Pin roller type one-way overrunning clutch device for motorcycle

A technology of one-way overrunning and clutch devices, applied in one-way clutches, clutches, mechanical equipment, etc., can solve problems affecting the reliability and service life of overrunning clutches, affect the performance of overrunning clutches, increase the weight of overrunning clutches, etc., and achieve the goal of connecting Strong and reliable, good reed positioning, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

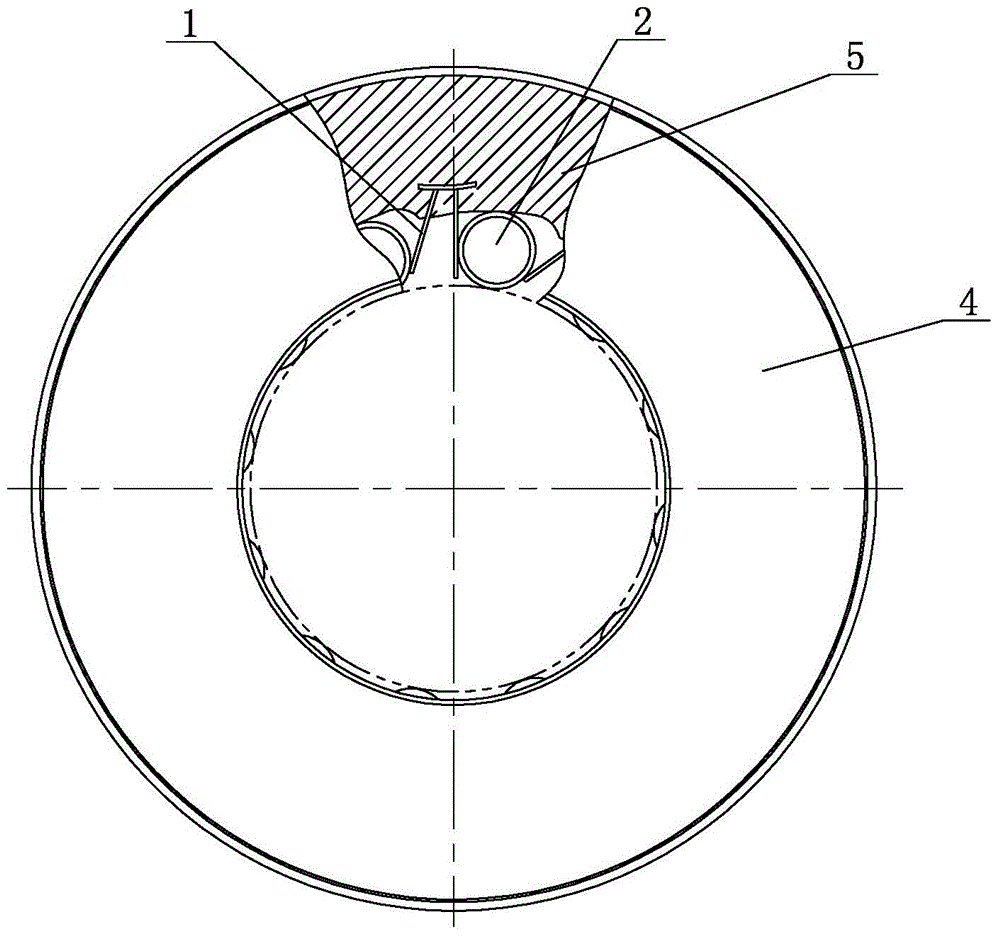

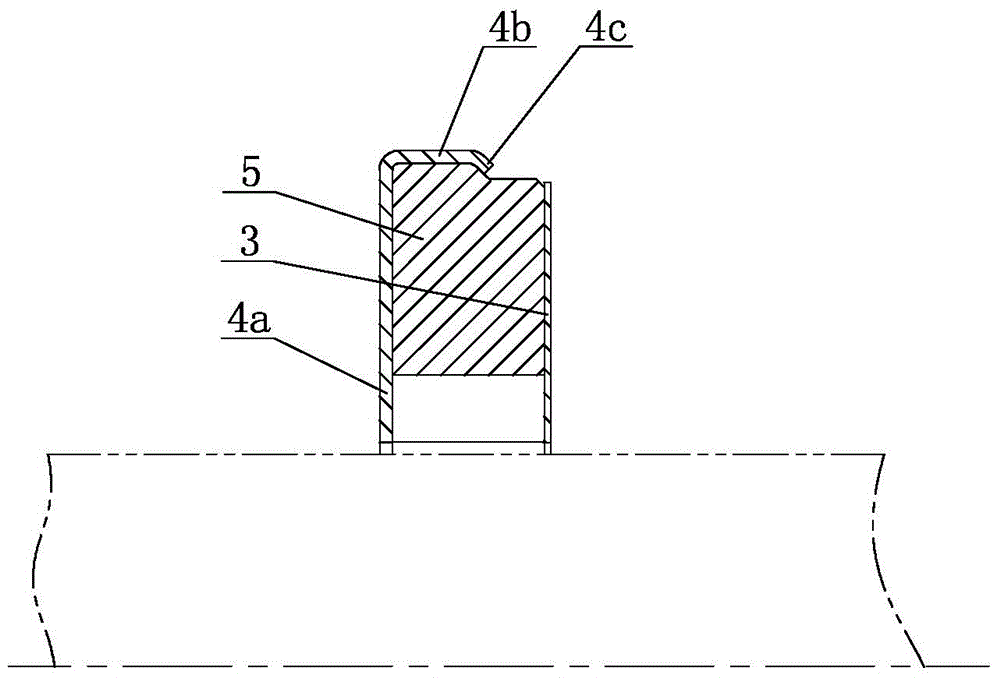

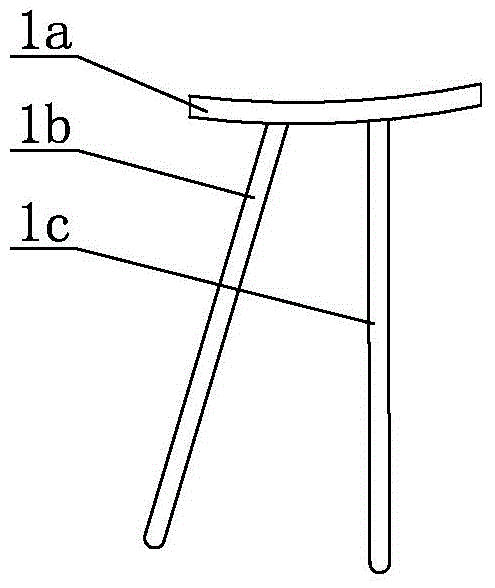

[0029] Such as figure 1 , figure 2 , Figure 4 As shown, the present invention is made of components such as integrated reed 1, roller 2, baffle plate 3, shield 4 and body 5. Wherein, the main body 5 is a ring structure, the peripheral side of the main body 5 is a stepped structure, and the transition between the large section and the small section of the main body 5 peripheral side is through a middle cone section. A shield 4 is provided on one side of the body 5, and a baffle 3 is provided on the other side. The shield 4 is a stamped steel part, consisting of an end 4a, a ring 4b and a bent portion 4c. The end 4a of the shield 4 is in close contact with the end face of the body 5, and the ring 4b of the shield 4 holds the body 5 weeks of extensive covering of the sides. The bending part 4c of the shield 4 is formed by flanging the free end of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com