Material rolling device used for PVC machining

A technology of coil material and material roller, which is applied in the field of coil material device for PVC processing, can solve the problems of inconsistent height on both sides of the film, lower product quality, PVC film wrinkles, etc., and achieve the effects of reducing the number of replacements, saving resources and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

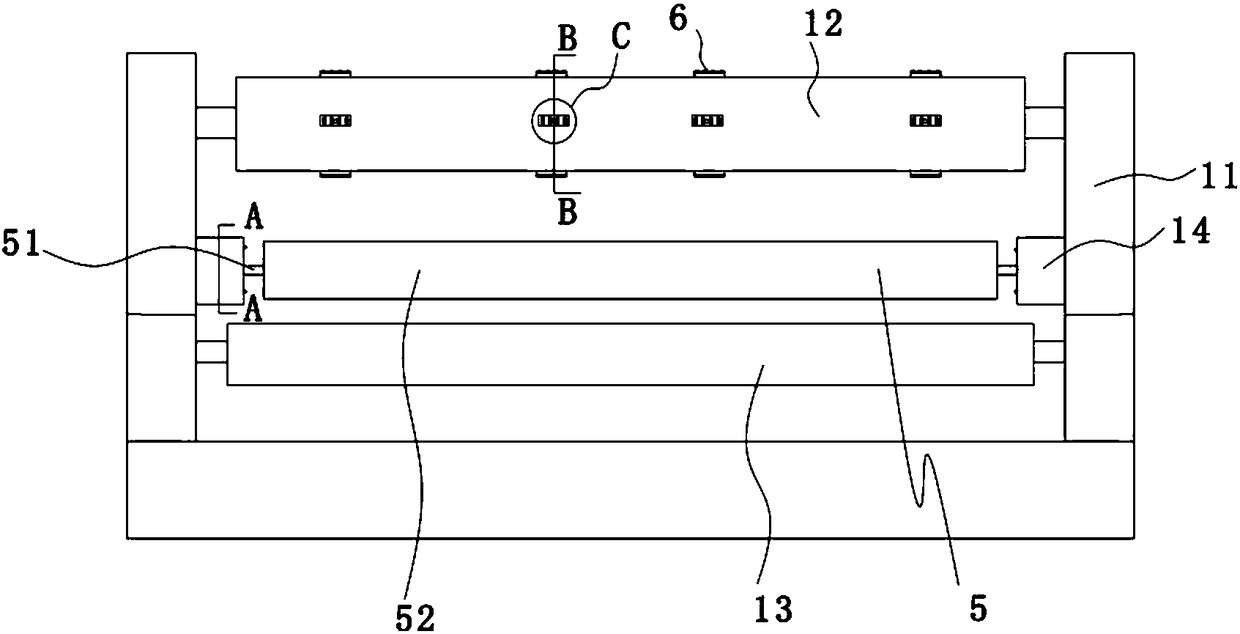

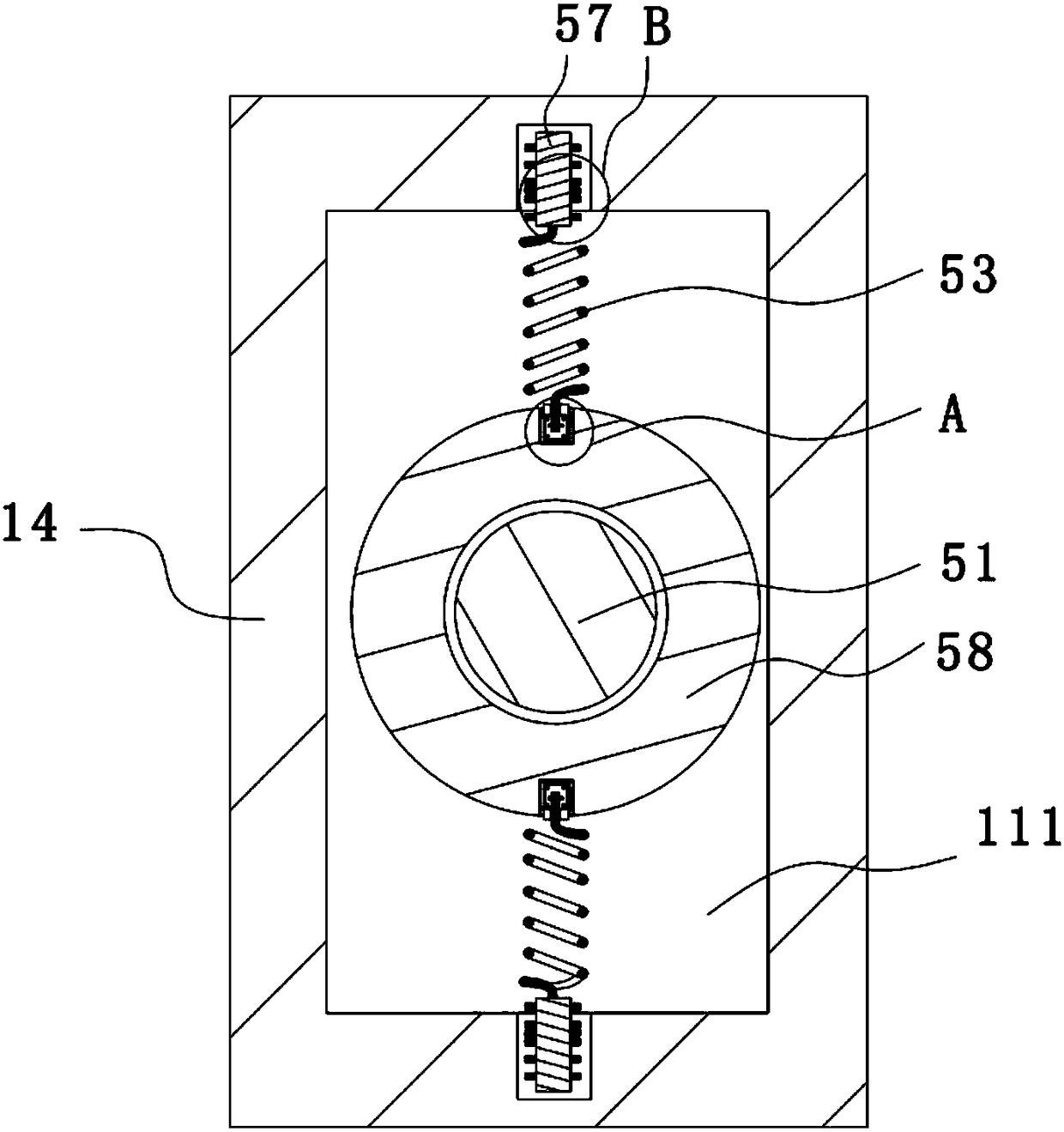

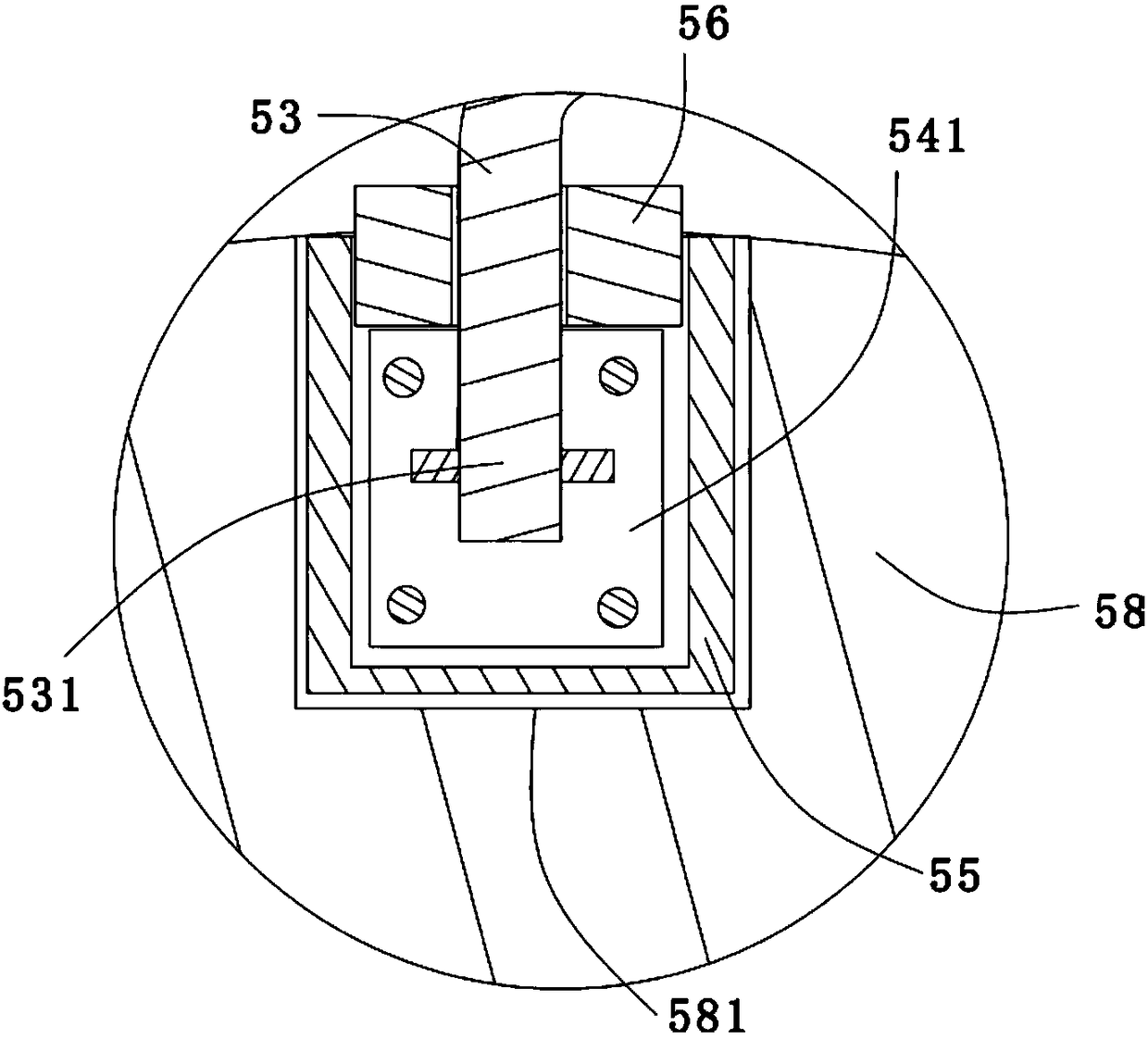

[0024] Such as Figure 1-10 As shown, a coiling device for PVC processing includes a frame 11, a receiving roller 12 and a delivery roller 13, and the receiving roller 12 is driven by a driving motor to rotate, and the coiling device also includes a balance roller 5. The balance roller includes a support shaft 51 and a roller 52 movably sleeved on the support shaft 51. The roller can roll around the support shaft under the action of an external force. The two ends of the support shaft 51 are respectively passed through an elastic The support structure can be connected to the frame 11 in a floating up and down manner. Specifically, the elastic support structure includes an acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com