Patents

Literature

35results about How to "Adjustable bending angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bending and punching integrated equipment for sheet metal part

InactiveCN111152032AImprove efficiencyShorten processing timeOther manufacturing equipments/toolsStructural engineeringManufacturing engineering

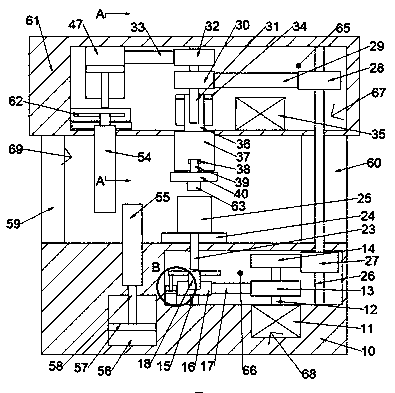

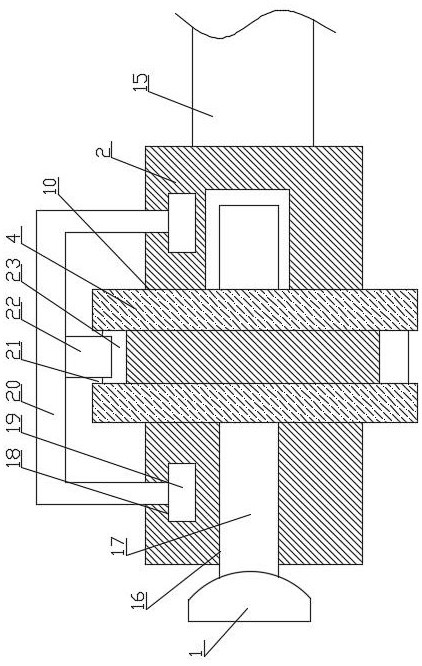

The invention discloses bending and punching integrated equipment for a sheet metal part. The bending and punching integrated equipment comprises a machine body, a transmission cavity 66 is formed inthe machine body 10, a left side stand column 59 and a right side stand column 60 are fixedly arranged on the upper side surface of the machine body 10, a top machine body 61 is fixedly arranged on the upper side of the left side stand column 59 and the upper side of the right side stand column 60, a punching cavity 65 is formed in the top machine body 61, and a rotating device 68 for rotating thesheet metal part is arranged in the transmission cavity 66. According to the bending and punching integrated equipment, the sheet metal part can be controlled to be punched and bent at the same time,machining of one of the processes can be independently carried out, the equipment can conveniently and synchronously carry out the bending and punching processes on the sheet metal part, the efficiency of sheet metal machining is improved, and the machining time is saved.

