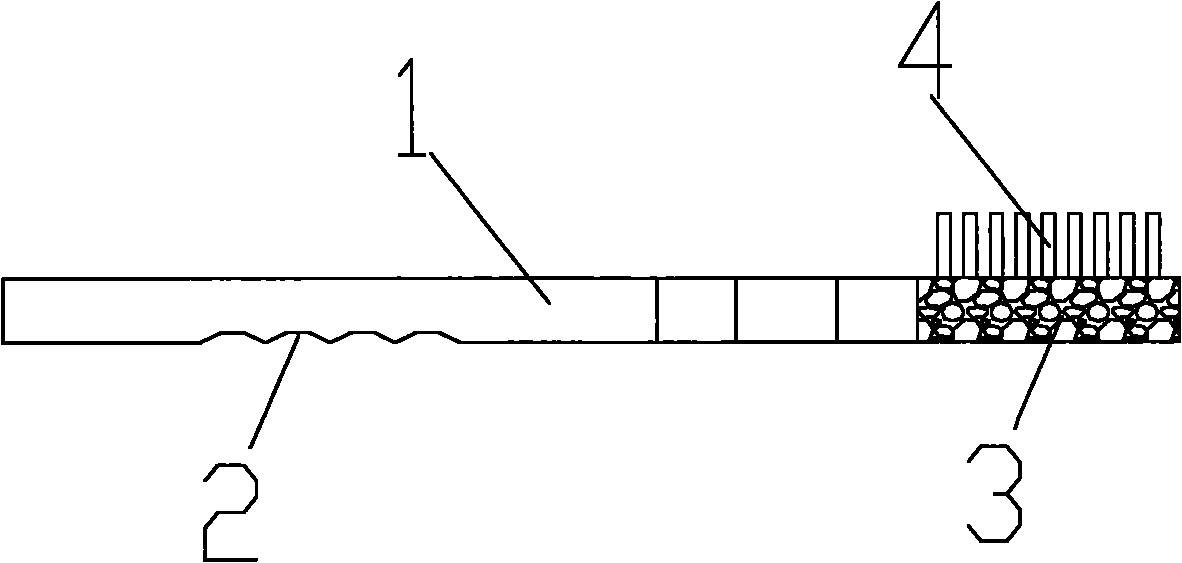

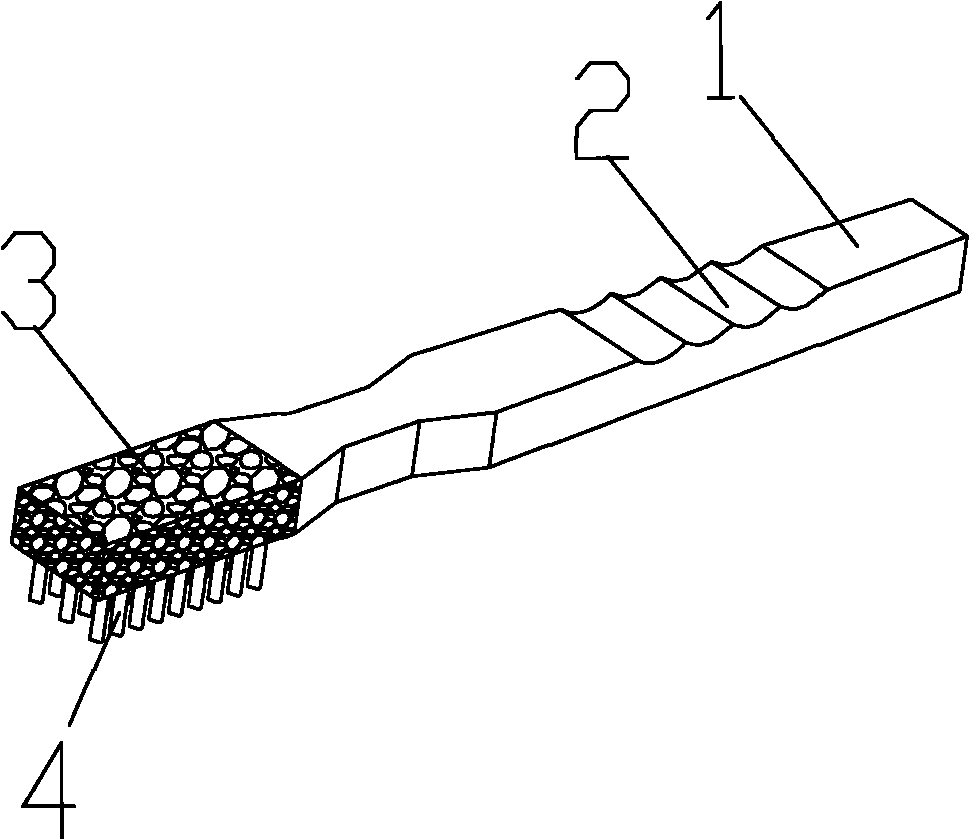

Oral cavity cleaning toothbrush

The invention discloses an oral cavity cleaning toothbrush which comprises a handle, a finger part, a bristle substrate and bristles; the bristles are arranged on the bristle substrate which is connected with the handle; the finger part is arranged on the handle, and the bristle substrate is made of porous foaming materials. For the oral cavity cleaning toothbrush, the bristle substrate is made of non-toxic, bright and clean, sot and elastic materials, so that the oral cavity cleaning toothbrush can be manufactured together with a common toothbrush, and can not be loosened and fall down; and the oral cavity cleaning toothbrush has a simple structure, various styles and low cost, is wide in application range, is used for cleaning the oral cavity while brushing teeth, and can also be used for cleaning the surface of a coated tongue so as to prevent and reduce oral cavity and tooth diseases.

