Angle adjustable valve

A valve and angle technology, applied in the field of valves, can solve problems such as unreliable locking, excessive temperature of electronic components, easy loosening, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

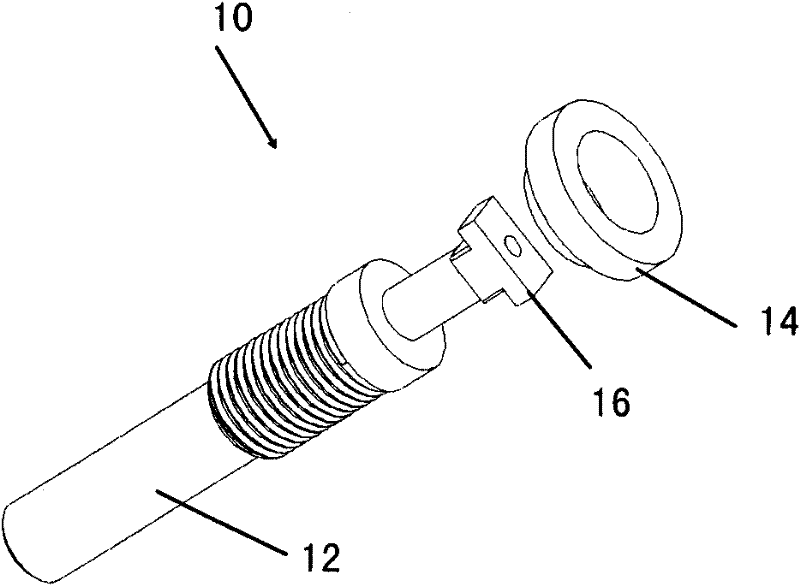

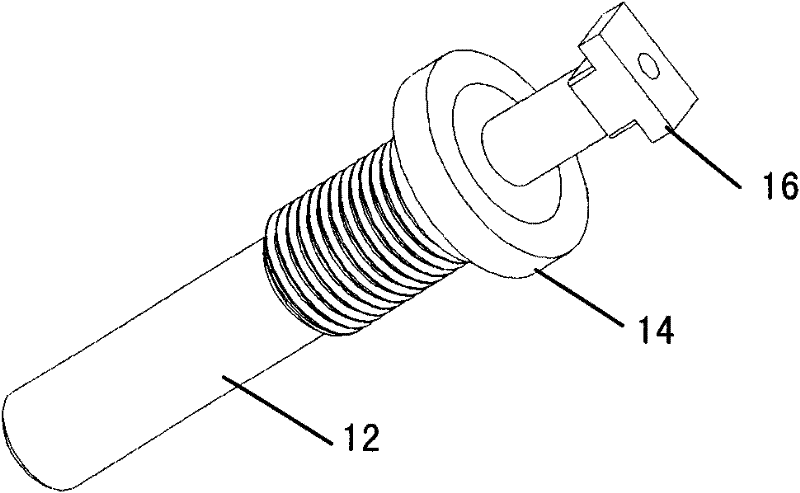

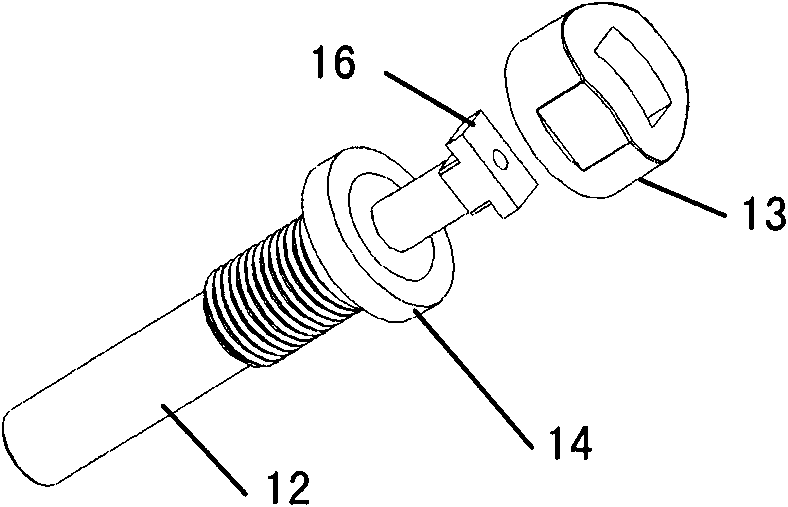

[0020] Figure 1-4 The basic structure of the valve and its assembly process of an embodiment of the present invention are shown. The valve described here does not cover the TPMS electronic signal box part. refer to Figure 1-4 As shown, the valve 10 includes a mouth stem 12 , a mouth stem cap 13 and a rubber pad 14 . In addition, the valve 10 also includes a nut 15, which will be referred to later Figure 8-10 describe. Most of the rod sections of the mouth rod 12 are smooth, and only some of the rod sections have threads. And the end of the mouth rod 12 has a rectangular stopper 16 . The rubber pad 14 and the mouth rod cap 13 are sequentially sleeved on the mouth rod 12 . In this embodiment, the outer contour of the mouth rod cap 13 may be a curved surface. The rubber pad 14 plays a role of sealing, but it can be understood that other elastic sealing pads or sealing means can also be used instead of the rubber pad 14 .

[0021] Figure 5-7 The assembly process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com