Owner:浦江县旭星机械科技有限公司

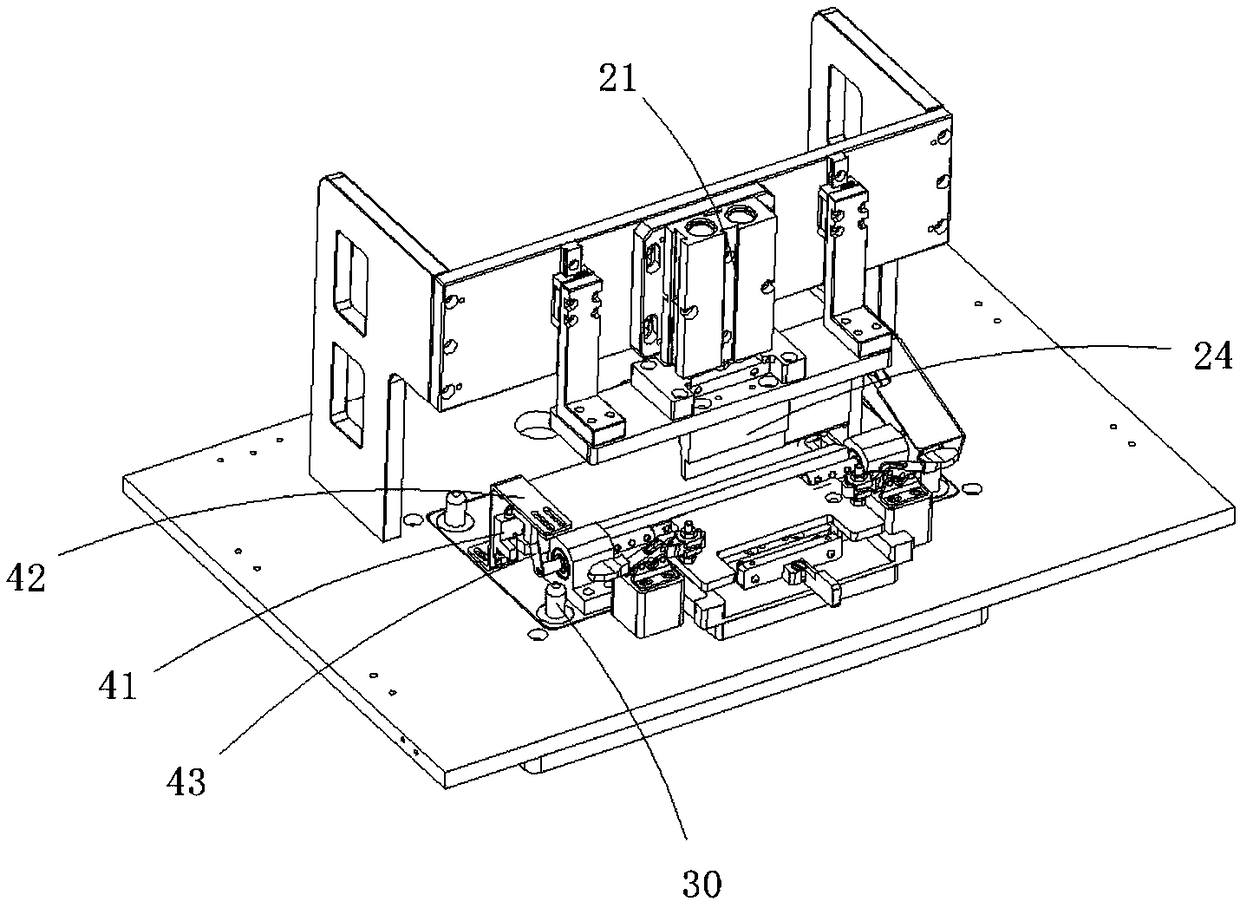

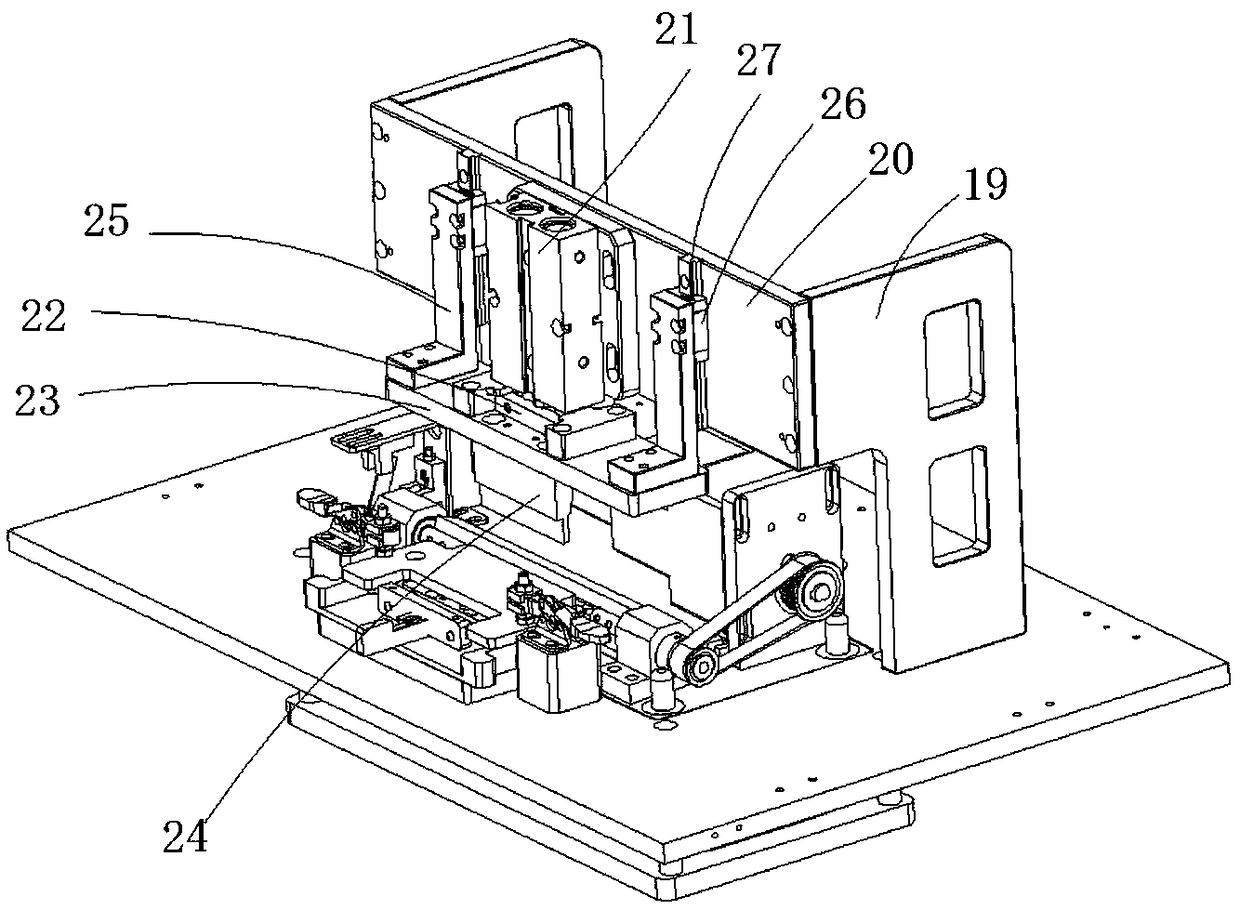

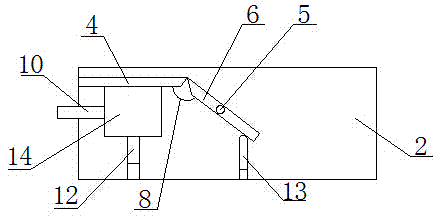

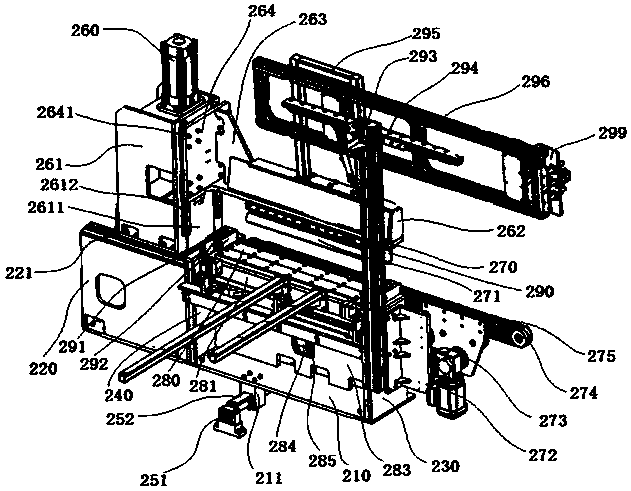

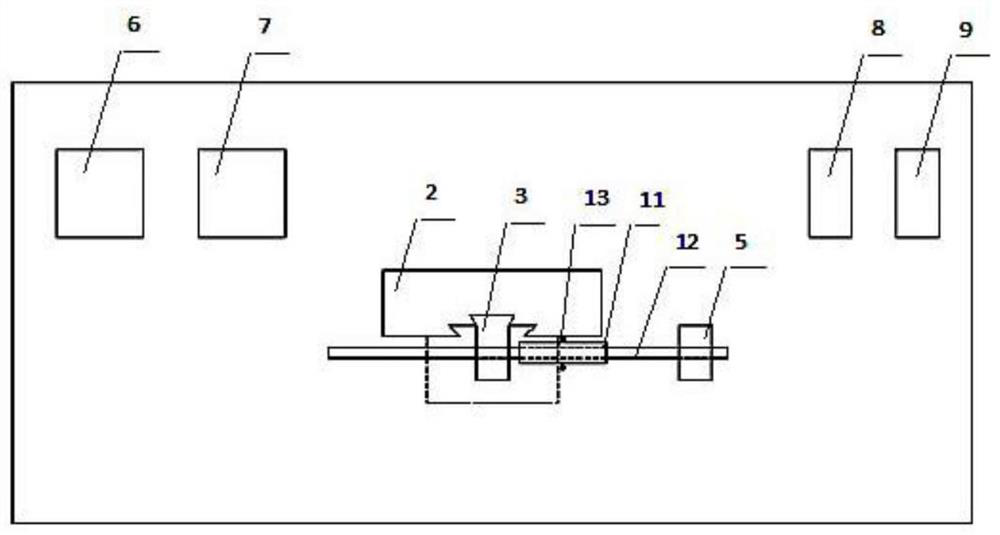

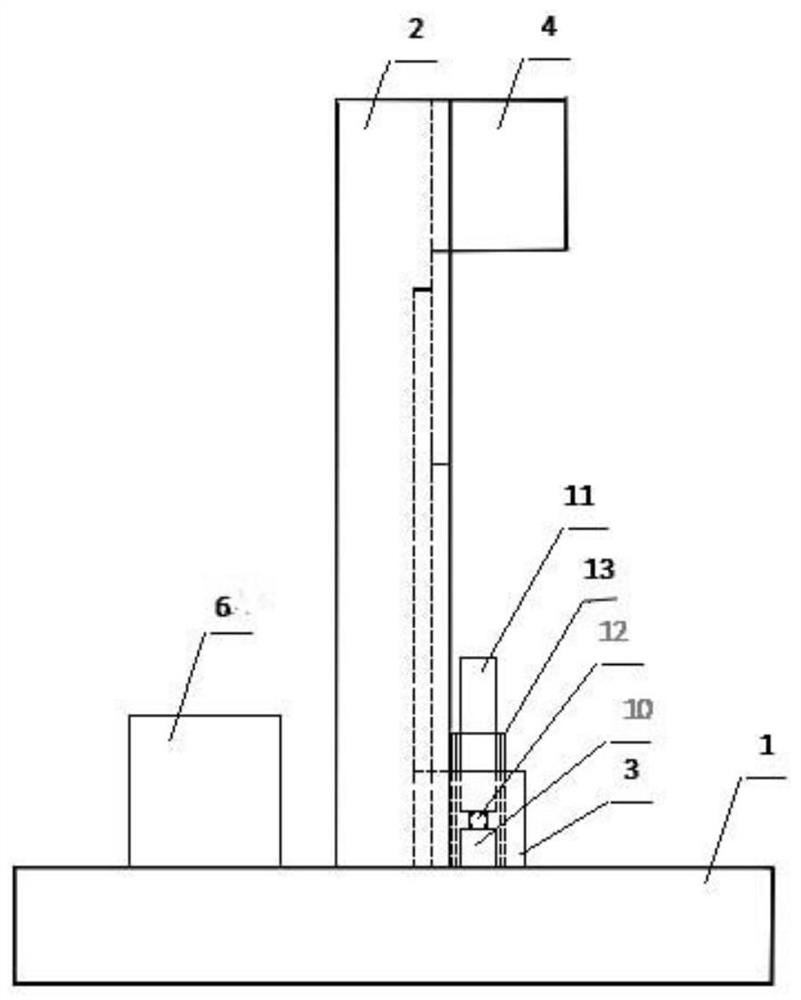

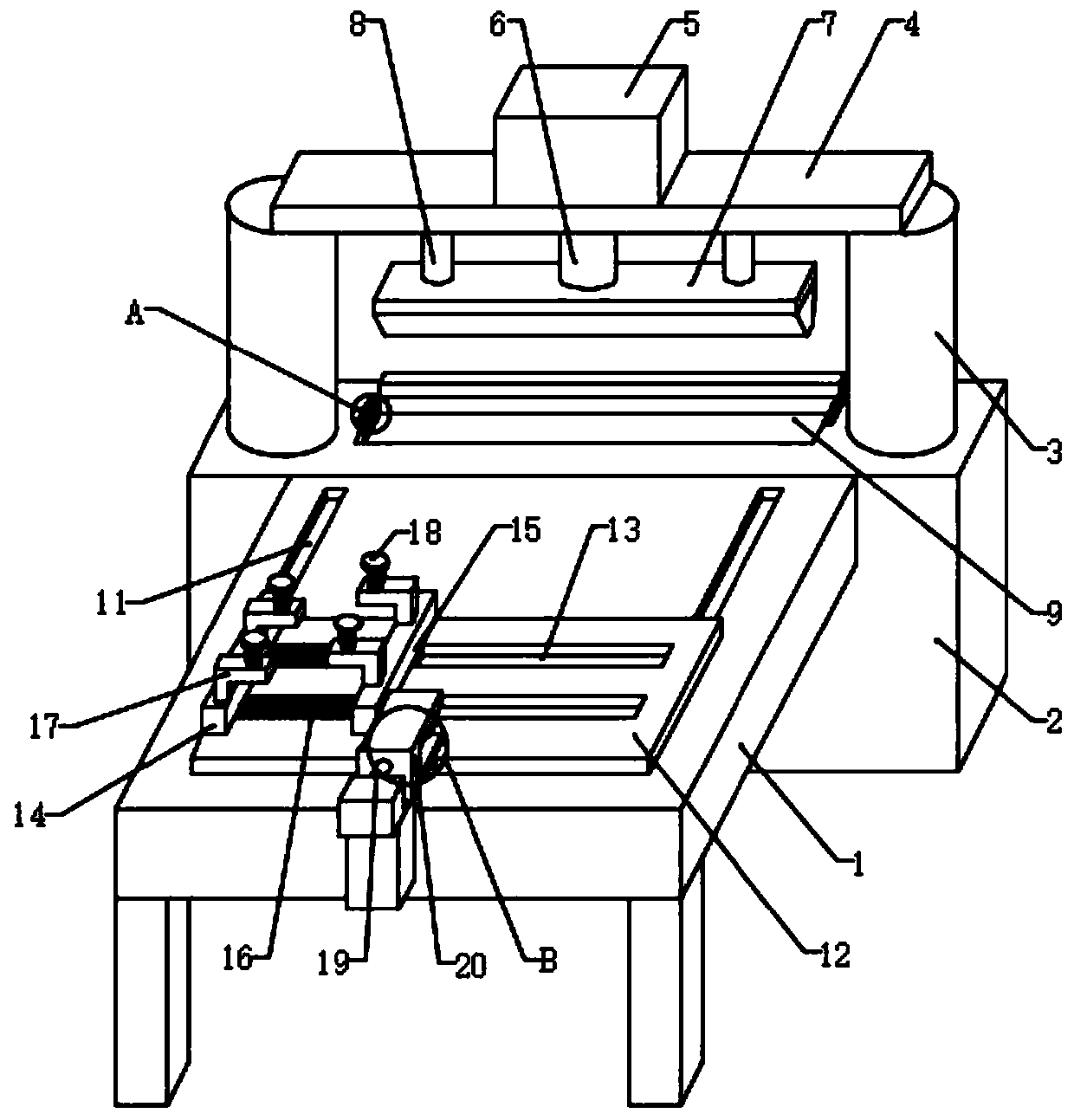

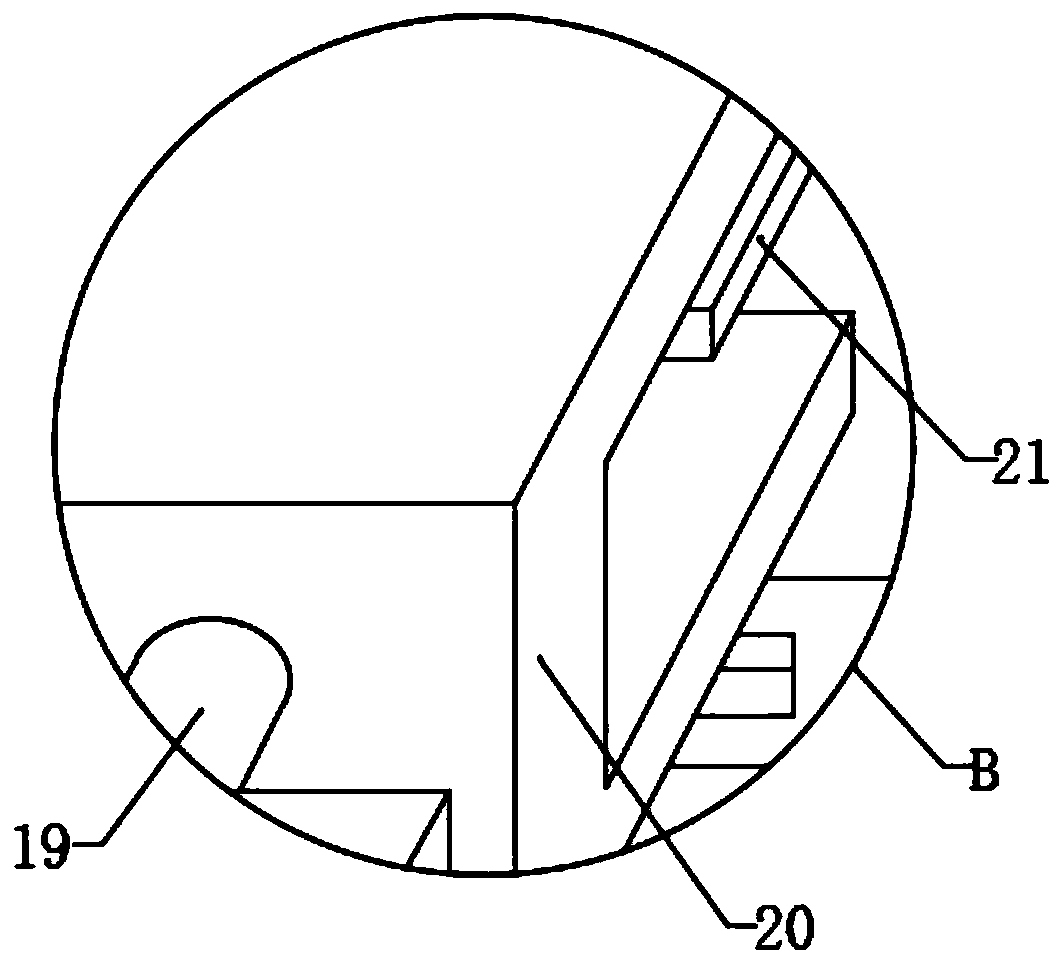

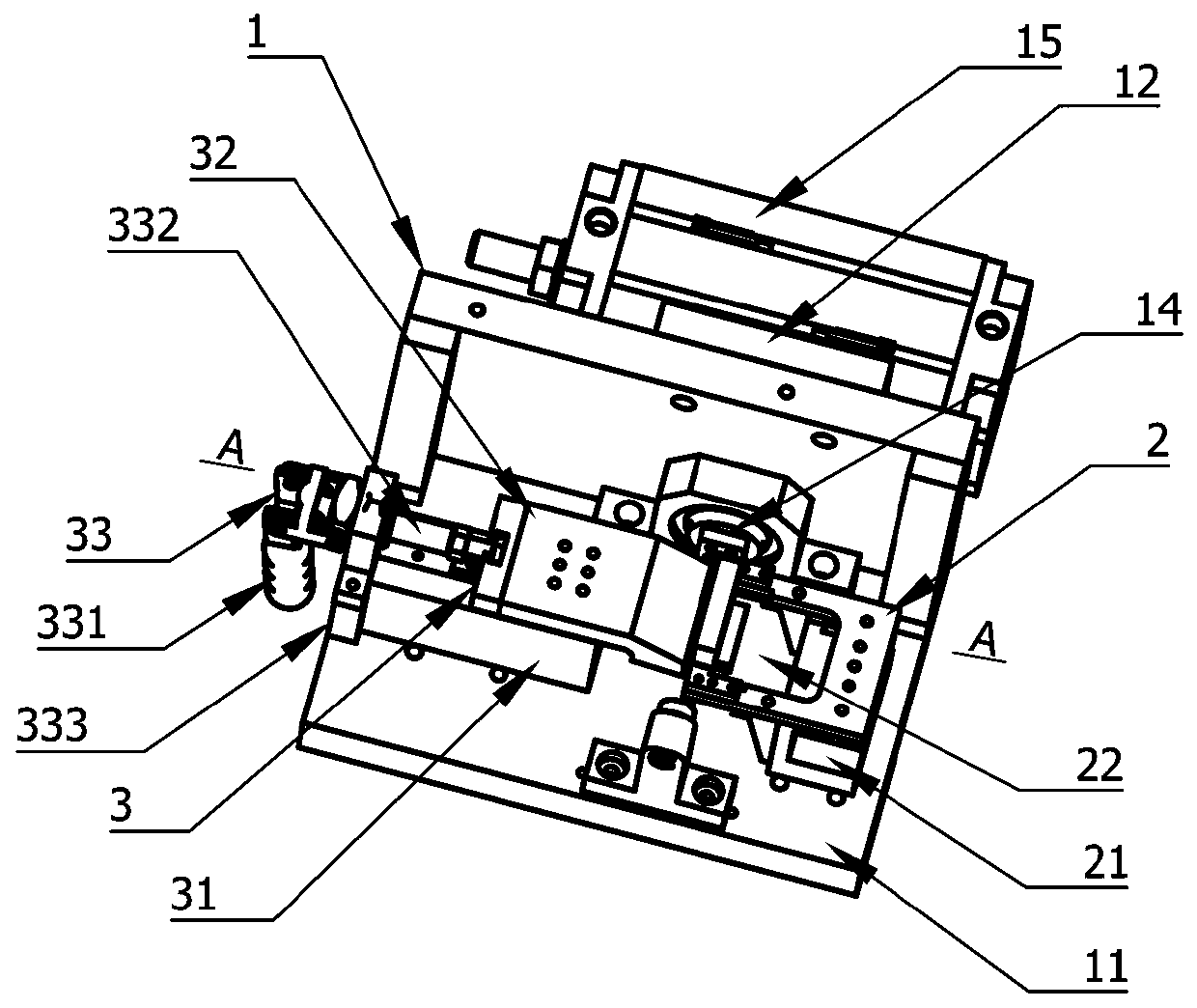

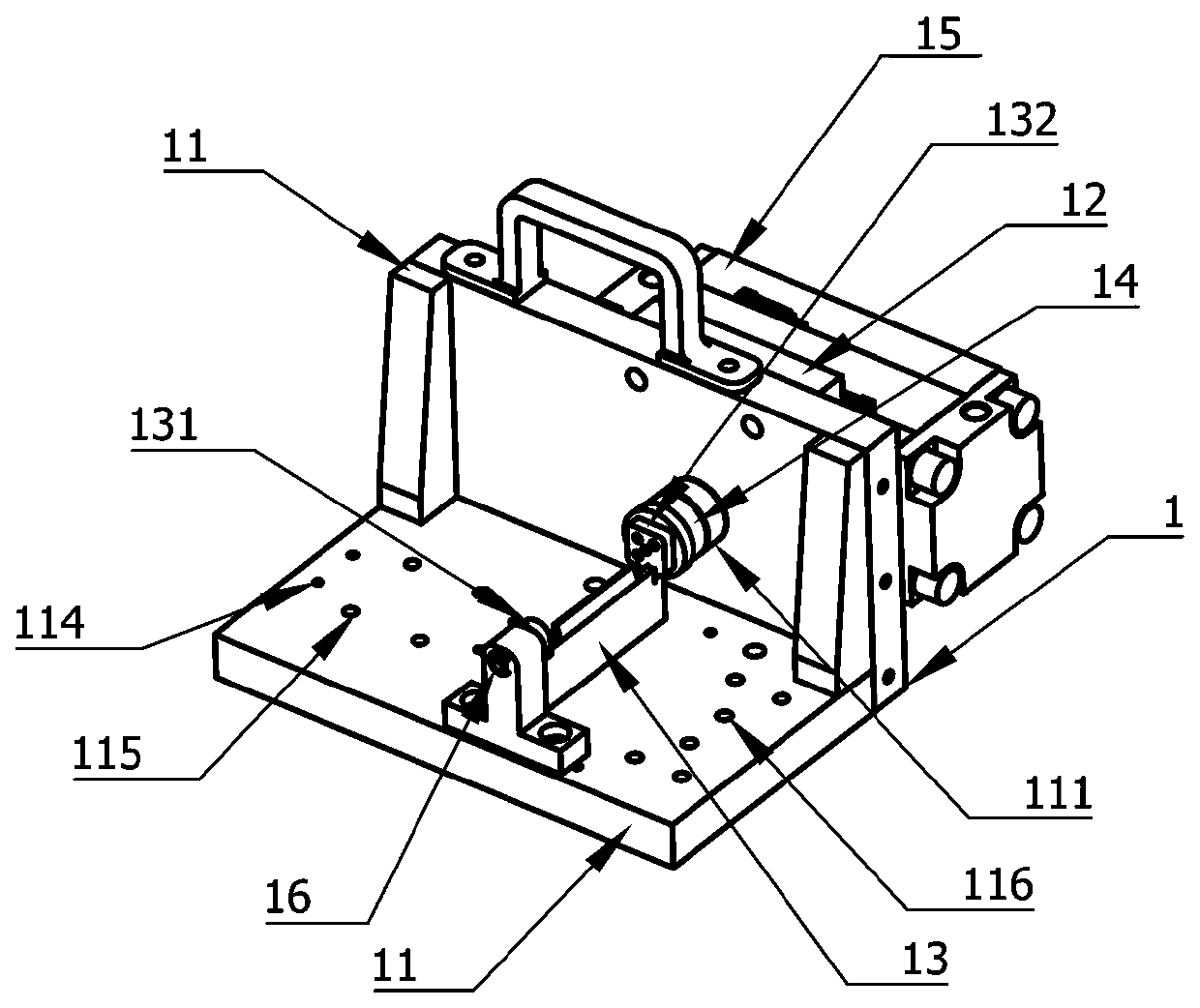

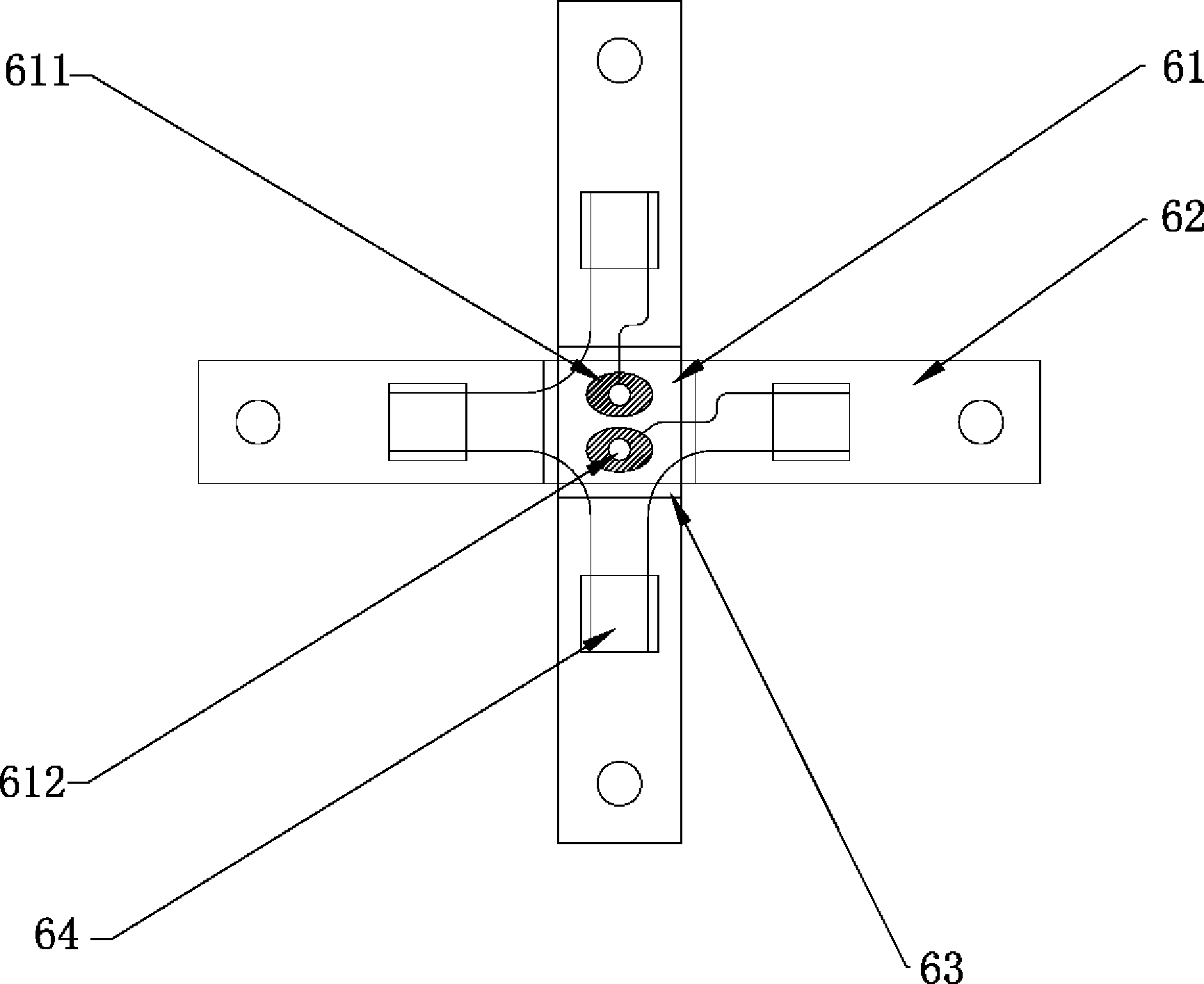

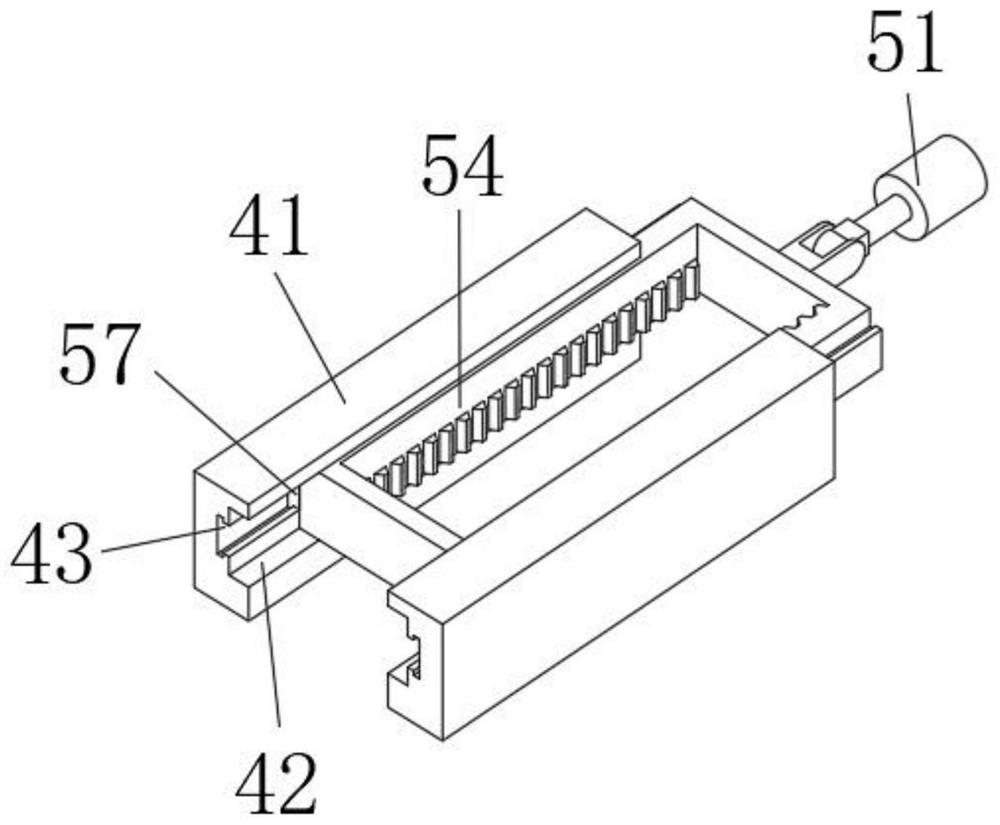

Electronic part bending mechanism

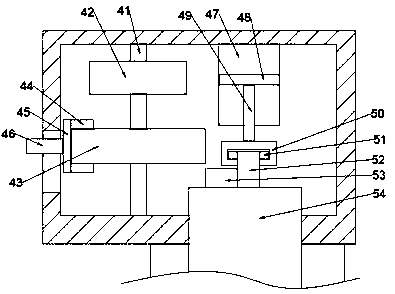

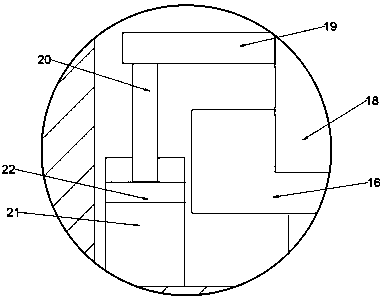

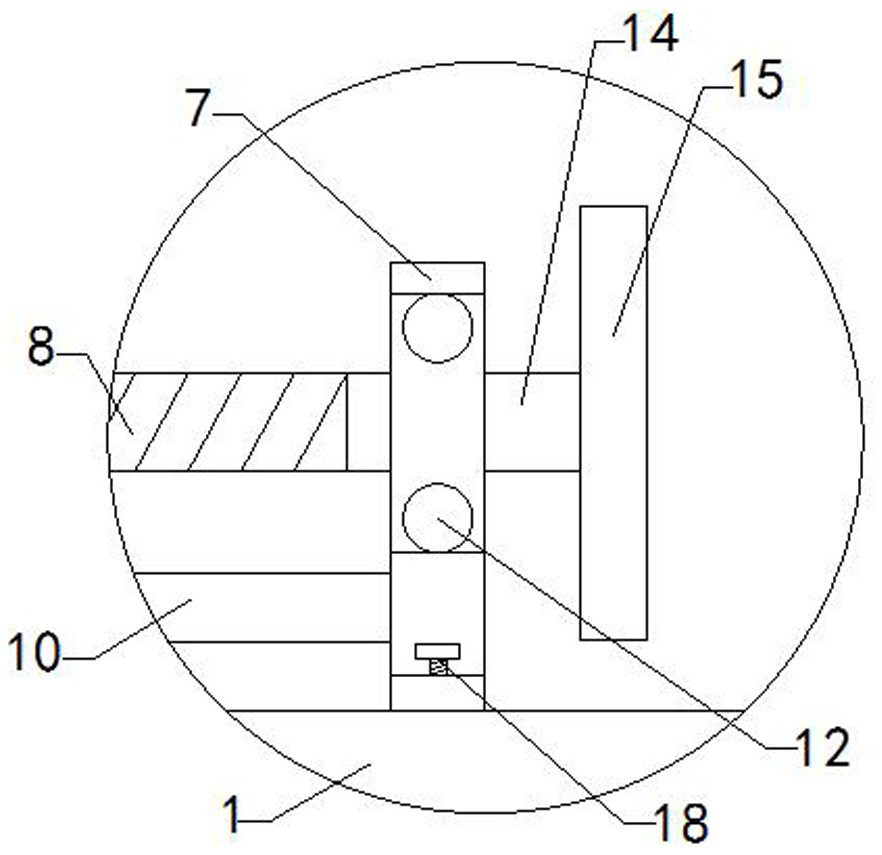

The invention relates to an electronic part bending mechanism. A carrier is placed on a base plate, a plurality of electronic components are installed in the carrier side by side, two pins which needto be bent are arranged on each electronic component, and tight press mechanisms which can tightly press the carrier and products are installed on the base plate and located on the left side and the right side of the carrier. A downward press mechanism which can press the pins is installed on the rear side of the top of the base plate. A square slotted hole is formed in the middle of the base plate, an ascending mechanism is installed at the bottom of the base plate, and an ascending plate of the ascending mechanism can pass through the square slotted hole. An upper bending mechanism is installed on the ascending plate, and comprises a rotating mechanism and a bending driving device, wherein the bending driving device can drive a rotating shaft of the rotating mechanism to rotate. An upperbending block which can conduct bending forming on the pins is installed on the rotating shaft. A sensor which can control the rotation angle of the rotating shaft is installed on the ascending plate, and an induction piece which is matched with the sensor is installed on the rotating shaft. By the adoption of the electronic part bending mechanism, bending operation of the electronic components can be achieved, the multiple products can be bent at one time, and the operation of bending with different angles can be achieved.

Owner:BOZHON PRECISION IND TECH CO LTD

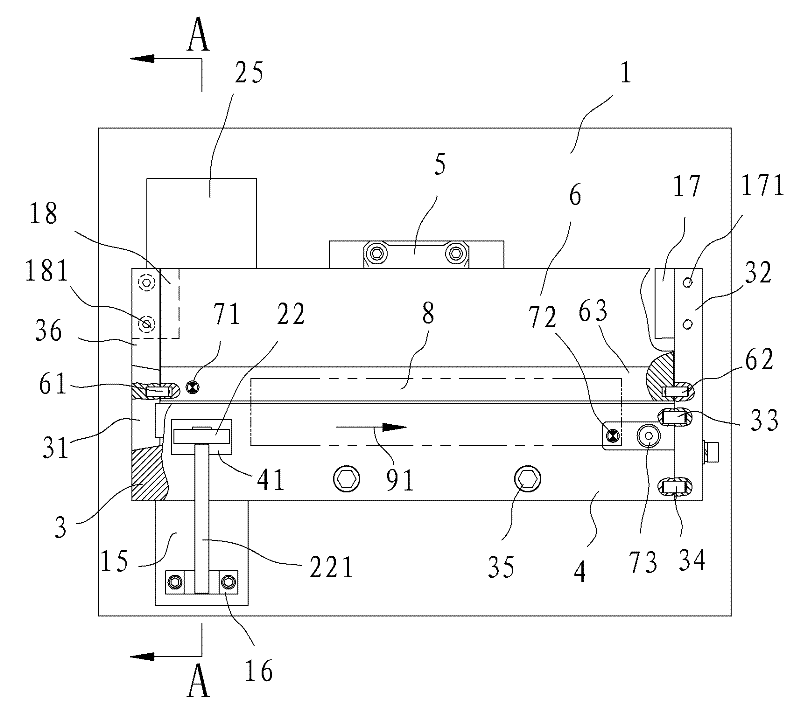

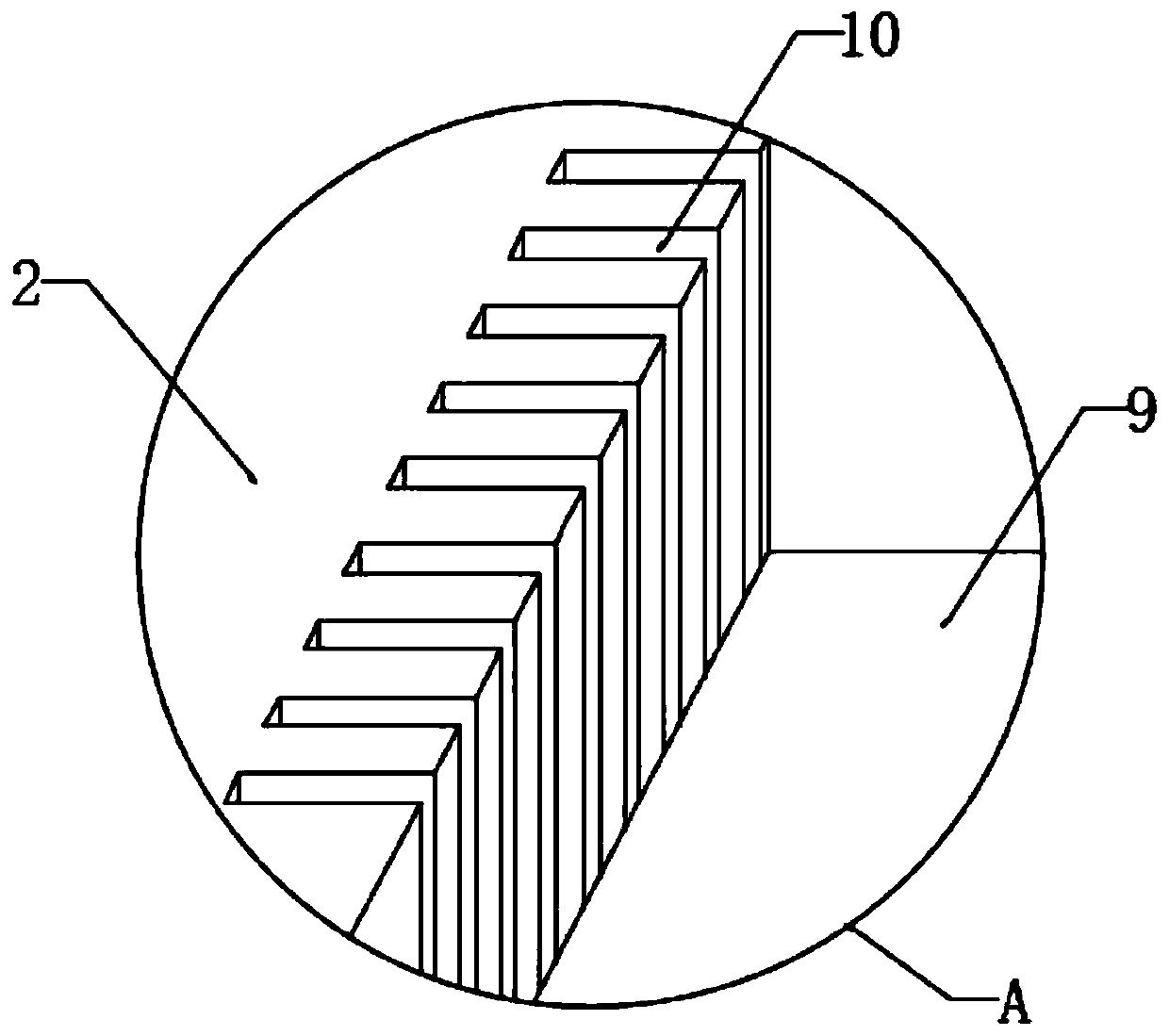

Lead frame bending device

InactiveCN102189157AAdjustable flip angleAdjustable bending angleMetal-working feeding devicesPositioning devicesEngineeringLead frame

The invention relates to a lead frame bending device which can bend a pin part and a radiating fin part on a lead frame into a certain angle. The lead frame bending device comprises a rack, a lead frame feeding guide rail arranged on the rack, a limit block which is arranged on the rack and is used for supporting a movable guide rail, a driving device used for driving the movable guide rail to turn upward and a feeding device composed of a feeding idler wheel, a pressing wheel and a corresponding driving device, wherein the side wall of the guide rail is provided with a horizontal slide rail which can be passed through by the pin part of the lead frame, the guide rail is provided with the movable guide rail used for supporting the radiating fin part of the lead frame at the outer side of the lower rail of the slide rail, and the two ends of the movable guide rail are hinged with the guide rail. By applying the lead frame bending device, the production efficiency is high, the consistency of processed workpieces is good, the error is small, the yield is high, and the manufacturing cost is greatly reduced.

