Fast connection pipe fitting

A technology of pipe fittings and tube cores, which is applied in the field of quick-connect pipe fittings, which can solve problems such as easy loosening of nuts, difficulty in disassembly, and influence on the sealing performance of pipe fittings, and achieve the effects of improved sealing performance, convenient installation, and convenient disassembly and assembly of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below:

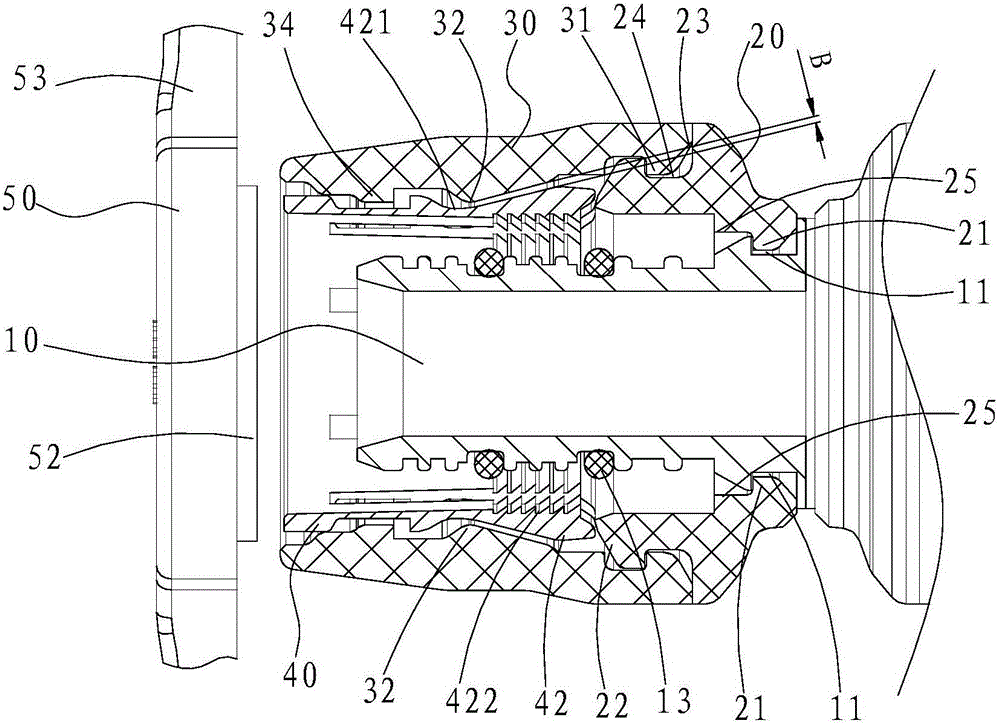

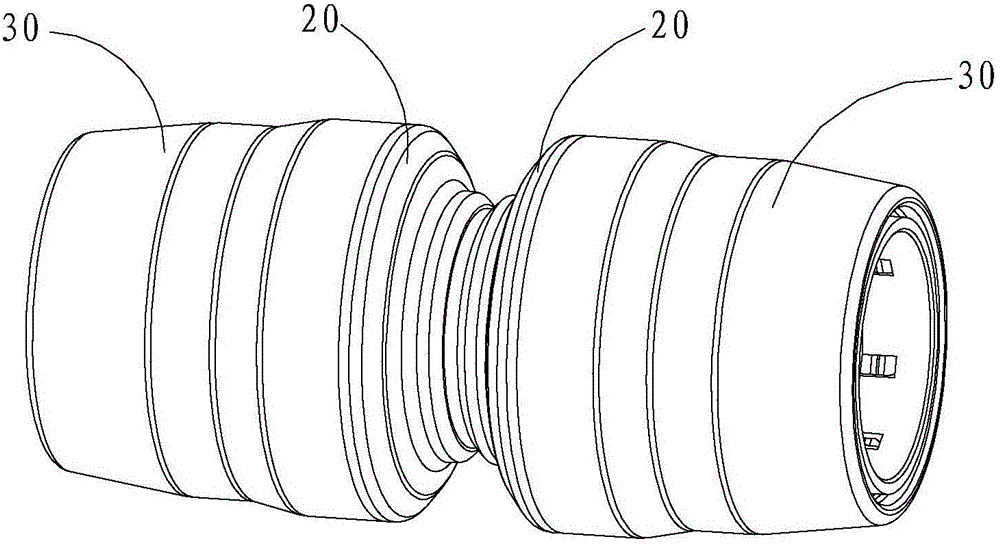

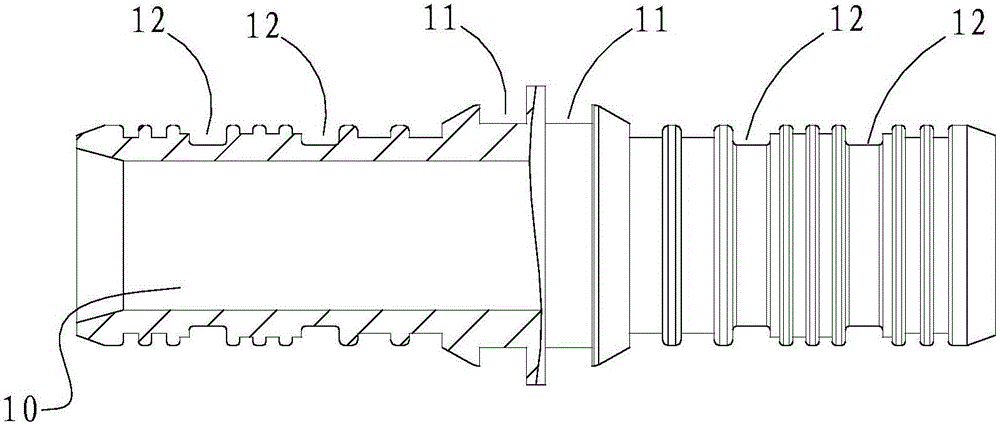

[0039] Such as figure 1 As shown, it schematically shows the structural diagram of the quick-connect pipe fitting of the present invention, figure 2 It shows the overall appearance of the quick-connect pipe fittings, Figure 3-13 Correspondingly, the structural diagram of each component of the quick-connect pipe fitting is indicated. The quick-connect pipe fitting of the present invention includes a tube core 10 , a housing base 20 , a housing sleeve 30 and a clamp sleeve 40 .

[0040] The outer wall of the tube core 10 is provided with a first mounting groove 11 . The shell seat 20 is provided with a channel for installing the die 10 . A first flange 21 is provided on the side wall for forming the channel. The first flange 21 is installed in the first installation groove 11 . The casing 30 is sleeved on the outside of the die 10 , and the end of the casing 30 is connected to the casing base 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com