Owner:王雪英

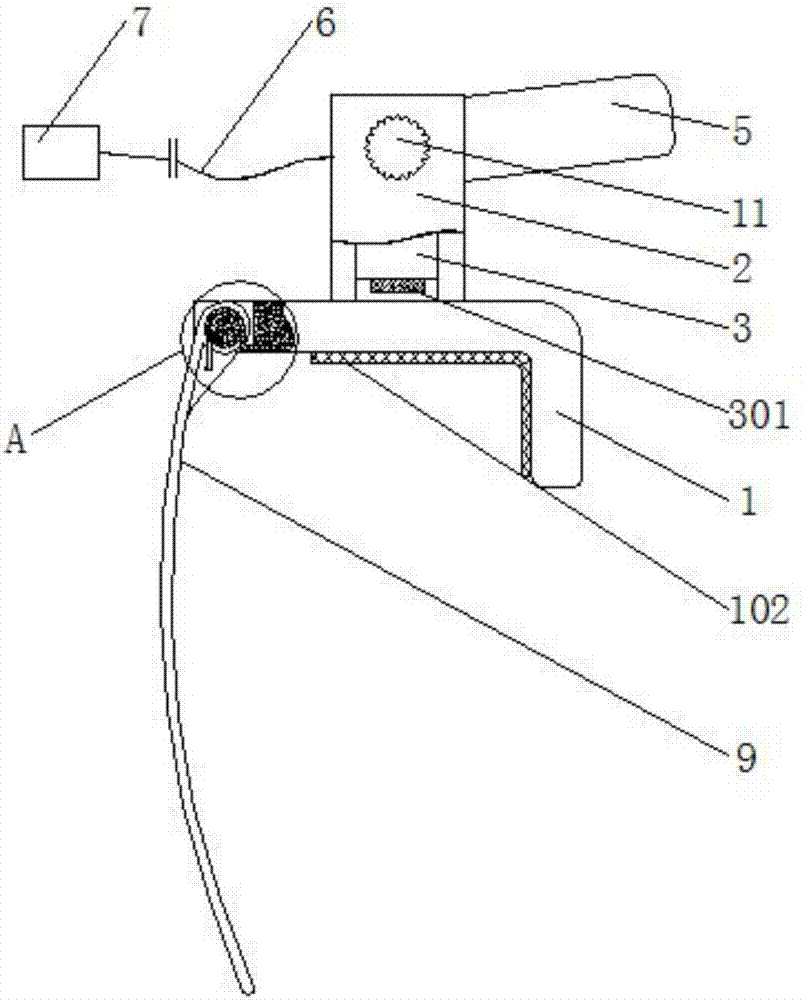

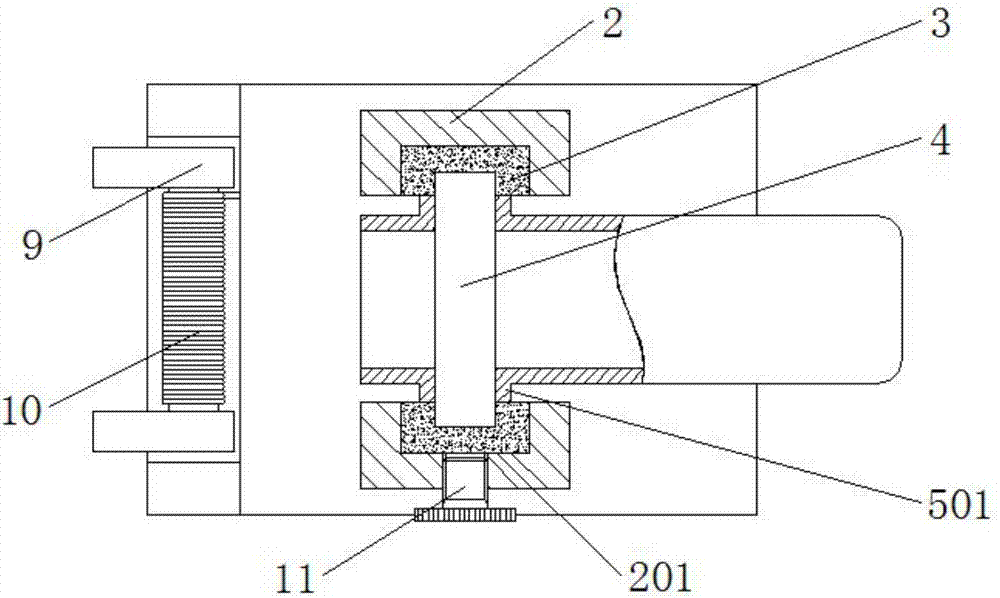

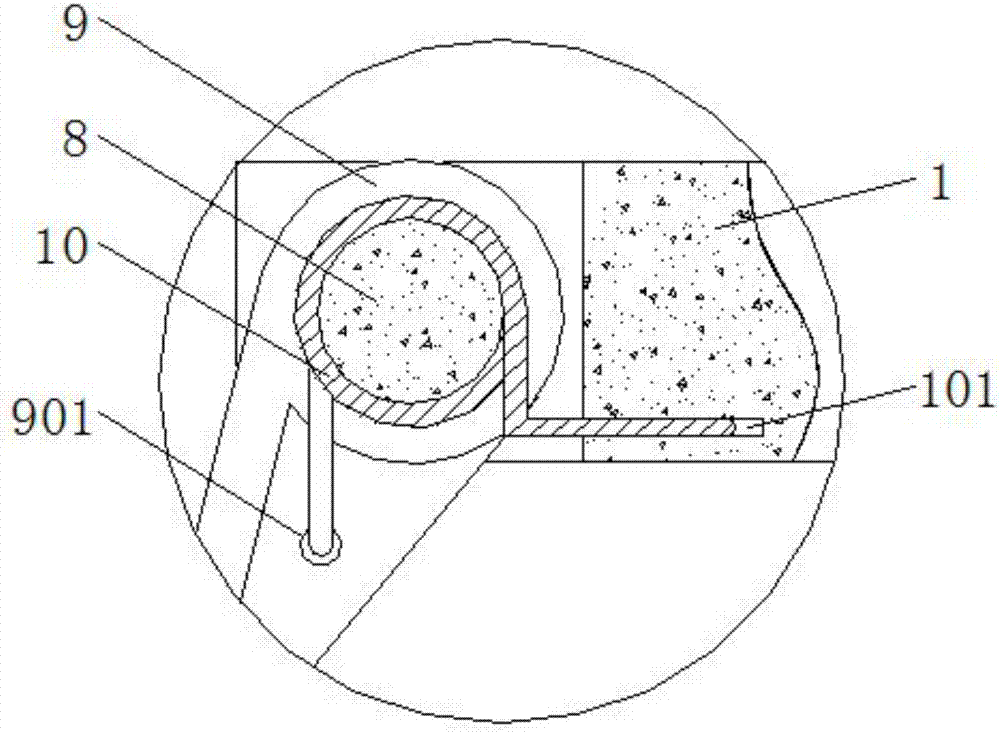

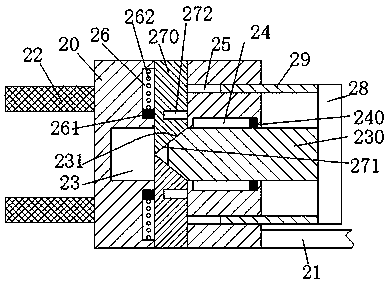

Liftable lighting lamp for display screen

InactiveCN107191847AWon't loosenNo situationLighting support devicesProtective devices for lightingEffect lightEngineering

The invention discloses a liftable lighting lamp for a display screen. The liftable lighting lamp comprises a fixing bracket (1), the fixing bracket (1) is provided with an installation seat (2), the installation seat (2) is internally provided with a lifting frame (3) through a guide slot (201), and the inner side of the lifting frame (3) is provided with an LED lamp body (5) through a first connection shaft (4); one end of the LED lamp body (5) is connected with a USB interface (7) through a power line (6), one end of the fixing bracket (1) is provided with a second connection shaft (8), and the second connection shaft (8) is provided with a movable clamping plate (9) through a torsional spring (10); and the upper end of the installation seat (2) is provided with a tightening screw (11), and the bottom of the lifting frame (3) is provided with a buffering cushion (301). The liftable lighting lamp can be freely installed on the edge of the display screen, the height of the lighting lamp can be adjusted, applicability is high, and the illumination range is wide.