Owner:TONGLING HUIZHI ELECTROMECHANICAL

Adjustable mechanical bending die

Owner:SUZHOU HUICHENG PRECISION MOLD

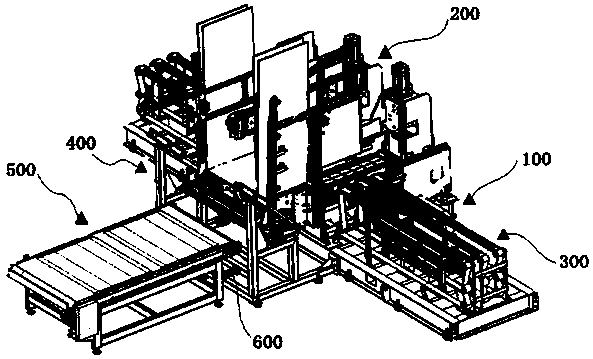

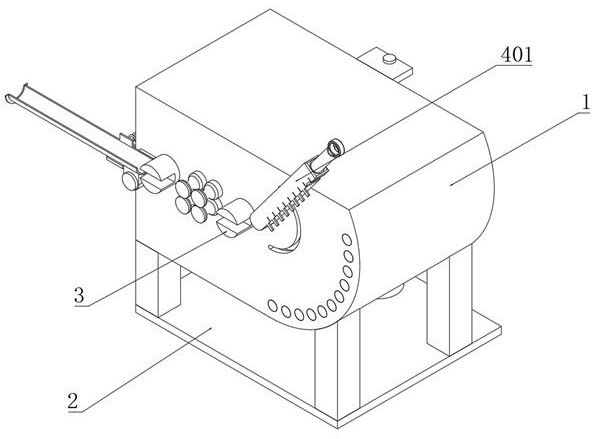

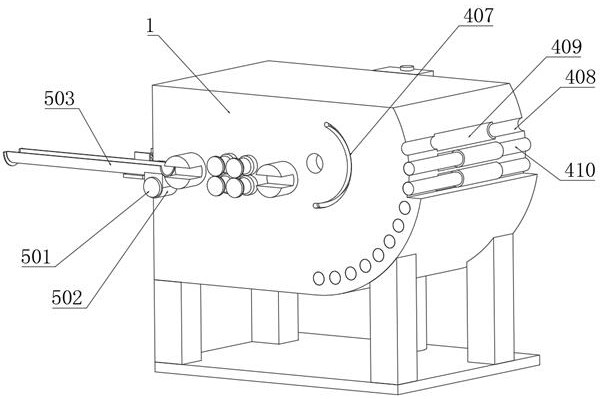

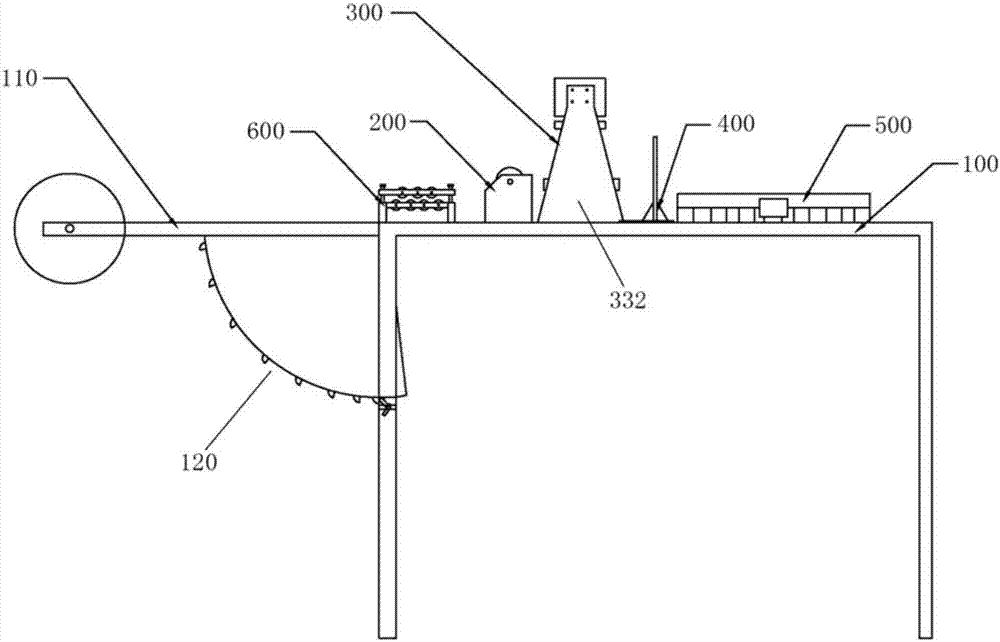

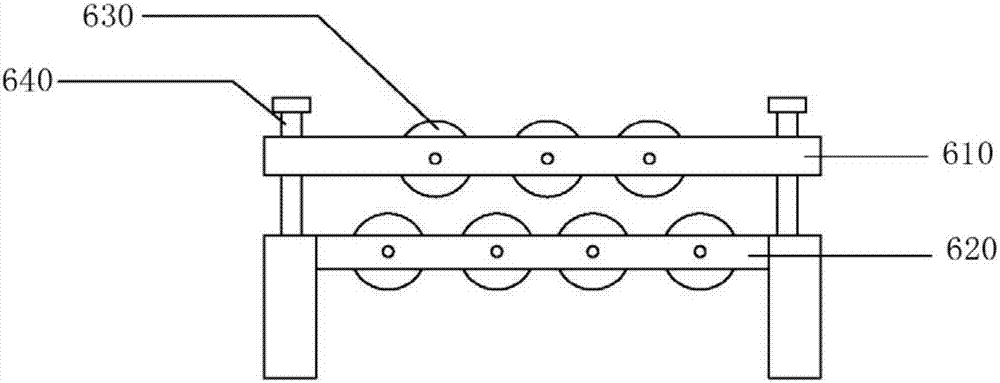

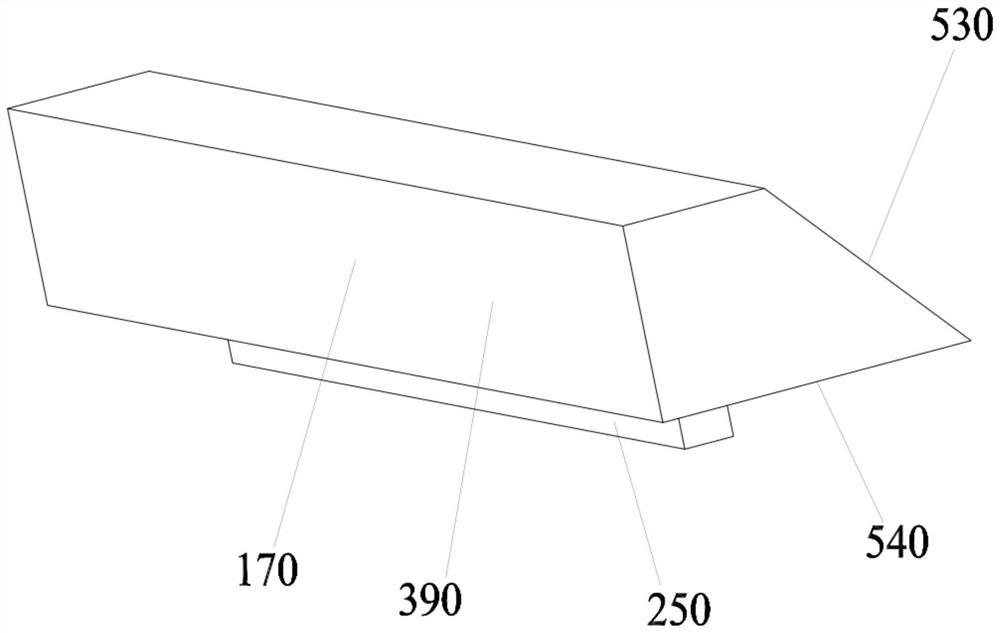

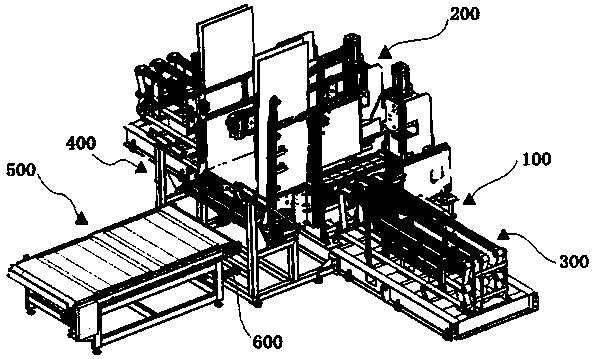

U-shaped bending turnover blanking machine

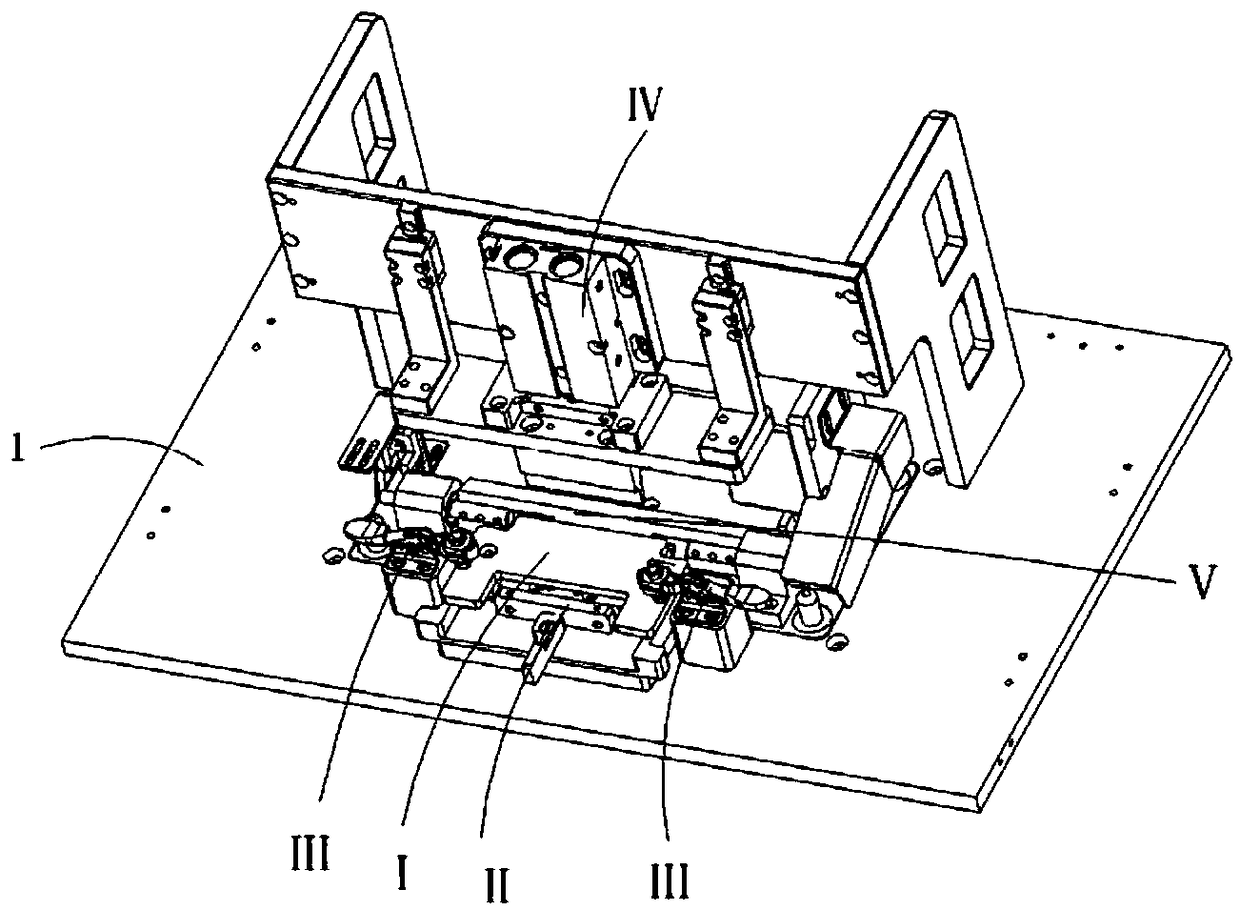

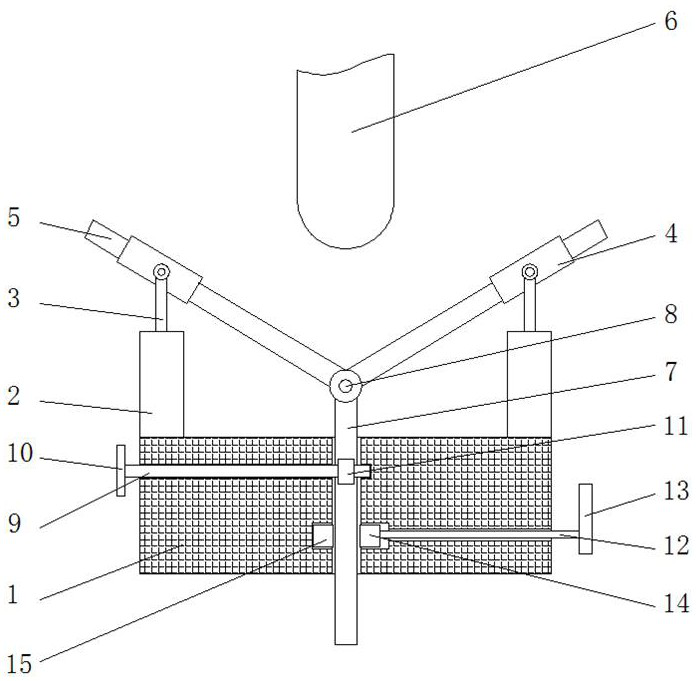

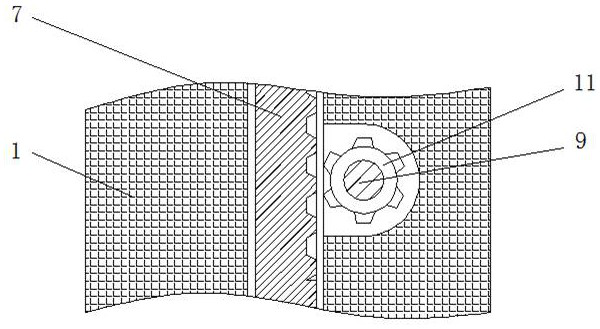

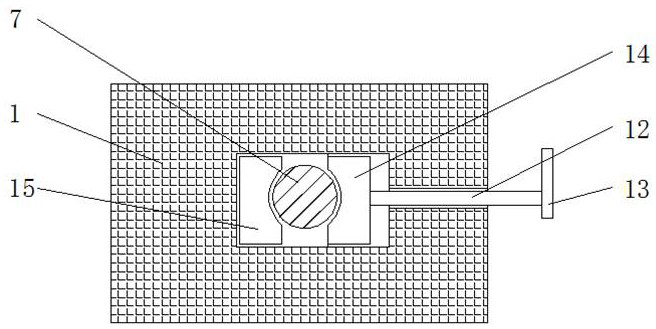

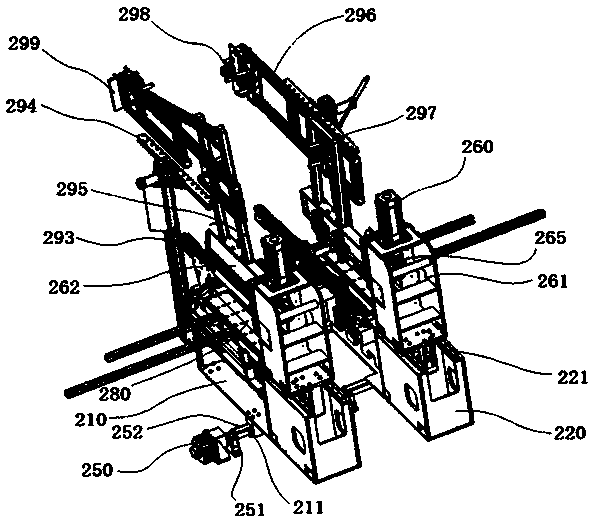

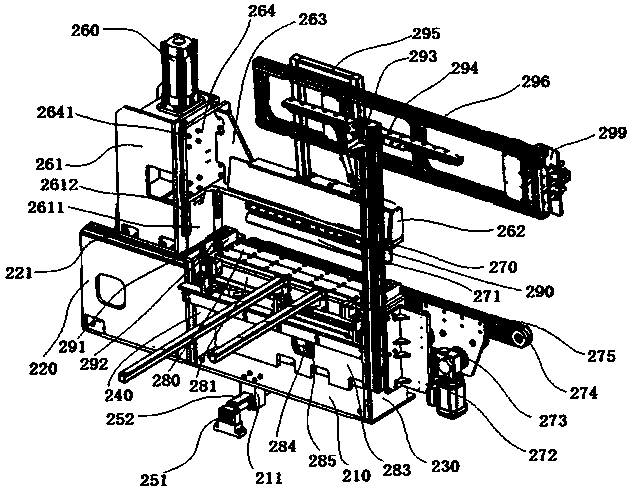

ActiveCN108994117ARealize one-time processing and transportationAdjustable bending angleStripping-off devicesPulp and paper industryManipulator

The invention discloses a U-shaped bending turnover blanking machine. The U-shaped bending turnover blanking machine comprises a base assembly, a U-shaped bending assembly, a conveying belt assembly,a suction turnover manipulator assembly, a blanking assembly, the U-shaped bending assembly and the conveying belt assembly are arranged at the upper end of the base assembly, the suction turnover manipulator assembly is arranged at the front end of the U-shaped bending assembly, and the blanking assembly is connected with the suction turnover manipulator assembly through a connecting rod; the U-shaped bending assembly comprises a bending assembly base, a bending mechanism, a side positioning mechanism and a U-shaped plate conveying mechanism; the sucking turnover manipulator assembly comprises a manipulator base and a suction turnover manipulator, and the manipulator base is arranged at the bottom of the suction turnover manipulator. According to the U-shaped bending turnover blanking machine, the U-shaped bending, sucking and turnover and blanking and the like of the plate material can be completed, the continuous blanking of the U-shaped plate material is realized, deviation and wrinkling are not easy to happen in the blanking process, the sucking and overturning process is stable, the acting is small, the cost is low, and the efficiency is high.

Owner:江苏天辰智能装备有限公司

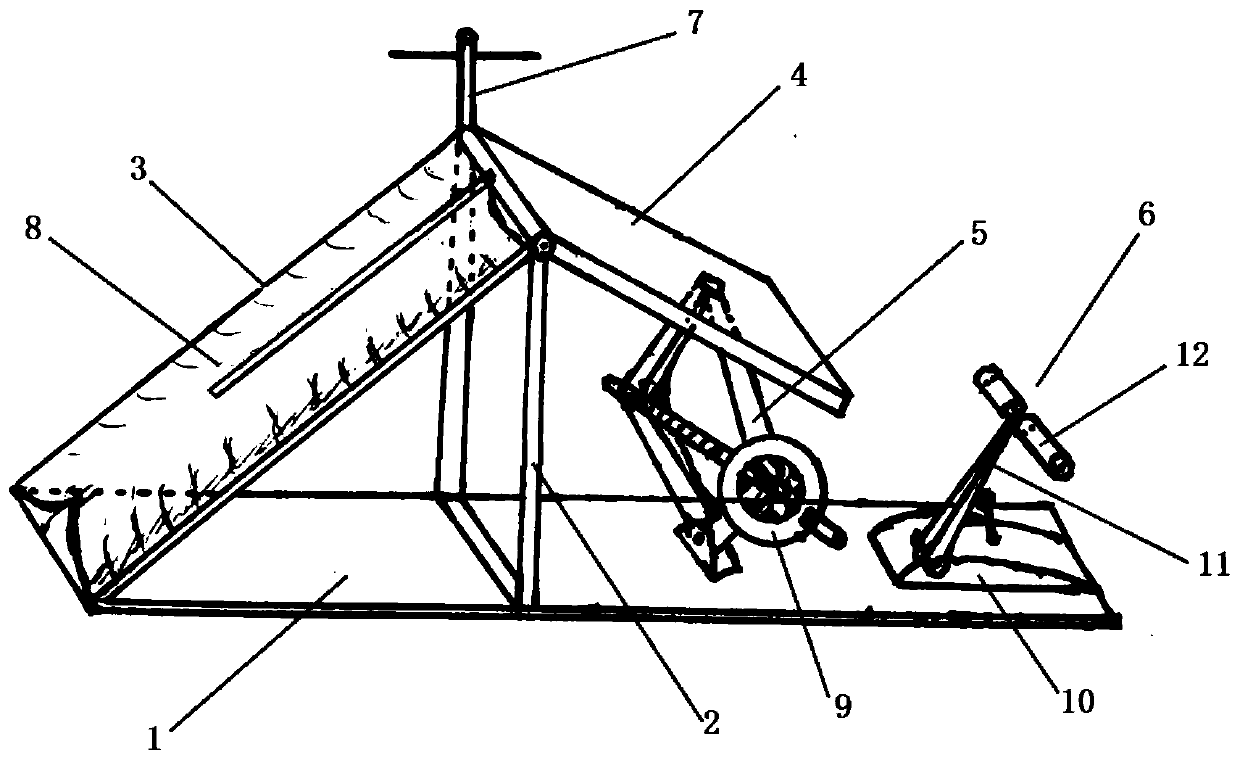

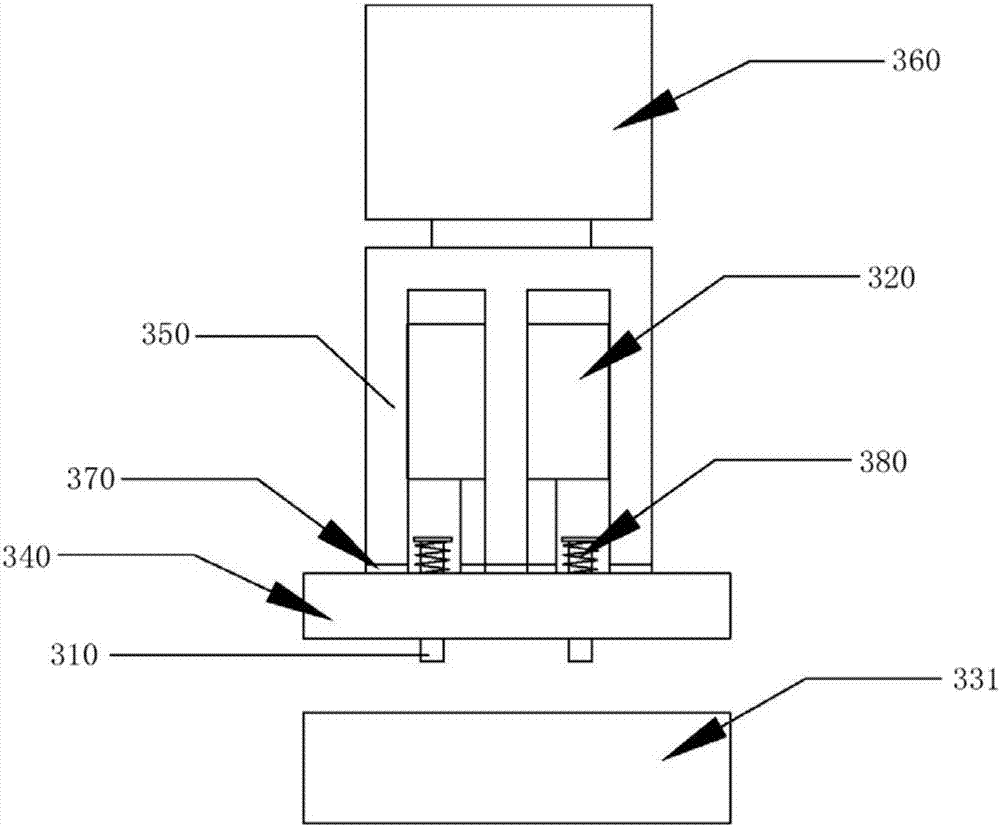

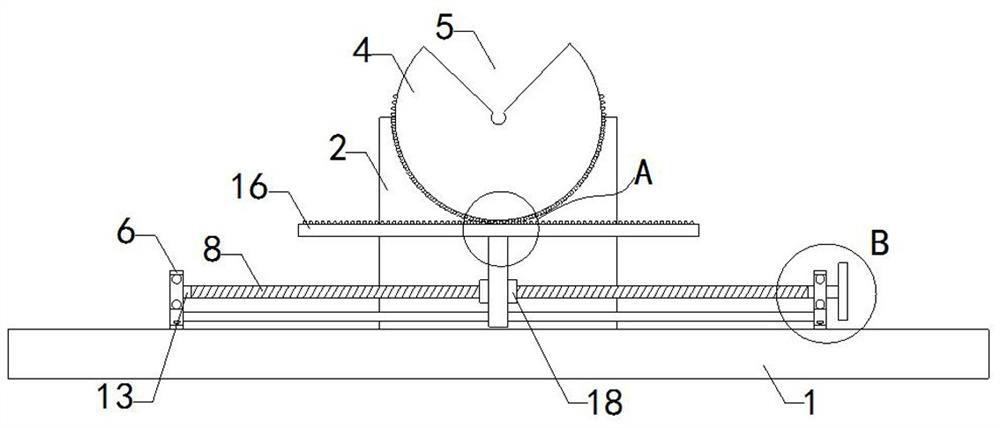

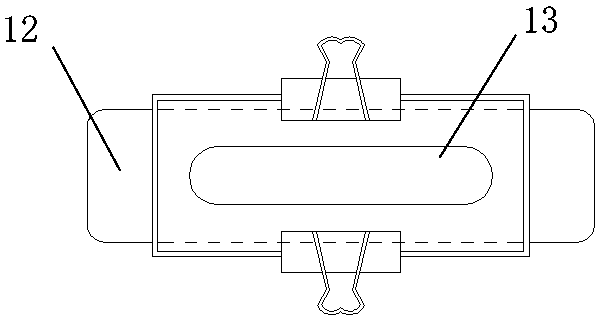

Portable shooting auxiliary device for knee joint axial position X-ray film

The invention discloses a portable shooting auxiliary device for a knee joint axial position X-ray film. The device comprises a horizontal bottom plate, a support, a thigh placing plate, a shank placing plate, a lifting structure and a foot hooking frame. The support is fixed to the horizontal bottom plate; the thigh placing plate is hinged to the shank placing plate; and the hinged position of the thigh placing plate and the shank placing plate is fixed to the top of the support. The end, away from the hinged position, of the thigh placing plate is fixed to the horizontal bottom plate; and the shank placing plate is connected with the lifting structure fixed to the horizontal bottom plate. The foot hooking frame is arranged at the end, close to the shank placing plate, of the horizontal bottom plate. When the device is used for shooting a knee joint axial position X-ray film, the body position of a patient during film shooting is adjusted according to the individual size of the patient and different anatomical forms of patella, so that a standard knee joint axial position film is shot. The device being portable one does not occupy a large space and can be used directly after beingplaced on a physical examination bed.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Elbow

