Light partition wall batten mounting structure and preparation method thereof

A light-weight partition wall slat and installation structure technology, which is applied in the direction of walls, ceramic products, manufacturing tools, etc., can solve the problems of low bending load and compressive strength, affecting the stability of the slat connection, troubles, etc., and achieve improvement The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

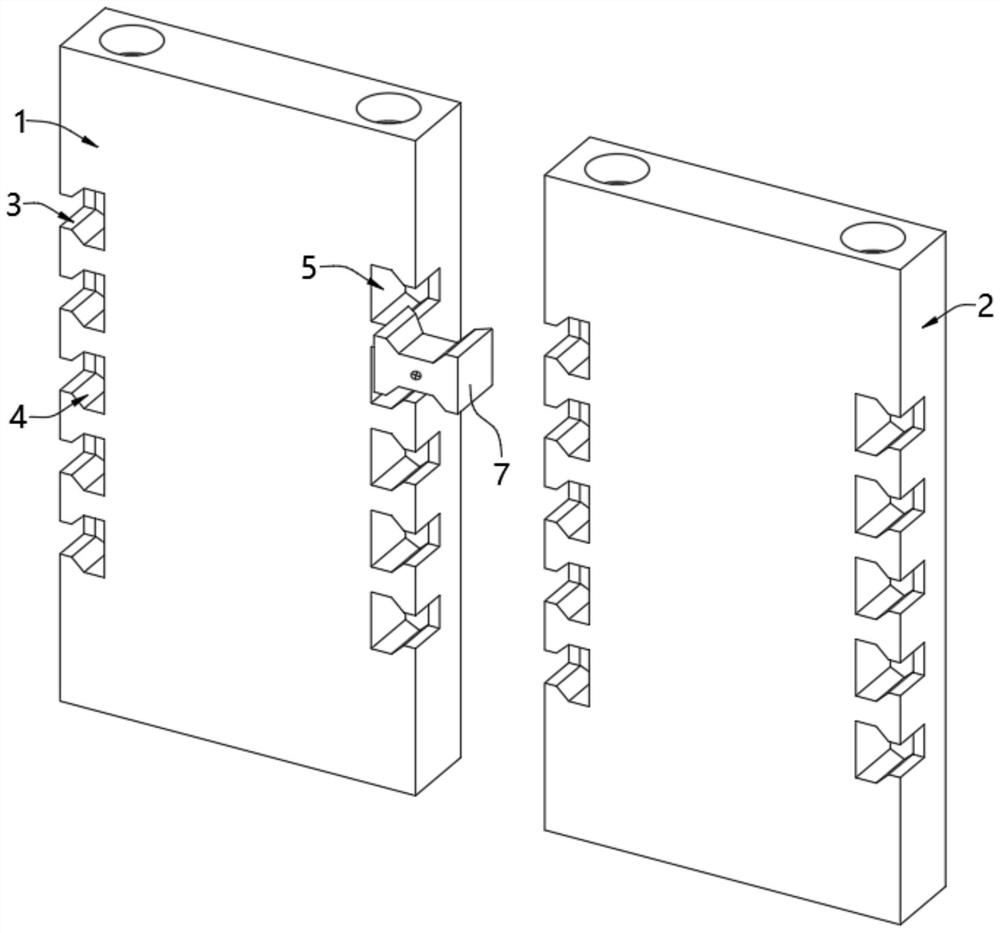

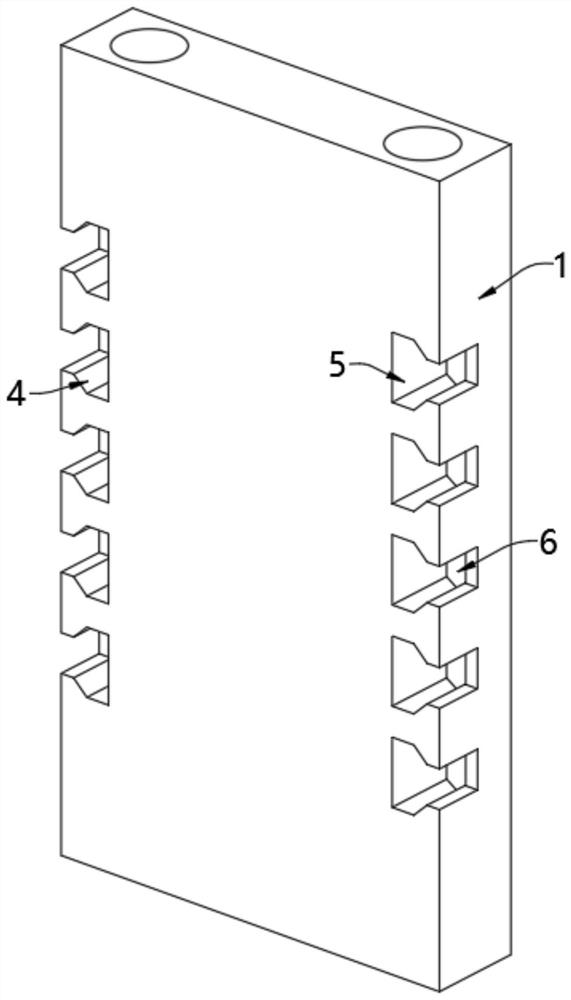

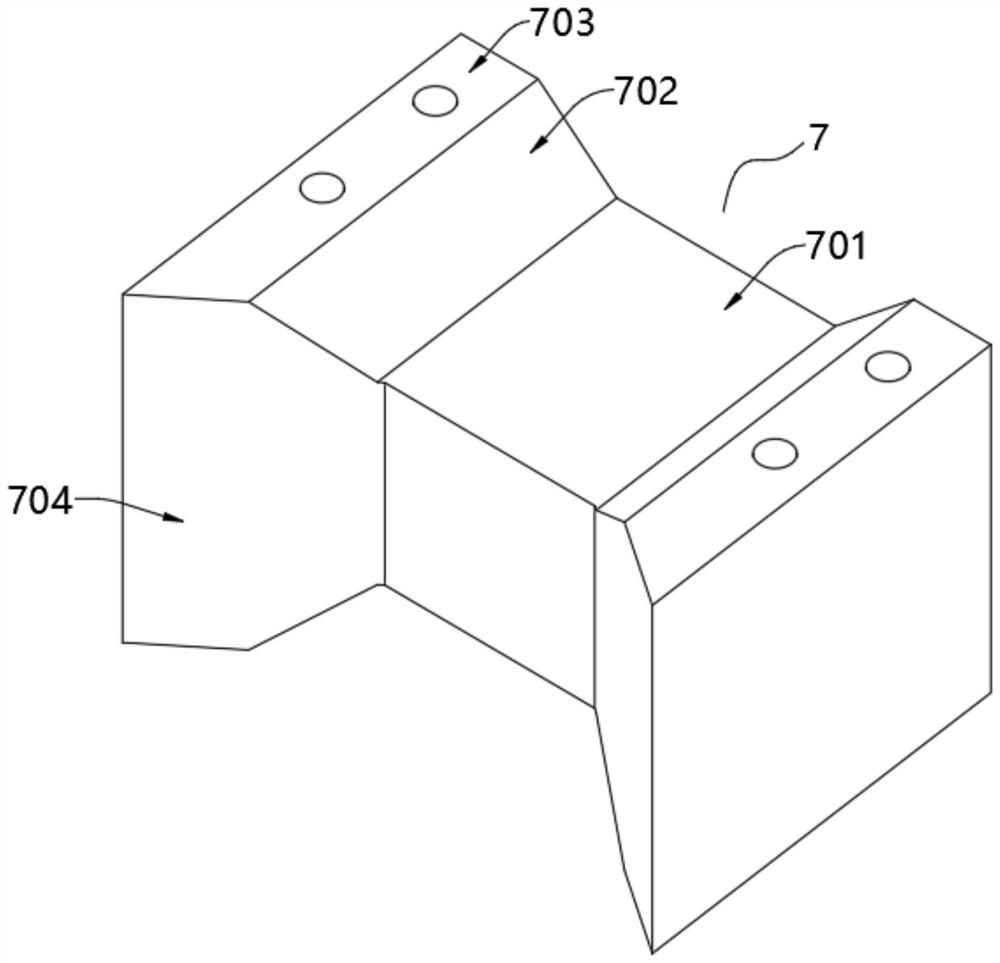

[0068] see Figure 1-Figure 5 , a lightweight partition wall batten installation structure, including a first batten 1 and a second batten 2, both sides of the first batten 1 and the second batten 2 are provided with side grooves 3, and the side grooves 3 face The inner side is provided with a slope groove 4 whose cross section is an isosceles trapezoid, and the inward side of the slope groove 4 is provided with a card groove 5, and the inner walls of the side groove 3, the slope groove 4 and the card groove 5 are movable and provided with a fixed pin 7 , the fixed pin 7 includes a connecting column 701, a slope plate 702 and a clamping plate 703, the two ends of the connecting column 701 are fixedly equipped with a slope plate 702, and the shape of the slope plate 702 matches the shape of the slope groove 4;

[0069] The outer side of the two slope plates 702 is fixedly equipped with a clamping plate 703, and the clamping plate 703 is movably arranged on the inner wall of the...

Embodiment 2