Owner:HUZHOU MINGRI LIGHTING TECH

Gear lever device

Owner:MANNOH CO LTD

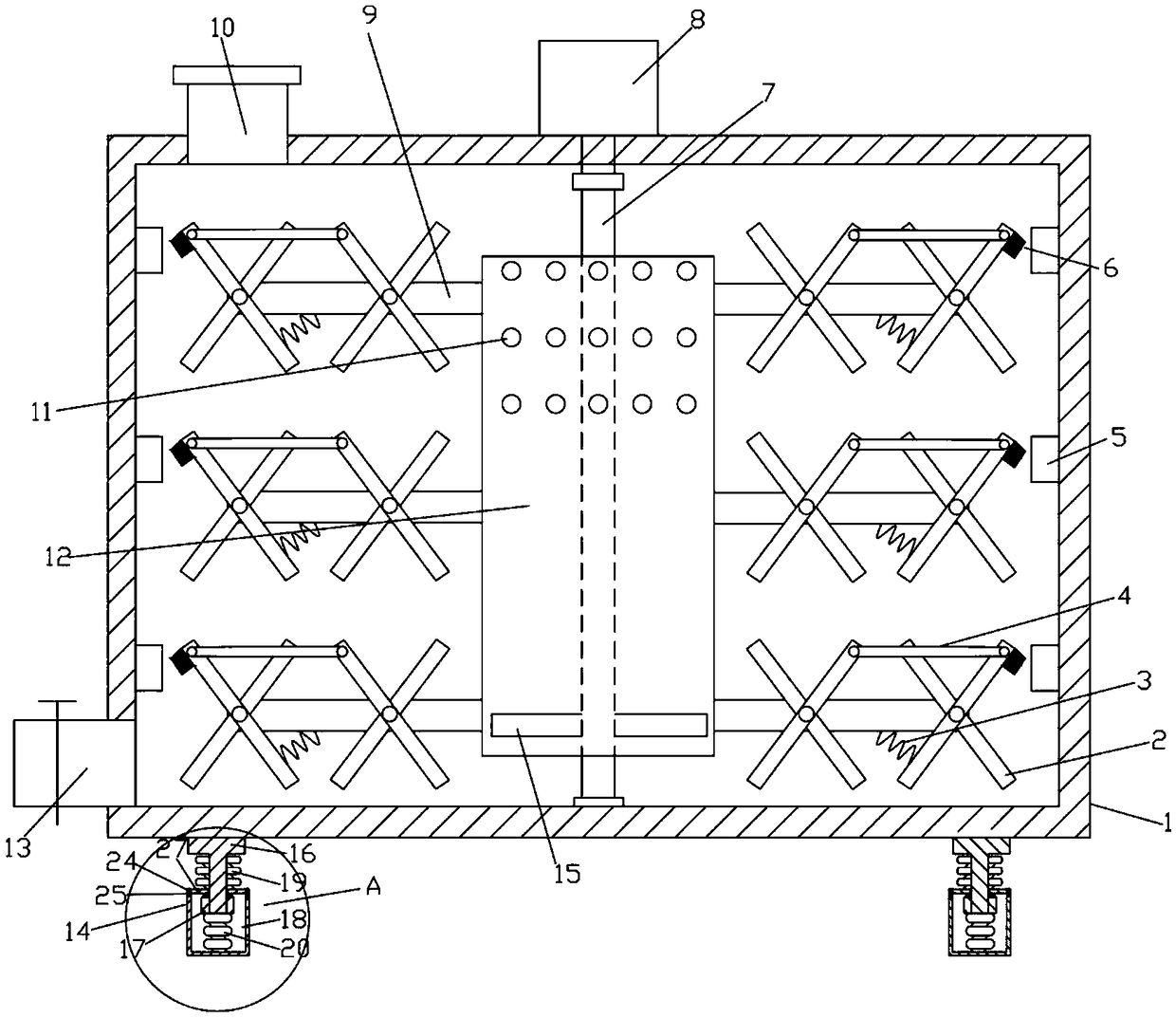

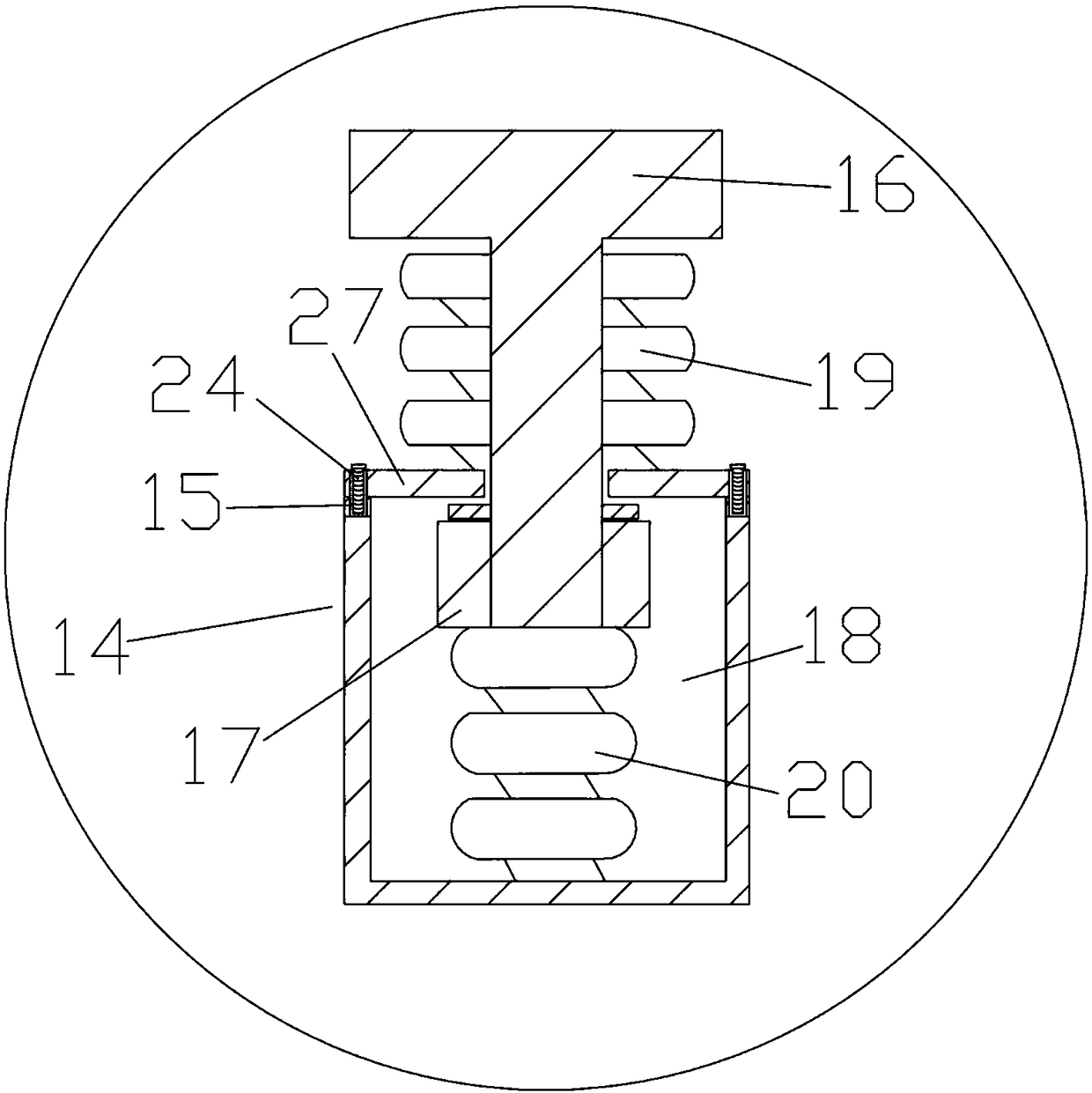

Washing machine plastic mixing equipment capable of absorbing shock

InactiveCN108481592ASolve the problem of not having shock absorbersExtended service lifeNon-rotating vibration suppressionEngineeringMechanical engineering

The invention discloses washing machine plastic mixing equipment capable of absorbing shock. The washing machine plastic mixing equipment comprises a mixing hopper, wherein feeding hoppers are communicated with the two sides of the top of the mixing hopper; a discharge pipe is communicated with the bottom of the right side of the mixing hopper; a valve is arranged on the top of the discharge pipe;a motor is fixedly connected to the center of the top of the mixing hopper. Through cooperative use of boxes, springs, moving plates, first sliding slots, first slide blocks, movable rods, a fixed block and a movable plate, the problem that the existing washing machine plastic mixing equipment cannot absorb the shock is solved; the washing machine plastic mixing equipment capable of absorbing theshock has the advantage of capability of absorbing the shock; in the mixing and stirring process, the stability of the equipment is not affected by vibration of the equipment itself, the using safetyis not affected, and Occurrence of a phenomenon that components loose or are damaged due to long-term vibration is avoided, so that the service life of the mixing equipment is prolonged and the mixing equipment is worth of popularization and use.

Owner:巢湖市荣达塑业有限公司

Improved power supply facility

InactiveCN108242661AWill not cause electric shock accidentsNot easy to kickLive contact access preventionElectric wireElectrical wiring

The invention discloses an improved power supply facility. The improved power supply facility comprises a plug socket fixedly mounted in a wall and a plug head connected with a power consumption apparatus via an electric wire, wherein the plug socket is provided with a sliding chamber which opens to the right, a sliding block is mounted in the sliding chamber in a sliding way, plugging grooves which open to the right are vertically symmetrically arranged in the sliding block, first elastic electric conduction sheets are mounted in the plugging grooves, a power supply block is fixedly arrangedon a left end face of the sliding block, a power supply groove matched with the power supply block is arranged in a left end wall of the sliding chamber, telescoping grooves that extend up and down are symmetrically arranged in upper and lower end walls of the sliding chamber, and sliding arms are mounted in the telescoping grooves in a sliding manner; second elastic electric conduction sheets arefixedly mounted on end faces, positioned away from the sliding chamber, of the sliding arms; third elastic electric conduction sheets opposite to the second elastic electric conduction sheets are mounted in the telescoping grooves, electric conduction arms matched with the plugging grooves are symmetrically arranged on an upper part and a lower part of a left end of the plug head, a lengthwise groove of which an upper end and a lower end are communicated with each other is arranged in the plug head, and a horizontal groove which opens to the left and runs through the lengthwise groove is arranged in the plug head.