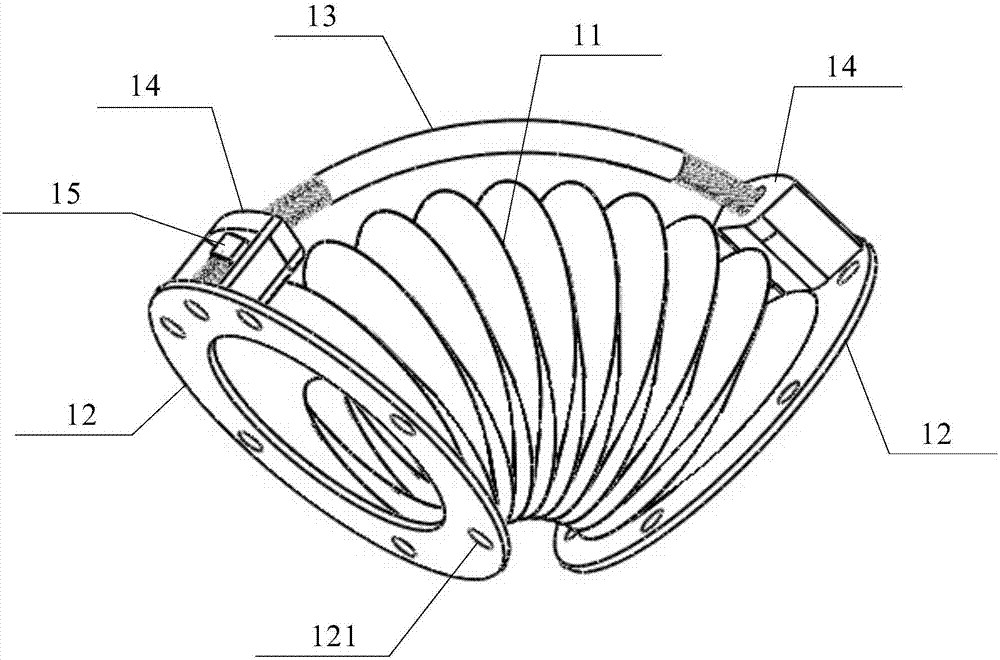

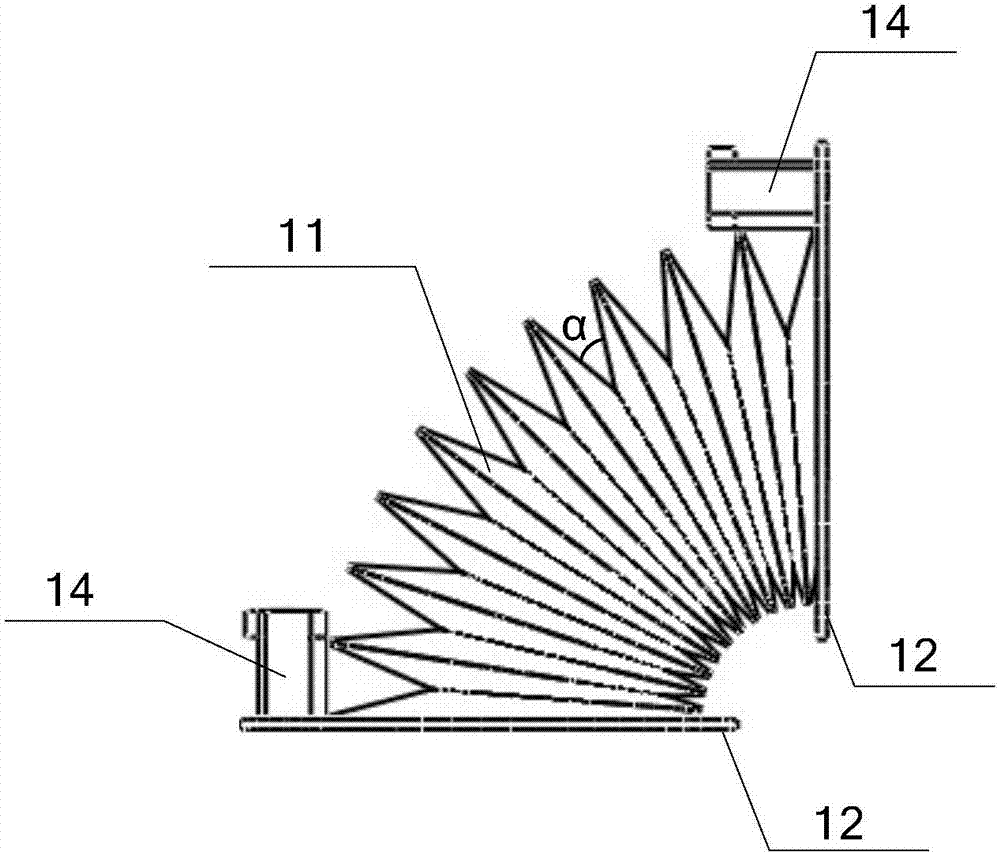

InactiveCN107255199AShorten the production cycleIncrease the scope of applicationRoof coveringPipeline expansion-compensationElbow jointsEngineering

The embodiment of the invention provides an elbow, and relates to the technical field of pipe connection. The bending angle of the elbow can be adjusted. The elbow comprises an elbow body, and the pipe wall of the elbow body is in a serration shape in the extending direction of the elbow body, so that the bending angle of the elbow body can be adjusted. The elbow is used for connecting pipes.

Owner:BOE TECH GRP CO LTD +1

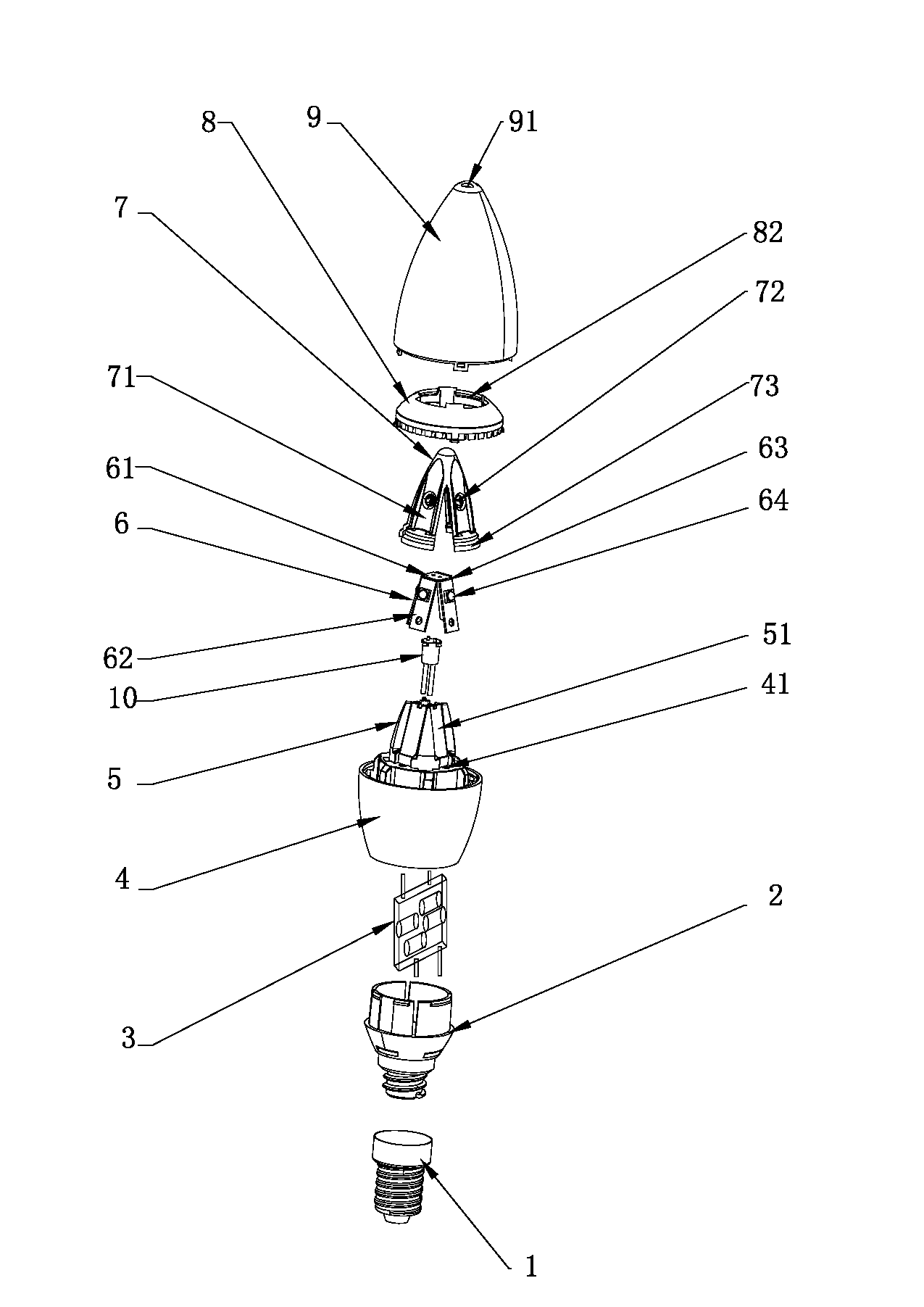

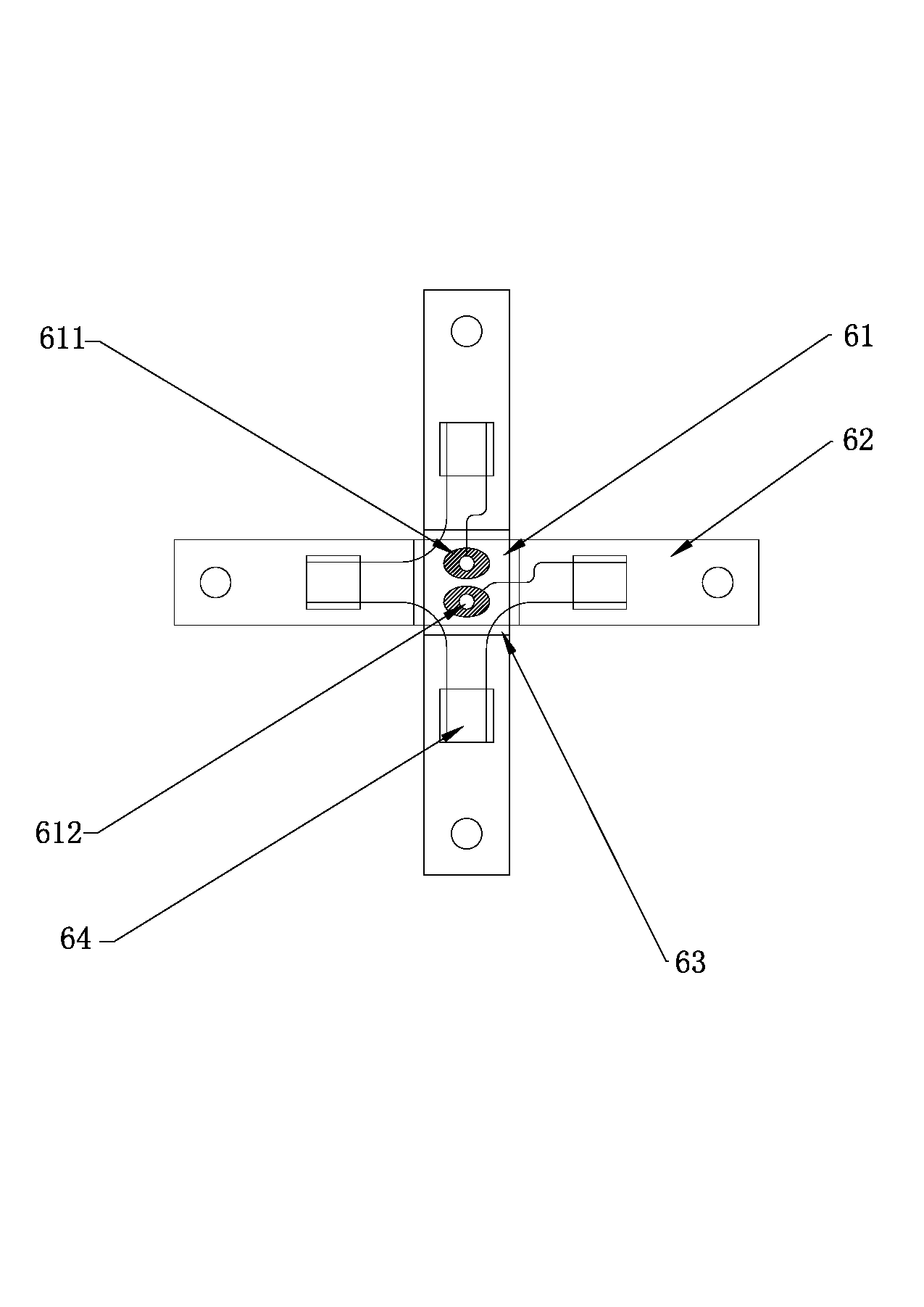

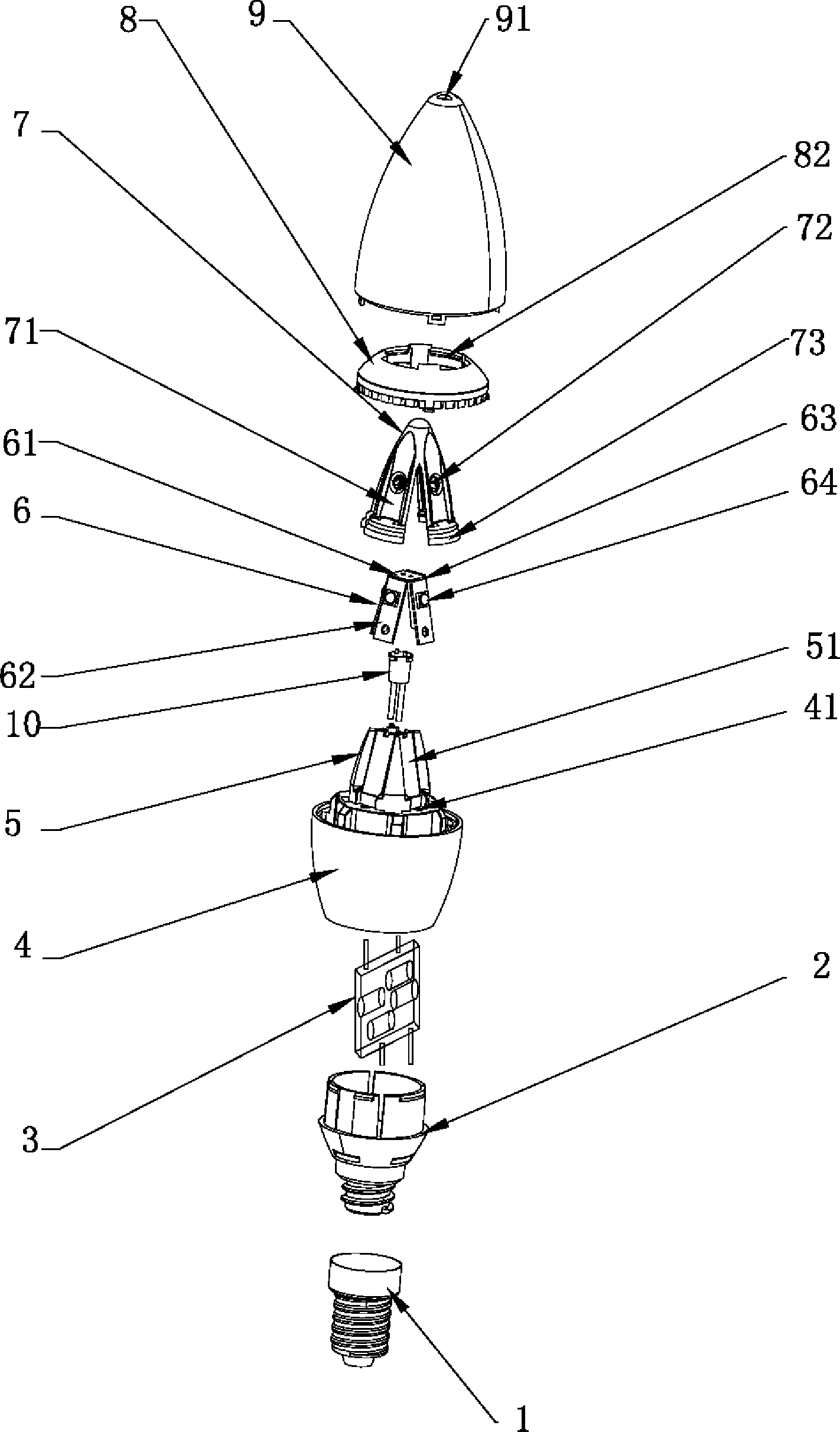

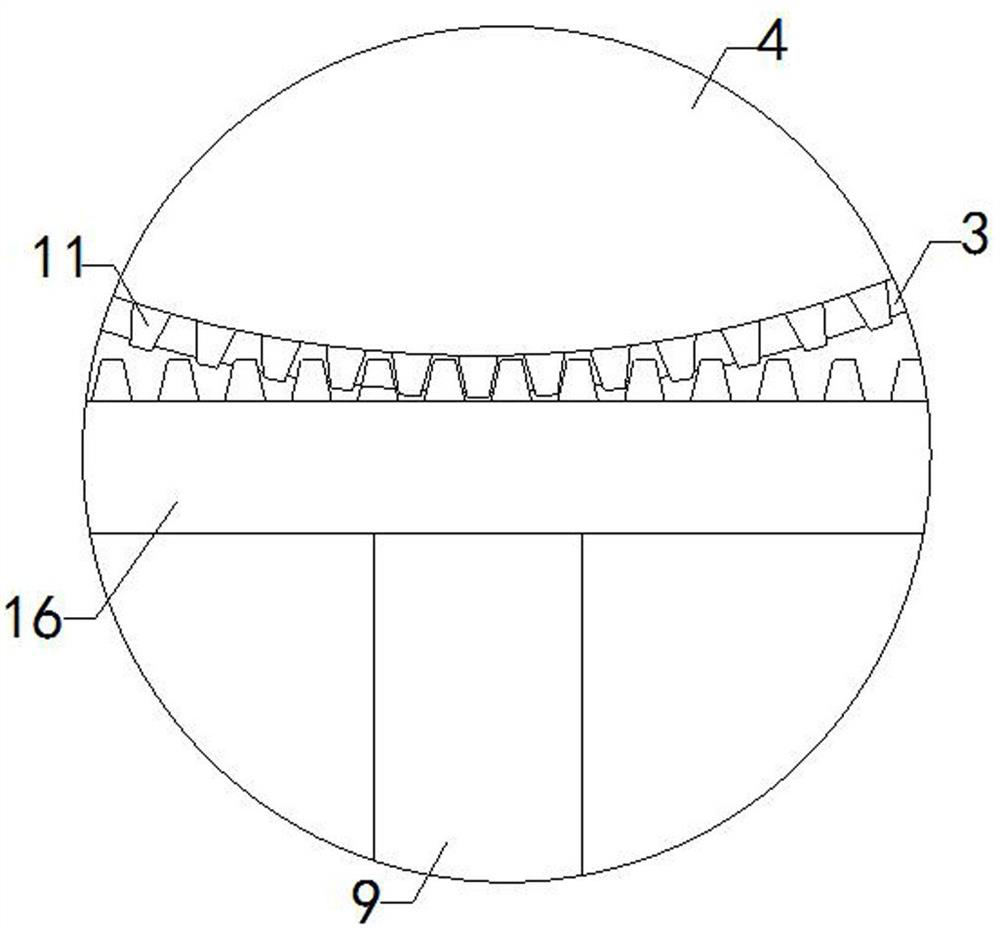

Light emitting diode (LED) candle lamp

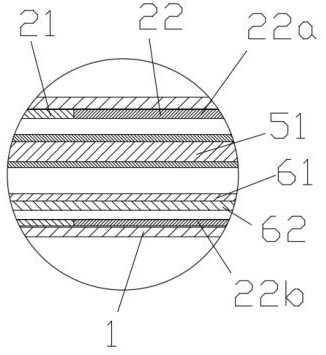

InactiveCN103196070AEasy to assembleAdjustable bending anglePoint-like light sourceElectric circuit arrangementsInsulation layerFlexible circuits

The invention relates to the technical field of a light emitting diode (LED) lamp, and in particular relates to an LED candle lamp. An LED module substrate of the LED candle lamp is provided with a crease area, the crease area is not provided with an aluminum substrate and only comprises a flexible insulation layer and a flexible circuit layer which has bending properties, an angle between an LED substrate area and a power connection area can be flexibly adjusted by bending the crease area, a planar LED module substrate can be changed to a three-dimensional module substrate which can be perfectly bonded with a heat conduction column; and when in assembling, the heat conduction column can be directly nested in the three-dimensional module substrate to be fixed. Compared with the prior art, the LED module substrate is simple to assemble and can be installed in place in one step after being bent; and moreover, the bending angle is adjustable, the LED module substrate can be effectively perfectly bonded with the heat conduction column, and the firmness and the heat radiation performance of the LED module substrate after being fixed can be improved.

