Gear lever device

A technology of shifting lever and cover plate, which is applied in the direction of control device, transportation and packaging, vehicle parts, etc., can solve the problems of high assembly cost and time-consuming assembly operation, and achieve the effect of easy and convenient assembly operation, and the effect of preventing loosening and floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

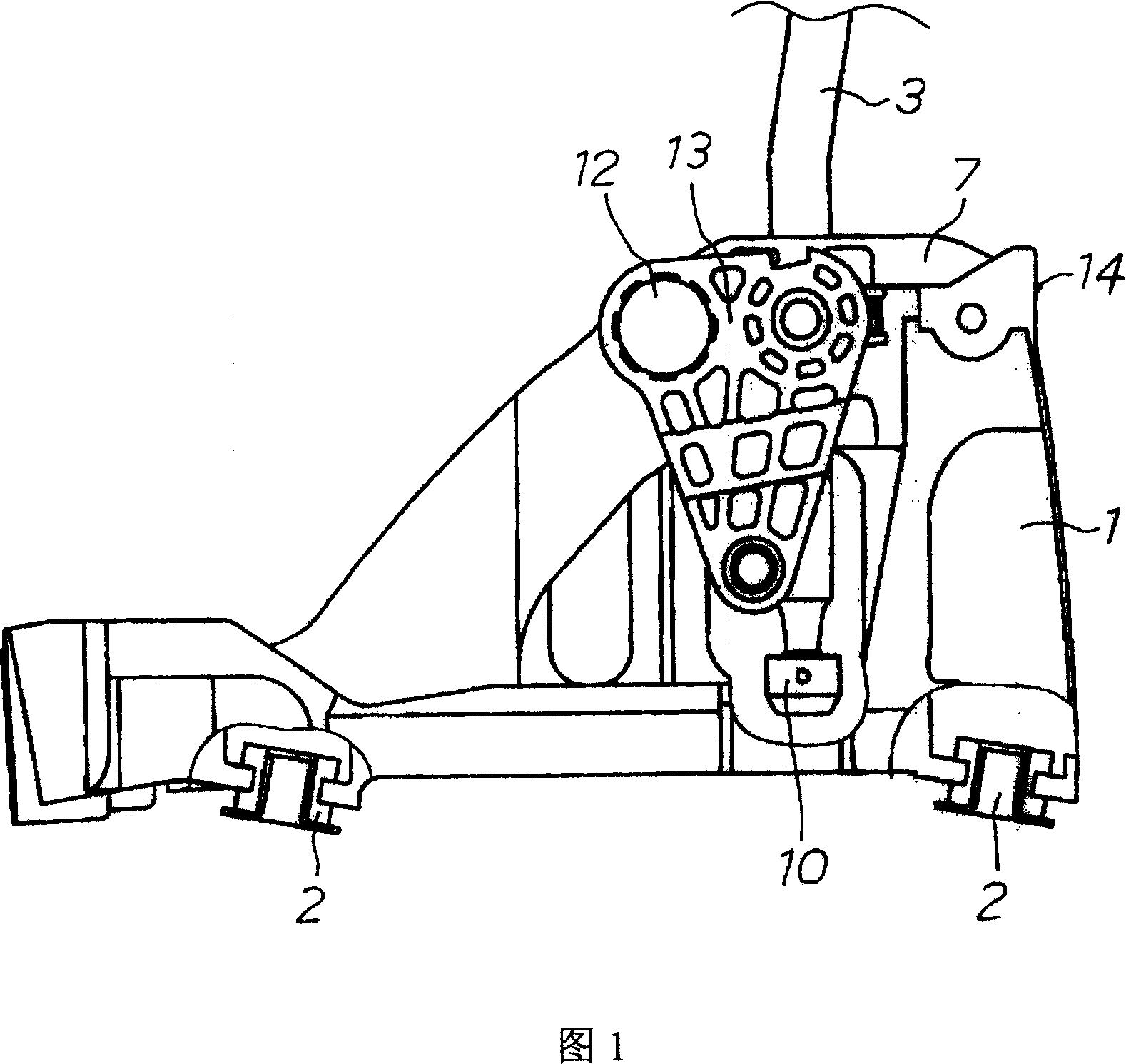

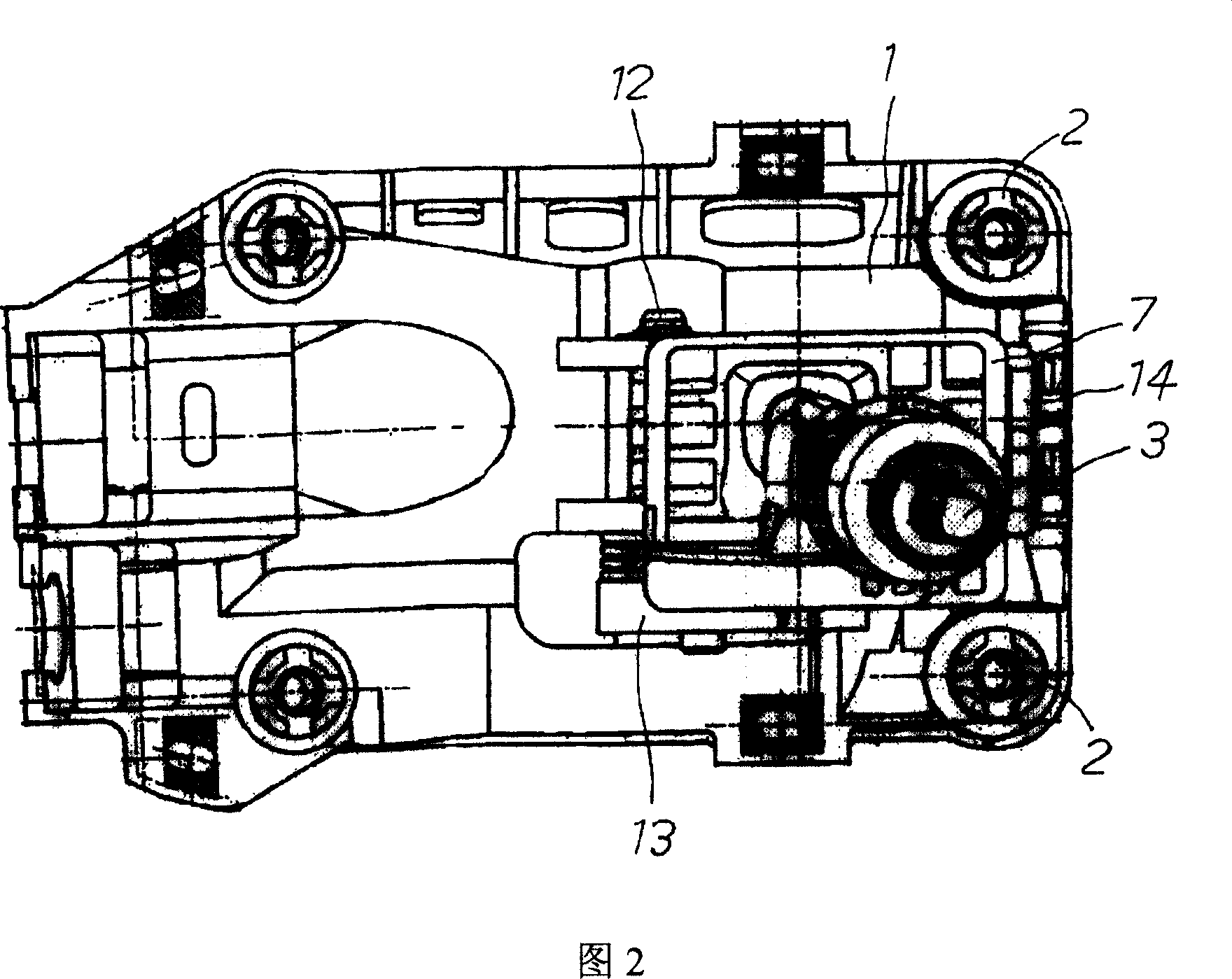

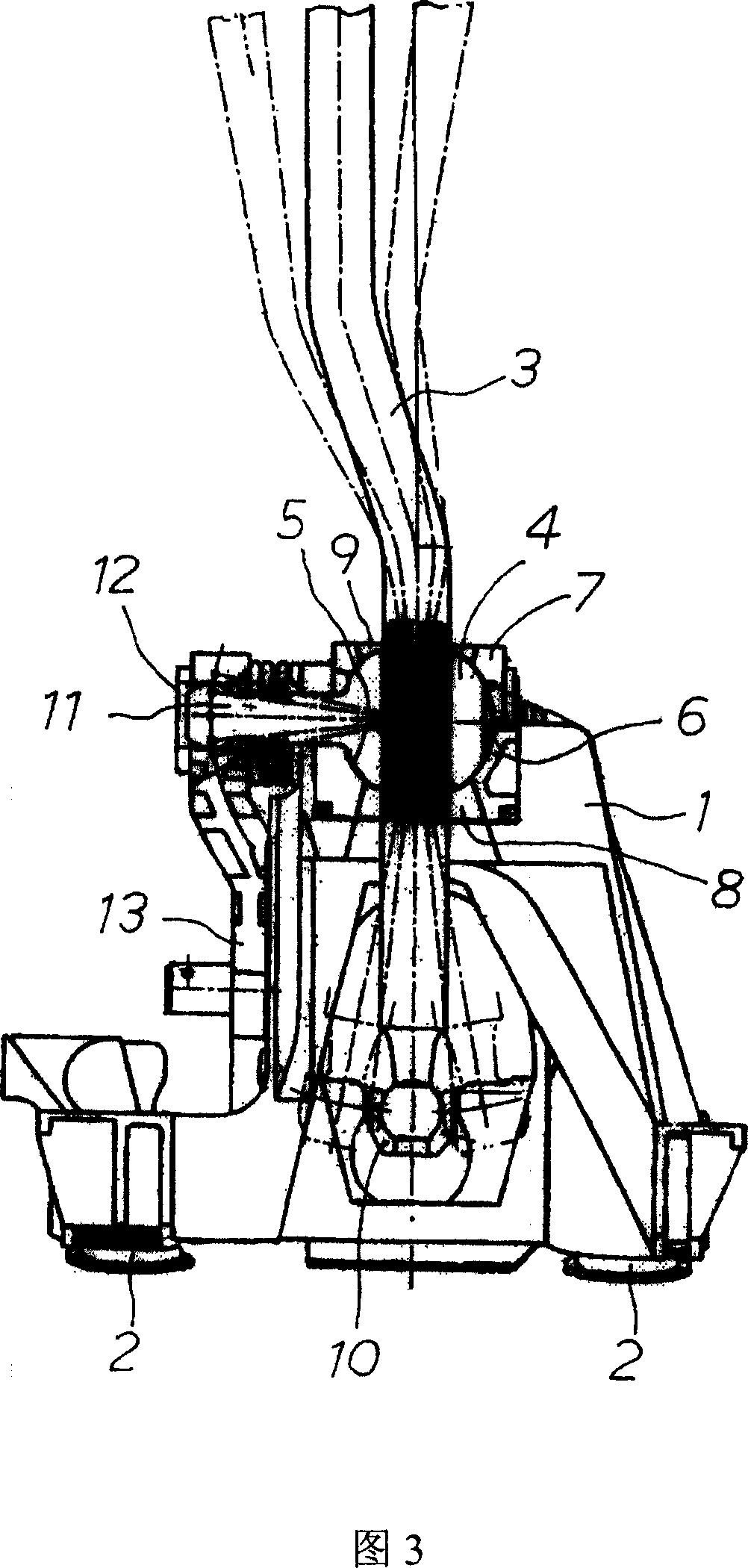

[0019] Preferred embodiments of the present invention are shown below.

[0020] FIG. 1 is a front view showing an embodiment of the present invention, FIG. 2 is a plan view thereof, and FIG. 3 is a cross-sectional view thereof. In these figures, 1 is a resin retainer, which has a structure in which bracket rubber 2 at four corners is fixed to the floor of the vehicle by unillustrated bolts. 3 is a rod body, and a large ball 4 is fixed on the outer periphery of its lower part. The lever body 3 can swing in the shifting direction (vehicle front-rear direction) and the selection direction (vehicle lateral direction) by supporting the large ball 4 on the spherical seat 5 on the upper part of the cage 1 .

[0021] The spherical seat 5 is formed between a seat frame 6 and a cover plate 7 covering its upper portion, and the seat frame 6 is fitted in a recess formed at the upper portion of the cage 1 . The seat frame 6 has a spherical concave portion constituting the lower half of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com