Owner:中山市新发装饰工程有限公司

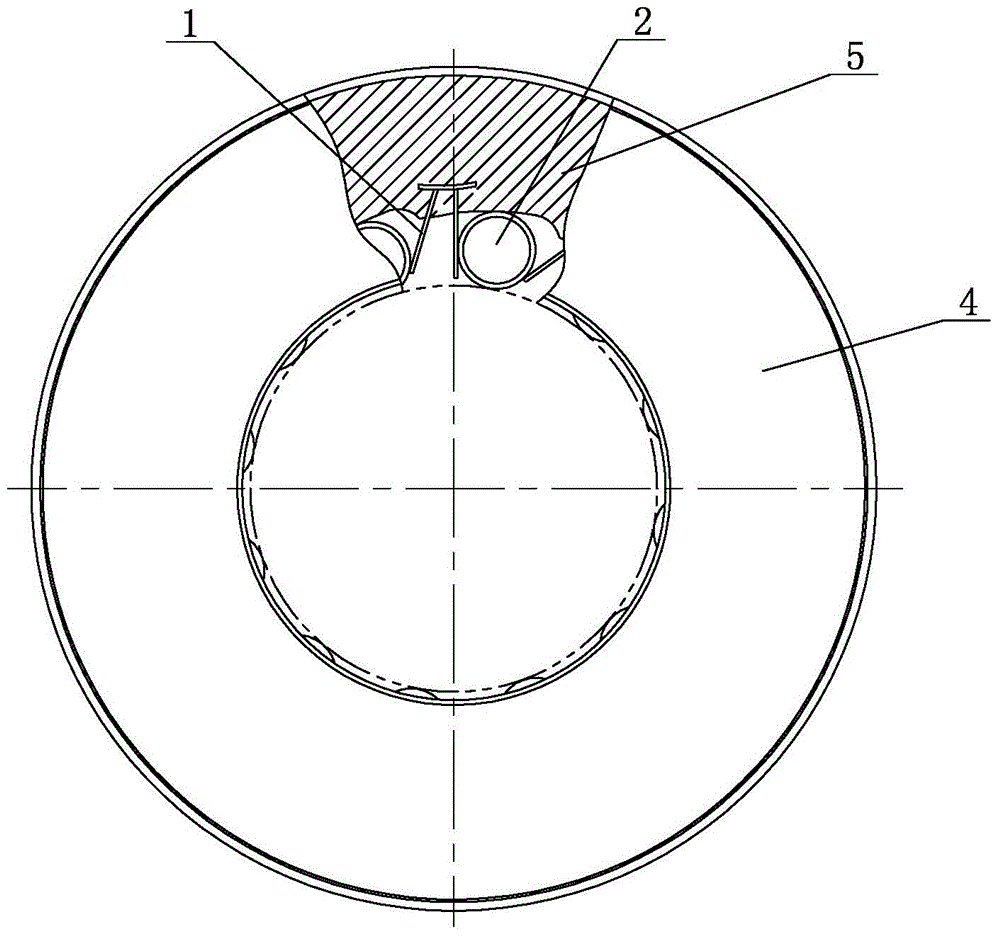

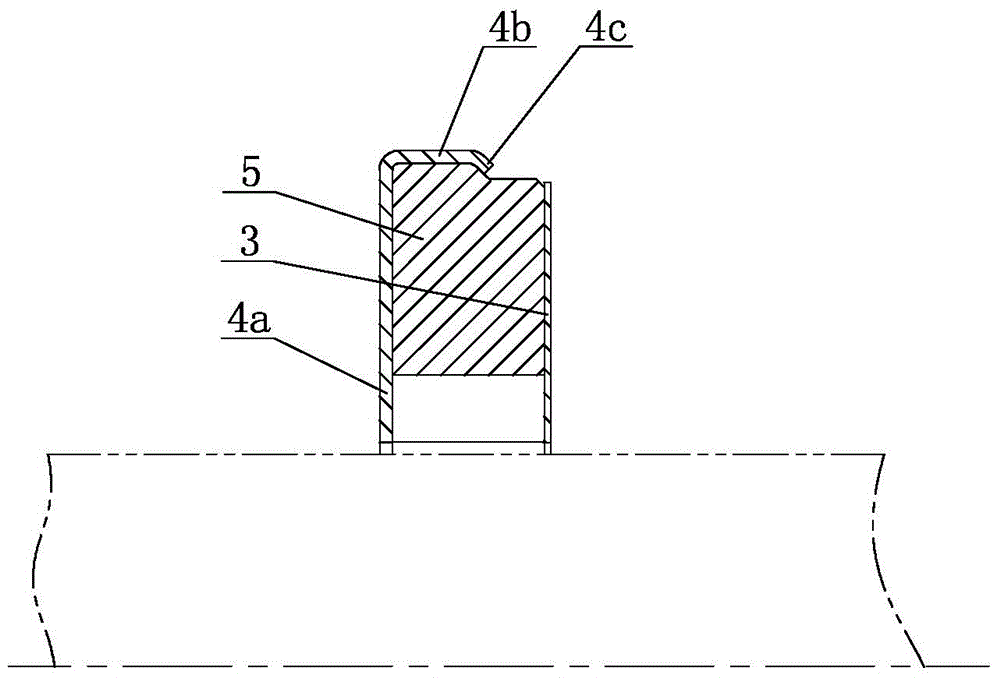

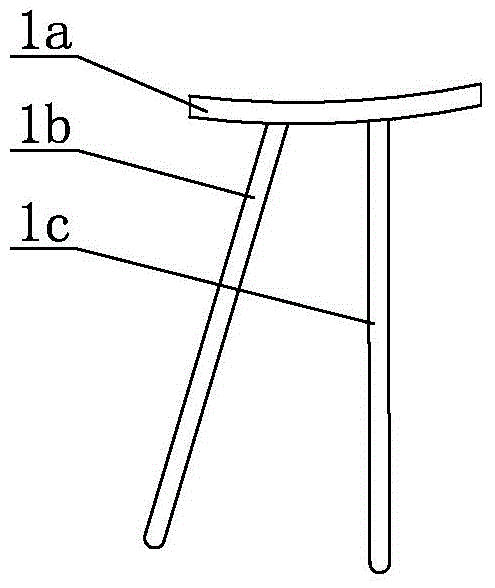

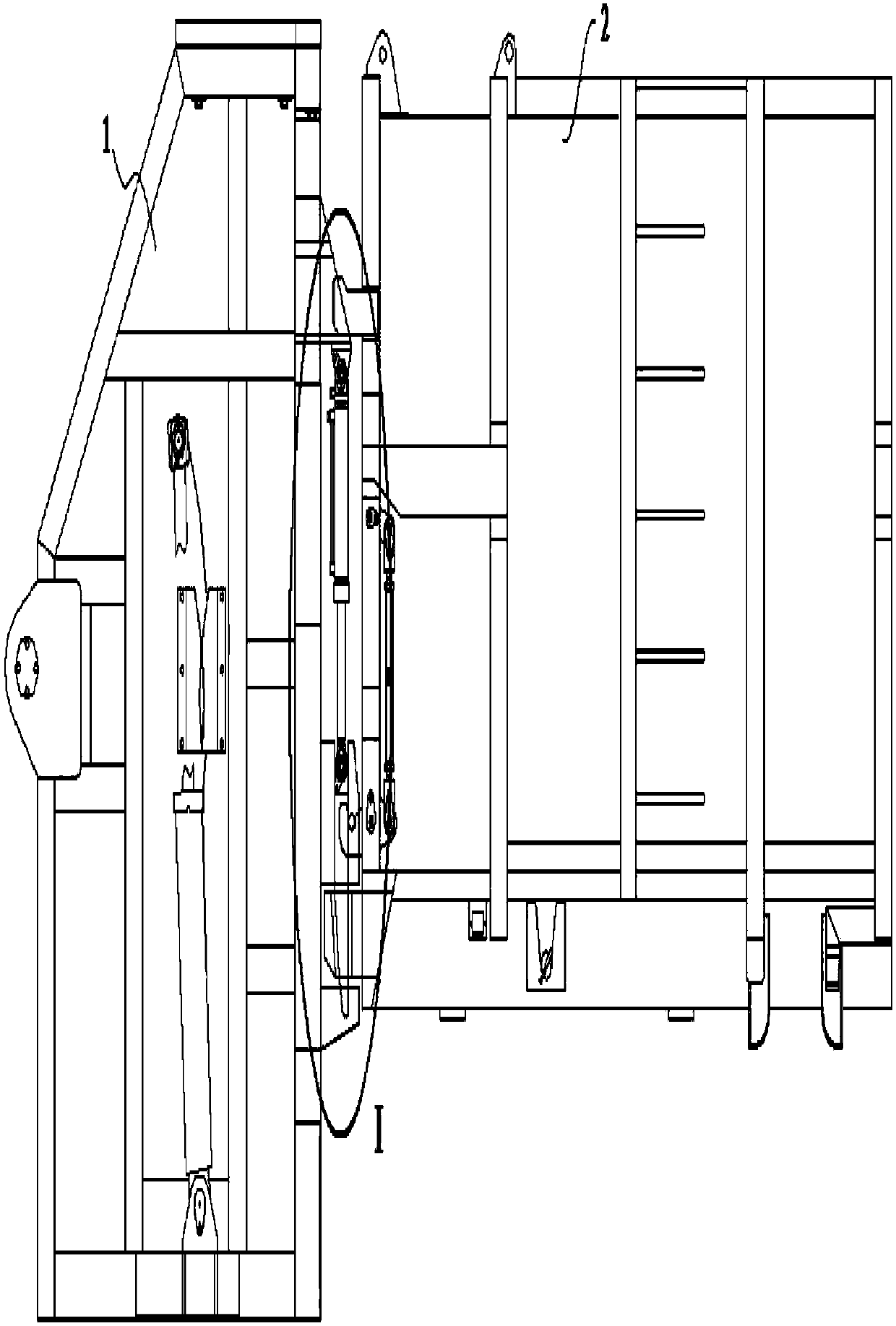

Pin roller type one-way overrunning clutch device for motorcycle

The invention discloses a pin roller type one-way overrunning clutch device for a motorcycle. The pin roller type one-way overrunning clutch device comprises a body (5), a protective cover (4), a baffle (3) and pin rollers (2). The pin rollers (2) are hollow cylinders. Annular grooves (2a) are formed in the middle portions of the pin rollers (2) in a rolling mode. An integrally-formed protruding edge (5a) in a wedge-shaped locating groove is embedded in the corresponding annular groove (2a). An integrated spring leaf (1) is arranged between every two adjacent pin rollers (2) on the circumference and is shaped like a Greek letter phi. According to the pin roller type one-way overrunning clutch device, the pin rollers are driven through the integrated spring leaves, synchronization of movement of the pin rollers can be guaranteed, the performance reliability of an overrunning clutch can be improved, and the service life of the overrunning clutch is longer; meanwhile, the protective cover is of an edge coating installation structure, the protective cover and the body are tightly connected, firmness is good, and the phenomenon of looseness or falling is avoided.