Owner:广东金达照明科技股份有限公司

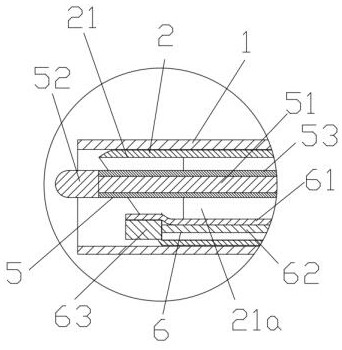

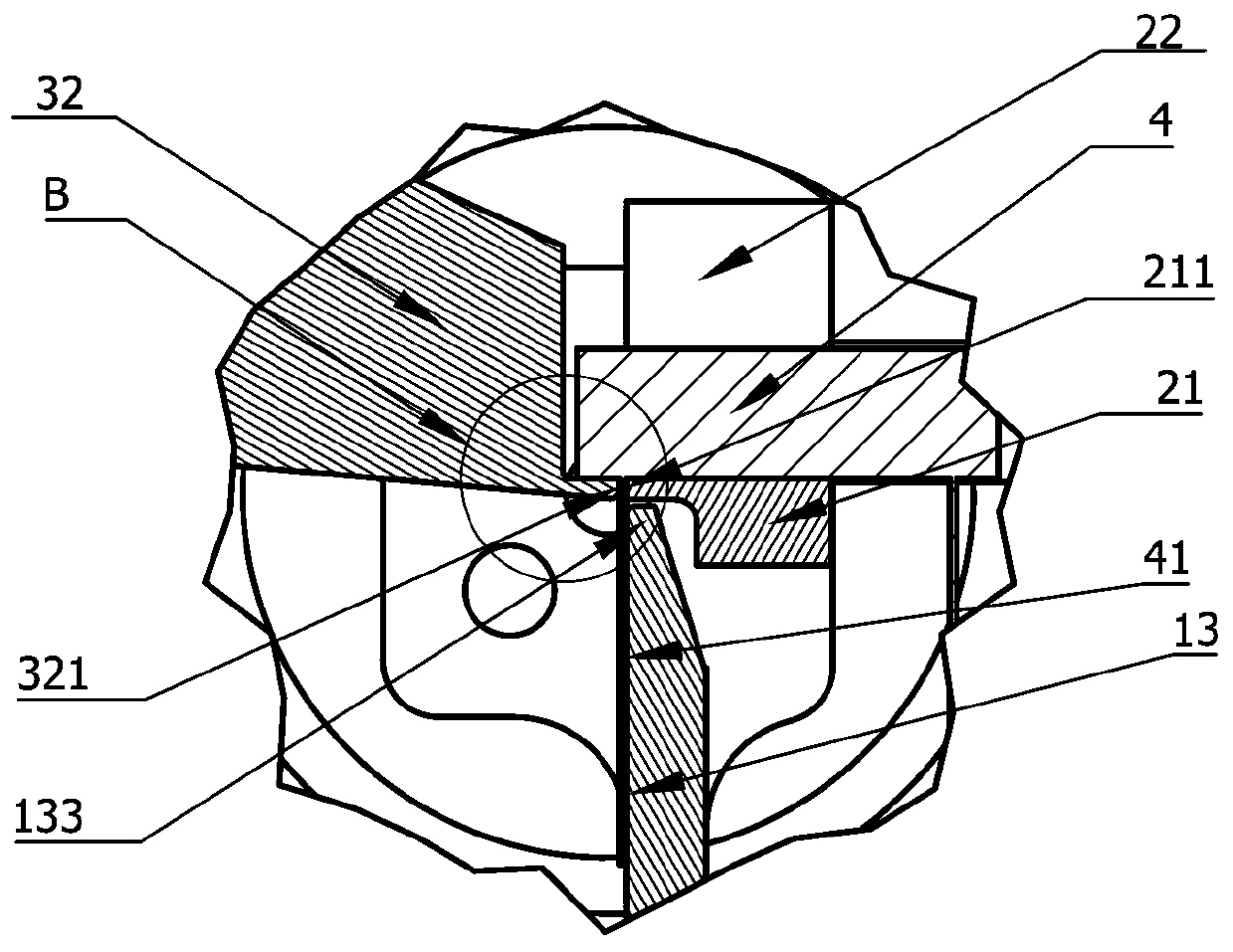

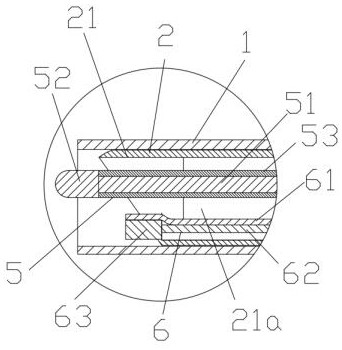

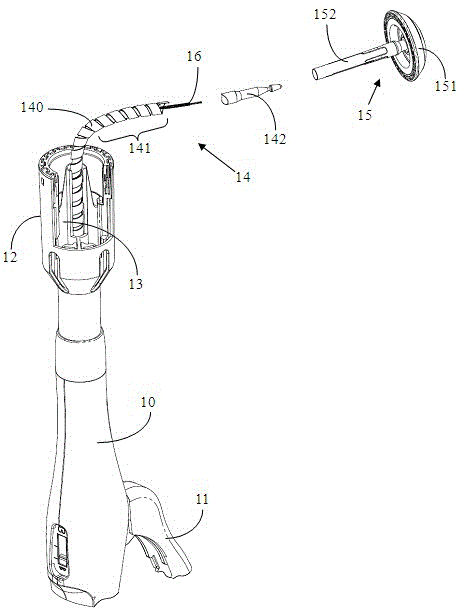

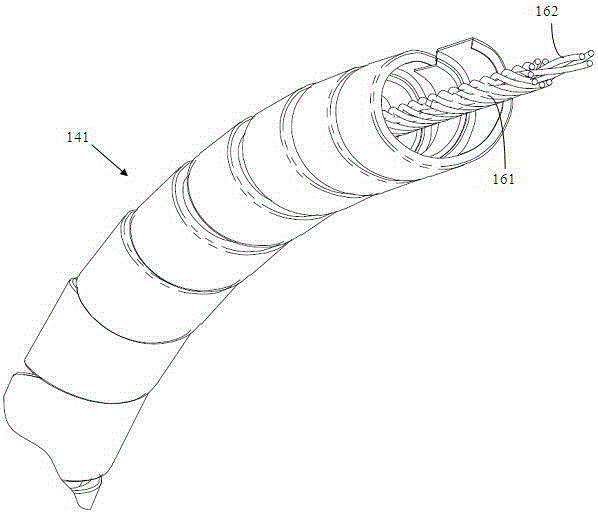

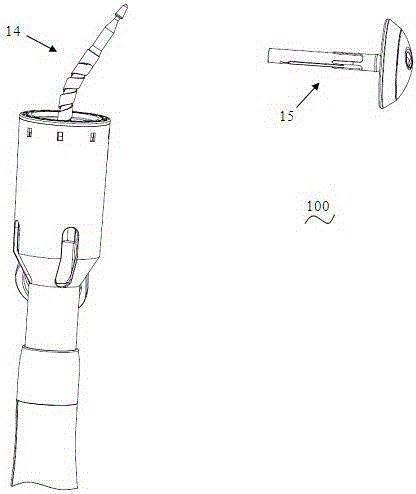

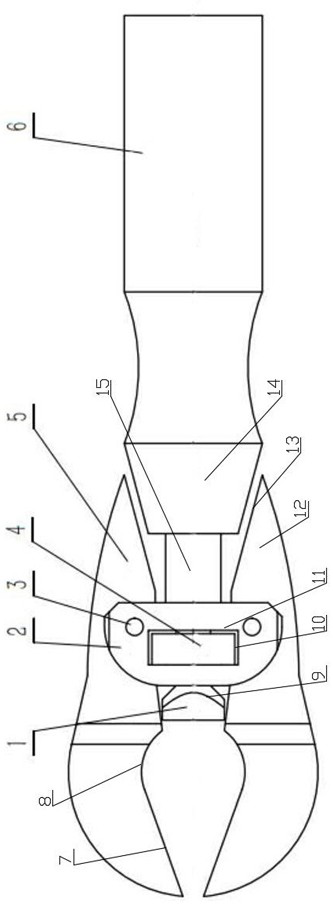

Bladder polyp minimally invasive surgical instrument

ActiveCN112190325AExpand field of viewSave the tedious back and forth transpositionEndoscopesSurgical instruments for heatingEyepieceEngineering

The invention discloses a bladder polyp minimally invasive surgical instrument. The instrument comprises an outer sleeve, an operating tube, a bending operator and a butt joint pivot, wherein the outer sleeve is a hollow tube, the operating tube is formed by sequentially connecting a front end tube part, a magnetic matching part, a bending connecting part, an iron core tube part and a rear end tube part from front to back, the bending operator comprises an operation shell, a sliding base conductive plate, a sliding block and a battery, a high-frequency current butt joint, an ocular lens, an argon inflation connector, an illumination optical fiber connector cone and a compensator are arranged in the butt joint pivot, a positive electrode tube comprises a high-frequency current wire, an electrode end and a wire protection layer, and a camera structure comprises an illumination optical fiber, an image transmission optical fiber and a camera. The instrument has the technical advantages that the operation is simplified, the curvature is adjustable, and the operation difficulty is greatly reduced.

Owner:韩从辉

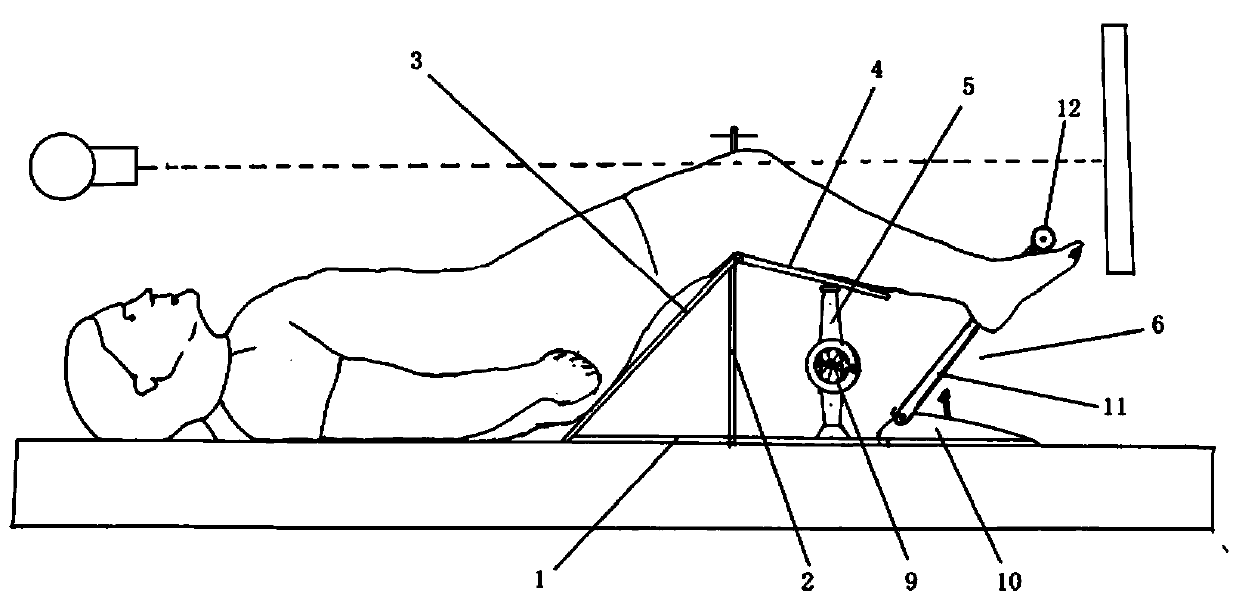

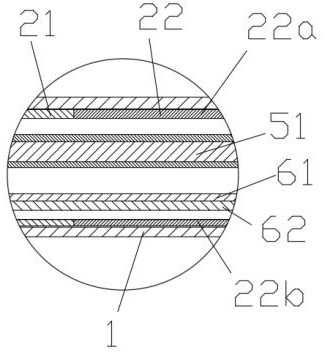

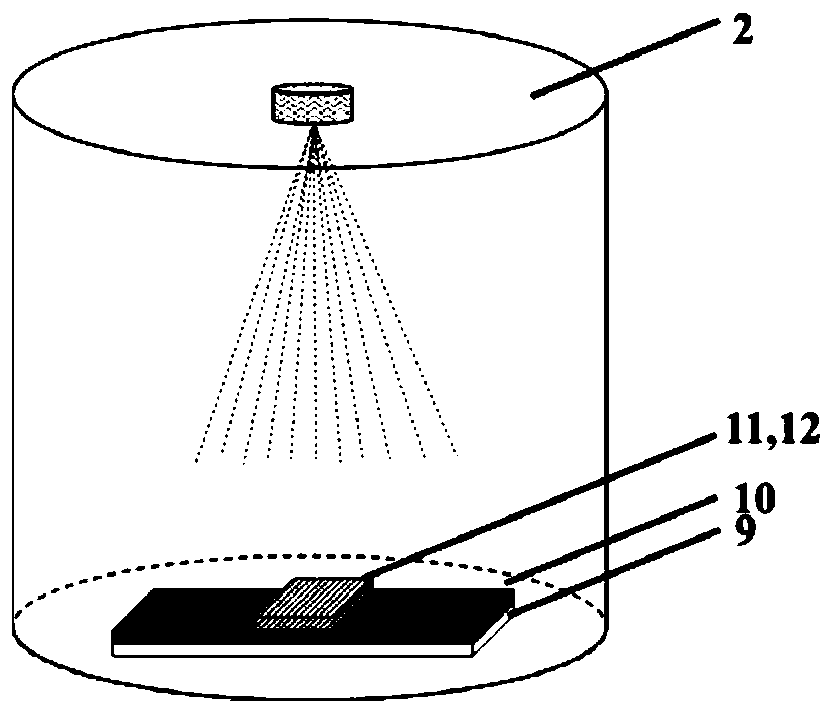

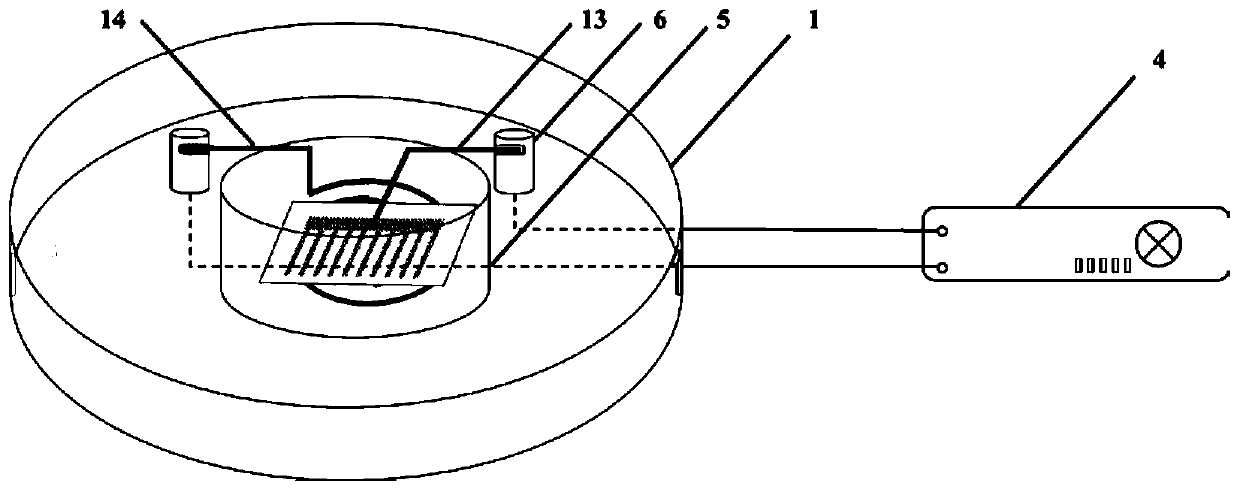

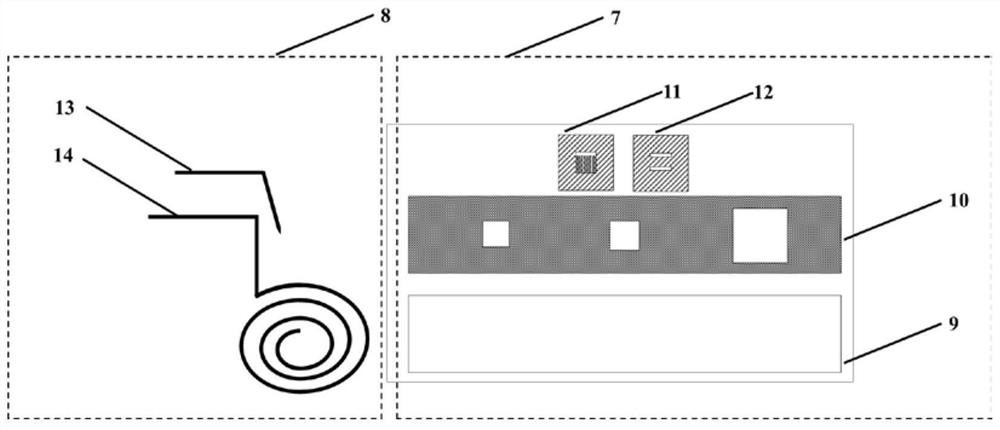

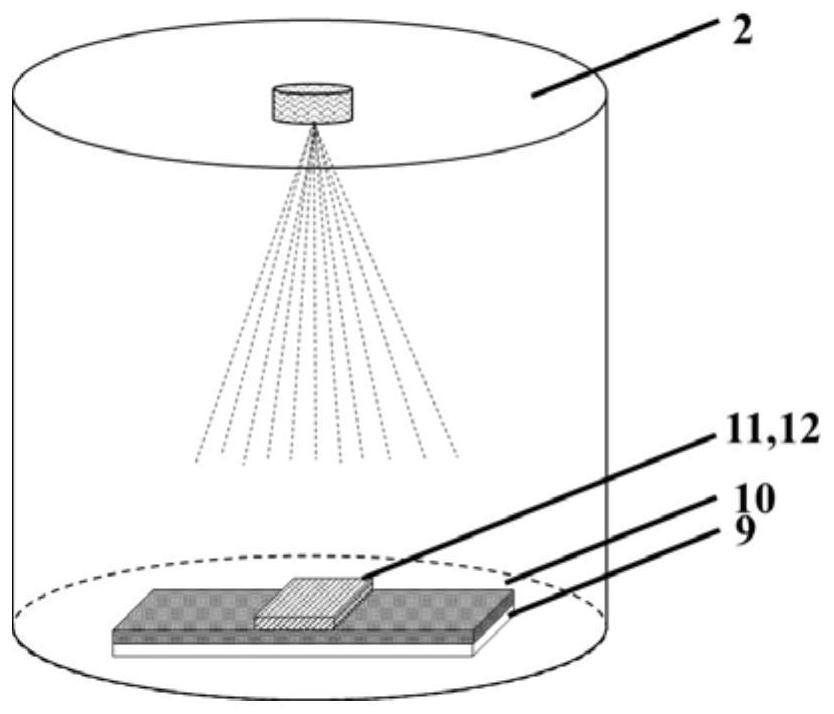

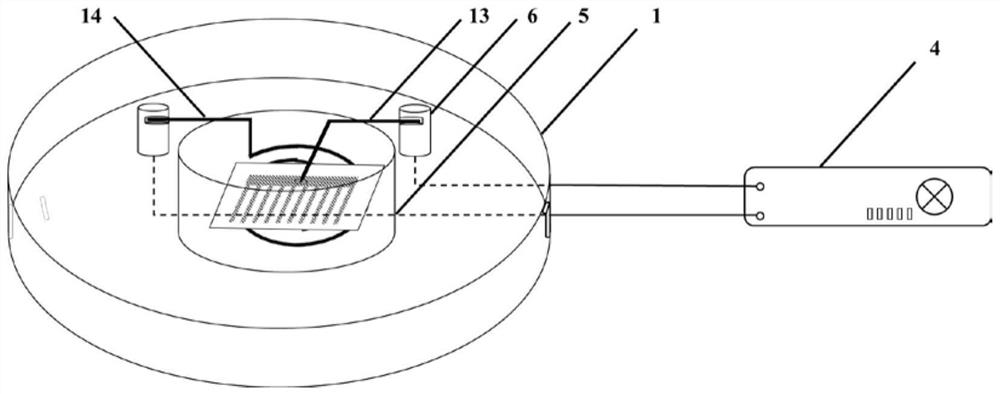

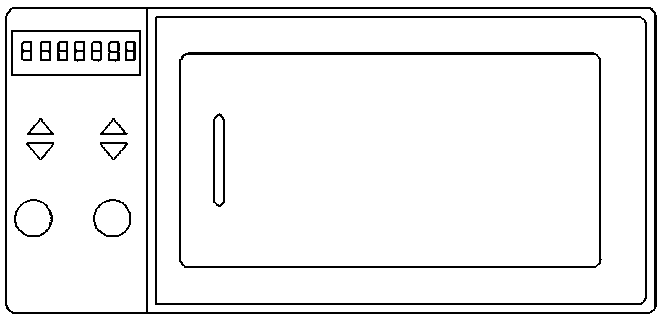

Test equipment and method of film electrode of solid oxide fuel cell

ActiveCN109725025APrecise control of shapeAvoid destructionResistance/reactance/impedenceMaterial resistanceSpecific testElectricity

The invention discloses test equipment and method of a film electrode of a solid oxide fuel cell, and belongs to the field of the electrochemistry test. The equipment comprises a high-temperature heating stage, an ohm meter, an electrochemical workstation, a current collection layer spraying mold and a probe test component; the current collection layer spraying mold comprises a glass baseplate, ablocking sheet, and a hollow masking sheet; the probe test component comprises a bevel probe and a plane spiral probe; the method comprises electrical test and electrochemical test, the film electrodecan be tested by using a test probe combination according to a specific test demand. Through the test equipment disclosed by the invention, the quick precise test of the electrical performance and the electrochemical performance of the film electrode in the temperature range of 600-1000 DEG C, and the test equipment has the features of being accurate in test, high in efficiency and space-saving.