[0074] see Image 6 On the basis of Embodiment 1, vertical grooves 13 are opened inside the two clamping plates 703, and the inner wall of the vertical grooves 13 is movably provided with a first slide plug 15 and a second slide plug 17, and the first slide plug 15 and the second slide plug The outward side of the two sliding plugs 17 is respectively fixed with a first clamping column 16 and a second clamping column 18, and the inner wall of the clamping groove 5 is provided with a locking groove matching the first clamping column 16 and the second clamping column 18. ;

[0075] The control device arranged inside the connecting column 701 and the slope plate 702 makes the first clamping column 16 and the second clamping column 18 extend in and out in the vertical groove 13, and the control device includes a first piston 10, a second piston 11 and a connecting rod. Groove 14, connecting column 701 and slope plate 702 are formed with inner cavity 8, the two ends of inner cavity...

Embodiment 3

[0082] see Figure 7-Figure 10 , on the basis of Embodiment 1 and Embodiment 2, it also includes a third strip 21, the edges of the upper and lower ends of the first strip 1 and the third strip 21 are provided with slots 22, and the two opposite slots A column 23 is inserted between the 22, and the length of the column 23 matches the sum of the depths of the two opposite slots 22;

[0083] The outer wall of the column 23 is covered with a deformable metal column 26, and the upper and lower ends of the deformable metal column 26 are fixedly equipped with a deformable metal plate 27, such as Figure 9 As shown, the deformable metal plate 27 is arranged in a cylindrical shape;

[0084] The outward end of the slot 22 is formed with a trapezoidal groove 24, the inner diameter of the trapezoidal groove 24 gradually decreases from the outside to the inside, and the edge of the inner bottom wall of the trapezoidal groove 24 is provided with a wing groove 25, and the wing groove 25 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com