Owner:CHONGQING CONGREN ELECTROMECHANICAL

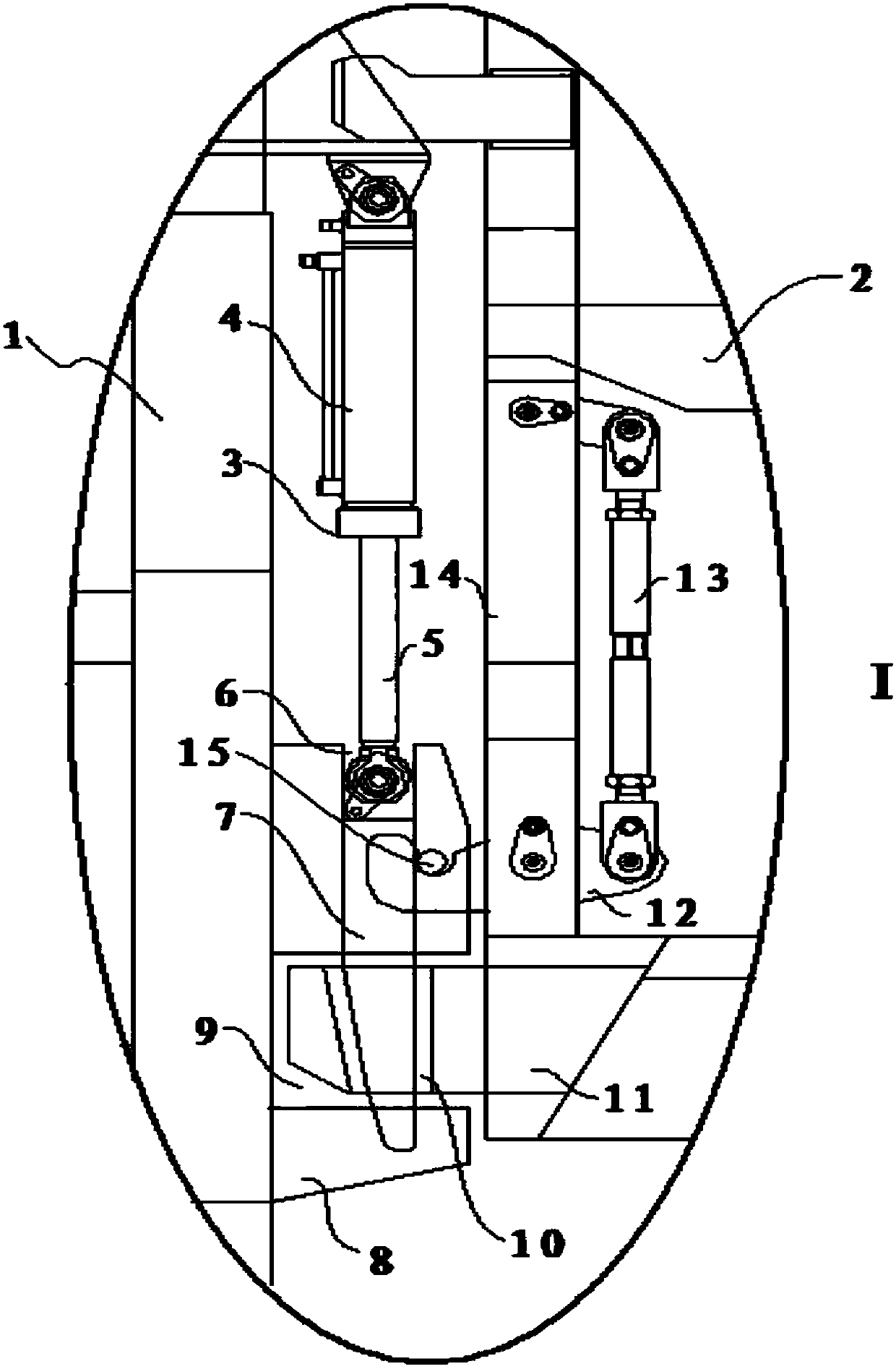

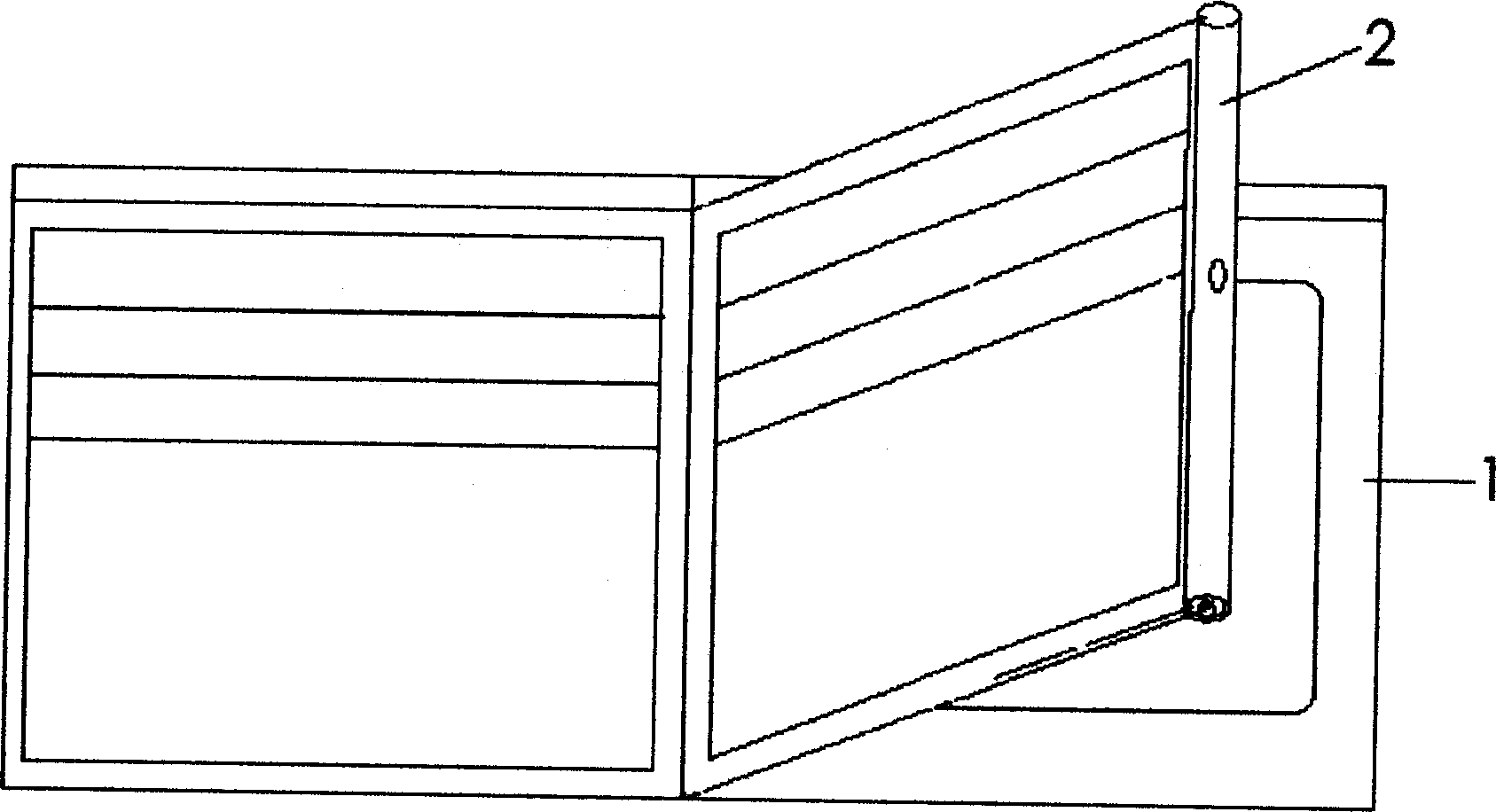

Jointing device for compressor and kitchen truck

The present invention relates to a jointing device for a compressor and a kitchen truck, comprising: a compressor and a garbage truck engaged with the compressor, and the corresponding parts of the compressor and the garbage truck are connected by a joint device, wherein: The engaging device includes: a hydraulic cylinder, the cylinder body of which is installed on one side of the compressor in a vertical horizontal plane, and the piston rod is fixedly connected with a bolt; a U-shaped groove, which is installed on the hydraulic cylinder with the U-shaped notch facing outwards On the side of the compressor below, there is a through hole from top to bottom. When the pin extends downward, it just passes through the through hole; one end of the connecting rod is connected to one side of the garbage truck, and the other end is opened with a pin. hole, when the compressor and the garbage transport vehicle are engaged with each other, the other end of the connecting rod is just located in the U-shaped notch, and the pin passes through the middle through hole to pass through the pin hole to connect and fix the compressor and the garbage transport vehicle. This mechanism makes the compressor More stable engagement with waste trucks.