Owner:TSINGHUA UNIV

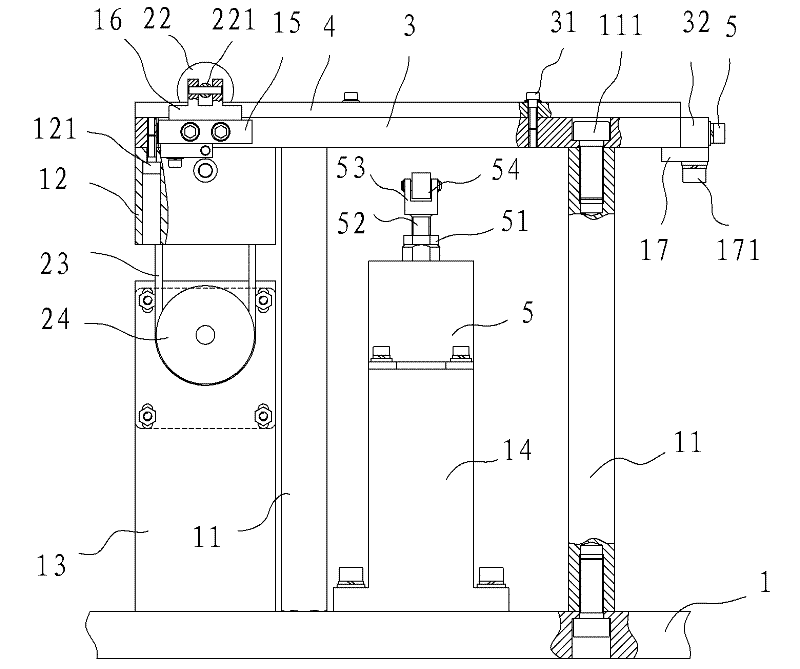

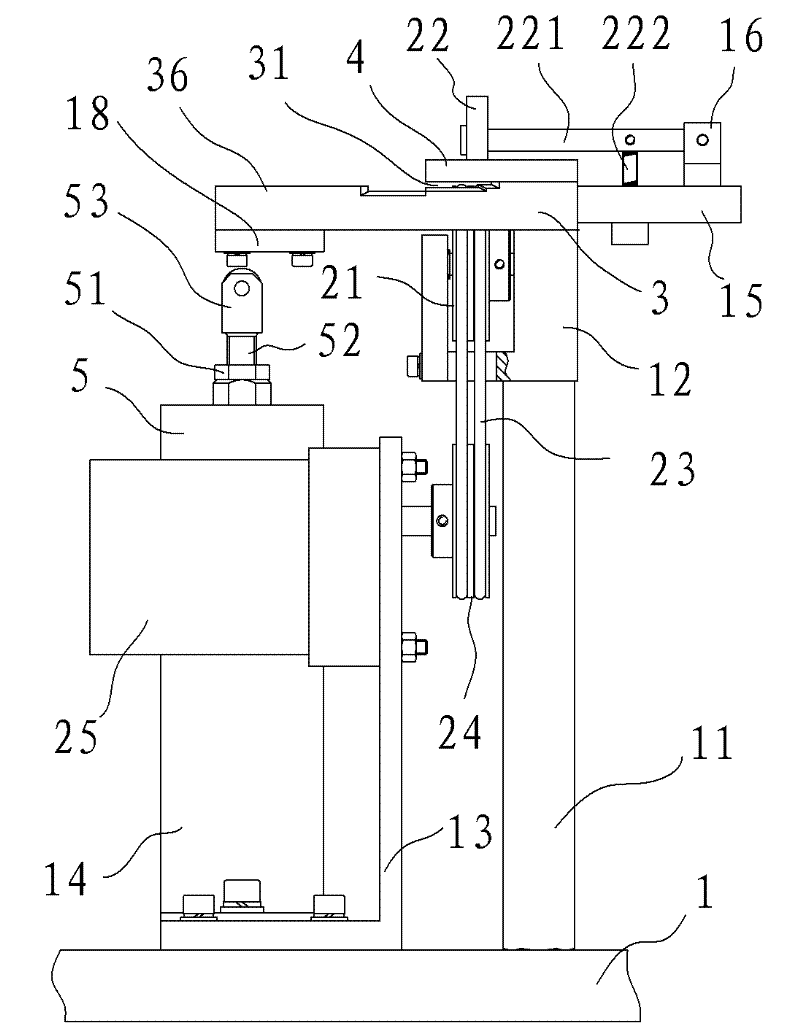

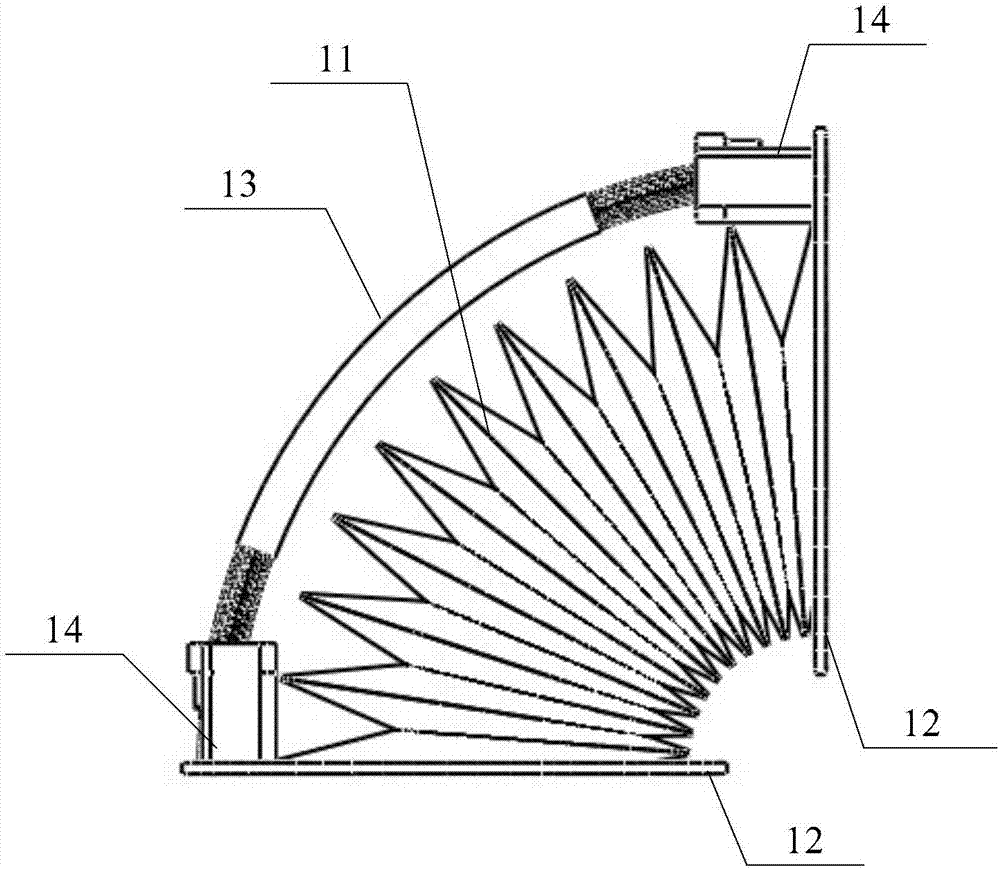

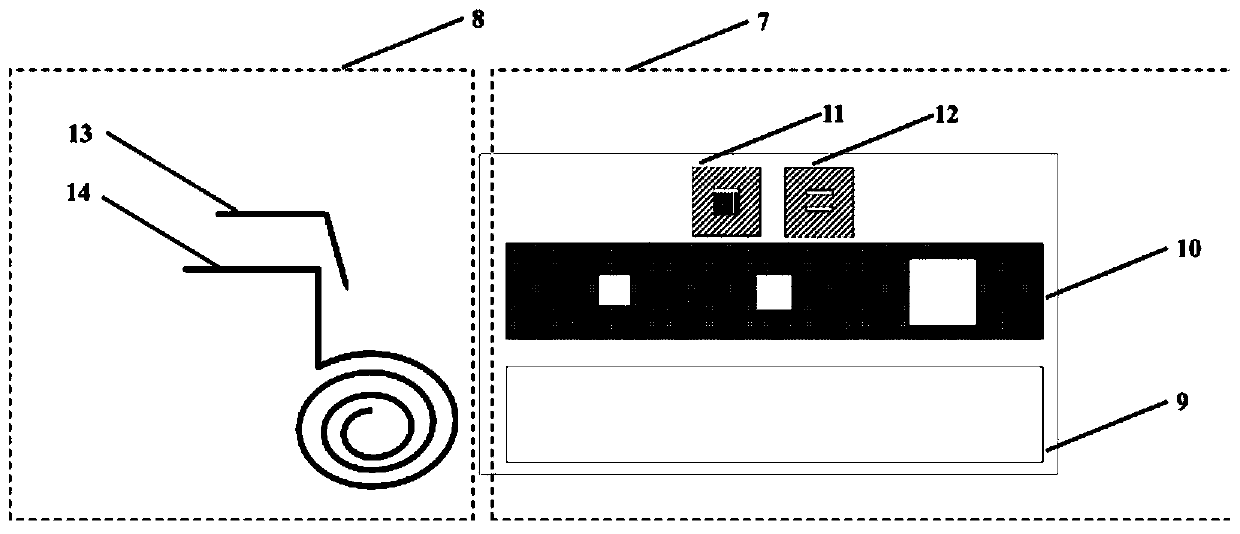

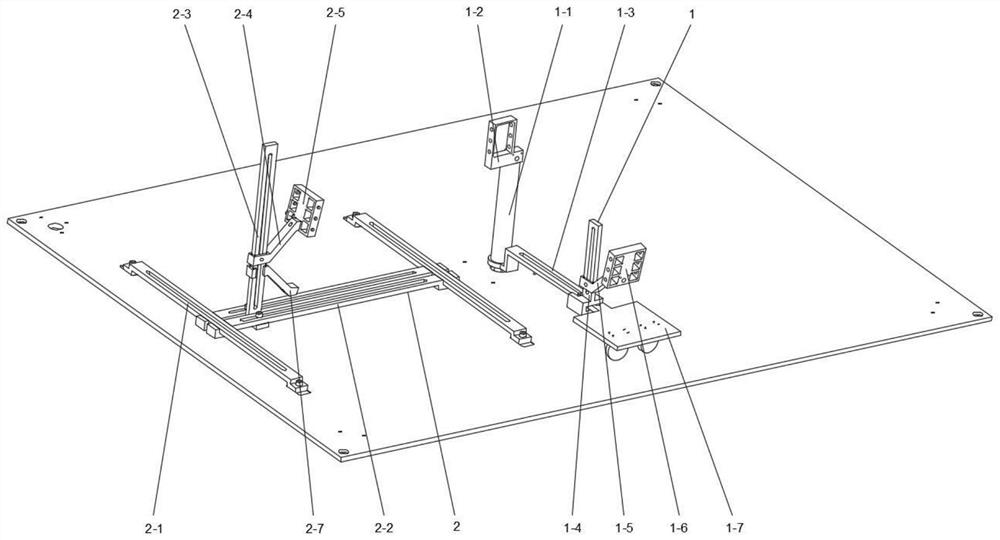

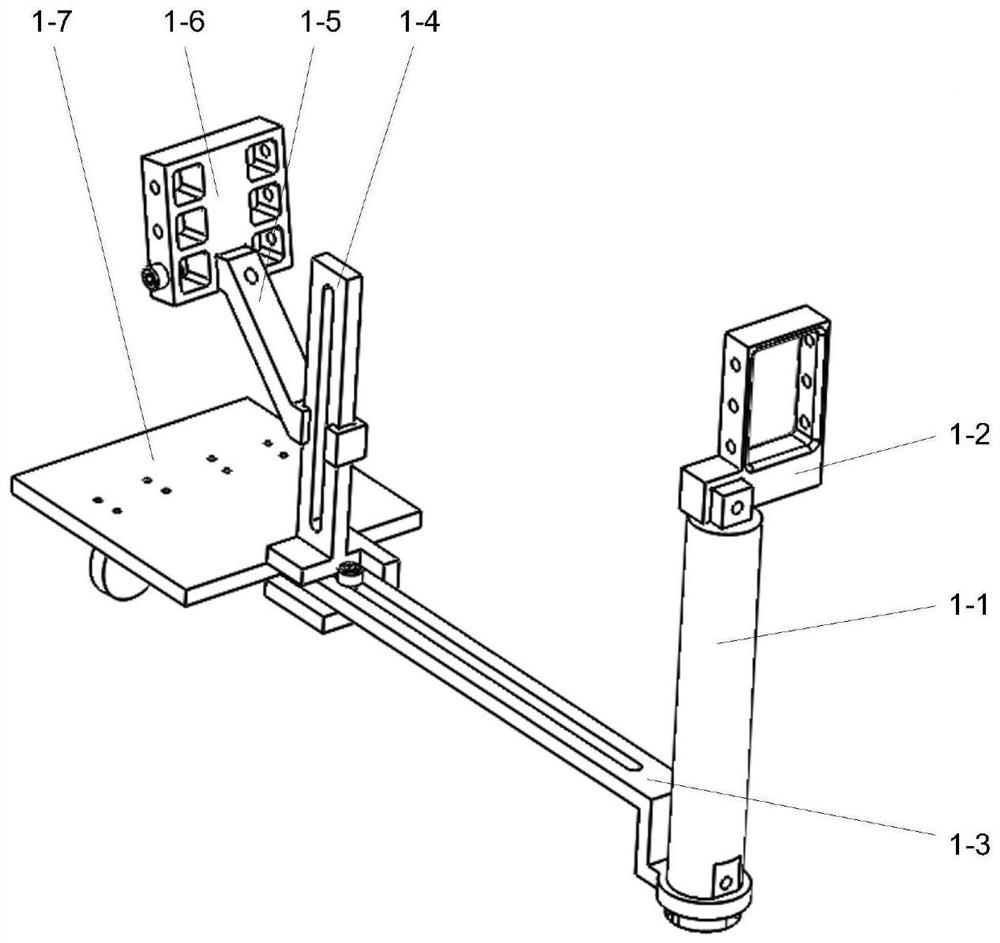

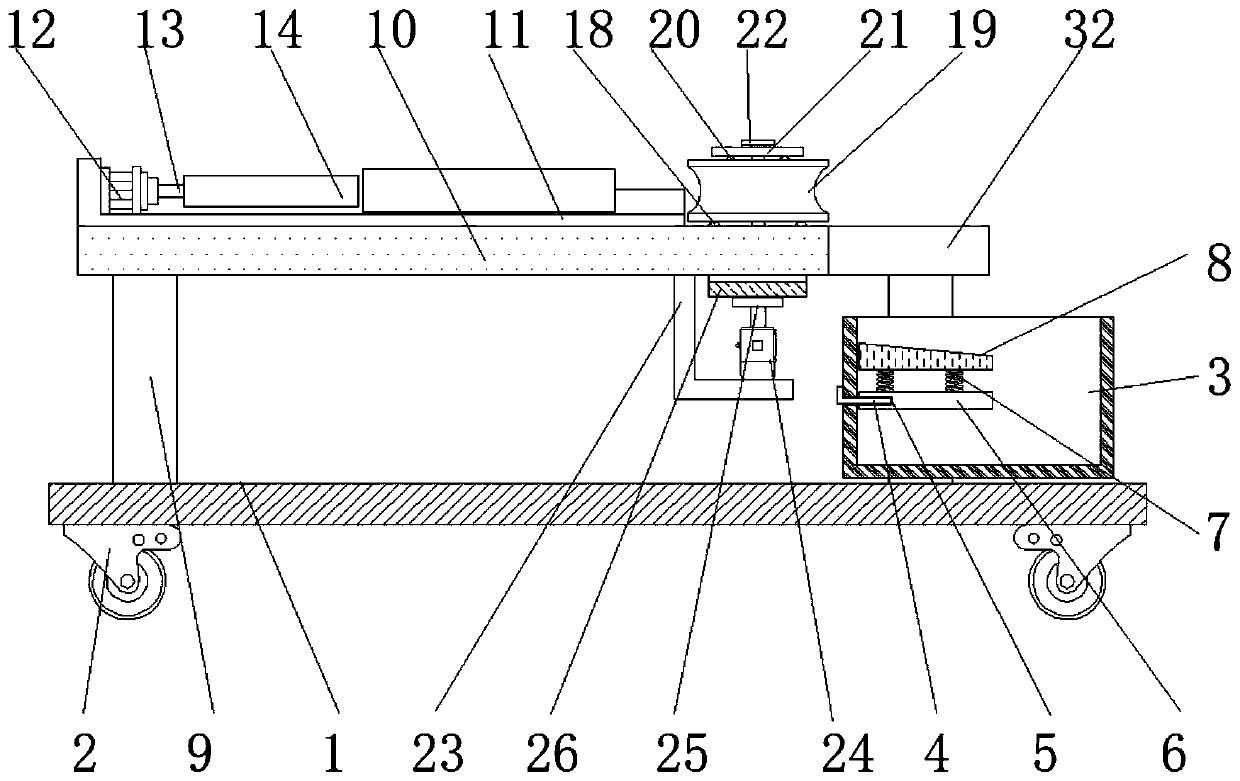

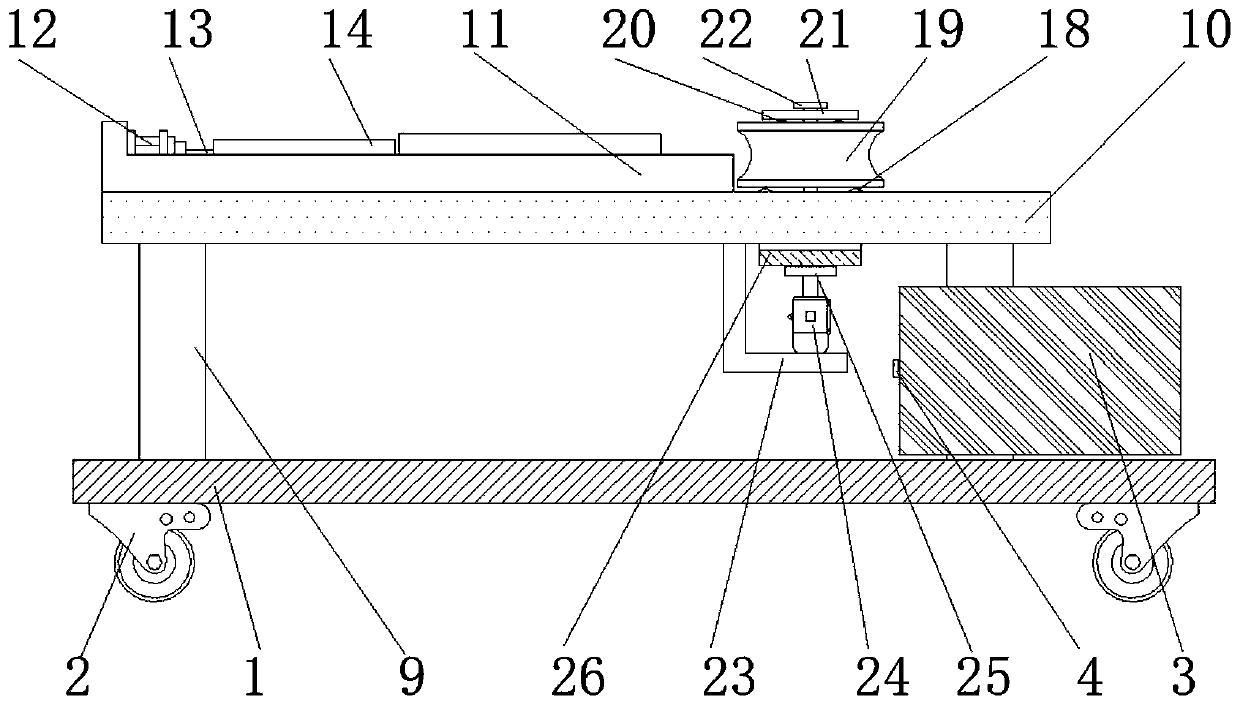

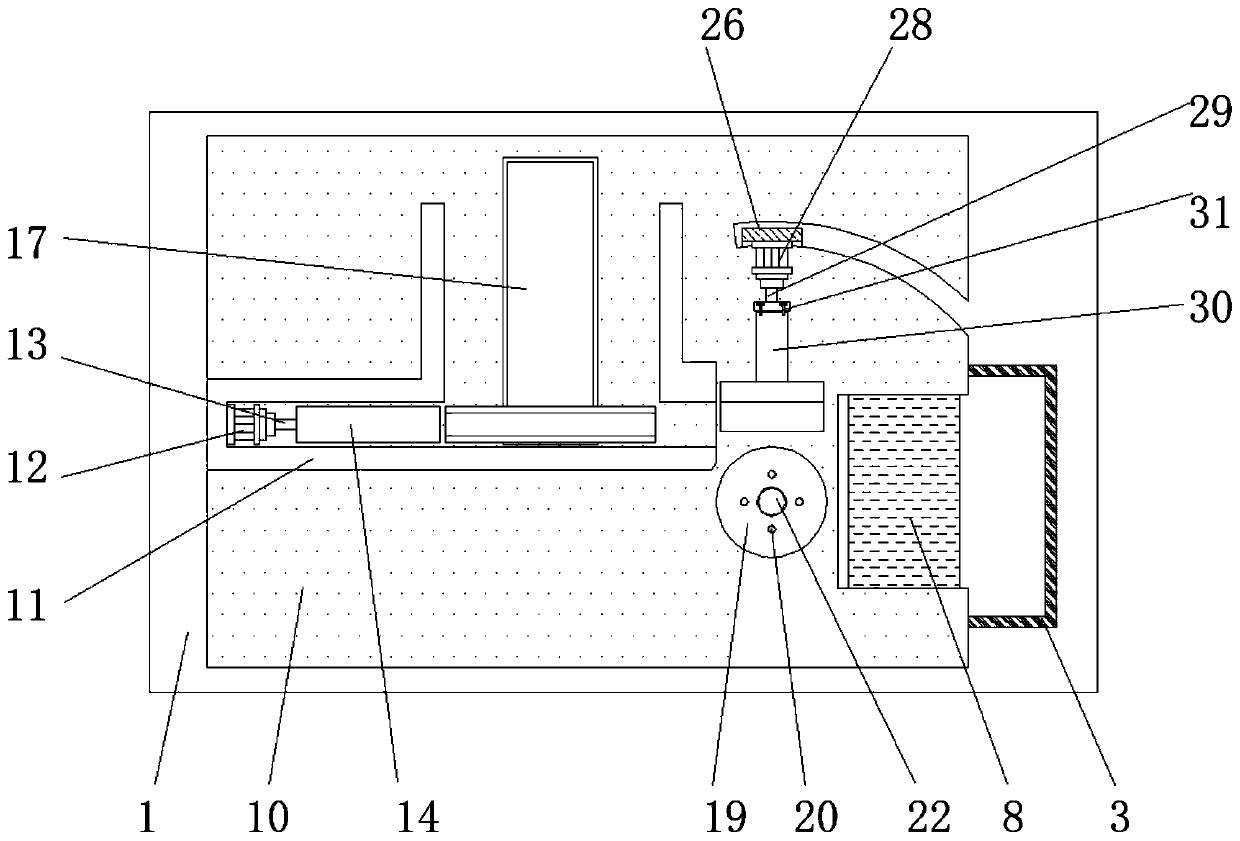

Novel folding cable test equipment

PendingCN114152520AConsistent bending angleAllows for adjustabilityMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesElectric machineryStructural engineering

A novel folding cable test device disclosed by the present invention comprises a platform, a bending assembly and a fixed end assembly, the bending assembly comprises a rotating shaft, a limiting block, a rotating plate, a bending end guide rail support, a connecting block and a rotating end clamp, a rectangular mounting block is integrally formed at the upper end of the rotating shaft, and the limiting block is fixedly mounted at the upper end of the rotating shaft. According to the cable bending device, cables can be automatically bent, multiple cables can be bent at the same time, the rotating shaft is driven by the motor to rotate, it is guaranteed that the bending angles are consistent every time, the bending angles are adjustable, the state of the cables in actual work can be more accurately simulated, the bending angles can be adjusted, and the cable bending device is convenient to use and high in practicability. Meanwhile, the bending frequency can be recorded through a PLC, after the bending frequency is reached, the equipment stops running, the appearance of the cable is observed, whether the performance meets the requirement or not is checked, in addition, the fixing position and the bending position of the cable can be adjusted, and the device has better applicability.

Owner:沈阳兴华航空电器有限责任公司

Pipe bending device for air conditioner production

InactiveCN107377705APrevent deviationEasy to holdMetal-working feeding devicesHeat exchange apparatusThreaded rodCopper tubing

The invention provides a pipe bending device for the production of an air conditioner condenser, which includes a movable block, a fixed plate, an electric telescopic rod, a limit groove, a notch, a nut 1, an arc chute 1, a threaded rod 1, a threaded rod 2, a circle Arc chute 2 and nut 2, the limit groove is set on the right side of the front face of the movable block, and the limit groove communicates with the notch, and the left end of the electric telescopic rod is installed on the right end face of the fixed plate. This design improves the For the limited clamping effect of the copper pipe, the lower end of the threaded rod is assembled in the arc chute 1, the annular side of the threaded rod 1 is equipped with the nut 1, and the lower end of the threaded rod 2 is assembled in the arc chute Inside, the ring side of the threaded rod 2 is equipped with a nut 2. This design realizes the purpose of adjusting the bending angle of the copper pipe in the present invention. Tuning, good stability and high reliability.