Owner:QINGDAO ALLITE AUTO TECHNIC

Wallet possessing note checking device

The invention provides a ultraviolet currency examiner, which is made from leather, fabrics and plastic through connection, the examiner can be integrated with the conventional purses for preventing loosening and dropping, the purse can be made into the form of a loose-leaf, or fixed form. The purse makes it easy for carrying currency, coins, magnetic cards, and for distinguish false bank notes.

Owner:上海广丽工贸有限公司

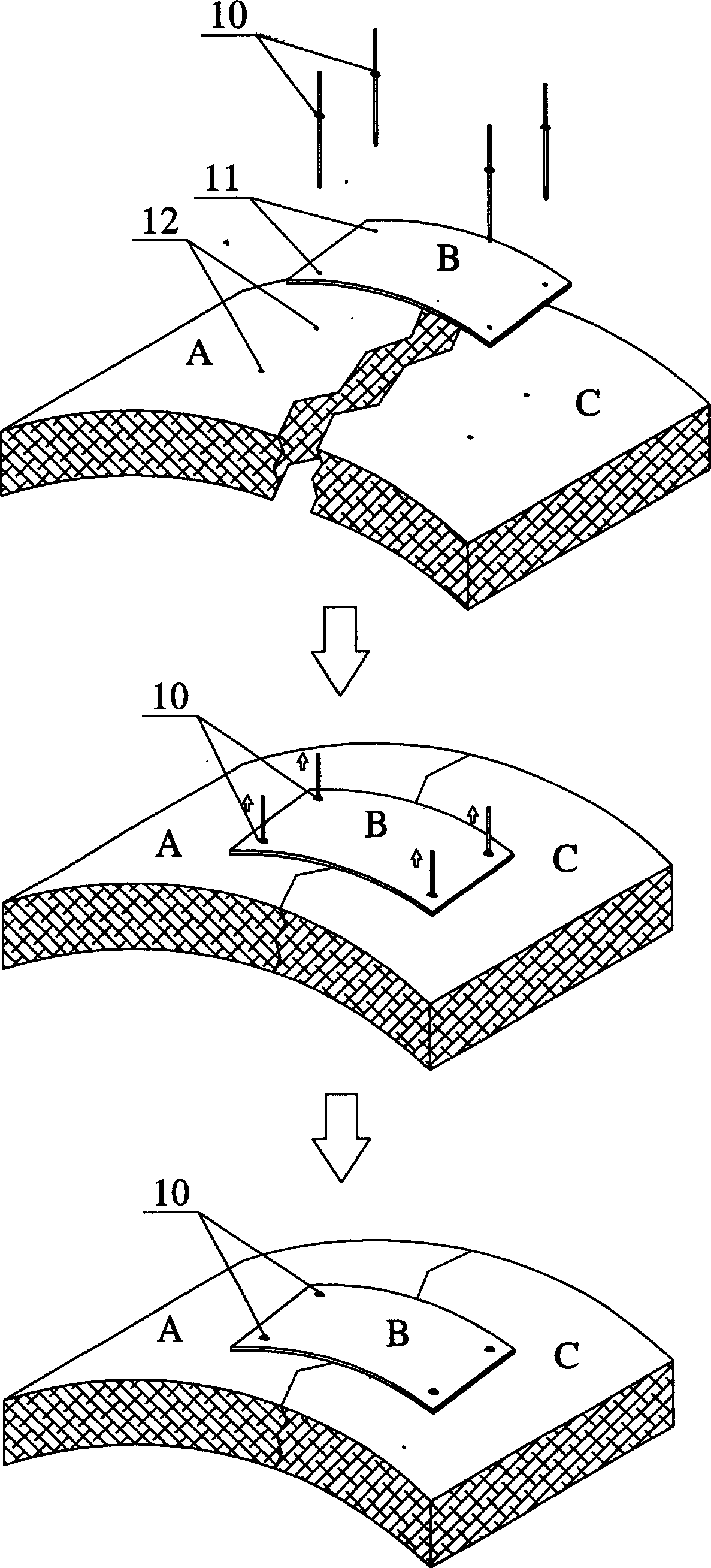

Cardboard stacking packaging device

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

Grounding line connecting device for power equipment

InactiveCN106684584AWon't loosenThose who won't breakCoupling device detailsClamped/spring connectionsEngineeringPower equipment

The invention relates to a grounding line connecting device for power equipment. The grounding line connecting device comprises a line fixing member and a grounding member, and further comprises an extensible member, the bottom of the line fixing member is connected with the extensible member, the bottom of the extensible member is connected with the grounding member, the line fixing member is rectangular and is provided with a rectangular penetrating cavity in the middle, a penetrating hole is formed in each of two sides of the line fixing member and communicated with the penetrating cavity, and the penetrating holes in the two sides of the line fixing member are coaxial; a pad seat is arranged on the extensible member, positioned at the bottom end in the penetrating cavity and fixed on the inner wall of the line fixing member, the penetrating holes in the two sides of the line fixing member and the pad seat are on a same straight line, and horizontal positions of the penetrating holes are lower than horizontal position of the highest end of the pad seat; the top end of the line fixing member is provided with a threaded hole and a bolt matched with the threaded hole, and the threaded hole is positioned right above the pad seat. Through the line fixing member, a grounding line is enabled to penetrate the penetrating holes in the two sides of the line fixing member, the grounding line in the penetrating cavity is set up at the highest end of the pad seat, and the bolt compresses the grounding line by rotating the bolt, so that the grounding line fixing device is convenient to mount and demount; by arranging the extensible member, the whole structure has extensible performance.