Owner:柴永朋

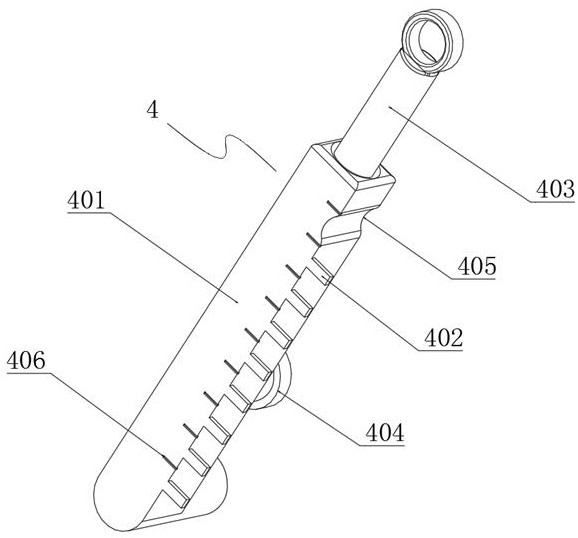

On-site reinforcing steel bar bending adjusting system for construction machinery

ActiveCN114192697AScientific and reasonable structureEasy to useMetal working apparatusLever pressingRebar

The invention discloses an on-site reinforcing steel bar bending adjusting system for construction machinery, which comprises a bending seat, the bottom of the bending seat is provided with a base, the front end face of the bending seat is provided with a reinforcing steel bar clamping block, and the front end of the bending seat is provided with a bending assembly.According to the on-site reinforcing steel bar bending adjusting system, a pressing rod is rotated to a horizontal state, and a reinforcing steel bar is pulled to a proper position according to scale marks; the position limiting rod at the corresponding position is pushed out of the sliding hole, the handheld rod is held to press the reinforcing steel bar downwards until the clamping arc groove in one end of the pressing rod is clamped with the pushed-out position limiting rod, after bending is completed, the position limiting rod is pushed into the sliding hole, then the pressing rod is rotated upwards, and finally the reinforcing steel bar is pulled out and taken away. By pushing the position limiting rods at different positions, different bending angles can be adjusted, the steel bars can be bent conveniently, the bending angles of the steel bars are adjustable, the multiple steel bars can be bent by the same angle through limiting of the position limiting rods, and the steel bar bending effect is better.

Owner:JINLING INST OF TECH

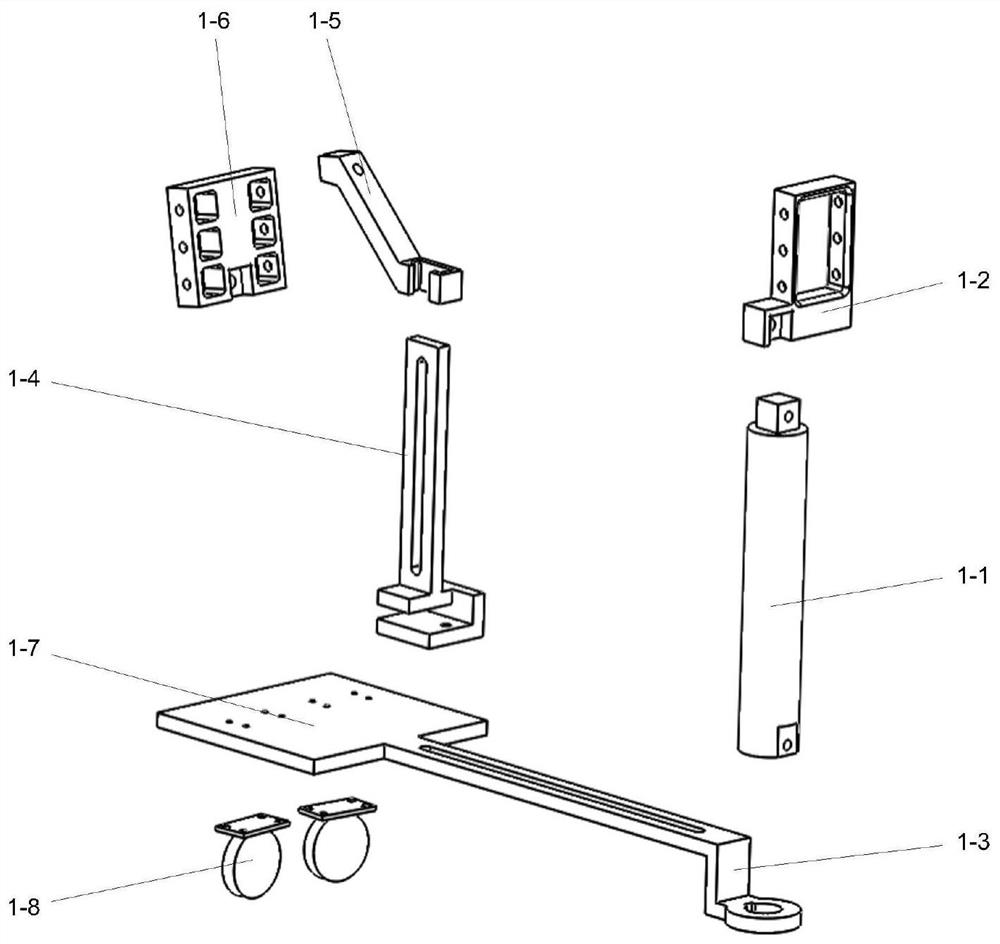

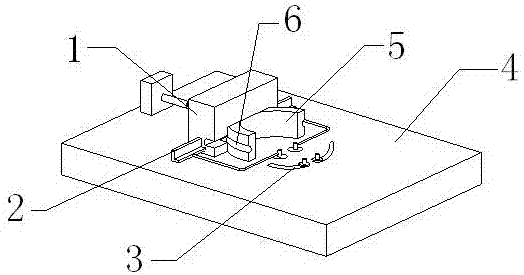

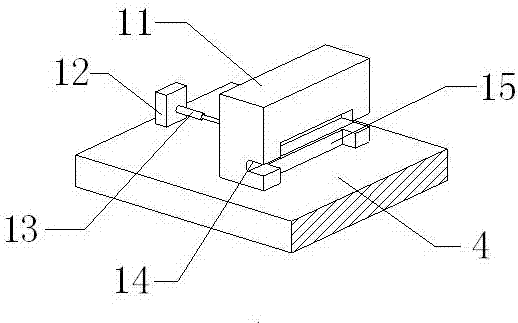

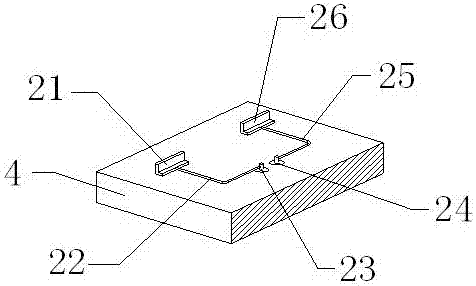

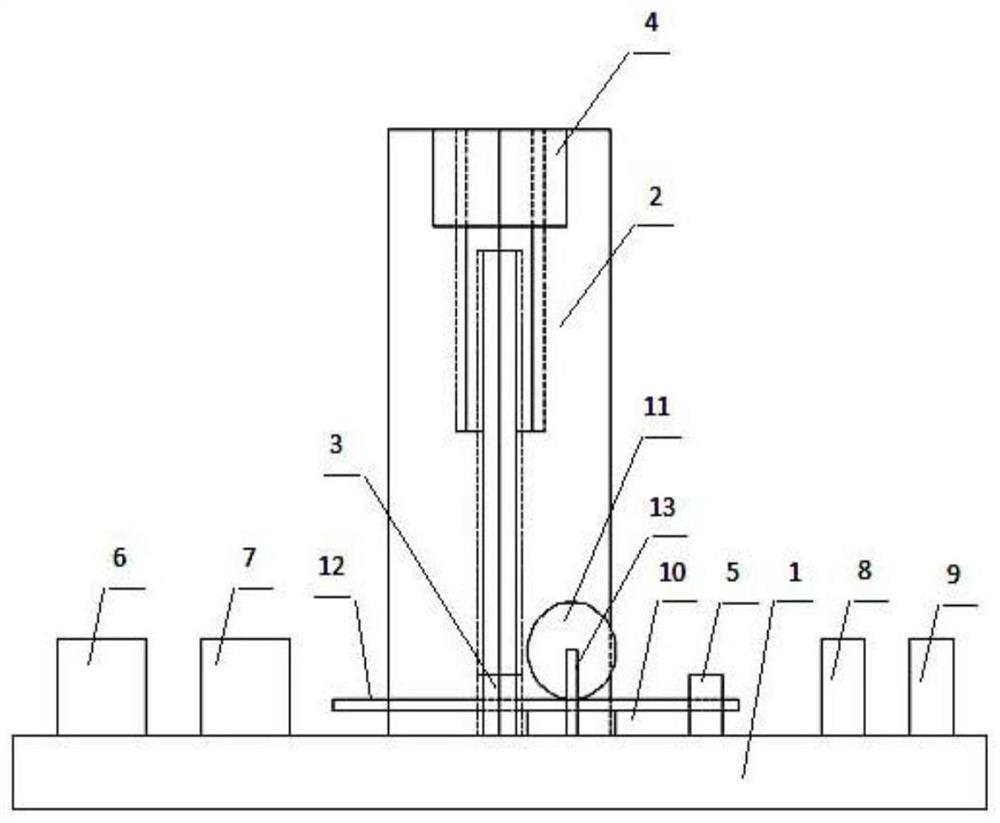

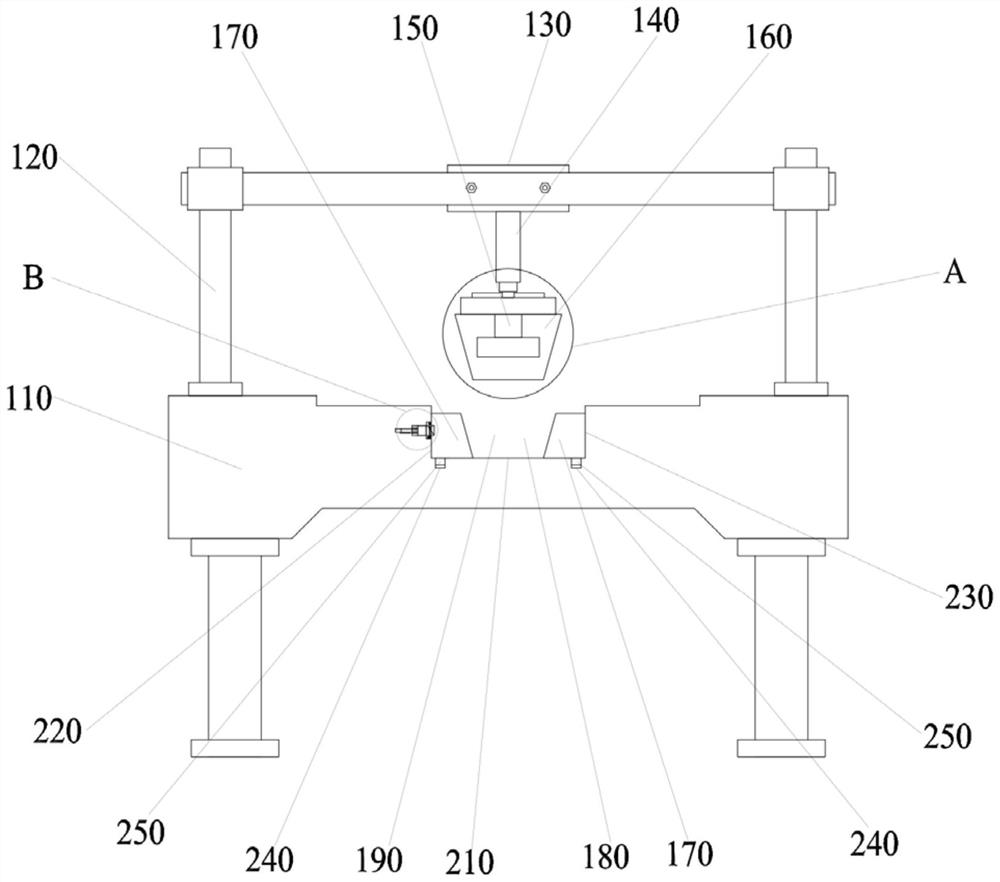

Elastic wire fatigue performance testing device and using method thereof

PendingCN111766167AWide range of applicationsTest bending angle adjustableMaterial strength using repeated/pulsating forcesStructural engineeringFatigue fractures

The invention discloses an elastic wire fatigue performance testing device and a using method thereof, and belongs to the technical field of material performance testing. The testing device is composed of a base, a sliding table, a sliding block, an electromagnet, a pressing block, a relay power supply, a relay, a timer, a timer power supply, a tested wire, a mandrel fixing rod, a mandrel and a cushion block. One end of the tested wire is fixed by the pressing block, and the other end of the tested wire is driven by the sliding block to repeatedly act around the mandrel until breaking. The sliding block is driven by the electromagnet controlled by the relay to pull a titanium-nickel alloy wire to repeatedly act around the mandrel, the deformation speed and the deformation degree can be controlled, when the wire is subjected to fatigue fracture, the timer connected with the wire stops working, and fracture time is recorded, so the fracture frequency is calculated. The test bending angleand the deformation speed of the device are adjustable, the action distance can be set, and the bending frequency and time can be automatically recorded. Mandrels with different diameters can be selected according to metal wires with different diameters, so the application range is wide.

Owner:GRINM MEDICAL INSTR BEIJING CO LTD

a bending machine

The invention provides a bending machine. The bending machine is characterized by comprising a worktable as well as a conveying device, a bending device, a cutting device and a pushing device which are arranged on the worktable in sequence in a conveying direction of a solder strip, wherein the bending device comprises a pair of bending rods perpendicular to the worktable and a motor connected to one end of the pair of the bending rods; the solder strip penetrates through the middle of the pair of the bending rods; and the motor can drive the bending rods to rotate for a set angle in a set direction by taking the center of a connecting line of the bending rods as the center of a circle, thereby bending the solder strip positioned between the bending rods. The bending machine provided by the invention is suitable for producing the photovoltaic solder strip with at least one bending angle, and the bending angle and the bending direction are adjustable.

Owner:TAICANG JUREN PV MATERIAL

A multi-point fixing device for a thick metal plate bending machine

ActiveCN109604391BSave human effortImprove efficiencyMetal-working feeding devicesPositioning devicesSlide plateManufacturing engineering

The invention discloses a multi-point fixing device of a thick metal plate bending machine. The multi-point fixing device comprises a conveying table and a bending device, supporting legs are fixedlyarranged on the edge, close to the front side, of the lower surface of the conveying table, the bending device is fixedly arranged at the rear end of the conveying table, and supporting cylinders arefixedly arranged on the two sides of the upper surface of the bending device in the vertical direction. According to the multi-point fixing device, an electric push rod and a sliding plate are arranged to be matched with each other, the thick metal plate pieces are pushed to the bending device in a sliding mode, labor is saved, and efficiency is improved; a connecting spring is arranged, so that afixing rod piece and a sliding rod piece can clamp the metal plate in the horizontal direction, a plurality of L-shaped fixing devices are arranged, the metal plates are fixed in the vertical direction, dislocation is avoided, and the bending line is inclined; and an anti-skid pad is arranged at the lower end of fastening nuts, a pressing mark is prevented from being left on the metal plate, a thin plate is additionally arranged in pressing grooves, so that the width of the pressing grooves is narrowed, and then the bending angle can be adjusted.

Owner:南通威力数控机床有限公司

Bending machine for elbow and capable of adjusting bending angle

InactiveCN110614301AAdjustable bending angleEasy to sendShaping toolsMetal-working feeding devicesHydraulic cylinderElectric machinery

The invention discloses a bending machine for an elbow and capable of adjusting the bending angle. The bending machine comprises a base and a threaded rod. An object placement platform is fixed to a support, a first hydraulic cylinder and a push rod are arranged on the inner side of a sliding channel, and a first motor is arranged on the rear side of the object placement platform. First universalballs are arranged in the object placement platform, and second universal balls are arranged on the upper end face of a bending mold. The threaded rod penetrates through a limiting plate and the bending mold and is connected with the object placement platform, and a bearing frame is fixedly arranged on the lower end face of the object placement platform. The upper side of a second motor is connected with a rotating frame through a second motor shaft, and the front side of a second hydraulic cylinder is connected with a press rod through a second hydraulic rod. A through hole is formed in the right side of the object placement platform, and a collecting box is arranged on the lower side of the through hole. According to the bending machine for the elbow and capable of adjusting the bendingangle, the rotating frame can rotate under the action of the second motor, and therefore the bending work is conducted on a material, and the bending degree of the material can be controlled by controlling the rotating angle of the rotating frame.

Owner:江苏新泰隆管件有限公司

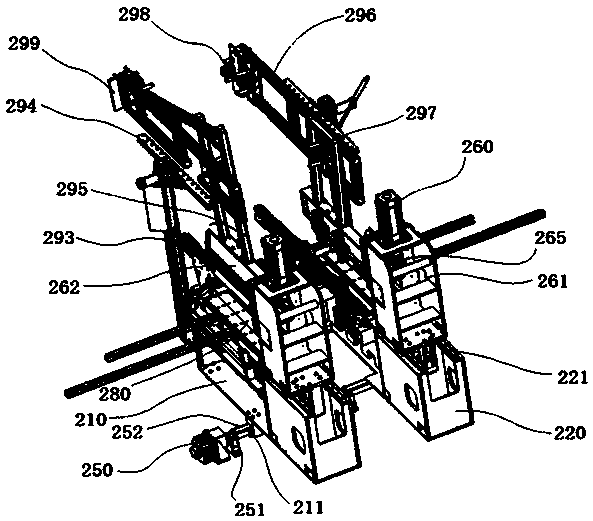

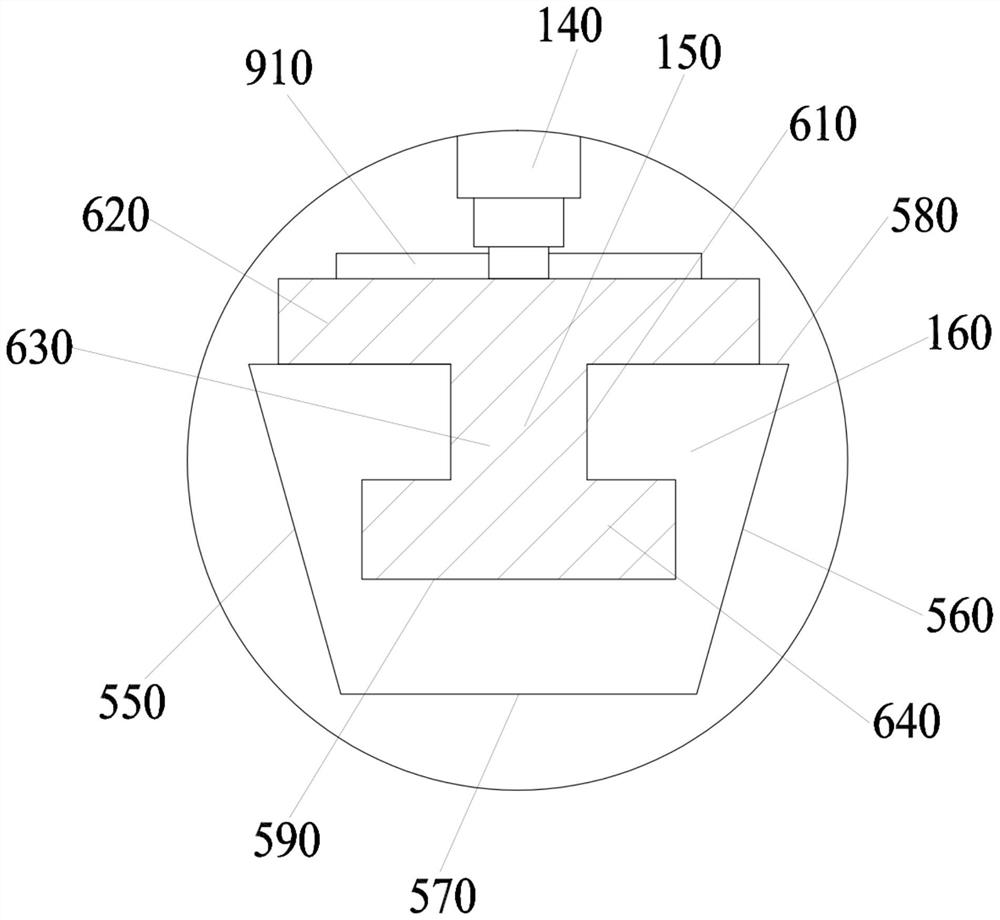

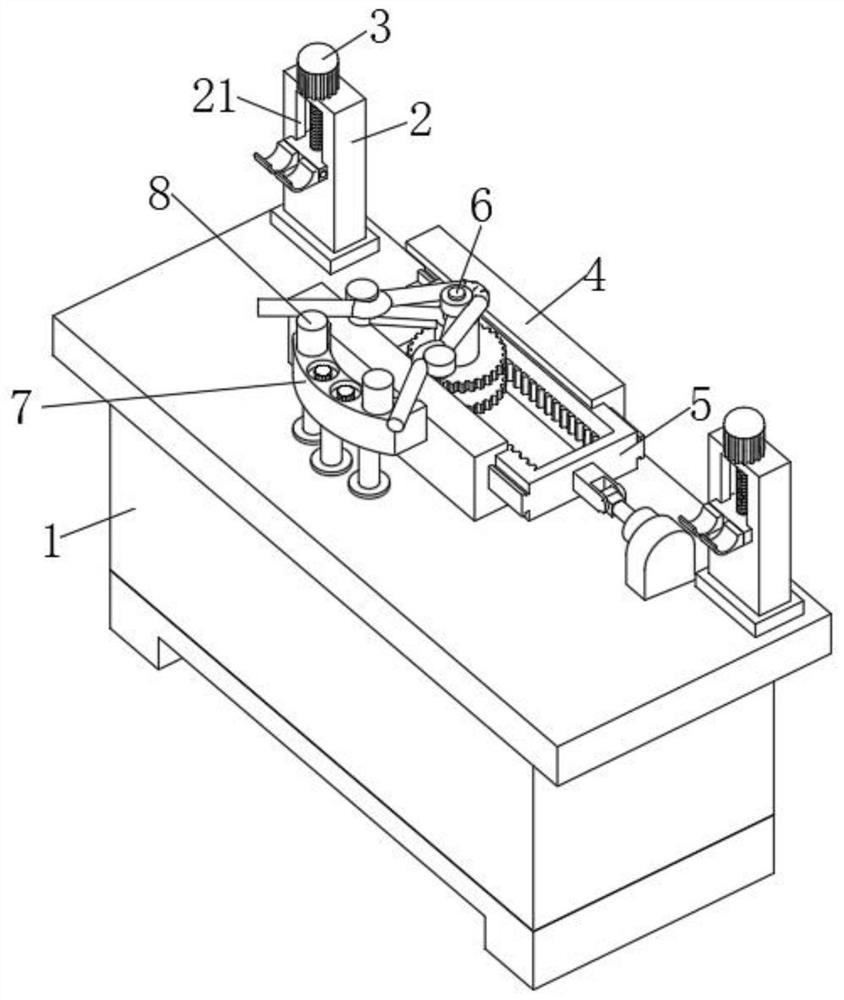

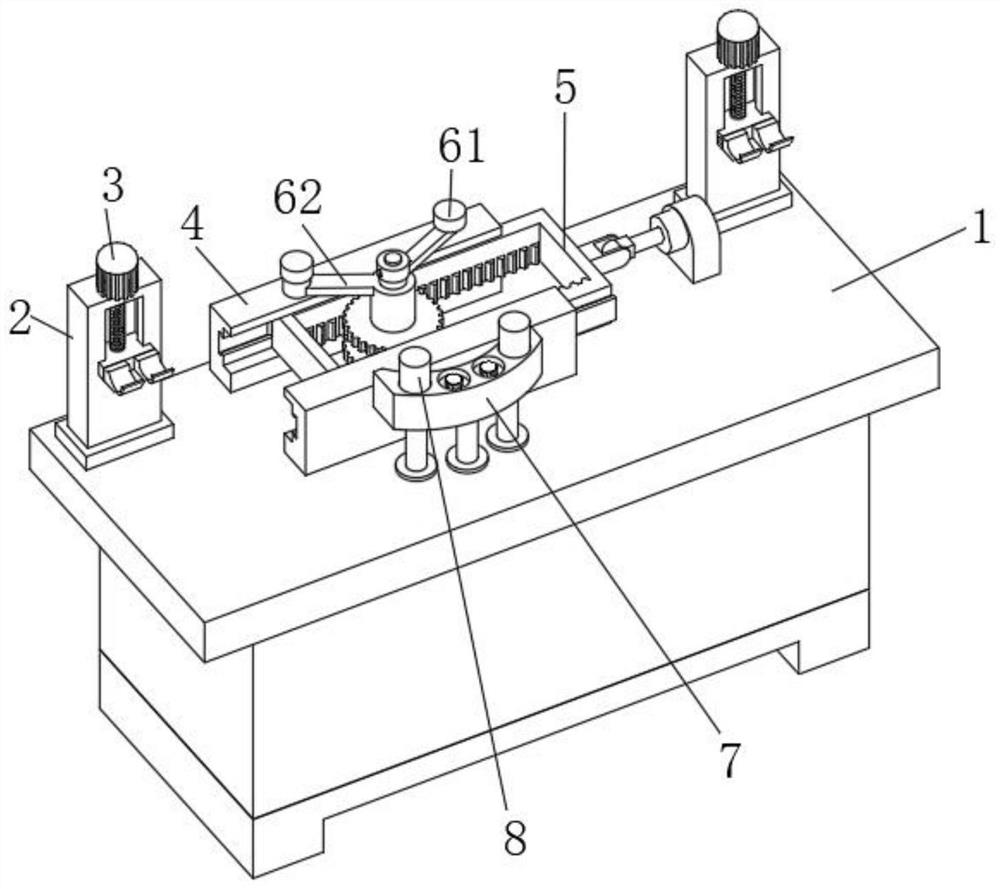

A bending device for chip pins

ActiveCN110252905BImprove assembly qualityExtended service lifeStructural engineeringMechanical engineering

The invention discloses a bending device of a chip pin. The bending device comprises a bending device, a jig frame and a clamping device. According to the bending device, a first clamping cutting edge is arranged on a clamping fixture of the jig frame, a second clamping cutting edge is arranged on a clamping block of the clamping device, the pins of the chips to be bent are clamped between the two cutting edges through a pushing mechanism, bending plates are driven by rotating air cylinders to be bent to the pins of the chips, the bending stress is blocked from the root of the pin to the chip in the bending process of the pin, in the bending process, the plate surface of the bending plate is in surface contact with the pin of the chip, the bending precision is high, the bending angle is adjustable, scratches or damage to the surface of the pin is completely avoided, so that the assembly quality of the chip is improved, and the service life of the chip is prolonged.

Owner:SHANGHAI WORKPOWER TELECOM TECH +1

Minimally invasive surgical instruments for bladder polyps

ActiveCN112190325BExpand field of viewSave the tedious back and forth transpositionEndoscopesSurgical instruments for heatingEyepieceReoperative surgery

The invention discloses a minimally invasive surgical instrument for bladder polyps, which includes an outer sleeve, an operating tube, a bending manipulator and a docking center. The connection part, the iron core tube part and the rear end tube part are connected in sequence. The bending manipulator includes the operation shell, the conductive plate of the slide seat, the slider and the battery. The high-frequency current butt joint, eyepiece, argon The gas-filled joint, the lighting fiber joint cone and the compensator, the positive electrode tube include the high-frequency current wire, the electrode tip and the wire sheath, and the camera structure includes the lighting fiber, the image transmission fiber and the camera. The invention has the technical advantages of simplified operation, adjustable curvature and greatly reduced operation difficulty.

Owner:韩从辉

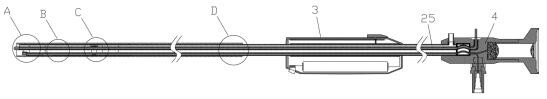

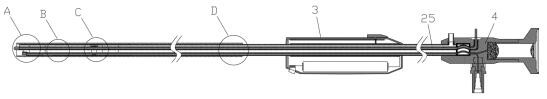

cutting stapler

ActiveCN103340662BEasy to bendAdjustable bending angleIncision instrumentsSurgical staplesEngineeringHumans tissues

The invention provides a cutting anastomat. The cutting anastomat comprises an anastomat body, a nail anvil assembly, a nail tube connected with the anastomat body and a nail anvil pull rod which can extend outside the end face of the nail tube, wherein the nail anvil pull rod is selectively connected with the nail anvil assembly, the nail anvil pull rod comprises a flexible part which is at least partially contained in the nail tube and a connecting part which is arranged at the far end of the flexible part, and the connecting part is connected with the nail anvil assembly in a dismounting manner. The cutting anastomat has the advantages that the nail anvil pull rod is easy to bend, a bending angle can be regulated at random, flexibility is good, the requirement of a small operation space can be met, or the cutting anastomat can bypass human tissues which stop the cutting anastomat from moving ahead, and anastomosis during operation can be smoothly completed.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

A testing device and method for a thin-film electrode of a solid oxide fuel cell

ActiveCN109725025BPrecise control of shapeAvoid destructionResistance/reactance/impedenceMaterial resistanceThin film electrodeFuel cells

The invention discloses test equipment and method of a film electrode of a solid oxide fuel cell, and belongs to the field of the electrochemistry test. The equipment comprises a high-temperature heating stage, an ohm meter, an electrochemical workstation, a current collection layer spraying mold and a probe test component; the current collection layer spraying mold comprises a glass baseplate, ablocking sheet, and a hollow masking sheet; the probe test component comprises a bevel probe and a plane spiral probe; the method comprises electrical test and electrochemical test, the film electrodecan be tested by using a test probe combination according to a specific test demand. Through the test equipment disclosed by the invention, the quick precise test of the electrical performance and the electrochemical performance of the film electrode in the temperature range of 600-1000 DEG C, and the test equipment has the features of being accurate in test, high in efficiency and space-saving.

Owner:TSINGHUA UNIV

Steel cable joint braiding clamp

PendingCN113146552AGuaranteed to bend naturallyPrevent slippageMetal-working hand toolsScrew threadSteel rope

The invention provides a steel cable joint braiding clamp comprising a jacking block, a T-shaped connecting block, connecting pins, an adjusting nut, clamping heads and an adjusting handle, a first screw rod is arranged at the right end of the jacking block, the adjusting nut is arranged on the first screw rod, the adjusting nut is arranged in the T-shaped connecting block, and a rotating cavity for containing the adjusting nut is formed in the middle of the T-shaped connecting block. The adjusting nut is in clearance fit with the rotating cavity, the upper portion and the lower portion of the T-shaped connecting block are connected with the clamping heads through the connecting pins, a second screw rod is arranged at the right end of the T-shaped connecting block, a threaded hole matched with the second screw rod is formed in the left end of the adjusting handle, and an adjusting inclined face is arranged at the left end of the adjusting handle. The adjusting inclined face is matched with and jacked against the right ends of the clamping heads by rotating the adjusting handle. By means of the steel cable joint braiding clamp, the angle of the steel cable joint can be adjusted within the range of 0-360 degrees the optimal braiding angle is found out, and therefore the braiding difficulty is effectively reduced, and the manual braiding time is shortened.

Owner:AIR FORCE ENG UNIV OF PLA AIRCRAFT MAINTENACE MANAGEMENT SERGEANT SCHOOL

Metal plate bending device with adjustable bending angle

The invention relates to the technical field of metal plates, and discloses a metal plate bending device with an adjustable bending angle. The device comprises an operation table, wherein a supporting seat is fixedly connected to the top of the operation table, a supporting rod is fixedly connected to the top of the supporting seat, a supporting block is movably connected to the top of the supporting rod, a lifting rod is slidably connected to the interior of the operation table, bearing plates are movably connected to the top of the lifting rod, punches are arranged above the bearing plates, an adjusting rod is movably connected to the position, located on the left side of the lifting rod, inside the operation table, and an adjusting disc is fixedly connected to the left side of the adjusting rod. By rotating the adjusting disc, the adjusting disc drives the adjusting rod to rotate, the adjusting rod drives a gear to rotate, the gear drives the lifting rod to move up and down, the lifting up-down movement drives the sides, close to the lifting rod, of the bearing plates to move up and down, and therefore the included angle between the bearing plates is changed, and the effect of adjusting the bending angle is achieved.

Owner:HUNAN UNIV OF TECH

Light emitting diode (LED) candle lamp

InactiveCN103196070BEasy to assembleAdjustable bending anglePoint-like light sourceElectric circuit arrangementsInsulation layerFlexible circuits

The invention relates to the technical field of a light emitting diode (LED) lamp, and in particular relates to an LED candle lamp. An LED module substrate of the LED candle lamp is provided with a crease area, the crease area is not provided with an aluminum substrate and only comprises a flexible insulation layer and a flexible circuit layer which has bending properties, an angle between an LED substrate area and a power connection area can be flexibly adjusted by bending the crease area, a planar LED module substrate can be changed to a three-dimensional module substrate which can be perfectly bonded with a heat conduction column; and when in assembling, the heat conduction column can be directly nested in the three-dimensional module substrate to be fixed. Compared with the prior art, the LED module substrate is simple to assemble and can be installed in place in one step after being bent; and moreover, the bending angle is adjustable, the LED module substrate can be effectively perfectly bonded with the heat conduction column, and the firmness and the heat radiation performance of the LED module substrate after being fixed can be improved.

Owner:广东金达照明科技股份有限公司

Metal plate bending device

InactiveCN112893529AAdjustable bending angleStable and smooth adjustmentIsosceles trapezoidManufacturing cost reduction

The invention relates to the technical field of bending accessory devices, and in particular relates to a metal plate bending device. The metal plate bending device is simple in structure, adjustable in metal plate bending angle and capable of reducing manufacturing cost. The metal plate bending device comprises a base; a supporting block is arranged at the top of the base; a mounting groove which is communicated in the front-back direction is formed in the top of the supporting block; multiple sets of protrusions are arranged on the inner side wall of the mounting groove; the section of each set of protrusions is in an isosceles trapezoid shape; the metal plate bending device further comprises a cylinder; a V-shaped groove which is communicated in the front-back direction is formed in the top of the cylinder; the bottom of the V-shaped groove coincides with the axis of the cylinder; multiple sets of grooves in sliding fit with the multiple sets of protrusions are formed in the outer side wall of the cylinder; the metal plate bending device further comprises a front moving mechanism and a rear moving mechanism; the front moving mechanism comprises a front supporting rod, a front stabilizing rod, a front threaded rod, a front moving block and a front transverse rod; and the rear moving mechanism comprises a rear supporting rod, a rear stabilizing rod, a rear threaded rod, a rear moving block and a rear transverse rod.

Owner:ZHANGJIAJIE INST OF AERONAUTICAL ENG

Bending machining device capable of adjusting bending angle

PendingCN114833221AImprove applicabilityAdjustable bending angleShaping toolsGlass productionStructural engineeringManufacturing engineering

The invention discloses a bending machining device capable of adjusting the bending angle. The bending machining device comprises a machine base and a mold set. A bending groove extending in the length direction of the machine base is formed in the upper surface of the machine base. The bending groove comprises a groove bottom wall which is horizontally arranged; the die set comprises an upper die and two side dies. The side die comprises a first die wall and a second die wall intersected with the first die wall; according to the bending machining device capable of adjusting the bending angle, the bending angle of a plate can be adjusted; the angles between the first mold walls and the second mold walls of the side molds of different mold groups are different, and the angles between the third mold walls and the fifth mold walls of the upper molds of different mold groups are different; the side die is detachably connected to the bending groove; and therefore, the plates can be bent at different angles by replacing different die sets, and the applicability of the bending machining device capable of adjusting the bending angle is greatly improved.

Owner:长沙顺和机械有限公司

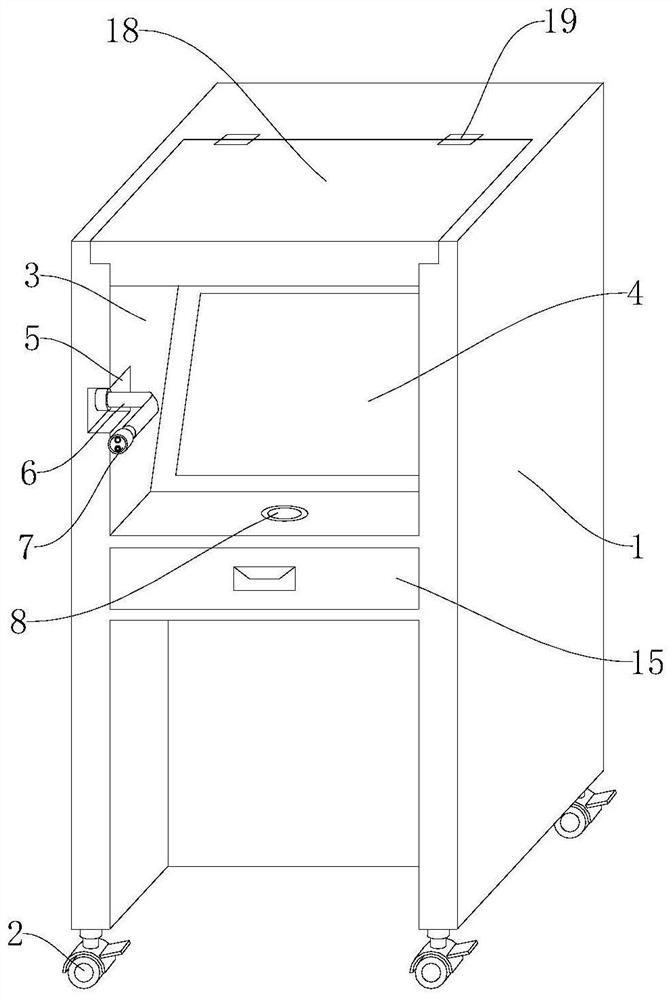

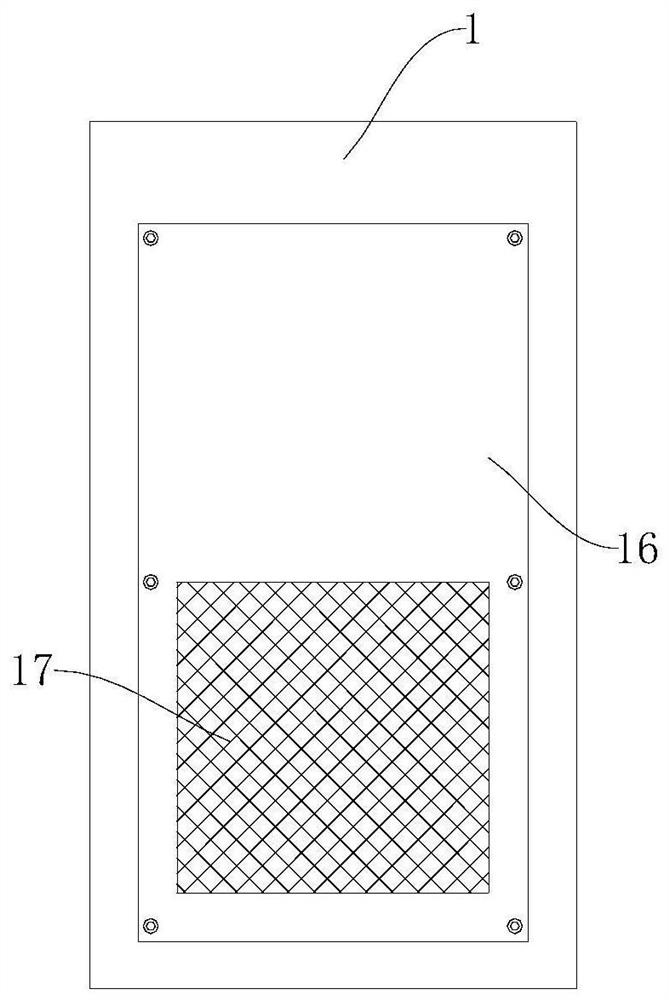

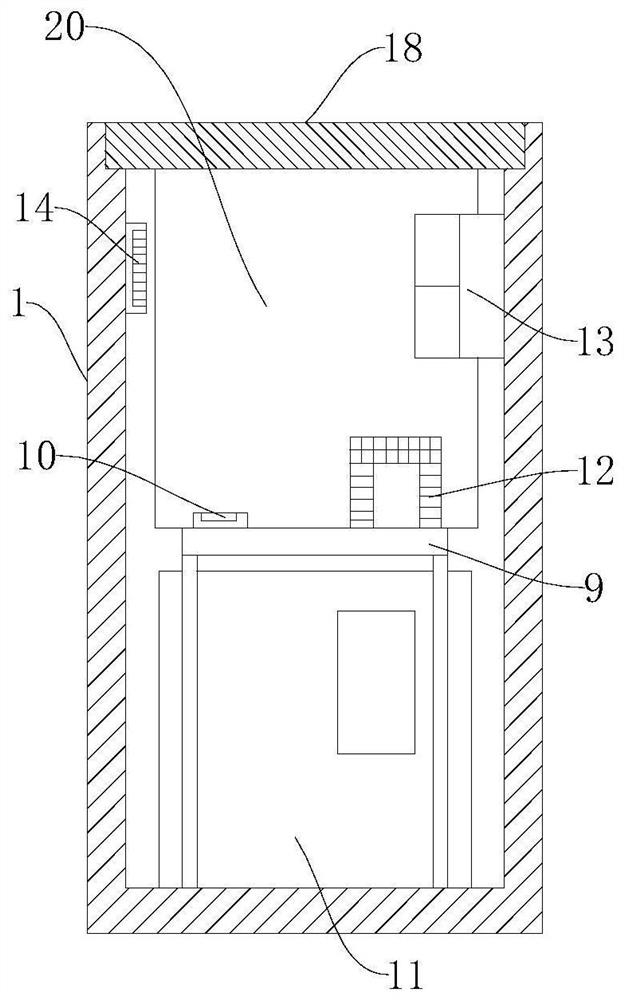

Information display device based on big data

PendingCN113391674AAdjustable bending angleSolve the problem of insufficient convenienceDigital data processing detailsCharacter and pattern recognitionRelevant informationDisplay device

The invention discloses an information display device based on big data. The information display device comprises a machine body, a connecting groove and a supporting frame, an operation bin is formed in the upper end of the front side of the machine body, a touch display screen is arranged in the middle of the inner wall of the inclined face in the operation bin, the connecting groove is formed in the front end of the inner wall of the left side of the operation bin, and a connecting coil pipe is arranged in the connecting groove, a camera is arranged at one end of the connecting coil pipe away from the connecting groove, a sound pickup is arranged in the middle of the inner bottom end of the operation bin located in front of the touch display screen, a supporting frame is arranged in the middle of the inner bottom end of the machine body, and a microprocessor is arranged on one side of the upper end of the supporting frame. According to the device, information of face recognition of a user through the camera can be compared with big data information, so that relevant alternative information is provided for the user, the user can adjust the bending angle of the connecting coil pipe and select whether to use the camera to perform face recognition to search for the relevant information, the user can further retrieve the relevant information through voice of the sound pickup, therefore, the device is very convenient to use.

Owner:深圳市方与圆展览策划有限公司

A U-shaped bending and flipping machine

ActiveCN108994117BRealize one-time processing and transportationAdjustable bending angleStripping-off devicesEngineeringManipulator

The invention discloses a U-shaped bending turnover blanking machine. The U-shaped bending turnover blanking machine comprises a base assembly, a U-shaped bending assembly, a conveying belt assembly,a suction turnover manipulator assembly, a blanking assembly, the U-shaped bending assembly and the conveying belt assembly are arranged at the upper end of the base assembly, the suction turnover manipulator assembly is arranged at the front end of the U-shaped bending assembly, and the blanking assembly is connected with the suction turnover manipulator assembly through a connecting rod; the U-shaped bending assembly comprises a bending assembly base, a bending mechanism, a side positioning mechanism and a U-shaped plate conveying mechanism; the sucking turnover manipulator assembly comprises a manipulator base and a suction turnover manipulator, and the manipulator base is arranged at the bottom of the suction turnover manipulator. According to the U-shaped bending turnover blanking machine, the U-shaped bending, sucking and turnover and blanking and the like of the plate material can be completed, the continuous blanking of the U-shaped plate material is realized, deviation and wrinkling are not easy to happen in the blanking process, the sucking and overturning process is stable, the acting is small, the cost is low, and the efficiency is high.

Owner:江苏天辰智能装备有限公司

Bending device for hardware machining and production

The invention discloses a bending device for hardware machining and production. The bending device comprises an operation table, each of the left side and the right side of the upper end of the operation table is fixedly provided with a fixing frame, each of the front ends of the two fixing frames is provided with a movable groove, each of the upper ends of the two fixing frames is connected with a lifting mechanism in a penetrating and inserting mode, a stabilizing frame is fixedly installed in the middle of the upper end of the operation table, a driving mechanism is slidably connected into the stabilizing frame, a bending mechanism is movably connected to the upper end of the operation table through a bearing, the bending mechanism is located in the middle of the interior of the stabilizing frame and is in transmission connection with the driving mechanism, radian control mechanisms are fixedly installed on the front portion and the rear portion of the upper end of the operation table, and each of the left side and the right side of the upper end of the radian control mechanism is detachably provided with a limiting blocking column. The bending device for hardware machining and production is compact in structure, high in automation degree, capable of achieving bending of multiple positions of reinforcing steel bars through one-time operation, adjustable in bending angle, high in bending precision and capable of being widely used and popularized.

Owner:屈洁

Device and method for detecting adhesion of galvanized layer on galvanized steel sheet

ActiveCN107505260BAdhesion detection implementationAdhesion testing requirements fulfilledUsing mechanical meansMaterial analysisSheet steelEngineering

The invention provides a detection device and a detection method of adhesion of galvanized layers of galvanized steel plates. The detection device comprises an electric heating air-blowing drying box, a high temperature-resistant fixer, a bending clamp and sealant. The detection method comprises the following steps: cleaning the surface of a galvanized plate sample and putting the galvanized plate sample under the high temperature-resistant fixer; filling a waist-type hole of the high temperature-resistant fixer with the sealant and enabling the sealant to be in contact adhesion with the galvanized plate sample; putting the sealant-coated galvanized plate sample and the high temperature-resistant fixer into the drying box and roasting; taking the galvanized plate sample and the high temperature-resistant fixer out of the drying box and cooling; bending the galvanized plate sample by using the bending clamp and enabling the sealant to be separated from the galvanized plate sample at the bending position; detecting and determining that the galvanized plate sample is qualified if the sealant-coated position of the galvanized plate sample is free of a zinc layer, and determining that the galvanized plate sample is unqualified if the zinc layer is formed in the sealant-coated position of the galvanized plate sample. The detection device and the detection method are capable of determining whether the adhesion of the zinc layer meets the requirement or not by using the sealant according to the chemical characteristic of adhesion of metal plates, achieving the detection of adhesion of the zinc layers of the galvanized plates and ensuring that the adhesion of the zinc layer of the galvanized plates meets the requirement.

Owner:SHENYANG LAIJIN AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com