Owner:吴文革

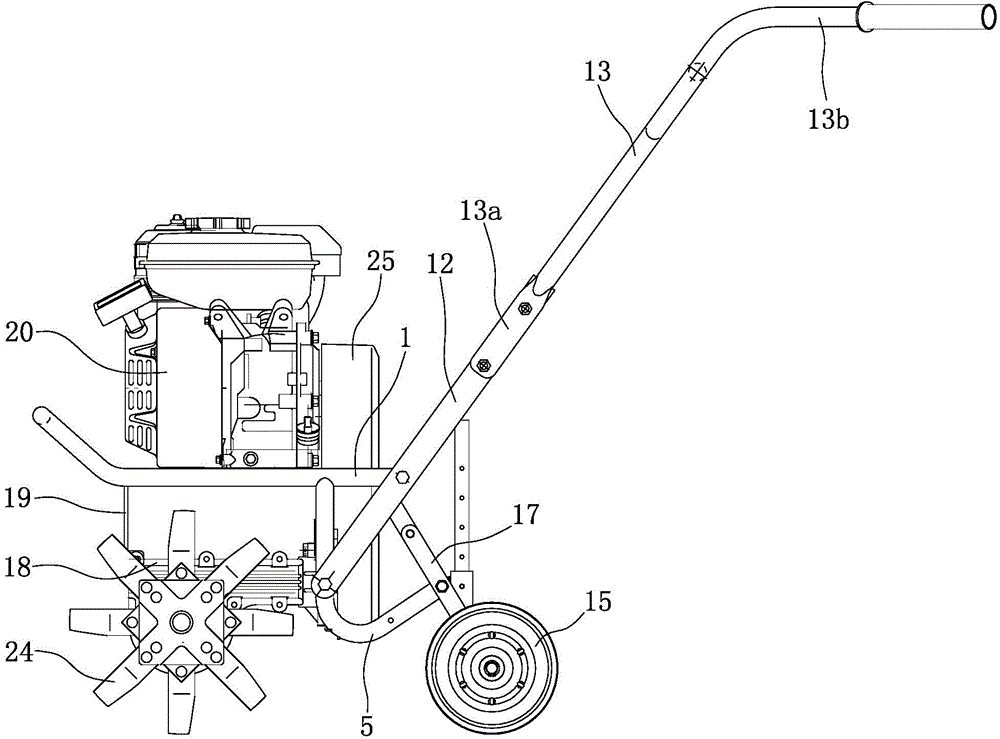

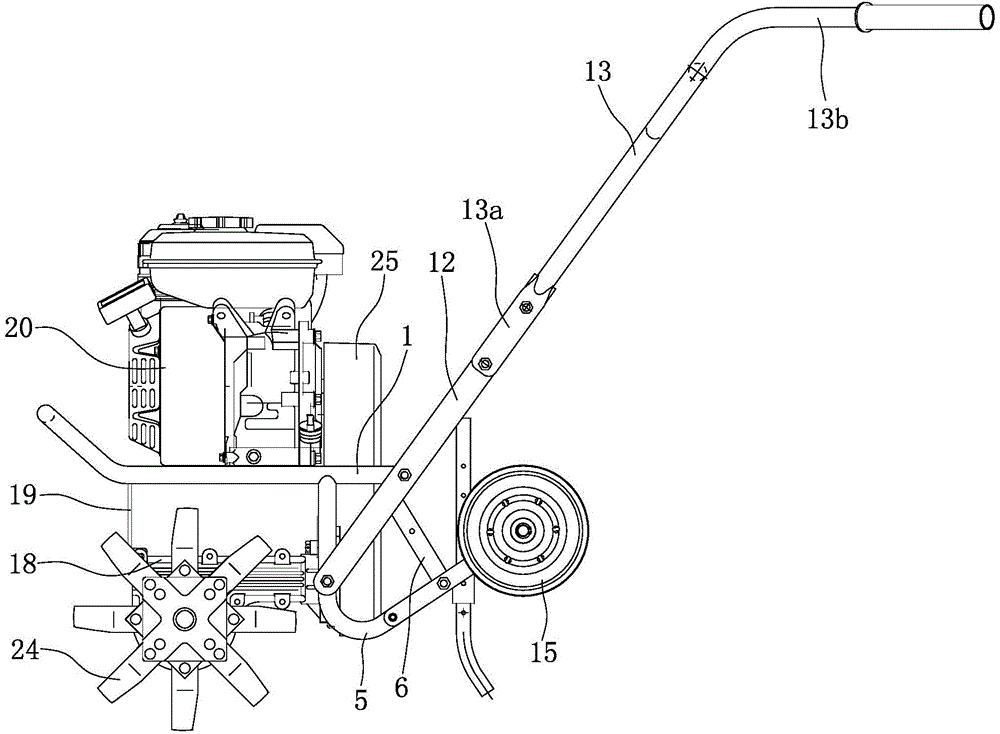

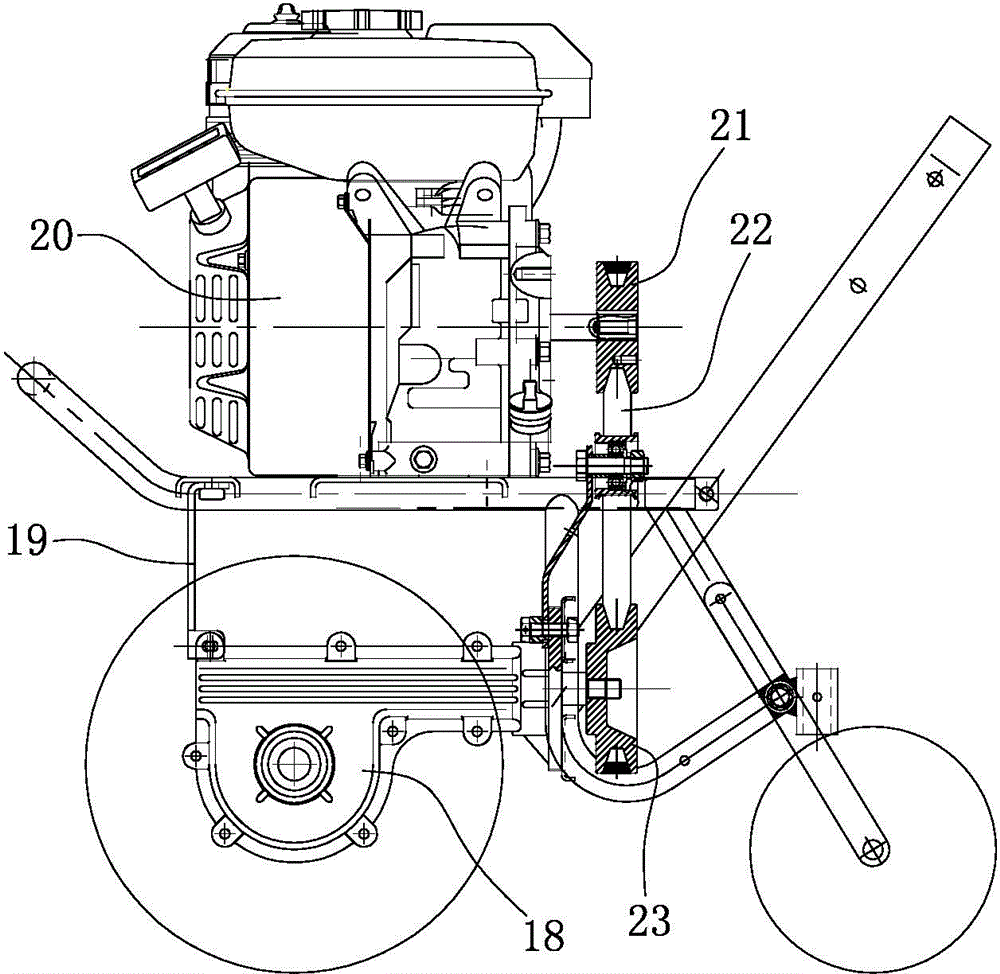

Portable micro-cultivator

ActiveCN104081900AEasy to shapeCompact structureAgricultural undercarriagesEngineeringMechanical engineering

The invention discloses a portable micro-cultivator. The bottom of a front support (19) is connected with the top of the front end of a screw transmission box (18); the middle located between two horizontal sections of a main pipe (1) is provided with a supporting plate (3); each end portion of the supporting plate (3) is fixedly connected with a pipe body of the corresponding horizontal section of the main pipe (1) in a welding mode; an engine (20) is supported on the supporting plate (3); a driving wheel (21) is arranged on an output shaft of the engine (20) in a sleeving mode; the driving wheel (21) is connected with a driven wheel (23) through a belt (22); the driven wheel (23) is arranged on an input shaft of the screw transmission box (18) in a sleeving mode. According to the portable micro-cultivator, a handgrip seat and a handgrip pipe which form each handgrip is of a split type structure and accordingly the detachment and installation is convenient; rear wheels can be put away or put down according to needs, the put-away and put-down operation is simple and rapid, and accordingly the working efficiency of the micro-cultivator can be effectively improved; the engine and the screw transmission box are arranged in a horizontal mode and accordingly the size of the micro-cultivator can be further reduced and the screw transmission box is firm and reliable in installation and good in stability.

Owner:CHONGQING JIAMU MACHINERY

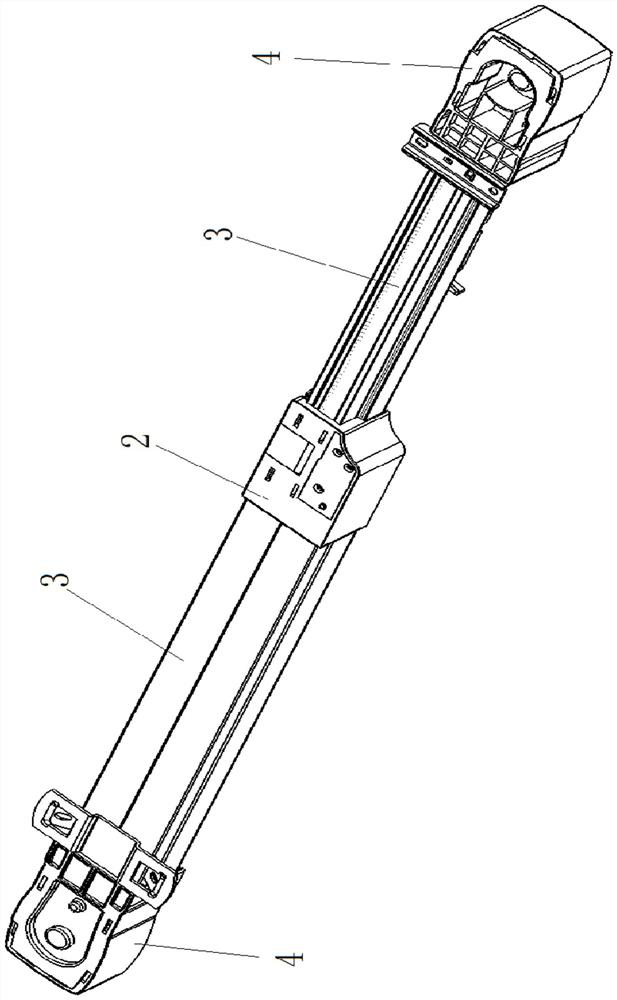

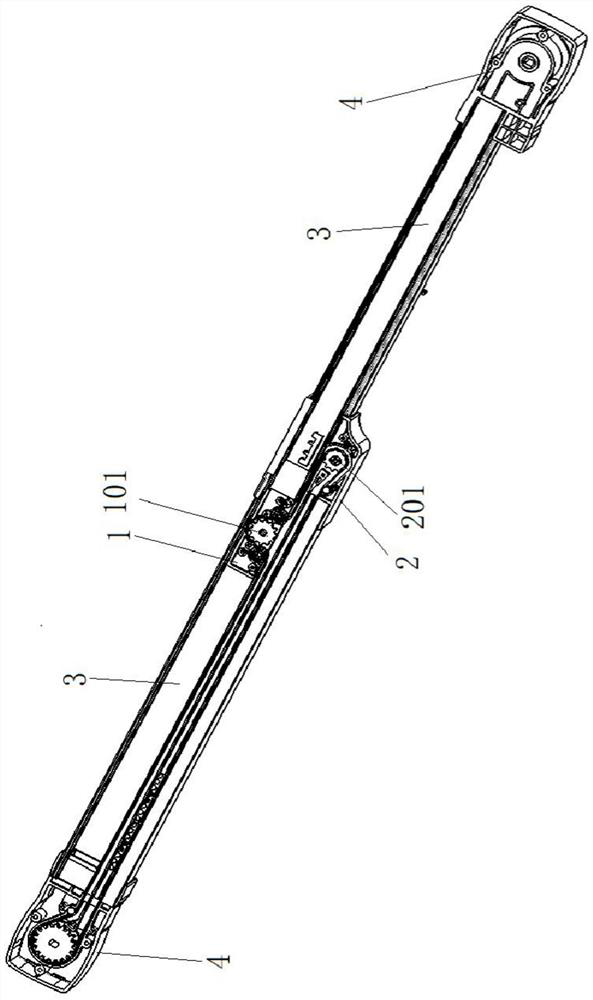

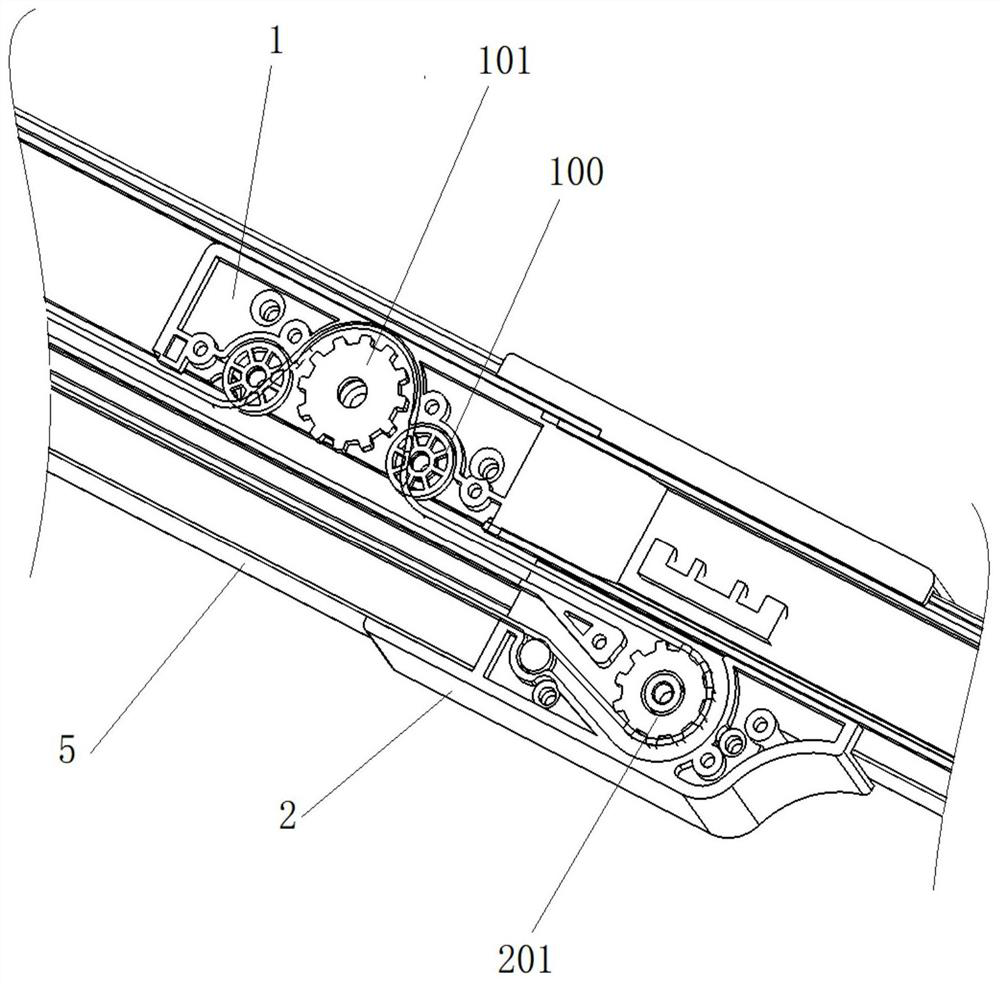

An electric curtain that can realize double-layer belt linkage and convenient distance adjustment

ActiveCN112641313BWon't loosenEasy to installCurtain accessoriesBuilding thermal performance improvementGear driveGear wheel

The invention provides an electric curtain that can realize double-layer belt linkage and convenient distance adjustment. The two ends of the main linkage device and the auxiliary linkage device are respectively connected with guide rails, and belts are respectively wound in the transmission boxes at both ends, and the belt of the transmission box at one end Extend from one of the guide rails into the secondary linkage, and wrap around the outside of the third gear, and continue to extend into the main linkage, and mesh with the first gear, and the belt of the transmission box at the other end is from the other The guide rail extends into the main linkage device and is meshed with the second gear for transmission connection. In use, when the overall length of the guide rail needs to be adjusted, the end cover is pressed down so that the transmission groove of the second gear is in phase with the transmission teeth of the first gear. Cooperate to realize the meshing of the first gear and the second gear, so that the first gear and the second gear drive the belt linkage at the same time, so that even after the distance of the guide rail is shortened or extended, the belt will not be too loose and shaken, so there is no need to move the belt The operation of removing, cutting and connecting again.

Owner:广东居意智能遮阳科技有限公司

A kind of production method of PBT colored point core-spun yarn

The invention discloses a method for producing PBT (Polythylene Terephthalate) color point core spun yarns. The method comprises the following steps: selecting yarn materials; performing process procedures of the PBT color point core spun yarns; implementing the specific production process. According to the method disclosed by the invention, acrylic fibers serve as raw materials of the points, the color point has rich colors, the color is bright, the stereoscopic impression is excellent, and the price can be saved by 20000 Yuan per tonnage compared with that of common chinlon points. A waterproof agent is diluted according to a ratio and uniformly sprayed onto the points, and the points are dried and roasted at a high temperature, so that the colored point achieves a water-repellent effect, the colored points are prevented from being loosened in the subsequent processing procedure, staining of dyes on the color points is reduced in the dyeing process, the shape and brightness of the color points can be guaranteed, and the quality of the yarns is improved. The PBT serves as the core yarn, viscose cotton serves as an outer packaging material, and the problems that the spandex core-spun yarns are poor in acid resistance and chlorine resistance and have non-ideal dyeing effect are solved. The color point core spun yarns produced by the method disclosed by the invention are excellent in fluffiness and crimpiness and high in elasticity and shape stability and have hand feel of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

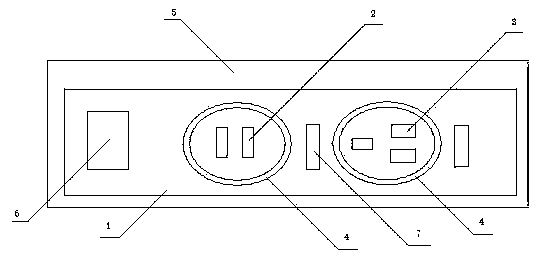

Multifunctional wall electric socket

InactiveCN107732592AWon't loosenWon't fall offIncorrect coupling preventionTwo-part coupling devicesBody regionStructural stability

The invention discloses a multi-function wall electric plug board, which comprises a plug board body installed on the wall, an electrical plug insertion area is provided on the plug board body, and a two-phase jack and a three-phase jack are arranged in the electrical plug insertion area. The two-phase jack and the three-phase jack are provided with electrical contact sheets, and the plug insertion area of the electrical appliance is provided with an annular groove, and the annular groove surrounds the two-phase jack and the three-phase jack respectively. Around the two-phase jack and the electrical plug inserted into the three-phase jack are fixed on the plugboard body through the annular groove. The two-phase jack and the three-phase jack are respectively provided with jack control switches. The surface of the board body is provided with a fluorescent coating. The invention adopts the annular groove, the electrical plug will not loosen or fall off after being inserted, the structure is stable, and a secondary control switch is separately equipped, which is convenient to control, easy to use, and has a wide range of applications.

Owner:郑惠允

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com